Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "High heat of combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

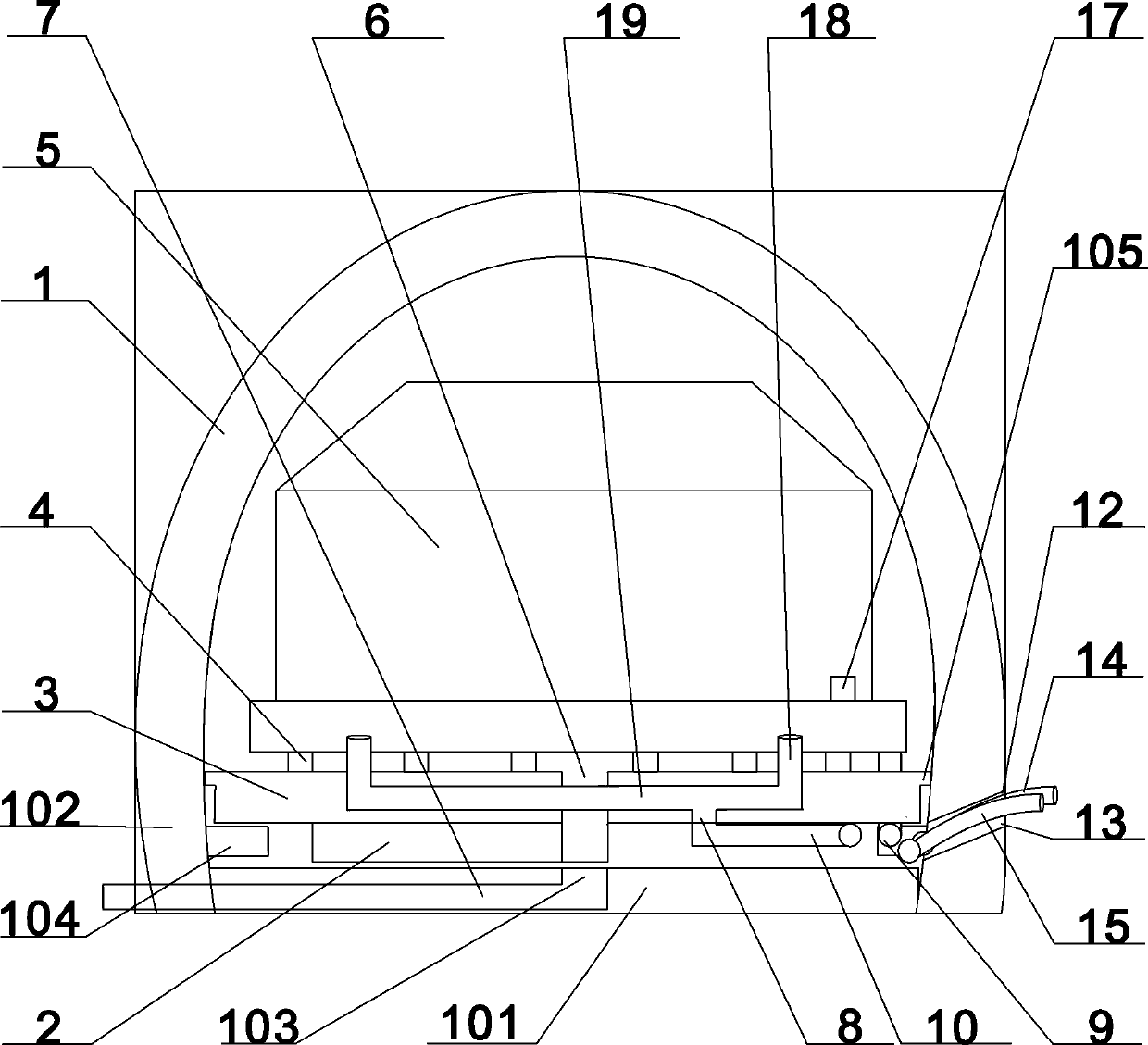

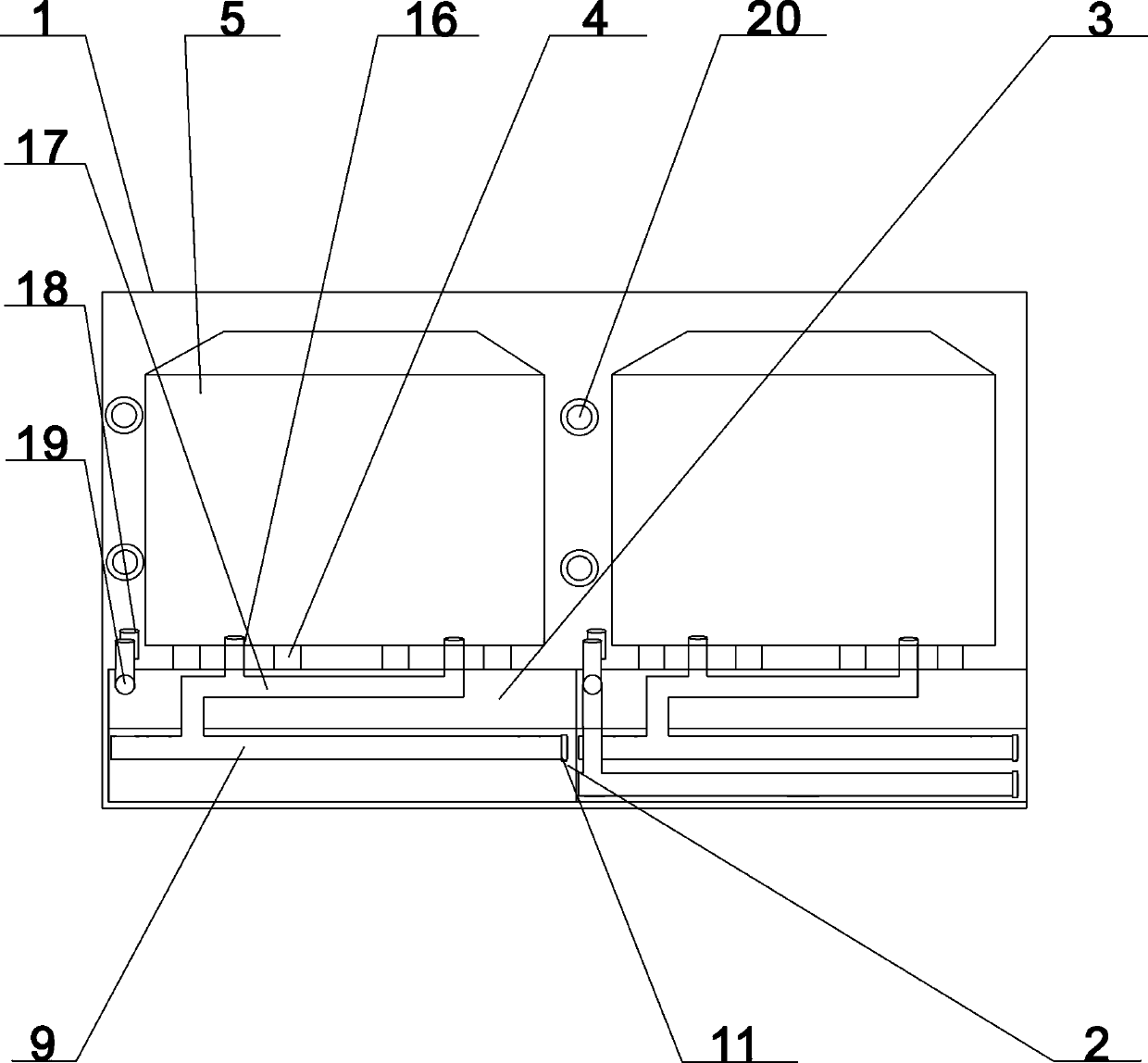

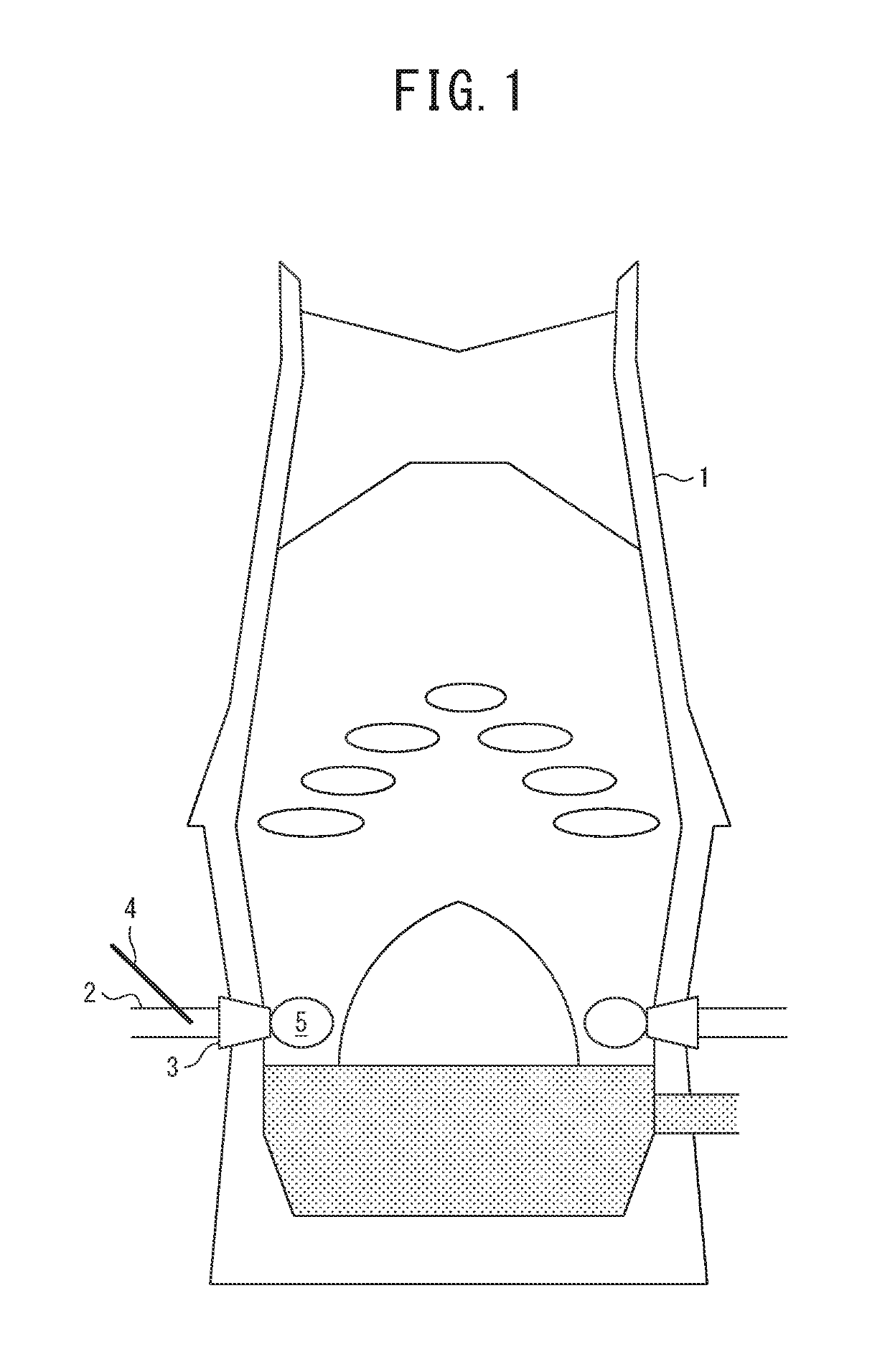

Environment-friendly efficient waste incinerator

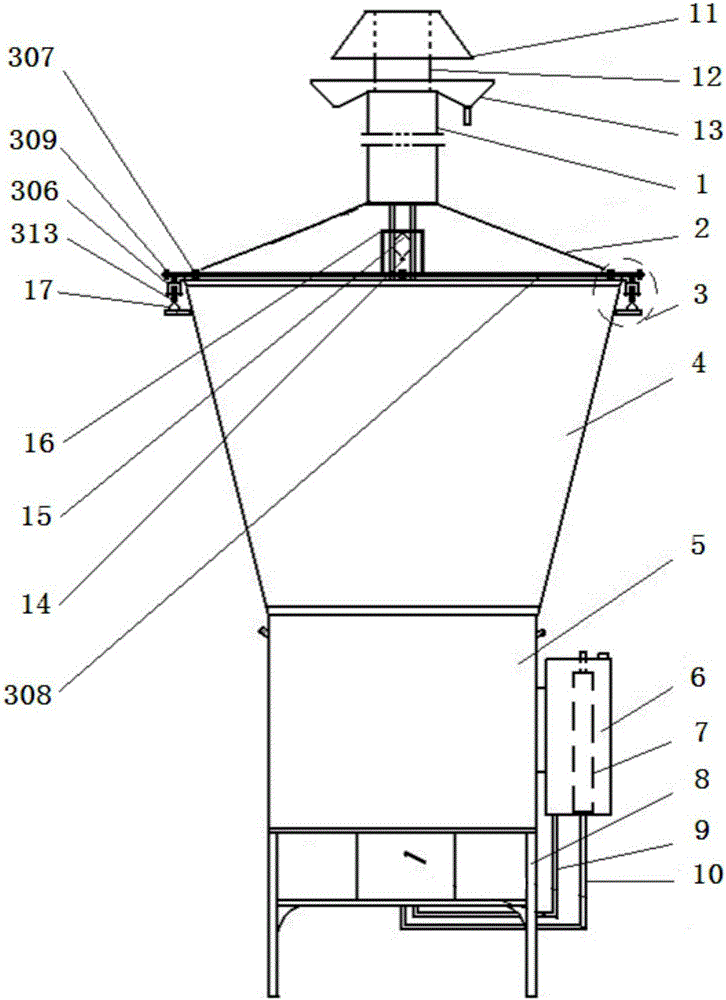

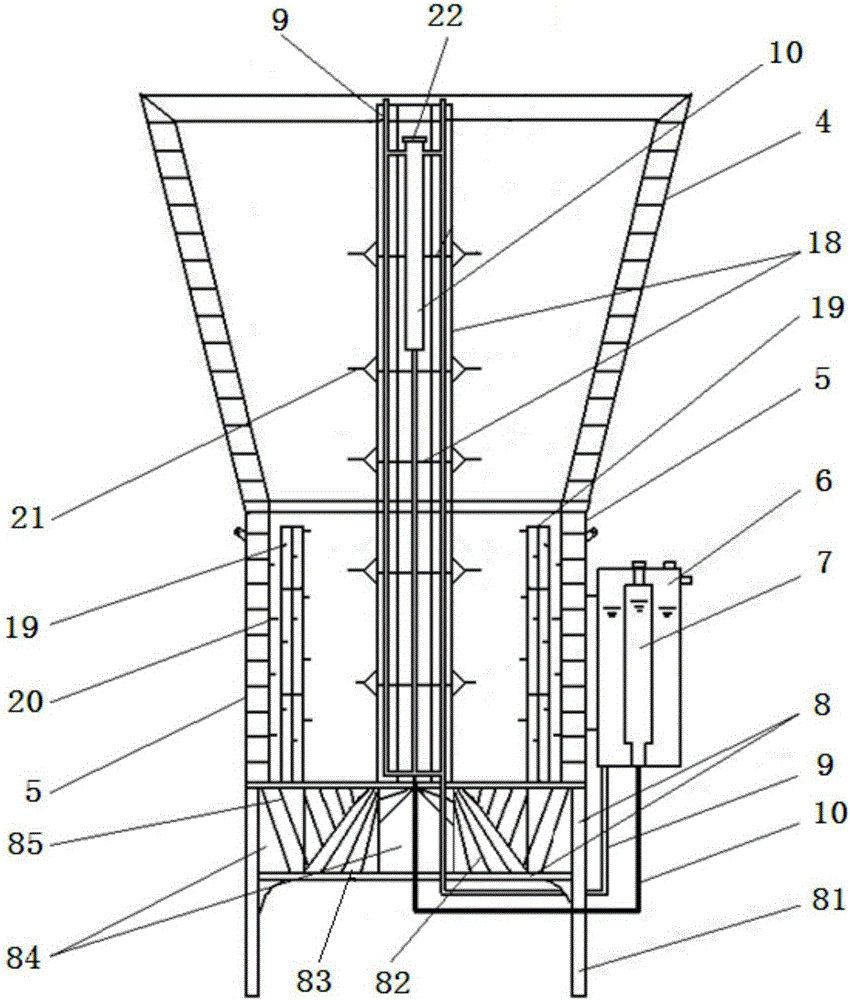

The invention discloses an environment-friendly efficient waste incinerator. The environment-friendly efficient waste incinerator comprises a lower incinerator body part, an upper incinerator body part, an internal chimney, a base, an incinerator cover and an external chimney. The upper incinerator body part and the lower incinerator body part of an incinerator body are welded into a whole. The internal chimney is arranged in the middle of the lower incinerator body part and the middle of the upper incinerator body part. A combustion chamber is formed by the lower incinerator body part and the internal chimney. Refractory bricks are arranged on the periphery of the lower incinerator body part and the periphery of the upper incinerator body part. The bottom end of the lower incinerator body part is connected with the base. Both the upper surface and the lower surface of the base are open. The incinerator cover is arranged on the upper incinerator body part. The external chimney is arranged at the top of the incinerator cover in a connected mode. A water tank is arranged outside the lower incinerator body part. An oil tank is further arranged in the water tank. A water pipe and an oil pipe are arranged in the internal chimney. The water pipe is communicated with the water tank. The oil pipe is communicated with the oil tank. According to the environment-friendly efficient waste incinerator, oil in the oil pipe can be gasified by means of heat generated during waste combustion, so that waste on the upper portion of the incinerator body can be combusted for the second time, continuous waste combustion is achieved, incineration is thorough and rapid, and the incineration effect is good; pollution to the environment is small, and the environment-friendly efficient waste incinerator is suitable for waste treatment in village and town communities, schools and hospitals.

