Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Guaranteed shape and position accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

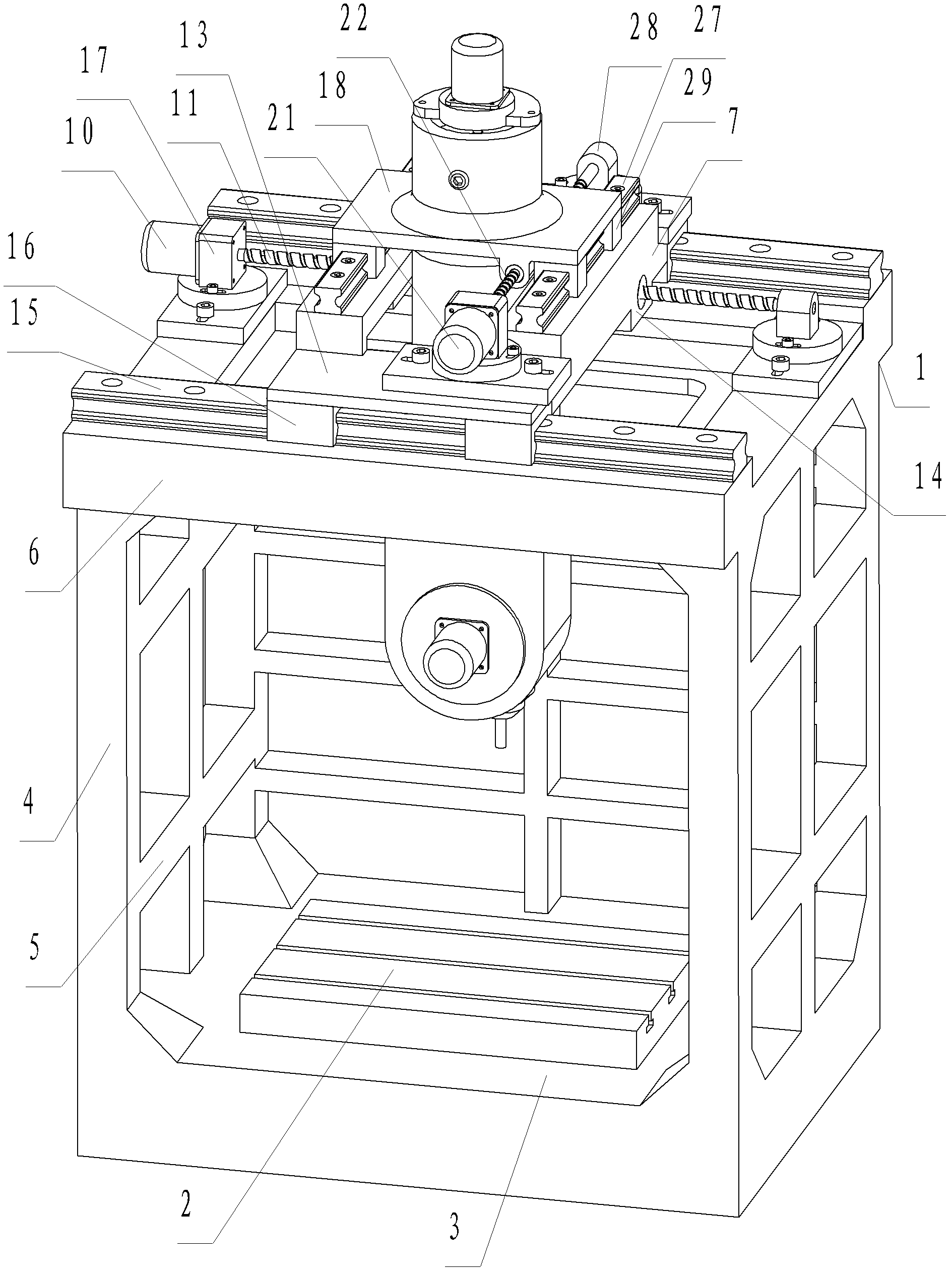

Numerical control equipment

InactiveCN102699768AGuaranteed shape and position accuracyAchieve rigid fixationFeeding apparatusLarge fixed membersNumerical controlEngineering

Numerical control equipment comprises a main frame and a workpiece clamping device. The main frame consists of a base, a first main support portion and a second main support portion, and the first main support portion and the second main support portion are arranged on two opposite sides of the base and are mounted with the base. The numerical control equipment is characterized in that the first main support portion and the second main support portion consist of separate first sides on the middle upper portions, a first driving device and a first driving device mounting portion, the first driving device drives an X-direction sliding seat to reciprocate, the first driving device mounting portion is connected with the first main support portion or the second support portion and is placed between an X-direction front guide rail and an X-direction rear guide rail, and the first driving device consists of an X-direction lead screw or a group of X-direction linear motors which drives the X-direction sliding seat to reciprocate and is parallel to the X-direction front guide rail and the X-direction rear guide rail. The X-direction lead screw penetrates through the X-direction sliding seat, and two ends of the X-direction lead screw are protruded out of a worktable and mounted on the first driving device mounting portion; or two ends of a stator of each X-direction linear motor are protruded out of the worktable and are fixed to the first driving device mounting portion. The numerical control equipment has the advantage that a workpiece is convenient to hoist.

Owner:杨东佐

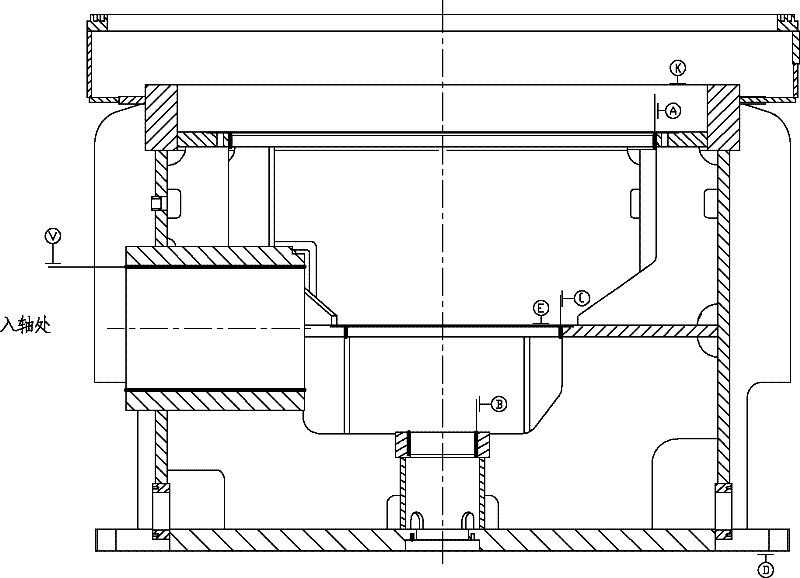

Machining method of perpendicularly intersected hole system of speed reducer body

InactiveCN102642114AReduce surface roughness requirementsGuaranteed shape and position accuracyMeasurement/indication equipmentsMetal working apparatusNumerical controlSurface finish

The invention discloses a machining method of a perpendicularly intersected hole system of a speed reducer body. Holes A-B on the vertical axis are machined by a vertical numerical control machining center so as to meet the concentric requirement of the holes on the axis, and simultaneously, a section of horizontal hole is bored based on the vertical axis; the horizontal hole is long in length, only a section of horizontal hole is bored to be used as an aligning basis in order to ensure the machining precision so as to avoid a mark error, so that the section of horizontal hole is used as an aligning basis for machining a horizontal hole V. In the same way, a hole V on the horizontal axis is machined by a high-precision numerical control boring and milling machine by not using a mark as an aligning basis but on the aligning basis on which the vertical holes are machined, and the aligning precision is high; and meanwhile, the space laser detection technology and the numerical control machining technology are matched to ensure the form-position precision of the perpendicularly intersected hole system of the body. The fine surface finishing technology and the numerical control simulation technology of a high-precision numerical control machine are applied to select reasonable cutting amount to meet the low roughness requirement of the surface of the perpendicularly intersected hole system of the body. Through the machining method, the amount of adjustment of assembly is greatly reduced, and the assembly precision is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

