Flame-retardant PVC profile for doors and windows and preparation method thereof

A profile, door and window technology, applied in the field of flame-retardant PVC profiles for doors and windows and its preparation, can solve the problems of poor flame-retardant properties of PVC profiles and potential safety hazards, and achieve excellent impact resistance, good flame-retardant effects, and heat resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

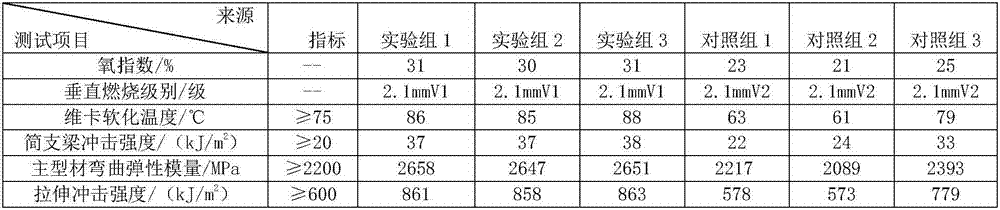

Examples

Embodiment 1

[0025] A flame-retardant PVC profile for doors and windows, which consists of: 60kg of PVC waste, 17kg of sawdust, 15kg of 600-mesh light calcium carbonate, 0.54kg of rutile titanium dioxide, 8.3kg of CPE impact modifier, and 0.96kg of fatty acid tin salt , barium laurate 0.10kg, calcium laurate 0.25kg, pentaerythritol 1.2kg and melamine phosphate 2.5kg.

[0026] The preparation method of flame-retardant PVC profiles for doors and windows is:

[0027] A. Put the PVC waste into powder and put it in the mixer, then add sawdust and light calcium carbonate into the mixer and stir at 135°C for 8 minutes;

[0028] B. Add fatty acid tin salt, barium laurate, calcium laurate, pentaerythritol, CPE impact modifier, melamine phosphate and rutile titanium dioxide to the mixture obtained in step A in sequence, stir at 83°C for 6min; then cool to room temperature, extrusion molding after discharge, and the flame-retardant PVC profiles for doors and windows are obtained.

Embodiment 2

[0030] A flame-retardant PVC profile for doors and windows, which consists of: 55kg of PVC waste, 13kg of sawdust, 18kg of light calcium carbonate with a specification of 450 mesh, 0.38kg of rutile titanium dioxide, 6.4kg of CPE impact modifier, tin maleate 0.72kg, barium laurate 0.12kg, calcium laurate 0.30kg, xylitol 0.9kg and magnesium hydroxide 1.3kg.

[0031] The preparation method of flame-retardant PVC profiles for doors and windows is:

[0032] A. Put the PVC waste into powder and put it in the mixer, then add sawdust and light calcium carbonate into the mixer and stir at 128°C for 13 minutes;

[0033] B. Add tin maleate, barium laurate, calcium laurate, xylitol, CPE impact modifier, magnesium hydroxide and rutile titanium dioxide to the mixture obtained in step A in sequence, and stir at 78°C for 9 minutes ; Then cool to room temperature, extrude after discharging, and obtain the flame-retardant PVC profiles for doors and windows.

Embodiment 3

[0035] A flame-retardant PVC profile for doors and windows, which consists of: 57kg of PVC waste, 15.8kg of sawdust, 16kg of 500-mesh light calcium carbonate, 0.45kg of rutile titanium dioxide, 7.2kg of CPE impact modifier, tin maleate Salt 0.84kg, barium laurate 0.112kg, calcium laurate 0.28kg, xylitol 1.06kg, melamine phosphate 1.2kg and magnesium hydroxide 0.9kg.

[0036] The preparation method of flame-retardant PVC profiles for doors and windows is:

[0037] A. Put the PVC waste into powder and put it in the mixer, then add sawdust and light calcium carbonate into the mixer and stir at 130°C for 11 minutes;

[0038] B. Add tin maleate, barium laurate, calcium laurate, xylitol, CPE impact modifier, melamine phosphate, magnesium hydroxide and rutile titanium dioxide to the mixture obtained in step A in sequence, at 81°C Stir at high temperature for 7 minutes; then cool to room temperature, discharge and extrude to obtain the flame-retardant PVC profile for doors and window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com