Device and method for preparation of ultra-high molecular-weight polyethylene sheet

A technology of ultra-high molecular weight and preparation equipment, which is applied in the field of ultra-high molecular weight polyethylene sheet preparation equipment, can solve the problems of continuous limitation of sheet width and processing, low production efficiency, complex process, etc., and achieve simple structure and high production efficiency. High efficiency and good plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

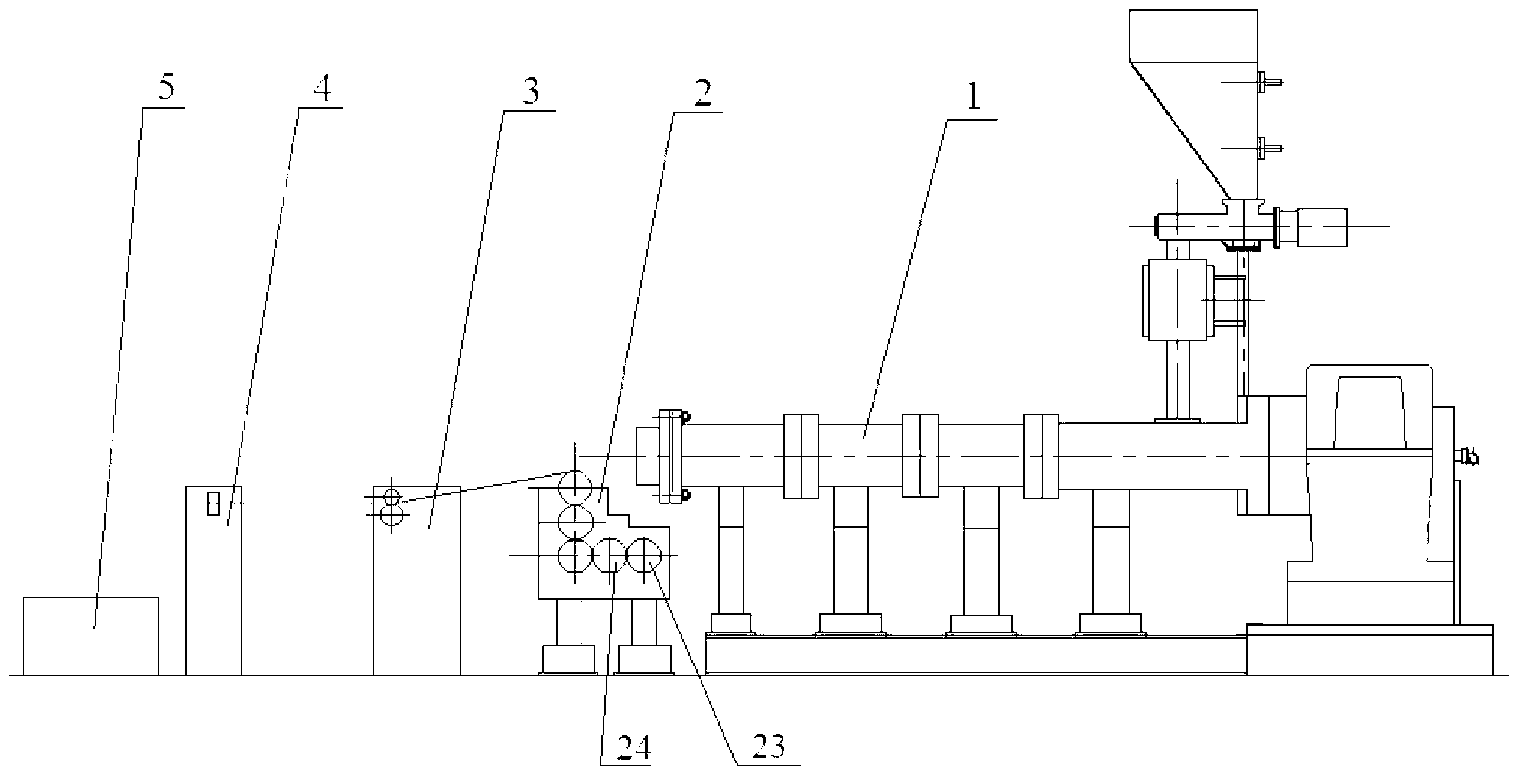

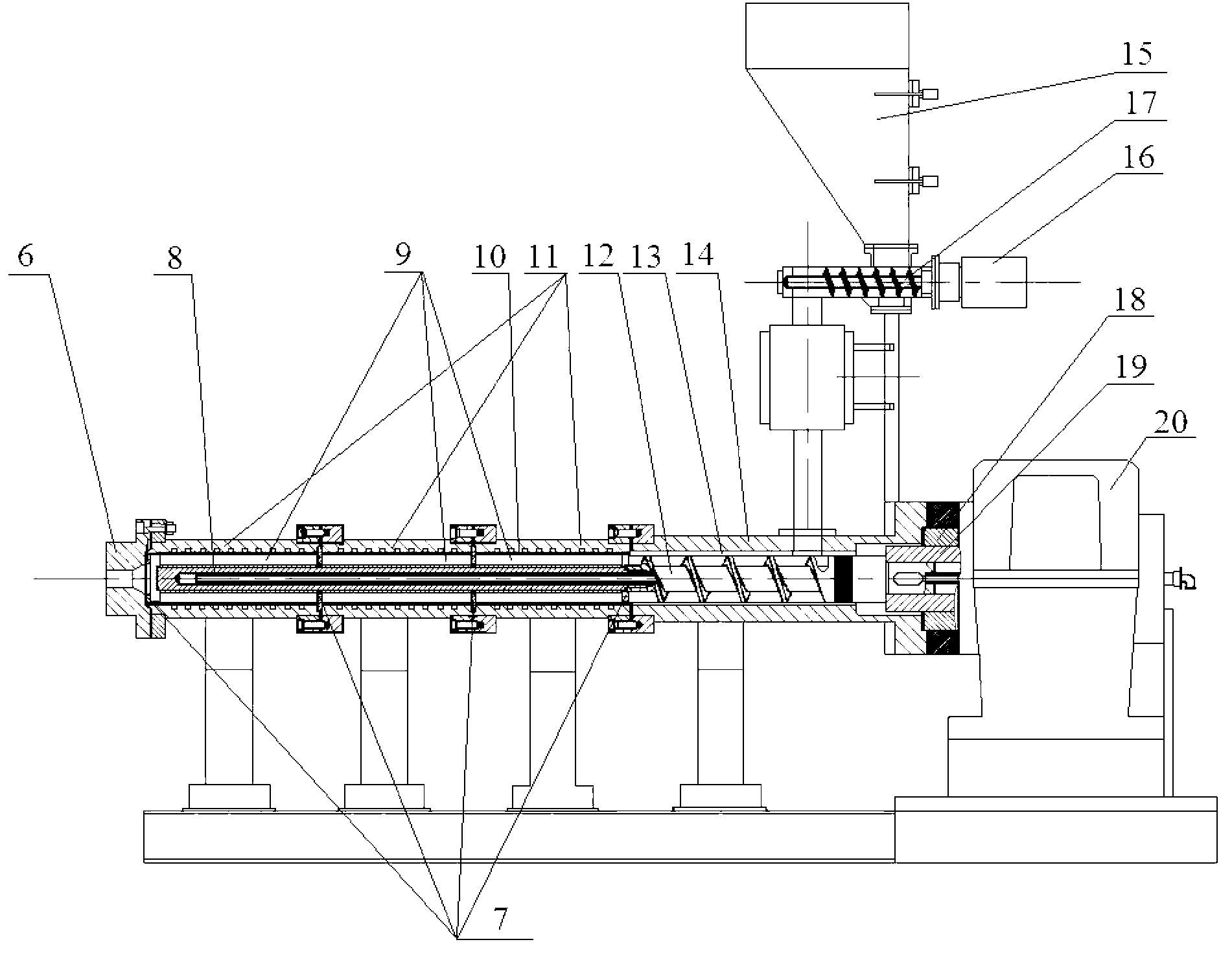

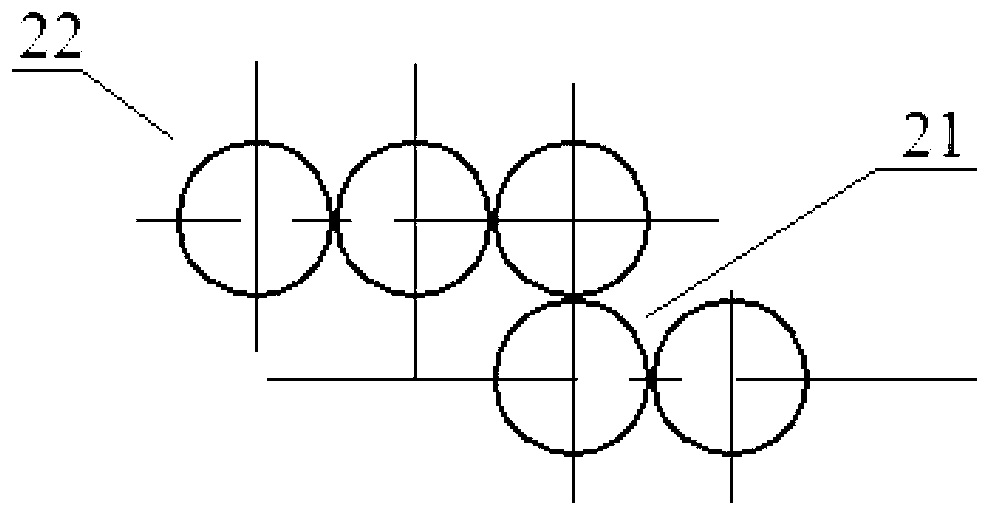

[0028] One embodiment of the present invention provides an ultra-high molecular weight polyethylene sheet preparation device, including an extrusion mechanism, a calendering mechanism, a traction mechanism and a cutting mechanism arranged in sequence; the extrusion mechanism includes a planetary screw extruder, the The planetary screw extruder includes a multi-section combined barrel mechanism, and the barrel mechanism includes a multi-section barrel connected to each other and a plurality of planetary screws nested in each section of the barrel; the polyethylene material is passed through the barrel. After being extruded by the extruding mechanism, it is calendered and formed into a sheet by the calendering mechanism, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com