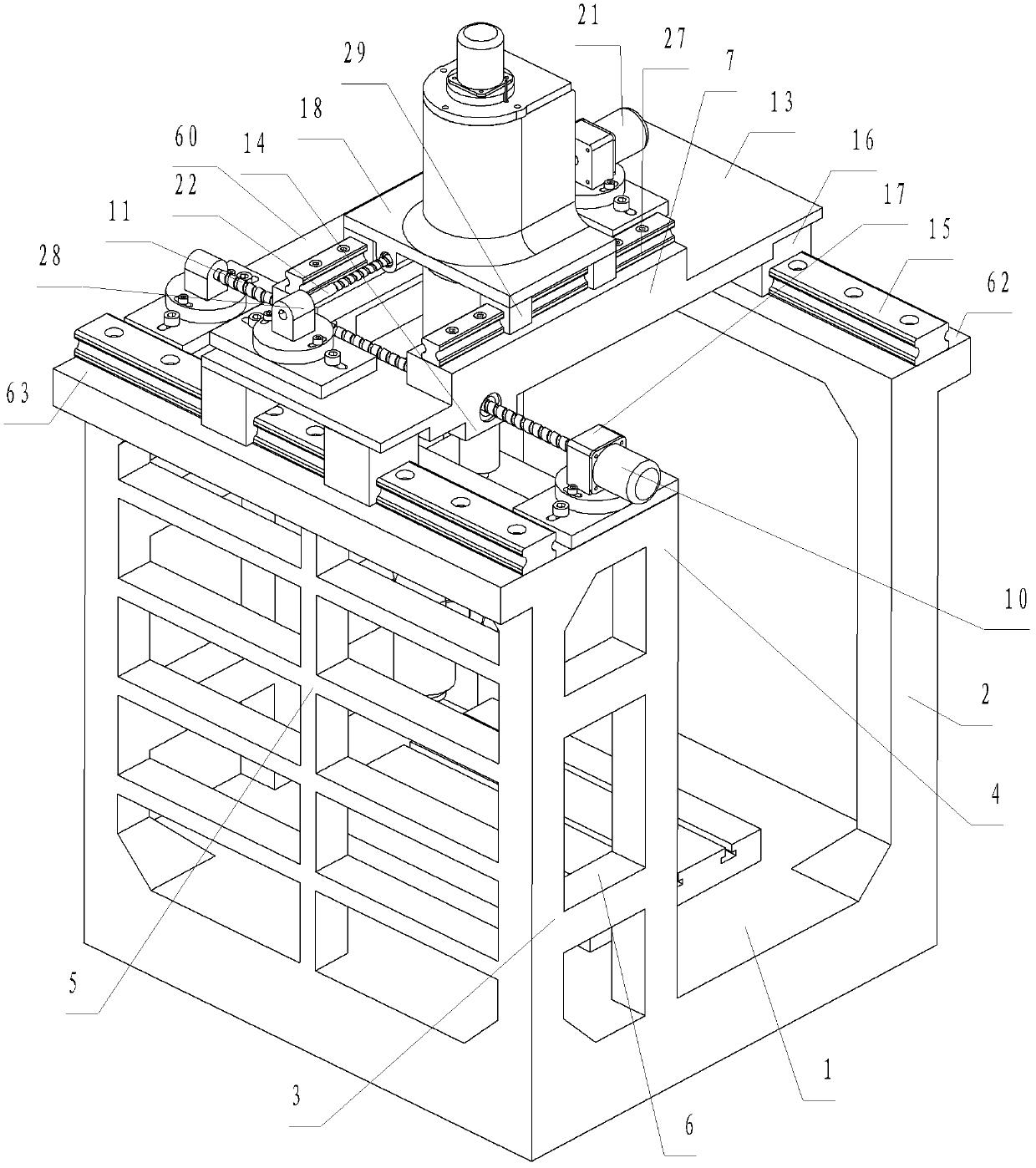

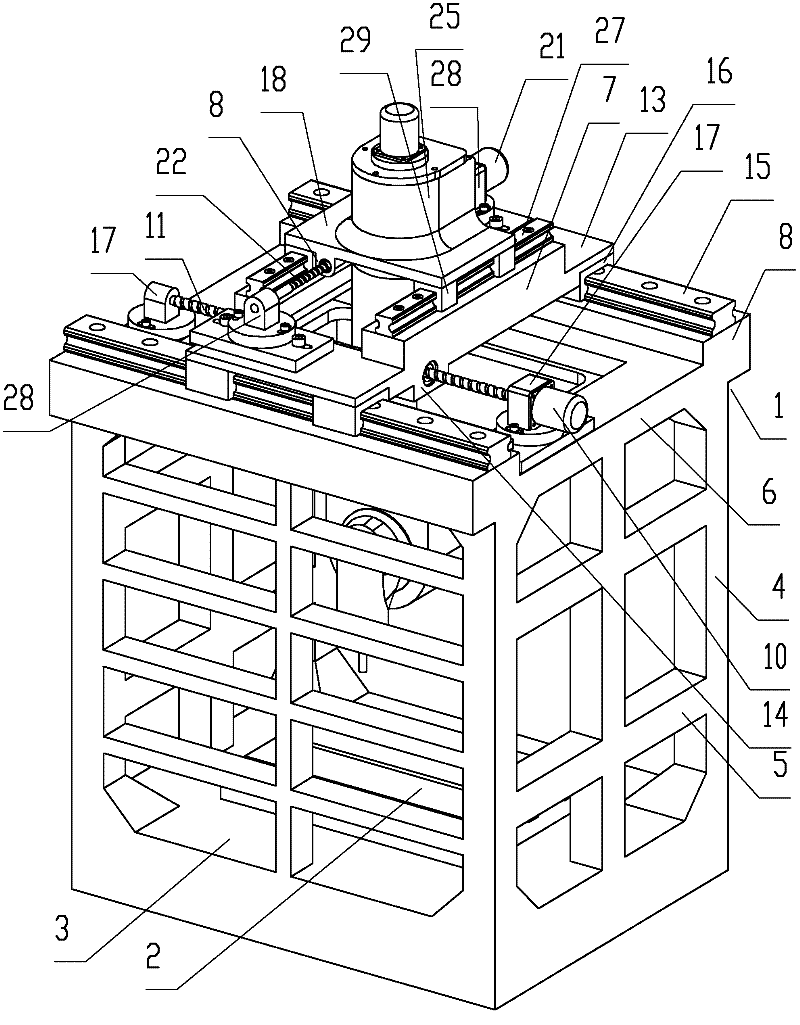

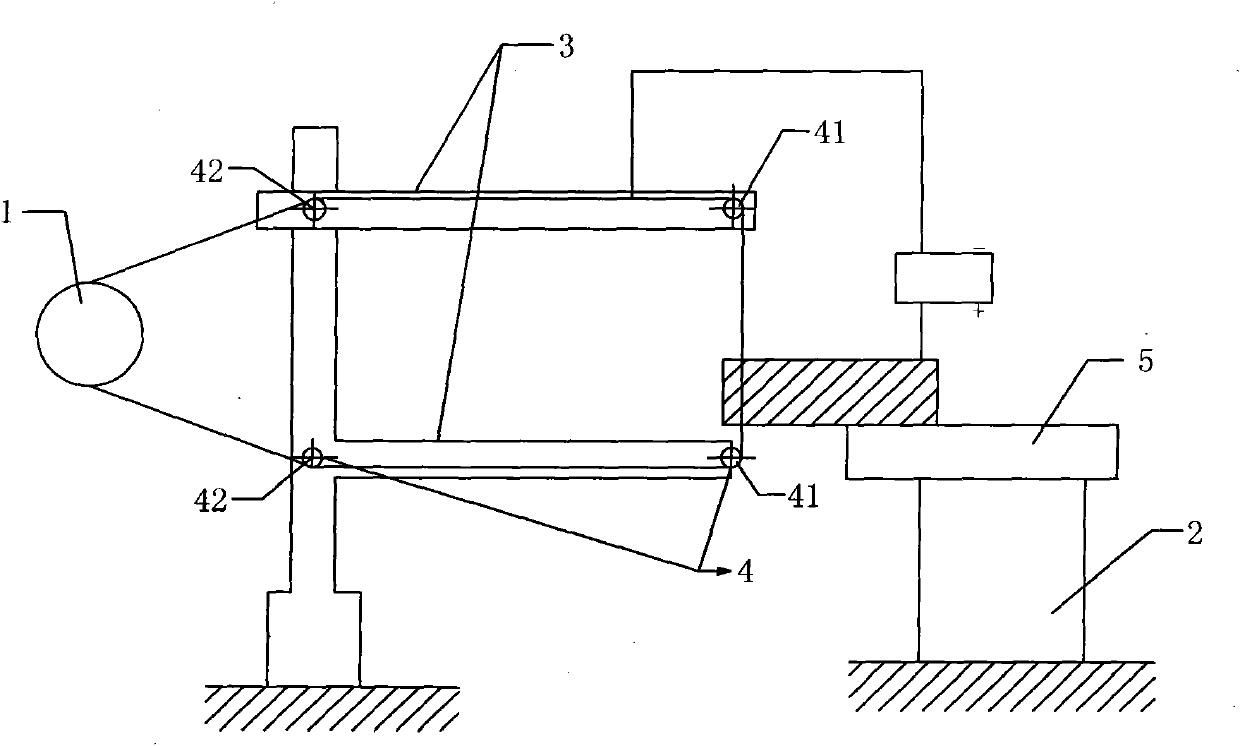

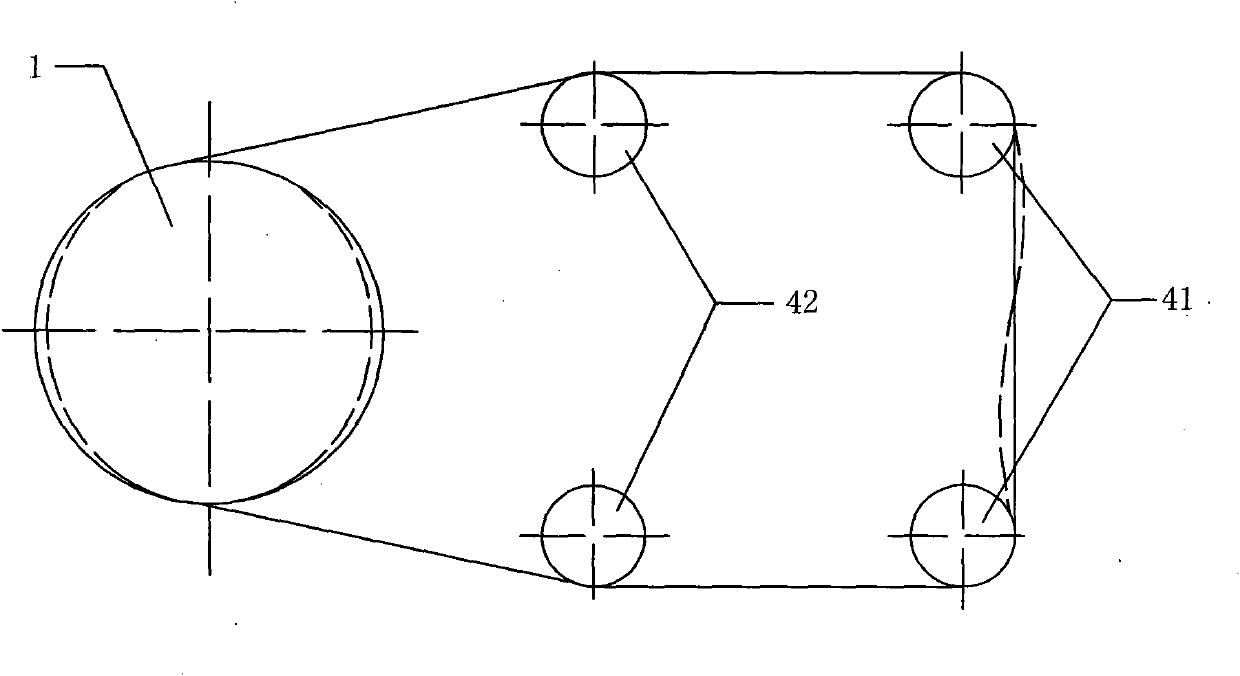

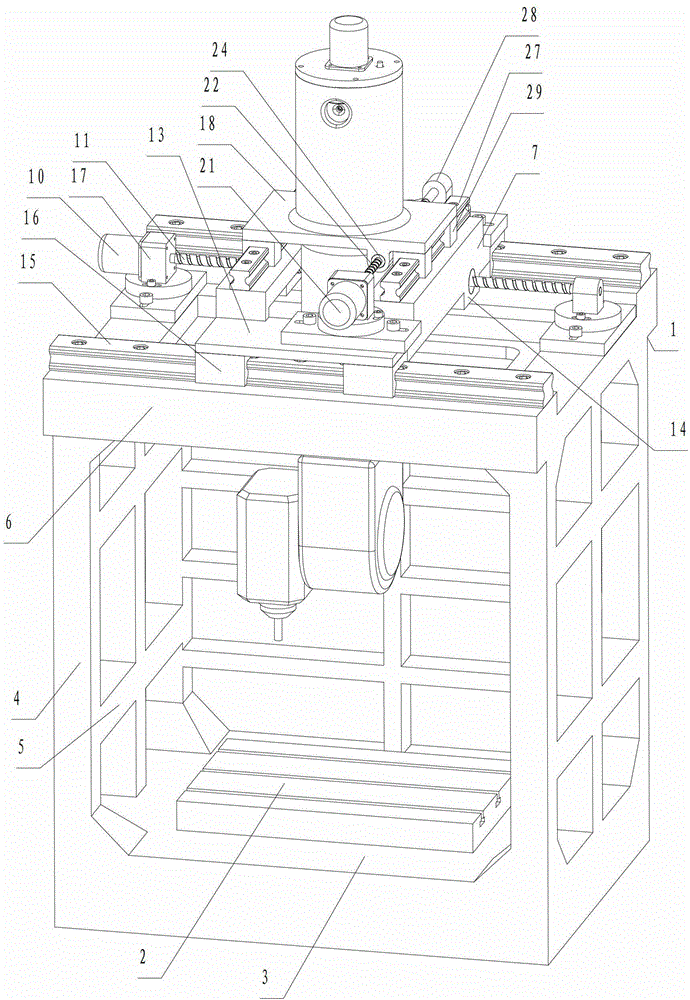

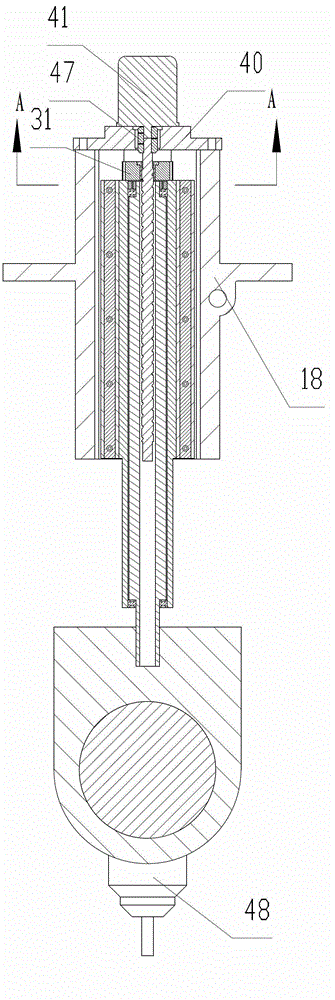

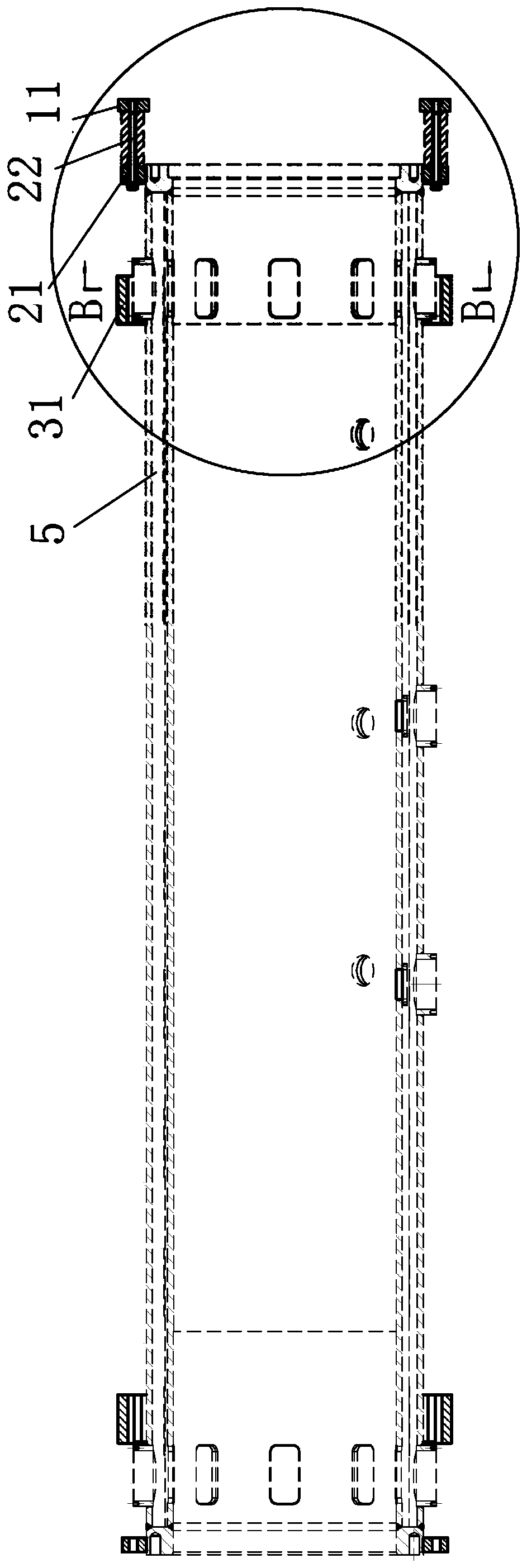

Numerical control equipment, machining process, numerical control production line and automatic article storage system

InactiveCN102528567AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersProduction lineNumerical control

Numerical control equipment comprises a main frame, a workpiece clamping device, an X-directional sliding seat, a first driving device, Y-directional sliding seat, a second driving device and a Z-directional guide device. The main support frame is of a closed-loop structure with a vertical opening; an X-directional front guide rail and an X-directional rear guide rail which are matched with each other are arranged between the main support frame and the X-directional sliding seat; the first driving device drives the X-directional sliding seat to move back and forth and comprises an X-directional lead screw positioned between the X-directional front guide rail and the X-directional rear guide rail; the second driving device drives the Y-directional sliding seat to move back and forth; the Z-directional guide device is mounted on the Y-directional sliding seat and comprises a Z-directional guide rod capable of vertically moving, and a third driving device for driving the Z-directional guide rod to vertically move; and a main machining head is arranged at the lower end of the Z-directional guide rod. The numerical control equipment has the advantages of fine stability, accuracy in positioning and smoothness in movement, and iron scraps falling after machining a workpiece basically cannot enter the guide rail above the machining head without special protection.

Owner:杨东佐

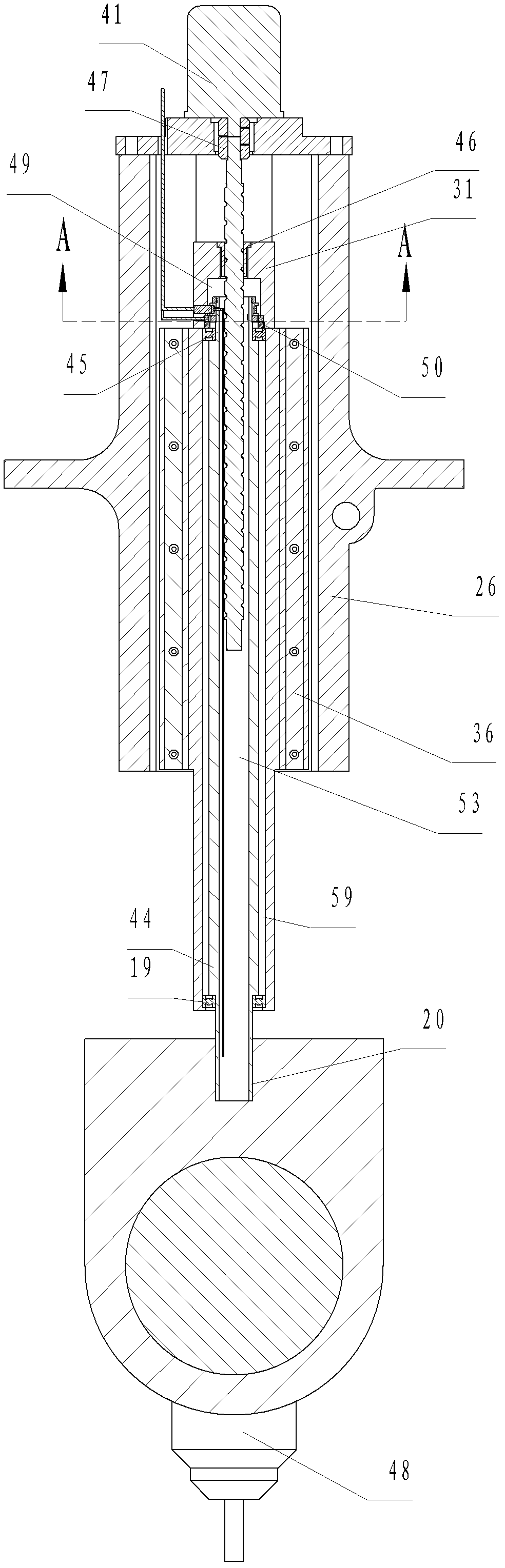

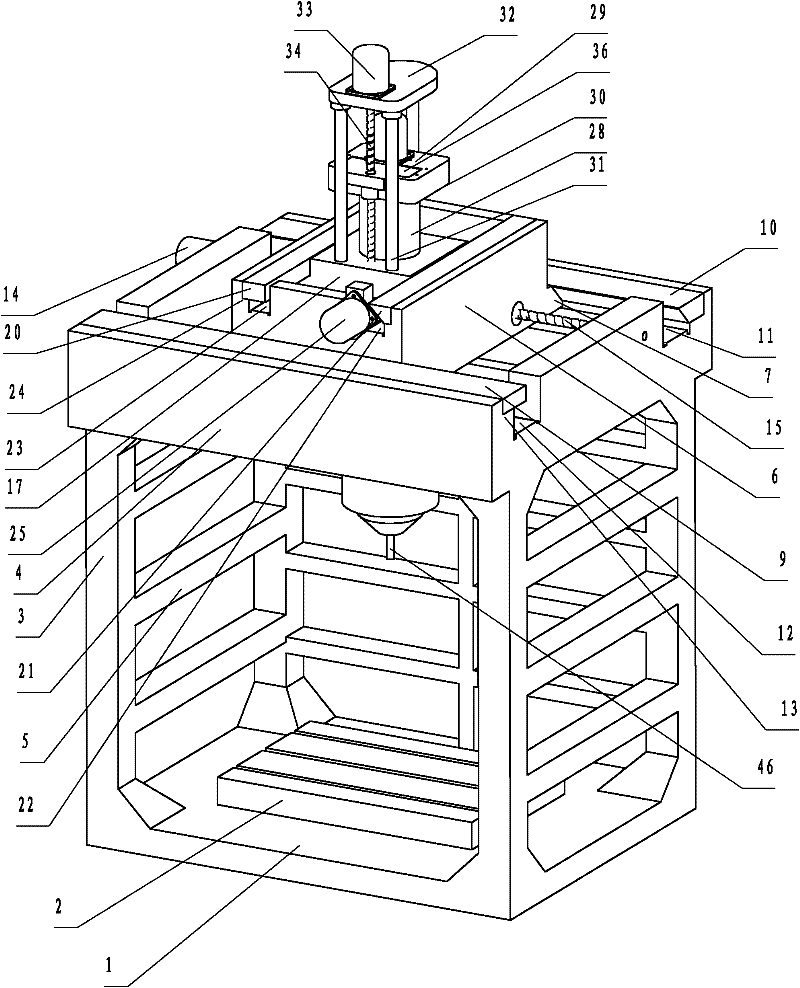

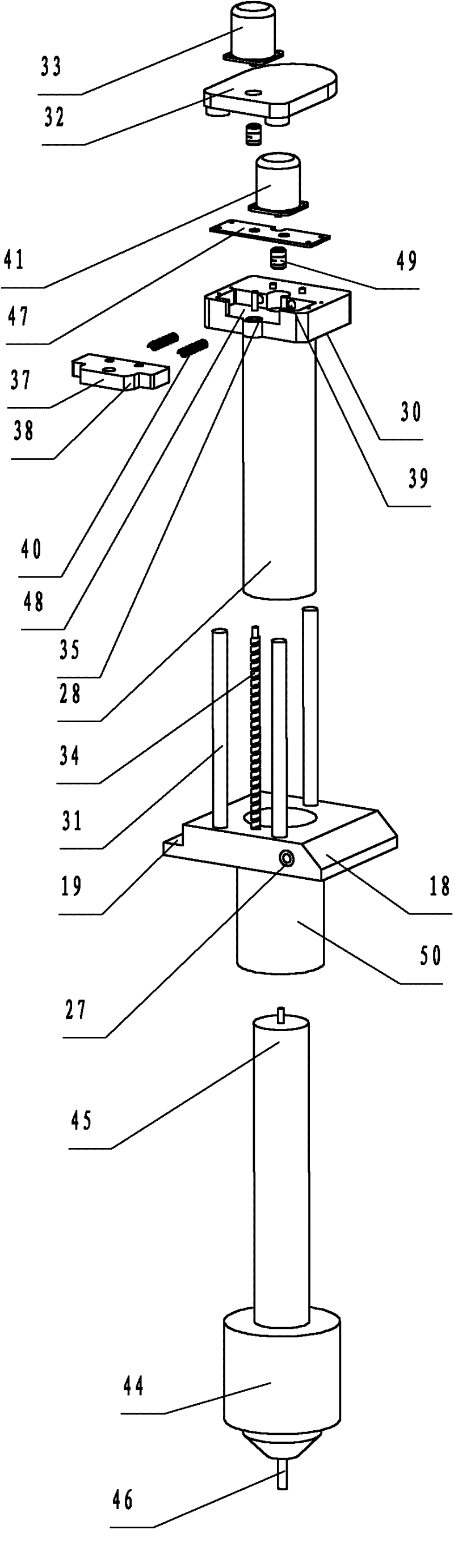

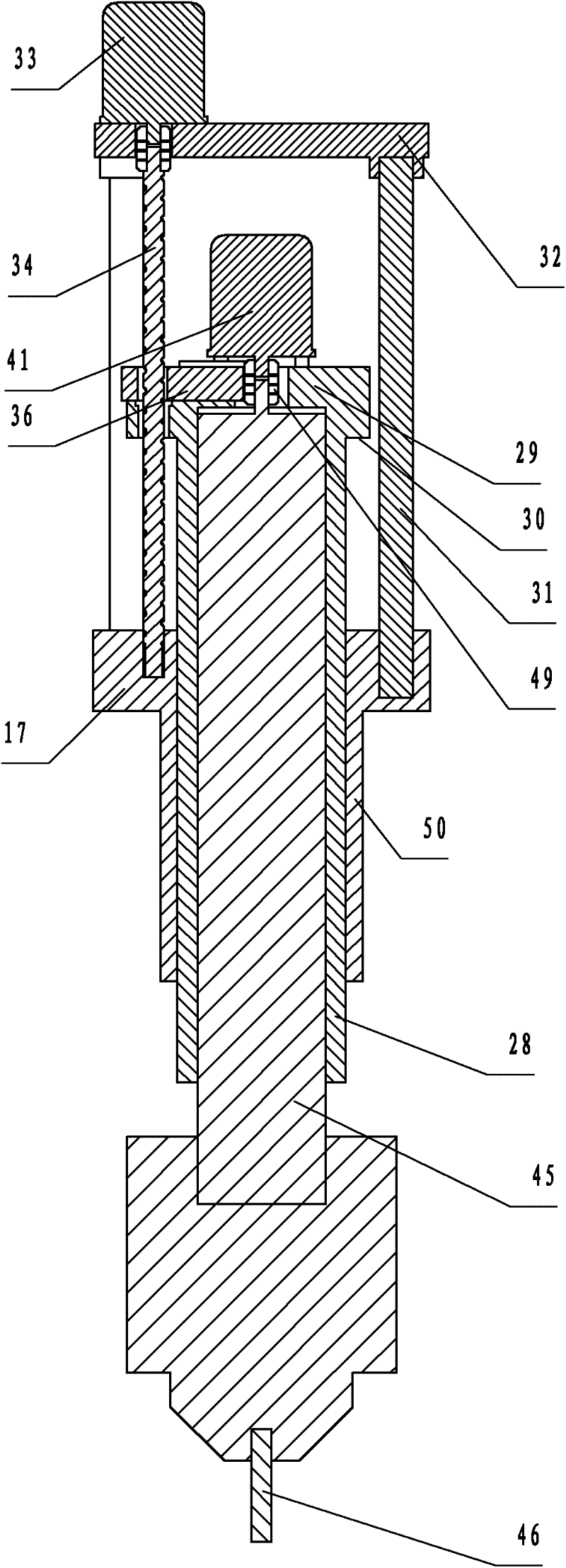

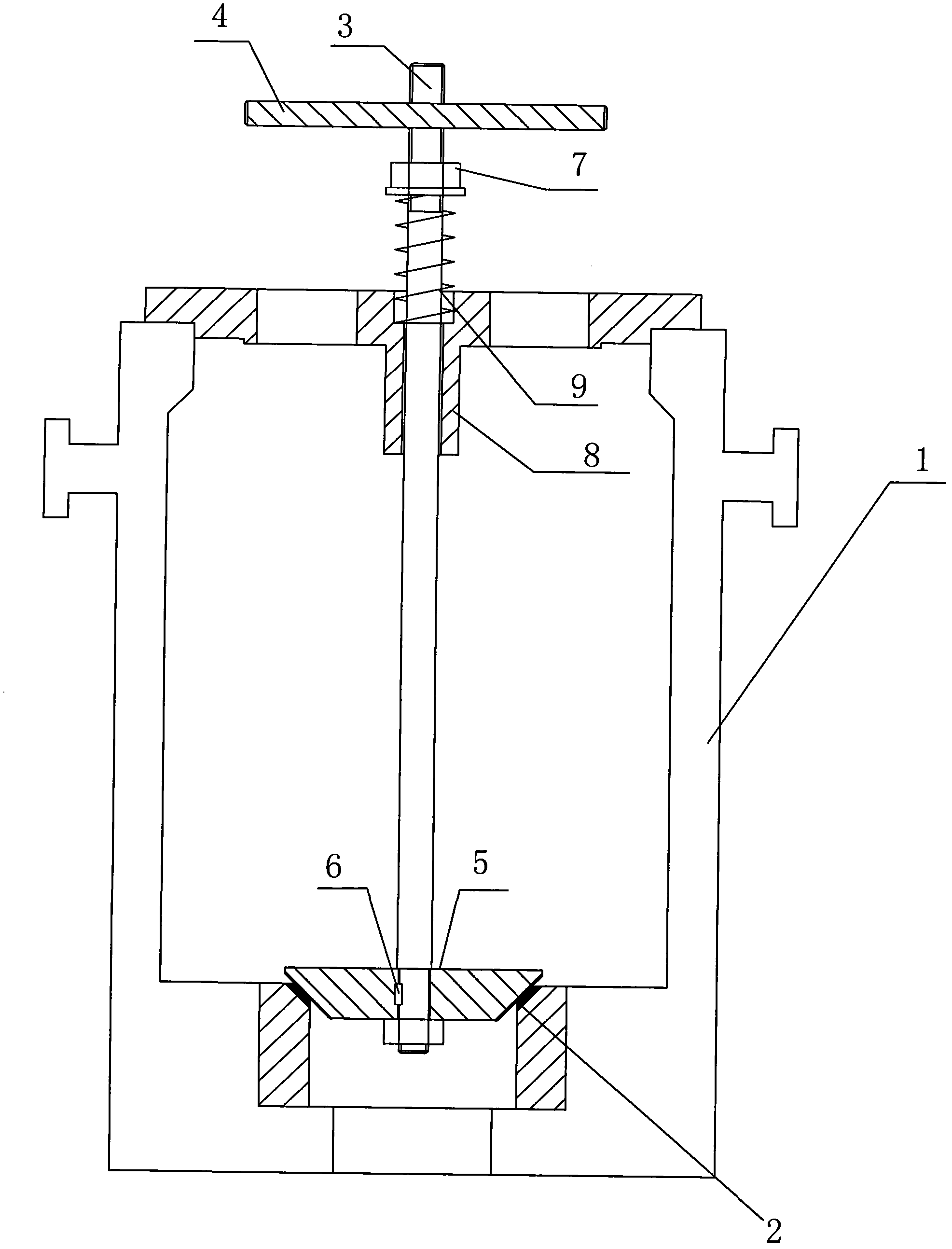

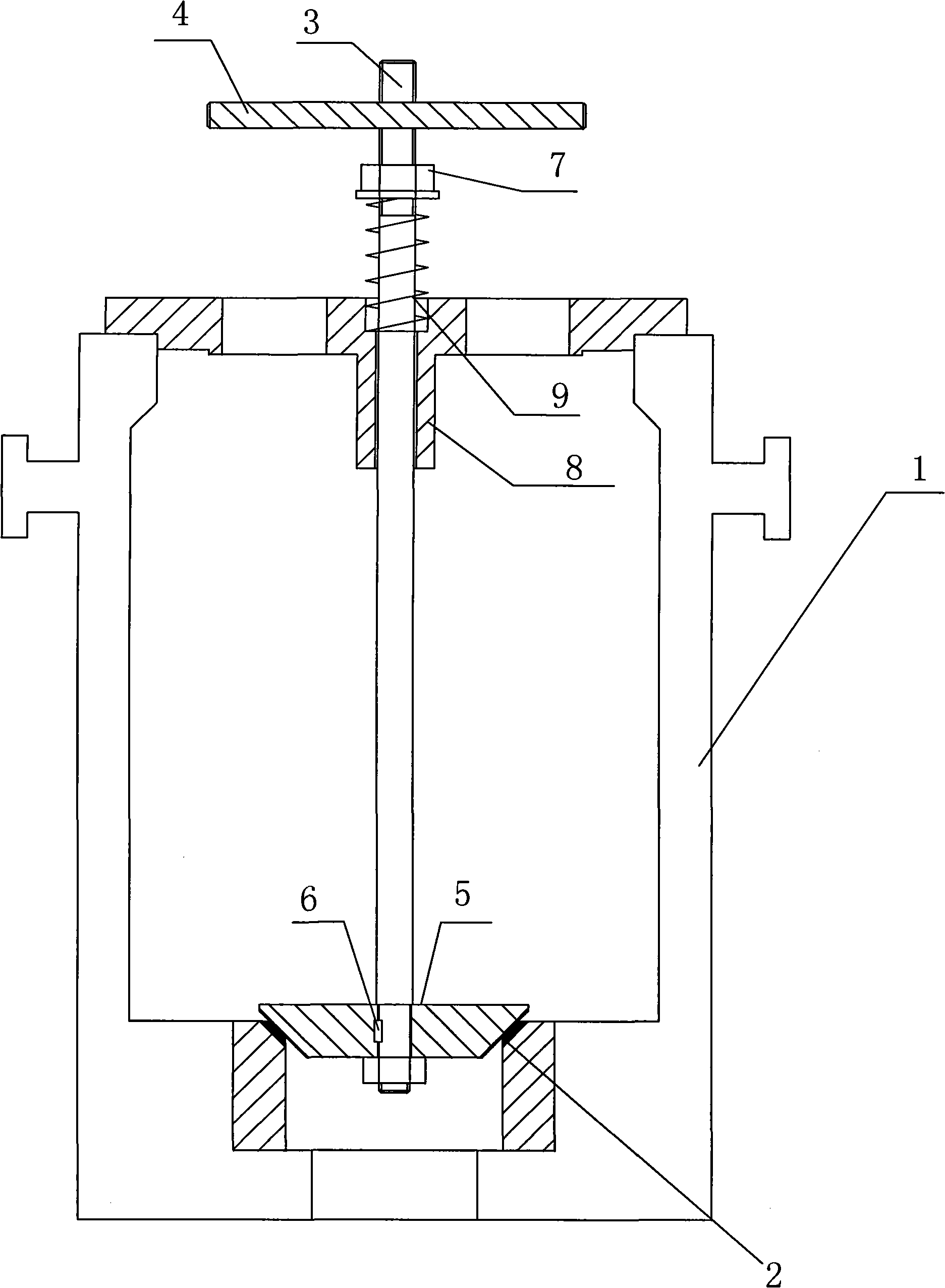

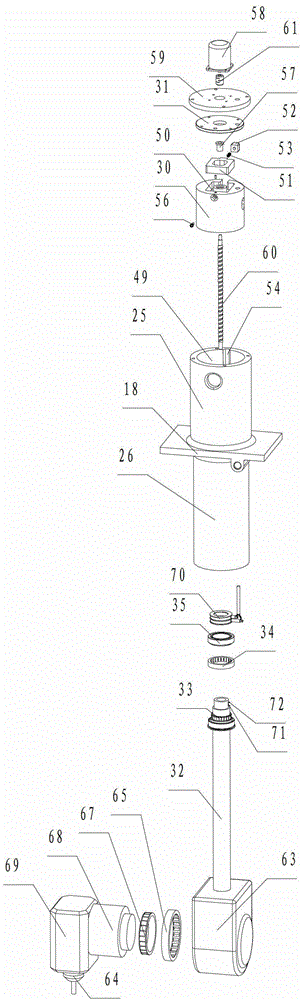

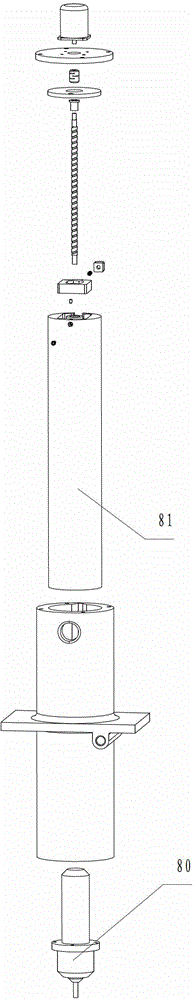

Grinding tool and grinding method for reheating main valve seat of steam turbine

InactiveCN101966686ASimple structureEasy to manufactureLapping machinesLapping toolsEngineeringCylinder block

