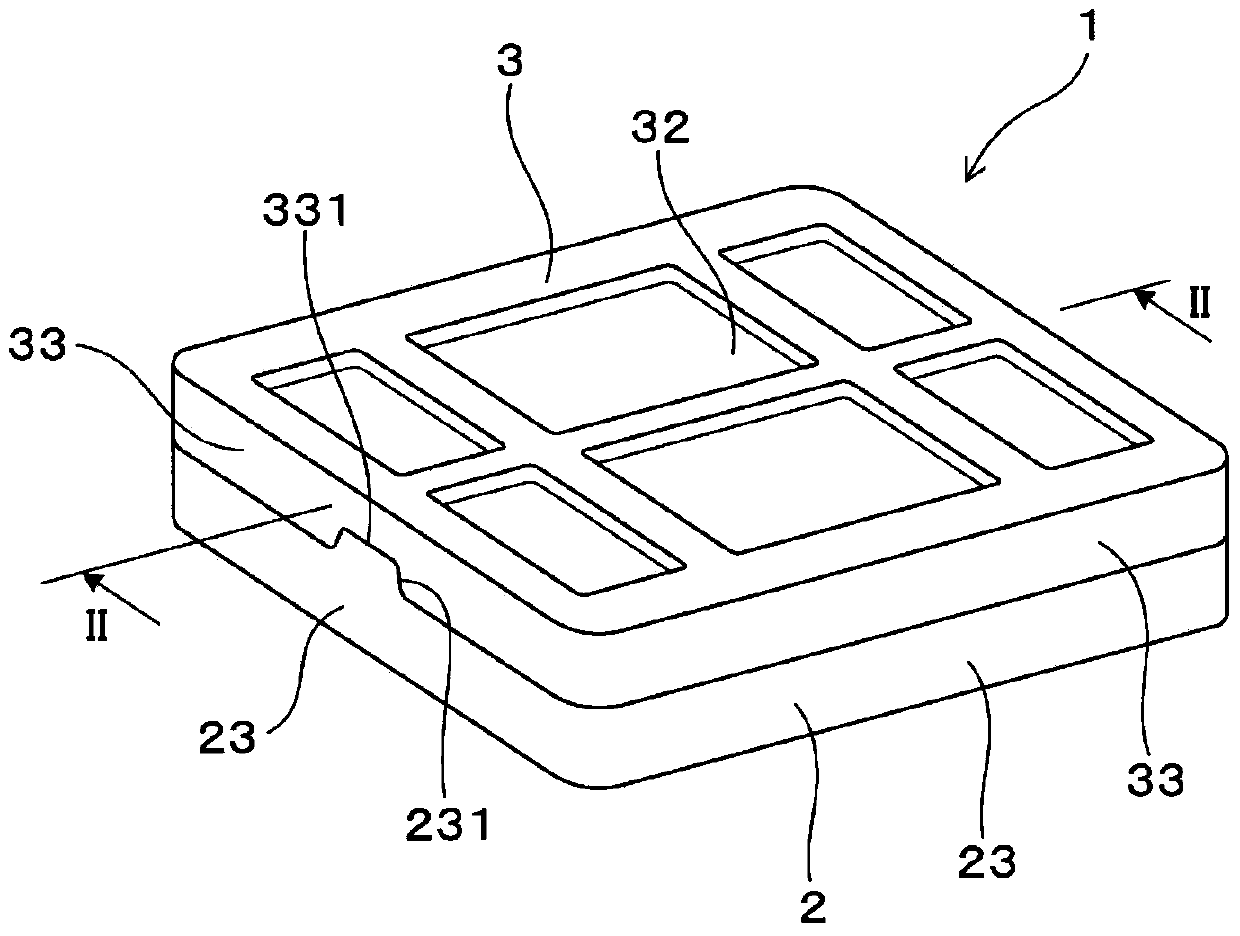

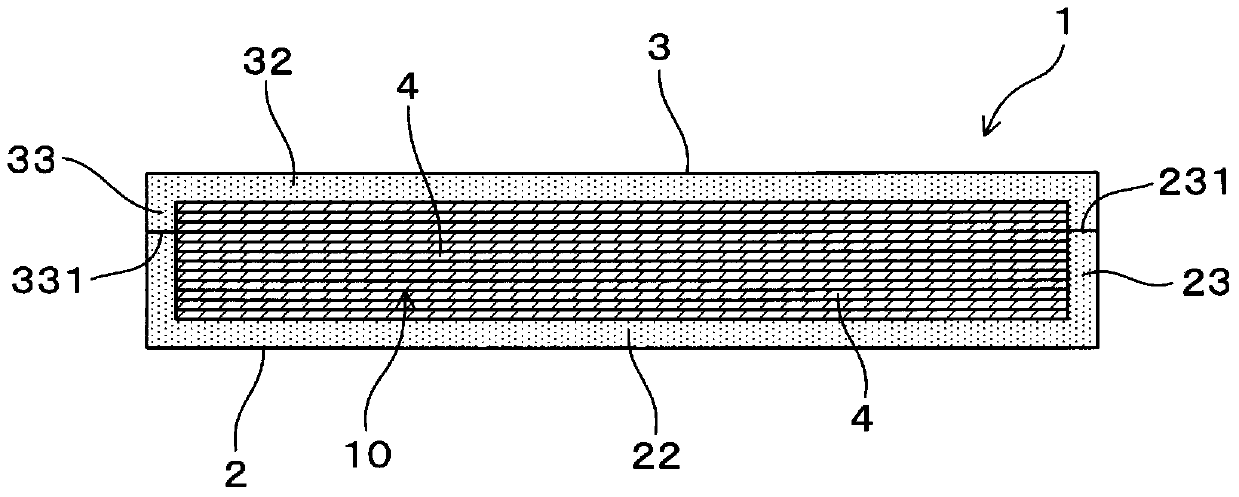

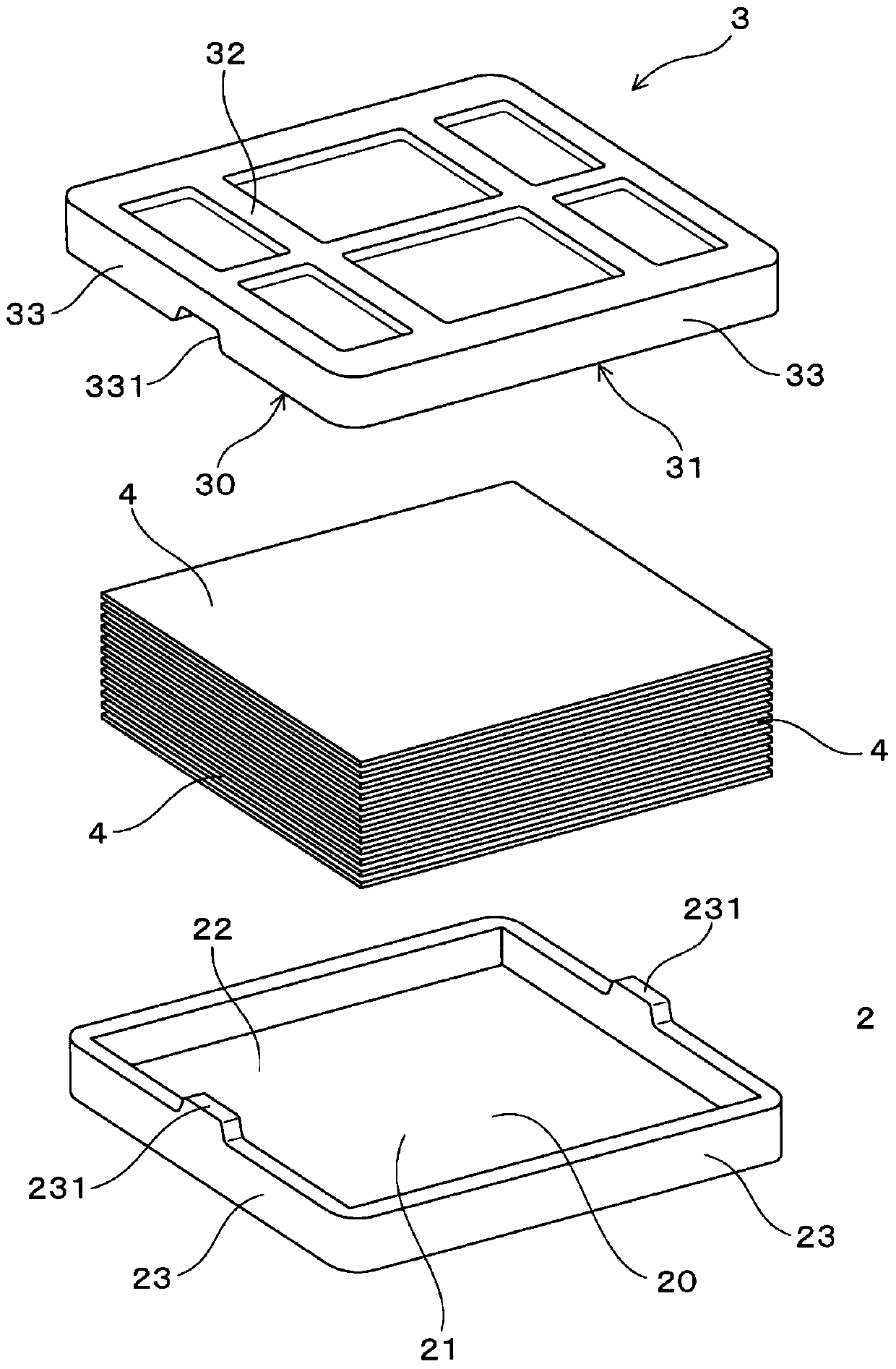

Panel Packaging Container

A technology for packaging containers and panels, applied in the field of foamed particle moldings, can solve problems such as falling off and breakage of liquid crystal panels, and achieve the effects of preventing cracking, high compression rigidity, and excellent flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Hereinafter, examples of the expanded bead molded body used in the panel packaging container will be described. In this example, as described below, composite resin expanded particles were produced from the core particles, and an expanded particle molded body was produced using the composite resin expanded particles.

[0121] (1) Preparation of nuclear particles