Owner:都安通达环保设备制造厂(普通合伙)

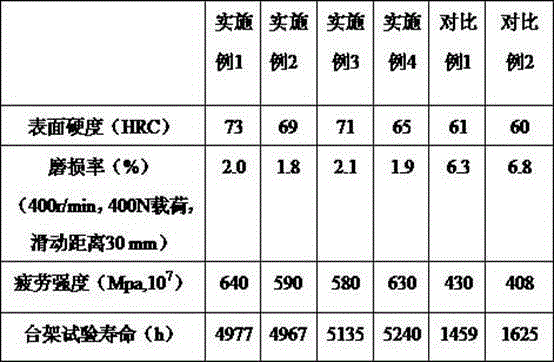

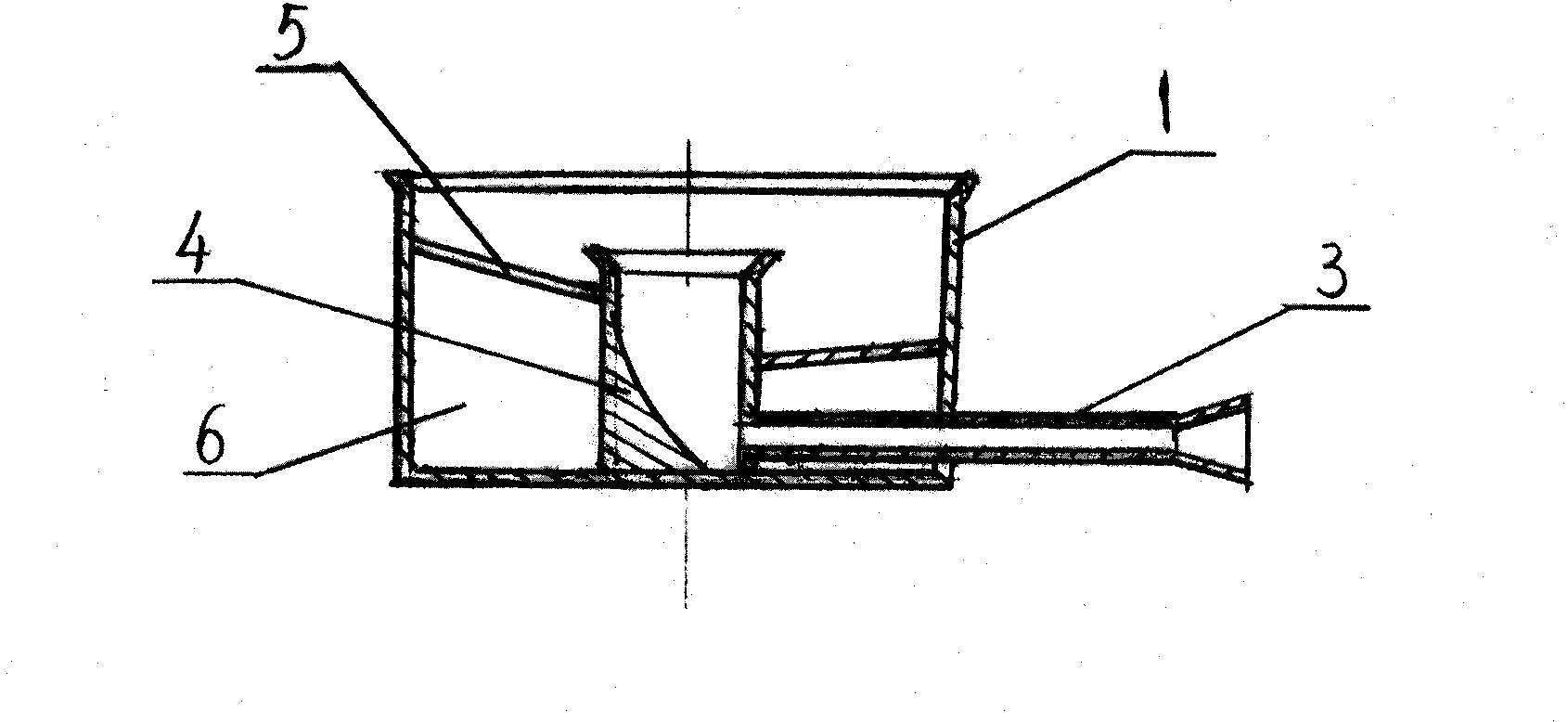

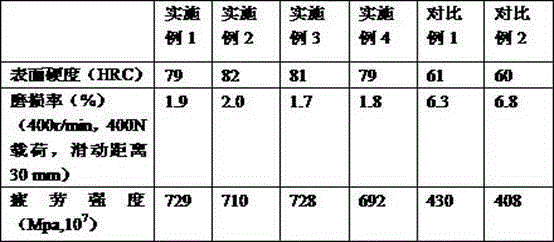

High-performance engine inlet valve and preparing method thereof

InactiveCN105296858AImprove high temperature performanceImprove antioxidant capacityMachines/enginesLift valveInlet valveUltimate tensile strength

The invention discloses an engine inlet valve and a preparing method thereof. The inlet valve is prepared from, by weight percentage, 0.32% to 0.40% of C, 0.17% to 0.37% of Si, 2.5% to 3.5% of Mo, 0.50% to 0.80% of Mn, 0.80% to 1.10% of Cr, 0.50% to 1.0% of W, smaller than or equal to 0.013% of Ni, smaller than or equal to 0.015% of P, smaller than or equal to 0.015% of S, smaller than or equal to 0.010% of Cu and the balance Fe. The inlet valve is manufactured through the processes including surface nanocrystallization, low-temperature nitriding, tungsten and zirconium alloy bead welding and the like. The inlet valve is large in surface strength, high in hardness, good in abrasion resistance and long in service life.

Owner:杨秋香

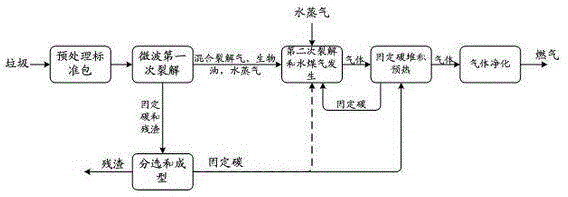

Process for preparing gas by microwave carbon pyrolysis of municipal solid waste

ActiveCN102719279ALarge amount of gasPromote lysisSolid waste disposalSpecial form destructive distillationWater vaporMaterials science

The invention relates to a process for preparing gas by the microwave carbon pyrolysis of municipal solid waste and belongs to the technical field of environmental protection. The process comprises the following steps of: removing dust from municipal solid waste which is accumulated for a certain time, press-packing, and feeding into microwave heating equipment for pyrolysis; separating fixed carbon and residue which are generated by the pyrolysis, and making the fixed carbon into a shape which is loose and through which gas can conveniently pass; continuously heating the fixed carbon, and fully cracking incomplete pyrolysis gas and biological oil to generate combustible gas; reacting water vapor and thermofixed carbon to generate water gas; and performing purification treatment such as desulfurization and dephosphorization on the gas to obtain harmless combustible gas. By the process, the yield of the gas is high, the calorific value is high, the energy is equal to or higher than the energy consumed by the process, and the operation cost is low; and toxic and substances with peculiar smell such as dioxin are eradicated while a large amount of harmless combustible gas is obtained, so that the environment is effectively protected.

Owner:SICHUAN HOPE MICROWAVE SCI & TECH

Method of producing honeycomb structure

ActiveUS20100194004A1Avoid componentsVariation in dimensional accuracy can be suppressedCeramic shaping apparatusCeramicwareMethyl celluloseHoneycomb structure

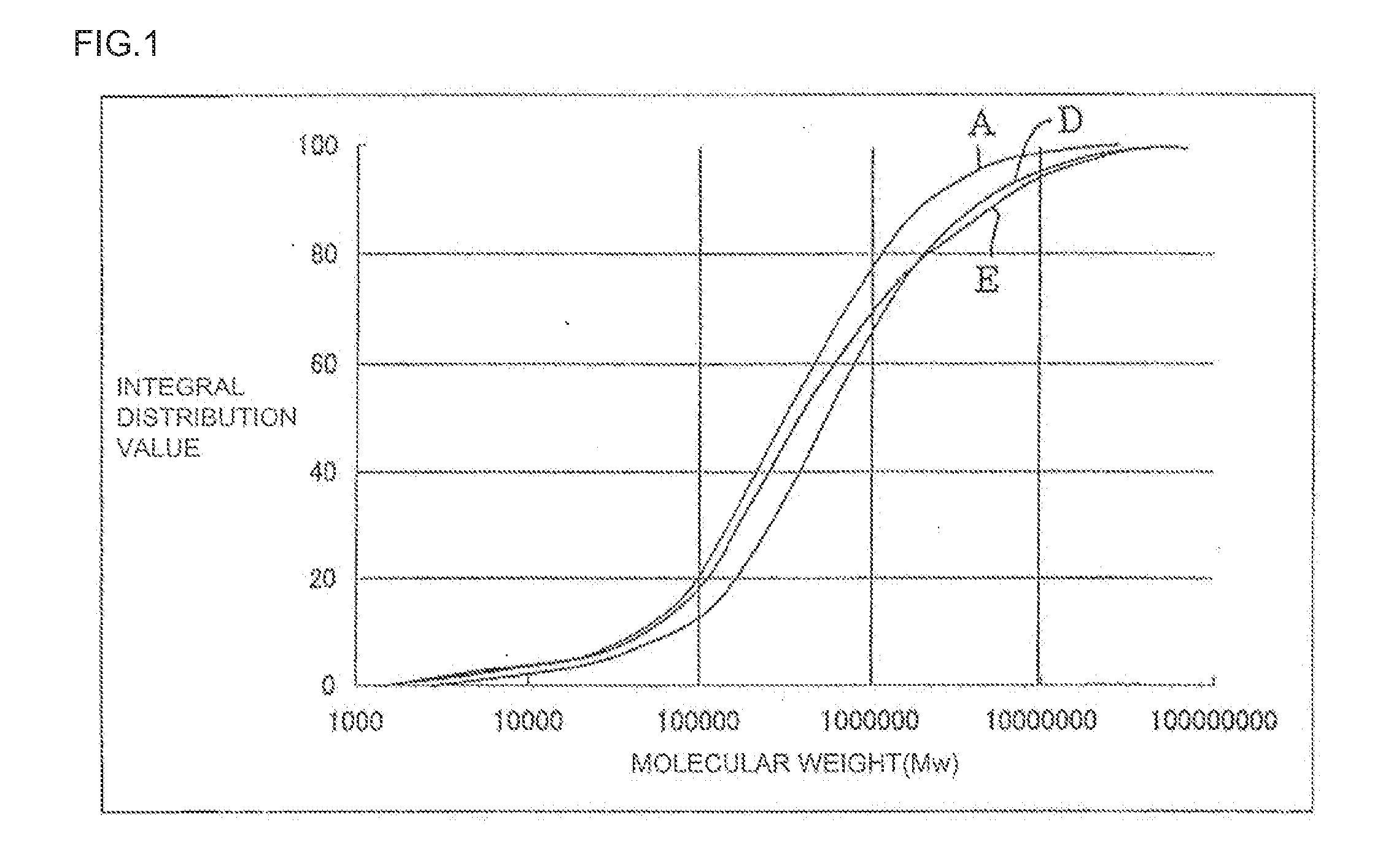

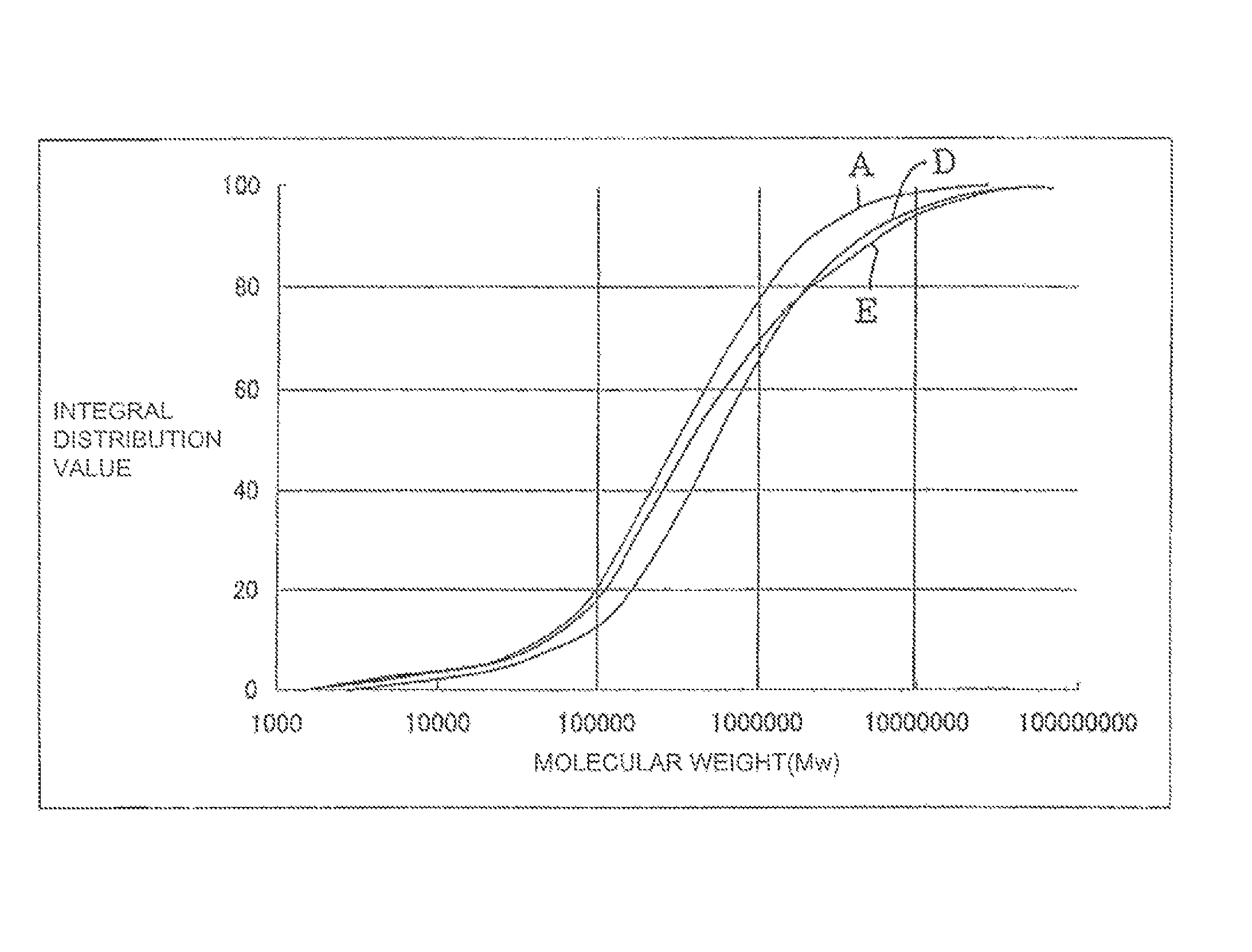

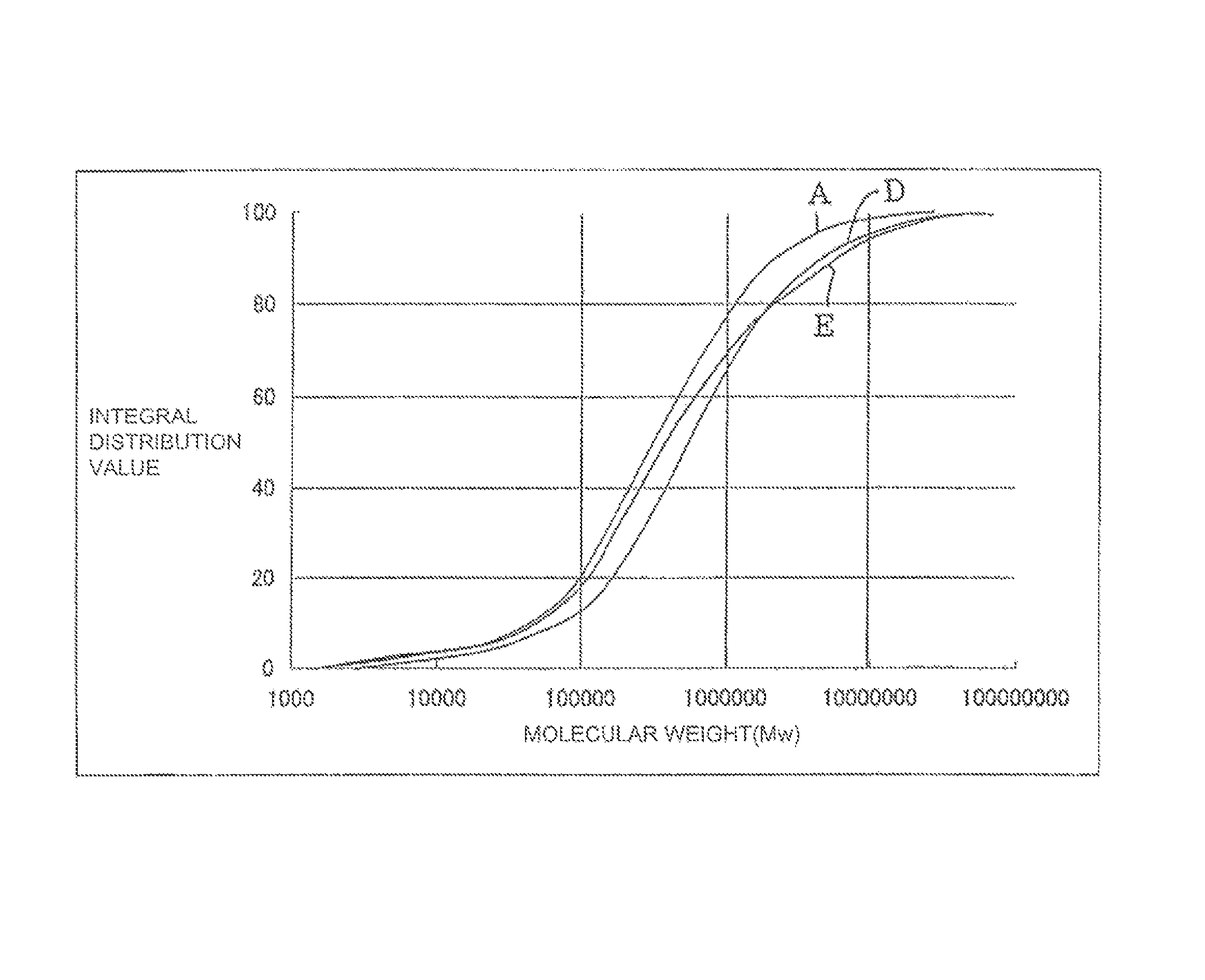

A method of producing a honeycomb structure includes producing a honeycomb structure using methyl cellulose as at least part of a binder, the methyl cellulose having a weight average molecular weight (Mw) of 4,000,000 to 5,000,000, and having an integral molecular weight distribution value of components having a molecular weight of 100,000 or less in the integral molecular weight distribution curve of 15 or less.

Owner:NGK INSULATORS LTD

Granular biomass fuel and preparation method thereof

The invention discloses a granular biomass fuel which comprises a biomass raw material and an additive, wherein the additive is calcium carbonate, magnesium carbonate or a mixture of calcium carbonate and magnesium carbonate; and the weight of the additive is 0.1%-1.8% of that of the biomass raw material. According to the granular biomass fuel disclosed by the invention, acidic volatile gas can be prevented from volatilizing into atmosphere; the problems of environmental pollution caused by the acidic volatile gas and insufficient combustion of the granular biomass fuel are solved; and the combustion efficiency of the granular biomass fuel is improved.