The invention discloses a grinding tool for a reheating main valve seat of a steam turbine. The reheating main valve seat of the steam turbine comprises a cylinder body, wherein a conical valve port is formed at the bottom of the cylinder body. The grinding tool comprises a screw rod, wherein the top of the screw rod is provided with a handle, while the bottom is provided with a conical lapper; the conical lapper adapts to the conical valve port; the screw rod passes through a guide flange and is connected with the guide flange in a sliding way; a nut is arranged above the guide flange and is in threaded connection with the screw rod; and a spring is arranged between the nut and the guide flange. The guiding tool performs guide positioning on the screw rod by using the guide flange, so that the conical lapper and the conical valve port are matched with each other more tightly and better grinding effect is achieved. The length of the screw rod in the cylinder body can be adjusted conveniently through the spring and the nut, so that the conical lapper is prevented from being collided with the grinding surface of the conical valve port and the conical valve port is prevented from being damaged. The invention has the advantages that: the grinding tool has a simple structure, is convenient to manufacture, and is reliable and practical.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

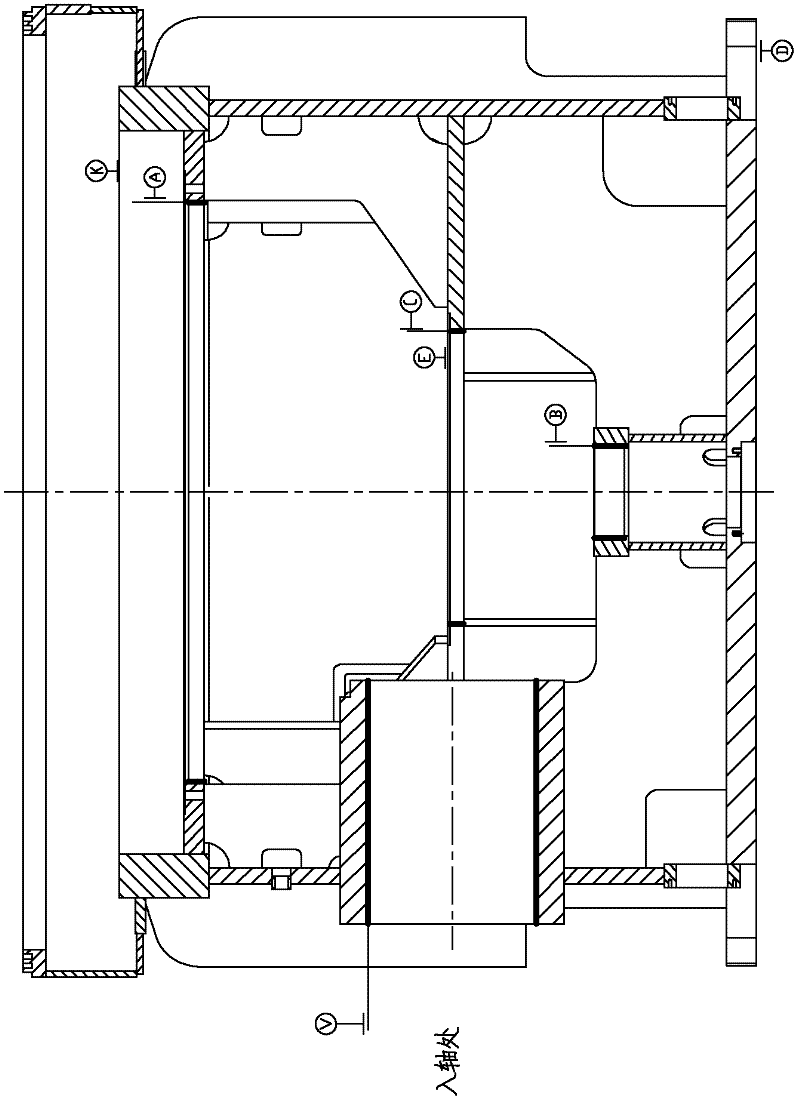

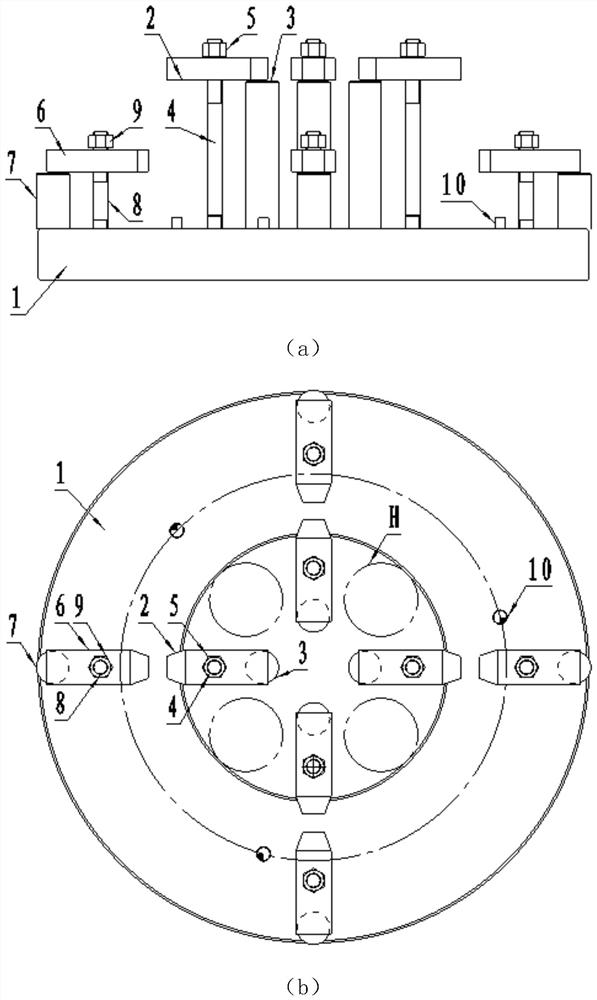

Special clamp for motor shell macropore series for fine boring rail train

InactiveCN102091806AEliminate freedom of movementEliminate deficienciesPositioning apparatusBoring/drilling componentsEngineeringDimensional precision

The invention discloses a special clamp for a motor shell macropore series for a fine boring rail train. The special clamp comprises a base, a supporting post, a positioning clamping plate and a tightening bolt; the upper end face of the positioning clamping plate is provided with a positioning seam allowance, a positioning plane and a tightening fixing hole; the positioning seam allowance is matched with a phi 465mm hole on a workpiece end face A; the tightening fixing hole corresponds to a mounting screw hole on a workpiece to be processed; the positioning clamping plate is fixed on the base through the supporting post; and the workpiece is fixed on the upper end face of the positioning clamping plate through the tightening bolt. The end face A, the phi 465mm hole on the face and a lateral surface B are adopted for positioning, and the workpiece is clamped by the tightening bolt 4, so the workpiece is positioned accurately and installed stably; axial tightening and fixing are performed by using a direct screwing mode of the tightening bolt and the existing screw hole on the workpiece, and the magnitude of the tightening force does not generate stress deformation in the radial direction of the processed pore series so as to ensure the dimensional precision and the form and position precision of the processed pore series.

Owner:CHANGZHOU HUADE MACHINERY

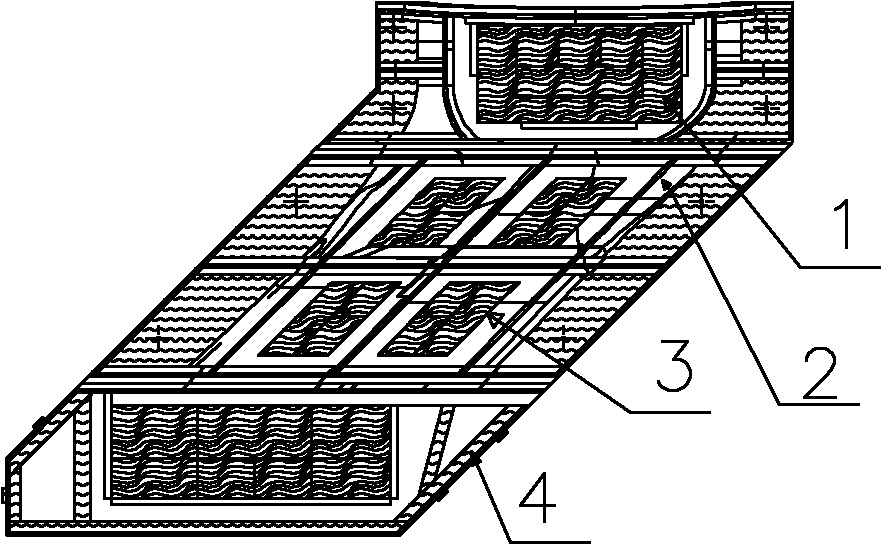

Manufacturing process of high-precision extrusion die for DeNOx catalyst

ActiveCN102039519AGuaranteed surface roughnessGuaranteed shape and position accuracySurface roughnessMachining process

The invention discloses a manufacturing process of a high-precision extrusion die for a DeNOx catalyst. The manufacturing process comprises the following steps: discharging, thermal refining, grinding, rough machining, grinding, boring holes, semi-fine grinding, thermal treatment, groove linear cutting, benching, fine grinding and protective treatment. In the process, by means of the methods such as reasonable control of machining amount, reasonable selection of equipment parameters and the like in the steps, the surface roughness, the dimensional precision and the form and position accuracy of holes (grooves) of machined parts of the extrusion die with multiple deep holes (grooves) for the catalyst are effectively ensured, wherein, the machining precision reaches 0.01mm, and the surface roughness reaches over Ra0.8; the machining process is stable and reliable; the qualification rate of the die product reaches over 99%; and the difficulty in manufacturing the complicated die with the multiple deep holes (grooves) is overcome. Compared with the prior art, the manufacturing process disclosed by the invention has the advantages of effectively avoiding scrap caused by size and location out-of-tolerance, greatly lowering production cost, improving machining efficiency and shortening production cycle.