[0122] As the vinyl resin, linear low-density polyethylene polymerized using a metallocene polymerization catalyst (specifically, "Nipolon-Z HF210K" manufactured by TOSOH Corporation) was prepared. The vinyl resin of this example is hereinafter referred to as "PE-1" as appropriate. MFR (unit: g / 10min), density (unit: kg / m3) of PE-1 at a temperature of 190°C and a load of 2.16kg 3 ), tensile modulus (unit: MPa), and melting point (unit: °C) are shown in Table 1 below. The MFR of PE-1 under the conditions of a temperature of 190° C. and a load of 2.16 kg is a value measured under condition code D based on JIS...

Embodiment 2

[0158] In this example, first, core particles were prepared in the same manner as in Example 1, except that the amount of the vinyl resin (i.e., PE-1) was changed from 8.65 kg to 9 kg, and the amount of the cell regulator masterbatch was changed to 9 kg. Amount changed from 1.35kg to 1kg. Next, composite resin particles were prepared in the same manner as in Example 1, except that 100 g of the core particles were used, a mixed monomer of 85 g of styrene and 15 g of butyl acrylate was used as the first monomer, and 300 g of styrene was used as the second monomer. Two monomers. Then, using the composite resin particles, an expanded particle molded body was produced in the same manner as in Example 1.

Embodiment 3

[0160] In this example, first, core particles were prepared in the same manner as in Example 1, except that the amount of the vinyl resin (i.e., PE-1) was changed from 8.65 kg to 8 kg, and the amount of the cell regulator masterbatch Quantity changed from 1.35kg to 2kg. Next, composite resin particles were prepared in the same manner as in Example 1, except that 53 g of the core particles were used, a mixed monomer of 38 g of styrene and 15 g of butyl acrylate was used as the first monomer, and 394 g of styrene was used as the second monomer. Two monomers. Then, using the composite resin particles, an expanded particle molded body was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com