Owner:海聚高分子材料科技(广州)有限公司 +2

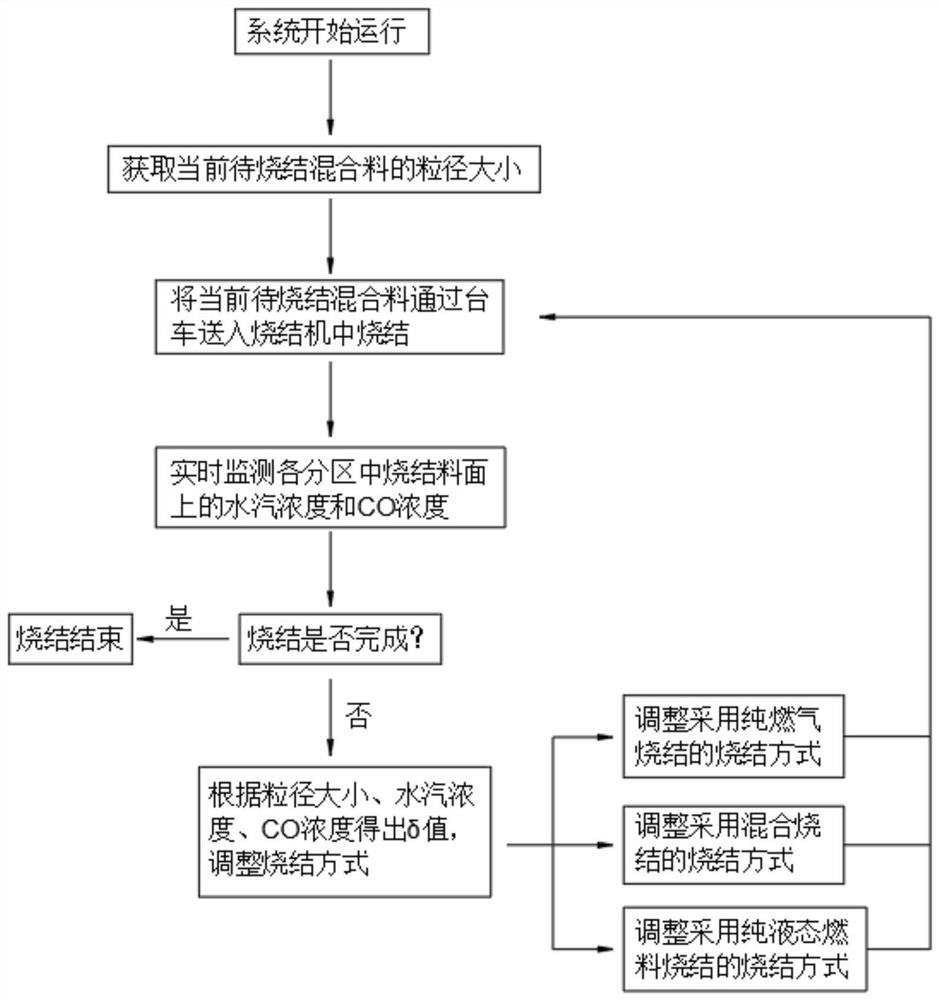

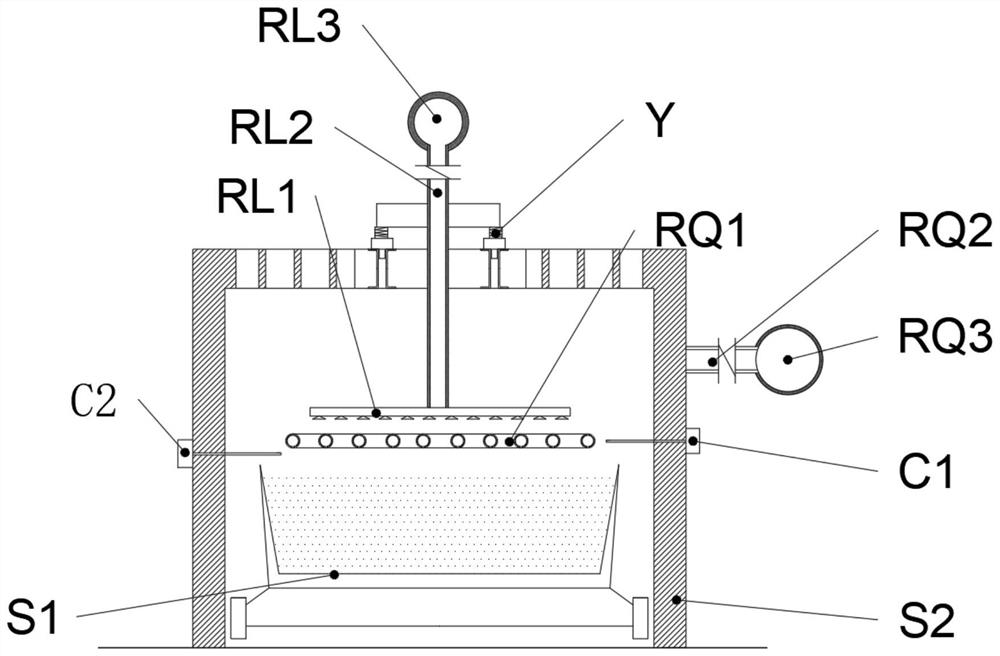

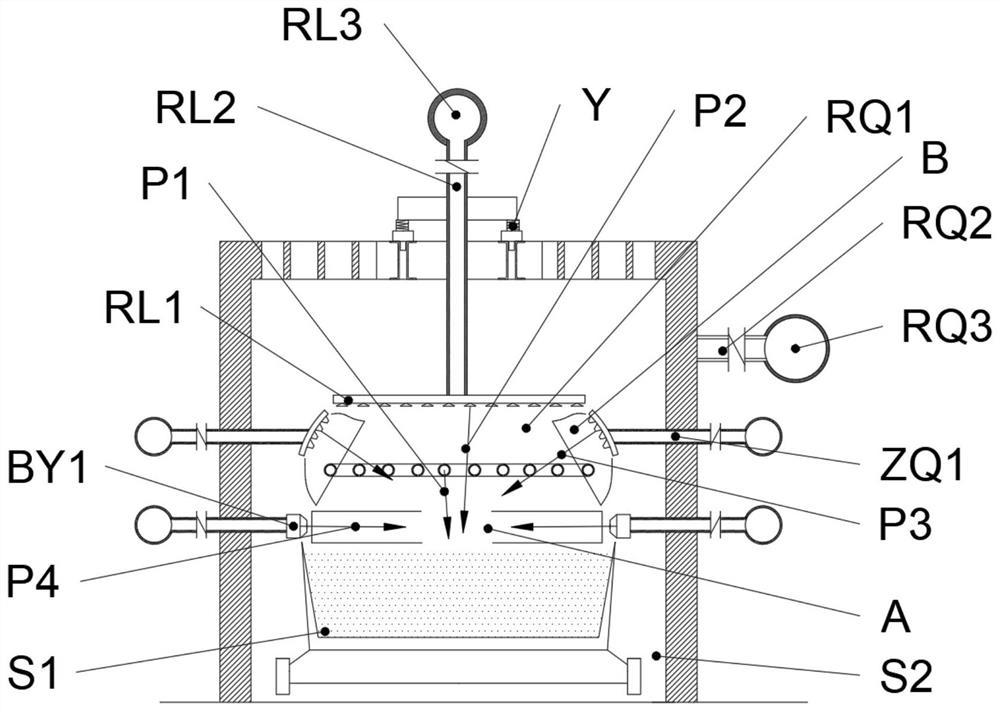

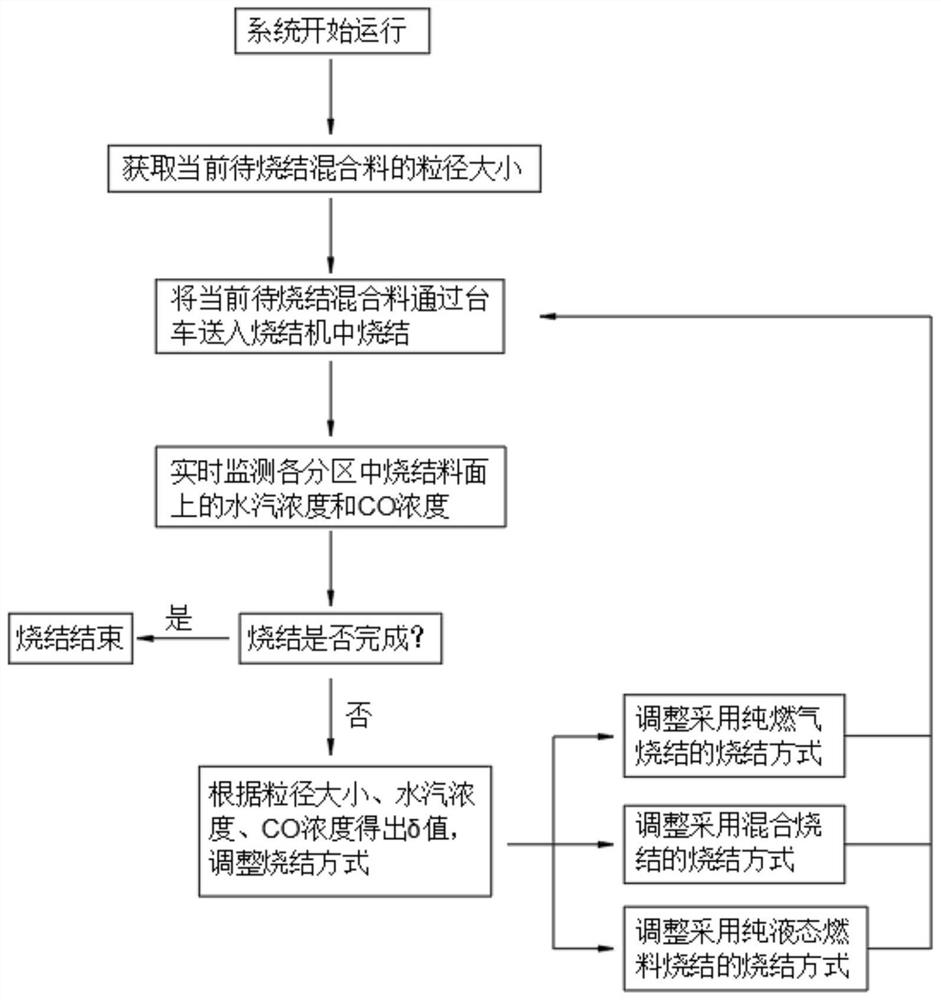

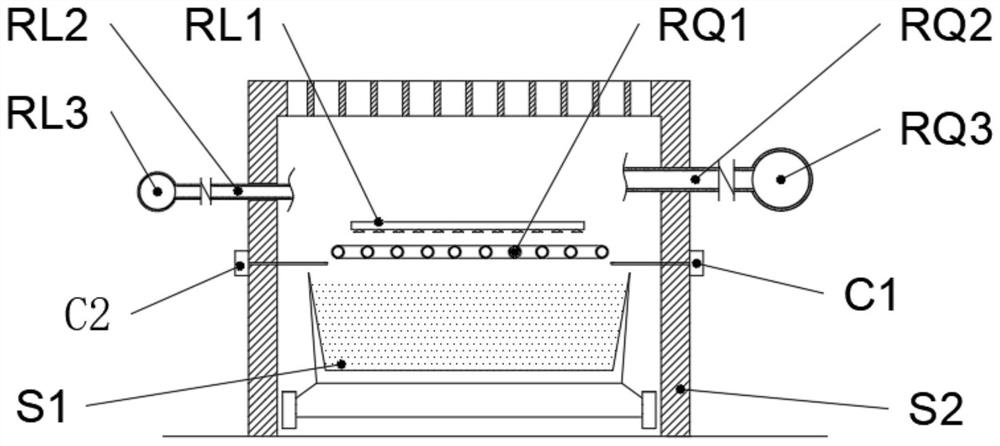

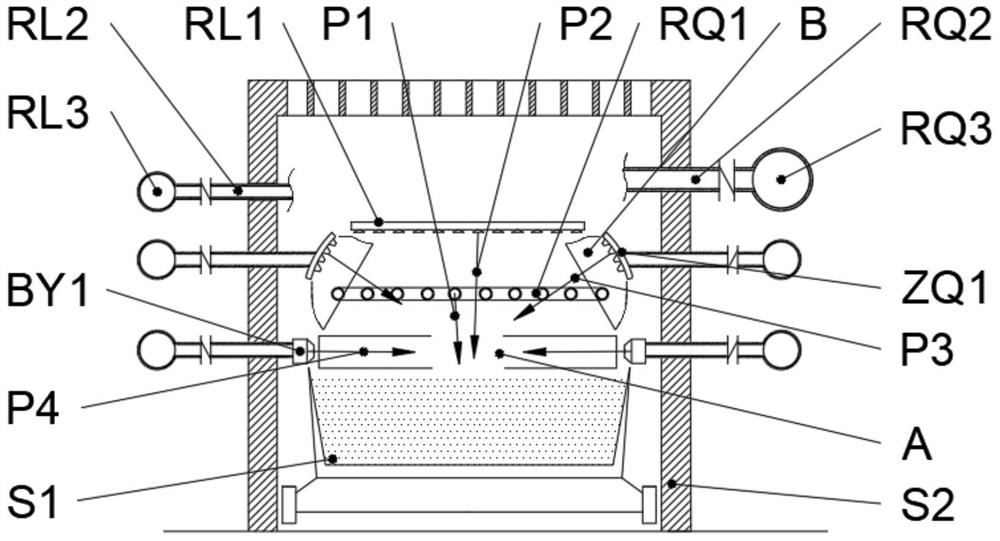

Liquid-gas two-phase medium coupling mobile injection sintering method and injection device

The invention relates to a liquid-gas two-phase medium coupling mobile injection sintering method and an injection device. The method comprises the following steps: 1) the particle size D of a currentmixture to be sintered is obtained; 2) the mixture to be sintered is fed into a sintering machine through a trolley for sintering, gaseous fuel is injected to the sintering material surface of the trolley in an integral form, and liquid fuel is injected to the material surface of the trolley in a moving form; (3) when the mixture to be sintered is sintered on the trolley, the water vapor concentration Cwater and the CO concentration CCO on sintered material surfaces in all node positions are monitored in real time; and 4) one of the injection sintering modes of pure gaseous fuel sintering, pure liquid fuel sintering and mixed sintering is selected, and the injection sintering mode in the step 2) is adjusted. According to the technical scheme, the atomized liquid fuel and the gaseous fuelare mixed, so that the combustion value of injection sintering technology is increased, the range of the injection amount of the injection sintering technology is widened, and the requirement for theextreme combustion injection amount is met.

Owner:CENT SOUTH UNIV

Gas generator ignition agent and preparation method thereof, and gas generator for vehicle safety airbag

ActiveCN108456126AImprove ignitabilityIncrease gas production ratePedestrian/occupant safety arrangementExplosive working-up apparatusStart timePotassium

The invention provides a gas generator ignition agent and a preparation method thereof, and a gas generator for a vehicle safety airbag. The gas generator ignition agent contains a fuel, an oxidant, abinder and an additive, wherein the additive is an oxazole-based energy-containing ionic compound. According to the present invention, by adding 5-aminotetrazole nitrate to a boron / potassium nitrateignition agent, on the basis of the ensuring of the combustion heat and the combustion temperature of the agent, the high-temperature and high-pressure gas amount can be increased, the output pressureof the ignition agent can be increased, and the output performance of the ignition pipe can be increased, such that the pressure starting time of the gas generator is advanced to less than 2 ms, andthe pressure value at 10 ms is increased by about 20 Kpa so as to improve the gas generating performance of the gas generator.

Owner:BYD CO LTD

High thermal-energy fuel or diesel additive and preparation method thereof

InactiveCN105132116AGood miscibilityHigh heat of combustionLiquid carbonaceous fuelsLubricant compositionCombustionEconomic benefits

The invention discloses a method of preparing a high thermal-energy fuel or a diesel additive. The method includes the steps of pre-treating waste engine oil, performing emulsification with water, performing cross-dissolution washing with water repeatedly to take away colloids, ashes, pigments and other impurities from the waste engine oil, and finally modifying layered oil to form the high thermal-energy fuel or the diesel additive. The high thermal-energy fuel is high in combustion heat energy and has important application value. In addition, the diesel additive is good in intersolubility with diesel, and has the effects of improving power, promoting sufficient combustion, being good in cleaning and dispersion, and lubricating and protecting an engine. The method is easy to carry out and mild in conditions, is good in economic benefit and is suitable for practical application.

