Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High flexural modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

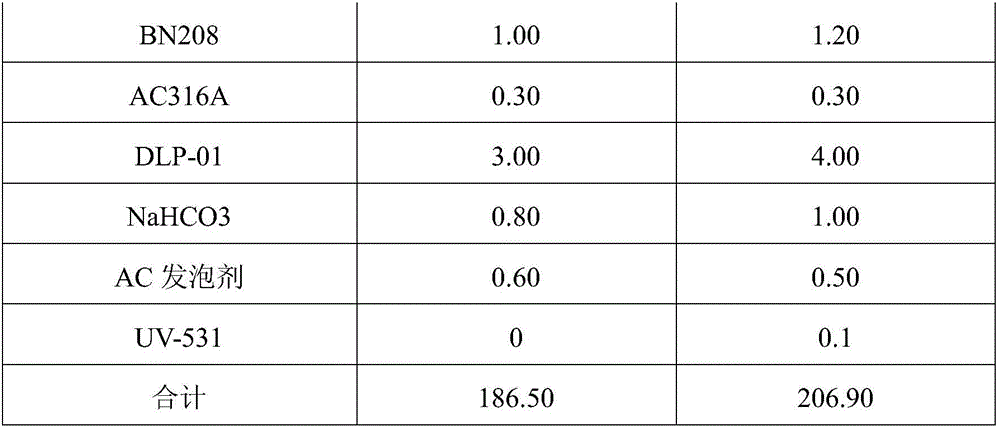

Composite 3D printing material and preparation method thereof

InactiveCN105176084AHigh flexural modulusHigh tensile strengthAdditive manufacturing apparatusEpoxyPolyetherimide

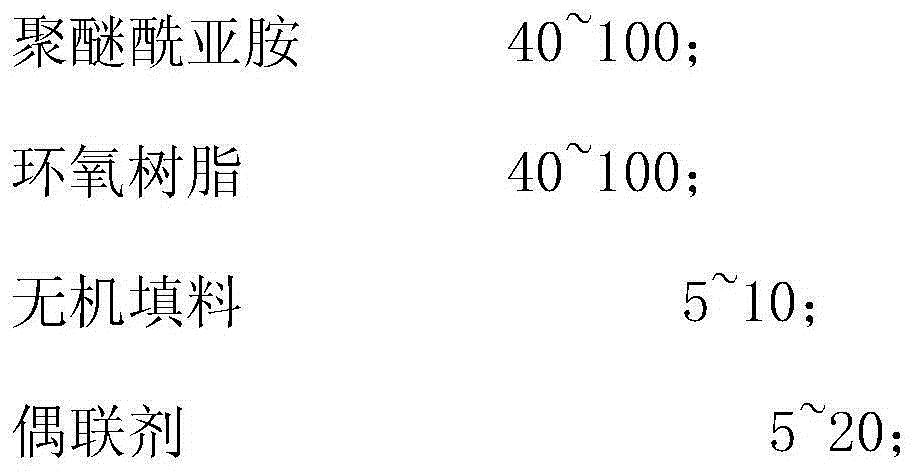

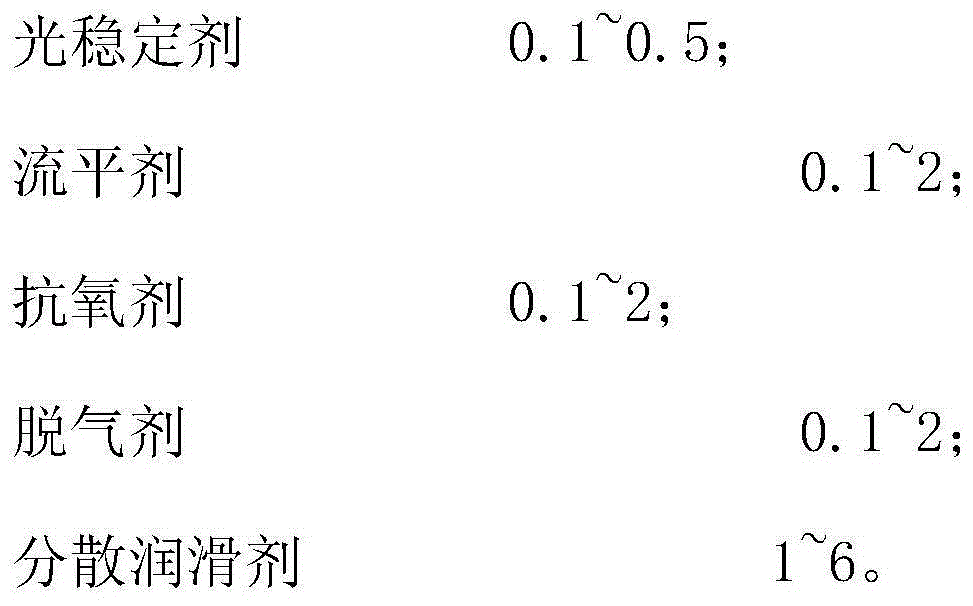

The invention provides a composite 3D printing material and a preparation method thereof. The composite 3D printing material is characterized by being prepared from, by weight, 40-100 parts of polyetherimide, 40-100 parts of epoxy resin, 5-10 parts of inorganic fillers, 5-20 parts of coupling agents, 0.1-0.5 part of light stabilizers, 0.1-2 parts of flatting agents, 0.1-2 parts of antioxidants, 0.1-2 parts of degassing agents and 1-6 parts of dispersed lubricants. Compared with a traditional polyetherimide material, the polyetherimide composite 3D printing material has higher strength and hardness and can be used at high temperature.

Owner:杨洋

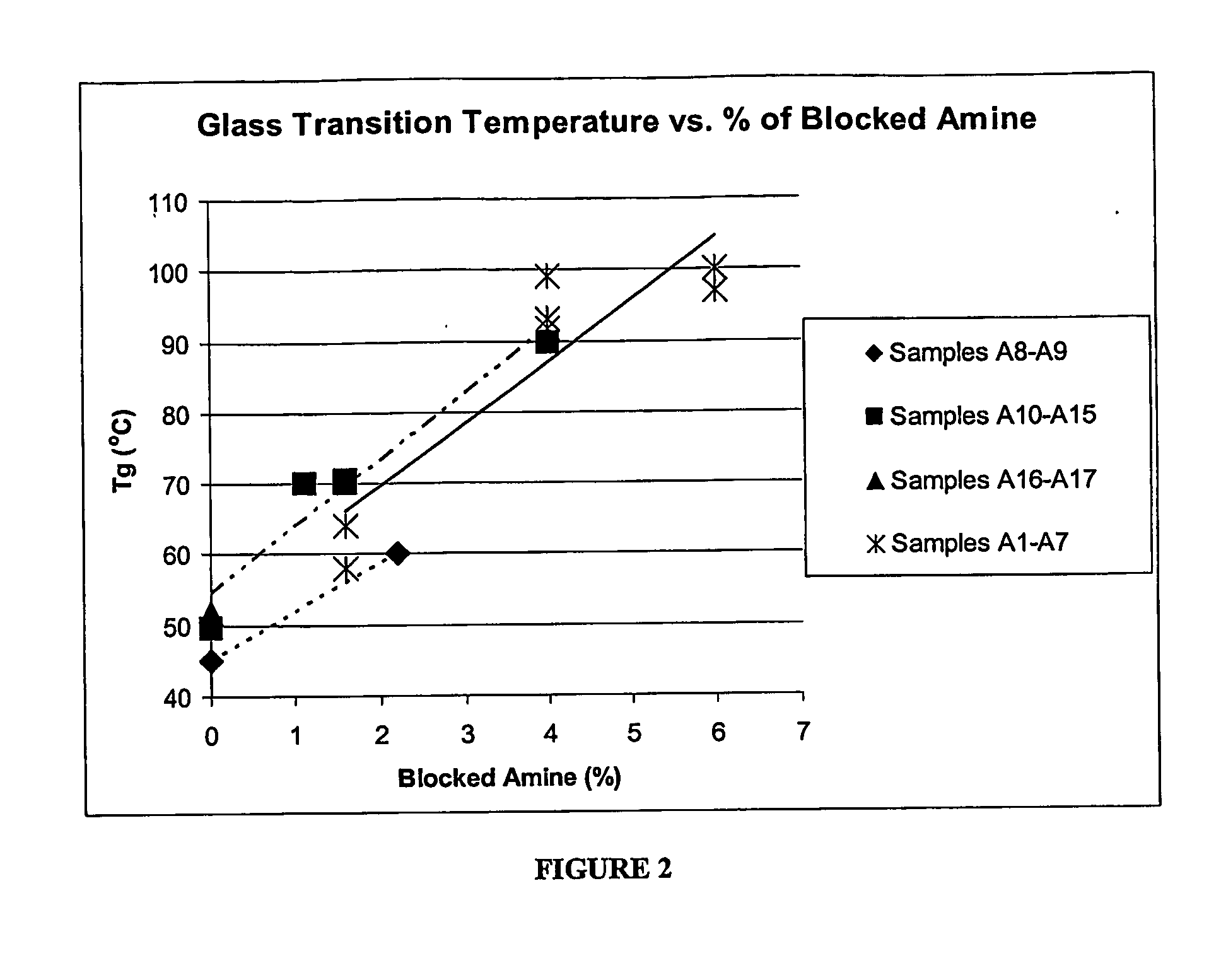

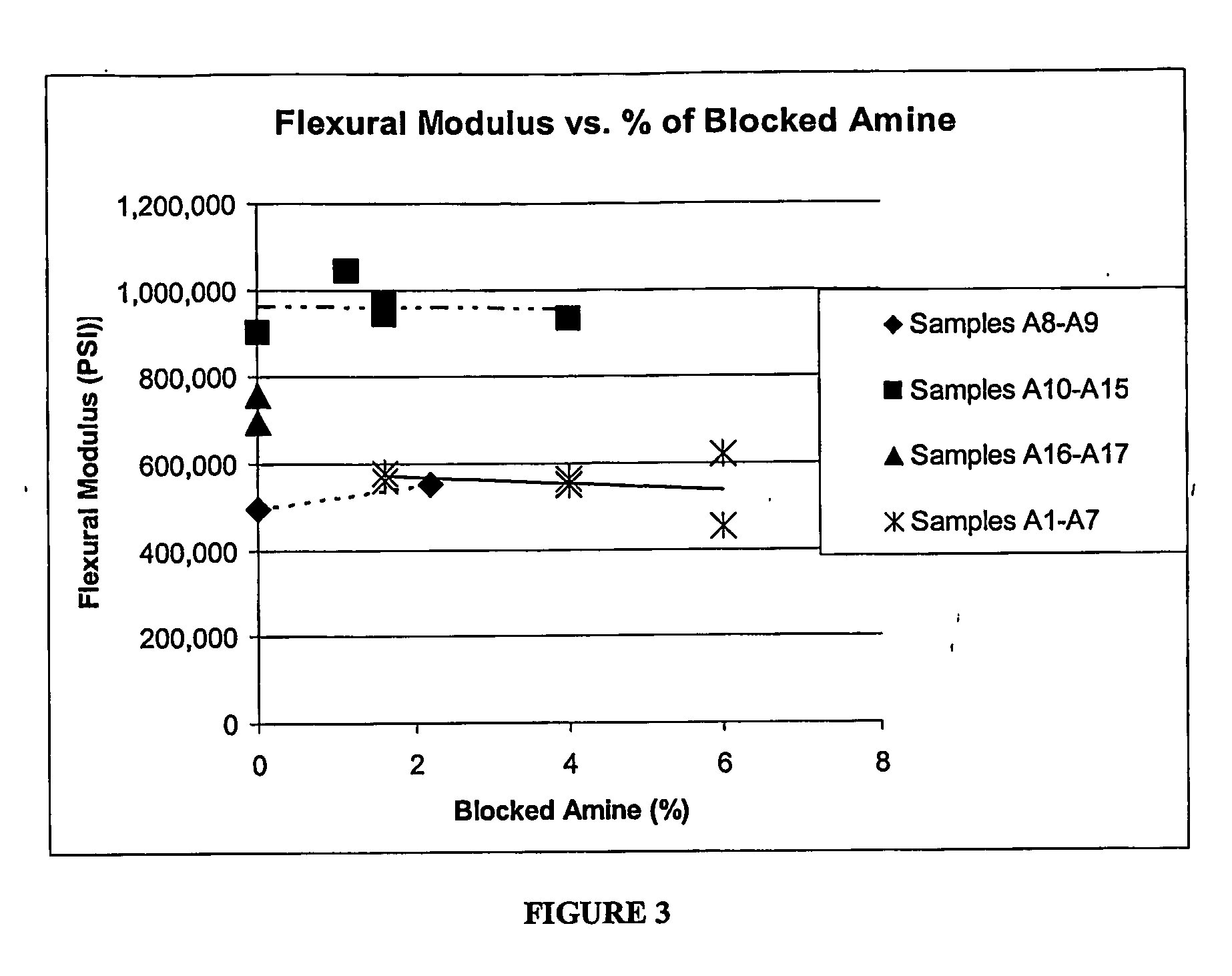

Structural composites with enhanced moduli of elasticity

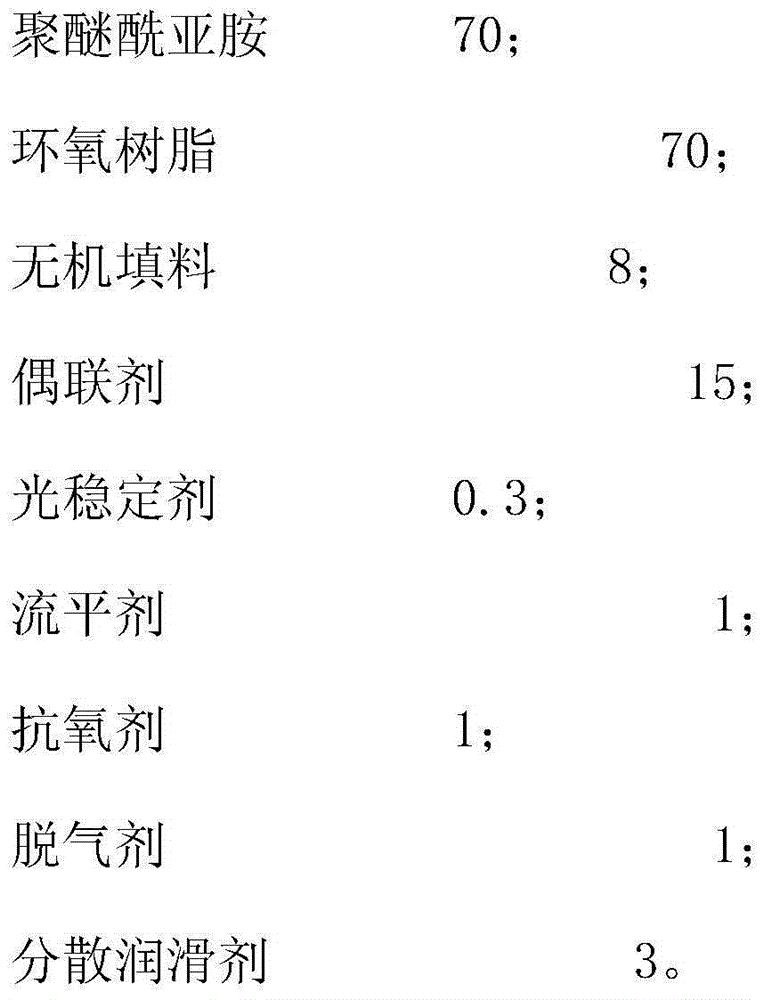

InactiveUS20070167540A1High flexural modulusGood dimensional stabilityUmbrellasPicture framesElastic modulusPolyolefin

