Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "High flexural modulus of elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

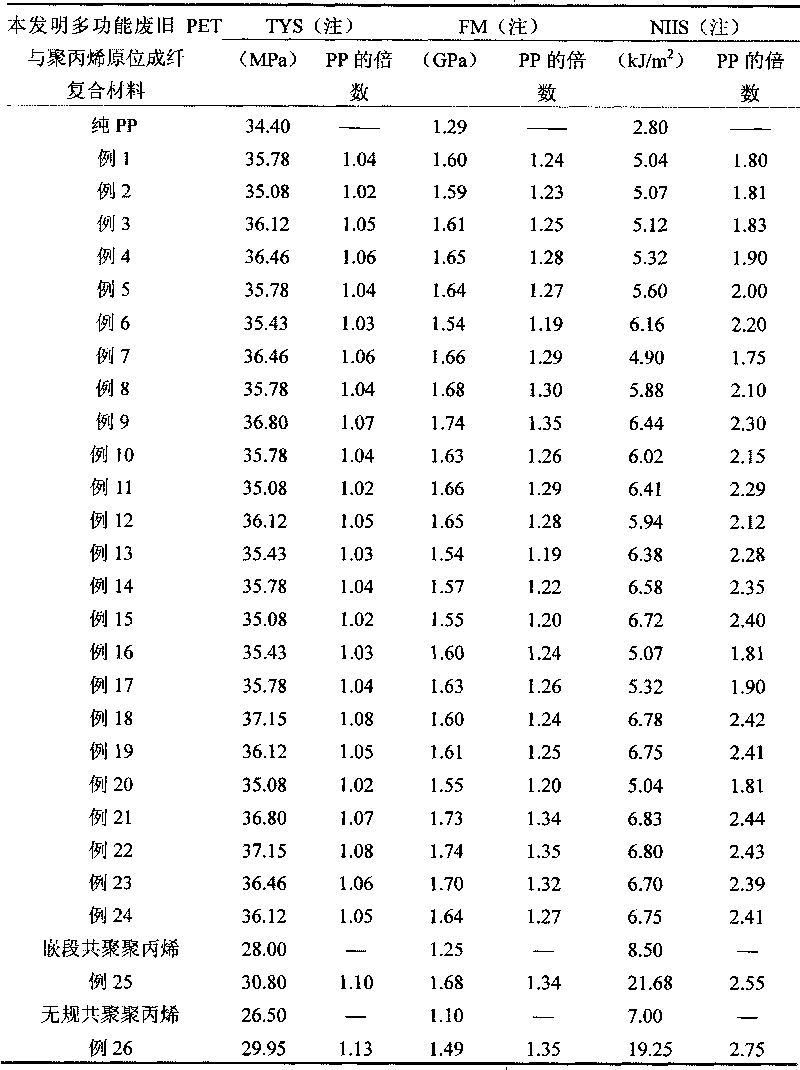

Multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared by multi-component compatiblizing and toughening agent

InactiveCN101717476ACompatibleGood compatibilityMonocomponent polyesters artificial filamentFiberElastomer

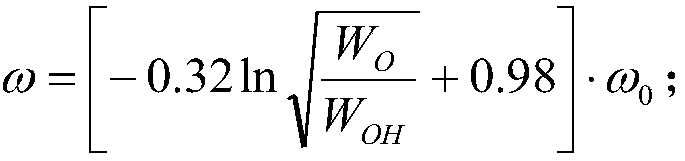

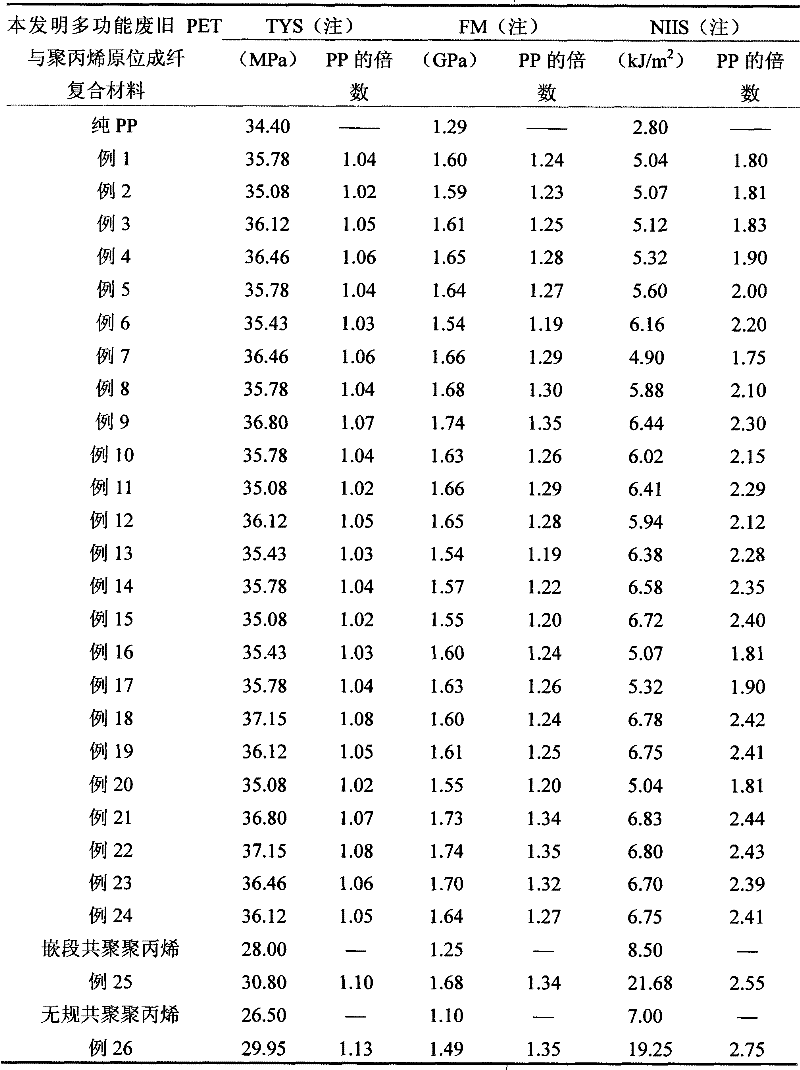

The invention discloses multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared from a multi-component compatiblizing and toughening agent. The multi-component controllable reactive compatiblizing and toughening agent is prepared from polypropylene, an elastomer 1, an elastomer 2, a difunctional group reactive monomer, a second monomer and a peroxide initiator. Then, multifunctional waste PET is prepared from an antioxidant and the prepared multi-component controllable reactive compatiblizing and toughening agent and waste PET; and finally, the in-site fiber-forming composite material is prepared by compounding the prepared multifunctional waste PET with polypropylene. The in-site fiber-forming composite material prepared by the technical scheme of the invention has obviously improved toughness (the notch impact strength of a cantilever beam) and rigidity (tensile yield stress and bending elastic modulus) in comparison with the raw material polypropylene and has relatively good reproducibility of mechanical performance; meanwhile, the invention also changes a great amount of waste which mainly refers to waste PET domestically generated every year into resources, thereby having remarkable economic and social benefits.