Owner:朱明

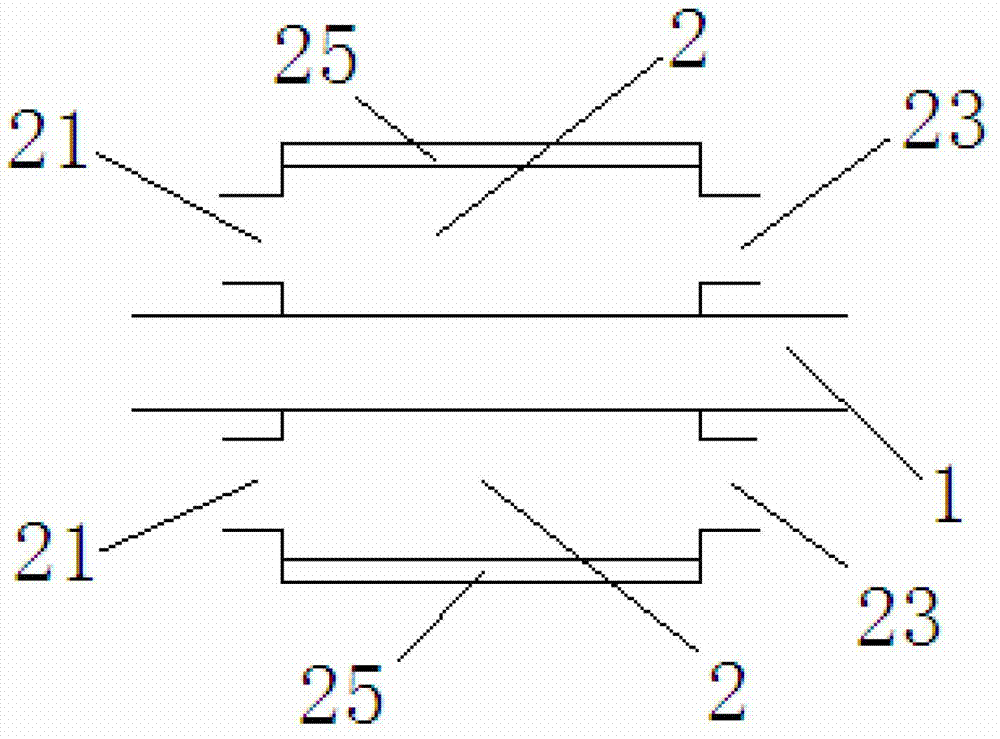

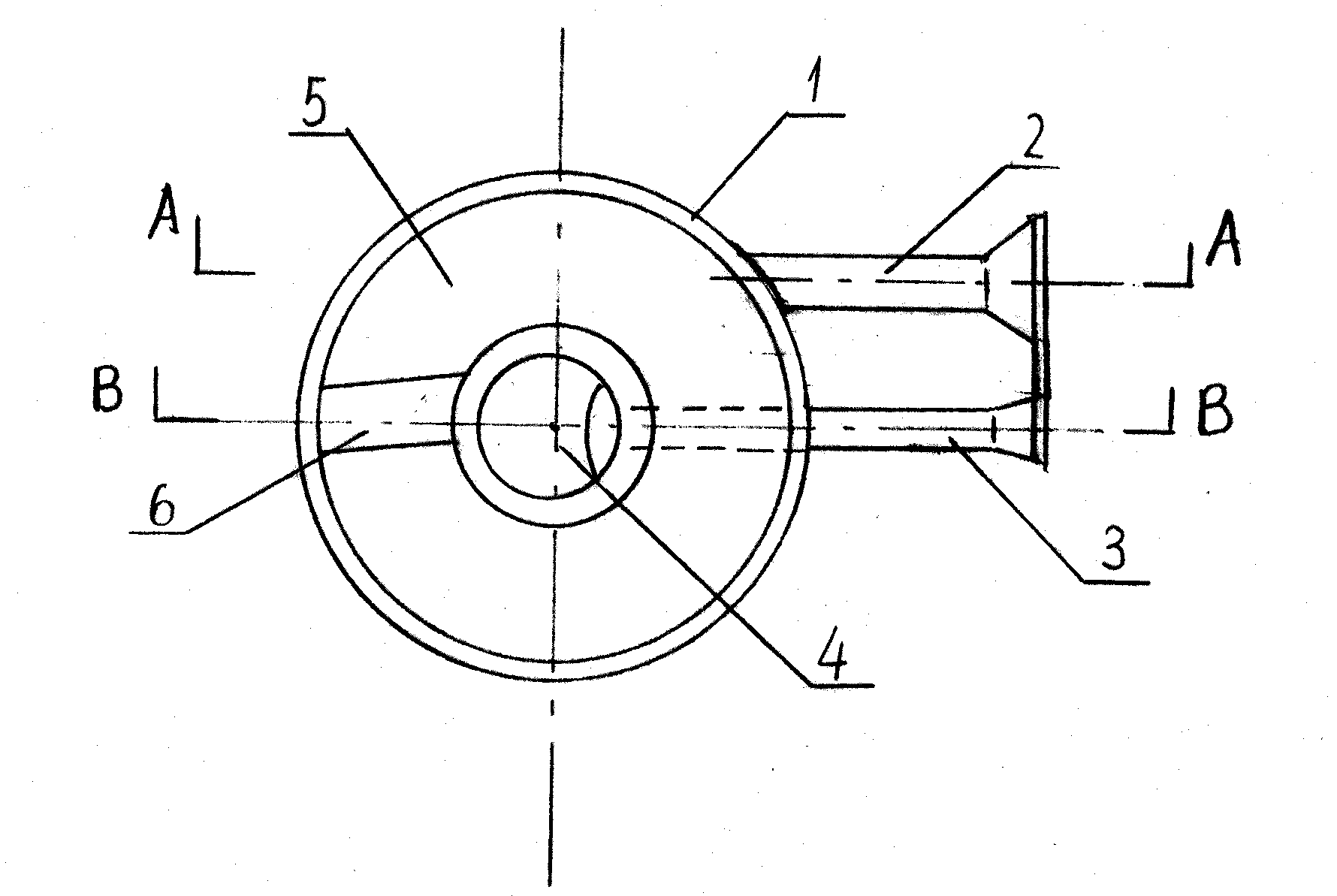

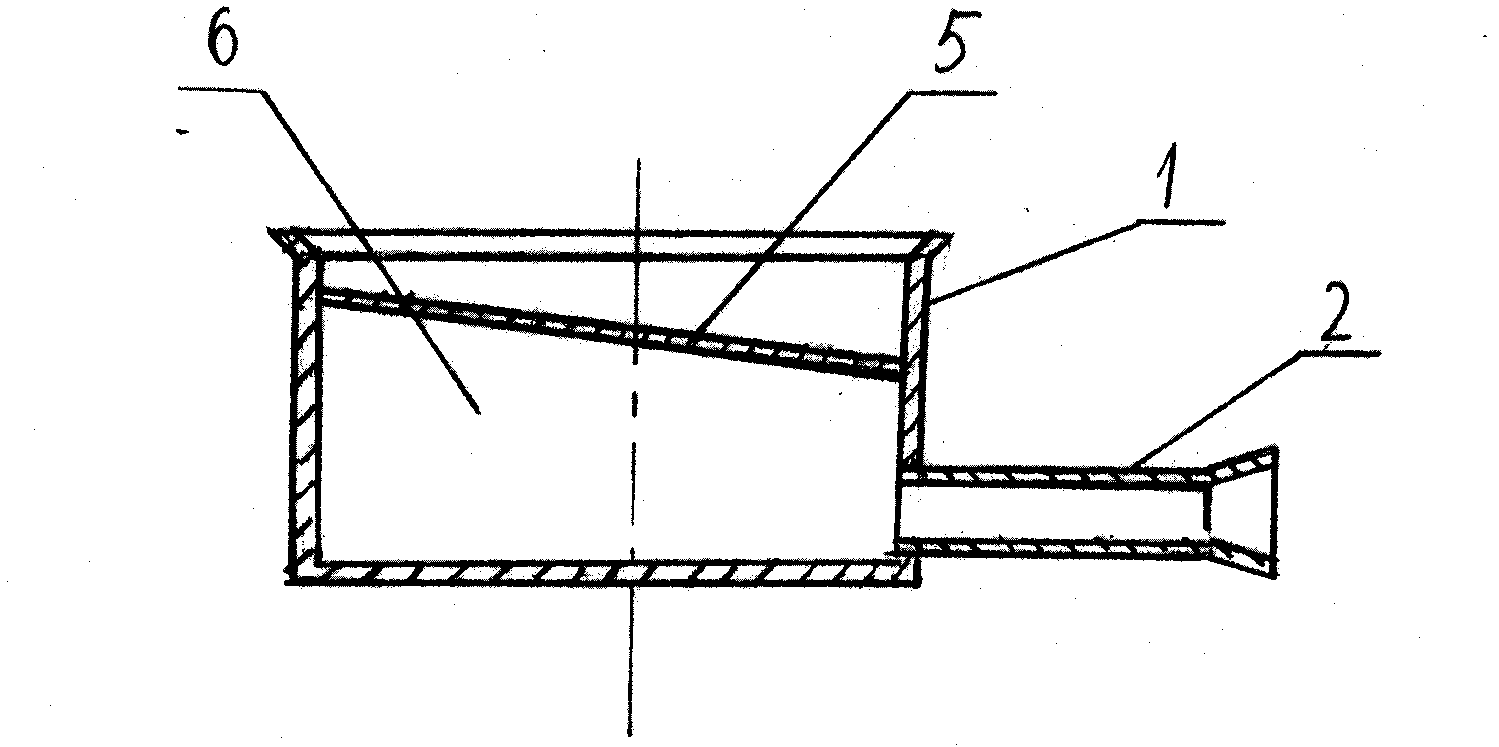

Blast furnace coal spraying tube, and method for reducing coke rate of blast furnace

InactiveCN103589818AReduce focal ratioHigh heat of combustionTuyeresBlast furnace detailsIgnition pointCoal dust

The invention discloses a blast furnace coal spraying tube. The blast furnace coal spraying tube comprises a blowing portion (1) connected with a spraying gun of the blast furnace coal spraying tube, and a heating portion (2) sleeved outside the blowing portion, wherein a thermal medium providing heat for coal dust in the blowing portion is accommodated between the heating portion and the blowing portion. The invention also discloses a method for reducing the coke rate of a blast furnace. The method comprises a step that the coal dust in the blast furnace coal spraying tube is preheated in a position of the blast furnace coal spraying tube adjacent to a coal dust inlet of the blast furnace. The preheated coal dust is blown into the blast furnace at a temperature close to the ignition point, and can be directly ignited without absorbing the combustion heat of coke in the blast furnace, so the effectiveness of the combustion heat of the coke is effectively improved, thereby the coke rate of the blast furnace is reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Copper bar production process

ActiveCN111014296AAchieve recyclingIncrease profitMetal rolling arrangementsCombustion chamberExhaust fumes

The invention relates to a copper bar production process which comprises the following steps of (1) melting copper: using a copper plate preheating furnace for melting a copper plate into molten copper, reflowing high-temperature waste gas after combustion into a nozzle in the period, preheating gas in an outer gas guiding pipe and an inner gas guiding pipe, increasing gas pressure in the outer gas guiding pipe and the inner gas guiding pipe, feeding the gas flowing out through the nozzle into a preheating chamber of a combustion chamber of the preheating furnace, and preheating a copper plateto be melted; (2) casting a rod: casting the molten copper to the surface of a core rod, and generating the casting rod; (3) hot-rolling: carrying out hot-rolling treatment on the cooled casting rod,and generating a copper rod; and (4) winding: winding the copper rod into a coil. According to the copper bar production process provided by the invention, the high-temperature waste gas reflows intothe nozzle and flows out through the nozzle to enter the preheating chamber so as to preheat the copper plate, so that the heat is recycled, and the utilization ratio of the heat is improved.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

Liquid-gas two-phase medium coupling partition blowing sintering method and blowing device

The invention provides a liquid-gas two-phase medium coupling partition blowing sintering method and a blowing device. The method comprises the following steps that (1) the particle size D of a to-be-sintered mixture is obtained; (2) the to-be-sintered mixture is fed into a sintering machine through a trolley to be sintered, and gas fuel and liquid fuel are blown to the material face of the trolley in a partition manner; (3) when the to-be-sintered mixture is sintered on the trolley, the water vapor volume concentration CCO of C water and CO on the sintered material face in each partition is monitored in real time; and (4) according to the data water and CCO in the step (1) and the step (3), one blowing sintering manner of pure gas fuel sintering, pure liquid fuel sintering and mixed sintering blowing sintering manners is selected, and the blowing sintering manner in the step (2) is adjusted. According to the technical scheme, atomized liquid fuel and gas fuel are mixed, the combustionvalue of the blowing sintering technology is increased, the blowing amount range of the blowing sintering technology is widened, and the requirement for the extreme combustion blowing amount is met.

Owner:CENT SOUTH UNIV

Combustion gas mixer used in gas-cooker

InactiveCN102692021AFierce firepowerHigh heat of combustionGaseous fuel burnerBarrel ShapedGas chamber

A combustion gas mixer used in a gas-cooker belongs to a gas stove appliance. Spiral rising combustion gas guide blades are arranged inside an annular combustion gas chamber. A bottom end of the spiral rising combustion gas guide blades contacts and is connectedly engaged with an inner wall surface at a bottom end of a barrel shape device body; a concave cambered projection is connectedly arranged between an inner wall surface and a sidewall internal surface at a bottom end of a bell mouth shaped center combustion gas output barrel, the concave cambered surface shaped projection faces a gas outlet of an inner combustion gas conveyer pipe. According to the invention, combustion gas is provided with assisting power for forced rapid rising in both the annular combustion gas chamber and the bell mouth shaped center combustion gas output barrel. The mixer of the invention has the advantages of strong flame, large combustion heat output, high temperature, full combustion gas combustion, rapid stove flame-up and flame-out responses, and good security.

Owner:杜博韬

Novel amorphous reinforced valve material

InactiveCN105385950AImprove high temperature performanceHigh strengthMachines/enginesLift valveInlet valveAlloy

The invention discloses a novel amorphous reinforced valve material and a preparation method thereof. An alloy adopted by a valve comprises, by weight percentage, 0.32%-0.40% of C, 0.17%-0.37% of Si, 2.5%-3.5% of Mo, 0.50%-0.80% of Mn, 0.80%-1.10% of Cr, 0.50%-1.0% of W, less than or equal to 0.013% of Ni, less than or equal to 0.015% of P, less than or equal to 0.015% of S, less than or equal to 0.010% of Cu and the balance Fe. The inlet valve material is machined through the process of smelting, forging and welding the amorphous alloy. The valve material is high in surface hardness, good in wear resistance and long in service life.

Owner:杨秋香

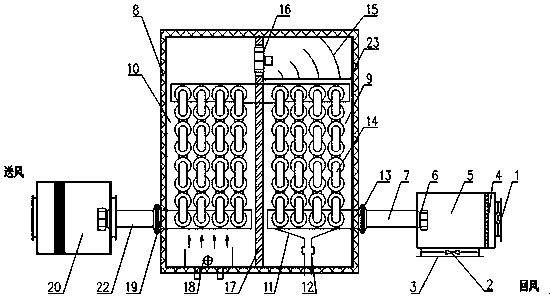

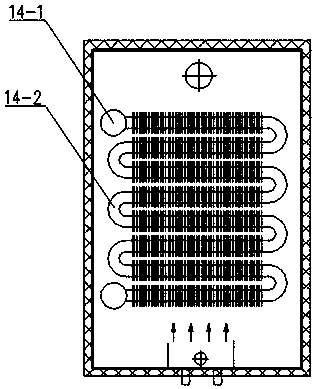

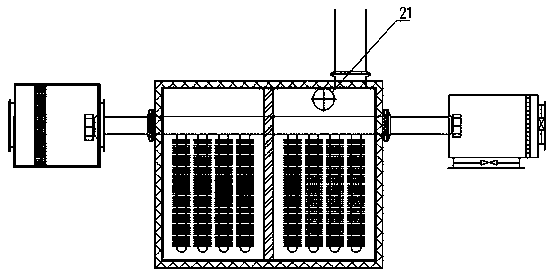

Household natural gas heat supply system

PendingCN110542148AHigh heat of combustionPollution-free bookCondensate preventionHeating and ventilation casings/coversCold airCombustion chamber

The invention relates to a household natural gas heat supply system. The system comprises a casing, a fresh air device, a heating device and a humidifier. The system is characterized in that the freshair device and the humidifier are mounted in a kitchen ceiling of a user and connected with the heating device through an air supply pipeline; the fresh air device comprises a fresh air return port,a filter net and a fan; the heating device is divided into a preheating cavity on the right side and a heating cavity on the left side; a condensate water disc and one part of an S-shaped tubular heatexchanger are placed in the preheating cavity, and a smoke exhaust pipe is horizontally arranged behind the preheating cavity; and a combustion chamber and the other part of the S-shaped tubular heatexchanger are placed in the heating cavity, and air in the S-shaped heat exchanger in the heating cavity communicates with the preheating cavity through a main pipe. Flue gas produced by combustion of natural gas is used for directly heating the air, low-temperature flue gas preheats cold air, and the temperature of exhausted flue gas is decreased.