The invention provides for structural composites made from biomaterials such as wood products, plant fibers and the like; and / or a non-biomaterial having free —OH groups; a thermoplastic resin such as a polyolefin; coupling agents such as a thermosetting resin or a second thermoplastic resin; a blocked catalyst, a crosslinker and other functional additives may be used.

Owner:BATTELLE MEMORIAL INST

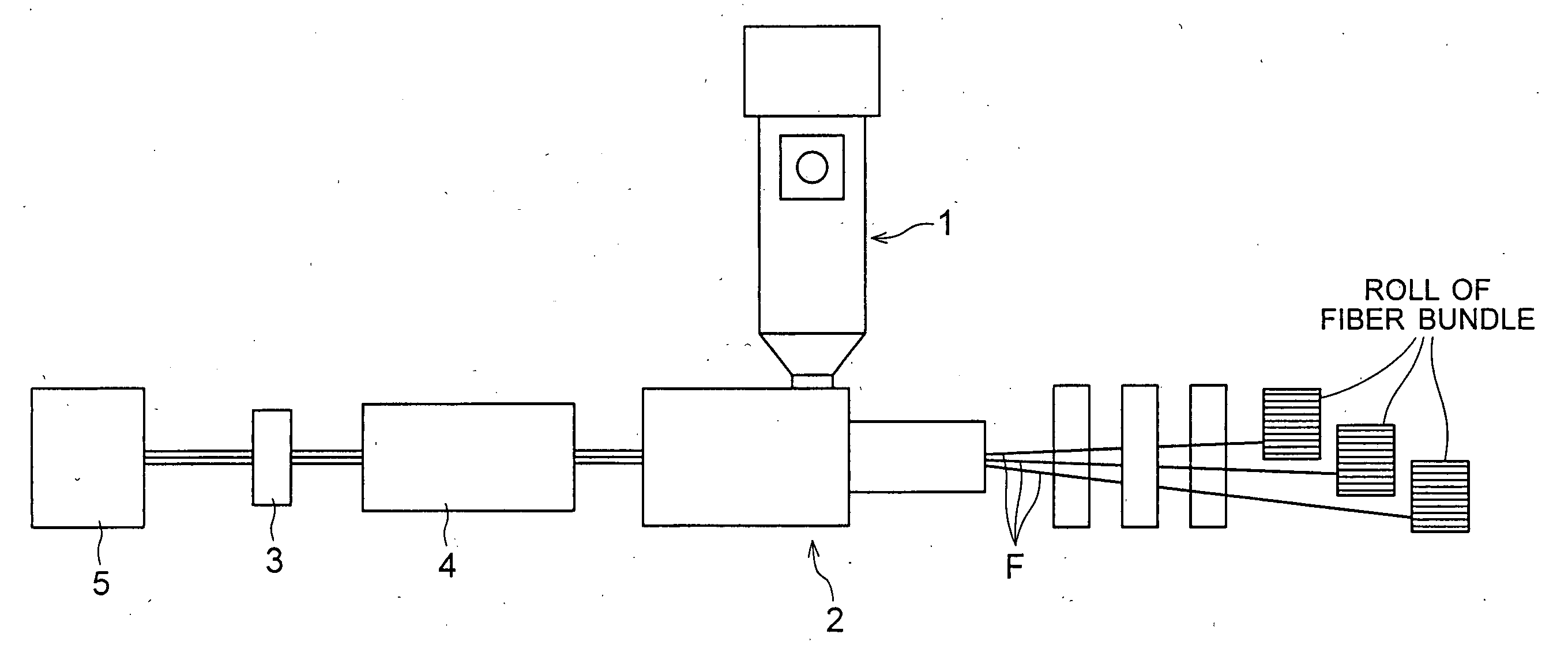

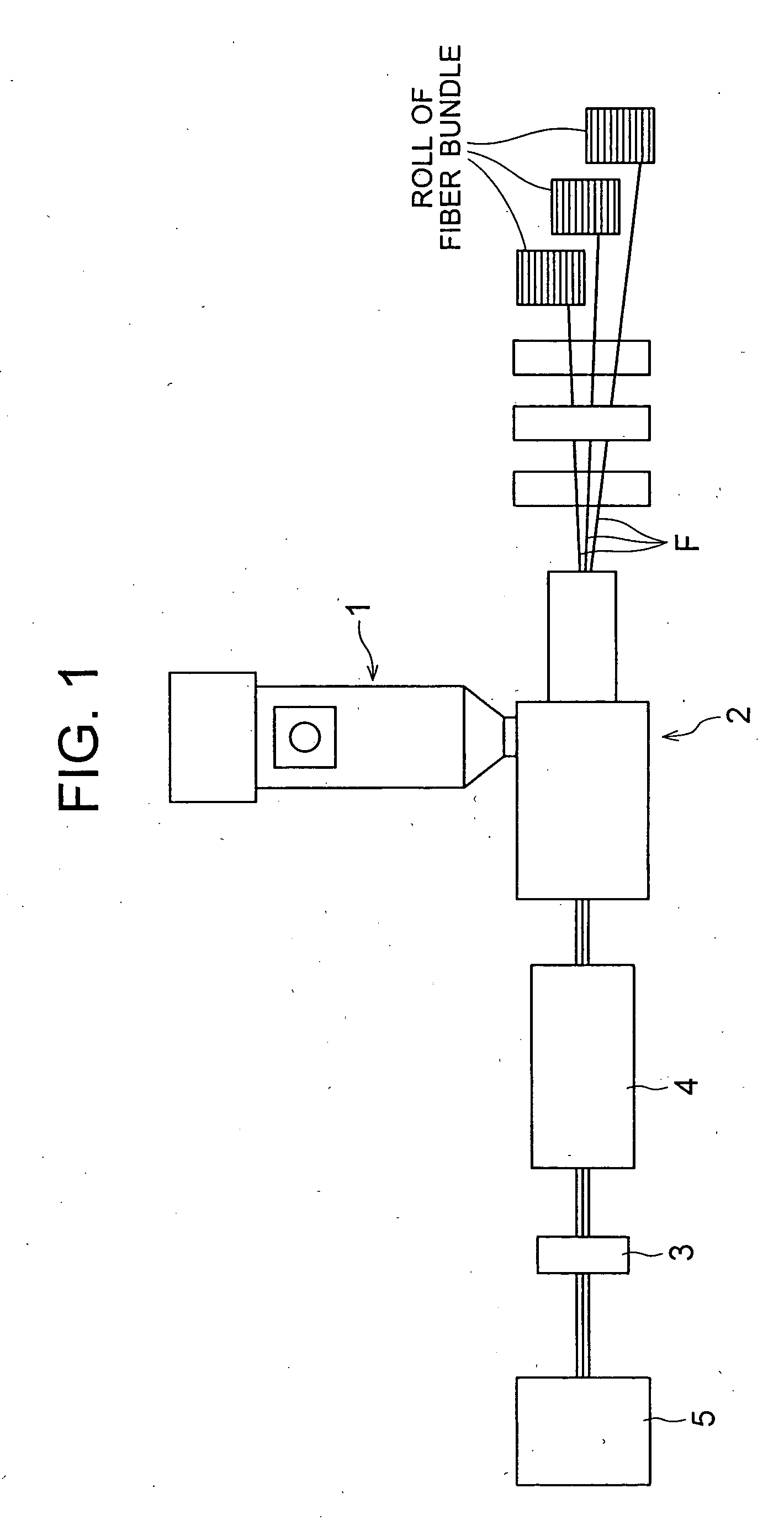

Flame-resistant acrylic fiber nonwoven fabric, carbon fiber nonwoven fabric, and method for production thereof

InactiveCN1703548ACompact structureThe overall thickness is thinCell electrodesNon-woven fabricsCarbon fibersFuel cells

A nonwoven fabric comprising flame-retardant acrylic fibers, characterized in that it has a weight per square-meter of 70 to 190 g / m<2>, a thickness of 0.1 to 0.3 mm, a density of 0.35 to 0.8 g / cm<3>; and a nonwoven fabric comprising carbon fibers, characterized in that it has a weight per square-meter of 50 to 150 g / m<2>, a thickness of 0.1 to 0.25 mm, a density of 0.3 to 0.7 g / cm<3>, a surface roughness Ra of 30 mu m or less, a tensile strength of 0.2 kgf / cm or more, and a maximum fracture radius being defined in the specification of 20 mm or less. Said carbon fiber nonwoven fabric is produced by subjecting the flame-retardant acrylic fiber nonwoven fabric to a carbonization treatment and can be suitably used as a material for forming an electrode of a fuel cell.

Owner:TORAY IND INC

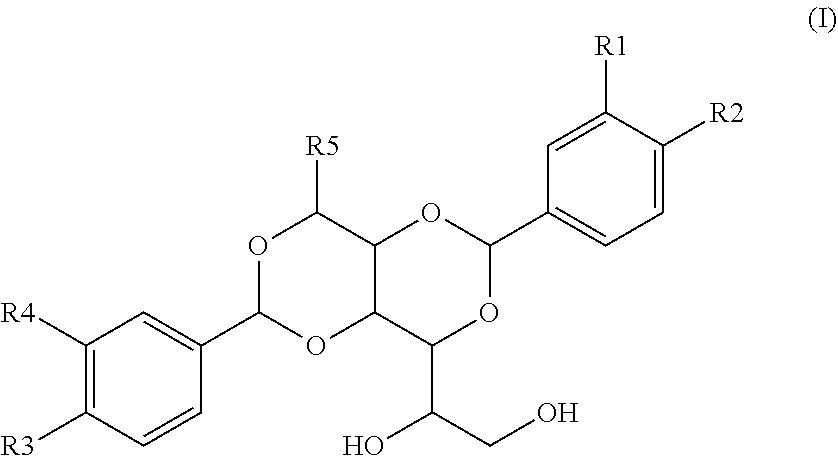

Epoxy resin composition, prepreg, and carbon-fiber-reinforced composite material

Provided are: an epoxy resin composition which enables the production of a carbon-fiber-reinforced composite material having excellent tensile strength and compressive strength and suitable as a material for structures; a prepreg; and a carbon-fiber-reinforced composite material. An epoxy resin composition characterized by comprising at least [A] an epoxy resin having a structure represented by formula (1), [B] an epoxy resin having at least one amine-type glycidyl group or at least one ether-type glycidyl group and having a liquid form at 40° C. and [C] a curing agent; and a prepreg and a carbon-fiber-reinforced composite material, each produced using the epoxy resin composition.(In the formula, R1 to R4 independently represent at least one atom or group selected from the group consisting of a hydrogen atom, an aliphatic hydrocarbon group having 1 to 4 carbon atoms, an alicyclic hydrocarbon group having 4 or less carbon atoms, and a halogen atom.)