Owner:洛阳石化吉润化工有限责任公司 +1

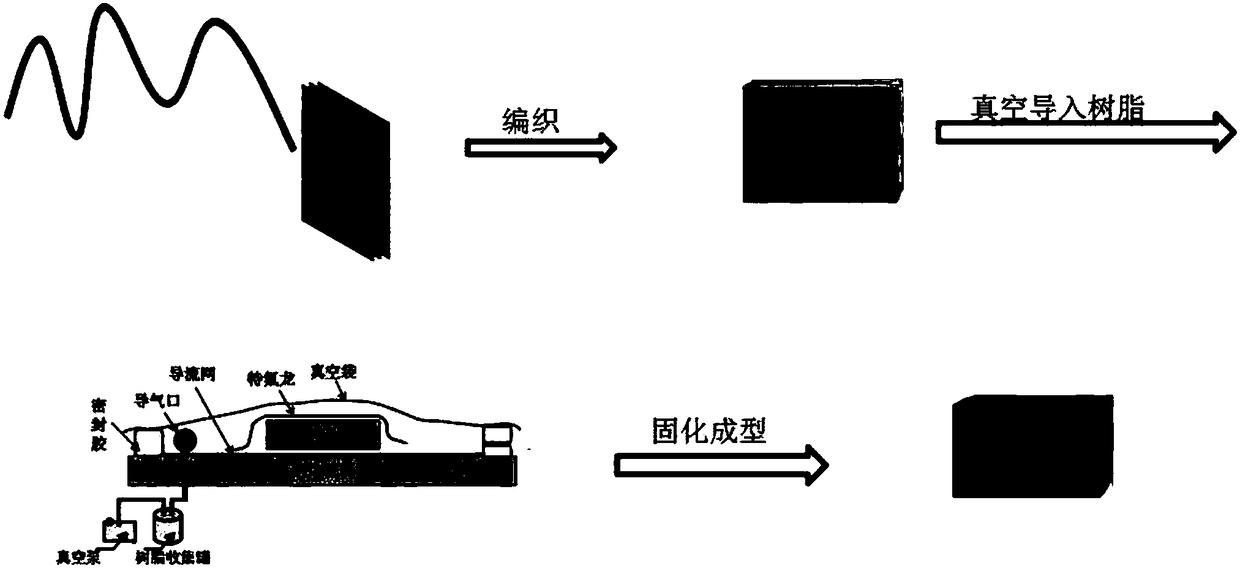

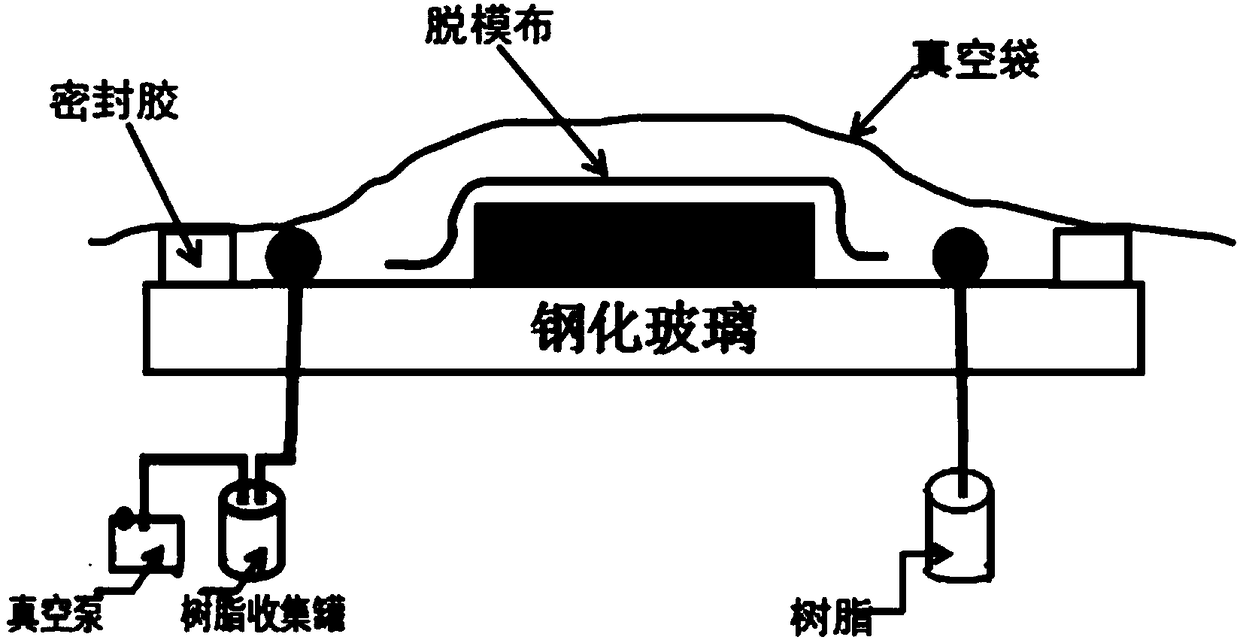

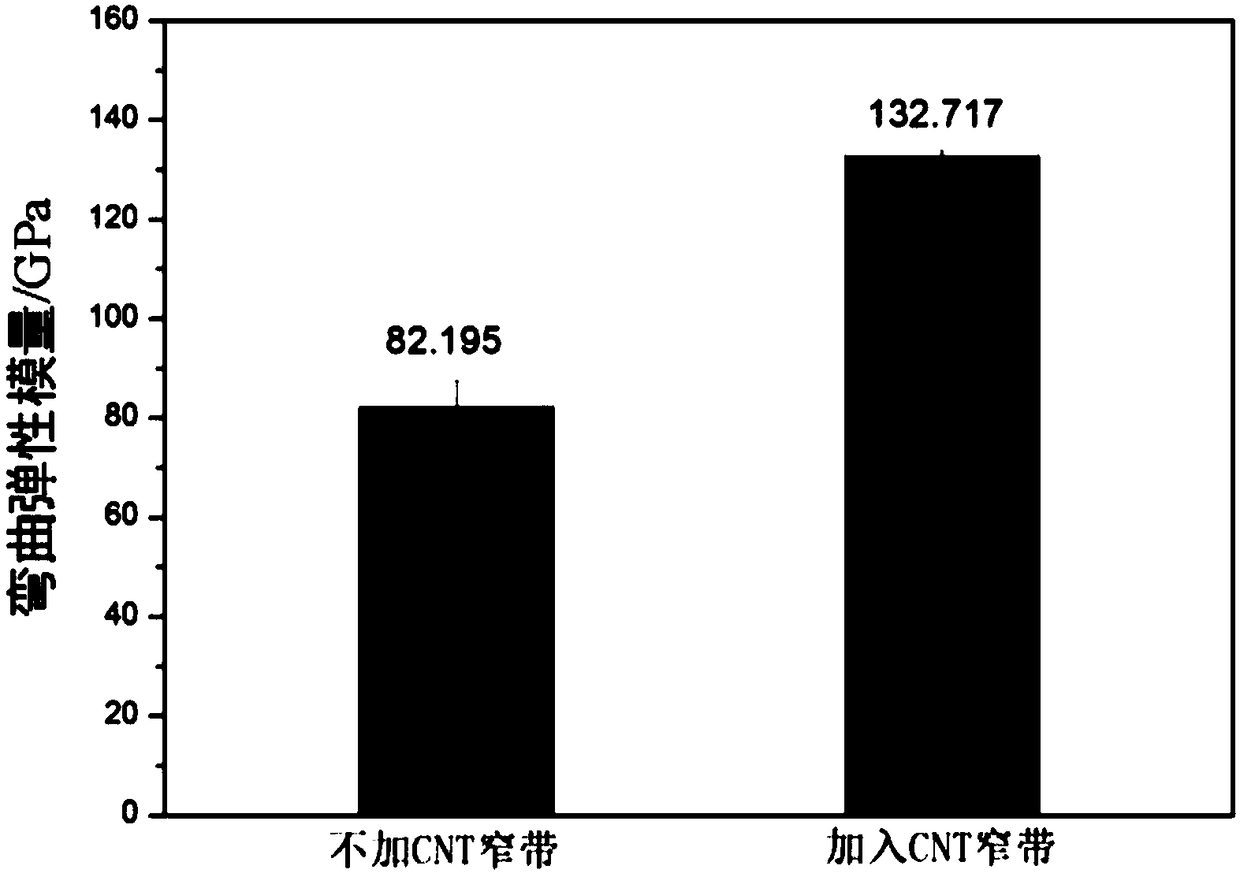

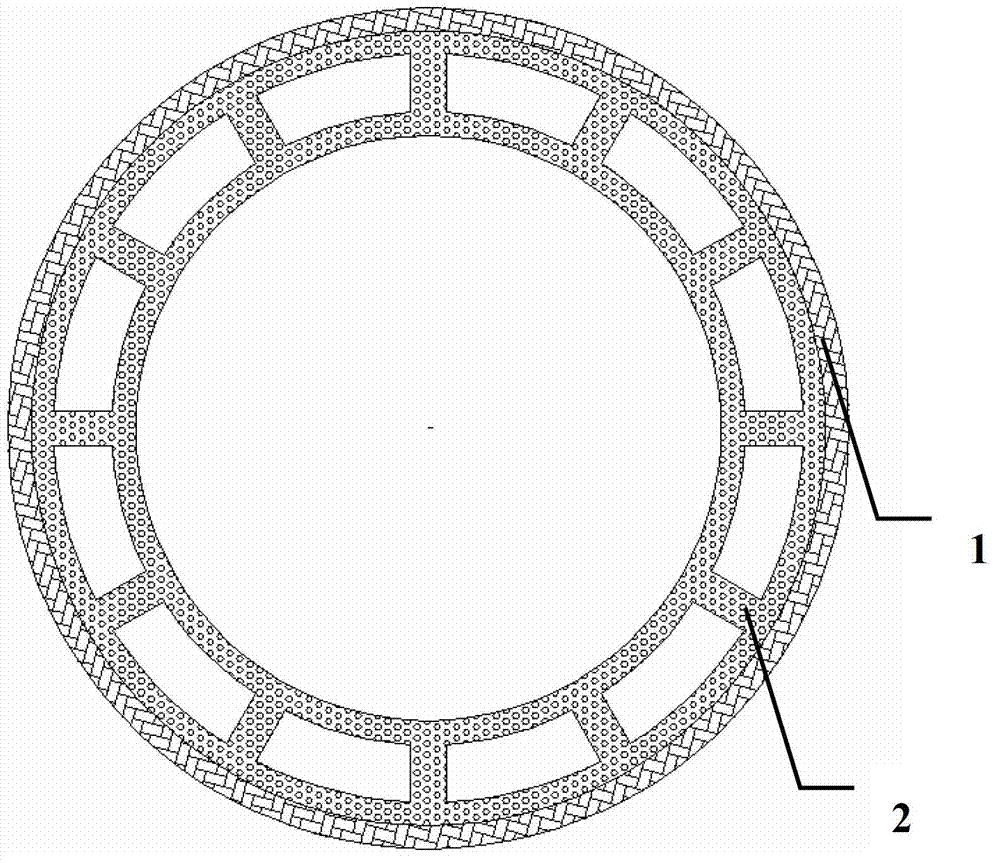

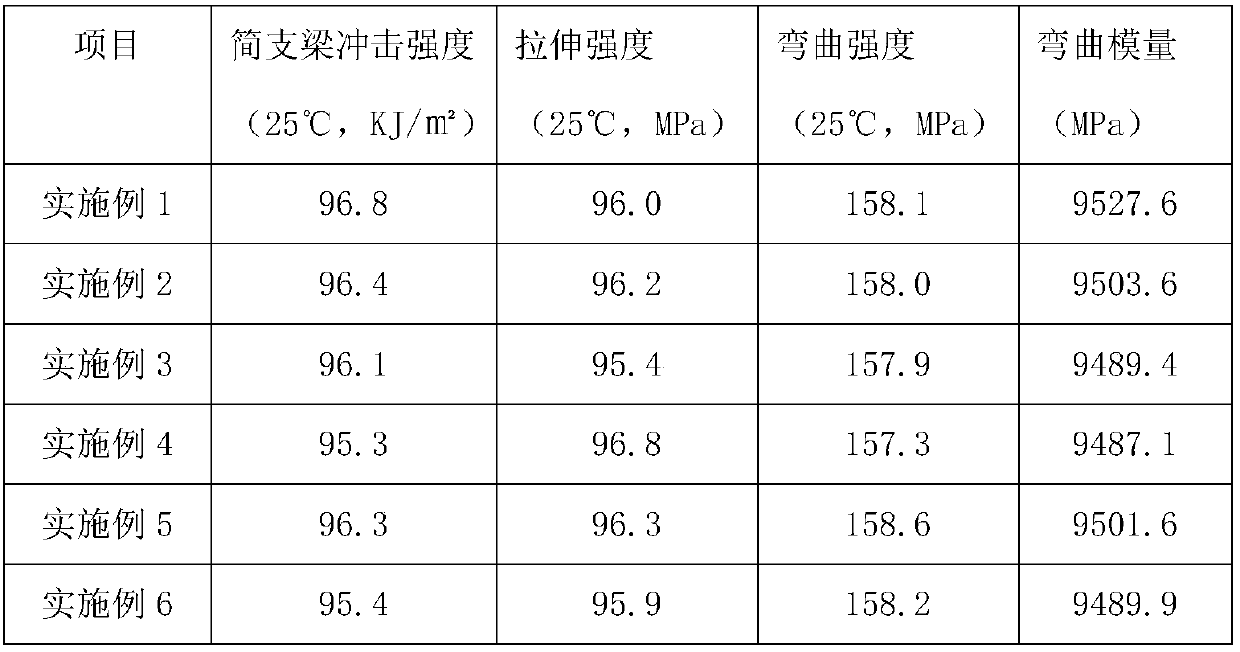

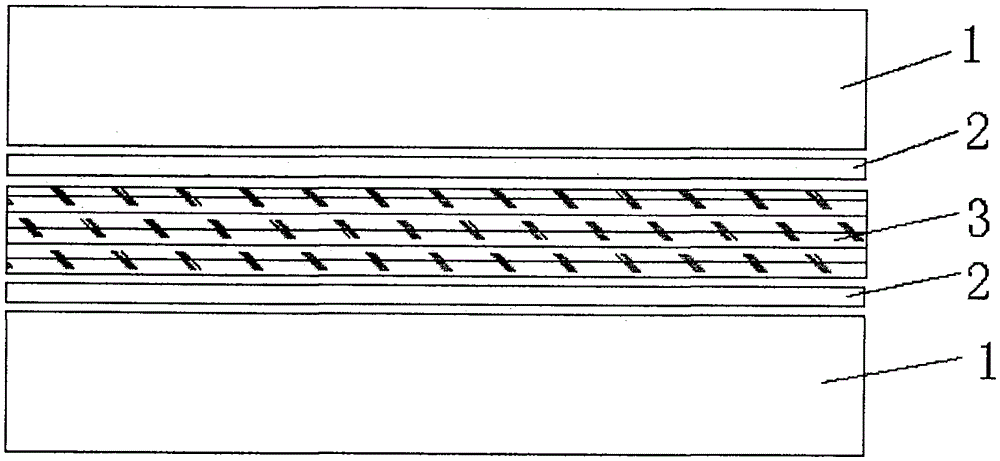

Interlayer toughened composite material and preparation method and application thereof

The invention discloses an interlayer toughened composite material and a preparation method and an application thereof. The preparation method comprises the following steps that a reinforcing body isprovided, the reinforcing body comprises a plurality of first fiber aggregates which are stacked in the thickness direction of the reinforcing body, wherein the first fiber aggregates comprise a plurality of first fibers which are arranged in a specified direction in an orientation manner; at least one braided body is woven with the plurality of first fiber aggregates in the thickness direction ofthe reinforcing body to form the braided structure, wherein each braided body continuously penetrates between every two adjacent first fibers in two or more first fiber aggregates; the weaving structure is soaked in a fluid containing a curable resin material, then curing treatment is carried out, and the interlayer toughened composite material is formed. According to the composite material and the method and the application, the nano-carbon material strips and the like are adopted as the weaving body to weave the reinforcing body in the thickness direction, gaps are avoided between the reinforcing bodies due to the fact that the strips are added, so that a large stress concentration point does not exist in the composite material, and the interlayer toughening performance of the compositematerial is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

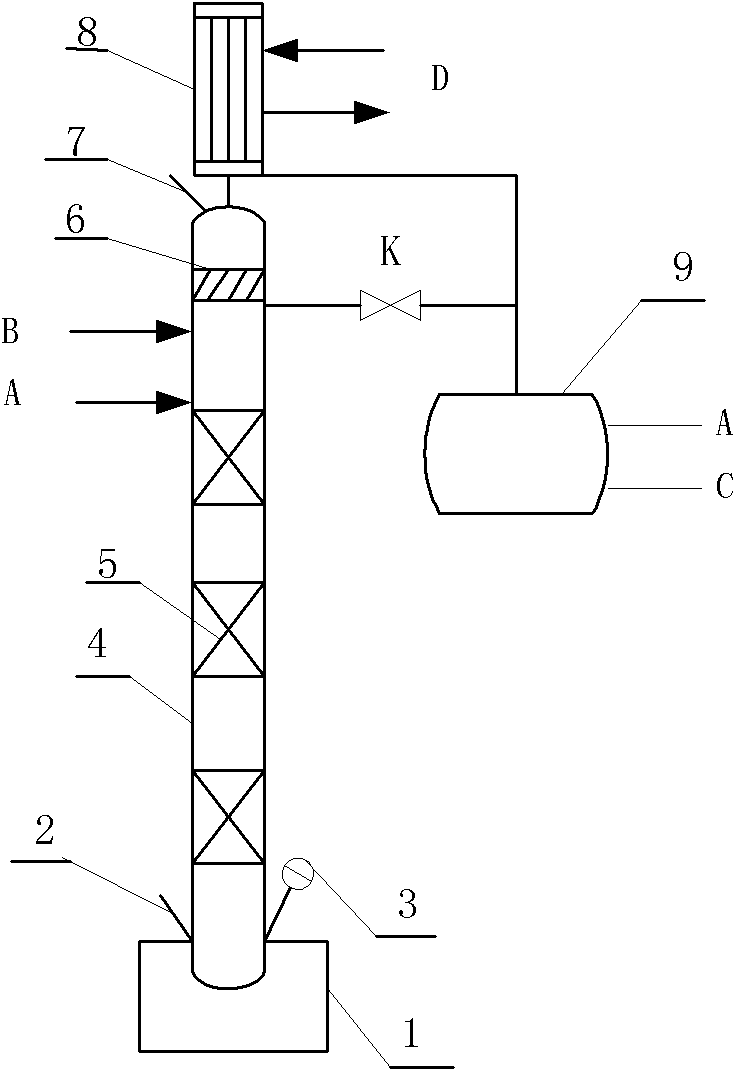

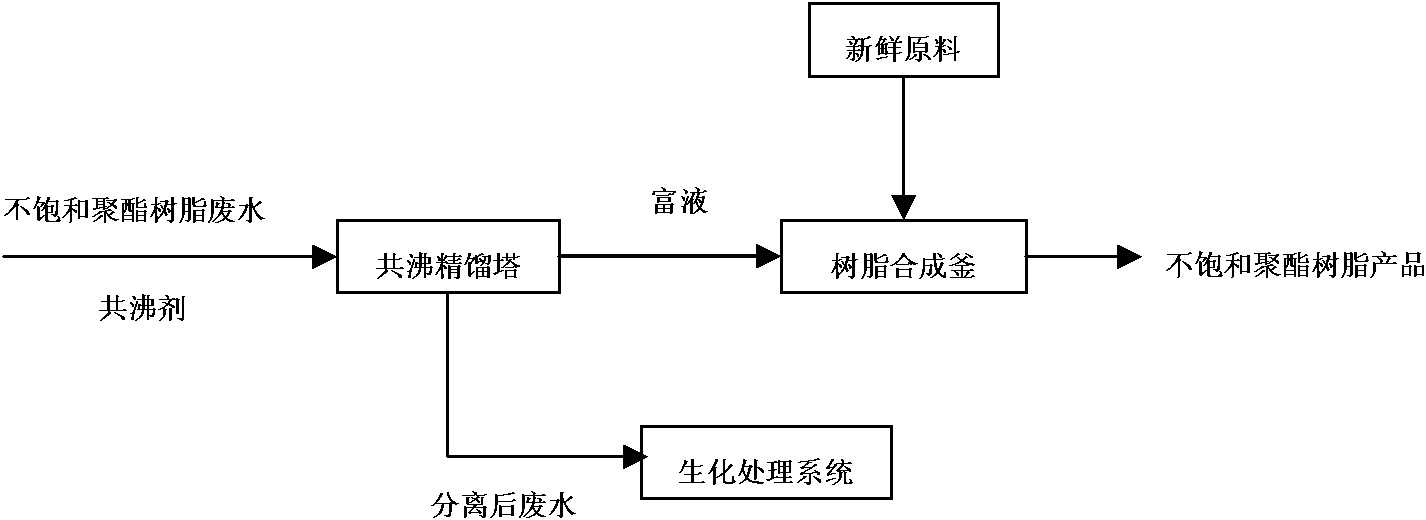

A process for recycling waste water from unsaturated polyester resin industry

InactiveCN102285697AImprove resource recoveryReduce energy consumptionWater/sewage treatment by heatingCircular economyChemistry

The invention discloses a process for recycling waste water from unsaturated polyester resin industry, which is characterized in that: usesful resources in the waste water are separated and recovered by an azeotropic distillation separation recovery technique; and the recovered ingredients are used to prepare a high-performance unsaturated polyester resin, so waste is changed into valuable materials and the product yield and performance of the unsaturated polyester resin are improved. The process solves the problem that resources in waste water cannot be separated and recycled with high efficiency and low energy consumption and burnt as waste in the current industry is solved, and the materials in the waste water are recovered and recycled to form the high-performance unsaturated polyester resin product; and thus, the environment pollution is reduced, and the development of circular economy is promoted. Therefore, the process has great economic and social benefit.

