Interlayer toughened composite material and preparation method and application thereof

A technology of toughening composite materials and resin materials, which is applied in the field of fiber reinforced composite materials and fiber reinforced resin base layers to toughen composite materials, which can solve the problem of changes, difficulty in accurately controlling the range of shear performance of fiber reinforced composite materials, and The space geometry of the binding yarn coils is complicated, etc., and the bending elastic modulus is improved, the interface interaction is good, and the effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

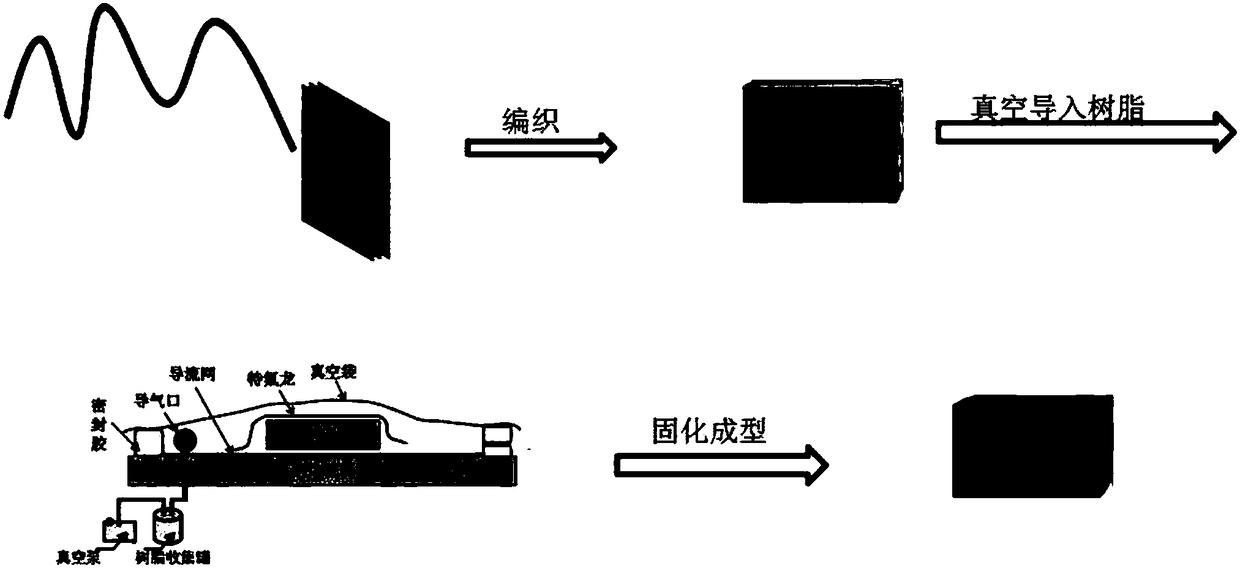

[0035] An aspect of the embodiments of the present invention provides a method for preparing an interlayer toughened composite material, which includes:

[0036] An embodiment of the present invention provides a method for preparing an interlayer toughened composite material, which includes:

[0037] A reinforcing body is provided, the reinforcing body comprising a plurality of first fiber aggregates stacked along its thickness direction, wherein the first fiber aggregate comprises a plurality of first fiber aggregates oriented in a specified direction (ie, a direction perpendicular to the thickness of the reinforcing body). fiber;

[0038] At least one braid is braided with the plurality of first fiber aggregates along the thickness direction of the reinforcement to form a braided structure, wherein each braid is continuously adjacent to two or more first fiber aggregates. pass between the first fibers;

[0039] The braided structure is infiltrated with a fluid containing a...

Embodiment 1

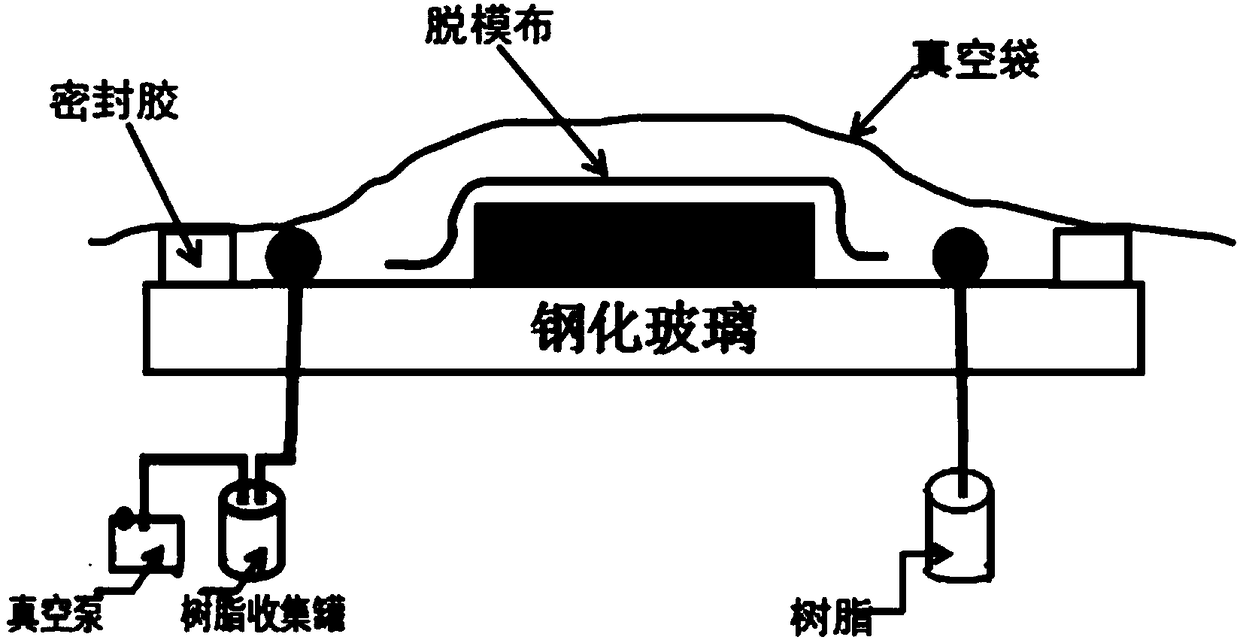

[0092] Embodiment 1: The preparation method of an interlayer toughened composite material involved in this embodiment specifically includes the following steps:

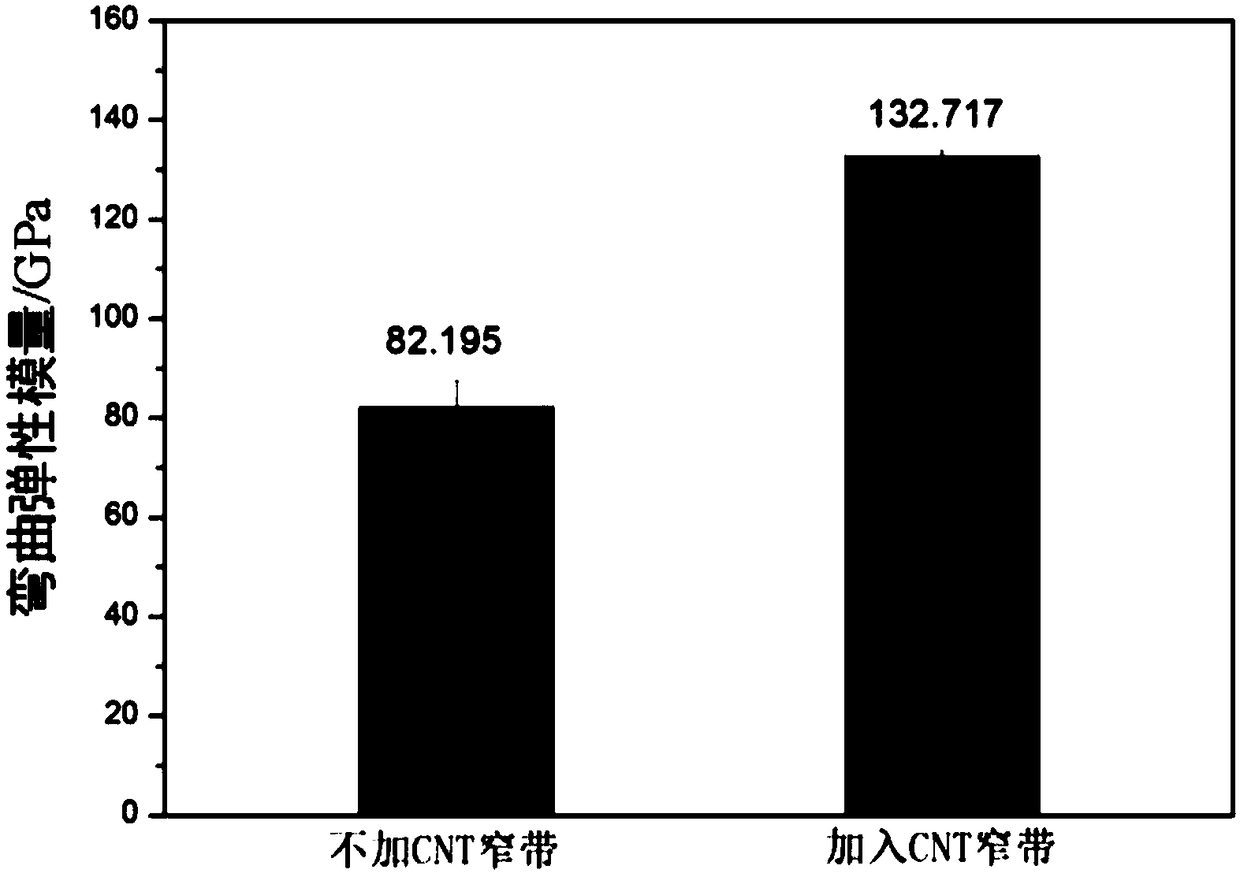

[0093] With carbon fiber as the reinforcing fiber, the multi-layer carbon fiber unidirectional cloth is arranged in parallel along the thickness direction, and the carbon nanotube strips with a thickness of about 15 μm and a width of 5 mm are perpendicular to the direction of the carbon fiber to weave the multi-layer carbon fiber cloth in the thickness direction. The auxiliary process is immersed in epoxy resin, cured and formed into a carbon fiber reinforced composite material, wherein the content of the resin material is 40wt%. Further, for the interlayer performance test results of the interlayer toughened composite material obtained by adding CNT strips in this example, please refer to image 3 shown. The results of the three-point bending test show that the flexural elastic modulus of the interlayer toughened c...

Embodiment 2

[0094] Embodiment 2: The preparation method of an interlayer toughened composite material involved in this embodiment specifically includes the following steps:

[0095] Using polysulfone fibers as reinforcing fibers, multi-layer polysulfone fiber unidirectional fabrics are arranged in parallel along the thickness direction, and graphene strips with a thickness of about 50 μm and a width of 50 mm are perpendicular to the direction of polysulfone fibers. The fiber unidirectional cloth is woven in the thickness direction, and epoxy groups are distributed on the surface of the graphene, which is immersed in unsaturated polyester resin by soaking method, and solidified and formed into a composite material reinforced by sulfonamide fiber, wherein the content of the resin material is 50wt%. The performance test data of the composite material obtained in this embodiment is basically consistent with that of the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com