Owner:TORAY IND INC

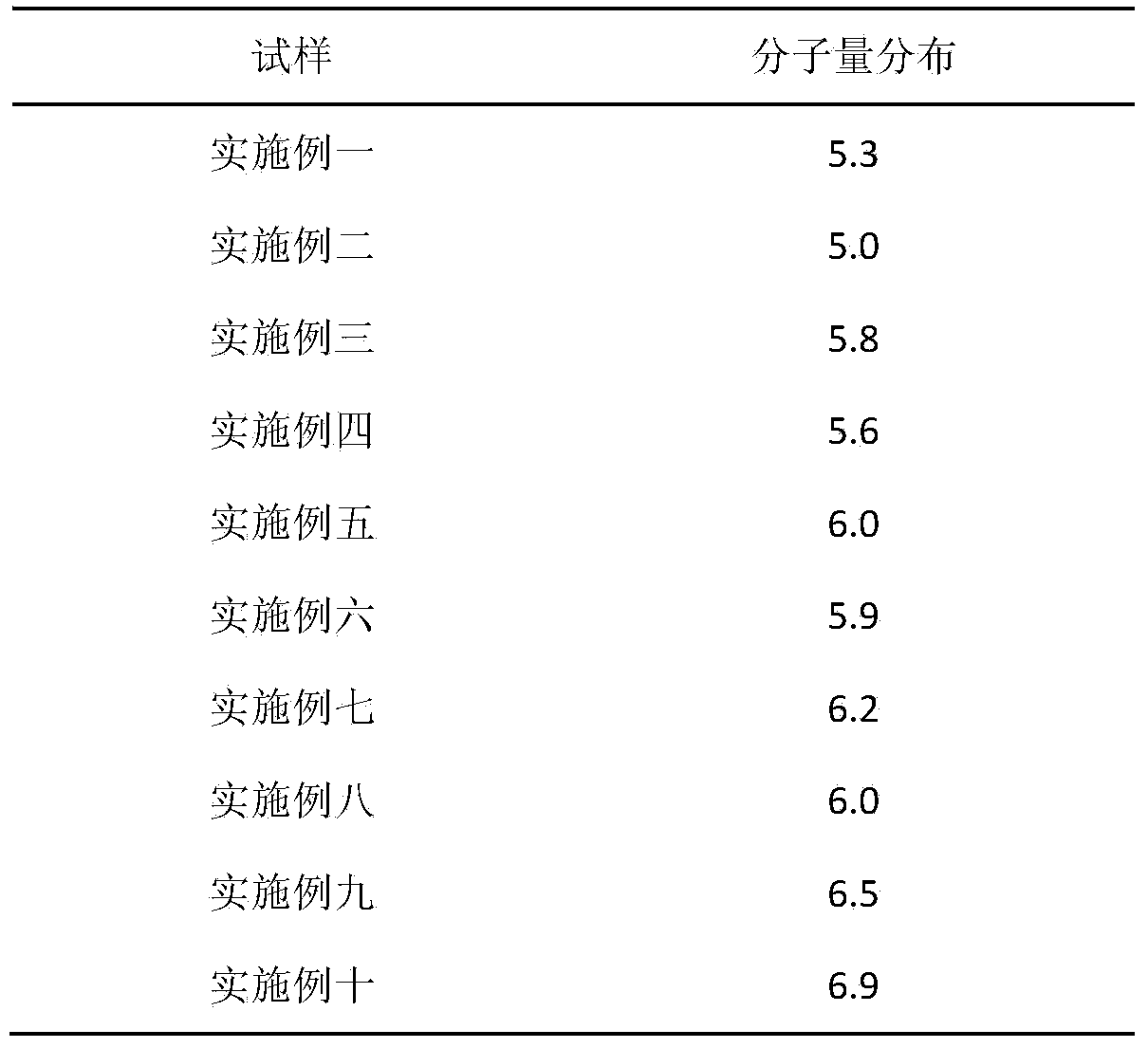

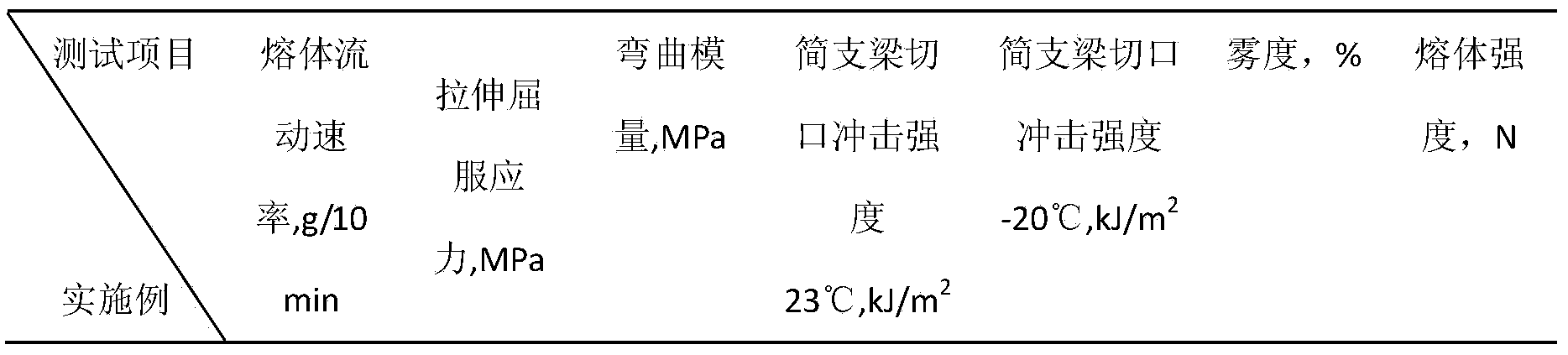

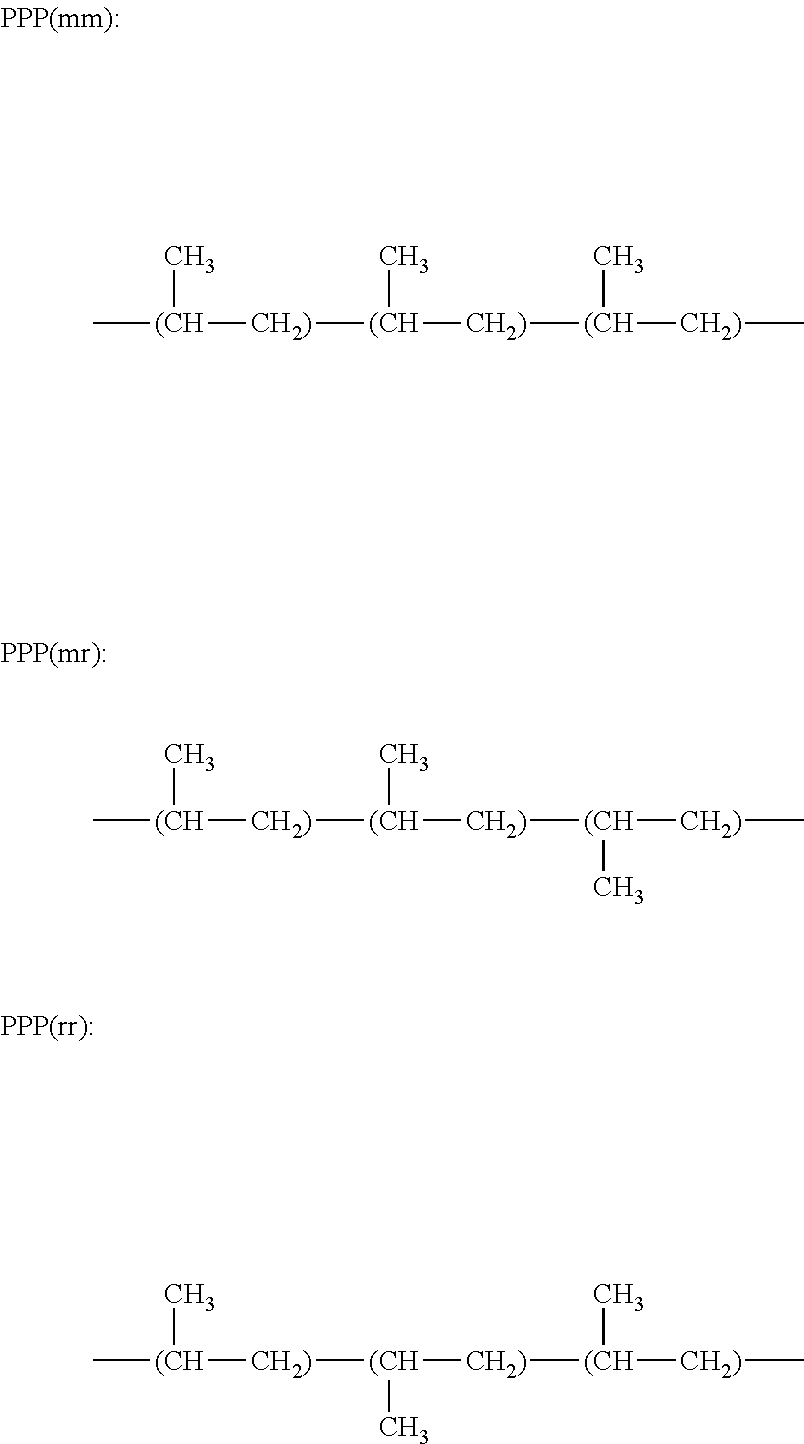

Random copolymerization polypropylene thermal forming special-use resin with wide molecular weight distribution and preparation method

The invention designs random copolymerization polypropylene thermal forming special-use resin with wide molecular weight distribution and a preparation method, the molecular weight distribution Mw / Mn of the random copolymerization polypropylene thermal forming special-use resin is 5-7; and the melt index is 3-7g / 10min. Ziegler Natta NDQ catalyst is used, ethylene is added into Spheripol process single loop tube polypropylene plant, the NDQ activity is 21000-39000g polypropylene / g catalyst, the ethylene addition amount is 1.2-2.2%wt, and by an auxiliary agent addition system, the random copolymerization polypropylene thermal forming special-use resin is produced. The synthetic method of the random copolymerization polypropylene thermal forming special-use resin with the wide molecular weight distribution can be used in industrial production using the Spheripol process single loop tube polypropylene plant of LBI company, and has the characteristics of simple technological operation and controllable polymer performance index.