Owner:NANJING UNIV OF TECH +1

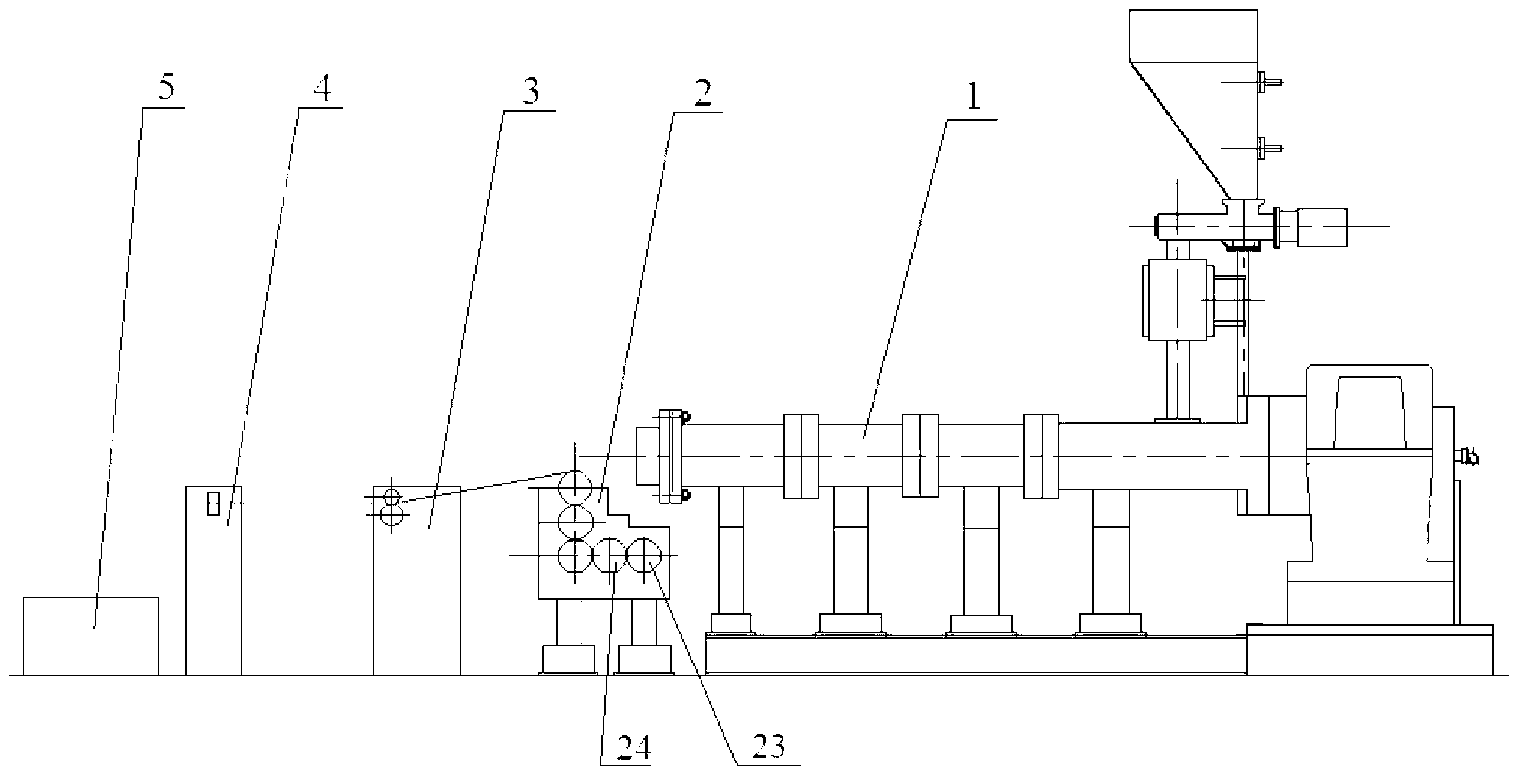

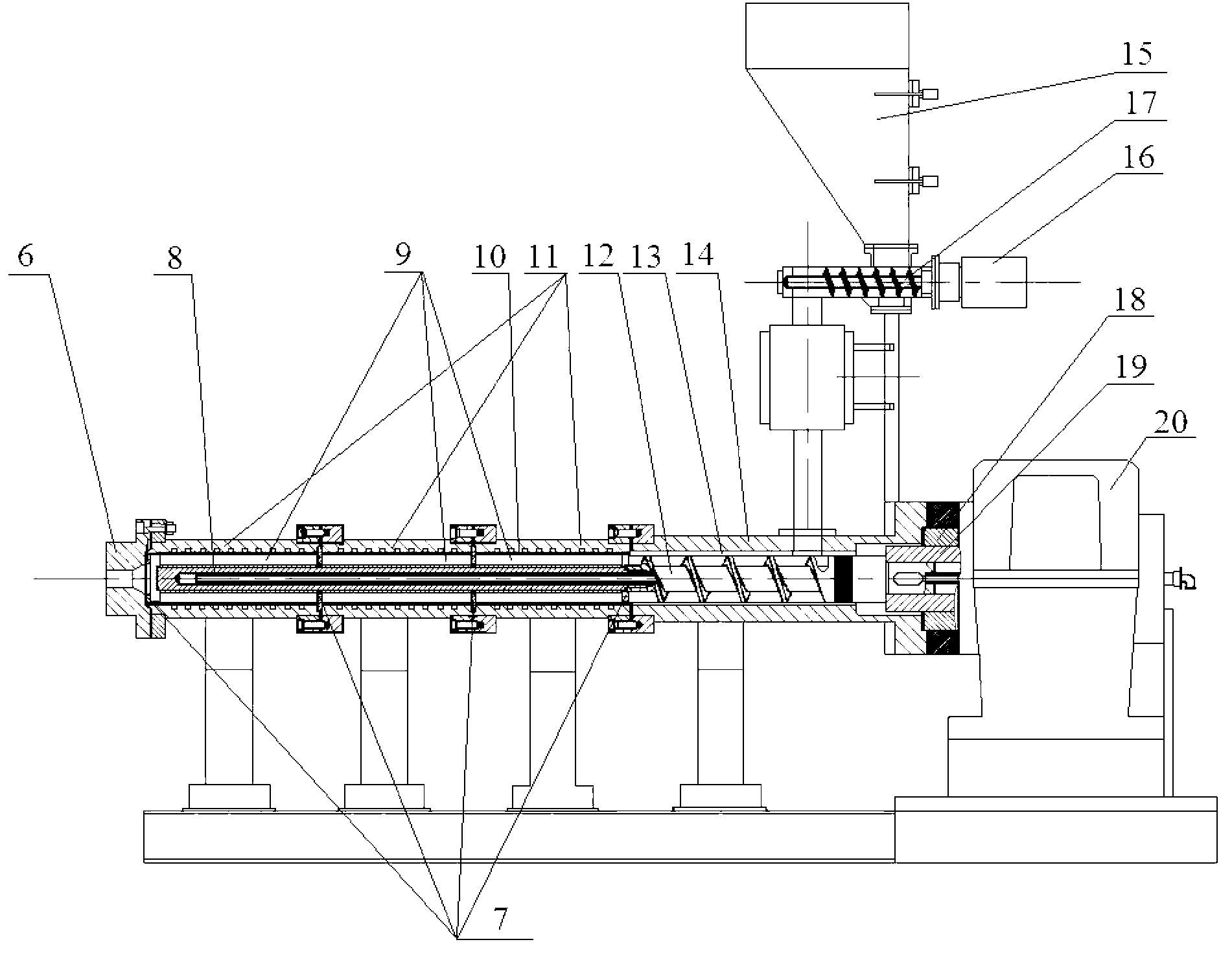

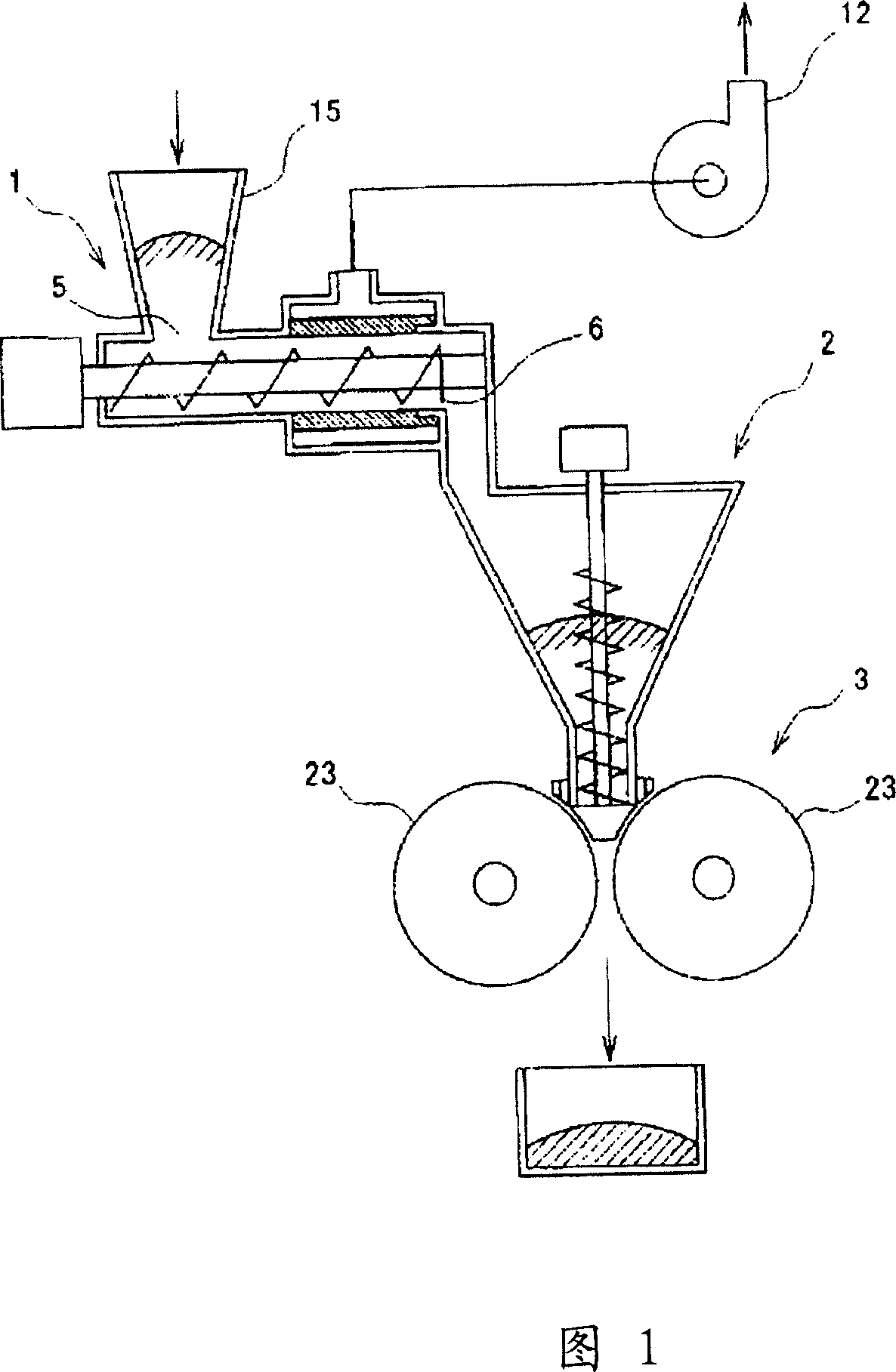

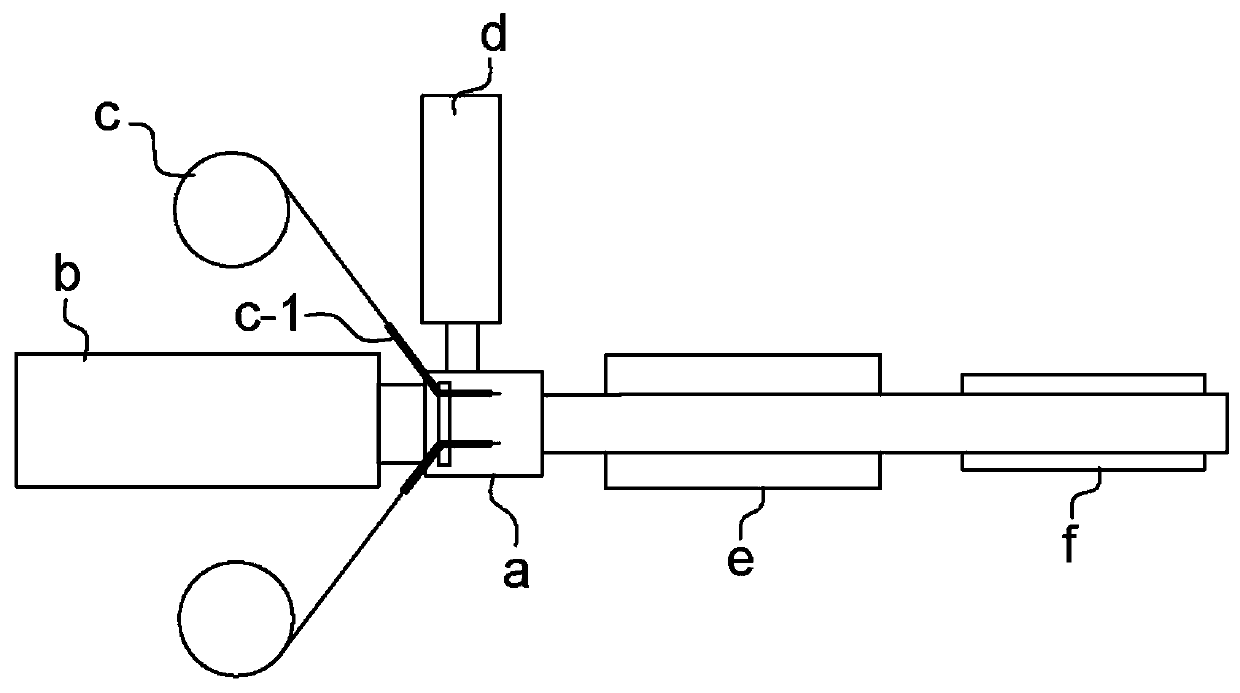

Device and method for preparation of ultra-high molecular-weight polyethylene sheet

ActiveCN103317731ASolve the shortcoming that is not suitable for the manufacture of ultra-high molecular weight polyethylene sheetHigh degree of automationFlat articlesEngineeringUltra-high-molecular-weight polyethylene

The invention discloses a device for preparation of an ultra-high molecular-weight polyethylene sheet. The device is characterized in that the device orderly comprises an extrusion mechanism, a rolling mechanism, a traction mechanism and a cutting mechanism; the extrusion mechanism comprises a planetary screw extruder; the planetary screw extruder comprises a multi-section combined cylinder mechanism; the multi-section combined cylinder mechanism comprises multiple cylinder sections connected with each other and multiple planetary screws embedded respectively in all the cylinder sections; a polyethylene material is extruded by the extrusion mechanism and then is rolled into a sheet by the rolling mechanism; and the sheet is drawn into the cutting mechanism by the traction mechanism and then is cut according to required sizes. The invention also discloses a method for preparation of the ultra-high molecular-weight polyethylene sheet. The device and the method for preparation of the ultra-high molecular-weight polyethylene sheet have a high automation degree and improve production efficiency.

Owner:北京华腾佳和科技有限公司 +1

Double-wall corrugated pipe with prefabricated sealing ring and preparation method thereof

The invention relates to the technical field of pipes, in particular to a double-wall corrugated pipe with a prefabricated sealing ring and a preparation method thereof. The corrugated pipe comprisesfollowing raw materials: 50-150 parts of polyvinyl chloride resin, 50-150 parts of polyethylene resin; 10-30 parts of a nanometer material, 0.5-5 parts of pigment, 2-20 parts of a lead-free stabilizer, 1-20 parts of a processing aid, 1-5 parts of a lubricant, 0.5-5 parts of an antioxidant, 0.5-2 parts of a light stabilizer, 1-25 parts of a compatibilizer, 1-15 parts of an impact modifier, 1-15 parts of a reinforcing agent and 0.5-10 parts of a coupling agent. The preparation method includes following steps: carrying out extrusion molding to obtain a pipe; carrying out injection molding to obtain a bell mouth reinforced sleeve; sleeving the outer wall of the bellmouth part with the bellmouth reinforcing sleeve, mounting the sealing ring on the flaring die core, and cooling to obtain the corrugated pipe with the prefabricated sealing ring. The corrugated pipe is high in ring stiffness, high in comprehensive strength, high in installation efficiency of the bell mouth and the spigot and good in sealing performance.

Owner:KANGTAI PLASTIC SCI & TECH GRP

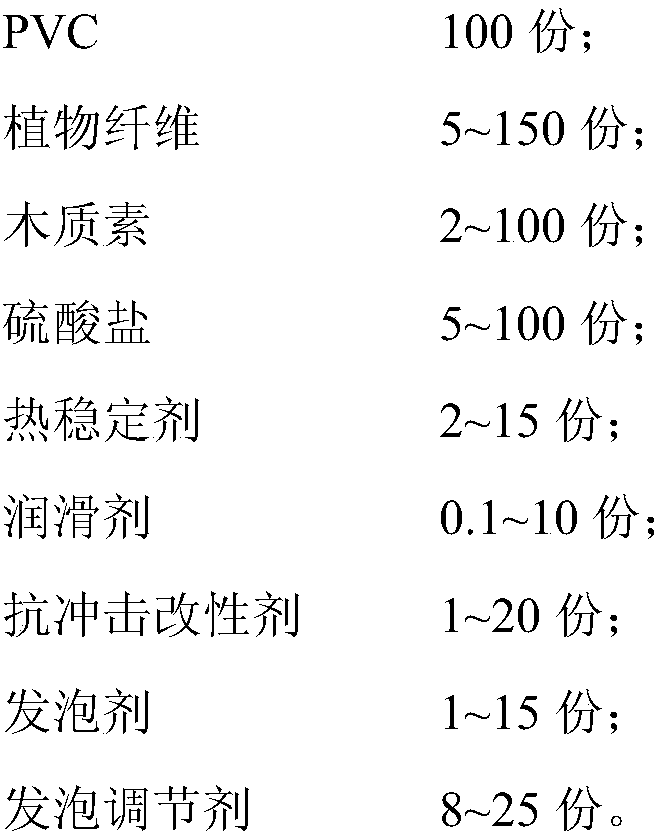

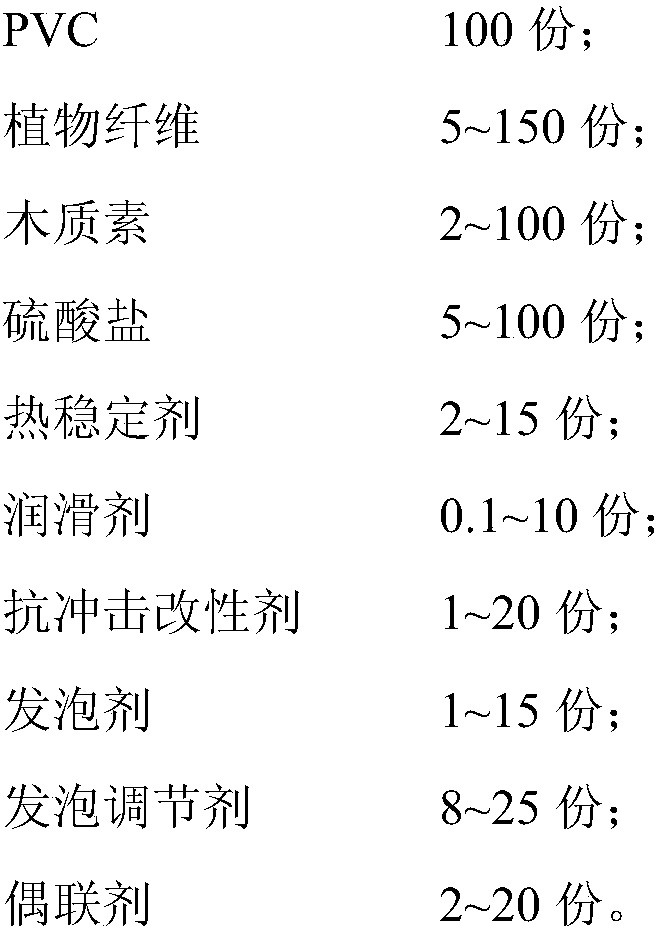

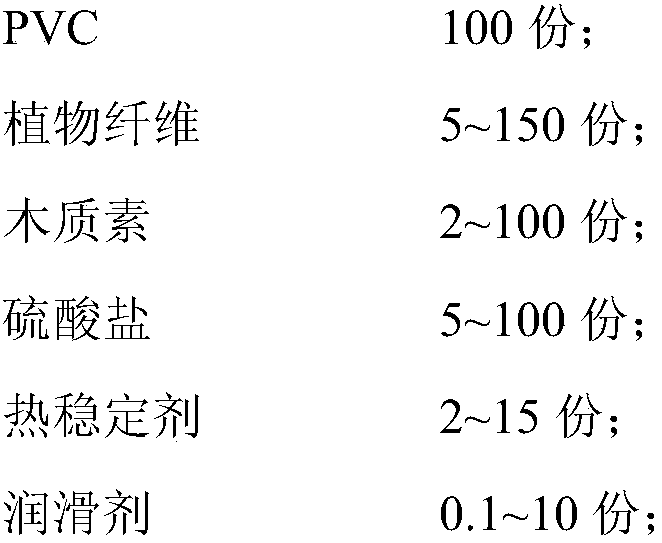

PVC (Polyvinyl Chloride)-lignin-sulfate wood-plastic composite material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride)-lignin-sulfate wood-plastic composite material and a preparation method thereof and belongs to the field of high molecular composite materials. The wood-plastic composite material is prepared from one or more of plant fibers, lignin, sulfate, PVC, a thermal stabilizer, a lubricant, a plasticizer, an anti-impact modifier, a coupling agent, a foaming agent and a foaming regulator, and is extruded and processed through a screw rod. Compared with the prior art, the lignin and the sulfate are added into the wood-plastic composite material at the same time, the flowability is improved and the mutual effect between molecules is improved, so that the filling amount of the plant fibers is improved, and the mechanical property, thermal stability property, and anti-ultraviolet, anti-ageing and bacterium corrosion resisting properties of the wood-plastic composite material are improved.

