Glaze-imitating colored plastic glazed tile and preparation method thereof

A glazed tile and imitation glaze technology, applied in the field of plastic products, can solve the problems of poor impact resistance and weather resistance, affect the ecological environment, use clay and other problems, achieve good impact resistance and weather resistance, reduce surface roughness, Brightness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

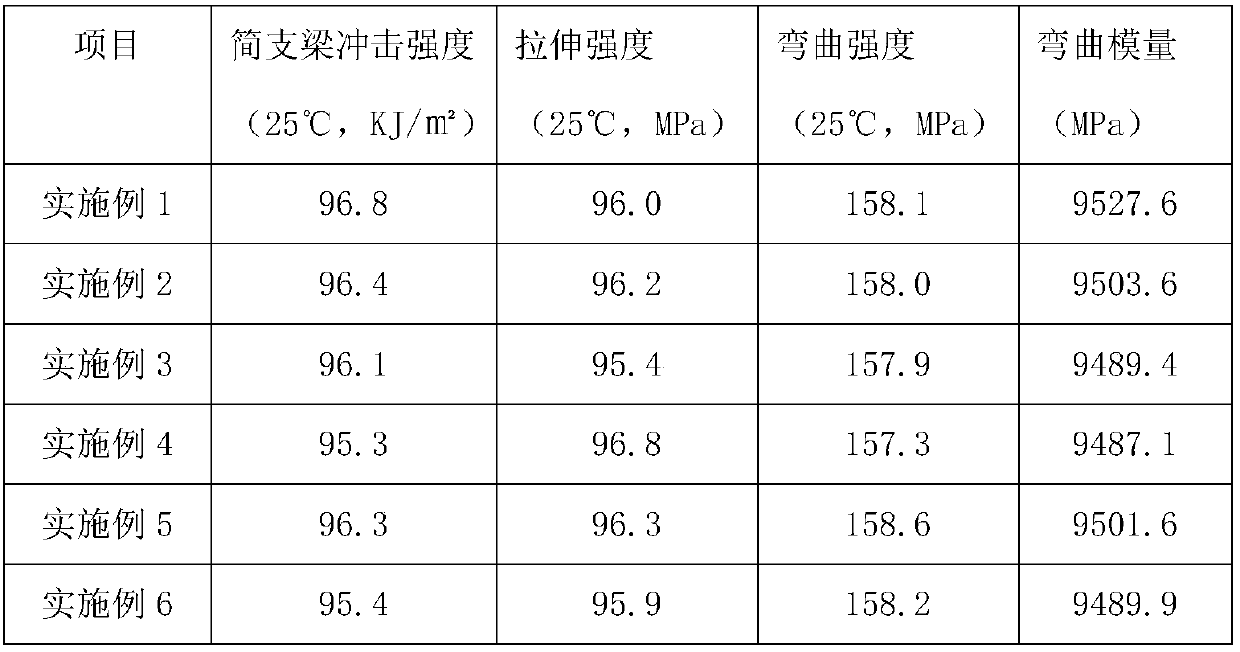

Examples

Embodiment 1

[0037] An imitation glazed red plastic glazed tile, including an upper layer and a lower layer, the upper layer is composed of the following raw materials by mass percentage: AS2200 67%, ASA031H 30%, transparent iron oxide red 2.25%, phthalocyanine blue 0.0092%, peach red 0.0048%, charcoal Black M430 0.2%, EBS 400A 0.49%, silane coupling agent 7007 0.05%; the lower layer includes the following raw materials in terms of mass percentage: five types of PVC 50%, nano-active calcium carbonate 40%, iron oxide 2.25%, phthalocyanine Blue 0.0092%, pink 0.0048%, carbon black M430 0.2%, AV-A 1%, EBS 0.5%, silane coupling agent 7007 1.2%, DOP 2.3%.

Embodiment 2

[0039] An imitation glazed yellow plastic glazed tile, including an upper layer and a lower layer, the upper layer is composed of the following raw materials in percentage by mass: AS resin 2200 75%, acrylate 18%, transparent iron yellow 1.9%, titanium dioxide 0.3%, pink 0.74%, EBS 0.9%, DOP 3.15%, silane coupling agent 7007 0.01%; the lower layer includes the following raw materials by mass percentage: PVC type V 60%, nano-active calcium carbonate 30%, transparent iron yellow 1.9%, titanium dioxide 0.3%, AV-A 1.5%, EBS 0.75%, DOP 2.9%, silane coupling agent 7007 0.35%.

Embodiment 3

[0041] An imitation glazed dark green plastic glazed tile, including an upper layer and a lower layer, the upper layer includes the following raw materials by mass percentage: AS resin 2200 65%, ASA031H 27%, phthalocyanine green 3.01%, carbon black 0.01%, EBS 0.95%, DOP3. 5%, silane coupling agent 7007 0.45%; the lower layer includes the following raw materials by mass percentage: PVC type five 56%, nano-active calcium carbonate 35%, phthalocyanine green 2.9%, carbon black 0.01%, EBS 1.2 %, AV-A 1.7%, silane coupling agent 7007 0.49%, DOP 2.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com