Owner:CHINA PETROLEUM & CHEM CORP

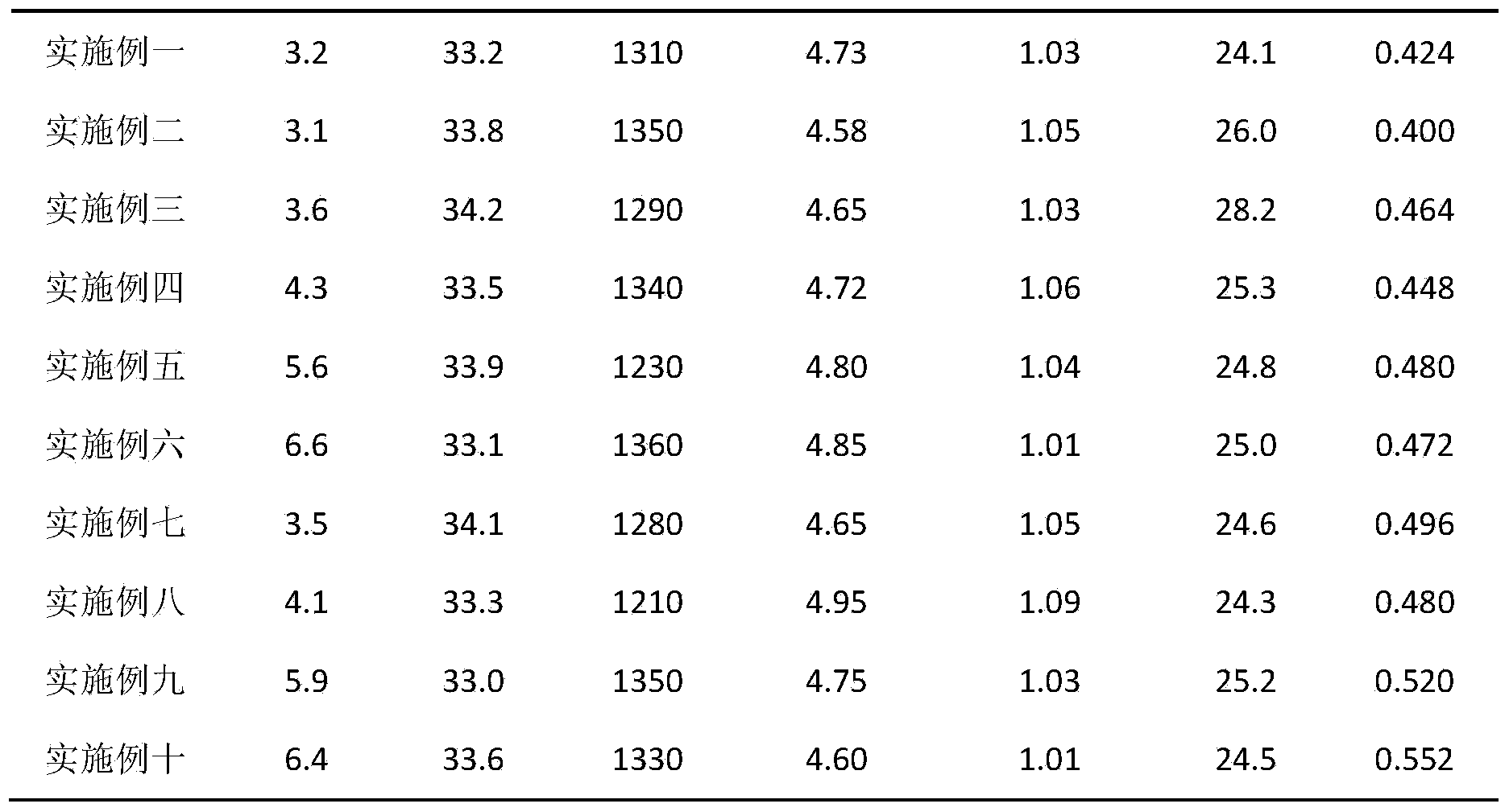

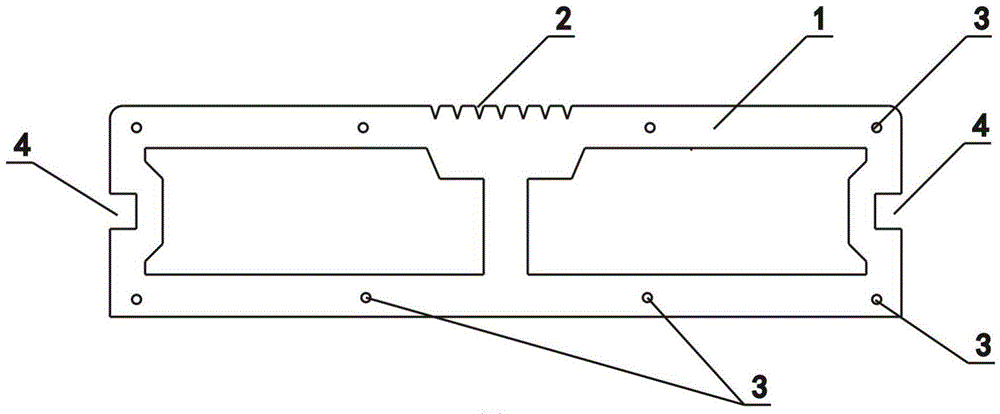

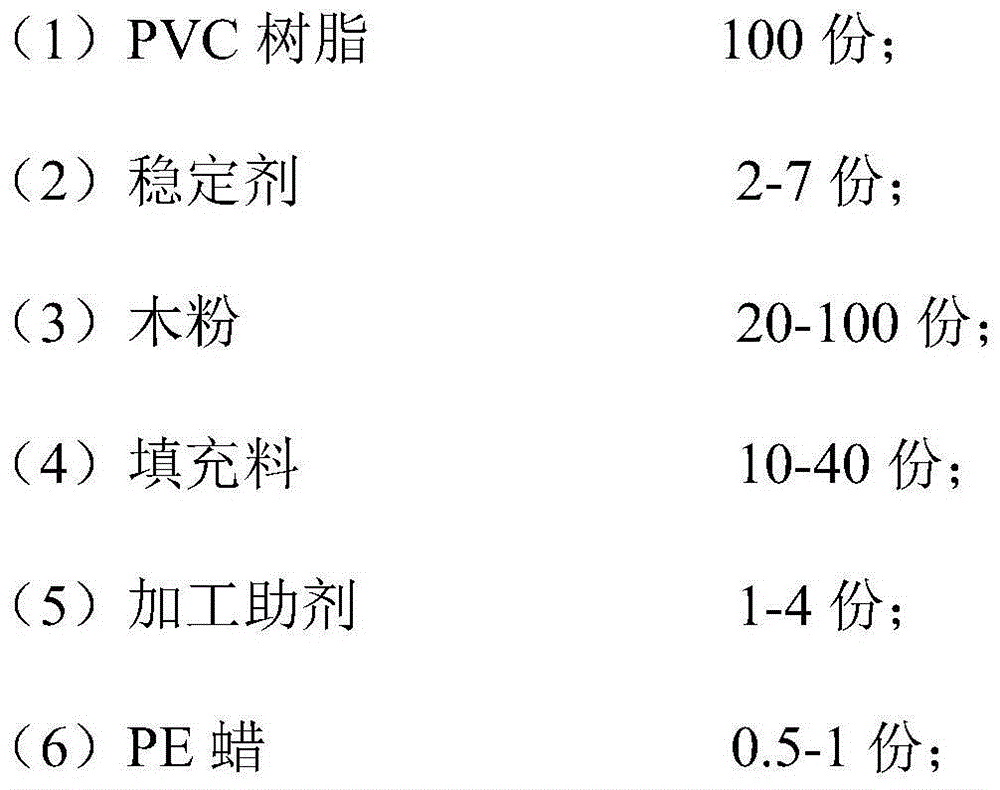

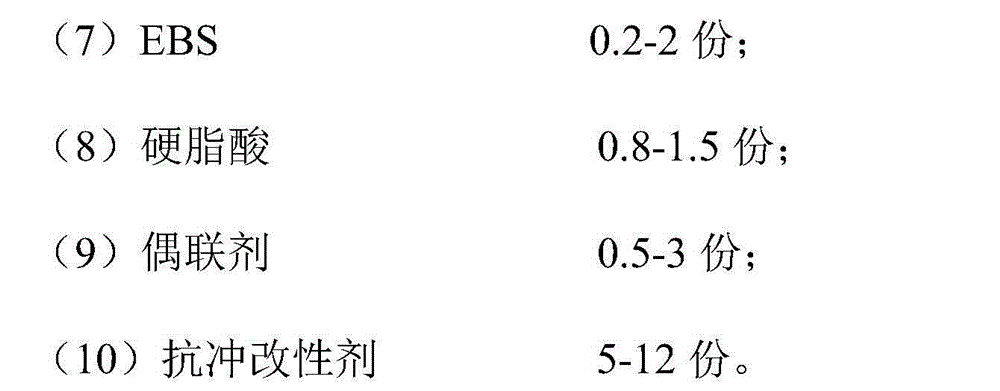

High-strength wood-plastic composite material, preparation method therefor, sectional material and application thereof

The invention relates to the technical field of composite materials and specifically relates to a high-strength wood-plastic composite material, a preparation method for the high-strength wood-plastic composite material, a sectional material of the high-strength wood-plastic composite material prepared by the preparation method and application of the prepared sectional material. The high-strength wood-plastic composite material contains PVC resin, a stabilizer, wood flour, filler, a processing aid, PE wax, EBS, stearic acid, a coupling agent and an impact modifier. The preparation method for the high-strength wood-plastic composite material comprises the following steps: (1) accurately weighing all raw materials according to a formula ratio; (2) firstly putting the weighed raw materials in a hot-mixing pot for stirring, and then, putting the hot-mixed material in a cold-mixing pot for stirring; and (4) putting the mixed mixture in an extruder, and carrying out extrusion molding from an extruder head, thereby preparing the sectional material of the wood-plastic composite material. The sectional material of the high-strength wood-plastic composite material is of a hollow strip sheet. The sectional material of the high-strength wood-plastic composite material serves as an auxiliary frame of doors and windows or a decorating material or a landscape viaduct or a rail fence or a fence rail.

Owner:JIANGSU HONGSHA DOOR & WINDOW

Master batch applied to polyethylene double-wall bellows and preparation method thereof

A disclosed master batch applied to a polyethylene double-wall bellows comprises the following raw materials in parts by weight: 60-150 parts of an ultrafine inorganic mineral powder, 20-50 parts of high-density polyethylene resin, 8-15 parts of EVA grafted resin, 8-12 parts of organic-group modified polysiloxane, 3-4 parts of a powdery surfactant, and 3-5 parts of a polyolefin oligomer. A three-dimensional stereo structure is formed by taking high-density polyethylene resin and EVA grafted resin as matrix resin, and is taken as a scaffold of a material, so that the material is endowed with relatively good toughness and processing performances; and also the units of the three-dimensional net structure formed by the matrix resin are effectively filled with the ultrafine inorganic mineral powder, the structure formed by combination of the inorganic mineral powder and the matrix resin enables the master batch to have relatively high bending elasticity modulus, thereby guaranteeing relatively high strength, toughness and bearing capability of the bellows.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