Owner:HEBEI UNIV OF TECH

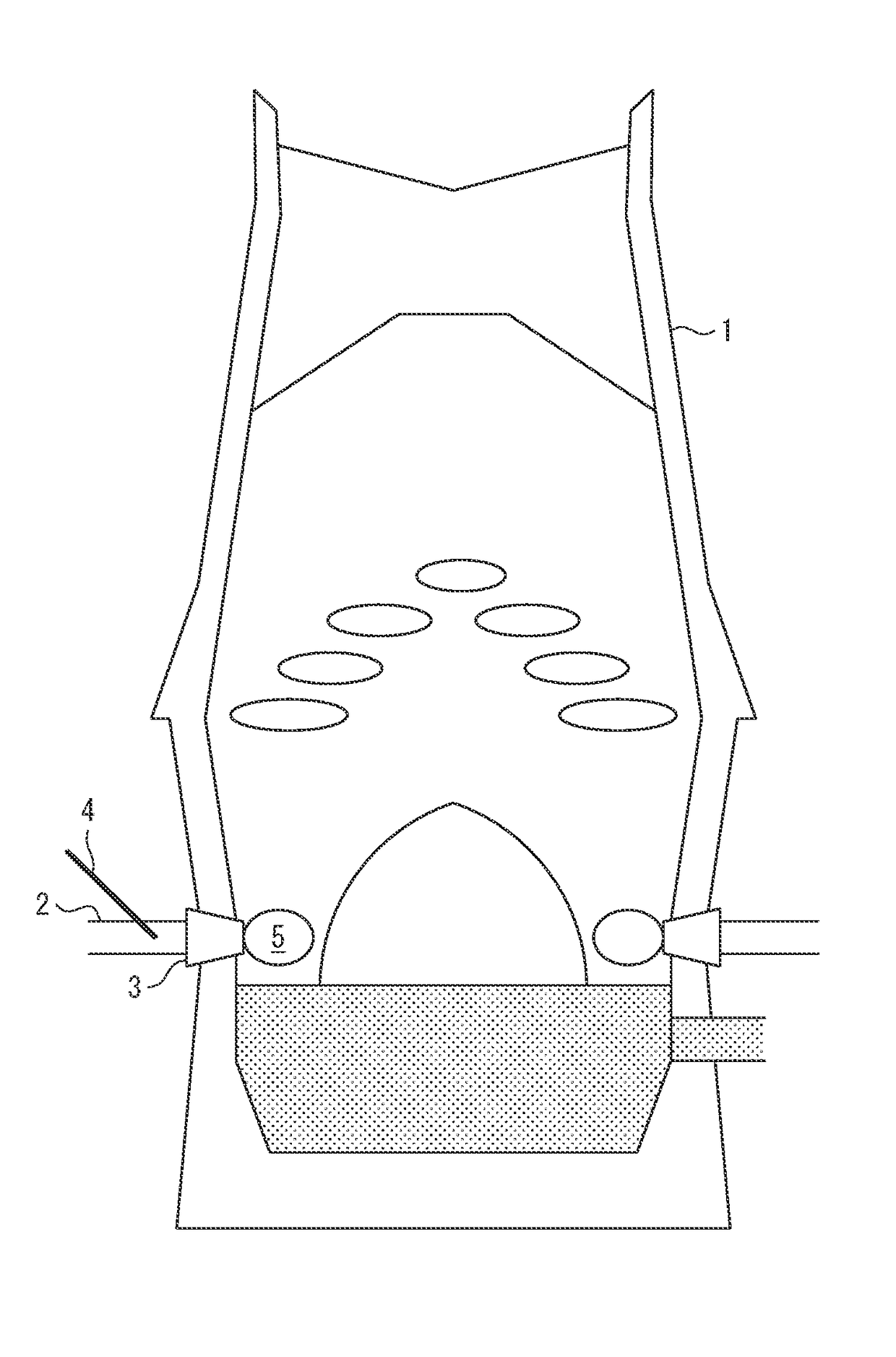

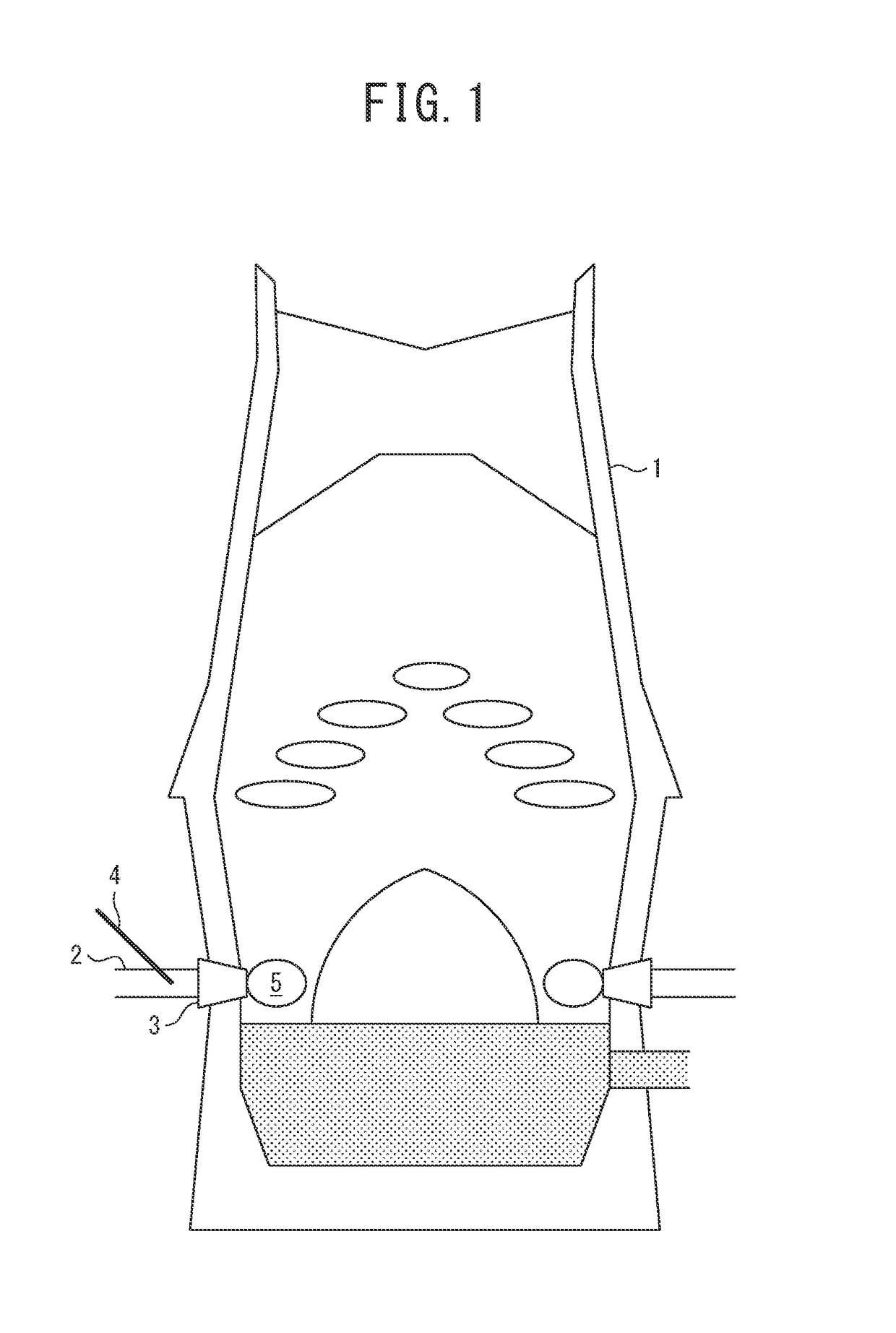

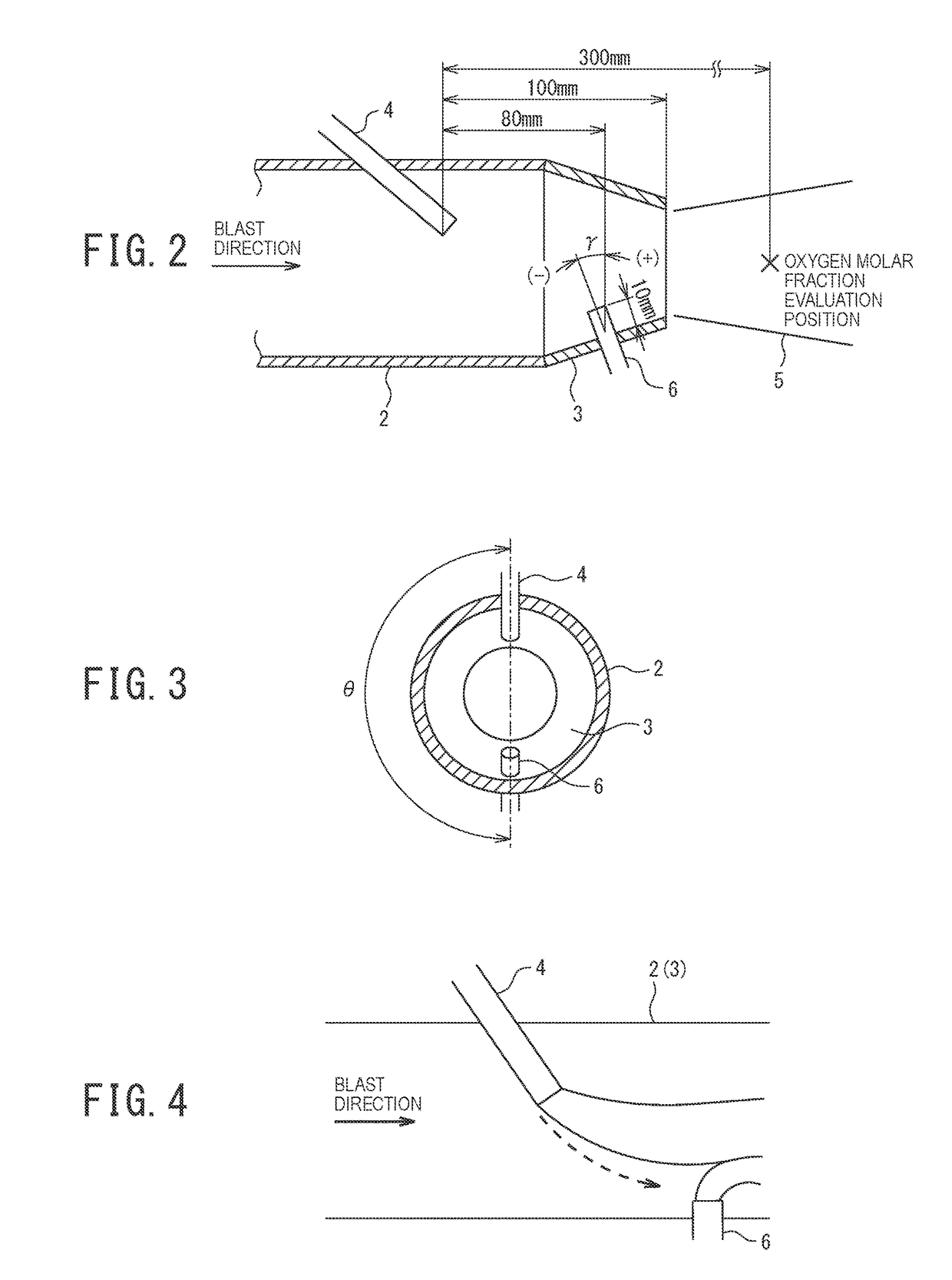

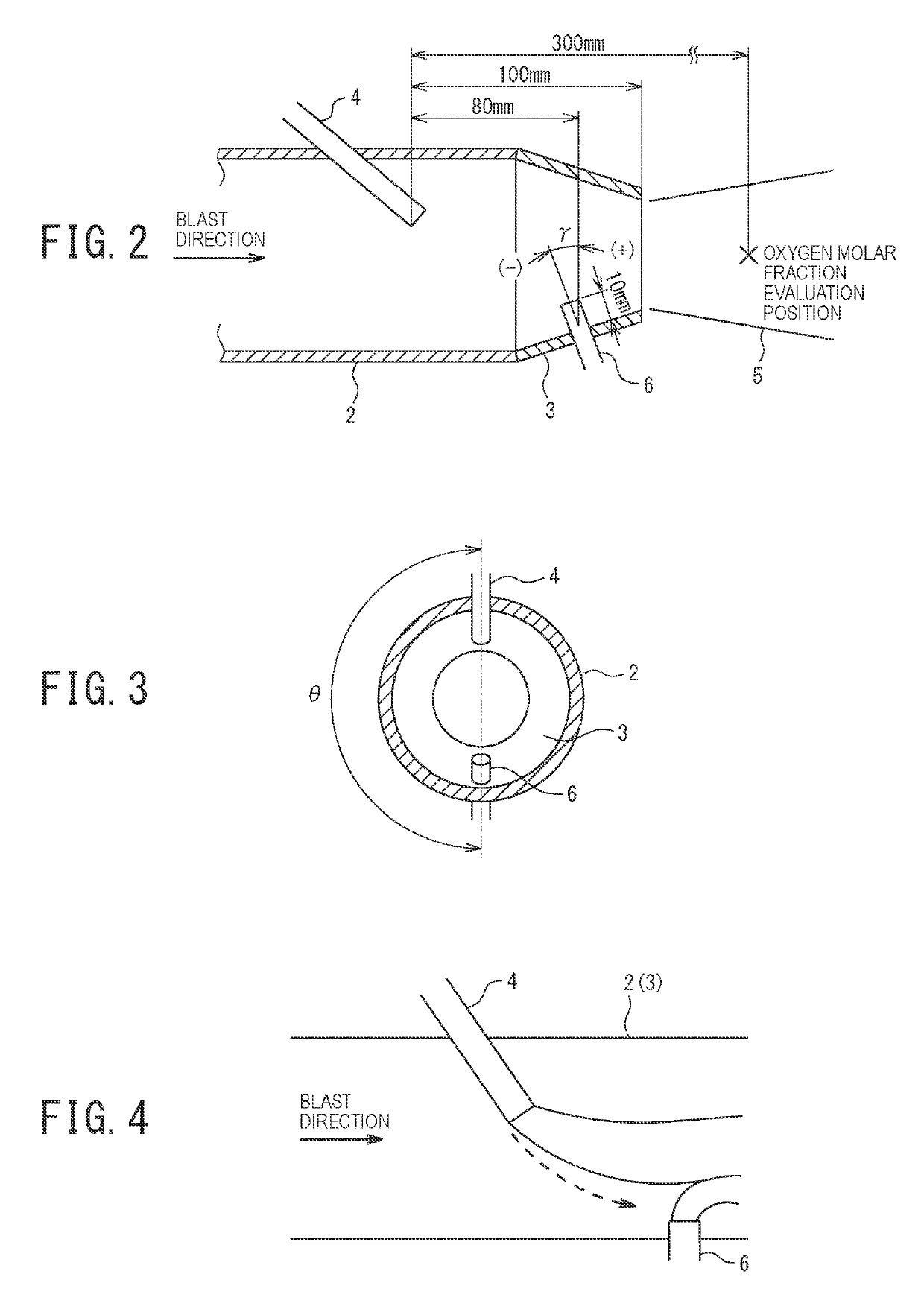

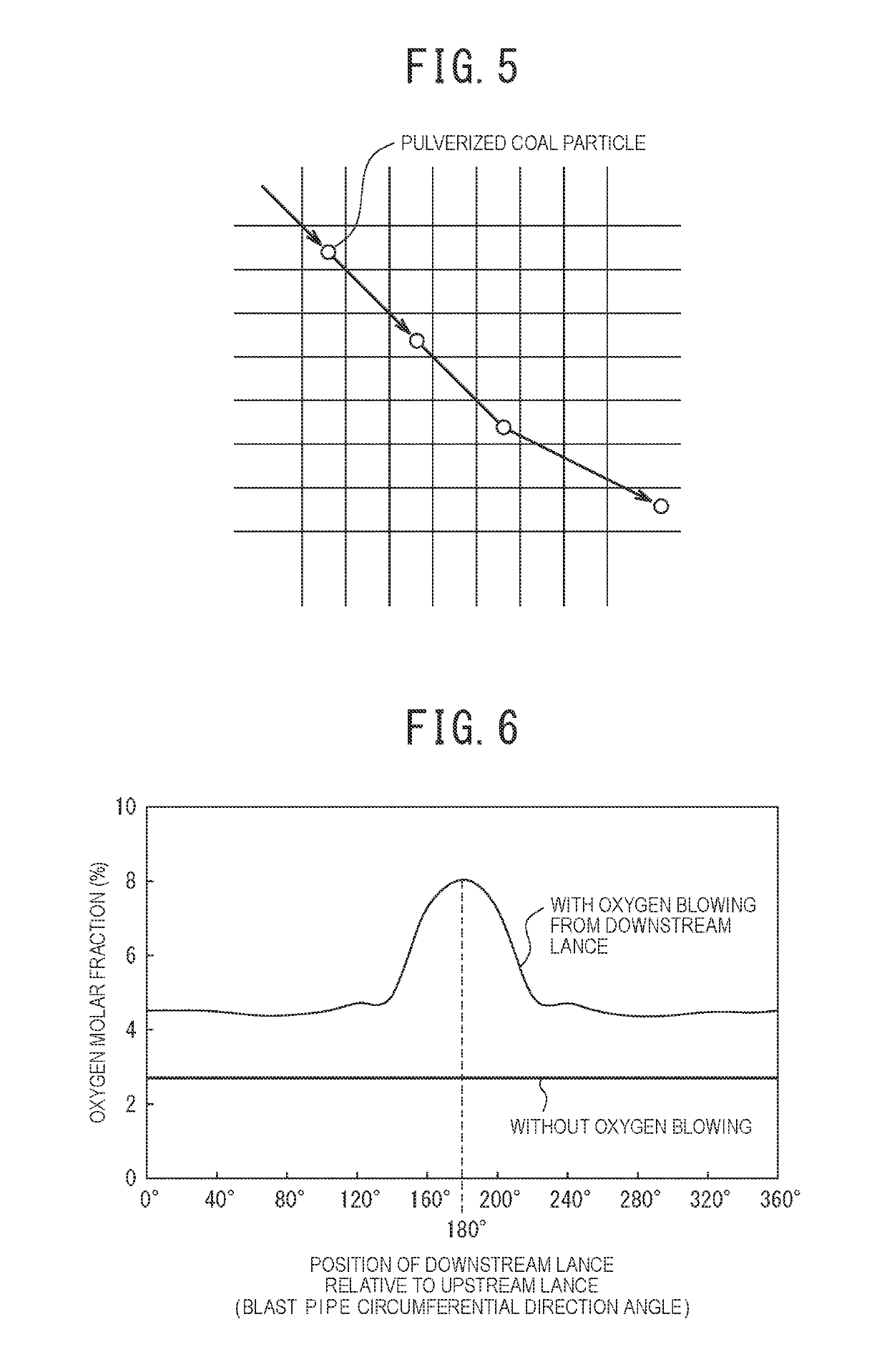

Method for operating blast furnace

ActiveUS20180044745A1Improve flammabilityHigh heat of combustionRotary drum furnacesMaintainance of heating chambersProduction rateDouble tube

To provide a method for operating a blast furnace with which the combustion efficiency of a solid fuel, such as pulverized coal, is improved, thereby making it possible to improve productivity and reduce CO2 emissions. Pulverized coal and LNG are blown from an upstream lance configured by a double tube, and oxygen is blown from a downstream lance on the downstream side in a hot air blast direction, so that oxygen used for preceding combustion of the LNG is supplied from the downstream lance, and the pulverized coal whose temperature has been increased by the combustion of the LNG is combusted along with the supplied oxygen. When a direction perpendicular to the hot air blast direction is designated as 0° , and a downstream direction and an upstream direction therefrom in the hot air blast direction are designated as positive and negative, respectively, a blowing direction of the oxygen from the downstream lance with respect to the blast direction ranges from −30° to +45° , and a blowing position of the oxygen from the downstream lance with reference to a position at which the upstream lance is inserted into a blast pipe ranges from 160° to 200° in terms of a blast pipe circumferential direction angle.

Owner:JFE STEEL CORP

Environment-friendly biomass fuel

The invention discloses an environment-friendly biomass fuel, which comprises the following raw materials in parts by mass: 12-15 parts of ethanol, 20-25 parts of sunflower straw powder, 25-30 parts of walnut shell, 18-22 parts of rice husk powder, soybean 16-18 parts of straw, 20-24 parts of peat, 8-14 parts of bamboo chips, 20-22 parts of pine tree chips, 4-8 parts of bagasse, 10-12 parts of cotton seed hulls, and 9-13 parts of corncobs. The invention has high combustion heat, complete combustion, no residue, is made of pure plants, does not contain pollutants such as sulfur, and will not cause damage to the environment.

Owner:青岛燕园海洋生物科技有限公司

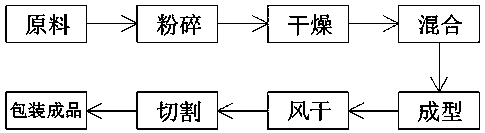

Method for producing biomass granular fuel from litchi residues

The invention relates to a method for producing biomass granular fuel from litchi residues. The preparation method comprises the following steps: crushing, drying, mixing, forming, air-drying, cuttingand packaging. According to the prepared biomass granular fuel, waste litchi peels, kernels and litchi branches and trunks are used as raw materials; the litchi biomass particle fuel can replace litchi branch log fuel and is used in meat baking, litchi fruity flavor is emitted from baked food, and the litchi biomass particle fuel has the advantages of being free of toxic gas in the burning process, sufficient in burning firepower, capable of easily controlling the heating degree and sufficient in fuel burning.