Owner:NANJING TECH UNIV

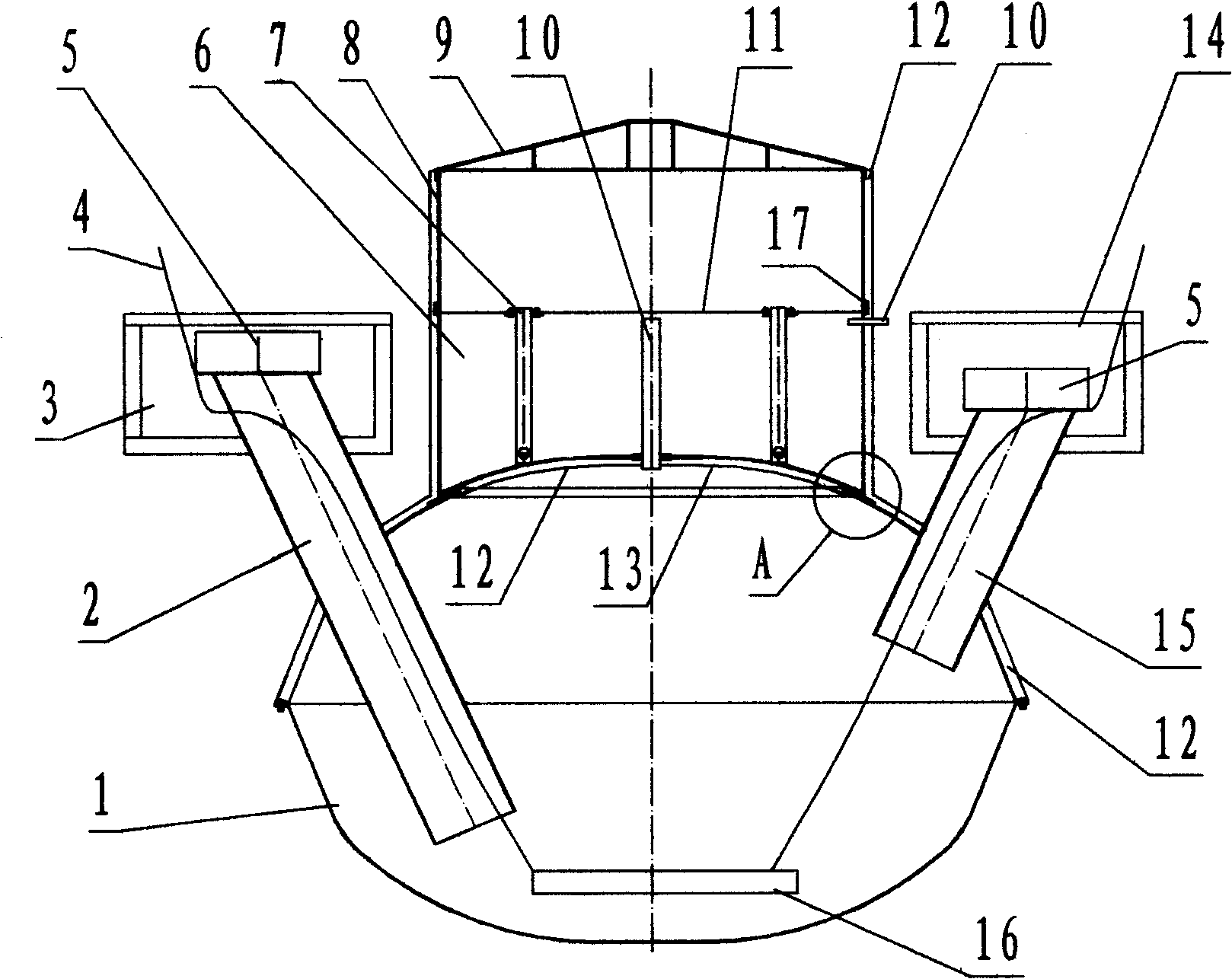

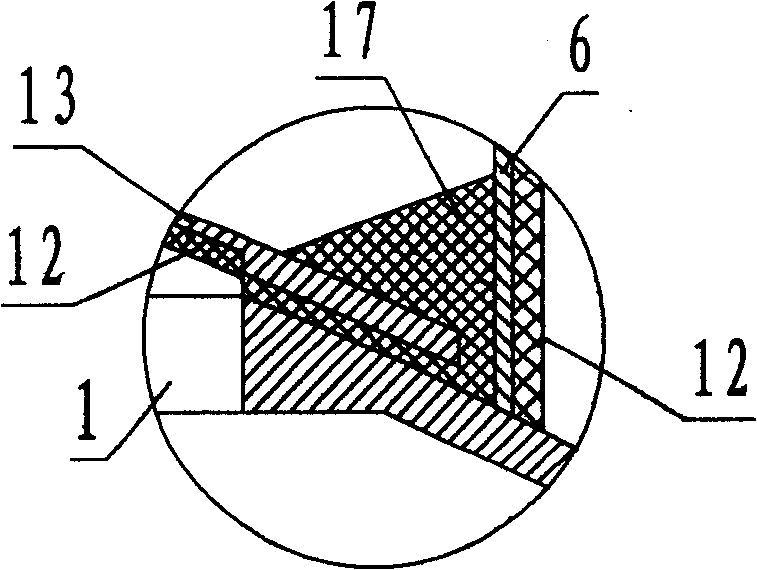

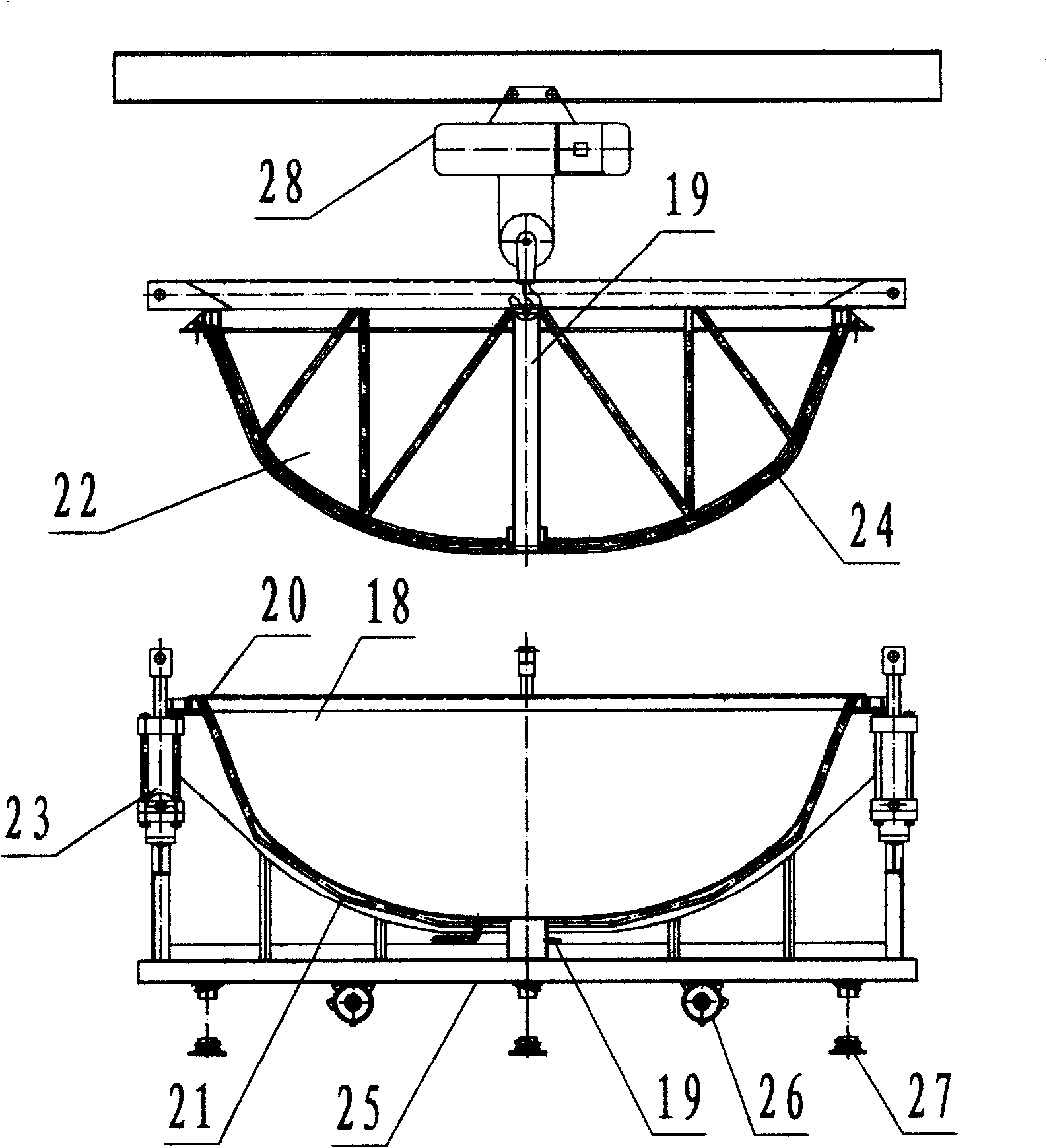

Dry and wet dual-purpose stem pressing glass reinforced plastics biomass pool, producing method and facility thereof

InactiveCN101265446ASimple structureEasy to useGas production bioreactorsWaste based fuelPlastics industryFlexural modulus

The invention relates to a wet and dry dual-purpose mould pressing fiber-glass reinforced plastics methane tank as well as the production method and the facility thereof, and is characterized in that dry ferment and wet ferment performed in a same fermentation tank is realized, air production can be improved by the dry ferment in winter, the discharging and the feeding are performed conveniently by the wet ferment in summer, the production method adopts positive or vibration, vacuum and pressure continuous mould pressing methods, and the production facility adopts a compacting tool set and a vibration-type vacuum hydraulic machine. Compared with the prior art, the production facility of the invention reduces 90 percents of investment cost, reduces 85 percents of energy consumption, reduces 5 percents of product cost on the precondition of same capacity; in addition, on the basis, the flexural modulus are improved by 1.5 times and 2 times respectively compared with the flexural modulus of the prior mould pressing fiber-glass reinforced plastics and the hand lay-up fiber-glass reinforced plastics; therefore, the safety factor is increased, the safety operation of the methane tank is ensured, the service life is prolonged, so as to facilitate the commercialization of the fiber-glass reinforced plastics methane tank and the technology improvement of the mould pressing fiber-glass reinforced plastics industry, and be suitable for the popularization in China.

Owner:季忠铁

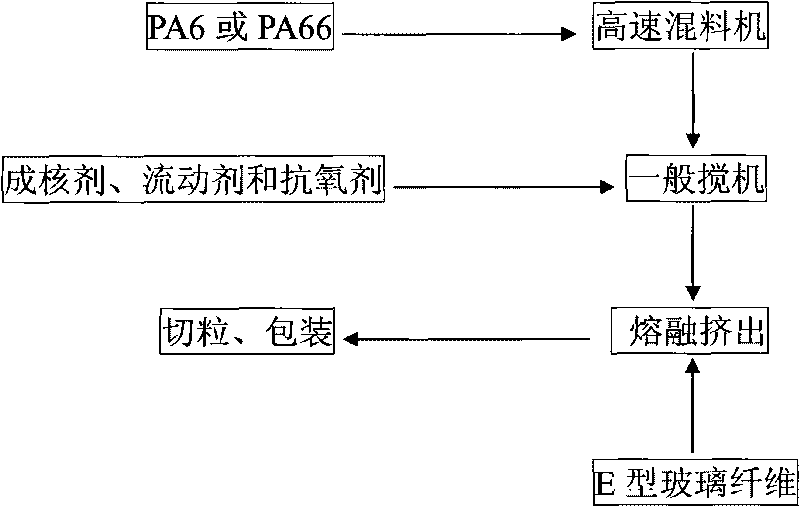

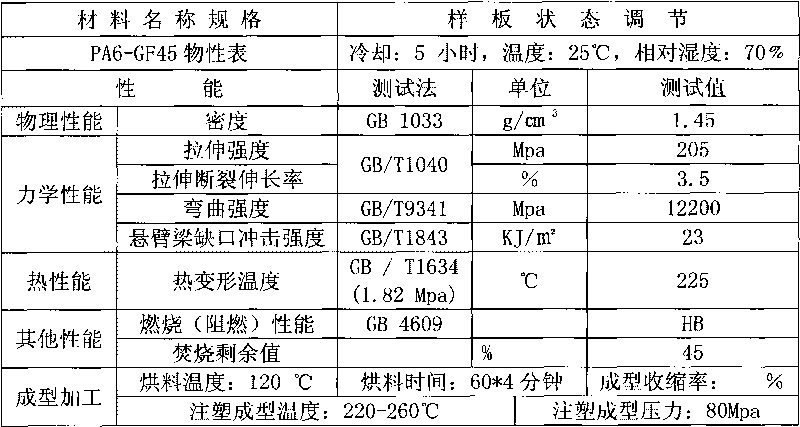

Precision injection molding polyamide composite and preparation method thereof

The invention provides a precision injection molding polyamide composite, which comprises the following components in percentage by weight: PA6 or PA66 40-60, E-type glass fiber 40-55, nucleating agent 0.1-0.3, flowable agent 0.1-0.3 and antioxidant 0.1-0.3, wherein the nucleating agent is calcium carboxylate of which the main ingredients are long carbon chains; the flowable agent is an optimized mixture of copolymers and montanic acid derivatives; and the antioxidant is an inorganic phosphate. The polyamide composite provided by the invention has the advantages that: a batch of small precision plastic injection-molded parts can be molded by the pin-hole injection at one time; degating is avoided and demolding is easy; meanwhile, the physical properties such as thermal deformation temperature, rigidity and transparency are improved and the dynamic performance such as elasticity bending modulus and impact strength is also improved.