Owner:CHONGQING YUANDA CATALYST MFG

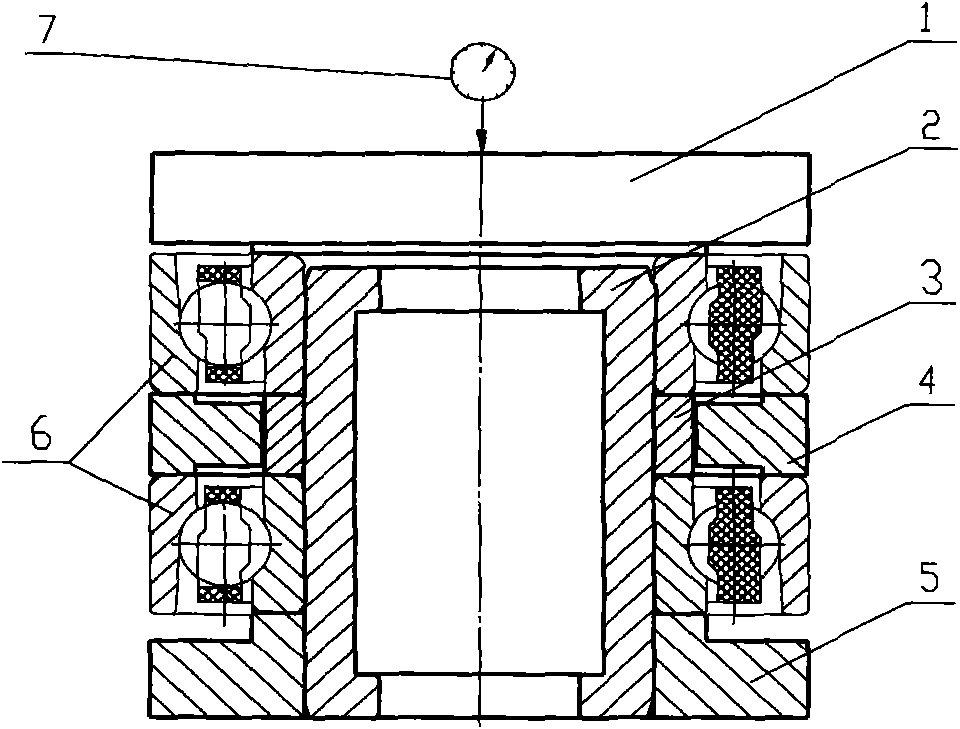

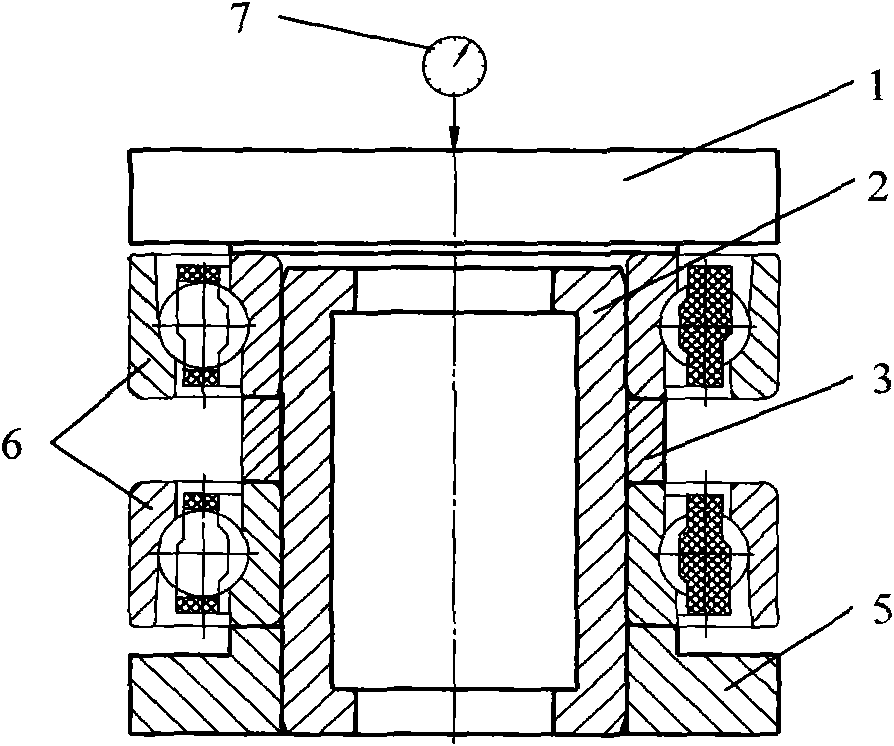

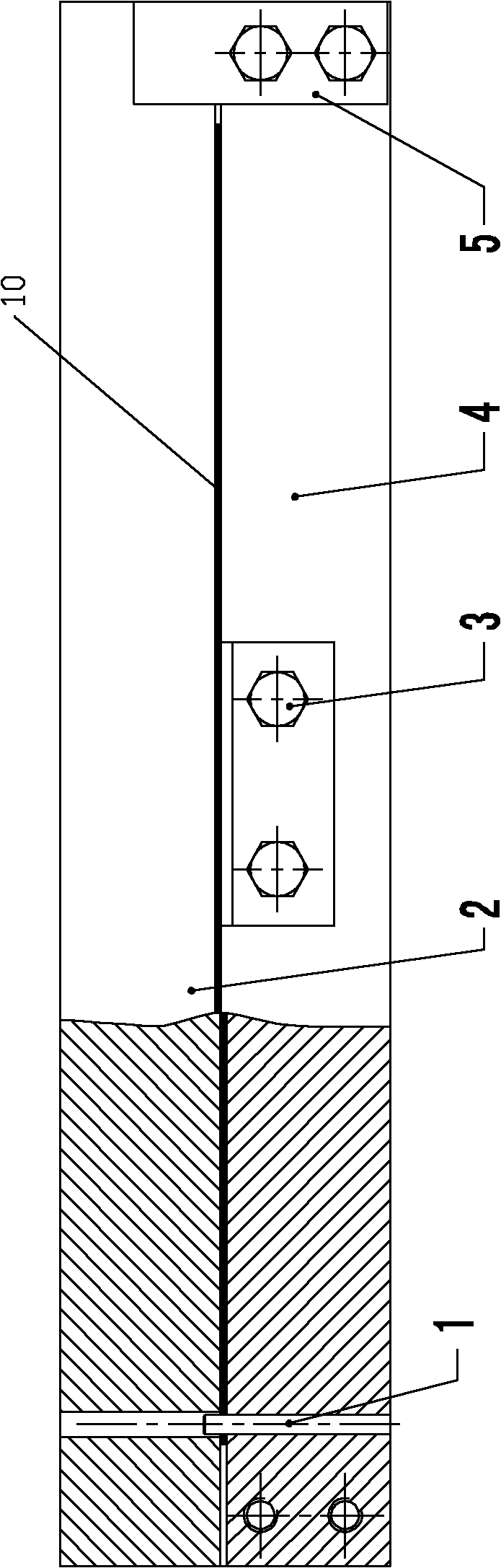

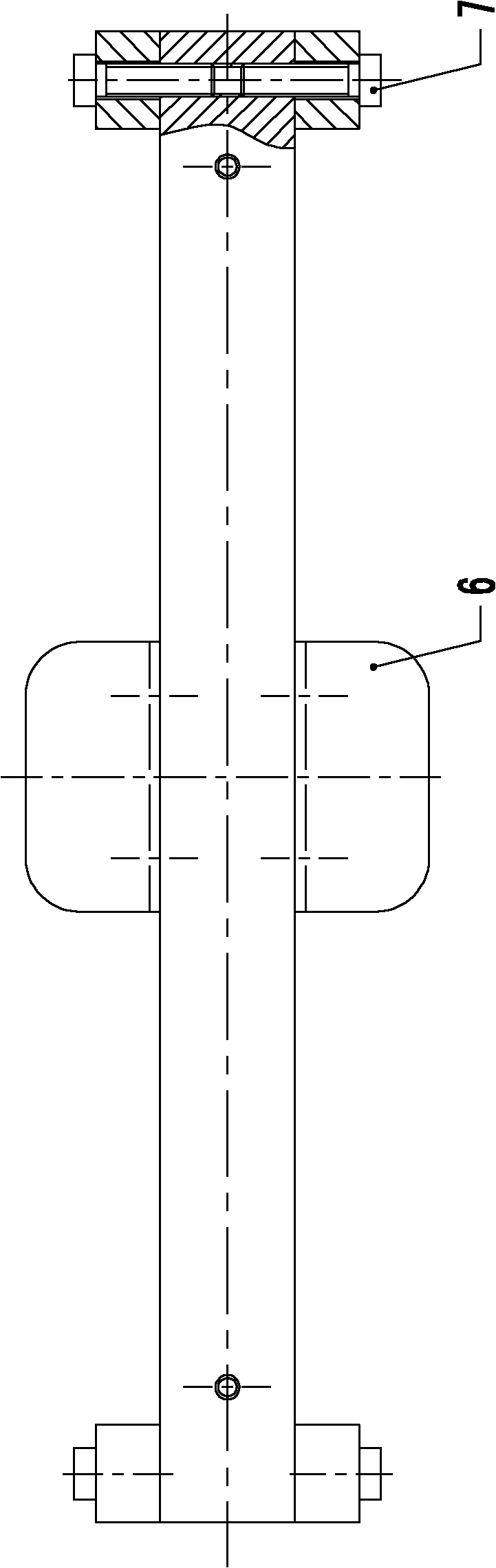

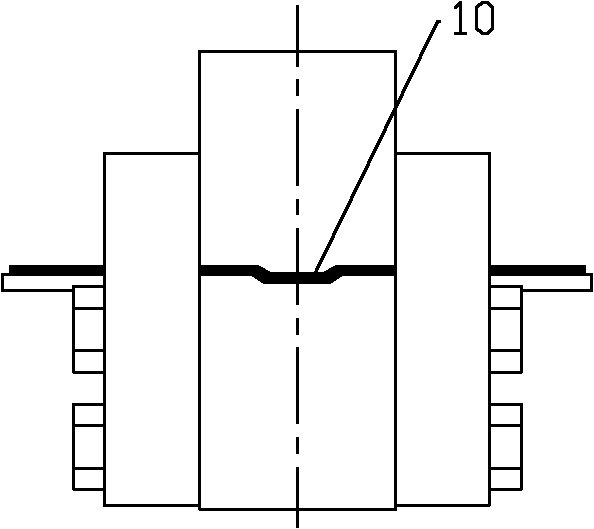

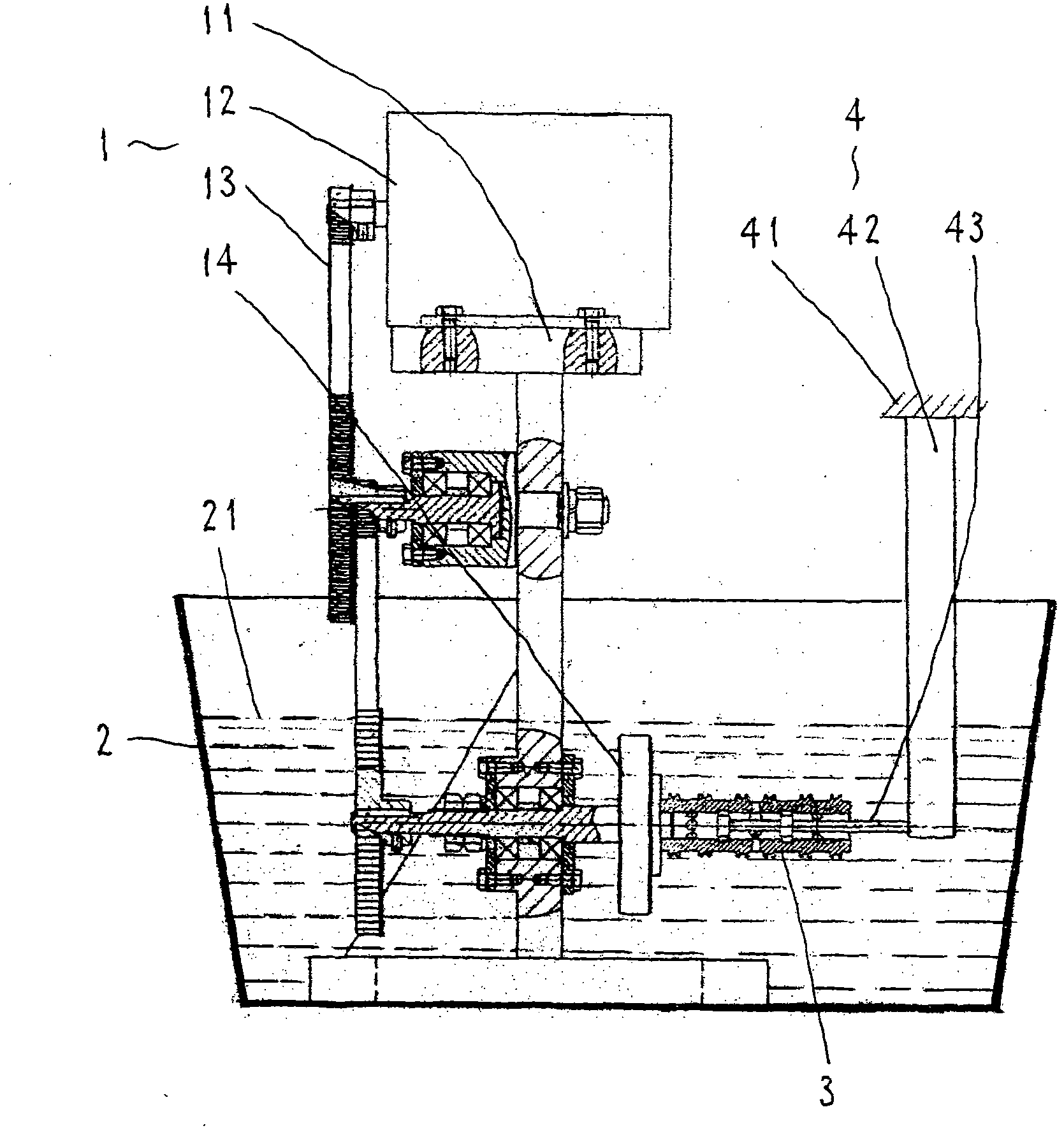

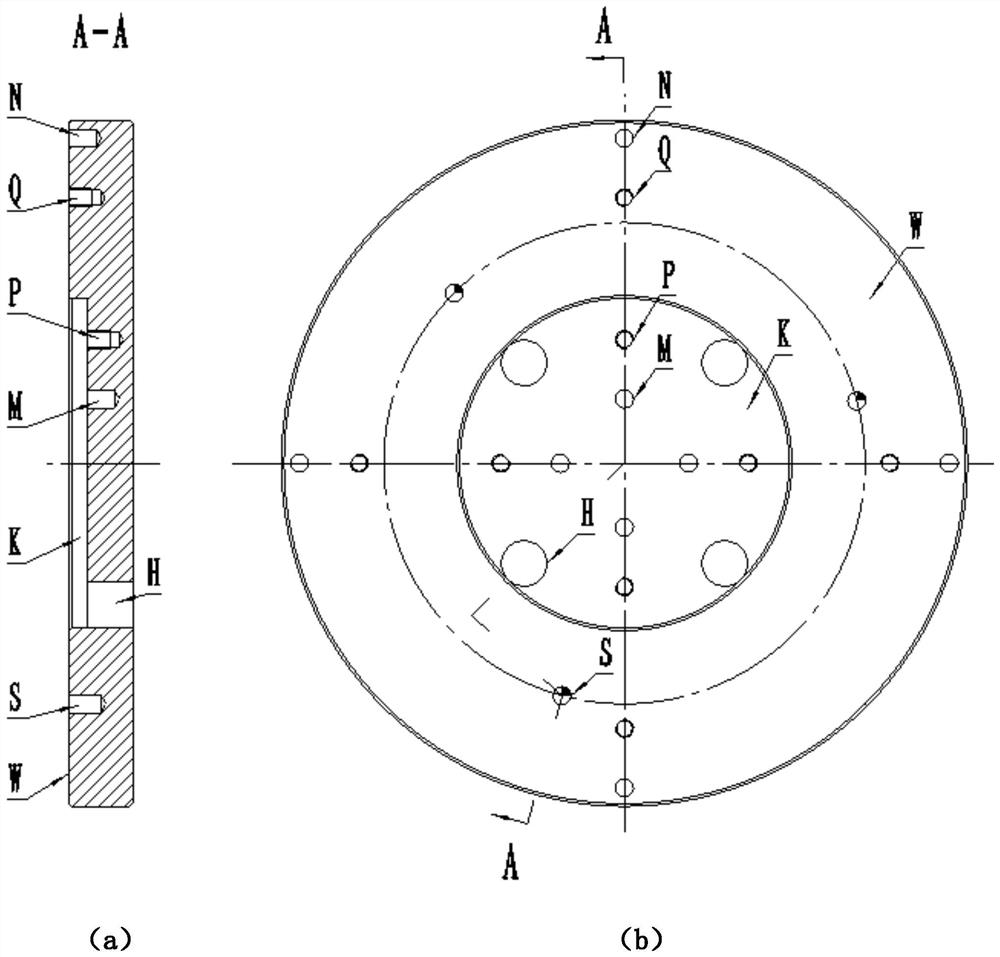

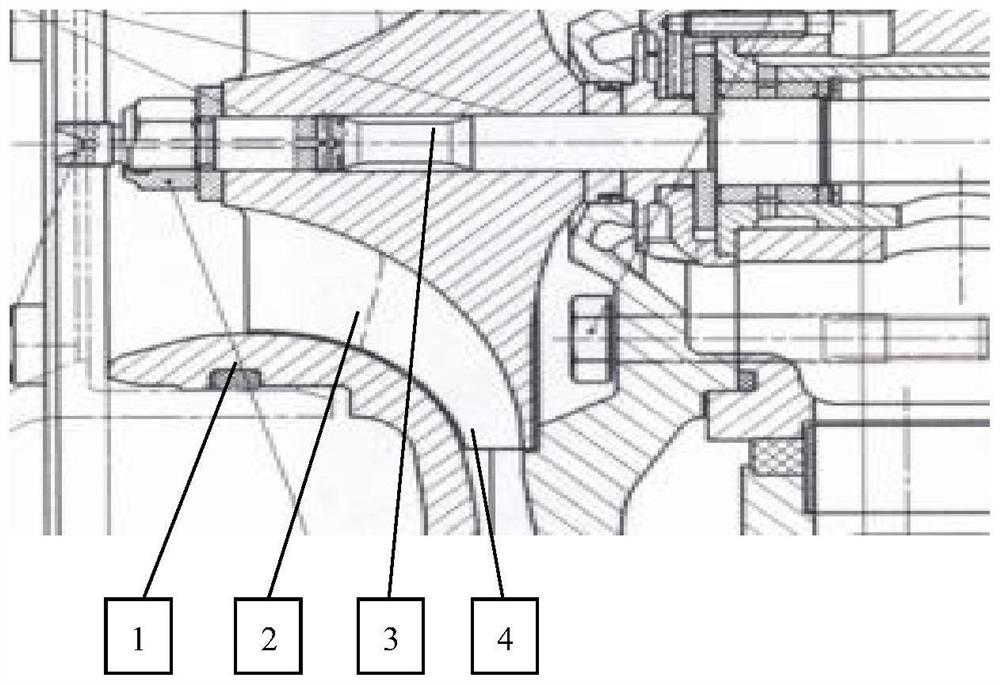

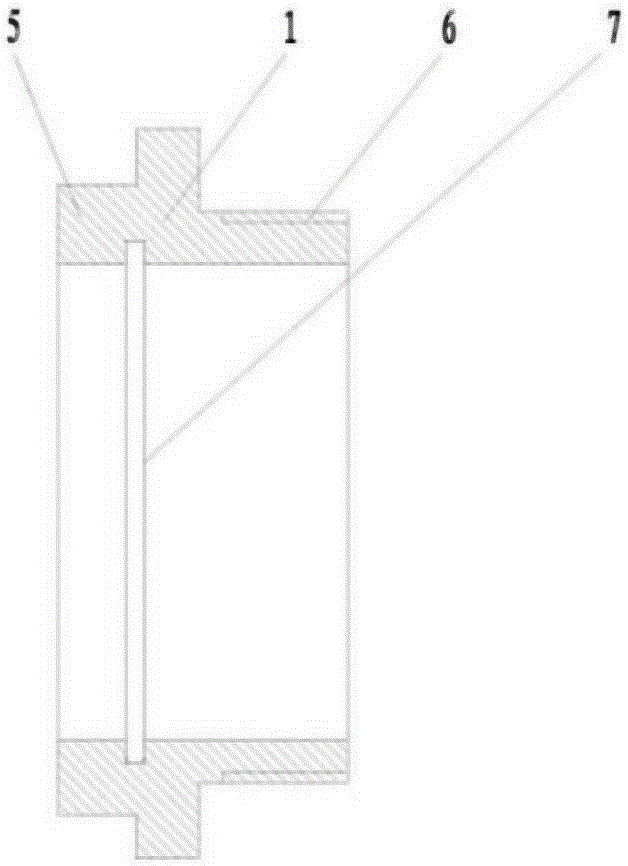

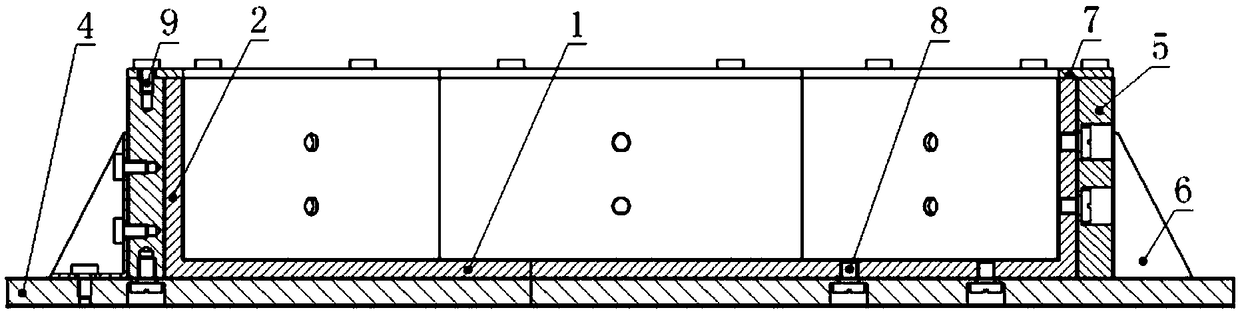

Device for measuring axial internal clearance of matched angular contact ball bearing

ActiveCN102022965AEasy to operateEasy to processMechanical clearance measurementsBall bearingMeasuring instrument

The invention discloses a device for measuring the axial internal clearance of a matched angular contact ball bearing, which relates to the technical field of bearing performance detection. The device comprises a load block (1), a centering sleeve (2), an inner space ring (3), an outer space ring (4), a washer (5) and a measuring instrument (7), wherein the centering sleeve (2) is arranged on a platform of the measuring instruments (7), the washer (5) is sleeved on the centering sleeve (2), measured bearings (6) are sleeved on the centering sleeve (2), the lower surfaces of the inner rings ofthe measured bearing (6) are supported by the washer (5), the load block (1) is arranged on the measured bearing (6), the inner space ring (3) is connected with the inner rings of the two measured bearings (6), and the outer space ring (4) is connected with the outer rings of the two measured bearings (6). The device provided by the invention has the advantages of simple structure, low cost, and high accuracy, and is convenient in operation, therefore, the device is suitable for the bearing processing factories in various sizes.

Owner:WAFANGDIAN BEARING GRP CO LTD

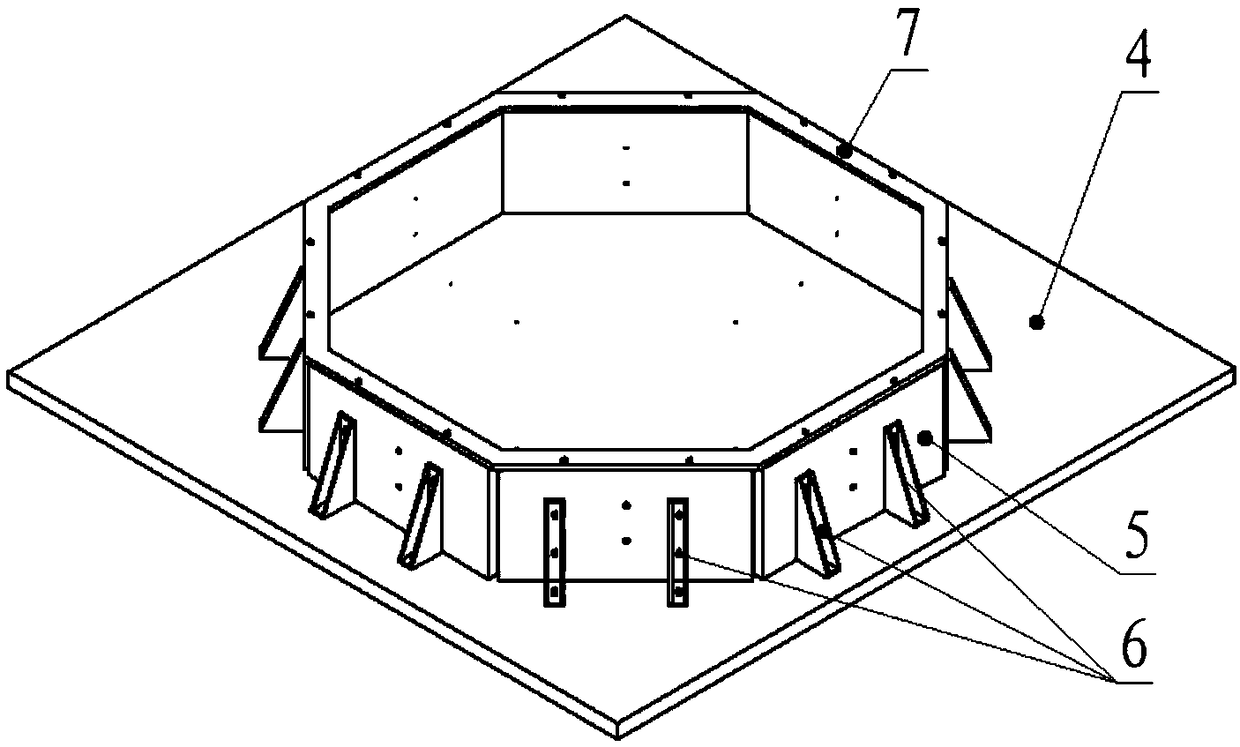

Silencer support frame welding mold

InactiveCN102328166AReduce or even eliminate additional stressEliminate additional stressWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses a silencer support frame welding mold, which comprises a bottom plate, a silencer positioning assembly and a silencer support frame positioning assembly, wherein the silencer positioning assembly comprises an exhaust pipe positioning assembly and a silencer casing positioning assembly, the silencer support frame positioning assembly comprises a positioning guide plate and a moving pin assembly, and a silencer support frame is aligned with a welding point of a silencer casing through being positioned behind a moving pin. The silencer support frame welding mold adopts a multi-point fast positioning structure and comprises the exhaust pipe positioning assembly, the silencer casing positioning assembly and the support frame positioning assembly, and in addition, the fast driven moving positioning structure is combined, so the welding positioning process is standardized, the form and position accuracy of the welding processing can be ensured, the work efficiency is improved, the additional stress after the installation of a silencer is reduced or even eliminated, the service life is prolonged, the work intensity of operators is reduced, and the production cost and use cost are saved.

Owner:CHONGQING BEIBEI DISTRICT FENGHUO MACHINERY MFG

Machining method of coarse pitch threads

InactiveCN102778861AUnique process methodGuaranteed shape and position accuracyProgramme controlThread cutting machinesSurface smoothnessMathematical model

The invention relates to a machining method of threads, in particular to the machining method of coarse pitch threads. The machining method comprises the following steps of building a right-angle trapezoidal thread finish machining outline and rough machining outline mathematical models; designing cutter paths according to the physical dimension of a designed non-standard cutter; building a numerical control macroprogram by applying the rough machining outline and cutter path mathematical models, selecting appropriate cutting parameters according to tool nose fillet radius R0.8 and combining with actual machining equipment and building a numerical control macroprogram by applying thread right-angle side finish machining outline and cutter path mathematical models, mathematical models right-angle sides by repeatedly feeding, and adopting sample plate and feeler gauge detection until required accuracy is achieved; and adjusting numerical control macroprogram contents, using the sample plate and feeler gauge to detect in a matched mode and completing machining of right-angle trapezoidal thread slope side according to machining results. The machining method is unique in process method, capable of effectively guaranteeing thread accuracy of forms and positions and surface smoothness, improving processing efficiency and shortening machining period.