Owner:NANNING JINDING BOILER MFG

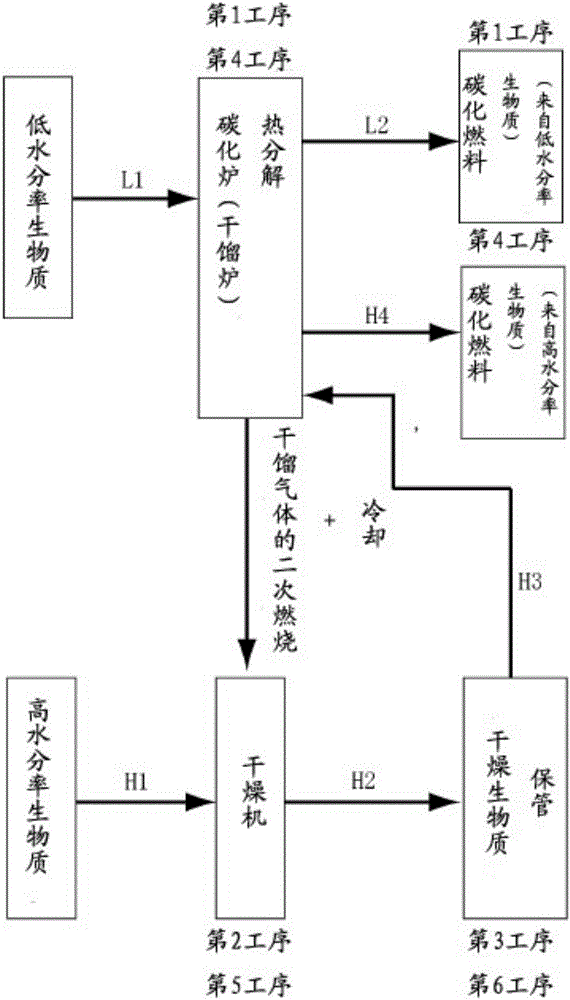

Carbonization method

InactiveCN105874037AReduce moisture contentIncrease heatSludge treatment by de-watering/drying/thickeningSolid waste disposalCarbonizationProcess engineering

Provided is a carbonization method which allows efficient carbonization treatment of high moisture content biomass by dry distillation without having to substantially upgrade already existing carbonization devices. In this carbonization method, the following three steps are performed continuously for a fixed period of time: a first step in which a distillation gas and a carbonized fuel derived from low moisture content biomass are obtained by thermal decomposition of low moisture content biomass in a carbonization furnace, a second step in which dry biomass is obtained by drying high moisture content biomass in a dryer by means of the high-temperature gas obtained by secondary combustion of the dry-distilled gas obtained in the first step, and a third step in which the dry biomass obtained in the second step is stored; thereafter, the following three steps are performed continuously for a fixed period of time: a fourth step in which the dry-distilled gas and a carbonized fuel derived from high moisture content biomass are obtained by thermal decomposition of stored dry biomass, a fifth step in which dry biomass is obtained by drying high moisture content biomass in a dryer by means of a high-temperature gas obtained by secondary combustion of the dry-distilled gas obtained in the fourth step, and a sixth step in which the dry biomass obtained in the fifth step is stored.

Owner:MEIWA IND CO LTD

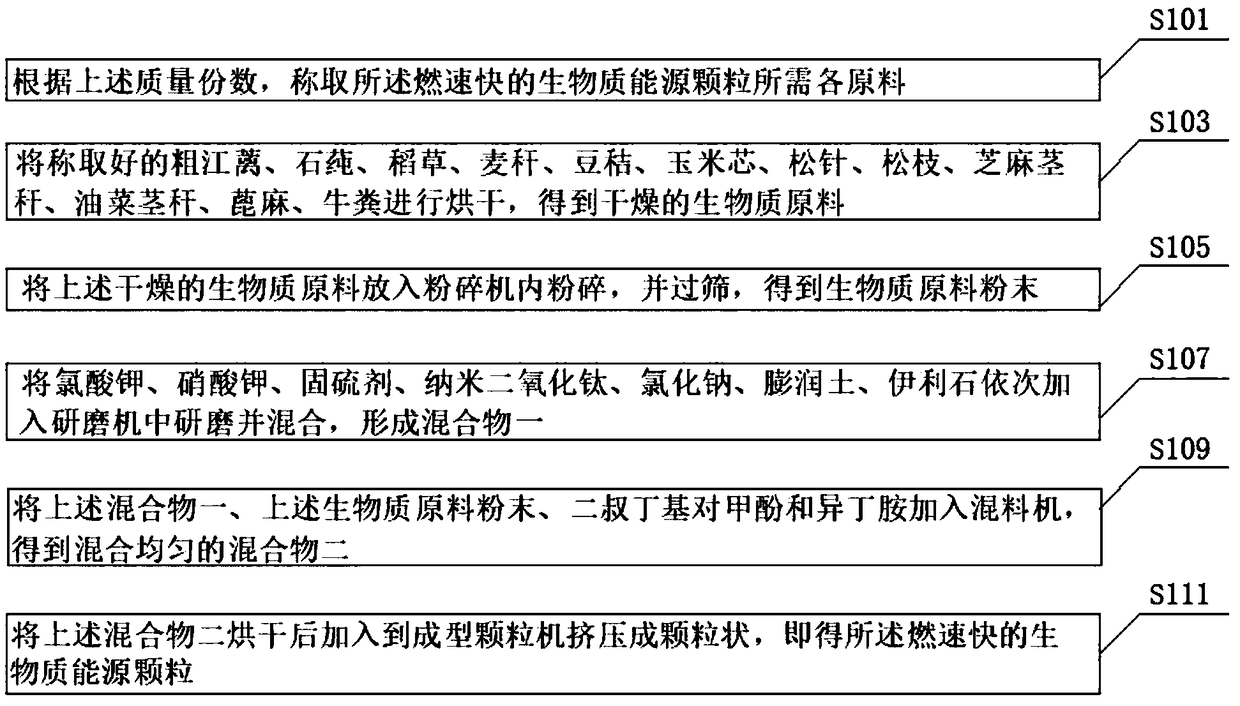

Biomass energy particle with high burning rate and preparation technology thereof

The invention discloses a biomass energy particle with the high burning rate and a preparation technology thereof. The biomass energy particle with the high burning rate is prepared from the followingraw materials in parts by mass: 30-40 parts of macroalgae, 60-80 parts of straw, 15-19 parts of corn cobs, 8-12 parts of pine needles, 10-16 parts of pine twigs, 10-18 parts of sesame stalks, 13-15 parts of rapeseed stalks, 10-14 parts of castor beans, 12-16 parts of cow dung, 6-12 parts of a combustion improver, 4-10 parts of a sulphur-fixing agent, 6-14 parts of a stabilizer, 2-6 parts of nano-titania, 3-7 parts of sodium chloride, 1-3 parts of bentonite, and 2-4 parts of illite. The biomass energy particle has the beneficial effects that the problem of environmental pollution caused by coal combustion burning is solved, meanwhile, energy sources are also saved, the biomass energy particle contains much oil family plants, the burning rate of biomass fuel can be effectively increased, the biomass energy particles can further be burned more sufficiently, burning heat is large, burning is stable, the environment is not polluted, and the biomass energy particle is an excellent new energy fuel.

Owner:梁丰

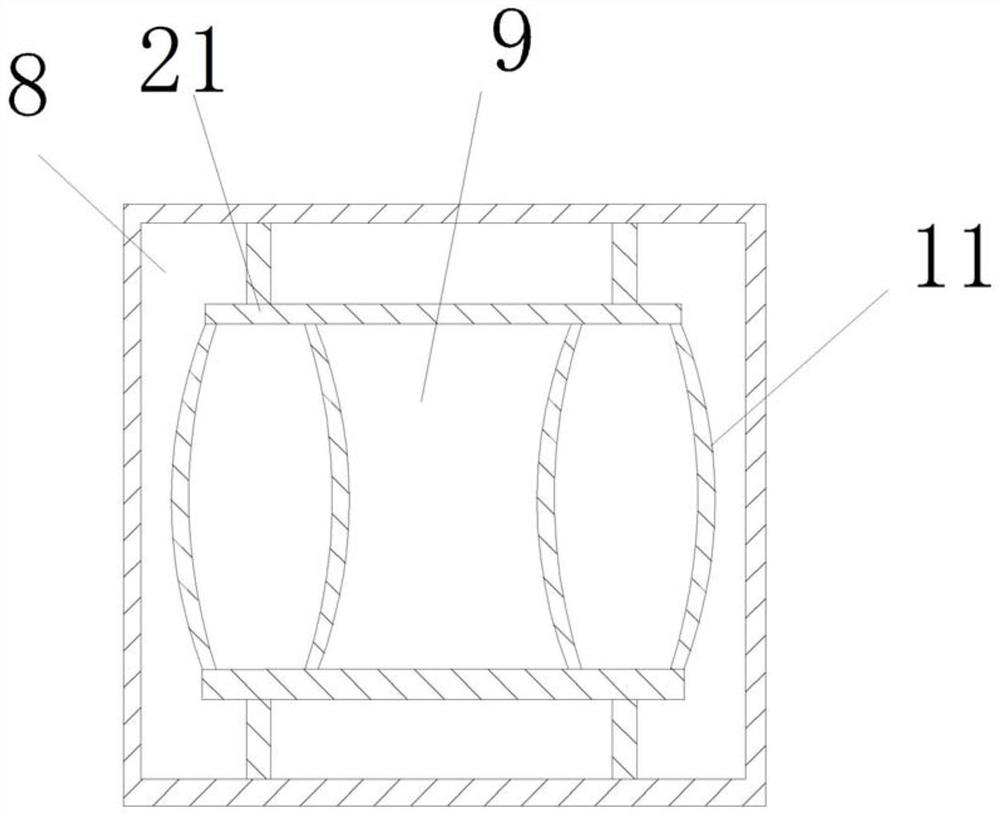

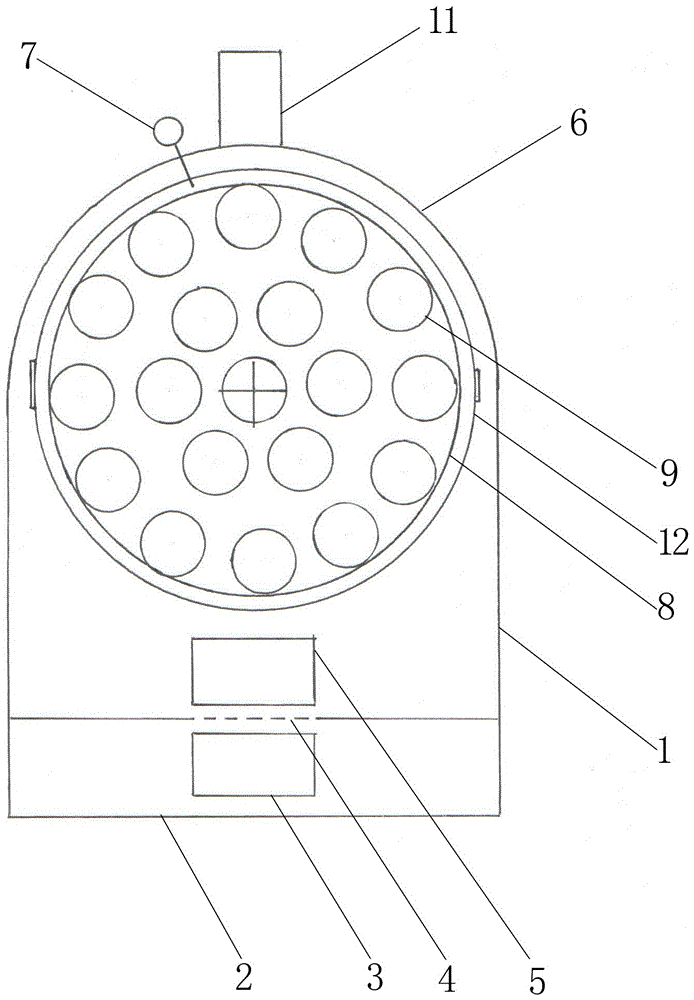

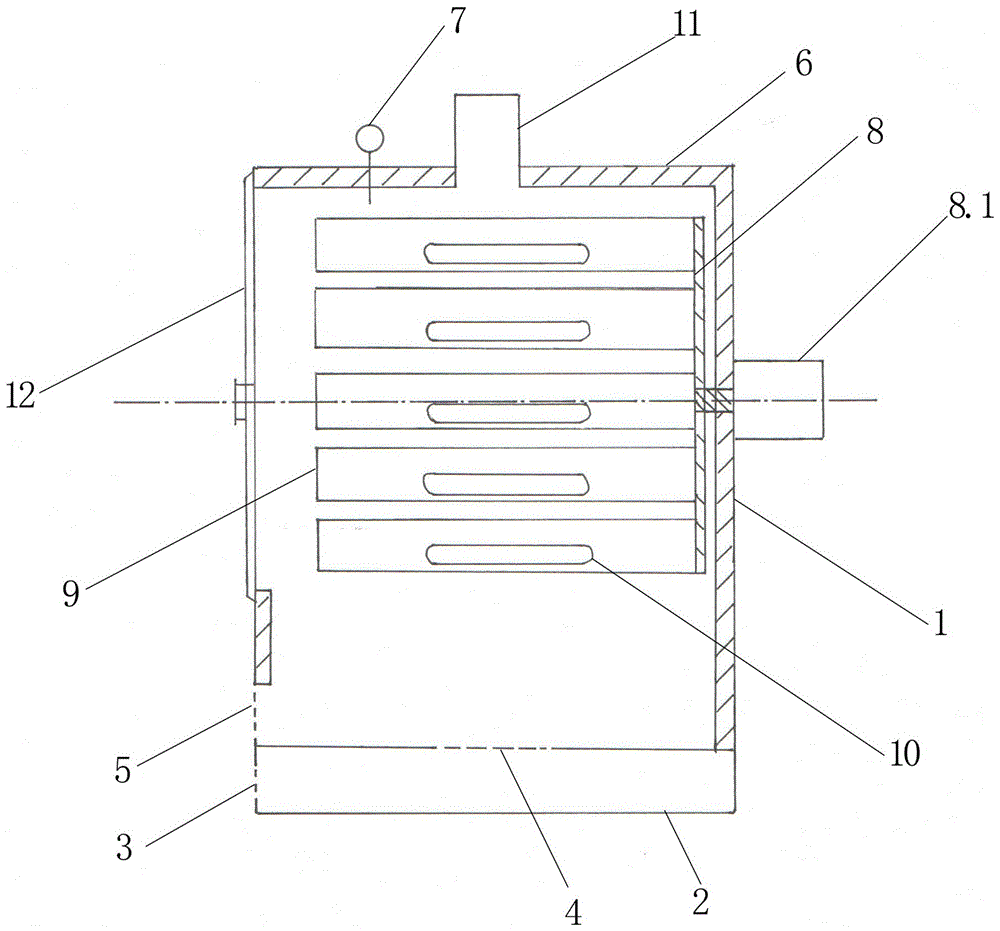

Energy-saving and environment-friendly device for burning organic matter in nitriding kiln

PendingCN110094969ASimple structural designSolve the pollution of the environmentFurnace typesGas emission reductionTunnel kilnDirect combustion

The invention belongs to the technical field of combustion of organic matter in a nitriding kiln, and discloses an energy-saving and environment-friendly device for burning the organic matter in the nitriding kiln. The device is characterized in that an air blowing hose hole and an air suction hose hole are through holes penetrating through the right side wall of a tunnel kiln, two binding agent discharging holes are horizontally and symmetrically arranged at the left and the right of the front of the inner bottom of a sagger respectively, a discharge porcelain tube penetrates through the twobinding agent discharge holes to extend to the inner bottom of the sagger, the discharge porcelain tube is arranged inside a refractory material layer, combustion porcelain tubes extend to the upper part of the refractory material layer, and the two combustion porcelain tubes fixedly communicate with a transverse ceramic tube transversely arranged in the refractory material layer. According to theenergy-saving and environment-friendly device for burning the organic matter in the nitriding kiln, direct combustion of a binding agent on a burner is realized, the combustion heat is increased, thecombustion amount of natural gas passing through the burner is saved, the heat energy consumption is reduced, and the environment is protected.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Method for operating blast furnace

ActiveUS10487370B2Improve productivityReduce CO2Rotary drum furnacesMaintainance of heating chambersProduction rateDouble tube

To provide a method for operating a blast furnace with which the combustion efficiency of a solid fuel, such as pulverized coal, is improved, thereby making it possible to improve productivity and reduce CO2 emissions. Pulverized coal and LNG are blown from an upstream lance configured by a double tube, and oxygen is blown from a downstream lance on the downstream side in a hot air blast direction, so that oxygen used for preceding combustion of the LNG is supplied from the downstream lance, and the pulverized coal whose temperature has been increased by the combustion of the LNG is combusted along with the supplied oxygen. When a direction perpendicular to the hot air blast direction is designated as 0°, and a downstream direction and an upstream direction therefrom in the hot air blast direction are designated as positive and negative, respectively, a blowing direction of the oxygen from the downstream lance with respect to the blast direction ranges from −30° to +45°, and a blowing position of the oxygen from the downstream lance with reference to a position at which the upstream lance is inserted into a blast pipe ranges from 160° to 200° in terms of a blast pipe circumferential direction angle.

Owner:JFE STEEL CORP

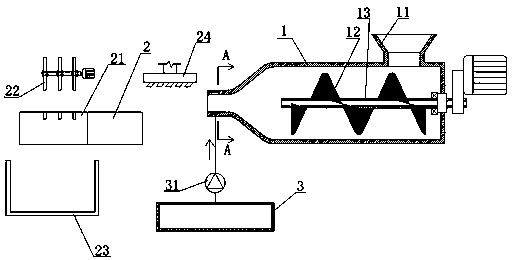

Method for manufacturing rock wool by using reducing agent graphene

PendingCN114262158ACoke burns moreCoke burns fully durableGlass making apparatusWoolMining engineering

The invention relates to a method for manufacturing rock wool by using a reducing agent graphene. Basalt rock debris is used as a main raw material, natural gas is used as a fuel, and graphene is used as a reducing agent, so that an iron element in basalt can be effectively reduced, the amount of waste gas generated in coke combustion is reduced while coke combustion heat is increased, and coke combustion is more sufficient and durable; the continuous and stable heat release of the coke in the production melting process is realized, the expected purposes of stable melting temperature, good fiber toughness and high product strength are achieved, and a major breakthrough is made for continuous production of high-quality rock wool. The stable and continuous production in one furnace period can reach 60 days, the temperature in the smelting furnace is stable, the quality of rock wool products is improved, the consumption of coke and the emission of waste gas are reduced, and the carbon emission requirement meets the national standard.