Owner:东莞市中洲石化有限公司

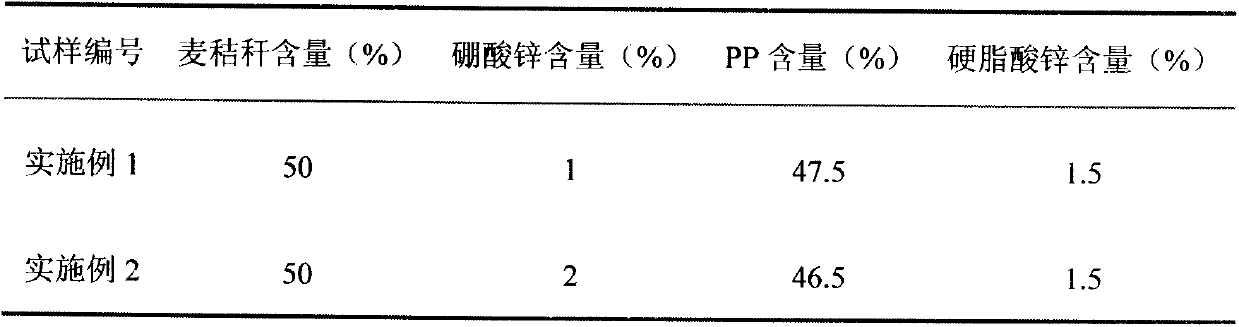

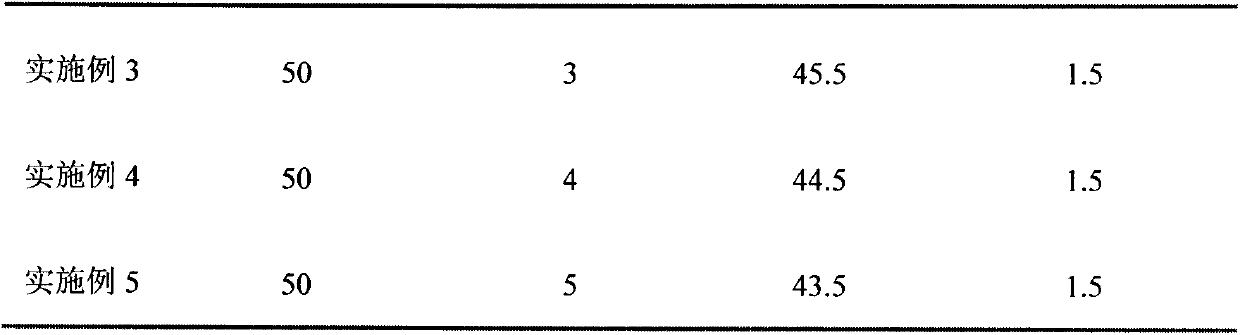

Formula for enhancing mold corrosion resistance of wheat straw/PP (polypropylene) wood-plastic composite material by using antimicrobial agent

InactiveCN104046048AExtended service lifeBest dosageWeather/light/corrosion resistanceZinc borateFilling materials

The invention relates to a formula for enhancing mold corrosion resistance of a wheat straw / PP (polypropylene) wood-plastic composite material by using antimicrobial agents. A filling material wheat straw modified by a coupling agent KH550 and a matrix PP are subjected to compounding and hot pressing to prepare the wheat straw / PP wood-plastic composite material with or without three antimicrobial agents (zinc borate, chlorothalonil and SD-36M); and five mold corrosion experiments are performed on the wheat straw / PP wood-plastic composite material with or without the antimicrobial agents to analyze the improvement action of the antimicrobial agents on the corrosion resistance of the wheat straw / PP composite material and obtain the optimal addition amounts of the antimicrobial agents. The result indicates that the zinc borate and chlorothalonil have favorable improvement action on the corrosion resistance of the wheat straw / PP composite material, and the improvement action of the SD-36M is small; the optimal addition amounts of the zinc borate and chlorothalonil are respectively 1% and 1.25%; and the wheat straw / PP composite material has favorable comprehensive properties after mold corrosion.

Owner:NANJING AGRICULTURAL UNIVERSITY

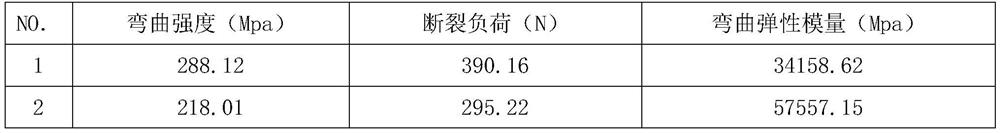

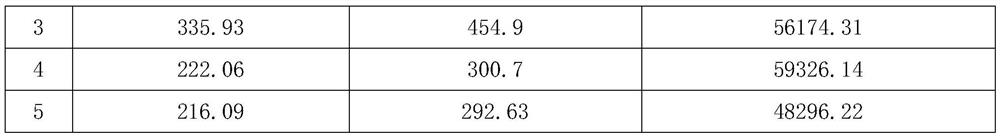

Basalt long-fibre-reinforced wood-plastic sectional material and preparation method thereof

The invention discloses a basalt long-fibre-reinforced wood-plastic sectional material and a preparation method thereof. The preparation method comprises three steps, including surface modification for basalt long fibres, granulation and extrusion, wherein the basalt long fibres subjected to the surface modification treatment are used for reinforcing a wood-plastic material, the compatibility is good, the basalt long fibres are inserted in the holes in a third area and a fourth area respectively; when passing through the third area, lots of fibres are sheared into middle and short fibres with the lengths of 3-10mm; when passing through the fourth area, the shearing force acting on the long fibres is small, and the fibres are generally 10-20mm long; in this way, the basalt fibres with the lengths of 3-20mm are distributed in the wood-plastic sectional material, and in combination with reasonable section of each component in parts by weight, such mechanical properties of the final product as bending strength, bending elastic modulus and impact-resistant strength are remarkably improved.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

Poplar sheet material surface layer reinforcement method

The invention relates to a poplar sheet material surface layer reinforcement method and belongs to the technical field of sheet material reinforcement. The poplar sheet material surface layer reinforcement method comprises the following steps of 1, sheet material preparation, 2, surface polishing, 3, surface layer softening, 4, surface layer compression and 5, stabilization treatment. Raw poplar is divided into sheet materials having a certain thickness by sawing, the sheet materials are subjected to surface polishing, the sheet materials subjected to surface polishing are subjected to softening treatment, the softened sheet materials are fast put into a compressor, the sheet materials are subjected to surface layer compression, and the compression-molded sheet materials are subjected to stabilization treatment. The poplar sheet material surface layer reinforcement method has the advantages that 1, only a surface layer having the thickness of 2-3mm is compressed, a sheet material yield is high, and resources are saved, 2, optimal properties are obtained in shortest time by a lowest cost, and 3, the poplar sheet material surface layer reinforcement method opens a novel approach for poplar value-added application and high-efficiency utilization.

Owner:NORTHWEST A & F UNIV

Transparent section and preparation process thereof

The invention relates to a transparent section and a preparation process thereof. At present, plastic profiles mainly have product structures such as white, white coextrusion, color coextrusion, whole color and spray color, the conventional products do not have transparency, the lighting effect is not optimal and the manufactured doors and windows do not achieve the maximum energy-saving effect. The preparation process for the transparent section comprises the following steps of: mixing vinyl chloride resin, an organic tin stabilizer, a polyol lubricant, an internal lubricant, ultramarine blue, a release agent and a toughening agent in a proportion at 110 DEG C; when hot mixing temperature of the materials reaches 110 DEG C, performing cold mixing in a cold pot to reduce the temperature to 45 DEG C, discharging, and putting into an extruder for extrusion, wherein the processing temperature range is 170 to 210 DEG C; and performing shaping, cooling and forming by using a mold, and performing cutting and packaging to obtain the finished product. The preparation method has a simple process; and the produced transparent section has transparent whole body, good transparency and clear visual effect, effectively improves the lighting effect of doors and windows, and improves the energy-saving effect.

Owner:西安中财型材有限责任公司

Polypropylene resin composition and process for producing the same

ActiveCN101014662AGood lookingHigh flexural modulus of elasticityDomestic articlesThin material handlingPolymer sciencePolypropylene

This invention provides a talc-containing polypropylene resin composition using in-line compounding, which can solve a problem that, when the degree of compression is reduced to eliminate white points derived from poor dispersion of an inorganic filler, the amount of introduced air is increased, leading to adverse effect of productivity particularly in the case of a large kneader, and a process for producing the same. The polypropylene resin composition comprises degassing compressed talc (A) and a polypropylene resin (B). The degassing compressed talc has a bulk specific gravity of 0.3 to 1.0 and a degree of compression of 3.1 to 7.0 and is produced by degassing compression of talc having an average particle diameter of 0.1 to 12 mum and a bulk specific gravity of 0.1 to 0.5. In this degassing compressed talc, the proportion of a fraction having a size of not less than 1,000 mum as sieved by a rotap method is not more than 15% by weight.

Owner:JAPAN POLYPROPYLENE CORP

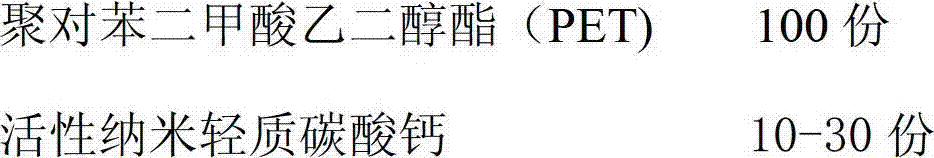

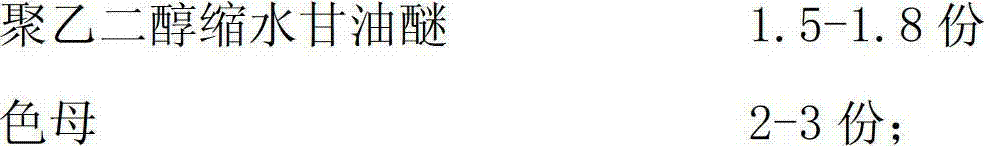

PET (Polyethylene Terephthalate) hollow foaming tubular product and manufacturing method thereof

InactiveCN102889435ARich sourcesSmooth and shiny surfaceFlexible pipesRigid pipesCorrosionWear resistance

The invention discloses a PET (Polyethylene Terephthalate) hollow foaming tubular product and a manufacturing method thereof, belonging to the field of a plastic water discharging pipeline. The PET hollow foaming tubular product is formed by a PET outer layer and a PET hollow foaming layer combined with an inner wall of the PET outer layer, wherein the PET outer layer is formed by the following components in parts by weight: 100 parts of polyethylene terephthalate, 10-30 parts of active nano light calcium carbonate, 1.5-1.8 parts of polyethylene glycol diglycidyl ether and 2-3 parts of color master batch; and the PET hollow foaming layer is formed by the following components in parts by weight: 100 parts of the polyethylene terephthalate, 8-20 parts of the active nano light calcium carbonate, 1.8-2.4 parts of the polyethylene glycol diglycidyl ether, 3-4 parts of the color master batch and 1.2-1.8 parts of imidazole compound foaming agent master batch. The tubular product disclosed by the invention has the good performances of light weight, corrosion resistance, scale prevention, wear resistance, good flexibility, high impact strength, good air tightness, recyclability, convenience and rapidness for installation, energy saving, sanitation, environmental friendliness and the like; and meanwhile, the tubular product has the advantages of good anti-ageing and weather-resisting performance, good noise reduction effect and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