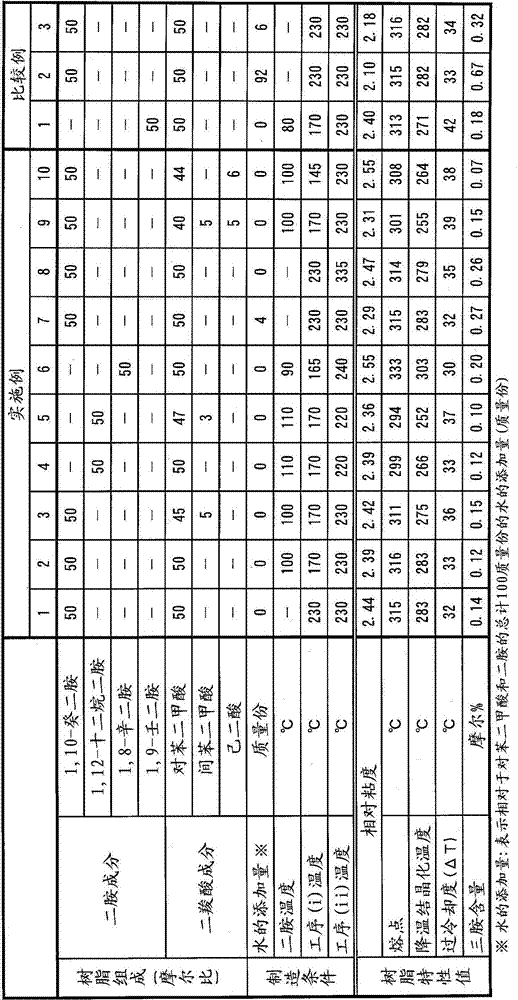

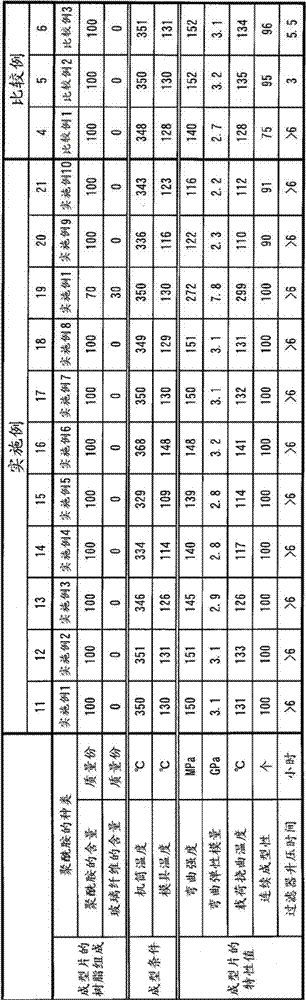

Semiaromatic polyamide and method for producing same

Owner:UNITIKA LTD

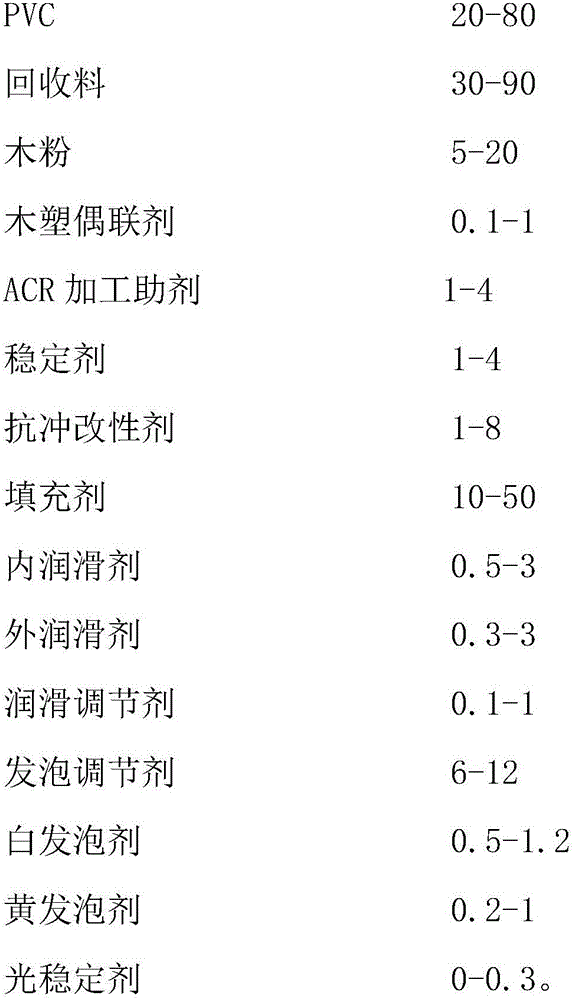

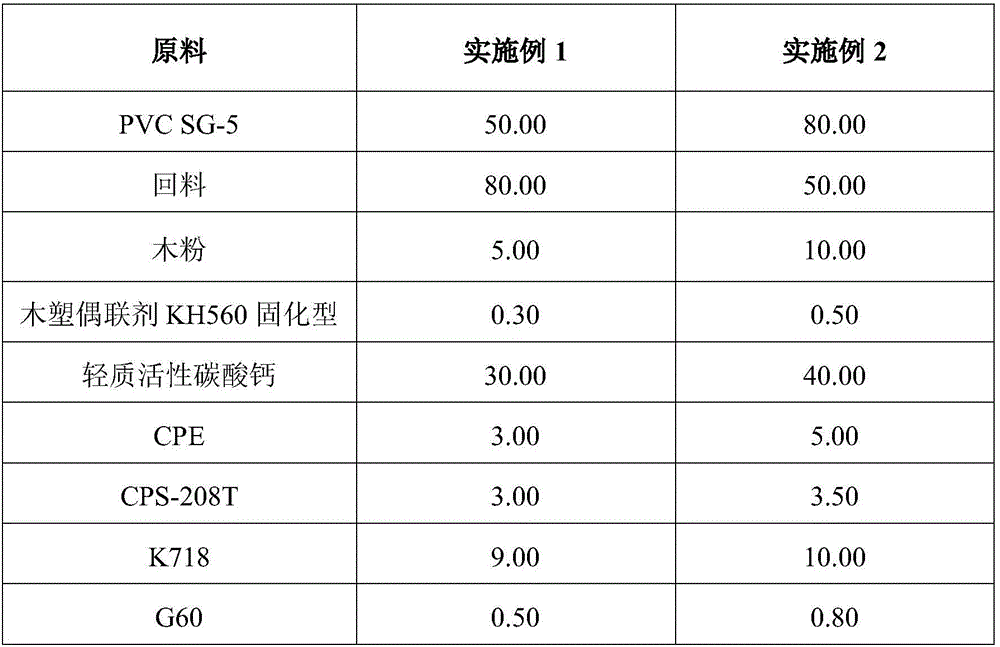

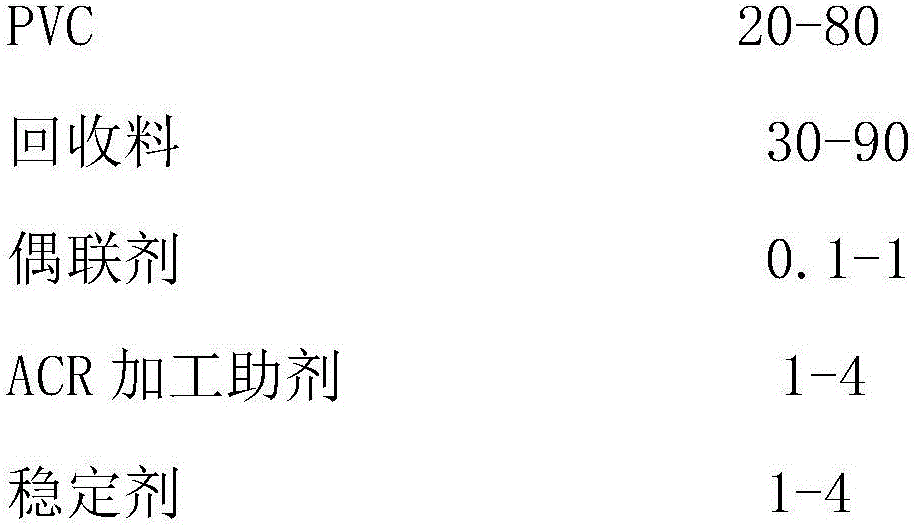

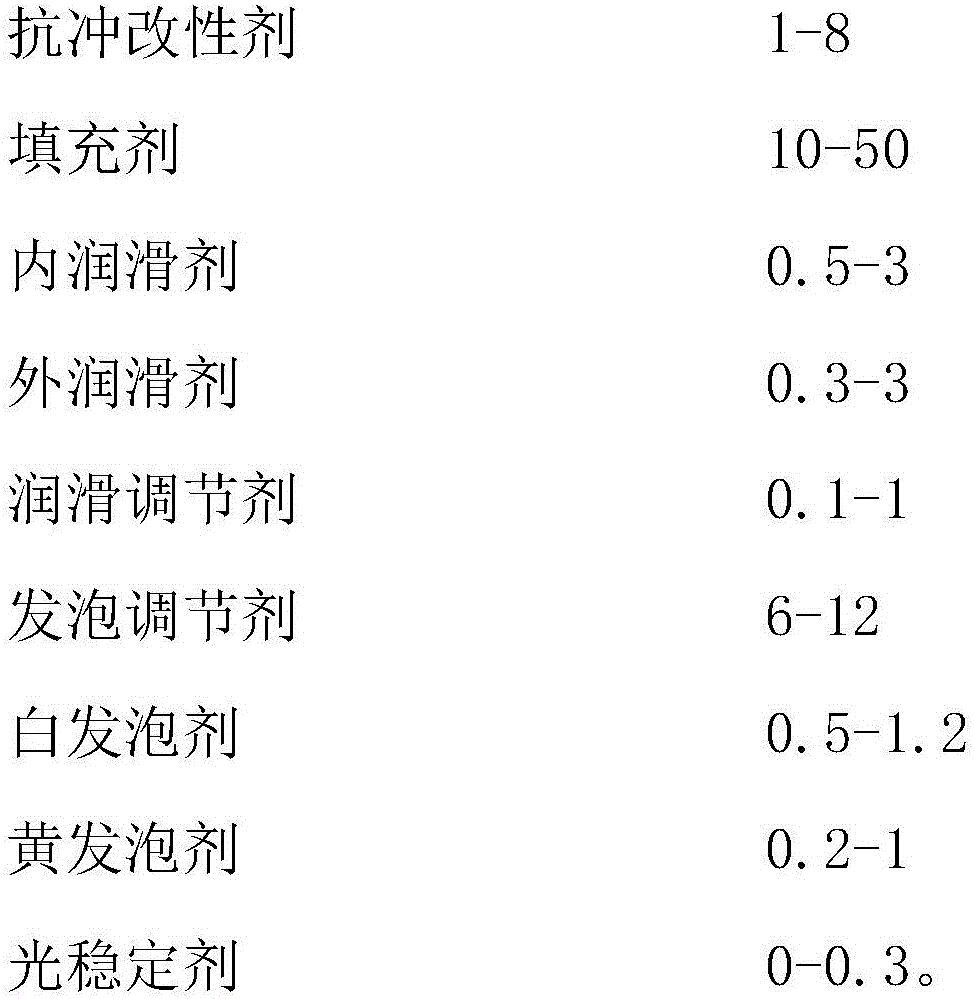

Wood and plastic building template and production method thereof

InactiveCN106221074AHigh static bending strengthHigh flexural modulusEngineeringCorrosion prevention

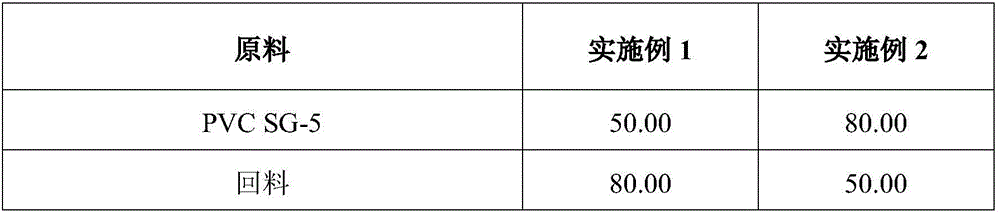

The invention provides a wood and plastic building template and a production method thereof. Reclaimed materials are used for designing a formula, and a production process is optimized according to formula raw material properties. Compared with the prior art, the production method is characterized in that the formula and the dosage proportion of raw materials are controlled to prepare the wood plastic building template, and the wood plastic building template has the advantages of high static bending intensity, high bending elastic modulus, high screw holding strength, flame retardance, good water resistance, acid and alkali resistance, corrosion prevention, energy saving and environment protection, and can be repeatedly recycled.

Owner:海螺(安徽)节能环保新材料股份有限公司

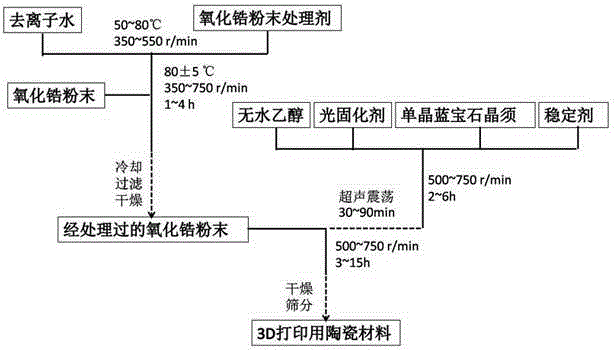

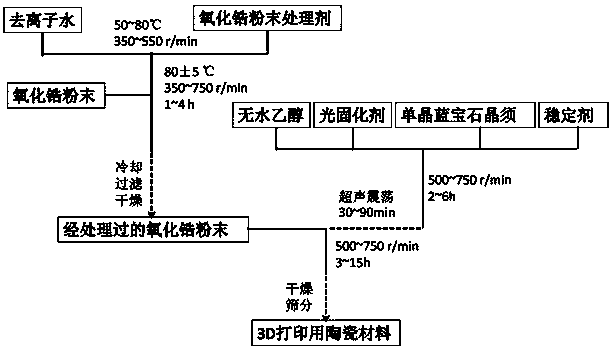

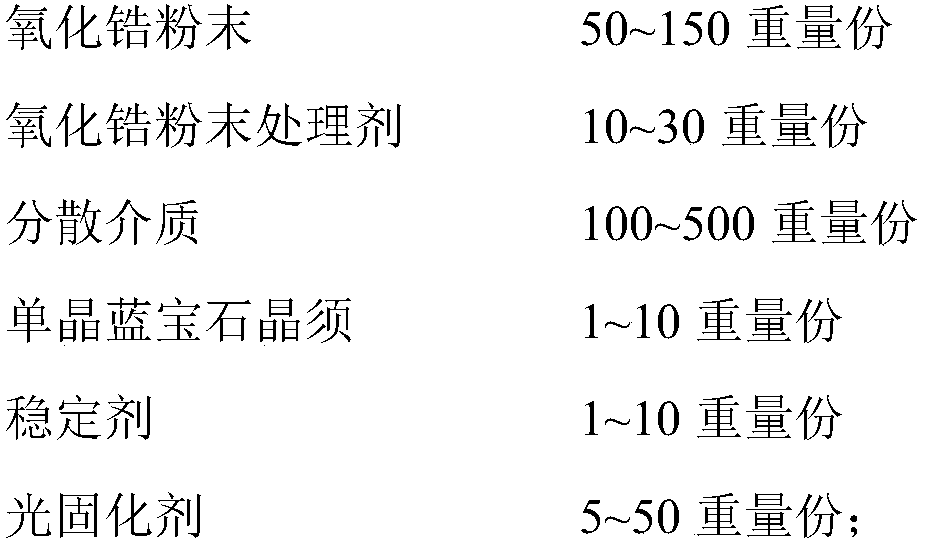

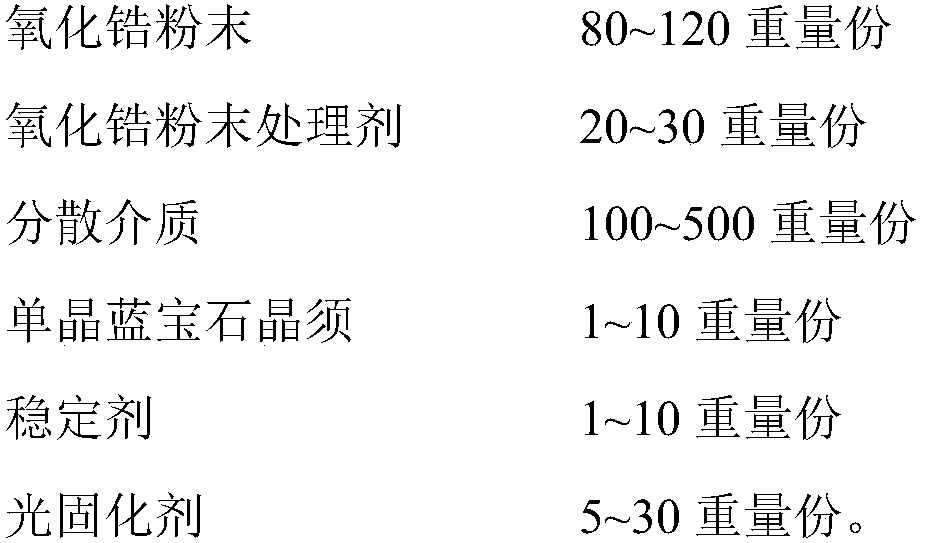

Ceramic material for 3D printing and preparation method thereof

The invention provides a ceramic material for 3D printing and a preparation method thereof. The ceramic material is prepared from, by weight, 50-150 parts of zirconia powder, 10-30 parts of zirconia powder treating agents, 100-500 parts of dispersion media, 1-10 parts of single-crystal sapphire whisker, 1-10 parts of stabilizing agents and 5-50 parts of light curing agents. The single-crystal sapphire whisker is added into the zirconia ceramics, so that the modulus of elasticity in static bending and the tensile strength of the product are significantly improved, and the preparation method is used for preparing high-strength and high-toughness fine engineering ceramics.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

Plastic building template and producing method thereof

InactiveCN106317689AHigh static bending strengthHigh flexural modulusForming/stuttering elementsEngineeringCurrent technology

The invention provides a plastic building template and a producing method thereof. The plastic building template uses reclaimed materials, designs formula, and optimizes productive technology according to formula property, compared with the current technology, the prepared plastic building template through controlling ingredients formula and dosage ratio is of high static bending intensity, high bending of elasticity modulus, strong power of gripping screw, inflaming retarding, good water resistance, acid and alkali resistance, corrosion protection, can be recycled repeatedly, save energy and protect environment.

Owner:海螺(安徽)节能环保新材料股份有限公司

High-aspect-ratio magnesium hydroxide

ActiveUS20130210988A1High aspect ratioHigh flexural modulusOxide/hydroxide preparationSynthetic resin layered productsOrganic acidWater soluble

Magnesium hydroxide having a high aspect ratio, a production method thereof and a resin composition comprising the same.The method of producing the magnesium hydroxide having a long diameter (width) of not less than 0.5 pm and aspect ratio of not less than 10, comprising the steps of:(A) adding an alkali to and coprecipitating it with a mixed aqueous solution of a water-soluble magnesium salt and a monovalent organic acid or a salt thereof, or(B) adding an alkali aqueous solution to and coprecipitating it with an aqueous solution of a water-soluble magnesium salt and adding a monovalent organic acid or a salt thereof to the resulting product; and(C) hydrothermally treating the obtained slurry at 100° C. or higher.

Owner:SEA WATER CHEM INST INC +1

Method for preparing homo-polypropylene resin with relatively wide molecular weight distribution

The invention discloses a method for preparing a homo-polypropylene resin with relatively wide molecular weight distribution. A novel wide molecular weight distribution catalyst is used on a Spheripol process single-loop polypropylene device to produce a basic resin with relatively wide molecular weight distribution (Mw / Mn=4.0-5.5), and then an efficient assistant system is added to produce the homo-polypropylene resin. The efficient assistant system is shown according to parts by weight, the homo-polypropylene resin with wide molecular weight distribution is 100 parts, the other assistant additives are 0.21-0.26 part, and the homo-polypropylene resin with relatively wide molecular weight distribution, which is the product of the invention, is obtained through the operations of high-speed sufficient blending, extruding by a double-screw extruder, cooling, grain-sized dicing and drying granules. The homo-polypropylene resin with relatively wide molecular weight distribution is easy to process, the product is non-toxic and harmless, meets the environmental protection requirement, is excellent in mechanical property, and is safe and sanitary.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of composition material for ball bearing retainer

The invention relates to a preparation method of a composite material for a ball bearing retainer. The method comprises the following steps of: dipping through an impregnator, conducting hot-pressing coiling through a three-roller tube coiling machine and performing post-curing treatment by taking aramid fiber cloth orthogonally weaved by wefts and warps as a base body and prepared phenolic resin as a bonder to prepare the composition material for the ball bearing retainer. The composite material for the ball bearing retainer can be used for a long time, wherein the temperature is in a range of 150-200 DEG C, the coefficient of linear expansion is less than or equal to 1.2*10 to the power of 6 / DEG C, the modulus of elasticity in static bending is greater than or equal to 40MPa, and the circular strength of extension is greater than or equal to 200MPa. The process parameters are reasonably set, which are the basic conditions for the composition material for the ball bearing retainer to be in a higher using temperature range, and the basic conditions for improving other performances. Therefore, the composite material for the ball bearing retainer prepared by the invention can satisfy the using demands of high-temperature high-speed precise ball bearing retainers.