Owner:KOCEL GROUP +1

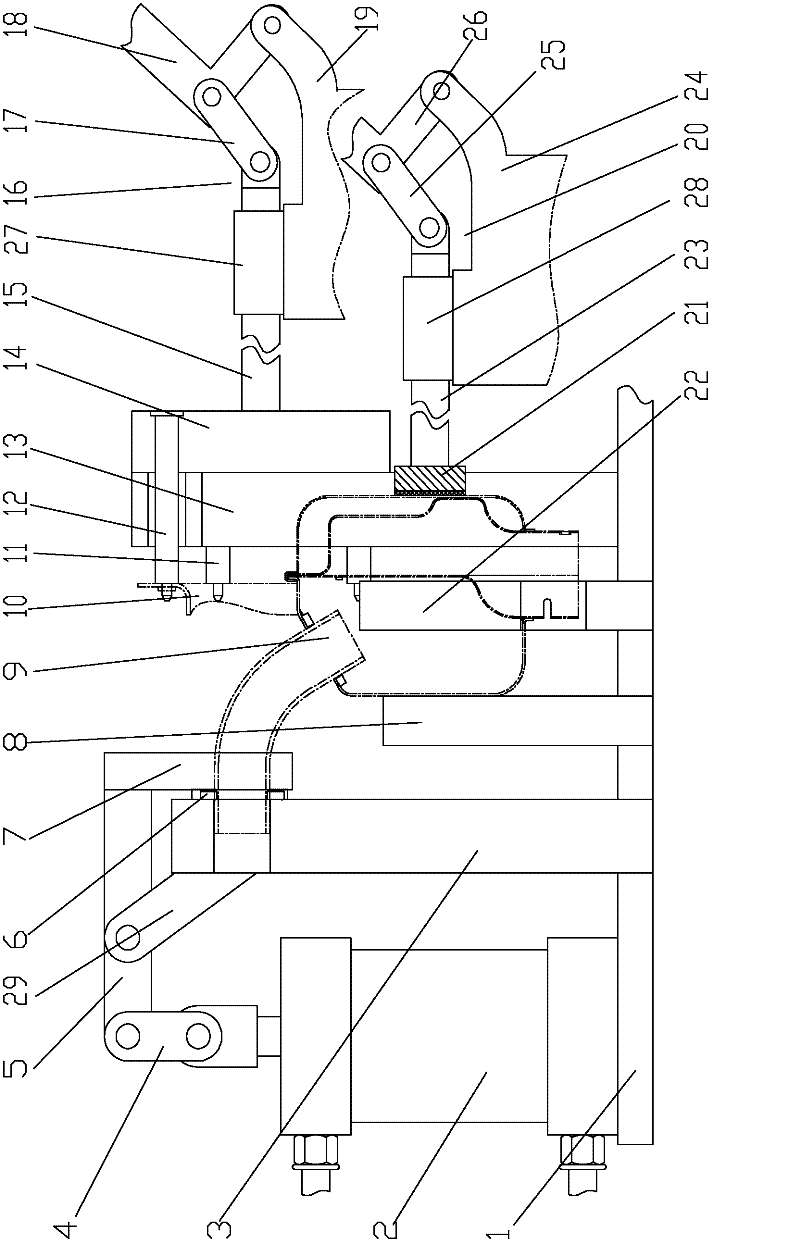

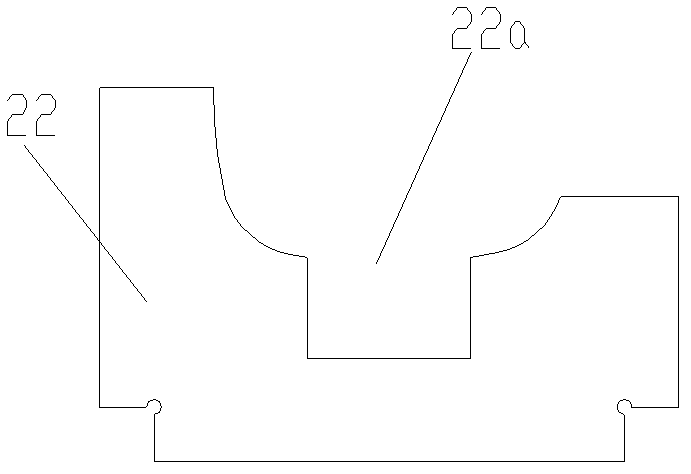

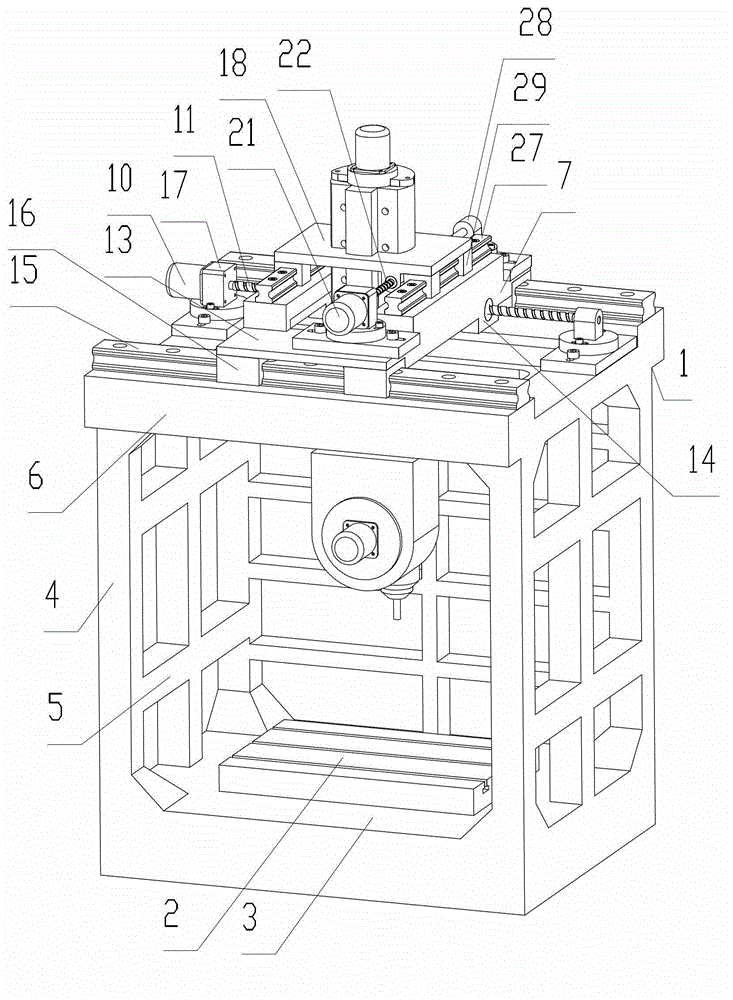

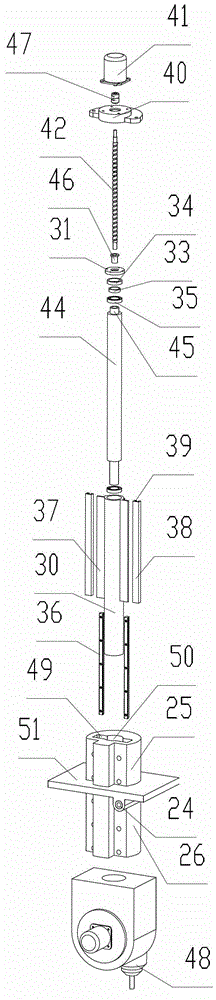

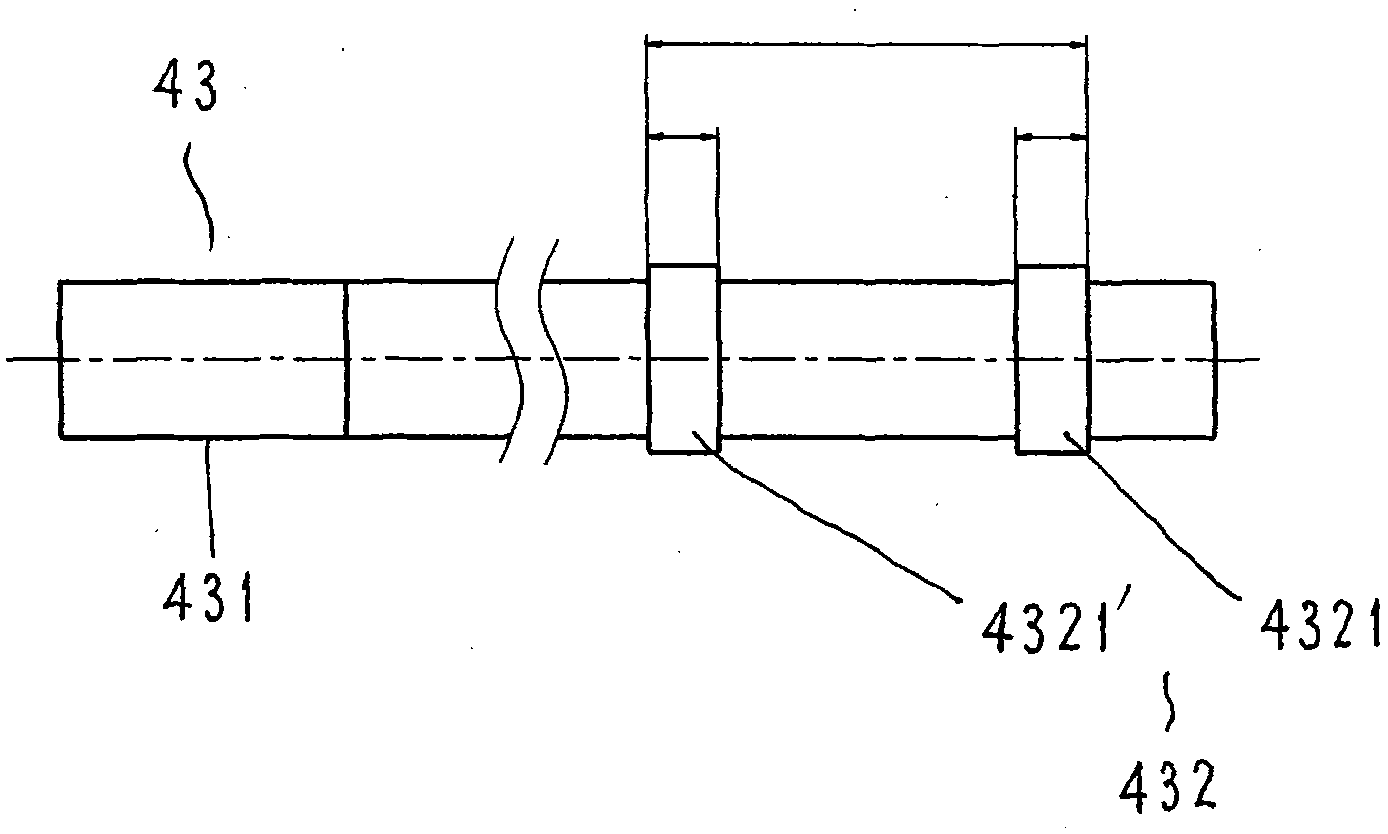

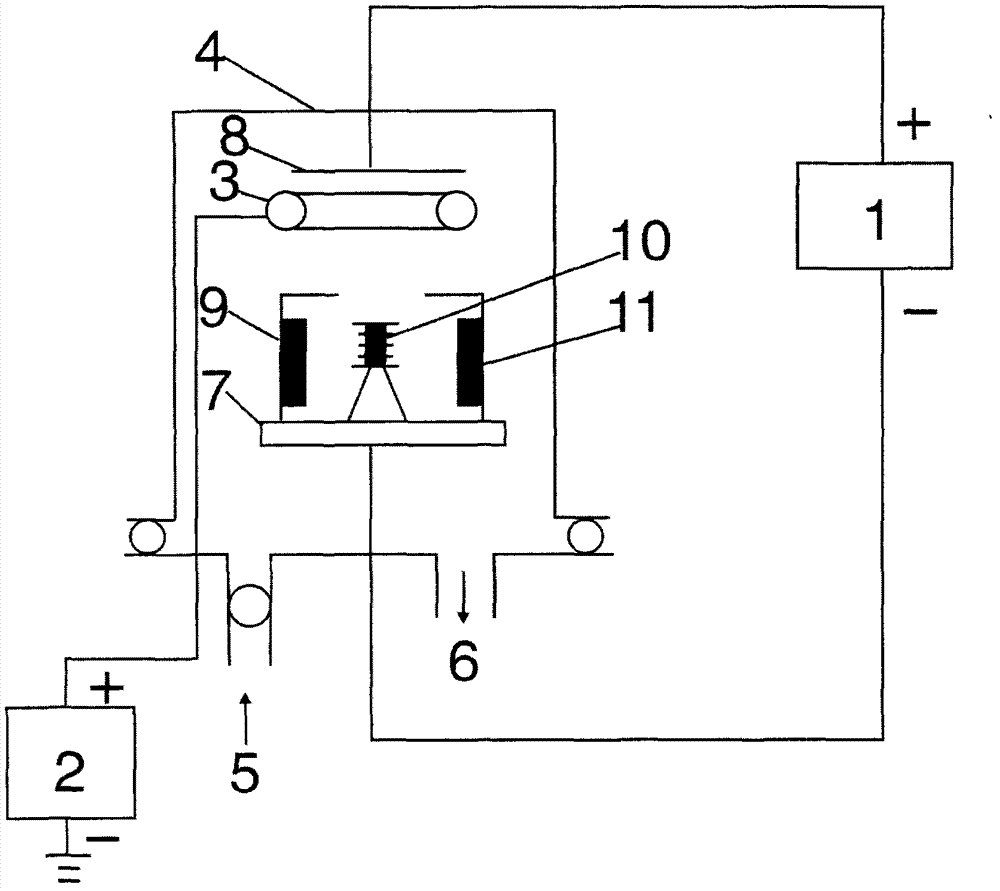

Numerical control equipment

InactiveCN102528568AGuaranteed shape and position accuracyImprove carrying capacityFeeding apparatusLarge fixed membersNumerical controlEngineering

Numerical control equipment comprises a Z-directional guide device, a sliding seat, a sliding seat fixing device, a sliding seat driving device, a workpiece clamping device, a main machining head and an electric control device. The Z-directional guide device is mounted on the sliding seat comprising a sliding seat bottom plate and a U-shaped part arranged on the sliding seat bottom plate; the Z-directional guide device comprises a Z-directional guide rod and a Z-directional guide rod driving device; two first Z-directional linear guide rails are fixedly arranged on a Y-directional sliding seat while second Z-directional linear guide rails are arranged on the Z-directional guide rod; the Z-directional guide rod can only be vertically and movably mounted together with the Y-directional sliding seat; and a main machining head is arranged below the Z-directional guide rod. By means of matching the first Z-directional linear guide rails with the second Z-directional linear guide rails to realize Z-directional guide, guide effects are fine, and the Z-directional guide rod no longer needs a rotation stop structure. When the first Z-directional linear guide rails and the second Z-directional linear guide rails are abraded, only the first Z-directional linear guide rails and the second Z-directional linear guide rails need to be replaced, while the Z-directional guide rod is not needed to be replaced.

Owner:杨东佐

Medium-speed wire cutting method based on high-speed wire cutting machine tool

InactiveCN102019472AGuaranteed shape and position accuracyHigh cutting size accuracyWire cuttingEngineering

The invention relates to a medium-speed wire cutting method based on a high-speed wire cutting machine tool, which is characterized in that the high-speed wire cutting machine tool used as a carrier is modified into a medium-speed wire cutting machine tool. The method comprises the following steps: (1) adjusting the cutting precision + / -0.03mm of a high-speed wire cutting machine tool into + / -0.01mm of a medium-speed wire cutting machine tool; (2) adjusting the cutting surface smoothness Ra3.2-1.6 of the high-speed wire cutting machine tool into Ra0.8; (3) adjusting the cutting speed 40-60mm<2> / min of the high-speed wire cutting machine tool into 120mm<2> / min; and (4) modifying the control system of the high-speed wire cutting machine tool into medium-speed wire cutting to form a multiple-time cutting control structure, thereby enhancing the precision and surface smoothness of the machined workpiece. The invention can control the cutting precision within the range of + / -0.01mm, thereby effectively enhancing the cutting precision; and the invention uses an alkaline cutting liquid as the working liquid for the high-speed wire cutting machine tool, thereby reducing the surface roughness of the machined workpiece.

Owner:广州市技师学院

Method for manufacturing space complicated curve surface core box mold

ActiveCN102430712AClever material selectionEasy to implementFoundry moulding apparatusRoughcastManufacturing efficiency

The invention relates to a mold manufacture method, in particular to a method for manufacturing a space complicated curve surface core box mold, which is applicable to ship support frames of deep water drilling ships and ocean exploration ships and is characterized in that the method comprises the following steps of: selecting materials, building a mold three-dimensional space model, manufacturing a main carrying steel frame, manufacturing a mold blank, processing the mold and carrying out mold detection. The method has the advantages that the method is unique, the intensity is high, the manufacture efficiency is high, the precision requirement of customers is met, the mold quality is improved, and in addition, the method is applicable to the ship support frames of the deep water drilling ships and the ocean exploration ships.

Owner:KOCEL EQUIP

Numerical control equipment

InactiveCN102941512AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersNumerical controlClosed loop

The invention provides numerical control equipment, wherein a main supporting frame is in a closed loop structure of which the opening faces the vertical direction; an X forward guide rail and an X backward guide rail which are matched with each other are arranged between the main supporting frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod; the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; a rotation stopping structure for preventing the Z-direction guide rod from rotating along the horizontal direction of the axis of the guide rod is also arranged; the rotation stopping structure comprises a third rotation stopping block, a fourth rotation stopping block, a third spring and a limit mechanism; an accommodation groove is formed in the top part of the Z-direction guide rod; the limit mechanism limits the third rotation stopping block and the fourth rotation stopping block to move in the setting range of the accommodation groove; a rotation stopping groove is formed in a guide hole matched with the Z-direction guide rod; the third spring is installed between the third rotation stopping block and the fourth rotation stopping block; and the third rotation stopping block protrudes from the outer periphery of the Z-direction guide rod and is matched with the rotation stopping groove. The numerical control equipment has the advantages that when a main processing head moves up and down, the stability is good and the imbalance torsion is not easy to generate.