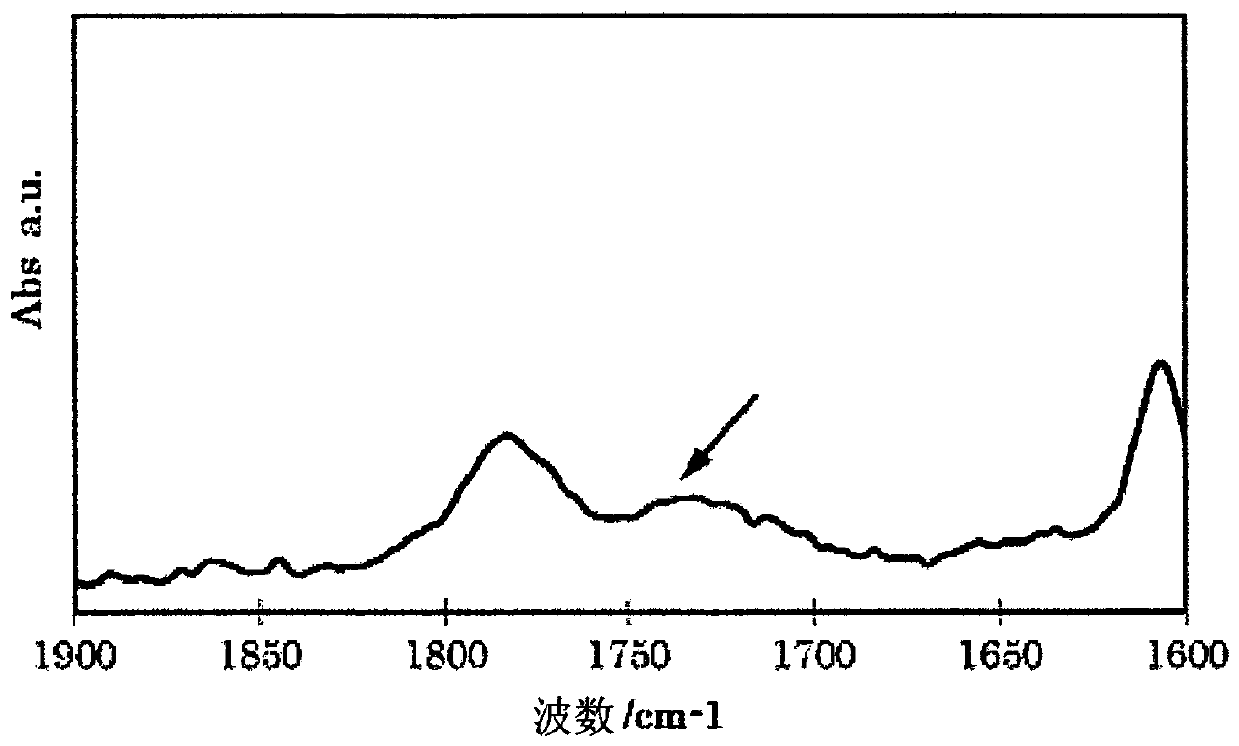

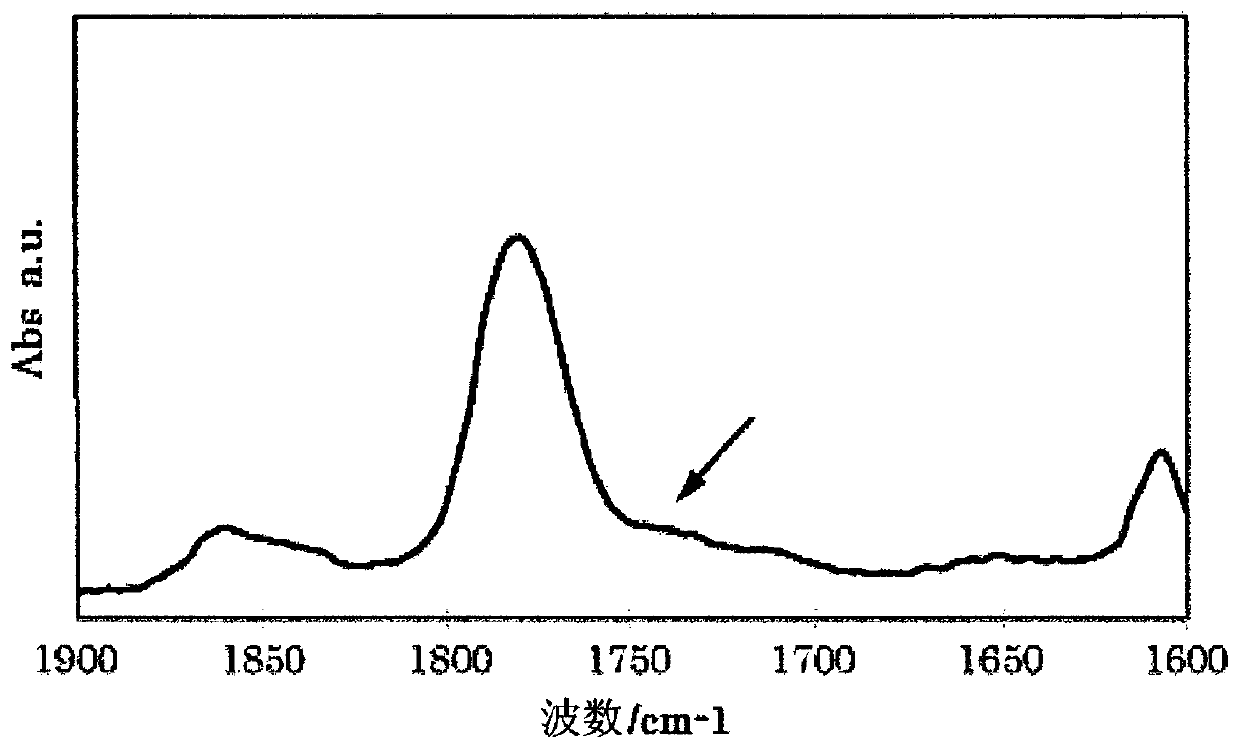

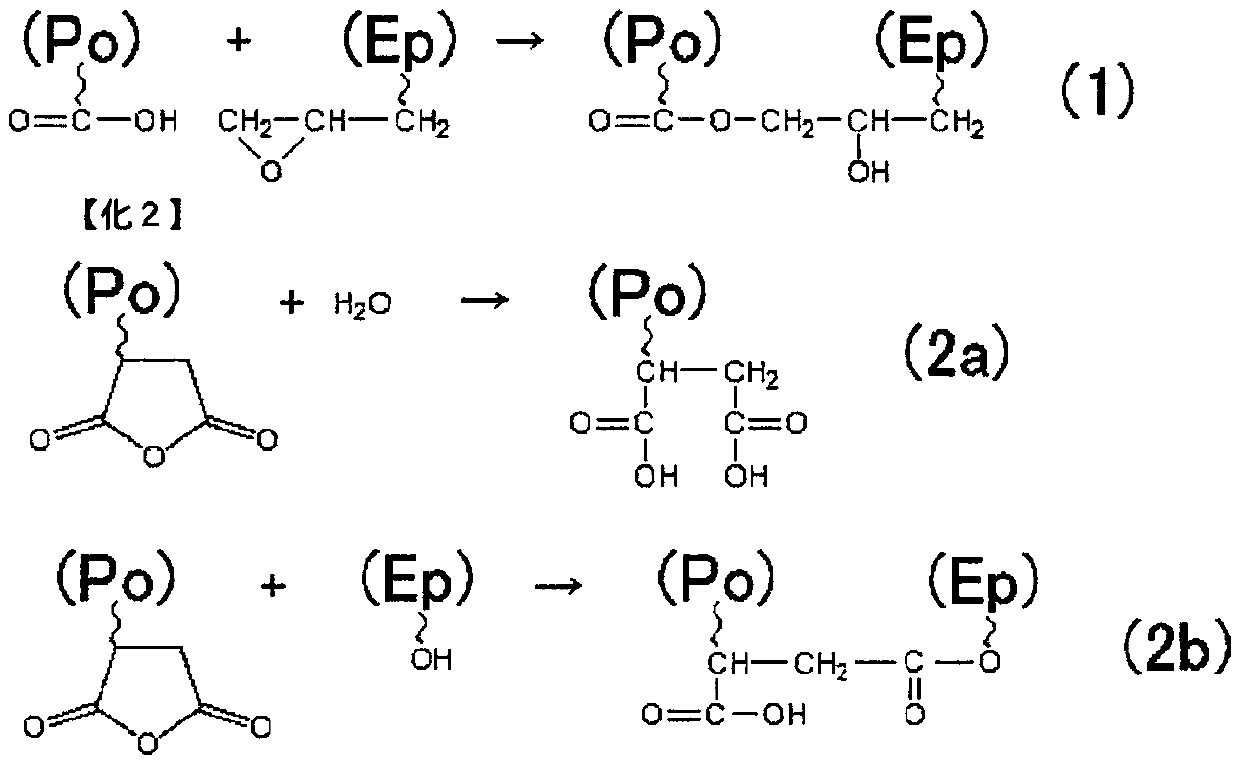

Adhesion improver for carbon-fiber-reinforced resin composition

PendingCN110431167AImprove bending strengthHigh flexural modulus of elasticityEpoxy resin adhesivesFiberEpoxy

Provided is an adhesion improver for carbon-fiber-reinforced polyolefin-based resin compositions which improves the mechanical properties including bending strength and bending modulus. The adhesion improver is for use in carbon-fiber-reinforced resin compositions which comprise carbon fibers and a polyolefin-based resin, and is characterized by comprising an acid-modified polyolefin-based resin unit and an epoxy resin unit, the acid-modified polyolefin-based resin unit and the epoxy resin unit having been bonded to each other by an ester structure and the epoxy resin unit containing a secondary hydroxy group.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

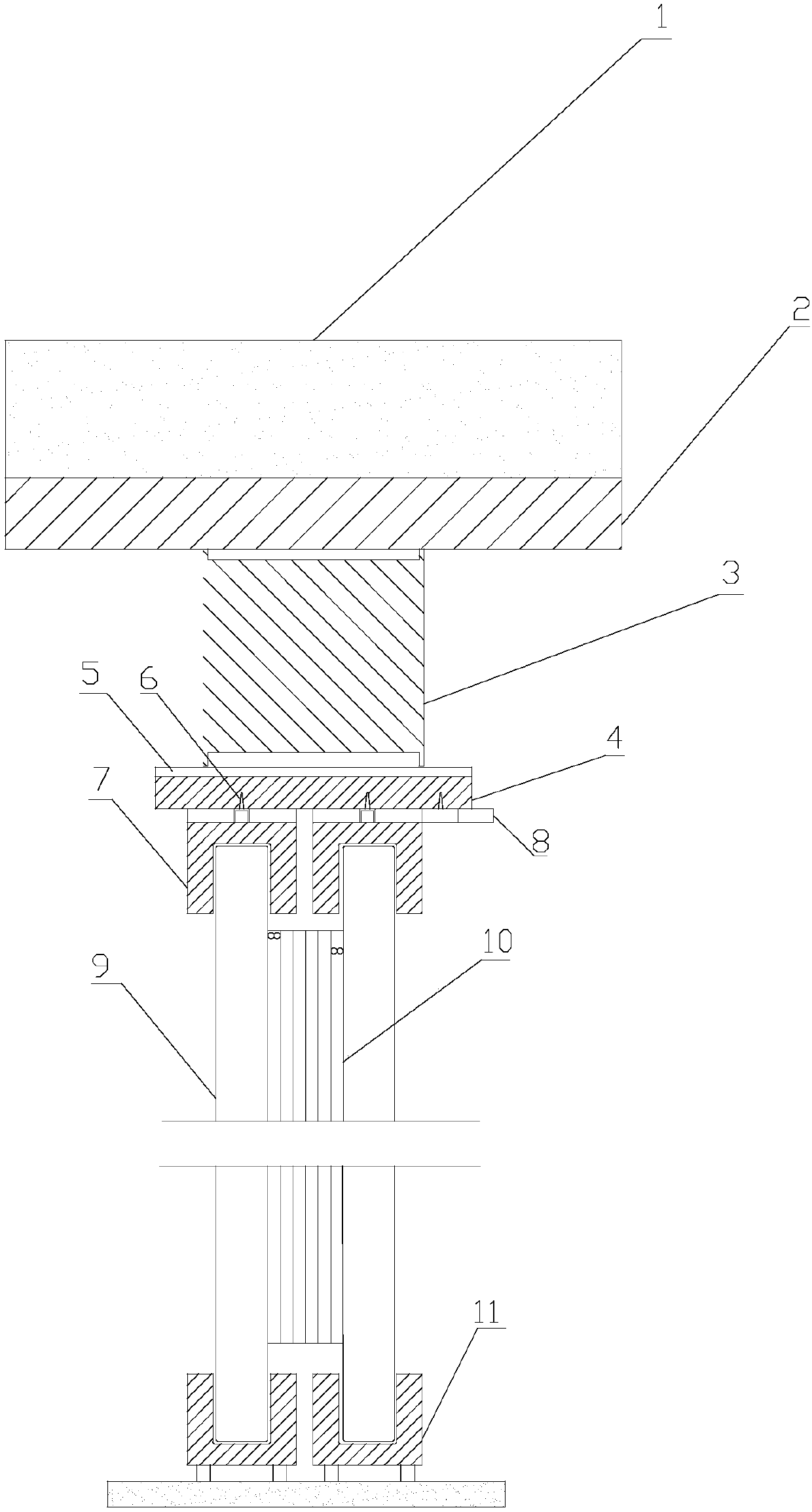

High-strength building wallboard

InactiveCN107761942AEasy to disassembleGive full play to high-strength characteristicsConstruction materialArchitectural engineeringHigh intensity

The invention relates to the technical field of building materials, in particular to a high-strength building wallboard. The high-strength building wallboard comprises a roof (1); a first PVC board (2) adheres to the lower portion of the roof (1), and an upper fixing frame (3) is mounted on the lower portion of the first PVC board (2); a second PVC board (5) vertically adheres to the lower portionof the upper fixing frame (3), and a cross beam board (4) adheres to the other face, corresponding to the face adhering to the upper fixing frame (3), of the second PVC board (5); a self-tapping screw (6) is fixed to an upper wallboard frame (7) which is fixedly connected with the cross beam board (4) through the self-tapping screw (6); and a building wallboard body (9) is clamped between the upper wallboard frame (7) and a lower wallboard frame (11), and a heat conduction pipe (10) is mounted in the center of the building wallboard body (9). According to the high-strength building wallboard,two outlets and two inlets which constitute the heat conduction pipe (10) are formed in the two side faces of the double-layer wallboard, the contact area of the heat conduction pipe and the double-layer wallboard is increased, and the double-inlet double-outlet effect is achieved through the heat conduction pipe, so that the indoor environment keeps balanced.

