Electroplated diamond wire saw

A technology for electroplating diamond and diamond, applied in the field of abrasives, can solve the problem that electroplating diamond wire saw cannot take into account the service life and cutting efficiency, etc., and achieves the effect of facilitating the sanding process, improving self-sharpening and cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

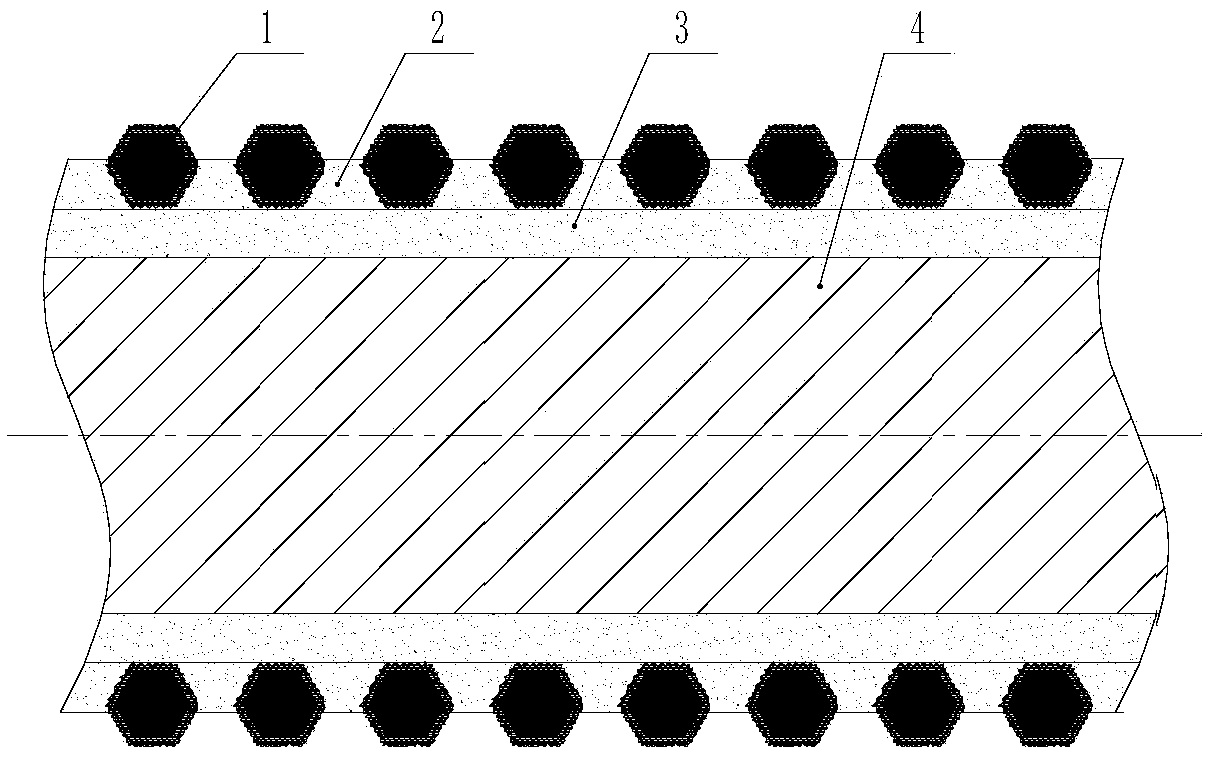

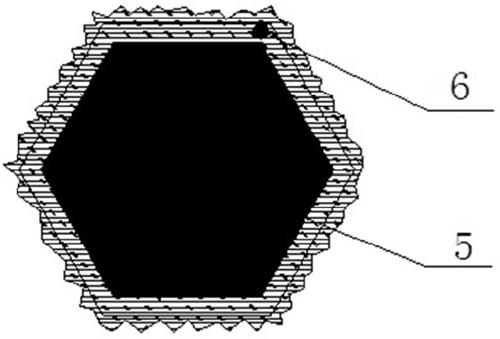

[0030] The electroplated diamond wire saw of the present embodiment, the structure diagram is as follows figure 1 As shown, it includes a base line 4 , a pre-plated metal layer 3 and a thickened metal layer 2 arranged on the base line from inside to outside in sequence, and the thickened metal layer is embedded with diamond abrasive grains 1 . Schematic diagram of the structure of diamond abrasive grains figure 2 As shown, it includes a diamond inner core 5 and a corroded carbide layer 6 with uneven surface coated on the outside of the diamond inner core 5 .

[0031] The diamond abrasive grains of the present embodiment are prepared in the following steps:

[0032] 1) Place the diamond micropowder with a particle size of 8 / 12 μm in alcohol, dry it after ultrasonic cleaning, and dry the diamond micropowder and silver-copper-titanium alloy powder (composition of Ag 72wt%, Cu 25wt%, Ti 3wt%) , particle size is 3 / 5 μ m) according to the mass ratio of 1:2 mixed evenly, to obtain...

Embodiment 2

[0038] The electroplated diamond wire saw of this embodiment has the same structure as that of Embodiment 1, and the diamond abrasive grains used are prepared by the following steps:

[0039] 1) Place the diamond micropowder with a particle size of 6 / 8 μm in alcohol, dry it after ultrasonic cleaning, and dry the diamond micropowder and nickel-chromium-phosphorus alloy powder (composition is Ni76wt%, Cr14wt%, P10wt%, particle size is 1 / 3 μm) and mixed uniformly according to the mass ratio of 1:1.5 to obtain the mixture A;

[0040] 2) Under a protective atmosphere, the mixture A was heated up to 930°C and kept for 20s to obtain the mixture B;

[0041]3) Sieve the mixture B, use the difference in particle size to remove unreacted nickel-chromium-phosphorus alloy powder, and sort out the corroded diamond powder; place the corroded diamond powder in alcohol for ultrasonic treatment (10KHz, 10min), remove the surface attachment, and obtain the diamond micropowder covered with carbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com