Owner:杨东佐

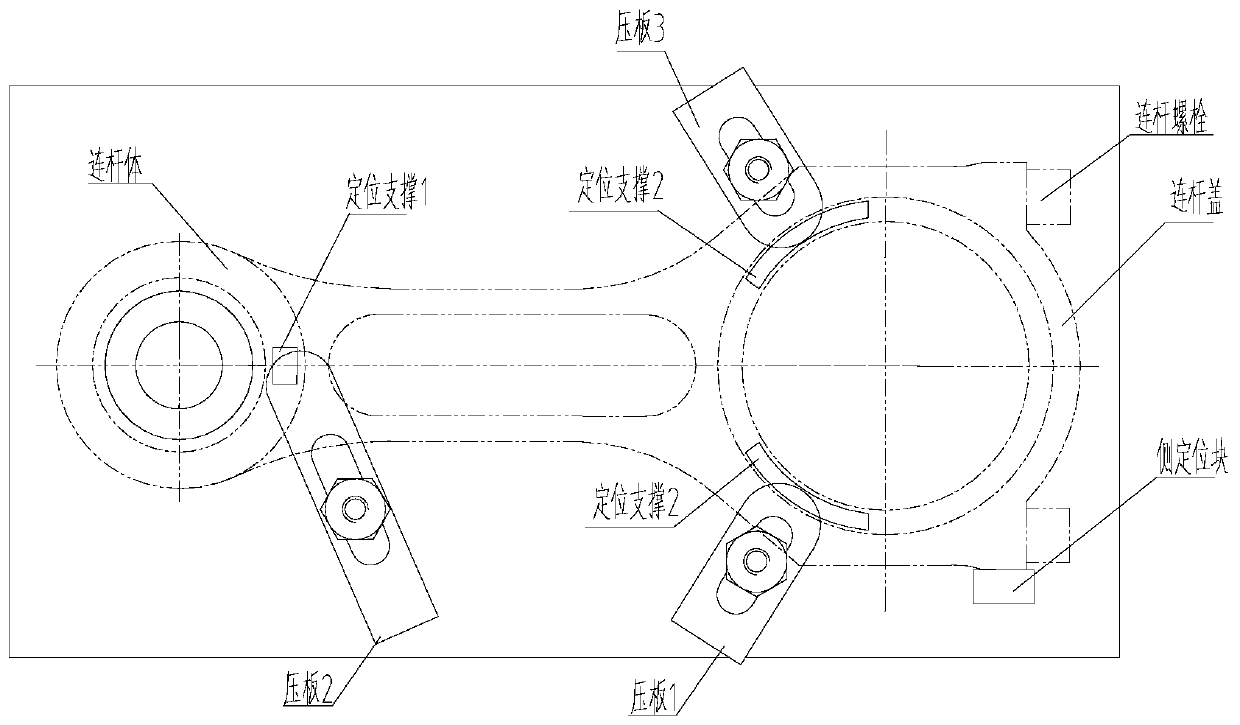

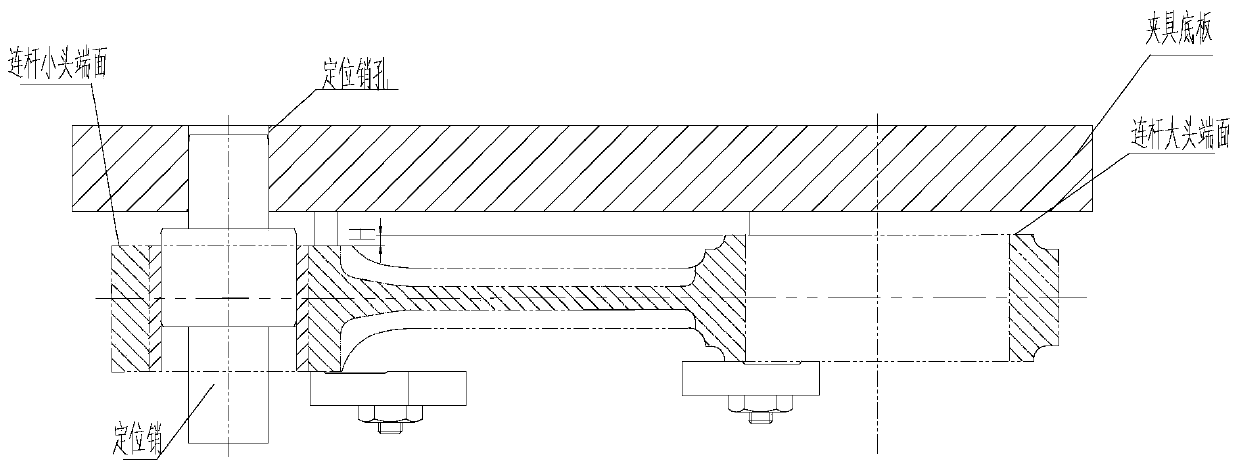

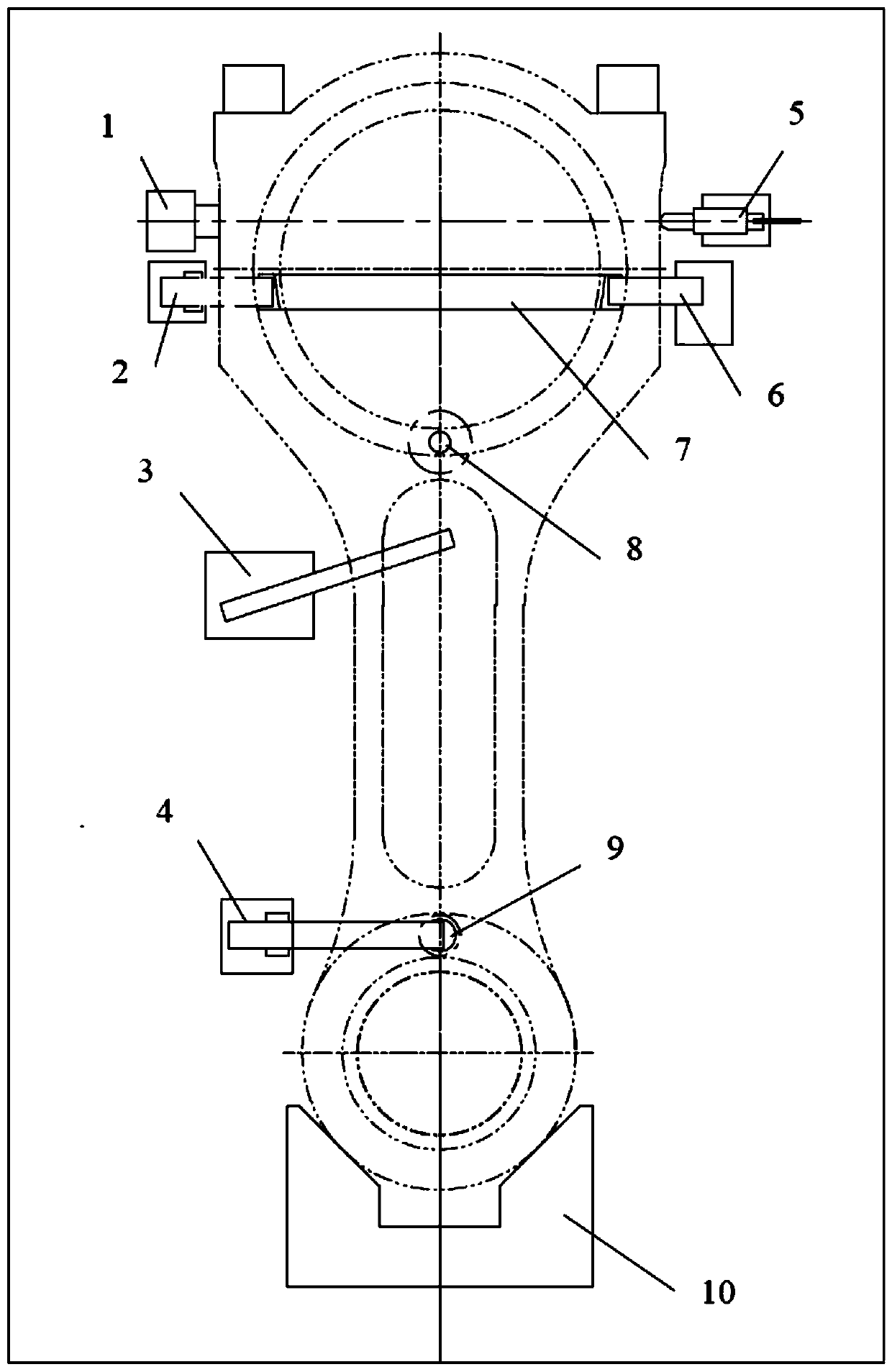

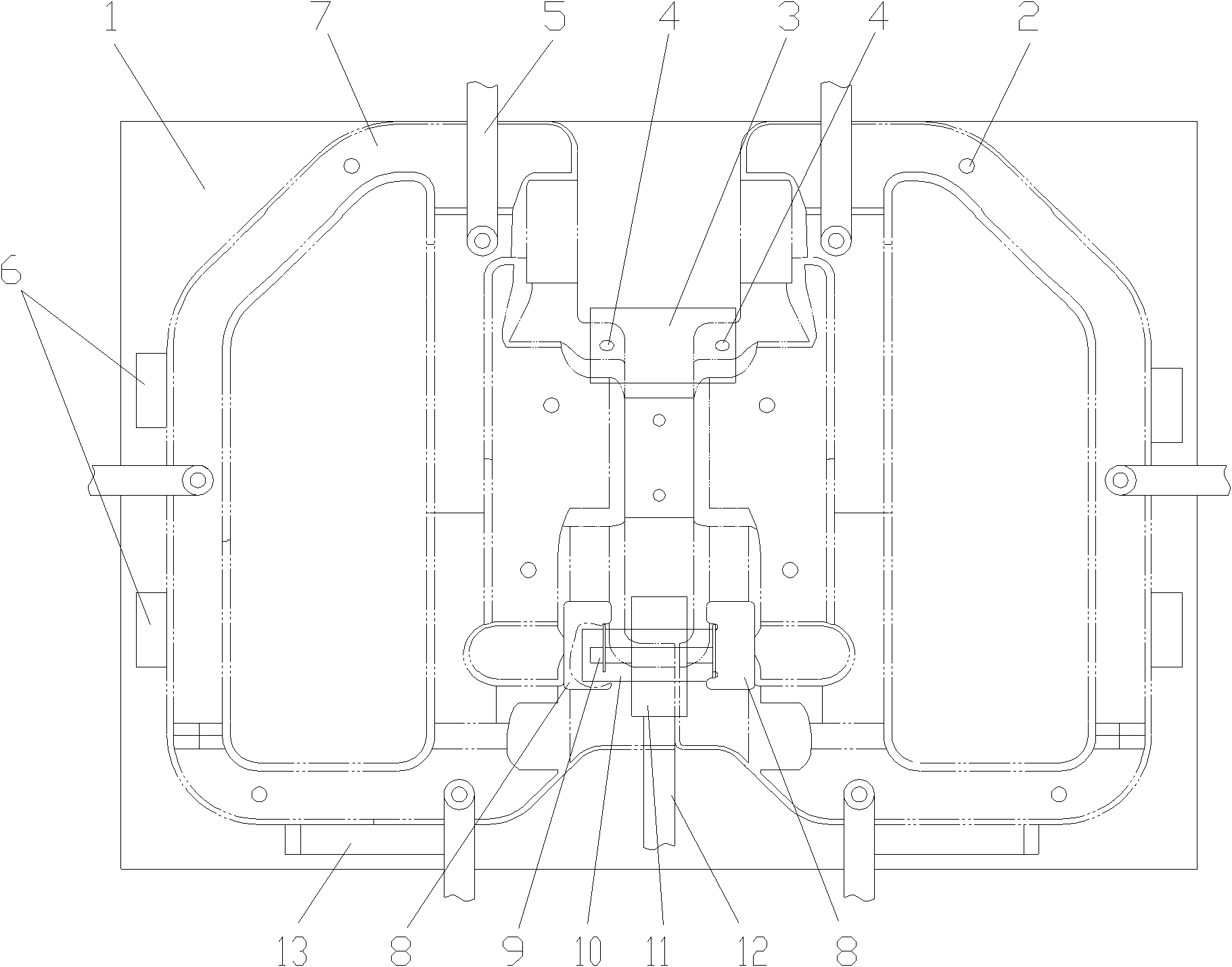

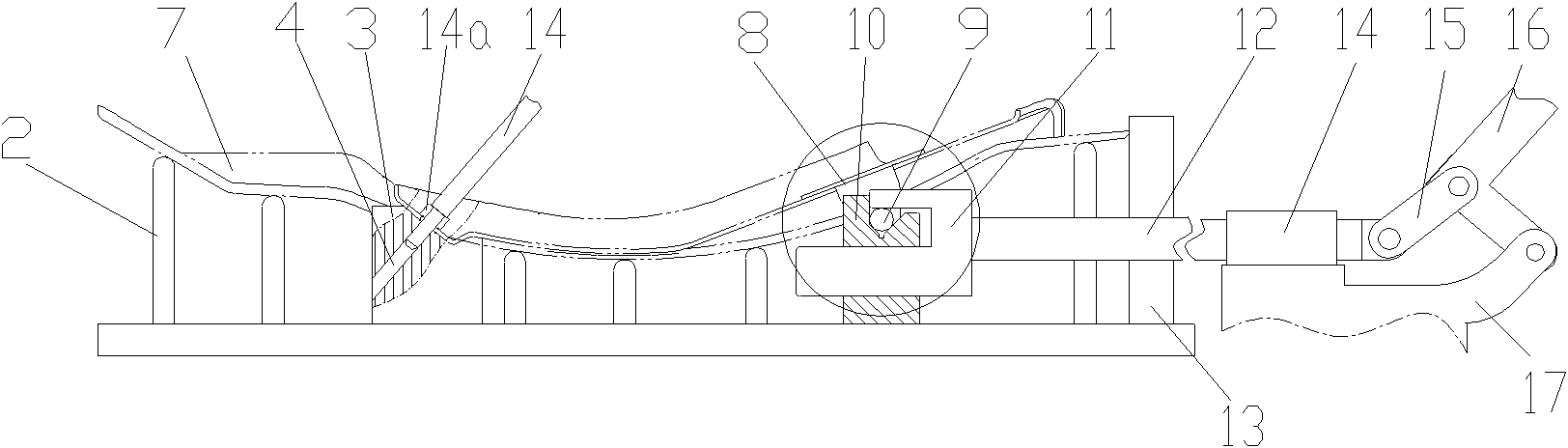

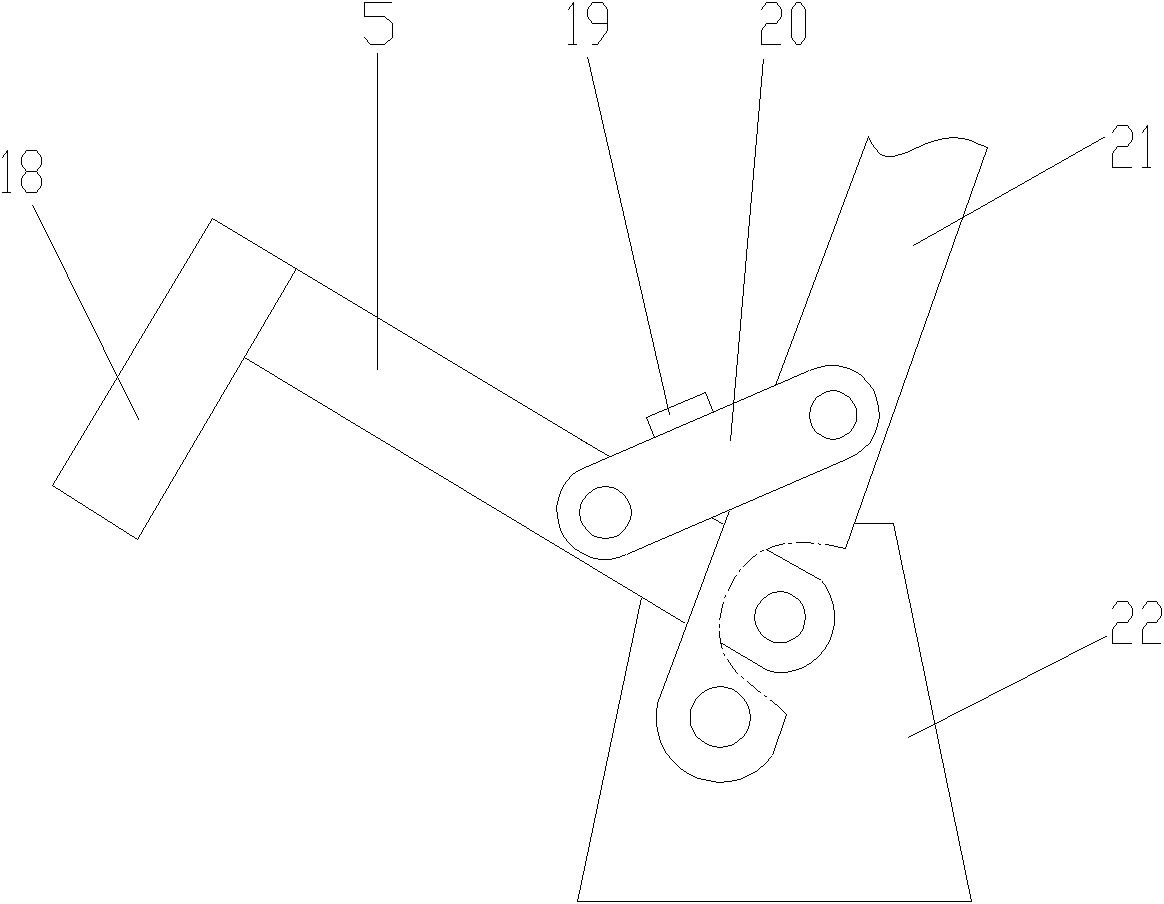

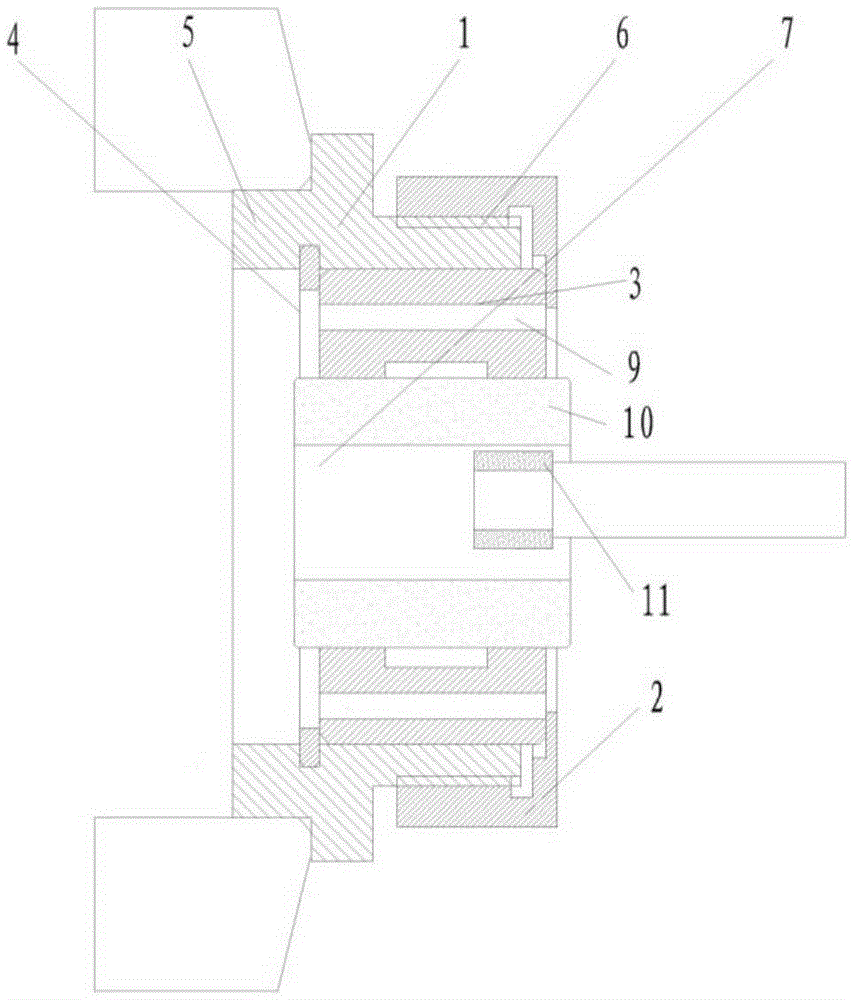

Machining and positioning device and machining method for lining holes at two ends of connecting rod

ActiveCN110170868AImprove machining positioning accuracyGuaranteed sizePositioning apparatusMetal-working holdersMachining deformationPulp and paper industry

The invention discloses a machining and positioning device for lining holes at two ends of connecting rod. The positioning device comprises a pressing mechanism, a bottom plate, a V-shaped support(10)fixed on the bottom plate, a floating support(9), a first bottom support(7), a second bottom support(8), and a side positioning block(1), the V-shaped support(10) is used for supporting and positioning the small head end of the connecting rod to be machined, the floating support(9) is arranged at the small head end of the to-be-machined connecting rod, the first bottom support(7) and the second bottom support(8) are arranged at the large head end of the to-be-machined connecting rod, the side positioning block(1) is arranged on one side of the large head end of the connecting rod to be machined, and the pressing mechanism presses and positions the large head end and the small head end of the connecting rod to be machined. The machining and positioning precision of the connecting rod sizehead hole can be improved, the accumulative error and the clamping and machining deformation are effectively avoided, the connecting rod large-head hole is ensured, the size and shape position precision of the small-head bushing hole are high, the precision is stable, the consistency is better controlled, and a good effect is achieved.