Owner:陕西合力保温材料制品有限责任公司

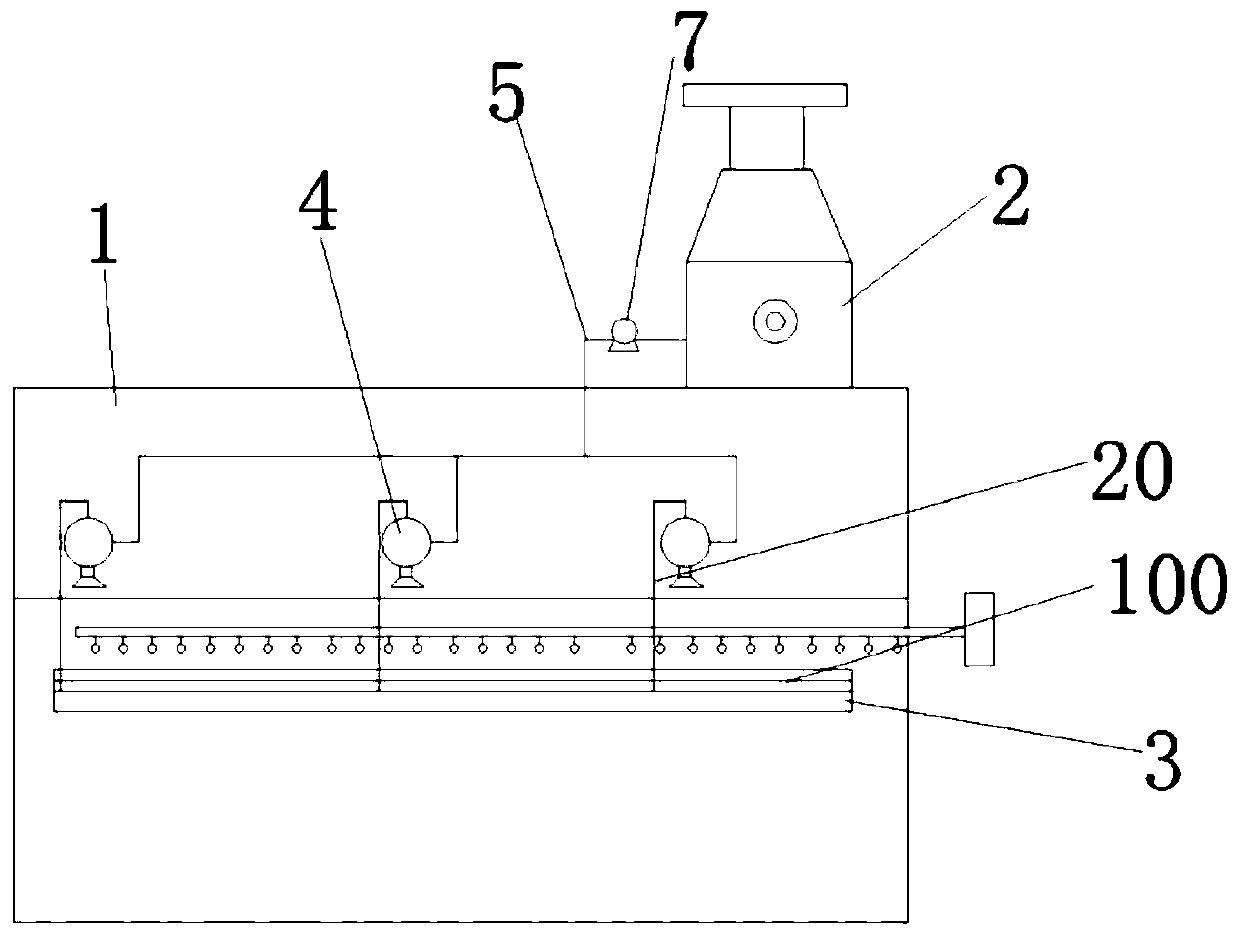

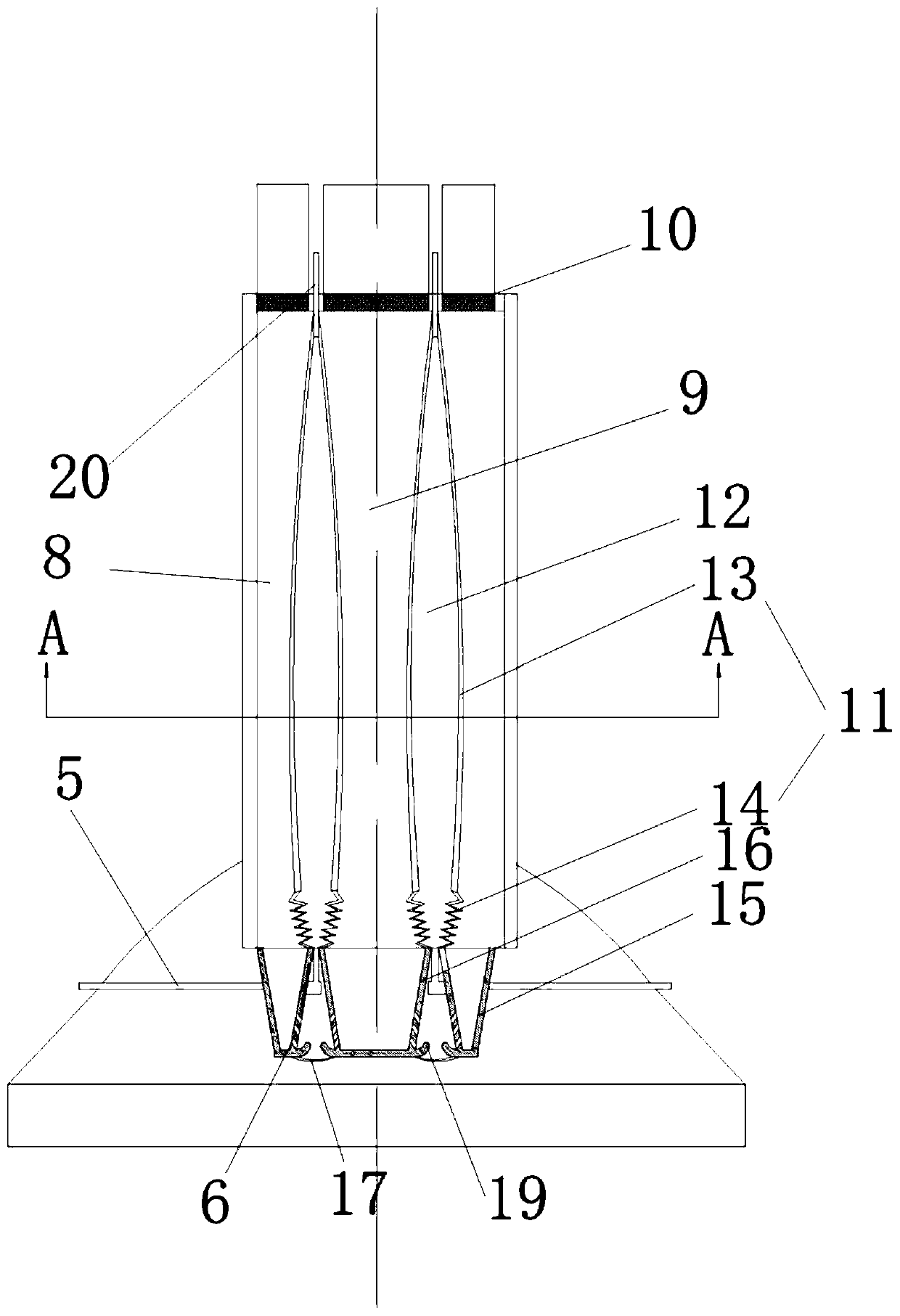

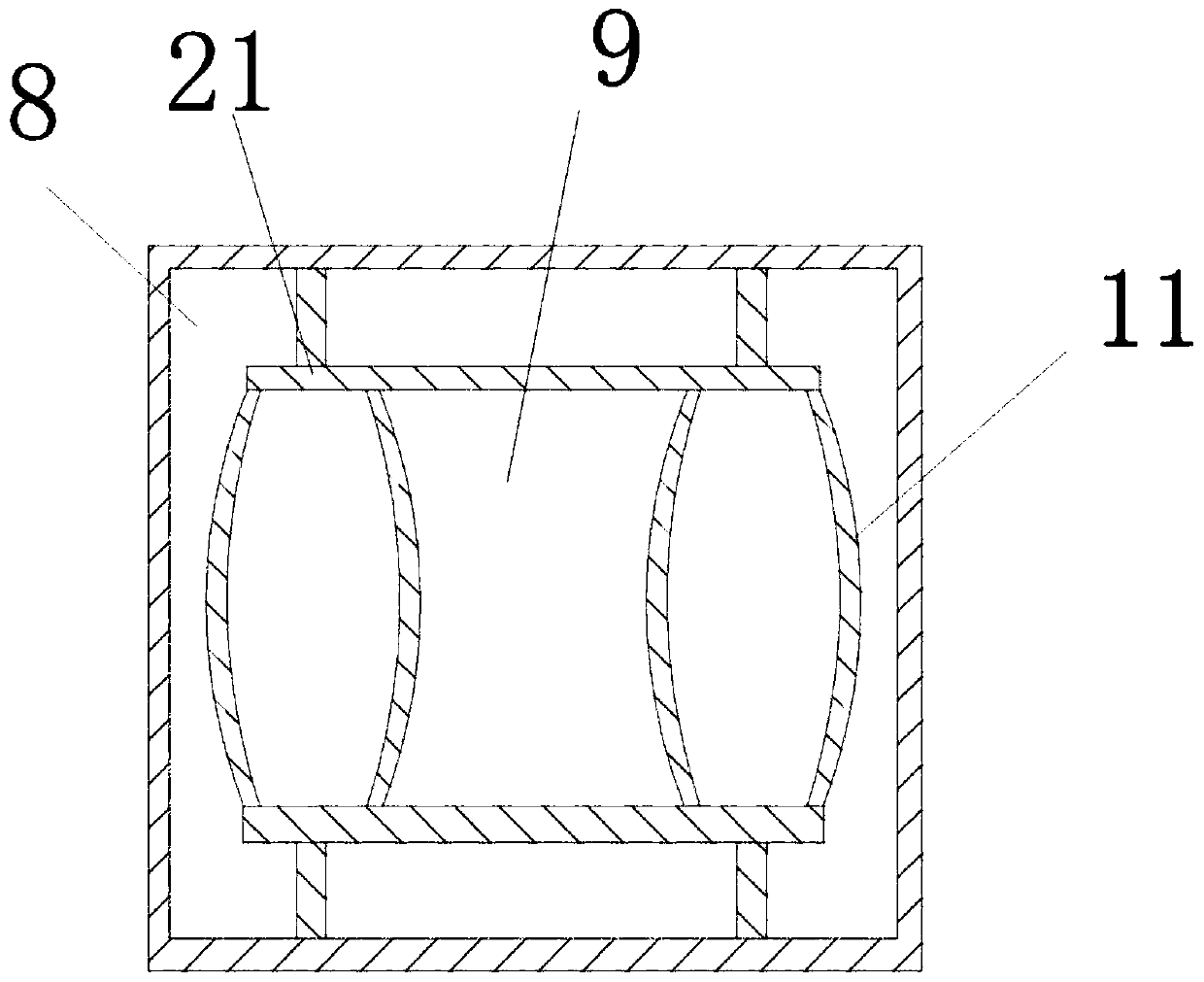

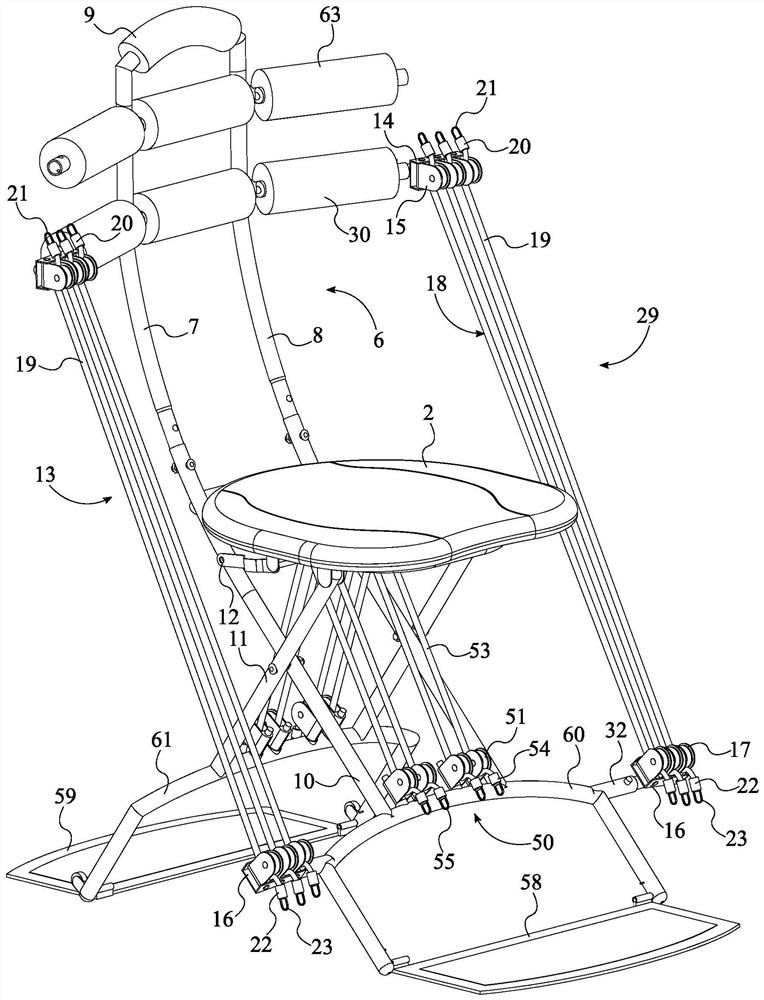

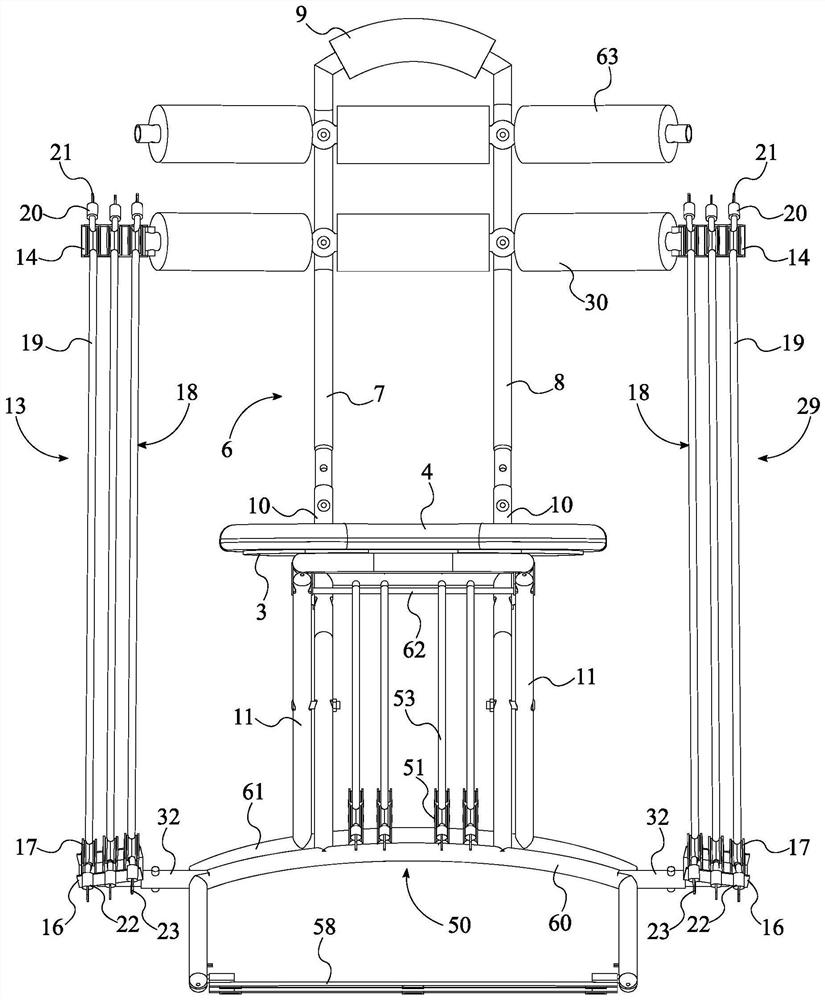

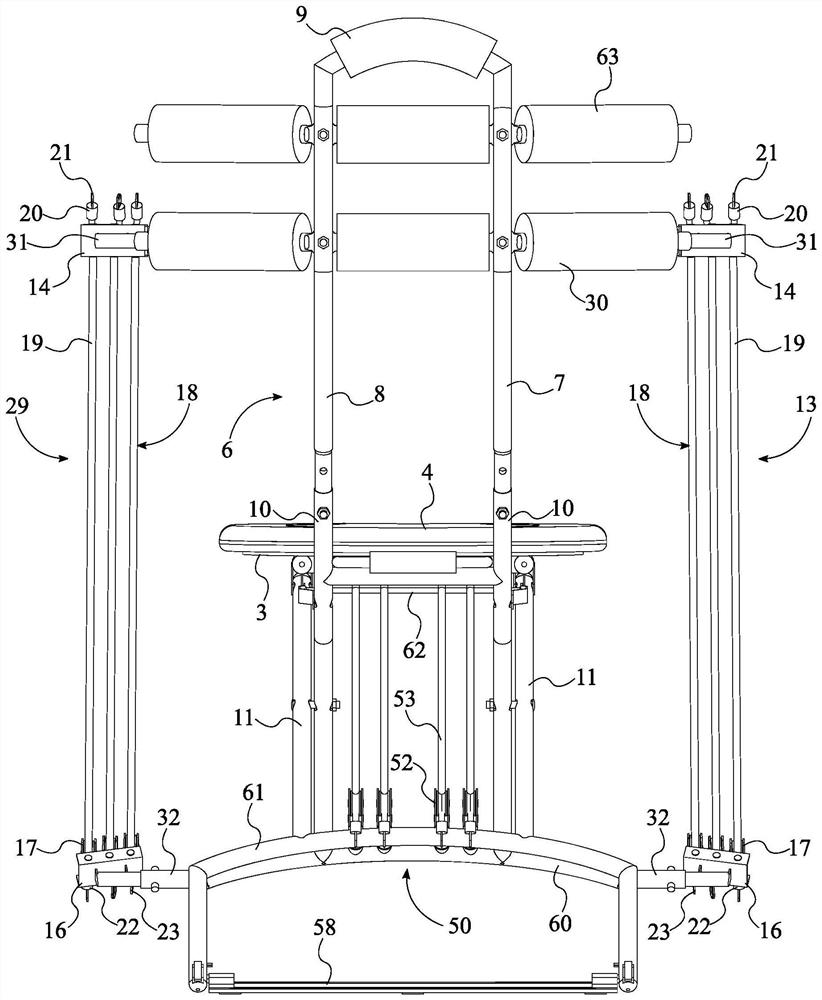

Folding exercise chair for resistance training

ActiveCN108721829BEasy to trainSimple and convenient solutionMuscle exercising devicesPhysical medicine and rehabilitationEngineering

A folding sports chair for resistance training includes: a foldable chair frame, a pair of resistance mechanisms, and a first pad cross bar. The foldable chair frame further includes: a seat and a height-adjustable back. The height adjustable chair back is a component that allows the user to adjust the height of the back frame of the folding chair frame. The first pad cross bar is connected to the position of the foldable chair frame relative to the seat, and is used for supporting the user's back so that the user can move more comfortably. The pair of resistance mechanisms are located on both sides of the foldable chair frame and are used for implementing resistance exercise training.

