Preparation method of steel backing drilling water-based lubricant

A water-based lubricant and steel-backed technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as shortening the service life of tools, and achieve the effects of reducing waste and defective products, fine debris, and fastening of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

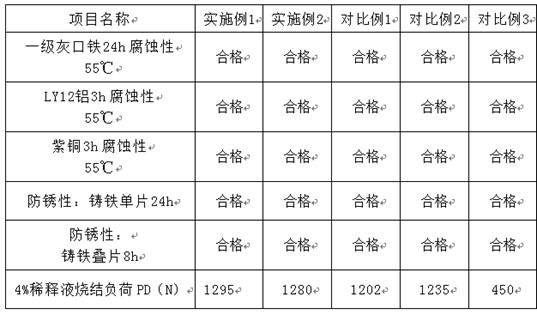

Examples

Embodiment 1

[0019] (1) In parts by weight, weigh the following raw materials: 15 parts of polyphenylene dispersion, 3.1 parts of ethylenediaminoethanesulfonic acid, 2.55 parts of sodium polyepoxysuccinate, 1.28 parts of sodium polymaleate , Adsorption solvent polyglycol methyl propyl ether 5 parts, 1,4-butanediol-2-sodium sulfonate 4.2 parts, nonoxynol ether 0.2 parts, deionized water 90 parts, stabilizer ethylenediamine 0.02 parts of sodium phenyl macroacetate;

[0020] (2) Fully stir and dissolve the adsorption solvent with deionized water to obtain a solution for later use;

[0021] (3) Add polyphenylene ester dispersion, sodium polyepoxysuccinate, sodium polymaleate, 1,4-butanediol-2-sulfonate sodium and nonoxynol ether to step (2) Thoroughly stir and dissolve in the solution to obtain a transparent solution;

[0022] (4) Slowly add stabilizer and sodium ethylenediaminoethanesulfonate to the transparent solution in the above step (3) and mix well to obtain fully synthetic glass cutt...

Embodiment 2

[0025] A preparation method of steel back drilling water-based lubricant, comprising the following steps:

[0026] (1) In parts by weight, weigh the following raw materials: 13 parts of polyphenylene dispersion, 2.8 parts of ethylenediaminoethanesulfonic acid, 2.4 parts of sodium polyepoxysuccinate, 1.25 parts of sodium polymaleate 2 parts of adsorption solvent polyglyme, 3.9 parts of 1,4-butanediol-2-sodium sulfonate, 0.1 part of nonoxynol ether, 80 parts of deionized water, 0.01 part of light stabilizer 2002 stabilizer;

[0027] (2) Fully stir and dissolve the adsorption solvent with deionized water to obtain a solution for later use;

[0028] (3) Add polyphenylene ester dispersion, sodium polyepoxysuccinate, sodium polymaleate, 1,4-butanediol-2-sulfonate sodium and nonoxynol ether to step (2) Thoroughly stir and dissolve in the solution to obtain a transparent solution;

[0029] (4) Slowly add stabilizer and sodium ethylenediaminoethanesulfonate to the transparent solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com