Owner:李彦平

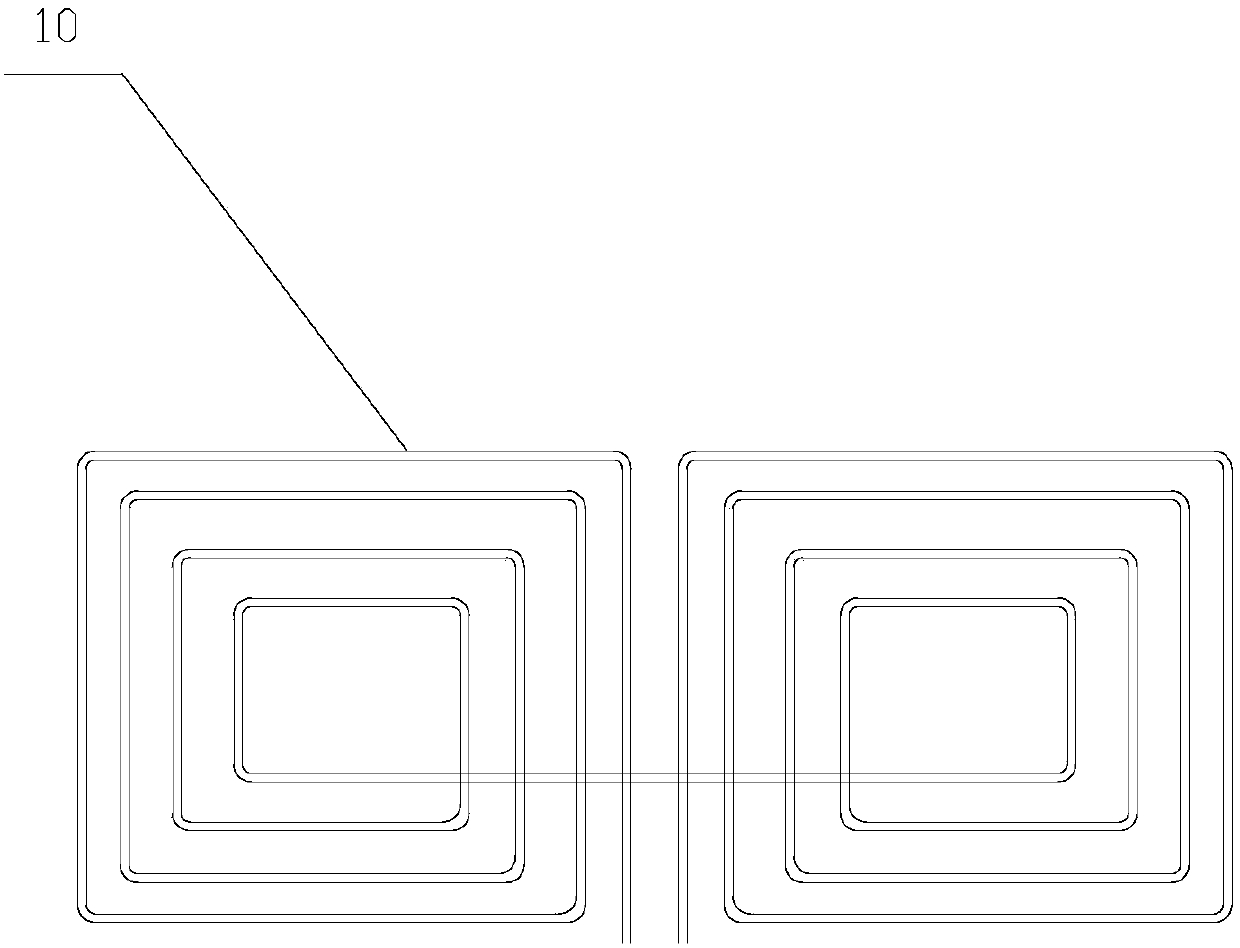

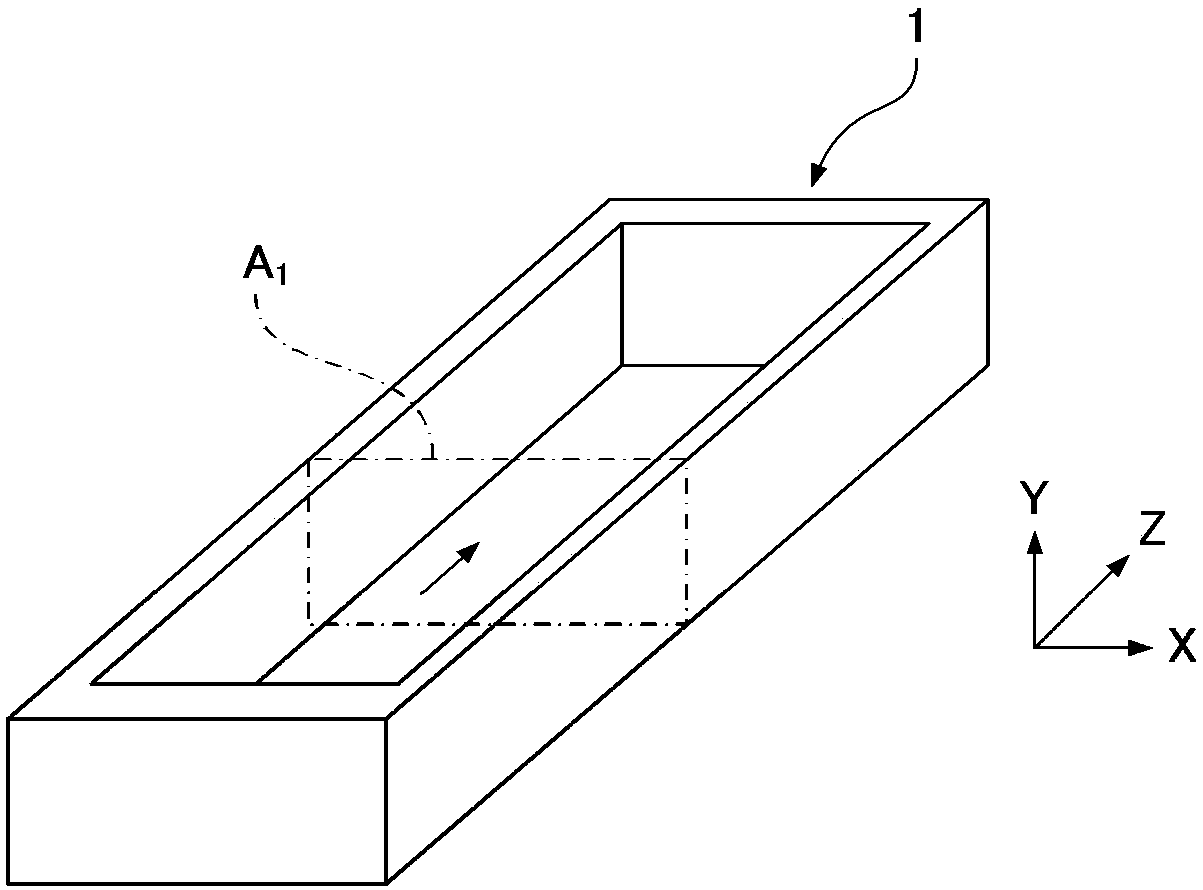

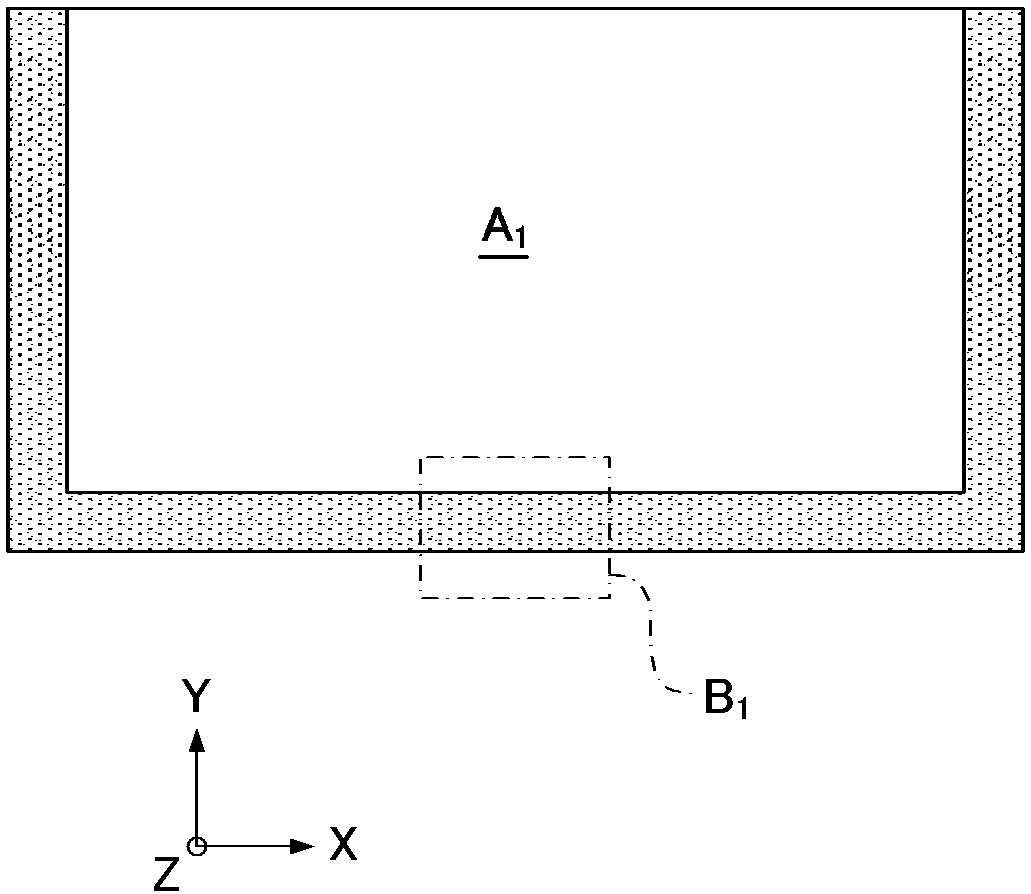

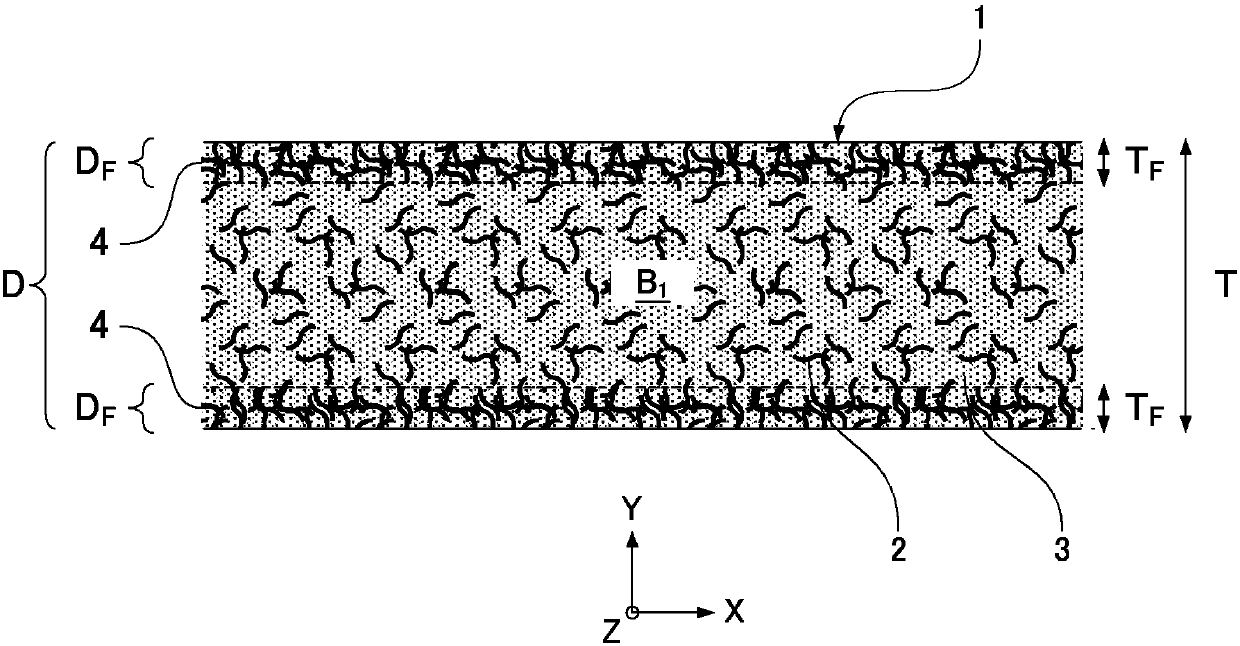

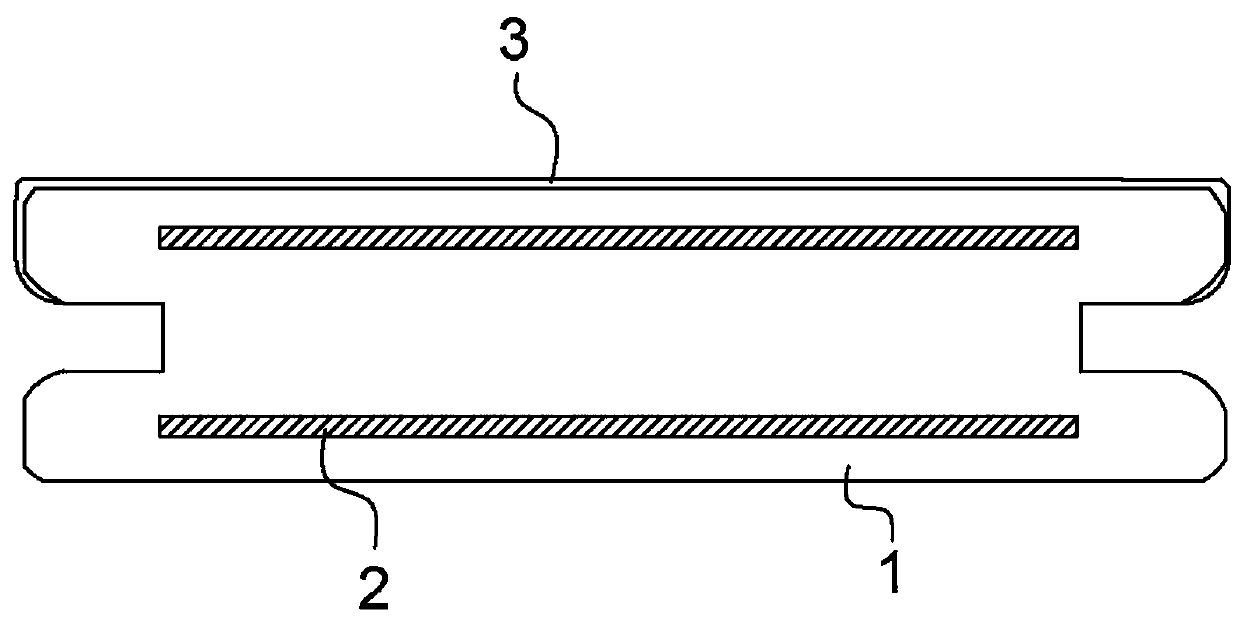

Molded article and molding method thereof

ActiveCN108568955AHigh modulus of elasticity in tensionHigh flexural modulus of elasticityCellulosic plastic layered productsCoatingsPolymer scienceCellulose fiber

The invention provides a molded article and a molding method thereof. A molded article 1 is made of a resin material 3 containing cellulose fibers 2. The molded article 1 has a surface portion 4 thatis in a range satisfying TF<=0.1xT where T is the thickness of the molded article 1 and TF is a distance from the surface of the molded article 1, and the molded article 1 satisfies DF>=1.1xD where Dis an average cellulose concentration of the overall molded article 1 and DF is an average cellulose concentration of the surface portion 4. Thus, the molded article suppresses an increase in bendingmodulus while considerably improving a tensile modulus.

Owner:PANASONIC HLDG CORP

Low-melting-point nylon wood/plastic product and preparation method thereof

The invention discloses a low-melting-point nylon wood / plastic product and a preparation method thereof. Nylon and metal halide are dried until the water content is 0.1% or lower, then modification is performed with an internal mixer or a pelletizer, the melting point of nylon is reduced to 200 DEG C or lower, then the modified low-melting-point nylon is mixed with wood fibers, a chain extender, a lubricant and a pigment for pelleting, and the wood / plastic product with excellent mechanical properties is obtained through extrusion or injection molding.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

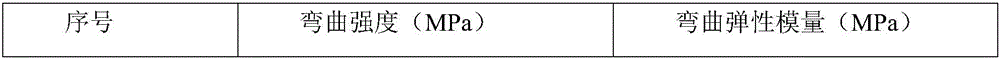

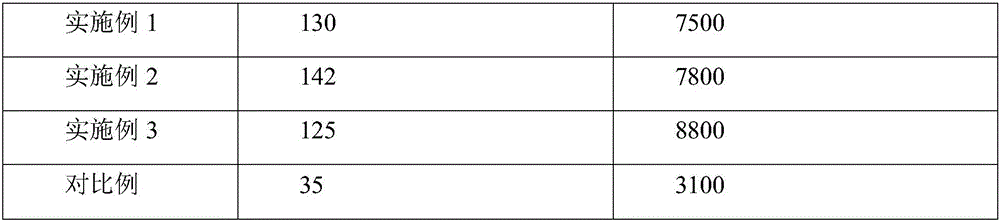

Novel PVC (polyvinyl chloride) profile and preparation method thereof

The invention discloses a novel PVC (polyvinyl chloride) profile which comprises the following components in parts by weight: 55-65 parts of PVC waste, 12-15 parts of wood dust, 13-15 parts of light calcium carbonate, 0.72-0.84 part of titanium white, 2.5-3.2 parts of EVA (ethylene-vinyl acetate) impact modifier, 1.8-2.3 parts of MBS (methyl methacrylate-butadiene-styrene) impact modifier, 0.84-0.96 part of organic tin stabilizer, 0.48-0.51 part of epoxy compound stabilizer, 0.63-0.77 part of aliphatic acid amine and 1.5-2.4 parts of coupling agent. The PVC profile has the advantages of smooth surface, regular edge, no cracks, pores, adhesion, bubbles or scars, and high glossiness (up to 56.53Gu). The PVC profile has excellent heat-insulating property, ending deformation resistance, tensile impact resistance and solderability.

Owner:CHONGQING WANSENDA TECH DEV CO LTD

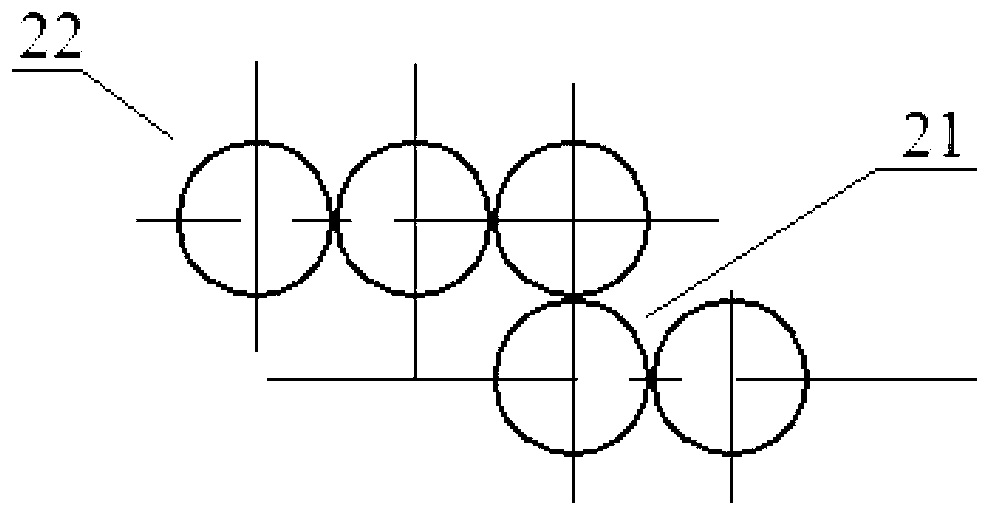

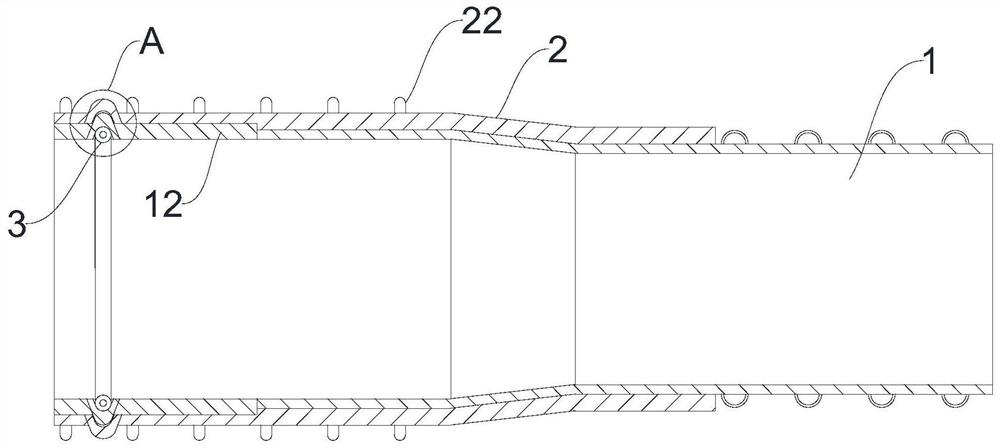

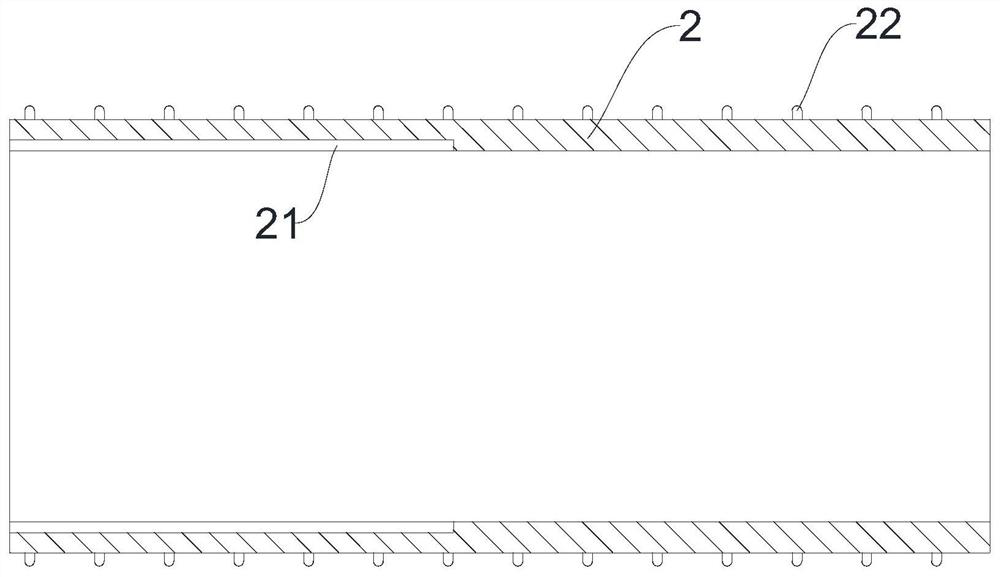

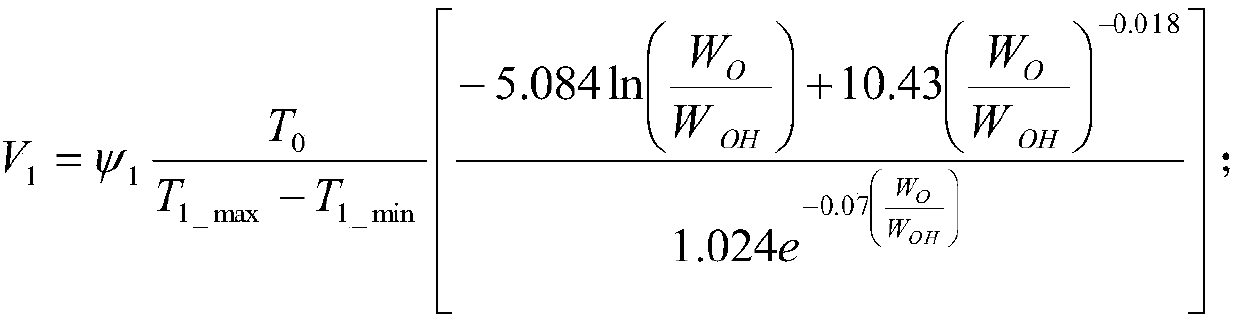

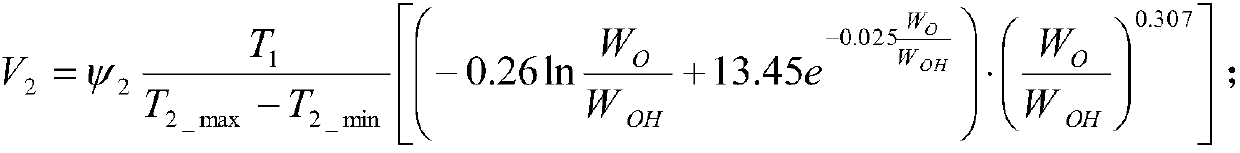

Composite floor and preparation equipment group thereof

InactiveCN111231260AHigh flexural modulus of elasticitySave installation spaceFlooringMechanical engineeringMaterials science

