PA6 composite material special for engine air intake manifolds

A technology of intake manifold and composite materials, which is applied in the field of PA6 composite materials for the production of engine intake manifolds. It can solve the problems of damage, affecting the welding rib area, and low blast resistance, and achieves the improvement of tensile strength and impact strength. , Overcoming easy breakage, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

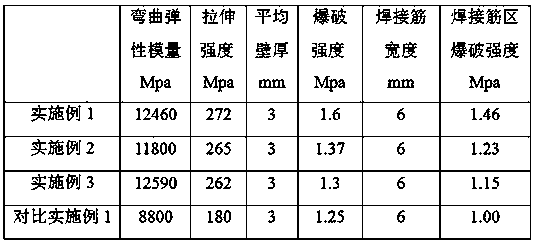

Examples

Embodiment 1

[0016] A special PA6 composite material for an engine intake manifold, consisting of the following raw materials in parts by weight: 66 parts of PA6 resin, 30 parts of glass fiber with a monofilament diameter of 8 µm, 0.8 part of dispersant zinc stearate, 4.2 parts of compatibilizer, Dow Corning Z6030 0.6 parts of coupling agent, 1.2 parts of carbon black, 1.2 parts of antioxidant; the compatibilizer is composed of maleic anhydride grafted butene-octene copolymer and N,N'-ethylene bis stearamide in parts by weight The ratio of 3:1 is compounded, and the weight ratio of maleic anhydride, butene and octene in the maleic anhydride grafted butene-octene copolymer is 3:56:41; the antioxidant is antioxidant 1010 and A compound of antioxidant 168. The above-mentioned raw materials are mixed by a high-speed mixer, and then extruded and granulated by parallel twin-screws in a disc-type mixing device.

Embodiment 2

[0018] A special PA6 composite material for an engine intake manifold, consisting of the following raw materials in parts by weight: 60 parts of PA6 resin, 25 parts of glass fiber with a monofilament diameter of 8 µm, 0.5 part of dispersant zinc stearate, 4 parts of compatibilizer, Dow Corning Z6030 0.5 parts of coupling agent, 1 part of carbon black, and 1 part of antioxidant; the compatibilizer is composed of maleic anhydride grafted butene-octene copolymer and N,N'-ethylene bis stearamide in parts by weight The ratio of 3:1 is compounded, and the weight ratio of maleic anhydride, butene and octene in the maleic anhydride grafted butene-octene copolymer is 3:56:41; the antioxidant is antioxidant 1010 and A compound of antioxidant 168. The above-mentioned raw materials are mixed by a high-speed mixer, and then extruded and granulated by parallel twin-screws in a disc-type mixing device.

Embodiment 3

[0020] A special PA6 composite material for an engine intake manifold, consisting of the following raw materials in parts by weight: 70 parts of PA6 resin, 35 parts of glass fiber with a monofilament diameter of 8 µm, 1 part of dispersant zinc stearate, 5 parts of compatibilizer, Dow Corning Z6030 1 part of coupling agent, 2 parts of carbon black, 2 parts of antioxidant; the compatibilizer is composed of maleic anhydride grafted butene-octene copolymer and N,N'-ethylene bis stearamide in parts by weight The ratio of 3:1 is compounded, and the weight ratio of maleic anhydride, butene and octene in the maleic anhydride grafted butene-octene copolymer is 3:56:41; the antioxidant is antioxidant 1010 and A compound of antioxidant 168. The above-mentioned raw materials are mixed by a high-speed mixer, mixed by a disc-type mixing device, and extruded and granulated by parallel twin-screws.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com