Owner:LUOYANG BEARING SCI & TECH CO LTD

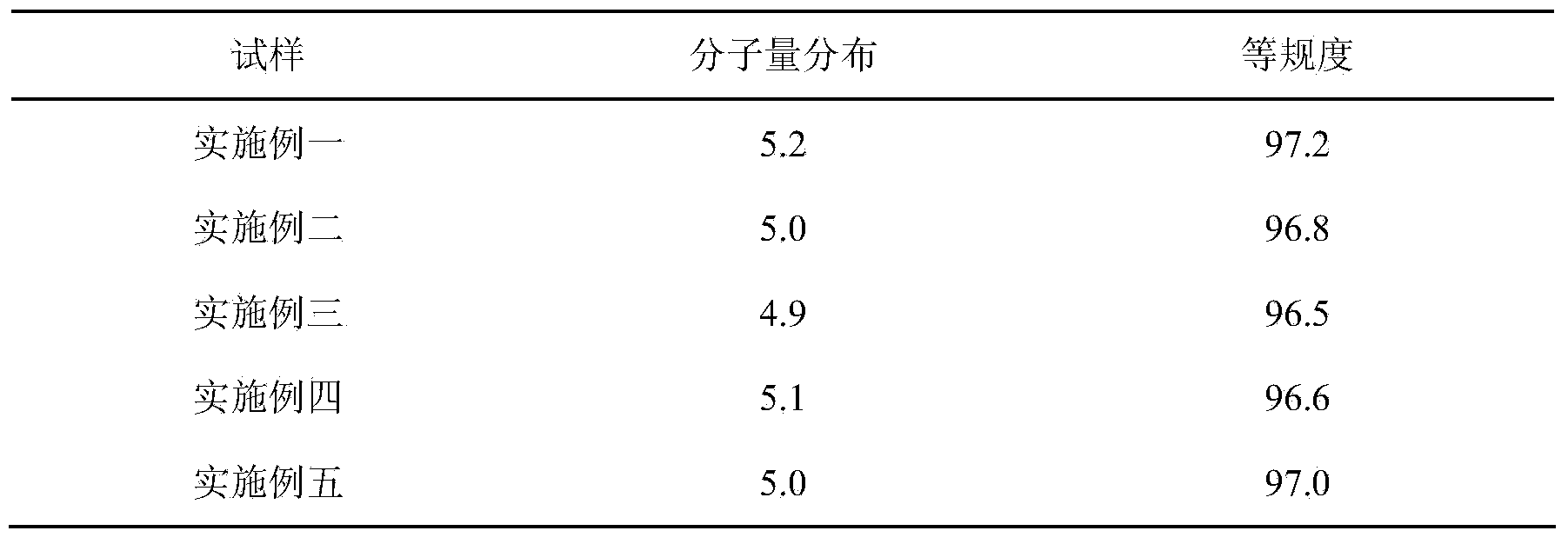

A kind of preparation method of wide molecular weight distribution homopolypropylene resin

The invention discloses a method for preparing a homo-polypropylene resin with relatively wide molecular weight distribution. A novel wide molecular weight distribution catalyst is used on a Spheripol process single-loop polypropylene device to produce a basic resin with relatively wide molecular weight distribution (Mw / Mn=4.0-5.5), and then an efficient assistant system is added to produce the homo-polypropylene resin. The efficient assistant system is shown according to parts by weight, the homo-polypropylene resin with wide molecular weight distribution is 100 parts, the other assistant additives are 0.21-0.26 part, and the homo-polypropylene resin with relatively wide molecular weight distribution, which is the product of the invention, is obtained through the operations of high-speed sufficient blending, extruding by a double-screw extruder, cooling, grain-sized dicing and drying granules. The homo-polypropylene resin with relatively wide molecular weight distribution is easy to process, the product is non-toxic and harmless, meets the environmental protection requirement, is excellent in mechanical property, and is safe and sanitary.

Owner:CHINA PETROLEUM & CHEM CORP

A preparation method of tensile, compressive and high temperature resistant modified polypropylene power pipe

The invention discloses a preparation method of a tensile compressive high temperature resistant modified polypropylene power pipe. The pipe comprises 100 weight parts of modified polypropylene, 0.5-15 weight parts of tackifier, 0.1-15 weight parts of nano material, 0.1-15 weight parts of liquid crystal material, 0.5-15 weight parts of shock resistant modifier, 0.1-15 weight parts of nucleating agent, 0-30 weight parts of filling masterbatch, 0.1-5 weight parts of color masterbatch, 0.5-30 weight parts of engineering plastic, 0.5-15 weight parts of compatibilizer, 0.05-5 weight parts of antioxidant, and 0.05-5 weight parts of light stablilizer, and is prepared by carrying out mixing granulation on the raw materials and then conducting extrusion molding through a mold. According to the invention, compared with existing MPP pipe, the bending strength of the produced MPP pipe disclosed herein is raised by 30-50%, the bending elastic modulus is raised by 25-60%, the welding tensile strength reaches 26-33 MPa, 70 DEG C ring hot compression force is raised by 30-50%, the photooxidation aging resistant time is prolonged by 5-15 years, the vicat softening point is raised by 5-20 DEG C, the shock strength and corrosion resistance are good, thus the produced MPP pipe disclosed herein can meet the requirements for high standard quality electric power engineering, and the engineering cost is reduced.

Owner:HONGYUE PLASTIC GROUP

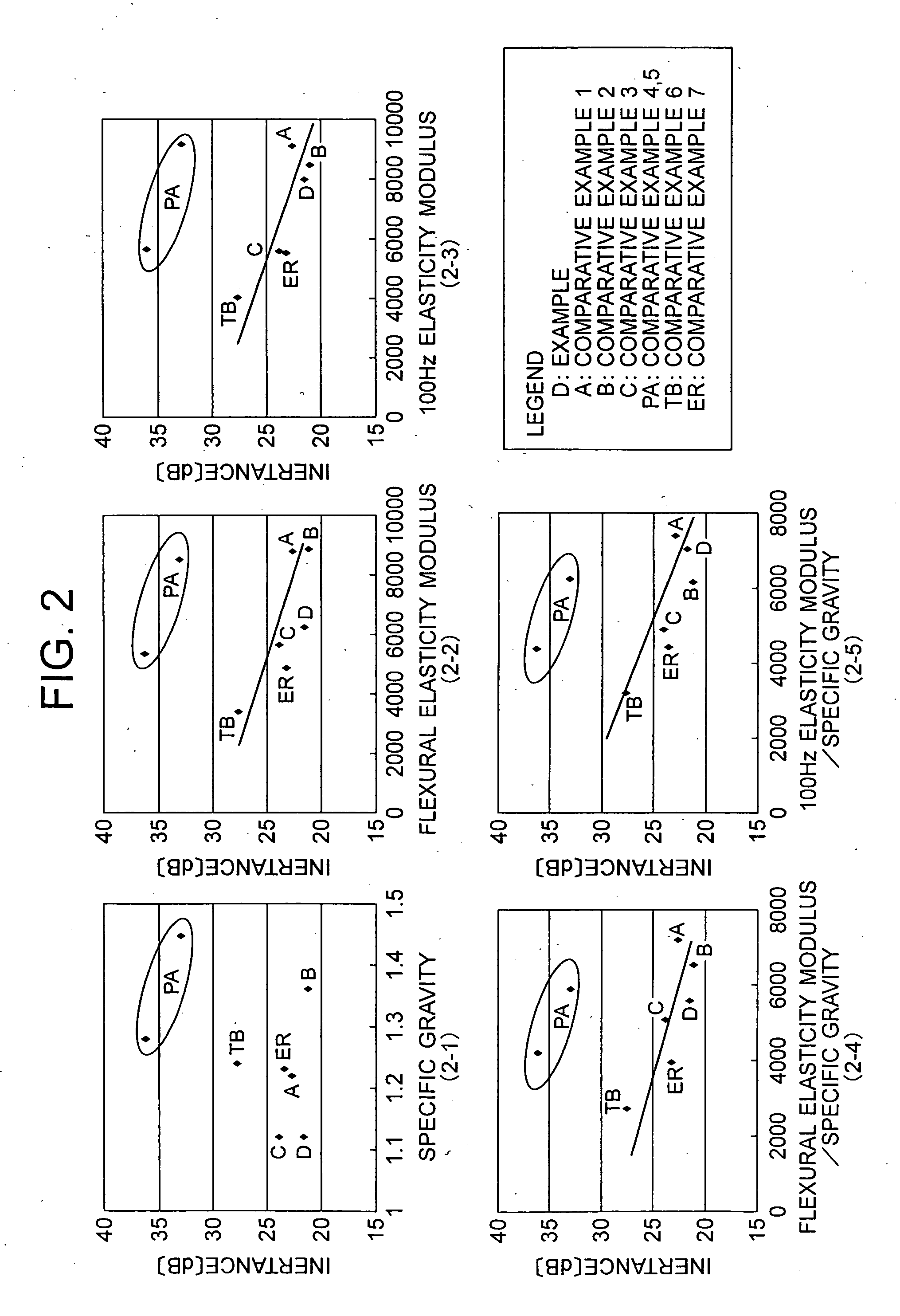

Fiber-reinforced resin composition for parts of air intake system of internal combustion engine

ActiveUS20060167161A1High flexural modulusReduced specific gravityFilm/foil adhesivesSpecial tyresFiberGlass fiber

Main object is to provide a composition for parts of the intake system, which is capable of enhancing the flexural elasticity modulus of the parts of the intake system and reducing the specific gravity of the parts. Disclosed is a fiber reinforced resin composition for parts of intake system on the internal combustion engine comprising a block polypropylene type resin which has a MFR in the range of 40-70 g / 10 minutes (at 230° C. and under a load of 2.16 kg) and which is in the range of 60-80% by weight of the composition, and glass fibers and mica the total of which are in the range of 20-40% by weight of the composition.