Owner:STATE RUN NO 616 FACTORY

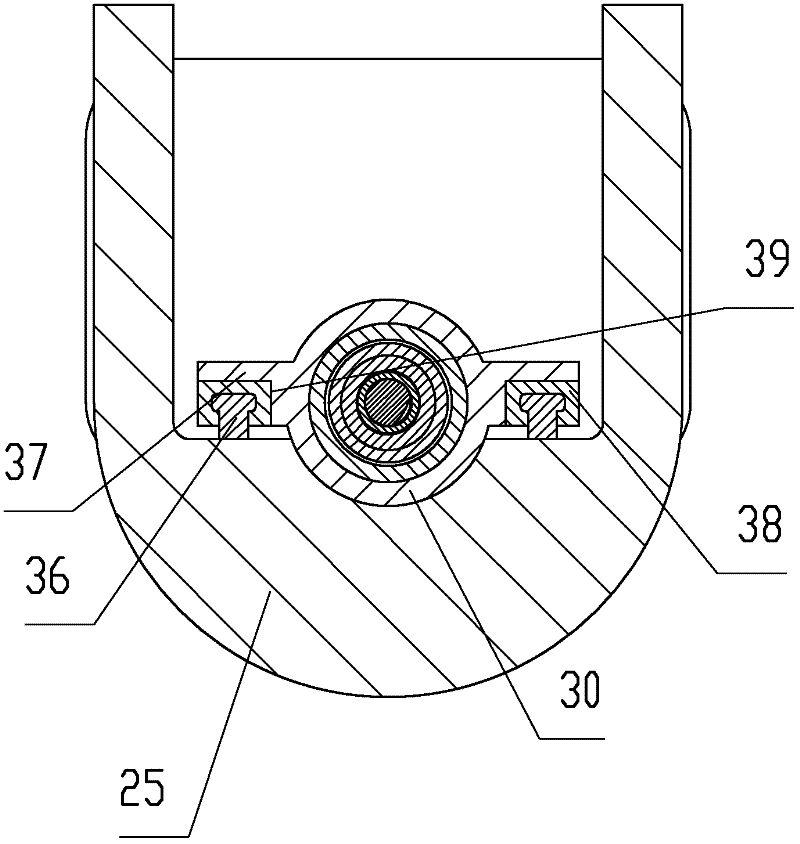

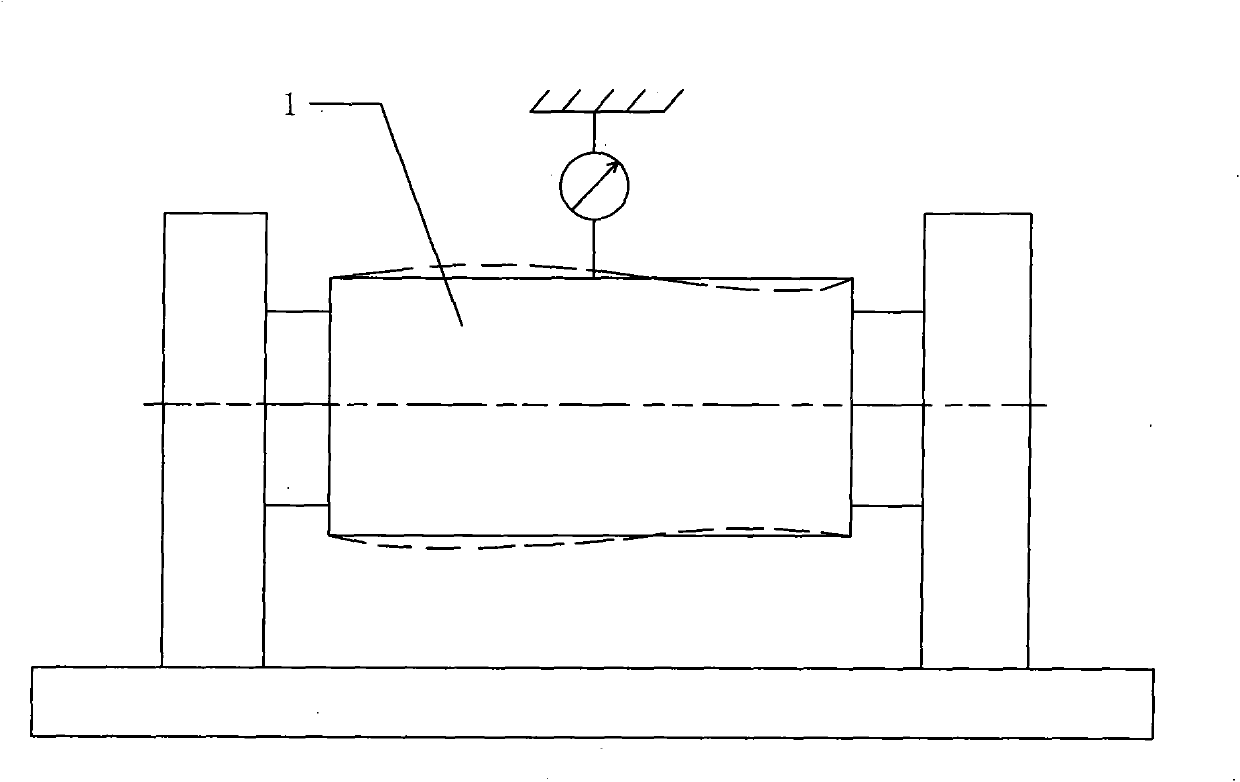

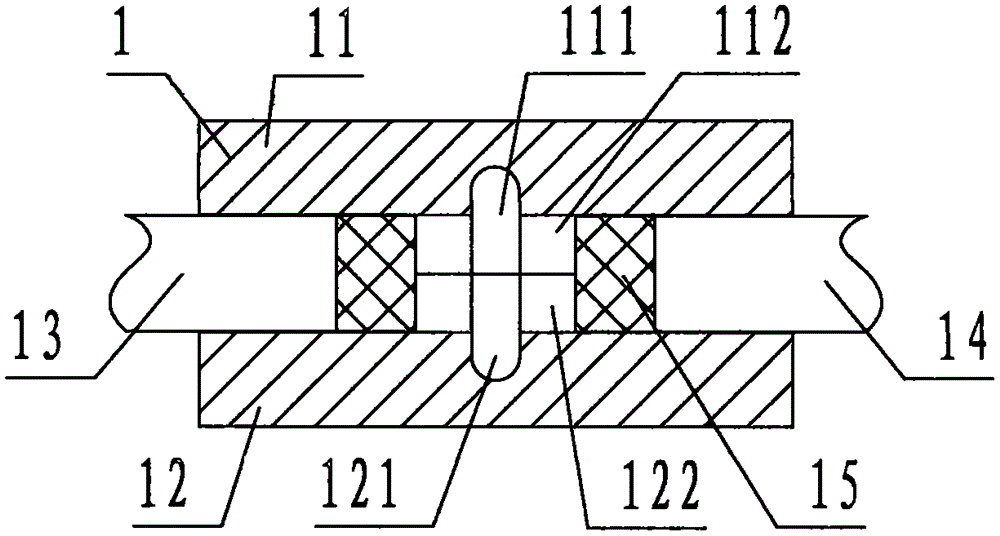

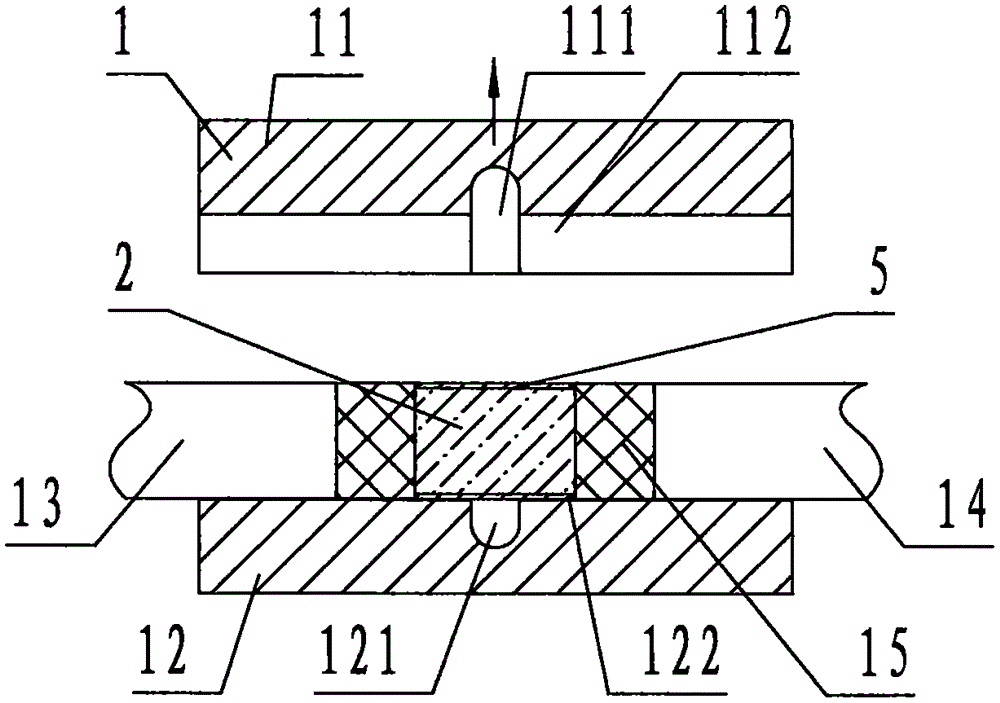

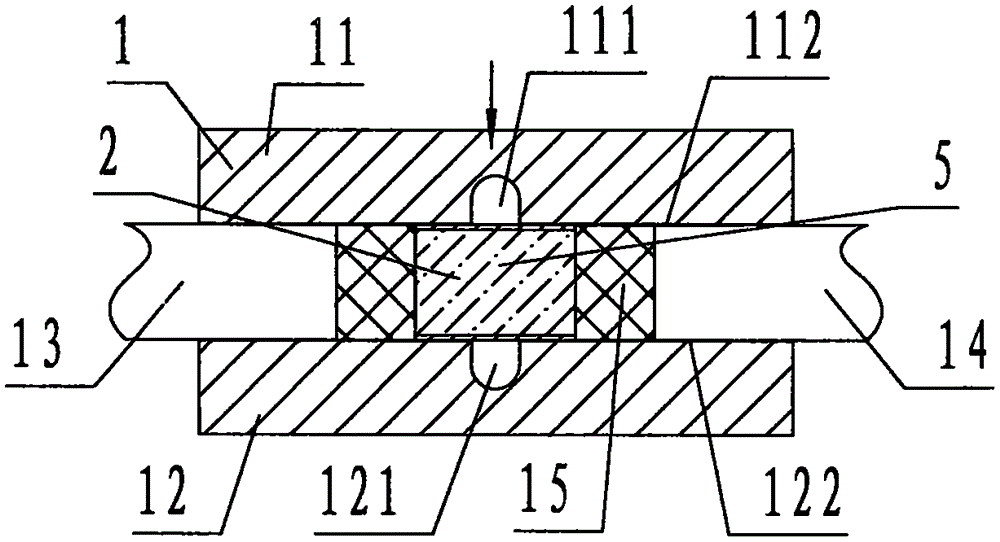

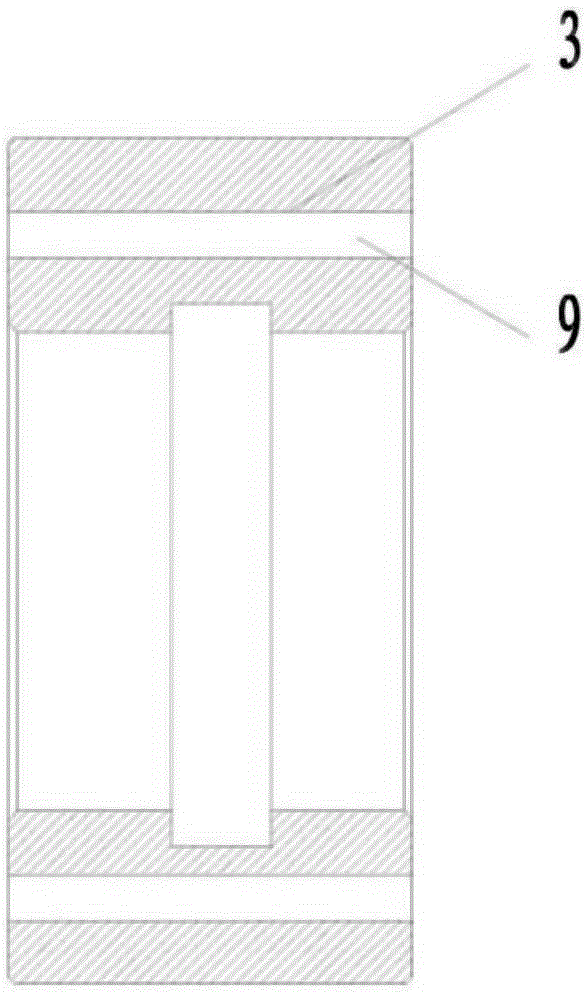

Forming method for hollow thin-wall uniform-thickness titanium alloy sealing ring

InactiveCN105642727AGuaranteed shape and position accuracyUniform wall thicknessPolyurethane elastomerWaste product

The invention discloses a forming method for a hollow thin-wall uniform-thickness titanium alloy sealing ring, and the forming method adopts a mould (1) and comprises a process method. According to the technical scheme adopted by the invention, polyurethane elastomers are separately arranged at the end head of a left punch of a mould and at the end head of a right punch of the mould, and a paraffin filling extrusion and expansion process method is adopted, so that the problems and the defects of poor quality, a high rejection rate, high cost, and proneness to occurrence of fatigue break hidden trouble in the prior art are overcome, and therefore, the production for the titanium alloy sealing ring achieves the purpose of improving quality, reducing waste products, reducing cost and eliminating the fatigue break hidden trouble.

Owner:刘洋

Numerical control equipment

InactiveCN102909611AGood orientationGuaranteed shape and position accuracyFeeding apparatusLarge fixed membersNumerical controlOrbit

Numerical control equipment comprises a Z-direction guiding device, a sliding seat mounted with the Z-direction guiding device, a sliding seat fixing device, a sliding seat driving device, a workpiece clamping device and a main processing head, further comprises a Z-direction linear guiding rail accommodating hole which penetrates a Y-direction sliding seat and a convex part of the sliding seat, wherein the sliding seat comprises a sliding seat baseplate and a convex part; the convex part protrudes out of the sliding seat baseplate; a first fixing plane is arranged on the outer side surface of the convex part; the Z-direction guiding device comprises a Z-direction guiding rod and a Z-direction guiding rail driving device; one side surface of the Z-direction linear guiding rail accommodating hole is a second fixing plane parallel to the first fixing plane; two first Z-direction linear guiding rail orbits are fixed on the second fixing plane; second Z-direction linear guiding rail orbits are arranged on the Z-direction guiding rod; and the main processing head is arranged under the Z-direction guiding rod. The numerical control equipment has the advantages that the guiding effect is good; a rotating prevention structure is required to be designed additionally; and when the first Z-direction linear guiding rail orbits and the second Z-direction linear guiding rail orbits are abraded, all that is needed is to replace the first Z-direction linear guiding rail orbits and the second Z-direction linear guiding rail orbits.

Owner:杨东佐

Numerical control equipment

InactiveCN102554712APrevent rotationSimple structureFeeding apparatusLarge fixed membersNumerical controlEngineering

Owner:杨东佐

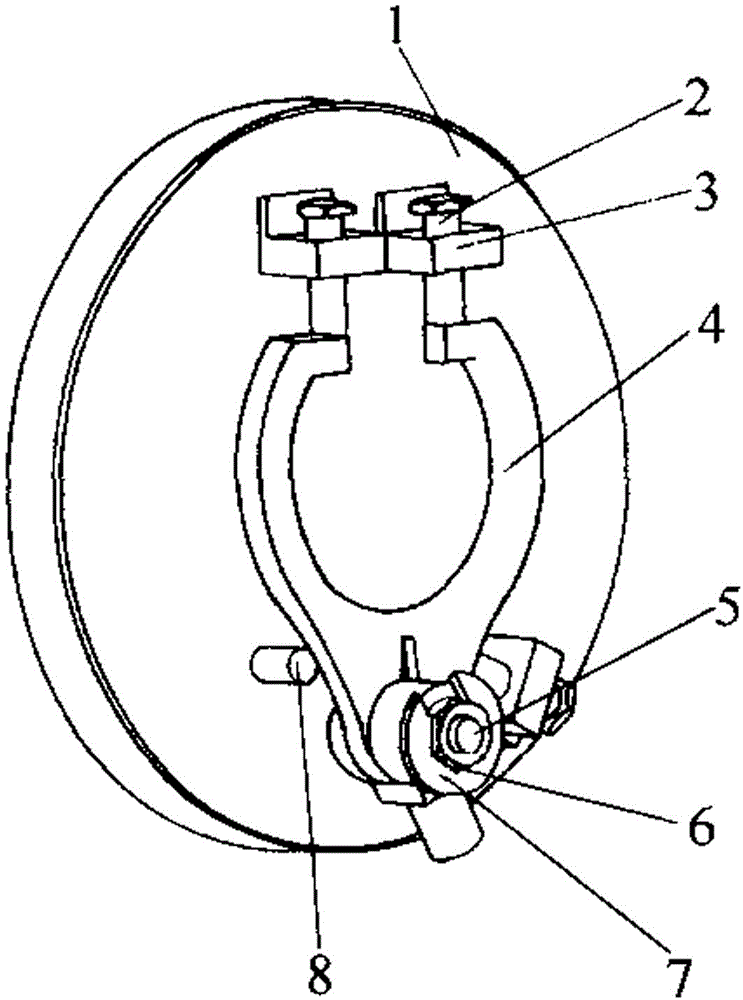

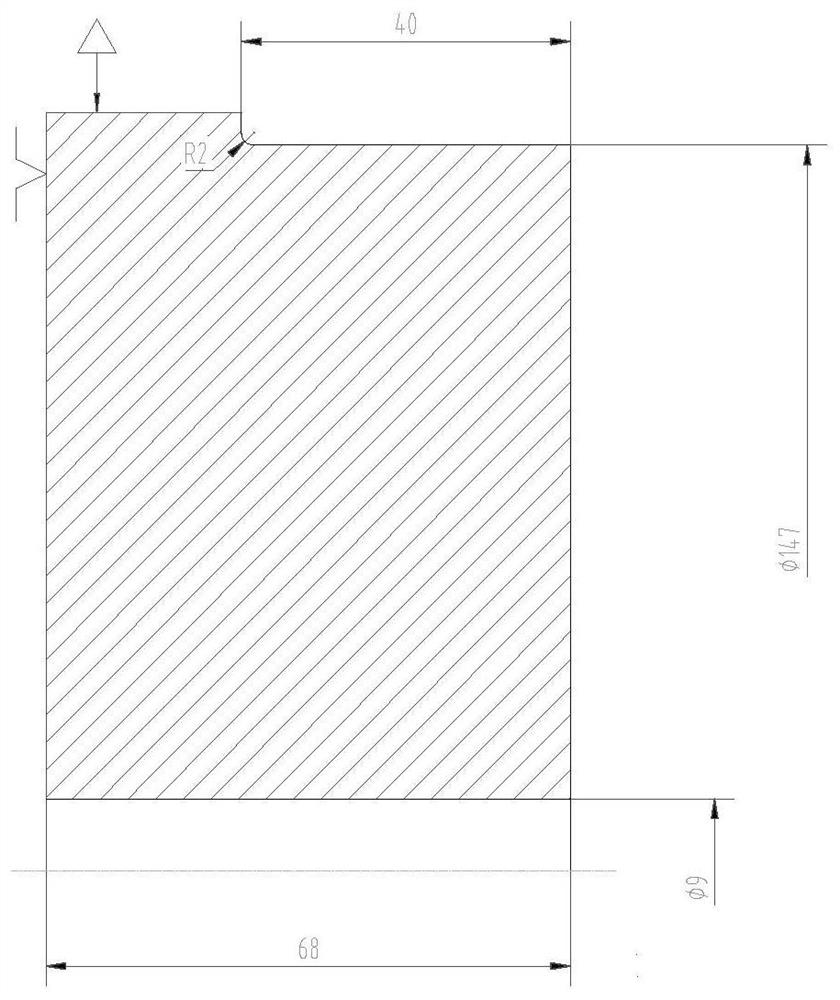

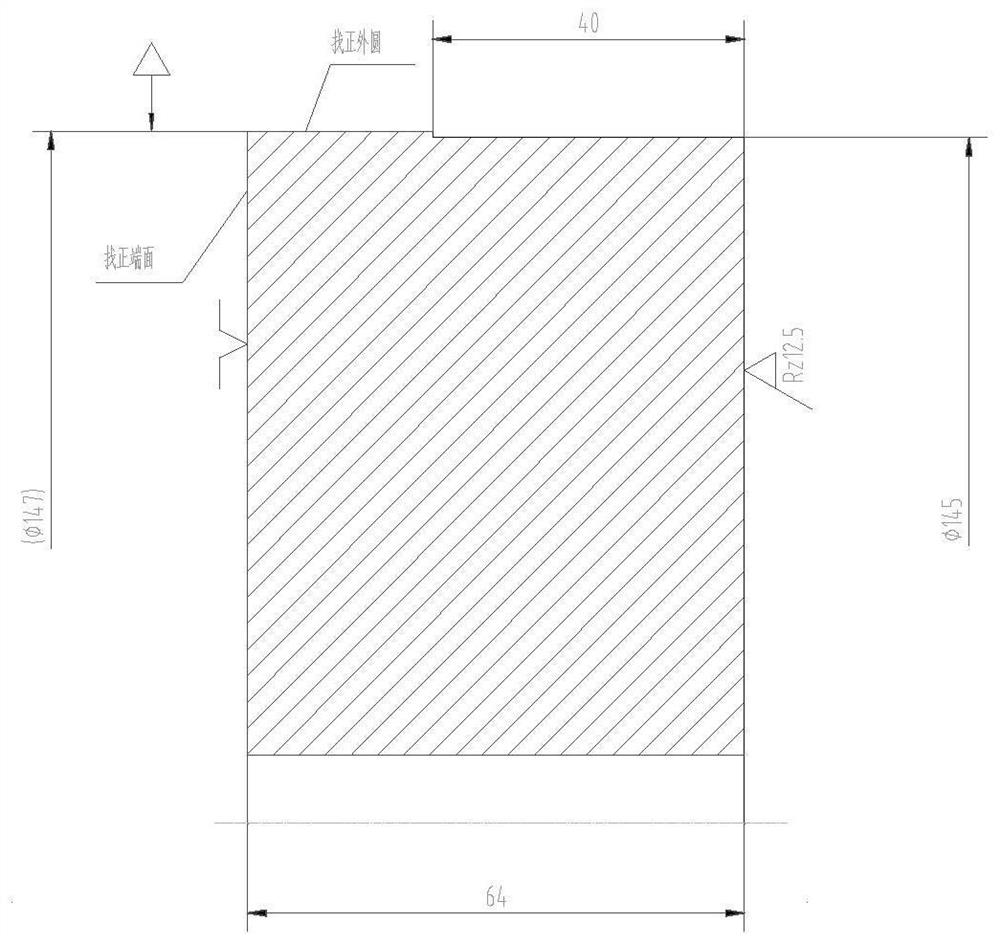

Thin-walled shifting fork turning clamp

InactiveCN105538010ASimple structureEasy to operatePositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a thin-walled shifting fork turning clamp, relates to the field of machining and in particular relates to the thin-walled shifting fork turning clamp which comprises a clamp main body, wherein the clamp main body is a cylindrical truncated cone; a plurality of stop dogs are arranged on one end surface of the clamp main body; two stop dogs are arranged on the clamp main body in parallel; each stop dog is connected with a bolt through a threaded hole; two cylindrical pins are also arranged on the clamp main body and are a center positioning pin and a limiting pin respectively; the center positioning pin and the stop dogs which are arranged in parallel with the center positioning pin are arranged on the circumference of a same circle; the center of the circle is coincided with the center of circle of the end surface of the clamp main body; threads are formed in the top end of the center positioning pin; and the top end of the center positioning pin is connected with a nut. The thin-walled shifting fork turning clamp has a simple structure, is convenient in operation, can well ensure the size, form and position accuracy when a workpiece is processed and improves the production efficiency.