The invention relates to a composite floor and a preparation equipment group thereof, and belongs to the technical field of co-extrusion foam boards. The composite floor comprises a core body, the core body is an integrally-formed platy piece made of foaming materials, and the composite floor further comprises a reinforcing layer arranged in the core body and a protective layer arranged on the surface of the core body. The preparation equipment group comprises a mold, a core material extrusion device, a reinforcing layer material conveying device, a protective layer material extrusion device,a cooling device and a traction device. The composite floor has excellent bending elastic modulus performance, and the equipment cost, the preparation energy consumption and the occupied space of equipment of the composite floor can be effectively reduced through the equipment group.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

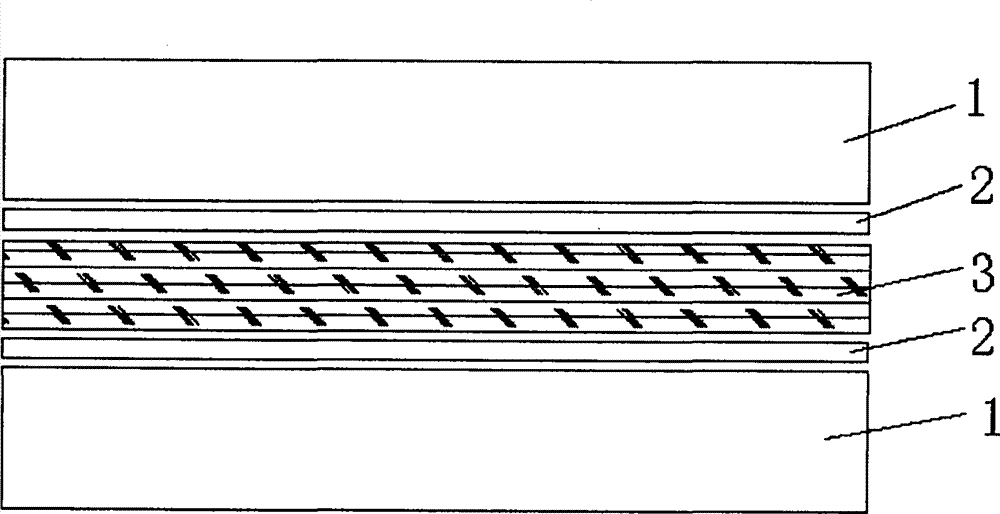

High-strength building wallboard

InactiveCN105822008AAvoid degradationImprove mechanical propertiesConstruction materialFlexural strengthMechanical properties of carbon nanotubes

The invention discloses a high-strength building wallboard, which comprises an upper layer, a middle layer and a lower layer, the middle layer is a reinforcement layer; the thickness of the reinforcement layer is 20% to 40% of the high-strength building wallboard, and the reinforcement layer is Metal plate; the upper layer and the lower layer are covering layers, the covering layer is made of wood-plastic material, and the covering layer and the reinforcing layer are bonded by adhesive. The product obtained by the invention can give full play to the high-strength characteristics of engineering plastic nylon, and the mechanical properties such as bending strength and bending elastic modulus are significantly improved. At the same time, the building wallboard of the present invention is used in combination with a thinner metal layer and a wood-plastic material layer, and has higher strength.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

Molding resin for improving insulation performance and heat deformation temperature of outdoor electrical appliance, and preparation method thereof

PendingCN109575256AHigh tensile strengthHigh modulus of elasticity in tensionHeat deflection temperaturePlasticizer

The invention discloses molding resin for improving the insulation performance and heat deformation temperature of an outdoor electrical appliance. The molding resin comprises 28.5-37.5 parts of diol,3-4.5 parts of phthalic anhydride, 21.5-26.5 parts of maleic anhydride, 4-8.5 parts of methyltetrahydrophthalic anhydride, 23-28 parts of styrene, 0.07-0.13 part of polymerization inhibitor, 0.08-0.41 part of retarder, 0.08-0.11 of antioxidant, 0.18-0.35 part of plasticizer and 7-15 parts of chelating agent. The invention also discloses a preparation method of the molding resin for improving theinsulation performance and heat deformation temperature of the outdoor electrical appliance.

Owner:镇江利德尔复合材料有限公司

Multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared by multi-component compatiblizing and toughening agent

InactiveCN101717476BCompatibleGood compatibilityMonocomponent polyesters artificial filamentFiberElastomer

The invention discloses multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared from a multi-component compatiblizing and toughening agent. The multi-component controllable reactive compatiblizing and toughening agent is prepared from polypropylene, an elastomer 1, an elastomer 2, a difunctional group reactive monomer, a second monomer and a peroxide initiator. Then, multifunctional waste PET is prepared from an antioxidant and the prepared multi-component controllable reactive compatiblizing and toughening agent and waste PET; and finally, the in-site fiber-forming composite material is prepared by compounding the prepared multifunctional waste PET with polypropylene. The in-site fiber-forming composite material prepared by the technical scheme of the invention has obviously improved toughness (the notch impact strength of a cantilever beam) and rigidity (tensile yield stress and bending elastic modulus) in comparison with the raw material polypropylene and has relatively good reproducibility of mechanical performance; meanwhile, the invention also changes a great amount of waste which mainly refers to waste PET domestically generated every year into resources, thereby having remarkable economic and social benefits.

Owner:洛阳石化吉润化工有限责任公司 +1

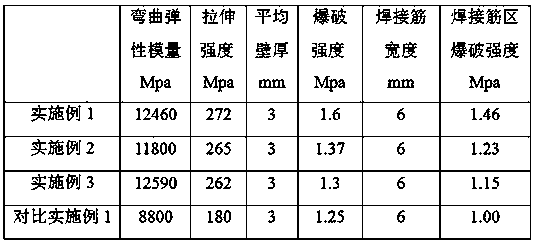

PA6 composite material special for engine air intake manifolds

The invention discloses a PA6 composite material special for engine air intake manifolds. The PA6 composite material comprises the following raw materials by weight: 60-70 parts of PA6 resin, 25-35 parts of glass fiber, 0.5-1 part of a dispersant, 4-5 parts of a compatibilizer, 0.5-1 part of a coupling agent, 1-2 parts of carbon black, and 1-2 parts of an antioxidant, and is prepared by: mixing the raw materials by a high-speed mixer, then conducting mixing milling by a millstone type mixing device, and carrying out parallel twin-screw extrusion granulation. The glass fiber is high strength glass fiber with a monofilament diameter of 8micrometer, the compatibilizer is formed by compounding of a maleic anhydride grafted butane-octene copolymer and N, N'-ethylene bis stearamide in a weight ratio of 3:1. The PA6 composite material special for engine air intake manifolds has good secondary fusion welding bondability and high strength after welding. The engine air intake manifolds preparedfrom the PA6 composite material special for engine air intake manifolds have the advantages of high integral strength, good toughness, little glass fiber exposure, strong blast resistance ability in awelded rib area and the like.

Owner:LIAONING FENGDI ENGINE AIR INTAKE SYST

Application of active silica fume

The invention discloses application of active silica fume as rubber and white carbon black which is an engineering plastic additive. Based on researches of the invention, silica fume collected by using smoke and dust separation and purification power complete equipment has a smaller granularity of 0.10-0.255mu m and an active index higher than 120%, achieves the activity of natural cinerite and materialization indexes similar to fumed silica (white carbon black), but has cost far lower than that of the white carbon black produced specifically. In addition, proved by the experiments of Shanghai Rubber Industry Institute, after the white carbon black in natural rubber and regenerated rubber is replaced by the active silica fume, the elongation, tear resistance and death resistance of the rubber can be improved greatly and the quality of the rubber can be guaranteed. The active silica fume can replace the function of the white carbon black in the rubber and engineering plastics, can replace powdery mineral filler ground by the traditional mechanical power, improve the cost performance of materials, and reduce the cost of materials.

Owner:上海山鹰环保科技股份有限公司

Glaze-imitating colored plastic glazed tile and preparation method thereof

ActiveCN108673987ASatisfy the use environmentGood weather resistanceSynthetic resin layered productsConstructions elementsPigmentChemistry

Belonging to the technical field of plastic products, the invention discloses a glaze-imitating colored plastic glazed tile and a preparation method thereof. The glazed tile comprises an upper layer and a lower layer, the upper layer comprises the following raw materials by mass percentage: 65-75% of AS resin, 15-30% of an AS resin modifier, 2.5-3.5% of a coloring pigment I, and 0.5-5% of an assistant I; the lower layer comprises the following raw materials by mass percentage: 50-60% of PVC resin, 30-40% of nano-active CaCO3, 3.5-5% of an additive II, and 0-3.5% of a coloring pigment II; the AS resin modifier is at least one of ASA resin and acrylic ester; the coloring pigment I is a transparent pigment; and the nano-active CaCO3 crystalline form is a cubic crystal form. The glazed tile provided by the invention has good appearance effect and glaze-imitating effect, and the weatherability, impact resistance and environmental friendliness are all superior to clay glazed tiles in the prior art.

Owner:成都菲斯特新材料有限公司

A method for strengthening the surface of poplar board

InactiveCN103831878BHigh yieldSmall density changeWood compressionWood treatment detailsCompression moldingPolymer science

The invention relates to a poplar sheet material surface layer reinforcement method and belongs to the technical field of sheet material reinforcement. The poplar sheet material surface layer reinforcement method comprises the following steps of 1, sheet material preparation, 2, surface polishing, 3, surface layer softening, 4, surface layer compression and 5, stabilization treatment. Raw poplar is divided into sheet materials having a certain thickness by sawing, the sheet materials are subjected to surface polishing, the sheet materials subjected to surface polishing are subjected to softening treatment, the softened sheet materials are fast put into a compressor, the sheet materials are subjected to surface layer compression, and the compression-molded sheet materials are subjected to stabilization treatment. The poplar sheet material surface layer reinforcement method has the advantages that 1, only a surface layer having the thickness of 2-3mm is compressed, a sheet material yield is high, and resources are saved, 2, optimal properties are obtained in shortest time by a lowest cost, and 3, the poplar sheet material surface layer reinforcement method opens a novel approach for poplar value-added application and high-efficiency utilization.

Owner:NORTHWEST A & F UNIV

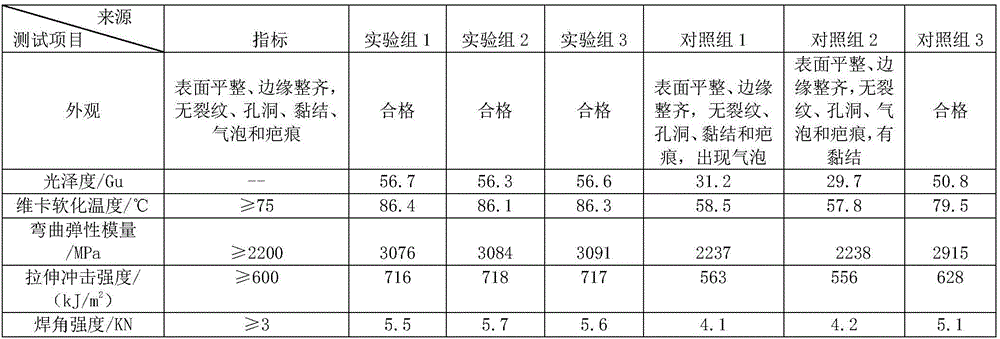

A kind of continuous fiber reinforced wood-plastic and its preparation method

The invention discloses a continuous-fiber-reinforced wood plastic and a preparation method thereof. The preparation method comprises the following steps: long fiber surface modification, granulation and extrusion. The long fibers subjected to surface modification are used for reinforcing the wood plastic material, so that the wood plastic material has favorable compatibility. The addition position of the long fibers is beyond the shearing position of the screw, so the long fibers do not have the action of shearing force in the extrusion forming technique and can not be destroyed, thereby forming continuous fiber distribution in the obtained wood plastic. By reasonably selecting the weight parts of the components, the bending strength, elastic modulus in bending, shock strength and other mechanical properties of the end product are obviously enhanced.

Owner:洪泽圣洛迪新材料有限公司

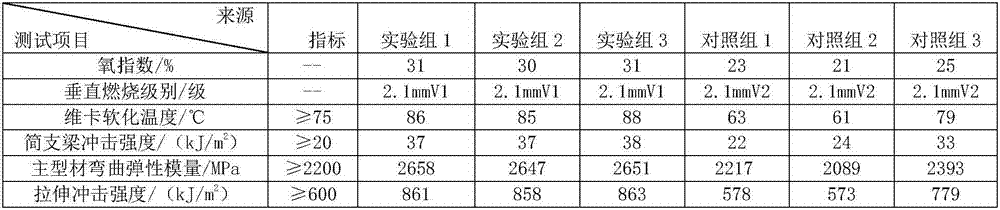

Flame-retardant PVC profile for doors and windows and preparation method thereof

InactiveCN105778353BImprove flame retardant performanceImprove heat resistanceHeat resistancePolyvinyl chloride

The invention discloses a flame-retardant PVC (polyvinyl chloride) profile for doors and windows and a production method thereof. The flame-retardant PVC profile comprises, by weight, 55-60 parts of PVC waste, 13-17 parts of wood flour, 15-18 parts of light calcium carbonate, 0.38-0.54 part of titanium dioxide, 6.4-8.3 parts of CPE impact modifier, 0.72-0.96 part of organic tin stabilizer, 0.35-0.42 part of metallic soap stabilizer, 0.9-1.2 parts of fatty alcohol lubricant and 1.3-2.5 parts of flame retardant. The PVC profile is good in flame retardant effect, can reach 2.1mmV1 level in vertical flammability and good in heat resistance. Meanwhile, the PVC profile has excellent impact resistance, bending deformation resistance and tensile impact resistance.

Owner:CHONGQING WANSENDA TECH DEV CO LTD

Preparation method of epoxy board with glass fabric sandwiched

PendingCN114267503AHigh flexural modulus of elasticityImprove performance qualityInsulatorsGlass fiberAdhesive glue

The invention discloses a preparation method of a glass fabric-sandwiched epoxy board. The preparation method comprises the following steps: S1, carrying out sizing permeation on mica paper and glass fabric by using organic silica gel water; and S2, carrying out paper receiving, weight balancing, glass fabric clamping and plate stacking, plate tearing, pressing and plate shearing, so as to prepare the glass fabric clamping epoxy plate. The bending elastic modulus of the produced glass fiber cloth product is improved in the aspect of performance, and the glass fiber cloth product is not prone to breakage and good in toughness.

Owner:PAMICA TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com