Owner:TOYO ROKI MFG CO LTD +1

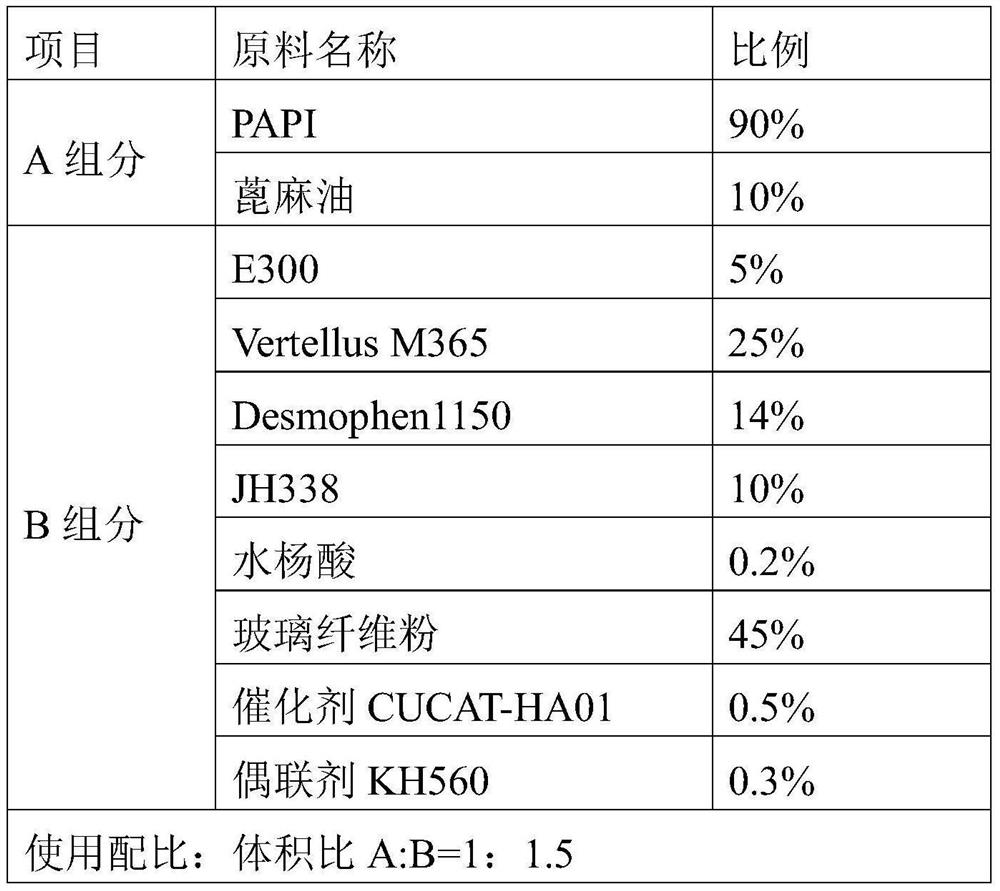

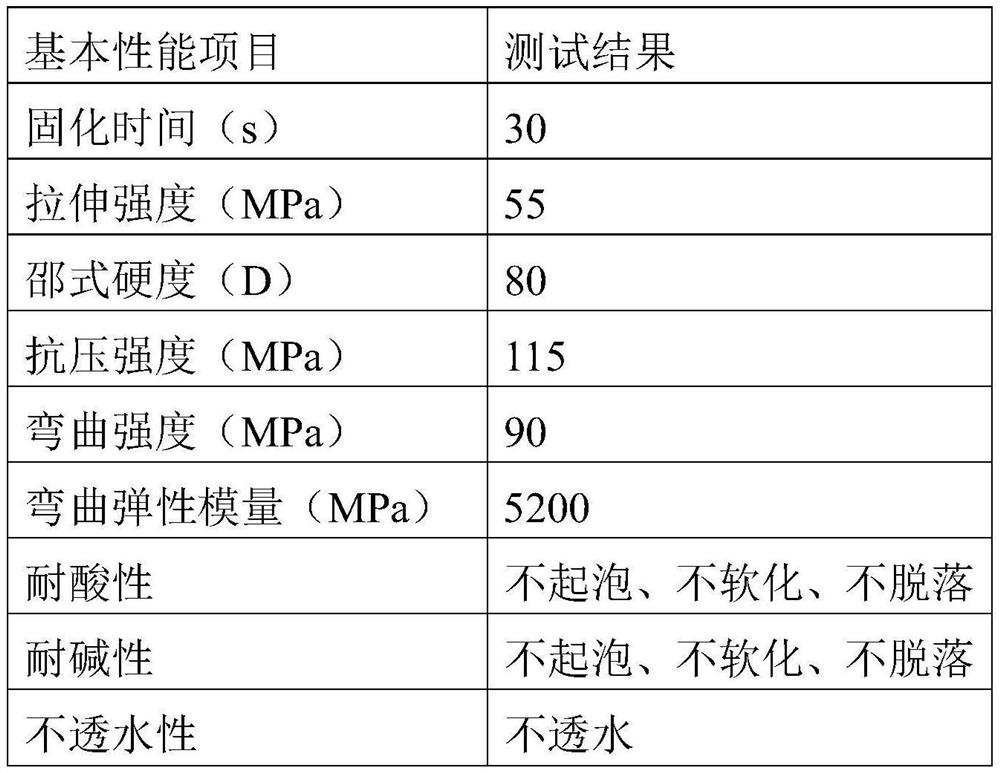

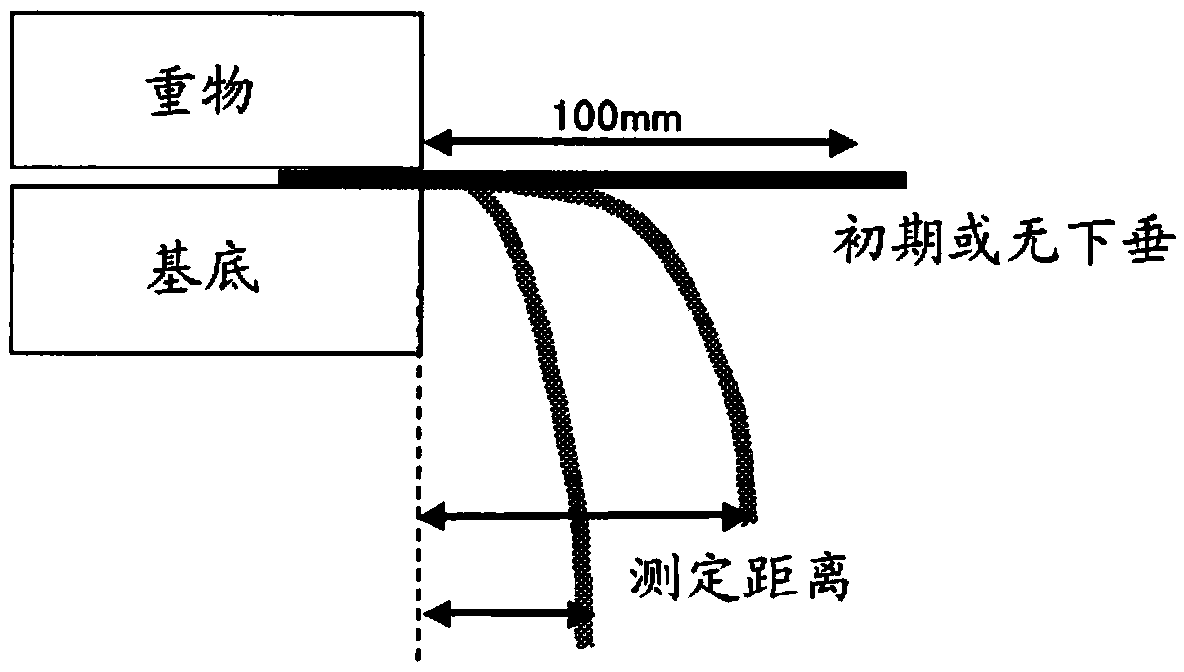

High-modulus rapid repairing and reinforcing material for cave depots

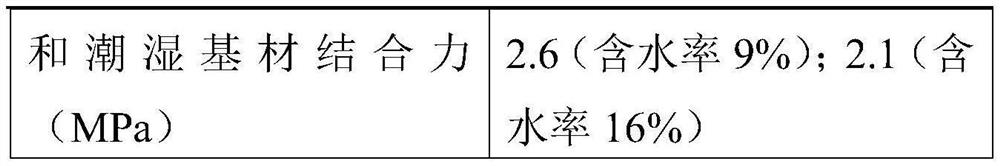

PendingCN113583566AHigh flexural modulusHigh modulusPolyurea/polyurethane coatingsPtru catalystSolvent free

The invention belongs to the technical field of solvent-free polyurethane spraying materials, and particularly relates to a high-modulus rapid repairing and reinforcing material for cave depots. The material is prepared by mixing a component A and a component B according to a volume ratio of 1: 1.5, wherein the component A is prepared from the following raw materials in percentage by mass: 90-100% of isocyanate, 0-10% of one or two of polyether polyol and castor oil; the content of NCO in the component A is 26.7 to 32 percent; the molecular weight of the polyether polyol is 1000-2000, and the functionality of the polyether polyol is 2; the component B is prepared from the following raw materials in percentage by mass: 14.5 to 44.5 percent of polyhydric alcohol with the functionality of 3 or polyhydric alcohol with the functionality of 4 or a mixture of the polyhydric alcohol with the functionality of 3 and the polyhydric alcohol with the functionality of 4, 5 to 10 percent of a chain extender, 35 to 50 percent of one or two of glass fiber powder or wollastonite powder, 0.3 to 0.6 percent of a catalyst CUCAT-HA01, 0.3 to 0.5 percent of a silane coupling agent, 10 to 20 percent of a latent curing agent and 0.2 to 0.4 percent of a hydrolysis accelerant. The material disclosed by the invention is used for quickly repairing a wet base material, is high in curing speed and can be put into application after being cured.

Owner:青岛费米新材料科技有限公司

Fire-proof and damp-proof PVC compound stabilizer wood-plastic composite and preparation method thereof

The invention discloses a fire-proof and damp-proof PVC compound stabilizer wood-plastic composite and belongs to the technical field of wood-plastic materials. The fire-proof and damp-proof PVC compound stabilizer wood-plastic composite is prepared from, by weight, 25-50 parts of fire-proof and damp-proof PVC compound stabilizer, 5-80 parts of wood fiber, 1-8 parts of epoxidized soybean oil and 1-6 parts of pigment. The invention further discloses a preparation method of the fire-proof and damp-proof PVC compound stabilizer wood-plastic composite. According to the fire-proof and damp-proof PVC compound stabilizer wood-plastic composite, by adding the metal halide modified PVC composite stabilizer, the fire-proof and damp-proof temperature is decreased to 200 DEG C or below; meanwhile, PE and PP are added for improving the impact resistance of the PVC composite stabilizer, so that the wood-plastic composite product has high bending strength, bending elastic modulus and gap-free impact resistance strength and can partially replace structural materials. The preparation method of the fire-proof and damp-proof PVC compound stabilizer wood-plastic composite has good practicability, and can produce good economic benefits and social effects.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

Foamed polyolefin resin sheet

InactiveCN103642107AReduce the number of bubblesHigh flexural modulusSynthetic resin layered productsAntistatic agentPolyolefin

PURPOSE: A foamed polyolefin resin sheet is provided to use in a container or glass substrate and to replace as a board alternative. CONSTITUTION: A foamed polyolefin resin sheet has 60-350 g / L of exterior density, 0.2-1.5 mm of thickness and 50-200 g / m^2. The number of foam in a thickness direction of the foamed sheet is 1-3. A polyolefin resin layer is laminated at least one side of the foamed sheet. 5-55 weight% of polymeric antistatic agent is mixed in the substrate resin with a resin layer.

Owner:JSP CORP

High-compression-resistance MPP solid-wall pipe and preparation method thereof

InactiveCN112048126AImprove bending strengthHigh flexural modulusEngineering plasticFlexural strength

The invention discloses a high-compression-resistance MPP solid-wall pipe and a preparation method thereof. The high-compression-resistance MPP solid-wall pipe is prepared from the following raw materials in parts by weight: 100 parts of modified polypropylene, 0.5-15 part of tackifier, 0.1-15 part of nano material, 0.1-15 part of liquid crystal material, 0.5-15 part of impact modifier, 0.1-15 part of nucleating agent, 0-30 parts of filling masterbatch, 0.5-5 part of color masterbatch, 0.5-30 part of engineering plastic. The high-compression-resistance MPP solid-wall pipe manufactured by usingthe raw materials is good in rigidity, high in bending strength, high in bending elasticity modulus, high in ring stiffness, good in impact strength and corrosion resistance, and good in long-term load resistance and compression resistance at high temperature due to good rigidity, high strength, so that the wall thickness can be reduced, the cost can be reduced, the energy can be saved, and the production efficiency can be improved. The solid-wall pipe can satisfy the requirements of high-standard quality electric power engineering.

Owner:杭州普昌科技有限公司

Stearic acid modified PVC wood plastic and preparation method thereof

The invention discloses a stearic acid modified PVC wood-plastic, which belongs to the technical field of wood-plastic materials, and comprises the following components in parts by weight: 25-50 parts of stearic acid-modified PVC, 5-80 parts of wood fiber, PE 1-8 parts of wax and 1-6 parts of pigment. The invention also discloses a preparation method of the wood plastic. A stearic acid-modified PVC wood plastic of the present invention, by adding a stearic acid-modified PVC composite stabilizer, reduces fire and moisture resistance to below 200°C, and at the same time adds PE and PP to improve the impact resistance of the PVC composite stabilizer, so that Wood-plastic products have higher flexural strength, flexural modulus and unnotched impact strength, and can partially replace structural materials; the preparation method of stearic acid-modified PVC wood-plastic of the present invention has good practicability and can Produce better economic and social effects.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

Polypropylene random copolymer composition for cold and hot water pipe applications

Polypropylene polymer compositions are disclosed that can be used to produce different types of molded articles, such as extruded piping structures. The polypropylene polymer composition contains a polypropylene random copolymer in combination with a property enhancing agent. The property enhancing agent is incorporated into the polymer composition so that the composition has relatively high impact resistance properties in combination with a relatively high flexural modulus.

Owner:WR GRACE & CO CONN

Masterbatch for polyethylene double-wall corrugated pipe and its preparation method

A disclosed master batch applied to a polyethylene double-wall bellows comprises the following raw materials in parts by weight: 60-150 parts of an ultrafine inorganic mineral powder, 20-50 parts of high-density polyethylene resin, 8-15 parts of EVA grafted resin, 8-12 parts of organic-group modified polysiloxane, 3-4 parts of a powdery surfactant, and 3-5 parts of a polyolefin oligomer. A three-dimensional stereo structure is formed by taking high-density polyethylene resin and EVA grafted resin as matrix resin, and is taken as a scaffold of a material, so that the material is endowed with relatively good toughness and processing performances; and also the units of the three-dimensional net structure formed by the matrix resin are effectively filled with the ultrafine inorganic mineral powder, the structure formed by combination of the inorganic mineral powder and the matrix resin enables the master batch to have relatively high bending elasticity modulus, thereby guaranteeing relatively high strength, toughness and bearing capability of the bellows.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

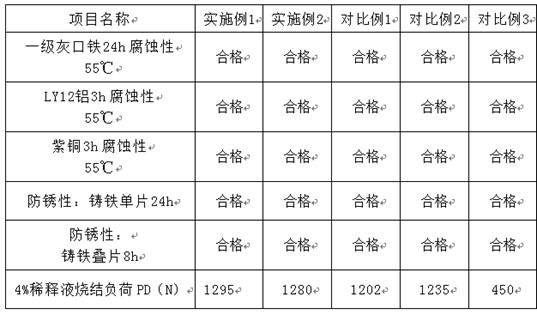

Preparation method of steel backing drilling water-based lubricant

InactiveCN112226271AEasy to prepareWide variety of sourcesLubricant compositionWorking environmentWaste product

The invention belongs to the technical field of water-based lubricants, and relates to a preparation method of a steel backing drilling water-based lubricant. The preparation method is simple and convenient; the range of raw material sources is wide; the water-based lubricant containing a polybenzoate dispersion liquid is utilized, chips generated during drilling are extremely small, winding of adrill bit is avoided, invalid idling of the drill bit is reduced, a drilling process is stable and smooth, the scrapping rate and defective rate can be greatly reduced. Compared with a common oil-based lubricant, the lubricant has more regular holes, and therefore, screw threads are not prone to slipping, part combination is firmer, invalid idle drilling is reduced through a drilling machine, a drill bit always acts on a drilling point, the drilling efficiency is improved compared with that of a common drilling process, drilled chippings are small, the chippings can be removed through light blowing of compressed air, and the working environment is clean and tidy.

