Multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared by multi-component compatiblizing and toughening agent

A toughening agent and multi-component technology, applied in the direction of single-component polyester rayon, etc., can solve the problems of reduced toughness and poor compatibility of rPET

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

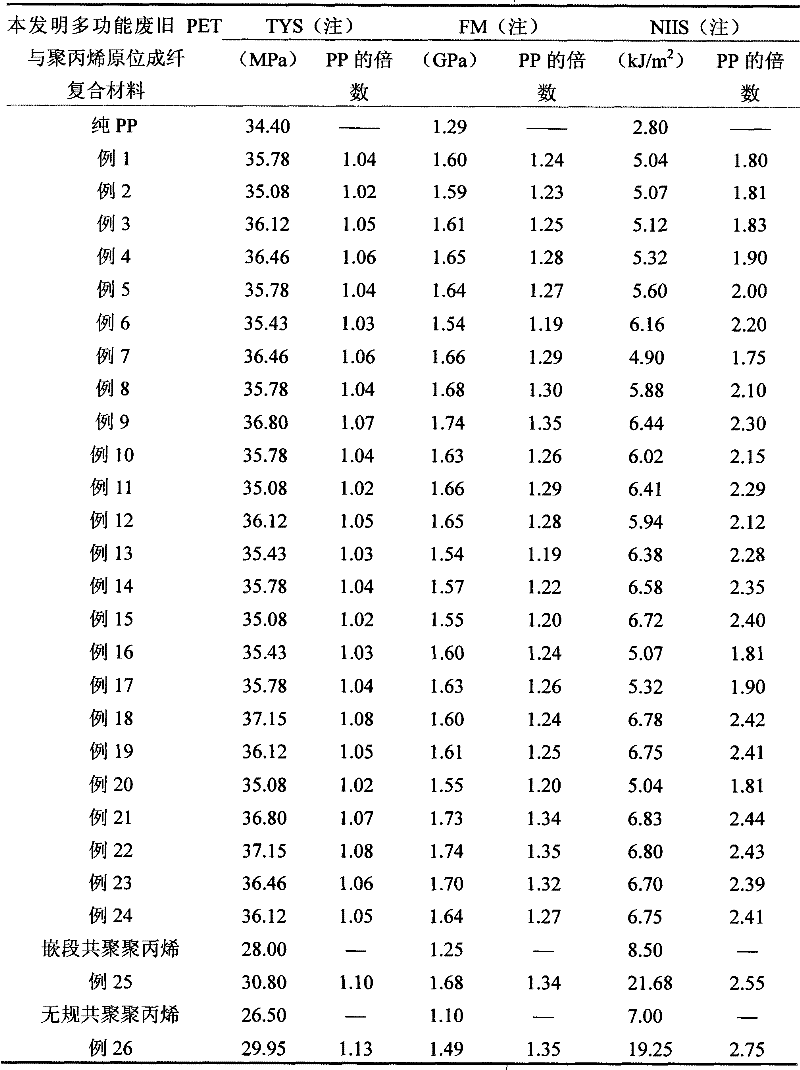

Examples

Embodiment 1

[0044] (1) Preparation of multi-component controllable reactive compatibilizer and toughening agent:

[0045] a. Raw material ratio: expressed in parts by weight, 70 parts of granular homopolypropylene PP, 24.0 parts of E-type EPDM rubber, 6.0 parts of linear SBS thermoplastic elastomer (S / B is 20 / 80), methyl 17.0 parts of glycidyl acrylate, 6.0 parts of styrene, 1.1 parts of dibenzoyl peroxide;

[0046] The melt flow rate of polypropylene is 6.5g / 10min under the conditions of 230°C and 21.168N.

[0047] B, take various raw materials according to step a, at first join solvent xylene in the reactor, the add-on of described xylene is 8.5 times of above-mentioned raw material gross weight, then add the raw material polypropylene that weighs, elastomer 1 Stir with elastomer 2, heat the jacket with steam, the stirring speed is 80-200r / min, when the temperature rises to 125°C, slowly add the bifunctional reactive monomer and the second monomer, at 125±2°C Stir at low temperature f...

Embodiment 2

[0054] Embodiment 2: the difference with embodiment 1 is:

[0055] (1) Preparation of multi-component controllable reactive compatibilizer and toughening agent:

[0056] a. Raw material ratio: expressed in parts by weight, 64 parts of granular homopolypropylene PP, 28 parts of ethylene-octene copolymer POE, 8 parts of linear SBS thermoplastic elastomer (S / B is 20 / 80), allyl 17.0 parts of glycidyl ether, 6.0 parts of styrene, 1.1 parts of dibenzoyl peroxide;

[0057] b. The amount of xylene added is 8 times the total weight of the above raw materials, and the reaction temperature is 128±2°C.

[0058] Others are the same as embodiment 1.

Embodiment 3

[0059] Embodiment 3: the difference with embodiment 1 is:

[0060] (1) Preparation of multi-component controllable reactive compatibilizer and toughening agent:

[0061]a. Raw material ratio: expressed in parts by weight, 60 parts of powdered homopolypropylene PP, 32 parts of D-type EPDM rubber, 8 parts of linear SBS thermoplastic elastomer (S / B is 30 / 70), acrylic ring 22.0 parts of oxyester resin, 7.5 parts of styrene, 1.5 parts of dibenzoyl peroxide;

[0062] b. The amount of xylene added is 9 times the total weight of the above raw materials, and the reaction temperature is 122±2°C.

[0063] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com