Owner:纳比尔拉劳尔

A propellant for a gas generator and a preparation method thereof, and a gas generator for an automobile airbag

ActiveCN108456126BImprove ignitabilityIncrease gas production ratePedestrian/occupant safety arrangementExplosive working-up apparatusTetrazoleAirbag

The invention provides a gas generator ignition agent and a preparation method thereof, and a gas generator for a vehicle safety airbag. The gas generator ignition agent contains a fuel, an oxidant, abinder and an additive, wherein the additive is an oxazole-based energy-containing ionic compound. According to the present invention, by adding 5-aminotetrazole nitrate to a boron / potassium nitrateignition agent, on the basis of the ensuring of the combustion heat and the combustion temperature of the agent, the high-temperature and high-pressure gas amount can be increased, the output pressureof the ignition agent can be increased, and the output performance of the ignition pipe can be increased, such that the pressure starting time of the gas generator is advanced to less than 2 ms, andthe pressure value at 10 ms is increased by about 20 Kpa so as to improve the gas generating performance of the gas generator.

Owner:BYD CO LTD

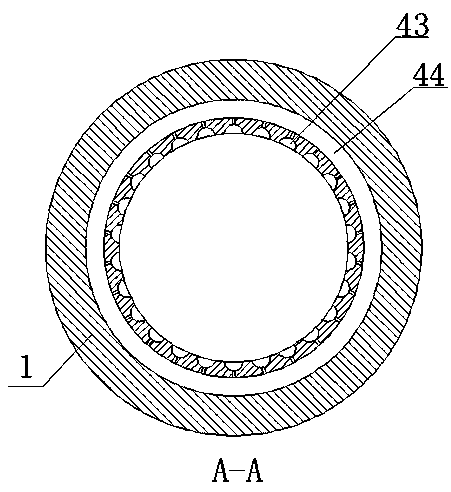

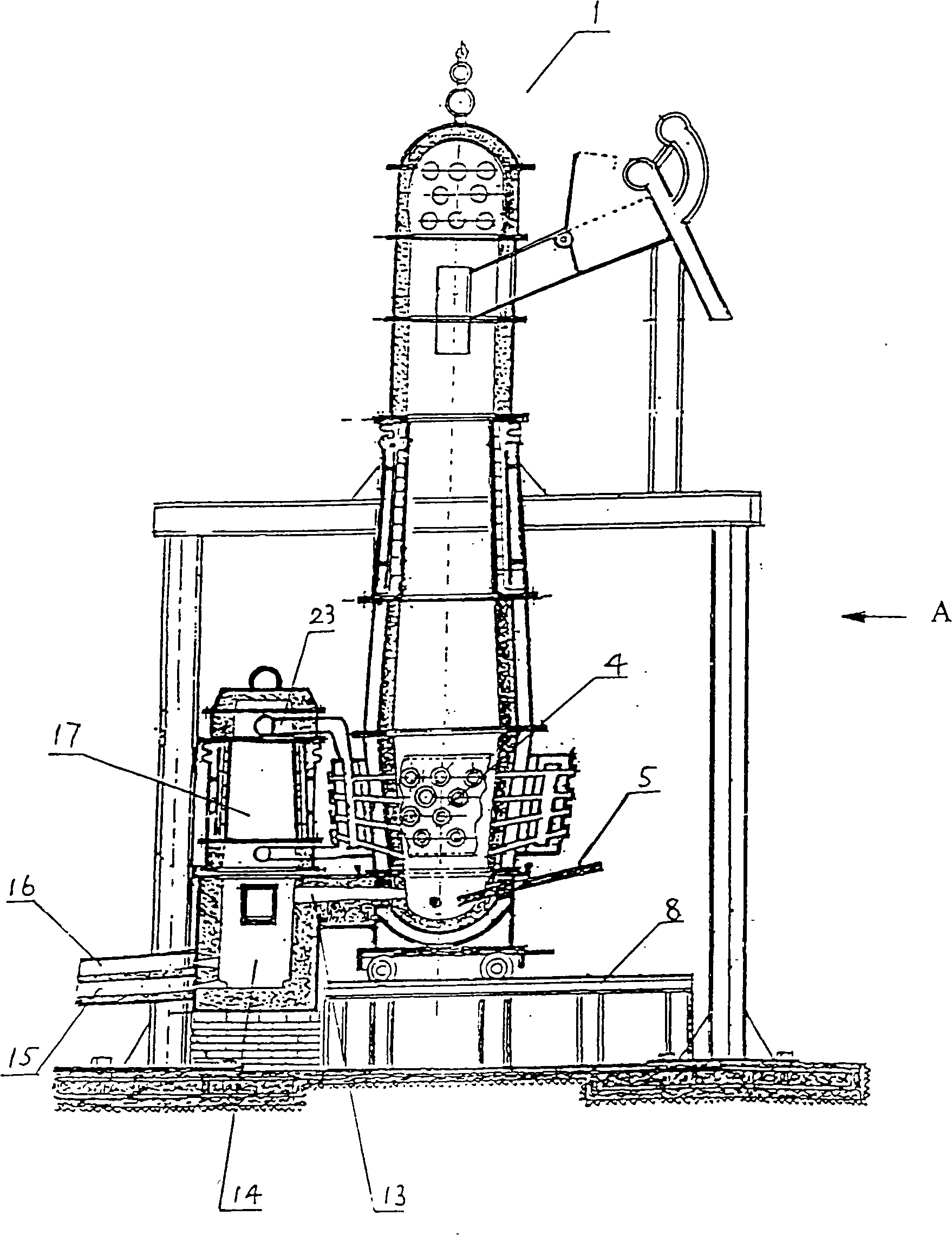

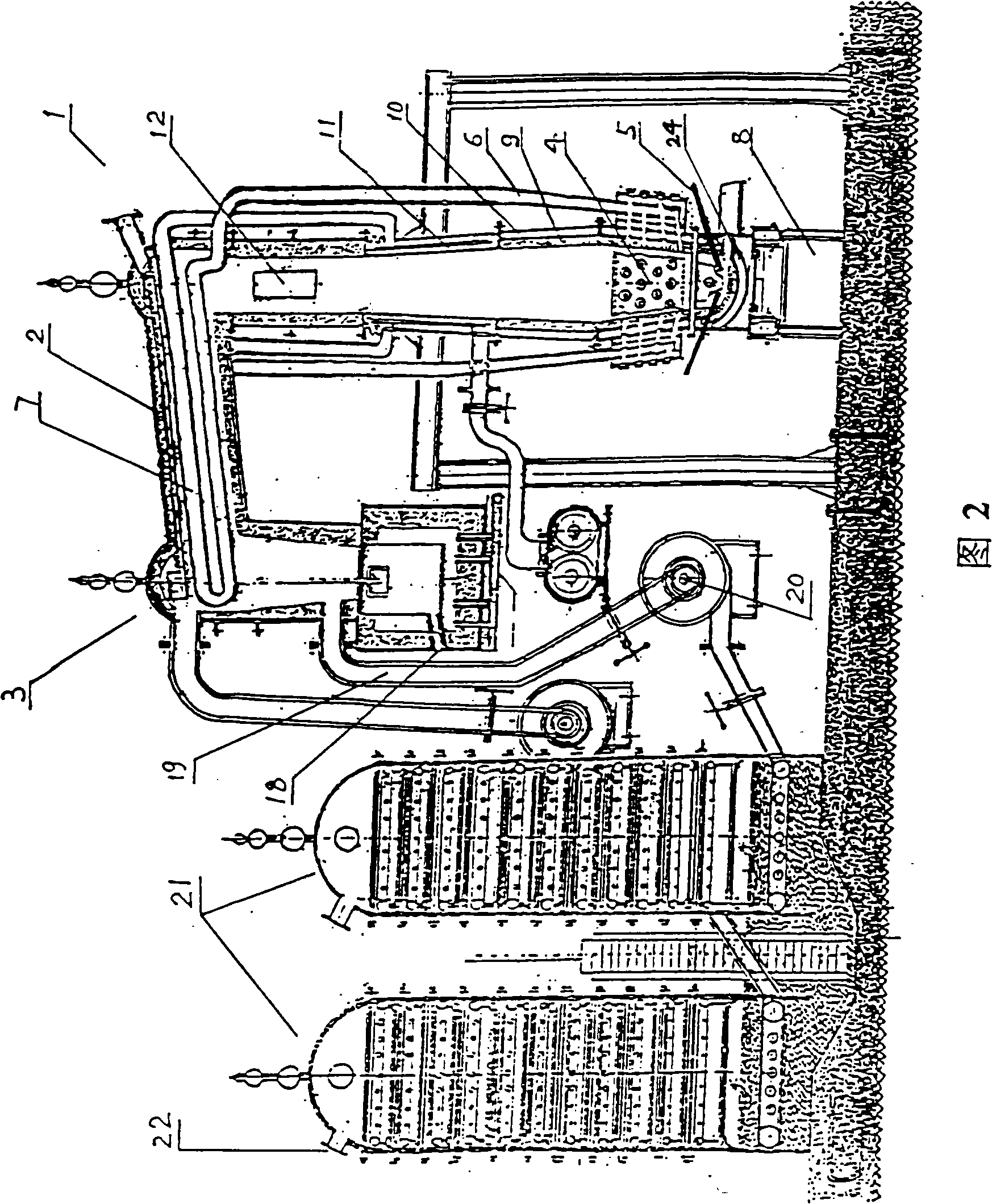

Method for smelting aluminum ore by carbon thermal reduction and non-ferrous metal smelting furnace therefor

InactiveCN101280367AReduce radiationSpeed up meltingFurnace typesProcess efficiency improvementFiberSlag

The invention relates to a method for reducing and smelting aluminum ore by using carbon heat and the nonferrous metal smelting furnace of the smelting aluminum ore, which belongs to the technical field of the metal ore smelting. The method is characterized in that the pellet preparation comprises the steps that, coal gangue, bauxite and waste fiber are crushed and levigated; binding agent is prepared; the powder or the short grained coal gangue and the bauxite are mixed uniformly with the fiber micro-particle in proportion; the mixture is made into the pellet by the binding agent; the pellet and the coke are put into smelting furnace alternatively. The smelting furnace is composed of a multi-hole melting zone connected with an air inlet pipe, a high temperature resistant furnace lining, a cooling atomizing sleeve, a pair of heating electrodes inserted at both sides of the smelting furnace bottom towards the centre and a cracking water burning chamber. After the method is applied, the polluted environment with black soot all over the sky is changed, and the distressed scene that the metal bearing slag is thrown away everywhere and the resources are wasted can be stopped; thus the resources is saved and used fully, and the environment is protected.

Owner:俞益根

Method of producing honeycomb structure

ActiveUS8419988B2Contamination can be suppressedReduce componentsCeramic shaping apparatusCeramicwareMethyl celluloseHoneycomb structure

A method of producing a honeycomb structure includes producing a honeycomb structure using methyl cellulose as at least part of a binder, the methyl cellulose having a weight average molecular weight (Mw) of 4,000,000 to 5,000,000, and having an integral molecular weight distribution value of components having a molecular weight of 100,000 or less in the integral molecular weight distribution curve of 15 or less.

Owner:NGK INSULATORS LTD

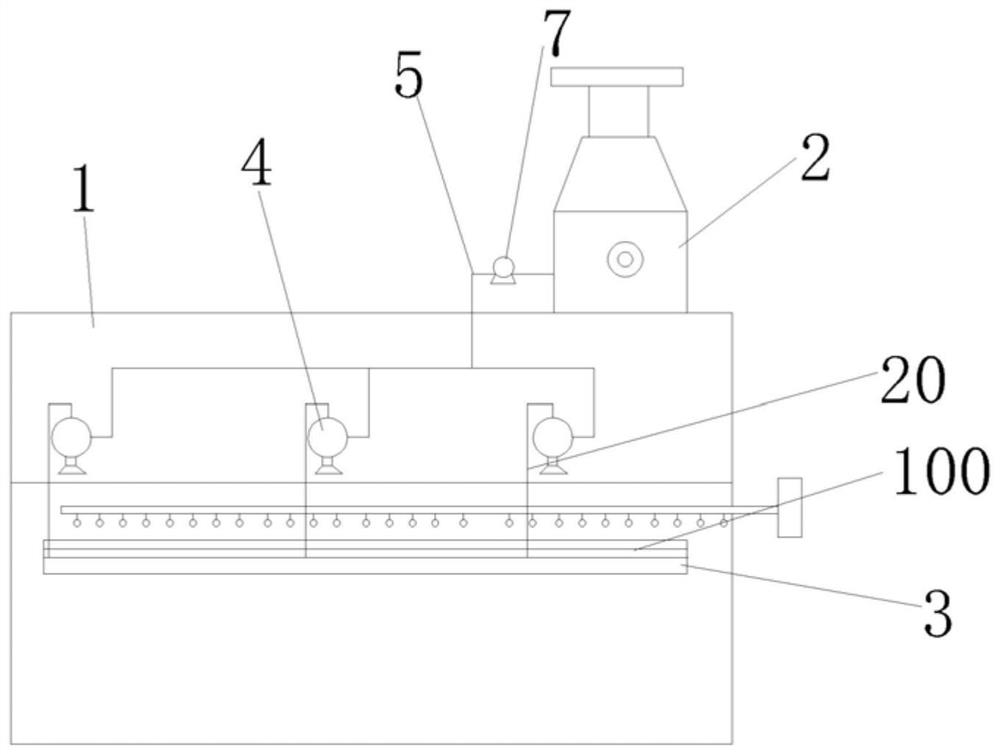

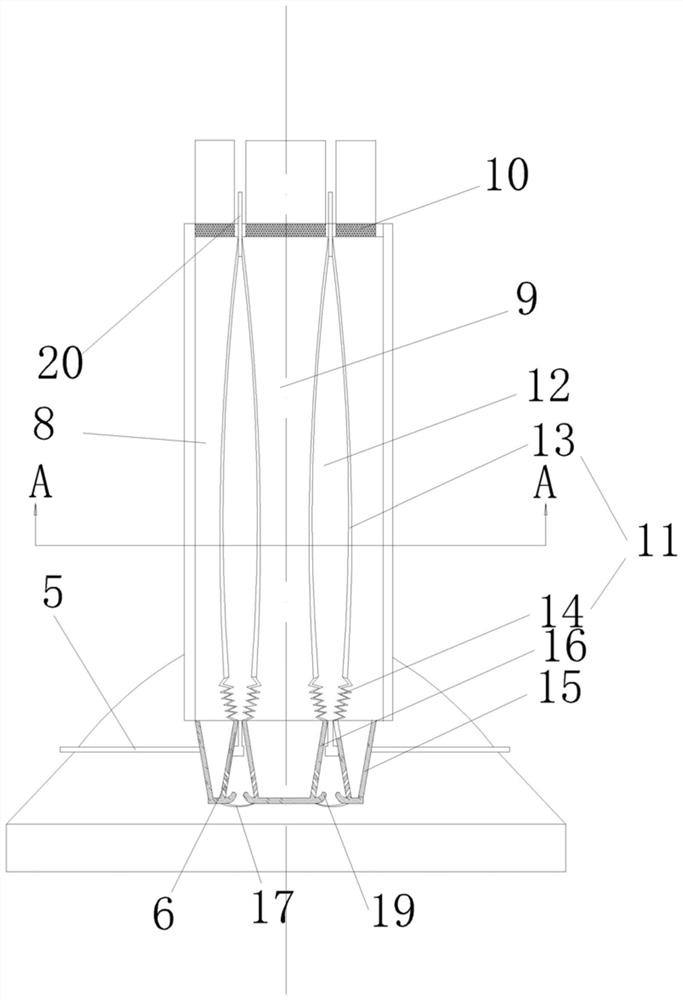

A copper rod production process

ActiveCN111014296BAchieve recyclingIncrease profitMetal rolling arrangementsCombustion chamberExhaust fumes

A copper rod production process of the present invention includes the following steps: 1) Copper melting process: use a copper plate preheating furnace to melt the copper plate into molten copper, during which the high-temperature exhaust gas after combustion is returned to the nozzle to preheat the outer air guide pipe and the gas in the inner air guide pipe, and increase the air pressure in the outer air guide pipe and the inner air guide pipe, and the gas flowing out through the nozzle enters the preheating chamber of the combustion chamber of the copper plate preheating furnace to preheat the copper plate to be melted; 2) casting rod Process: casting the molten copper on the surface of the core rod to generate a cast rod; 3) hot rolling process: hot rolling the cooled cast rod to generate a copper rod; 4) winding process: winding the above copper rod Make a circle. In the invention, the high-temperature exhaust gas is returned to the nozzle, and then flows out through the nozzle into the preheating chamber to preheat the copper plate, thereby realizing the recovery and utilization of heat and improving the utilization rate of heat.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

A kind of biomass particle fuel and preparation method thereof

ActiveCN104629848BAchieve clean combustionPrevent volatilizationBiofuelsSolid fuelsParticulatesCarbonate

Owner:海聚高分子材料科技(广州)有限公司 +2

Long zhuang bun production method

The invention relates to bun production methods, particularly to a long zhuang bun production method. The long zhuang bun production method comprises the following steps of, firstly, kneading doughs, specifically, mixing, by weight part, 1 part of high protein wheat flour into 0.3-0.4 part of warm water into doughs; secondly, making bun blanks, specifically, making out dough pieces of 50-100 grams from the doughs kneaded from the first step, and rolling the dough pieces on a kneading board into bar-shaped bun blanks with a diameter of 15-25 mm and at a length of 120-200 mm; thirdly, rotatingly baking the bun blanks in tubes, specifically, shoveling the bar-shaped bun blanks with a semicircular bun shovel into rotary stainless steel tubes, and then baking the tubes in an oven at 220-240 DEG C; lastly, discharging buns, specifically, when the bun blanks baked in the stainless steel baking tubes appear to be yellowish on the surface when observed through a glass door, opening the glass door, shoveling out the yellowish long zhuang buns through a semicircular tubular bun shovel to complete production of the long zhuang buns, then filling new bun blanks in to start a next round of long zhuang bun production. The long zhuang buns produced through the long zhuang bun production method is yellowish in color, crisp in crust taste, soft and rich in wheat flavor in inside and good in taste.

Owner:张彬彬

A kind of pure coal water slurry and production method thereof

ActiveCN103421559BHigh heat of combustionReduce tensionLiquid carbonaceous fuelsHydrofluoric acidCoal water

The invention relates to pure coal water slurry and a production method thereof, and provides the production method of the pure coal water slurry. The production method comprises the steps of soaking feed coal with an aqueous solution of hydrochloric acid / sulfuric acid, and an aqueous solution of hydrofluoric acid in sequence to remove ash in the feed coal, and then preparing coal water slurry from the processed feed coal. The pure coal water slurry produced according to the production method is high in combustion heat; smoke and dust generated during the combustion of the pure coal water slurry can meet national smoke and dust emission standards, without the treatment of any dust removing equipment; noncombustible coal ash and coal slag cannot be left; the pure coal water slurry can be used in areas with high environment protection requirements; the condition of fuel shortage can be beneficial for being alleviated.

Owner:LUZHOU LANDLONG CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com