Owner:安徽瑞荣汽车零部件有限公司

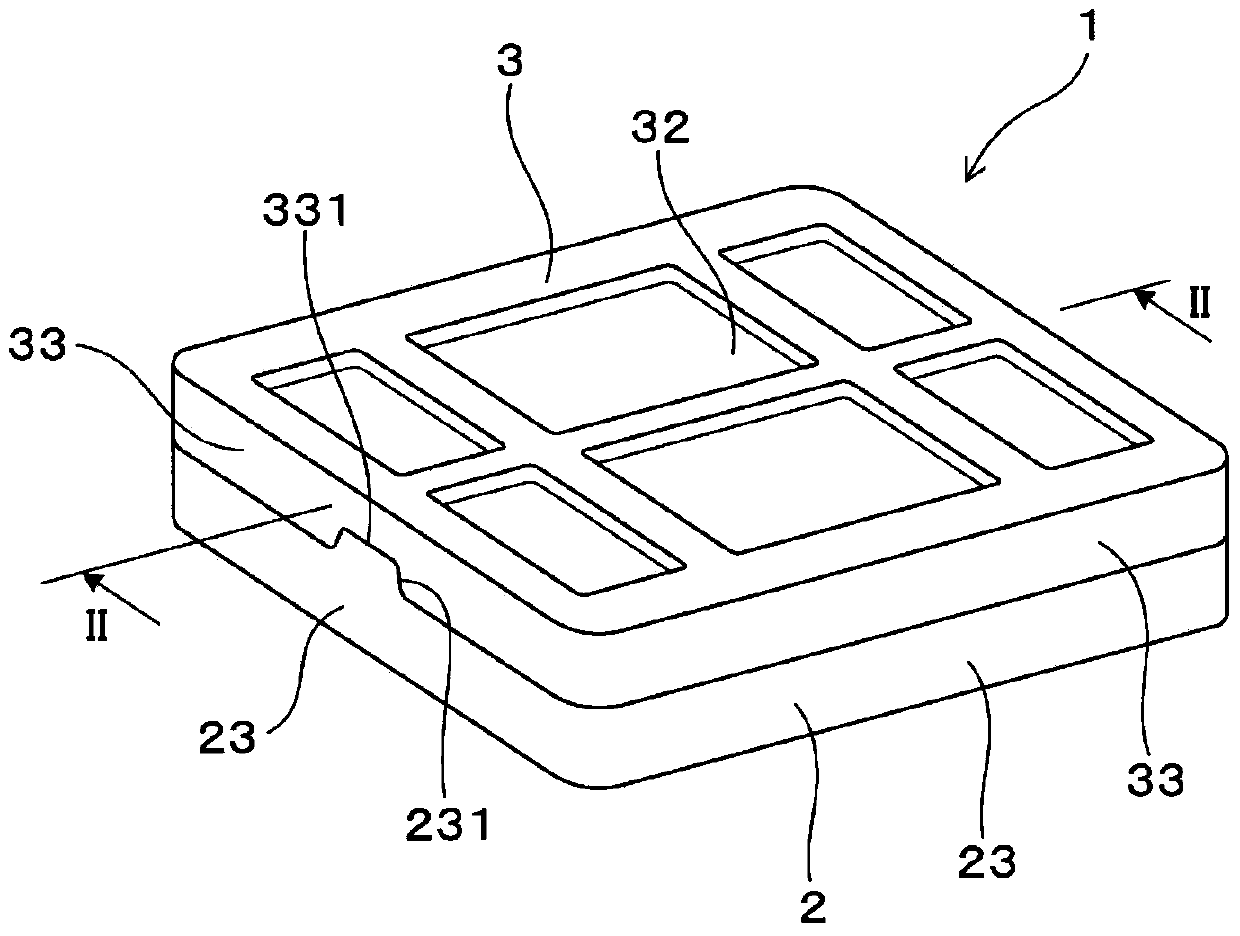

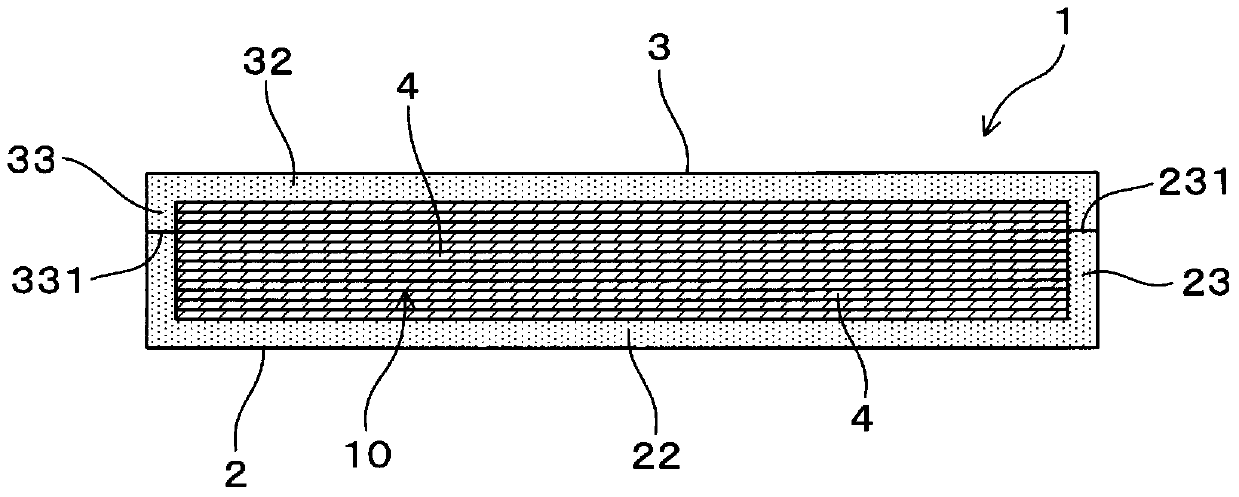

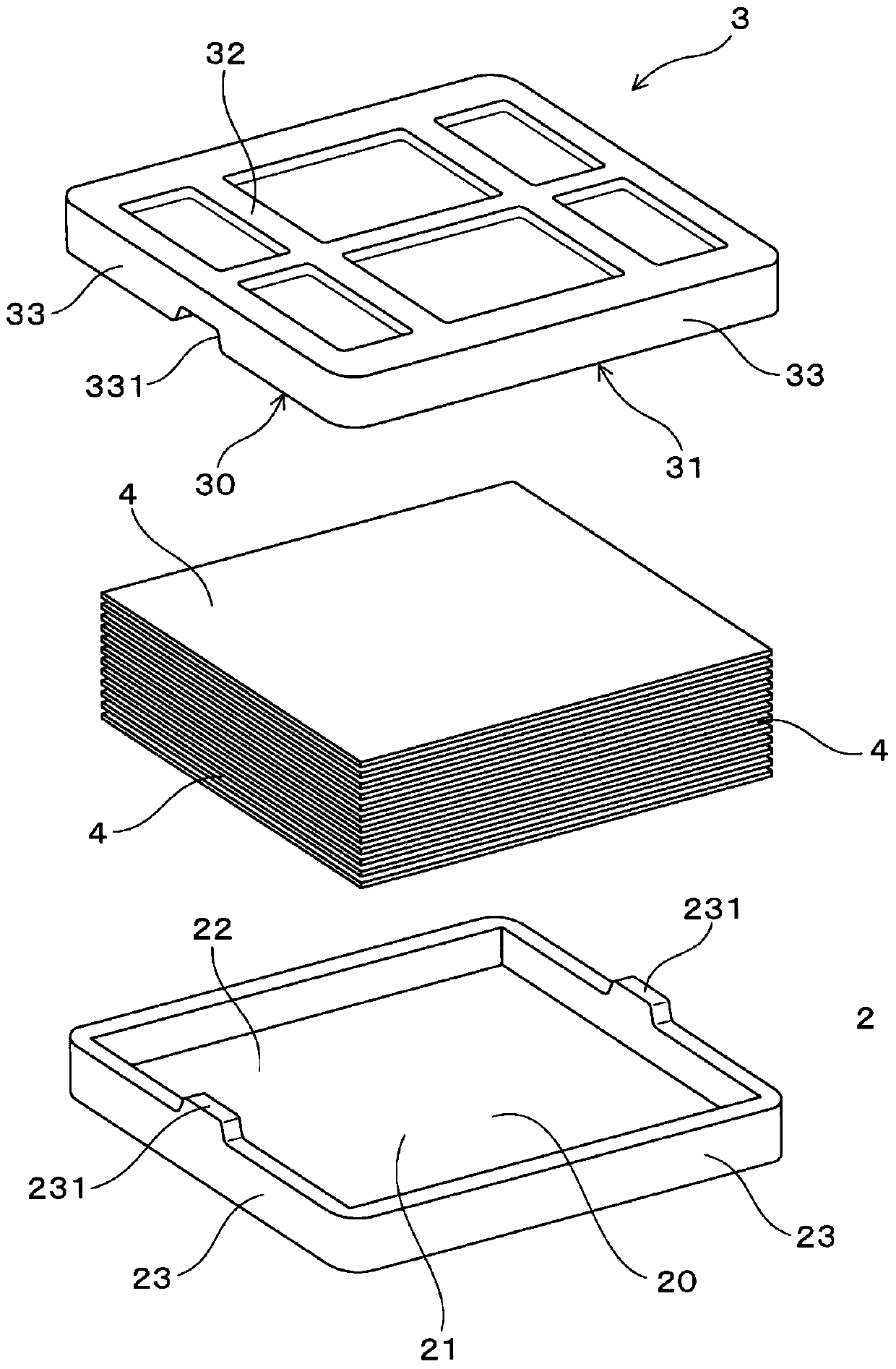

Panel Packaging Container

The invention provides a panel packaging container. The panel packaging container has excellent compression rigidity and bending resistant performance and is capable of preventing deformation. The panel packaging container (1) has an accommodating part (10) which can accommodate a plurality of panels (4) that are laminated along the thickness direction. The panel packaging container (1) comprises a molded body, which is made of molding composite resin foamed particles with an apparent density of 40 to 100 kg / m3 in a mould. The composite resin that forms the foamed particle molded body is prepared by dipping 100 parts by weight of ethylene resin in 400 to 900 parts by weight of styrene monomers. For the composite resin, the swelling capacity of the mixed insoluble component composed of the xylene insoluble component in Soxhlet extraction of xylene and the xylene solution containing an acetone insoluble component after Soxhlet extraction in methyl ethyl ketone with a temperature of 23 DEG C is more than 1.25. The bending elasticity of the foamed particle molded body is greater than 18 MPa, the bending rupture energy is more than 150 J / cm2, and the 50% compression stress is greater than 400 kPa.

Owner:JSP CORP

Flame-retardant calcium carbide sythetic-wood and preparation method thereof

The invention discloses flame-retardant calcium carbide sythetic-wood, and belongs to the technical field of sythetic-wood materials. The flame-retardant calcium carbide sythetic-wood comprises the following components in parts by weight: 25-40 parts of flame-retardant calcium carbide, 5-80 parts of wood fiber, 1-8 parts of a lubricant and 1-6 parts of pigment. The invention further discloses a preparation method of the flame-retardant calcium carbide sythetic-wood. According to the flame-retardant calcium carbide sythetic-wood disclosed by the invention, as the calcium carbide is modified by adding metal halide, the flame retardant temperature is reduced to be lower than 200 DEG C, meanwhile due to addition of PE and PP, the impact resistance of the calcium carbide can be improved, and thus a sythetic-wood product is relatively good in bending strength, bending elastic modus and notch-less impact resistance and can partially replace structural materials; the preparation method of the flame-retardant calcium carbide sythetic-wood is very good in practicability, relatively high in economic benefit and relatively good in social effect.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

Flame-retardant calcium carbonate wood plastic and preparation method thereof

The invention discloses flame-retardant calcium carbonate wood plastic and belongs to the technical field of wood plastic materials. The flame-retardant calcium carbonate wood plastic comprises, by weight, 20-95 parts of flame-retardant calcium carbonate, 5-80 parts of wood fibers, 1-8 parts of lubricant and 1-6 parts of pigment. The invention further discloses a preparation method of the wood plastic. According to the flame-retardant calcium carbonate wood plastic, calcium carbonate modified through metal halide is added, so that flame retardancy is lowered to 200 DEG C or below; meanwhile, PE and PP are added to improve impact resistance of calcium carbonate, so that a wood plastic product is high in bending strength, flexural modulus and unnotched impact strength, and the flame-retardant calcium carbonate wood plastic can partially replace structural materials; by means of the preparation method of the flame-retardant calcium carbonate wood plastic, good practicability is achieved, and good economic benefits and social effects are achieved.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

A kind of ceramic material for 3D printing and preparation method thereof

The invention provides a ceramic material for 3D printing and a preparation method thereof, comprising the following components by weight: 50-150 parts by weight of zirconia powder; 10-30 parts by weight of zirconia powder treatment agent; 100-500 parts by weight of dispersion medium 1-10 parts by weight of single crystal sapphire whiskers; 1-10 parts by weight of stabilizer; 5-50 parts by weight of photocuring agent. The invention can significantly improve the flexural elastic modulus and tensile strength of the product by adding single-crystal sapphire whiskers to the zirconia ceramics, and is used for preparing high-strength, high-toughness fine engineering ceramics.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

High-fiber polyester composite wood plastic and production method thereof

The invention discloses a high-fiber polyester composite wood plastic, and belongs to the technical field of wood plastic materials. The high-fiber polyester composite wood plastic comprises, by weight, 25-50 parts of a high-fiber polyester complex, 5-80 parts of wooden fibers, 1-8 parts of vegetable cellulose and 1-6 parts of a pigment. The invention also discloses a production method of the wood plastic. Addition of metal halide modified PVC reduces the moisture-proof temperature to 200DEG C or below, and simultaneous addition of PE and PP improves the shock resistance of the modified PVC in order to make the wood plastic product have high bending strength, bending elasticity modulus and unnotched impact resistance and partially substitute structure materials; and the production method of the high-fiber polyester composite wood plastic has very good practicality, and can generate good economic and social effects.

Owner:NANJING XUHUA SUNDI NEW BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com