Energy-saving and environment-friendly device for burning organic matter in nitriding kiln

A nitriding furnace, energy saving and environmental protection technology, applied in the direction of furnace, furnace type, furnace components, etc., can solve the problems of polluting the environment and increasing the heat of combustion, and achieve the effect of protecting the environment, increasing the heat of combustion, and saving the amount of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

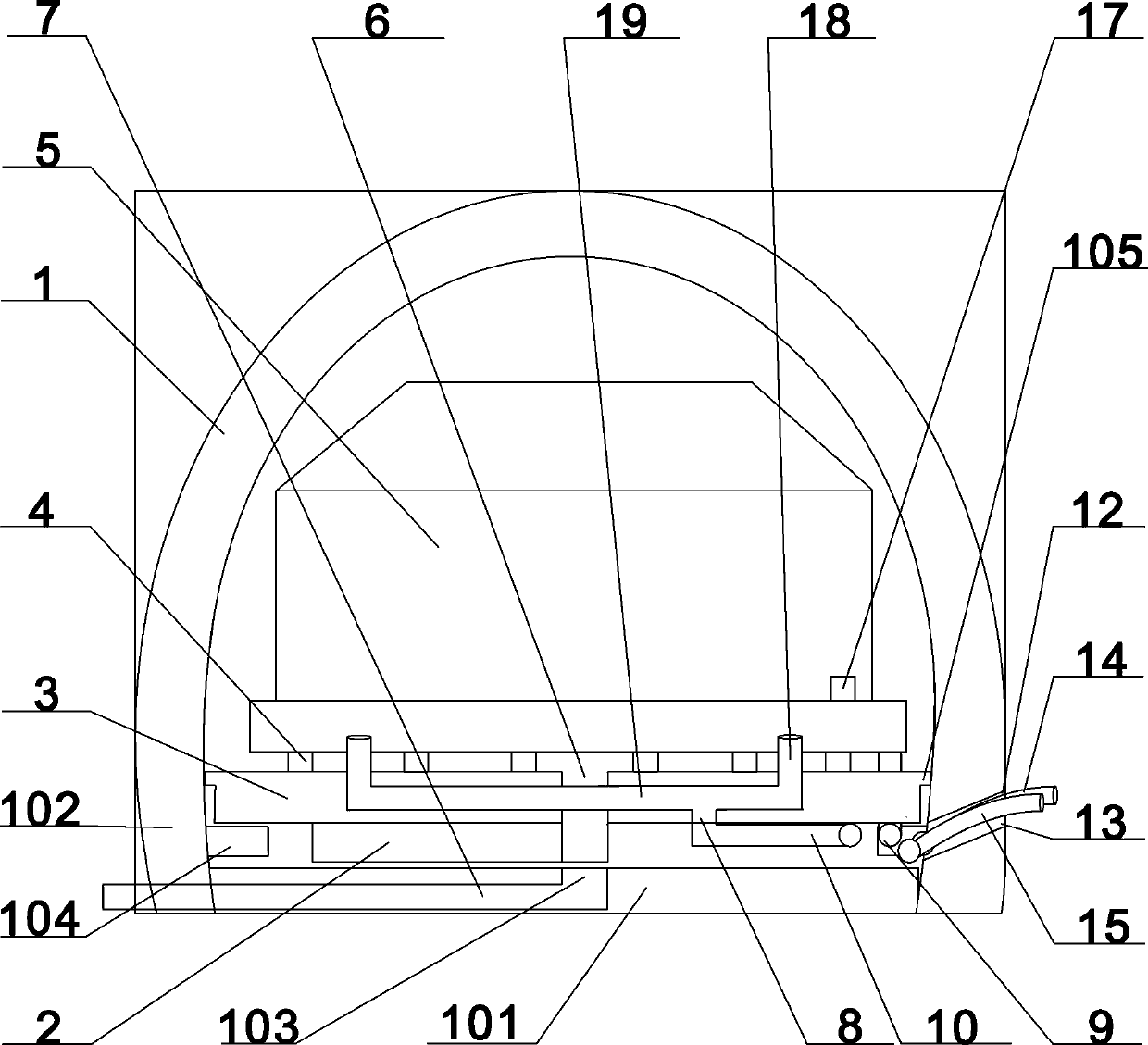

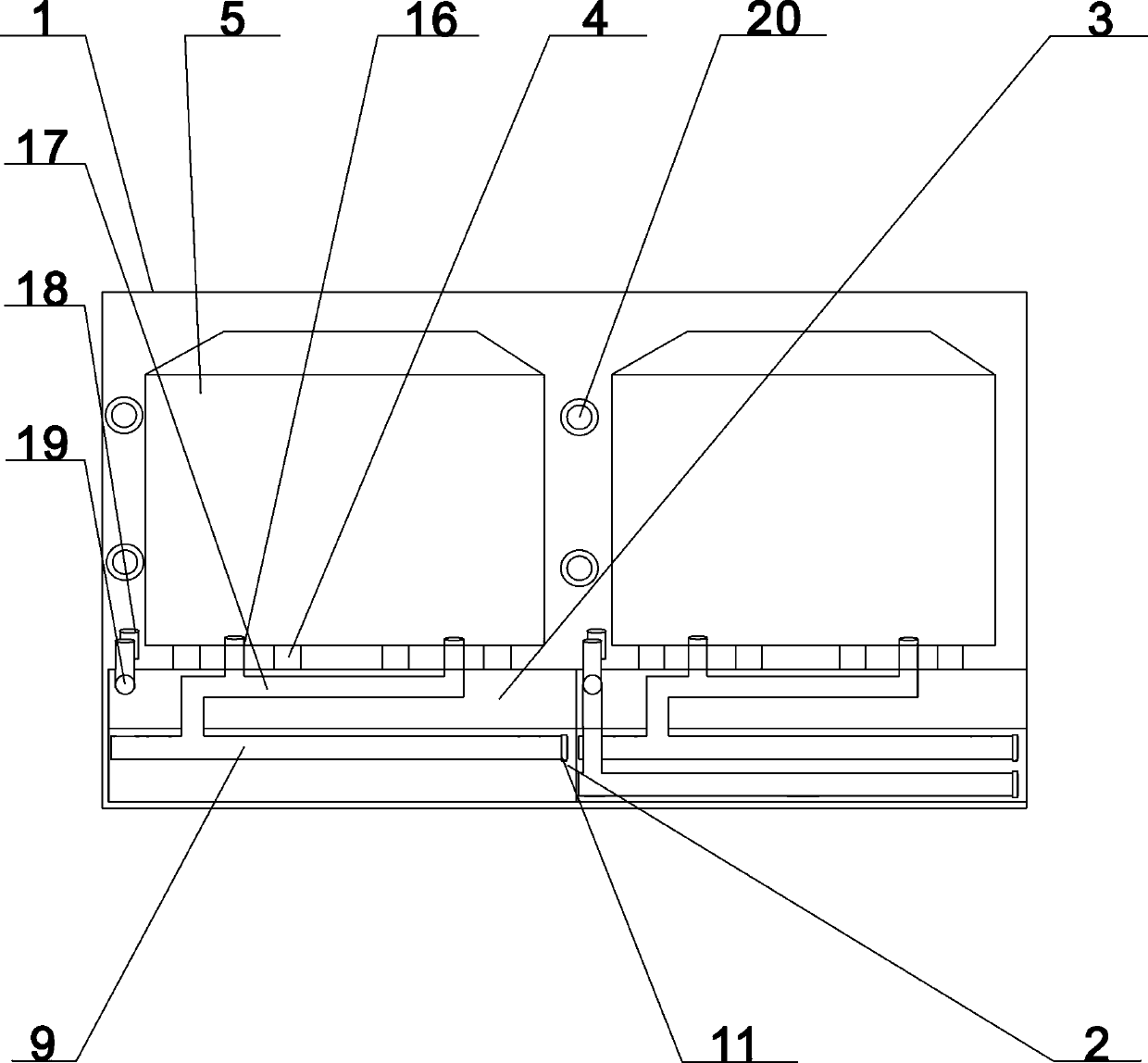

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022]As shown in the figure, the technical solution adopted by the present invention is: an energy-saving and environment-friendly device for burning organic matter in a nitriding kiln, including a shuttle kiln 1, a kiln car body 2, a refractory material layer 3, and a sagger support Refractory material 4; the outer shell of the shuttle kiln 1 is a cuboid, and the inner part is a dome shape; the kiln car body 2 is welded by channel steel to form a mobile kiln car, and the kiln car body 2 is set on the inner track of the shuttle kiln 1 , the refractory material layer 3 is fixedly arranged on the upper part of the kiln car body 2, and the sagger support refractory material 4 is fixed horizontally at equal intervals around the refractory material layer 3; the sagger 5 is fixedly placed on the sagger support refractory mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com