Owner:陕西天财工程造价咨询有限公司

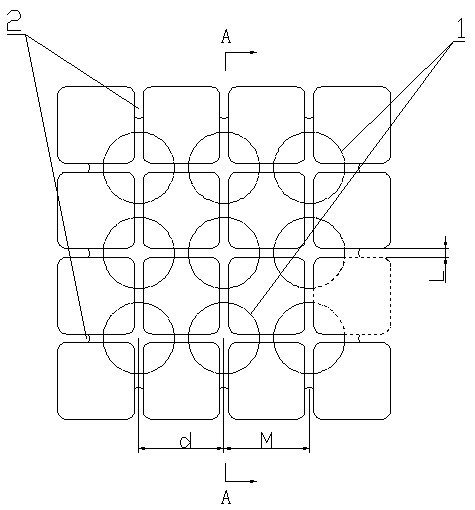

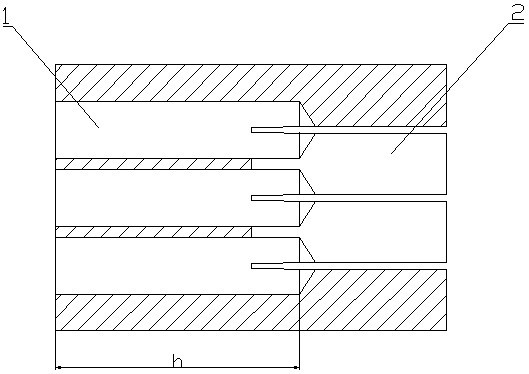

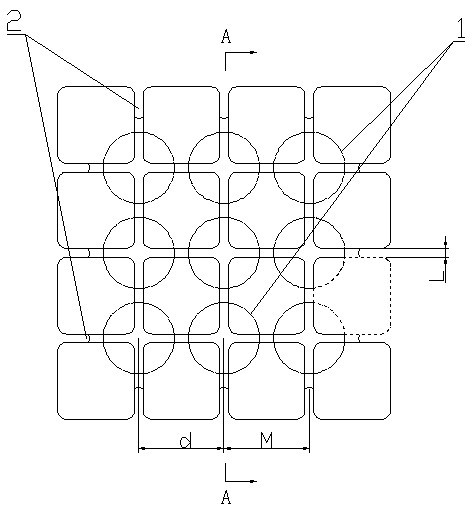

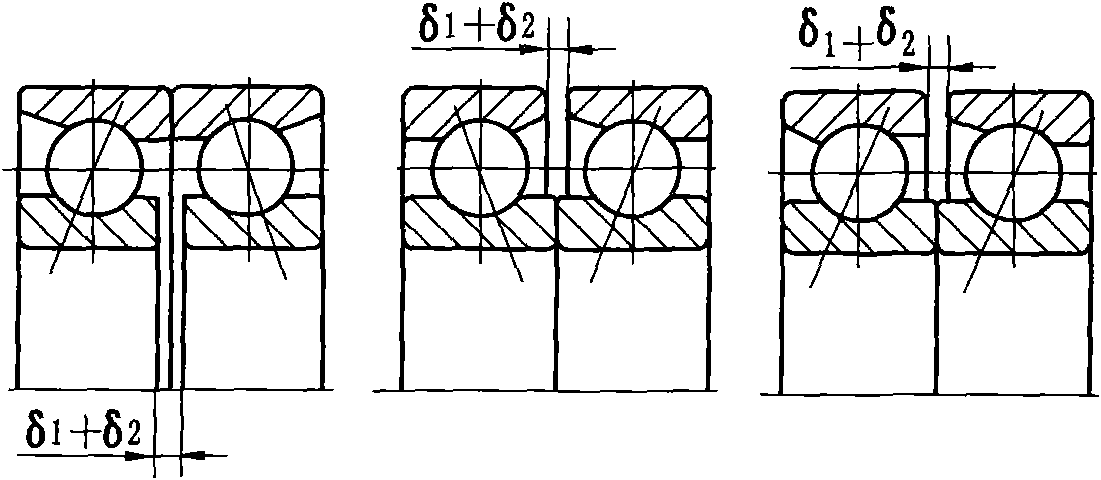

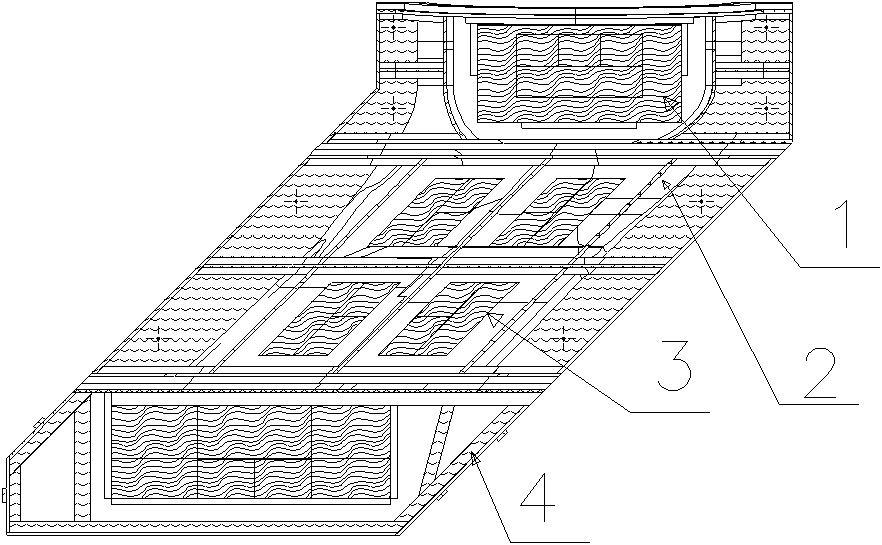

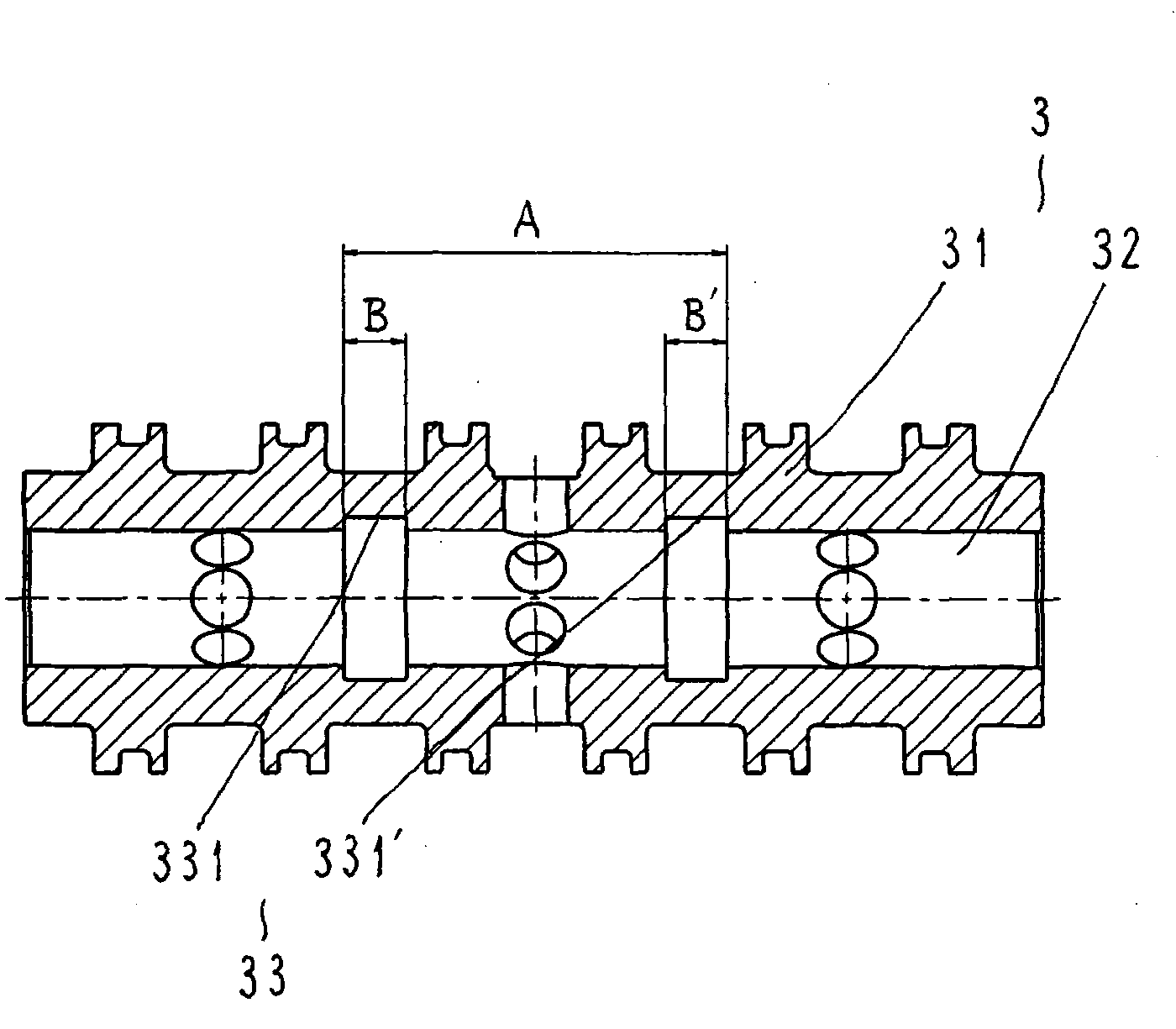

Multi-row joist type large-bushing baseplate molding method and mould

InactiveCN101791647AGuaranteed shape and position accuracyGuaranteed shape accuracyGlass making apparatusJoistAlloy

The invention provides a molding mould which can guarantee the shape and position precisions of a multi-row joist type platinum alloy bushing baseplate convex groove and a manufacture method thereof. The molding mould mainly comprises an upper mould and a bottom mould for molding the baseplate convex groove, wherein the upper mould and the bottom mould are opposite to each other, both sides of the bottom mould are fixed with a side stop block for guaranteeing the mould closing precision, and both ends of the bottom mould are respectively provided with a positioning pin. The molding method comprises the following steps of: punching a discharge spout mounting hole and positioning holes on a plate, wherein each pair of positioning holes determine the position of a convex groove and are respectively arranged at both ends of the plate in the longitudinal direction, the distances between each pair of positioning holes are all equal, and spaces between every two adjacent pairs of positioning holes are equal; positioning and placing the plate on the bottom mould through the two positioning pins, then closing the mould and placing the molding mould in a press for pressing out the convex grooves; gradually molding to obtain a baseplate with multiple convex grooves; and finally, removing allowance parts with the positioning holes at both ends of the baseplate and shaping to obtain a baseplate conforming to the requirements.

Owner:SINOMA SCI & TECH

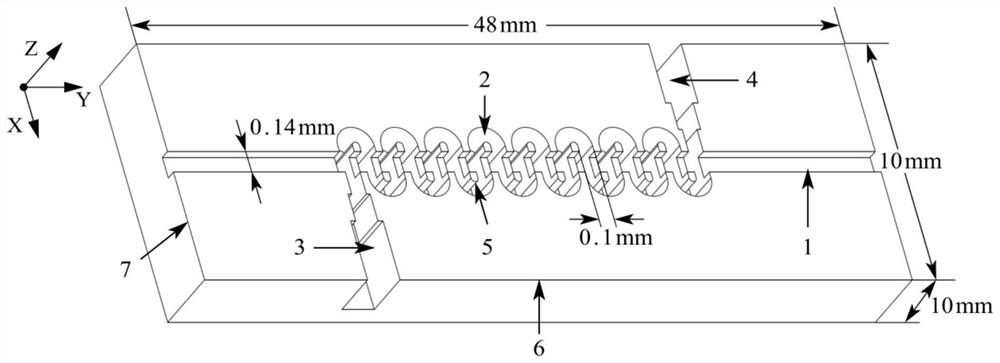

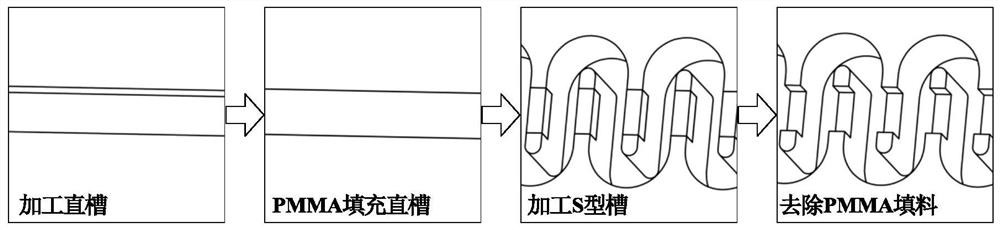

Micro-milling burr inhibition method applied to folded waveguide slow wave structure

InactiveCN112276176AMeet the requirements of high machined surface qualityRemove inhibitionMeasurement/indication equipmentsMilling equipment detailsWave structurePolymer science

The invention relates to a micro-milling burr inhibition method applied to a folded waveguide slow wave structure. The method comprises the steps that after a straight groove in the slow wave structure is generated through micro-milling machining, a cavity of the straight groove is filled with PMMA colloid; after the PMMA colloid is cured, micro-milling machining of an S-shaped groove in the slowwave structure is carried out; and after a workpiece is machined, the workpiece is placed in an organic solvent to dissolve a PMMA curing layer, and cleaning and drying are carried out, wherein the PMMA colloid is prepared by uniformly mixing polymethyl methacrylate and an acrylic curing agent according to the mass ratio of (1-1.4): 1. According to the micro-milling burr inhibition method appliedto the folded waveguide slow wave structure, the machined cavity of the straight groove is filled with the PMMA colloid in a coated mode to serve as an auxiliary supporting material, the PMMA colloidis used for enhancing the plastic deformation resistance of the boundary of a dispersed oxygen-free copper material in the cutting process, and then formation of burrs at the groove top, the groove shoulder and the island root is inhibited.

Owner:HARBIN INST OF TECH

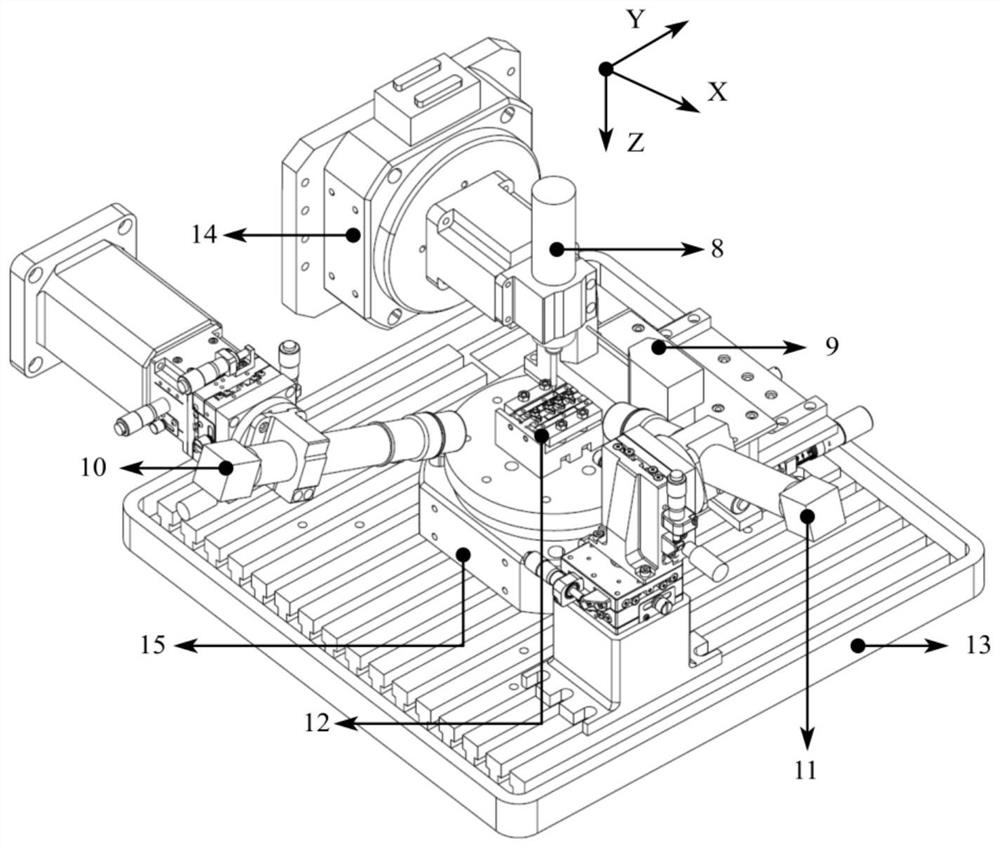

Full peripheral process unit for electric erosion machining valve bushes

InactiveCN102133665AGuaranteed axial dimensional accuracyGuaranteed shape and position accuracyElectrical-based auxillary apparatusCopper–tungstenMechanical engineering

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

Cultivator fender assembly and welding tool

InactiveCN102416546AAdaptableReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti point

The invention discloses a cultivator fender assembly and welding tool, which comprises a bottom plate, supporting columns, limiting blocks, a shim block, a fixed block, a movable pressing block and a compaction device, wherein the supporting columns are distributed on the bottom plate in a height adjustable manner and used for supporting two parts to be assembled and welded with fenders; and the limiting blocks are positioned on the edges of the two parts to be assembled and welded with the fenders, fixedly distributed on the bottom plate and used for limiting the freedom degree of the horizontal direction of the two parts to be assembled and welded with the fenders. By adopting a multi-point quick positioning structure comprising positioning in the vertical and horizontal directions and on the edges and combining a quickly driven mobile positioning structure, the welding positioning process is standardized and the form and position accuracy of welding can be ensured; and the tool is provided with the supporting columns capable of adjusting the height according to the requirement of the plate-like welding structure, so that bottom positioning is realized, the tool has adaptability to the irregular plate-like structure, the work efficiency is improved, the service life of the tool is prolonged, the labor intensity of an operator is reduced, and the production and using costs are saved.

Owner:CHONGQING BEIBEI DISTRICT FENGHUO MACHINERY MFG

High-performance ceramic piston ring manufacturing technology

InactiveCN103194719AHigh hardnessReduce coefficient of frictionVacuum evaporation coatingSputtering coatingManufacturing technologyCeramic coating

The invention relates to a high-performance ceramic piston ring manufacturing technology. At present, the existing piston ring surface treatment technologies comprise chromium electroplating, surface nitridation, PVD and CVD film coating, molybdenum plasma spraying and ceramic coating plasma spraying, and have different performance detects and no ideal effects. The high-performance ceramic piston ring manufacturing technology comprises that through a double glow plasma surface metallurgy technology, molybdenum (or chromium or titanium or tungsten) is deeply permeated into the surface layer of a common low-alloy steel piston ring, and through vaccum ion carbonization and follow-up heat treatment, a ceramic piston ring having high hardness, high wear resistance and good comprehensive mechanical performances is obtained.

Owner:曾云发

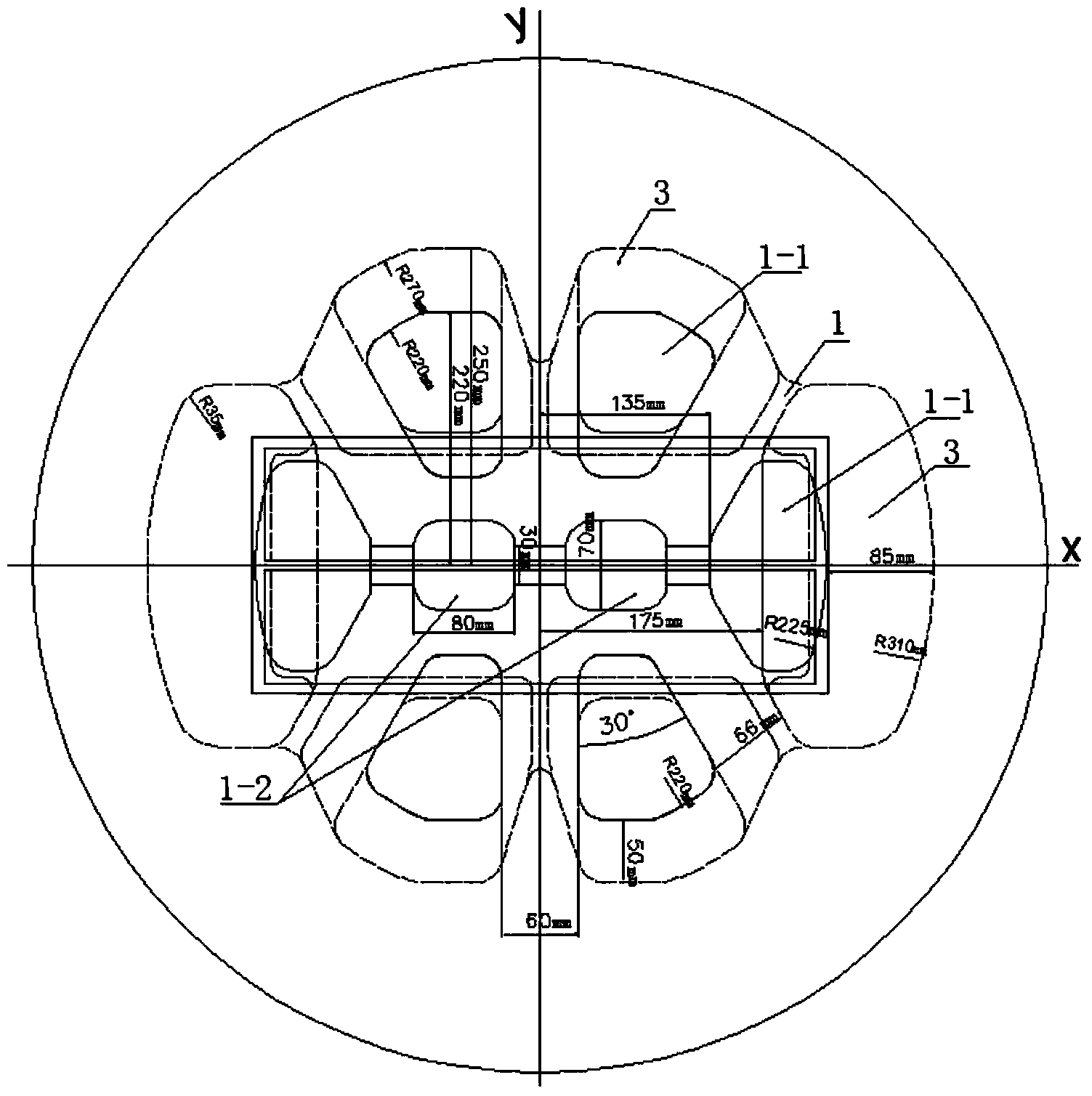

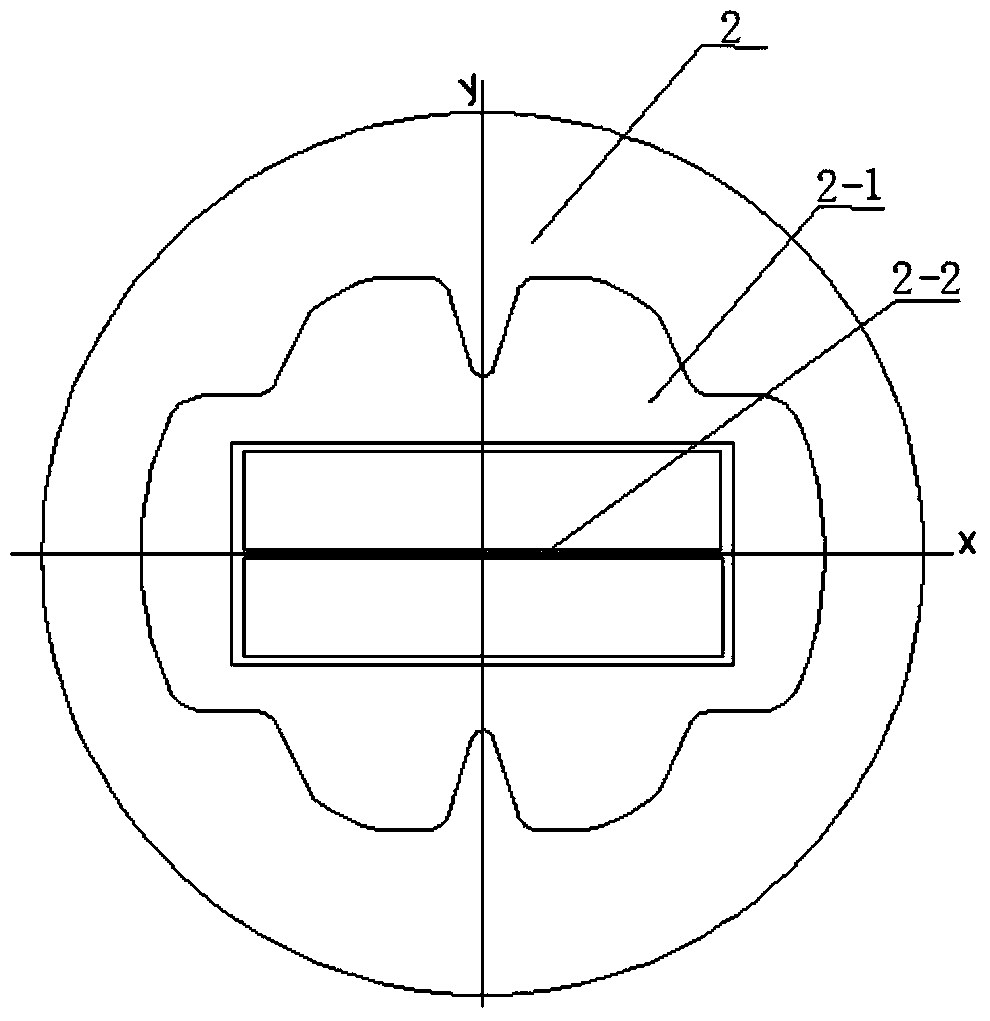

Mold structure of large double-hole pipe profile with horizontal reinforcing ribs and processing method thereof

ActiveCN103464502ASimple structureReduce the difficulty of productionExtrusion diesAutomatic processingEngineering

The invention discloses a mold structure of a large double-hole pipe profile with horizontal reinforcing ribs and a processing method of the large double-hole pipe profile. The mold structure is characterized in that a broadening and flow-distributing combined mold is formed by adopting an upper mold and a lower mold; the periphery of the upper mold is provided with six flow distributing holes which are uniformly distributed, and the middle part of the upper mold has two horizontal and serial stepped type flow-distributing holes; the flow-distributing holes are horizontally broadened, the broadening angle is 23 degrees, and the broadening amount is between 150-200mm; a welding chamber of the lower mold is externally connected with a circle with the diameter being 600mm and the depth of the welding chamber is 40mm; the mold is made of a 4Cr5MoSiV1 hot-work mold, a CAD / CAM / CAE full-automatic processing method is adopted, the mold structure of the double-hole pipe profile is accurately designed, and the mold is treated by processes such as high-temperature quenching, tempering and nitridation, so that the improvement on the hardness value of the surface of the mold is ensured. The mold disclosed by the invention has the advantages that the structure is simple and reasonable, the welding quality in processing the pipe material is guaranteed, the high-quality large double-hole pipe profile with the horizontal reinforcing ribs can be processed, the manufacturing difficulty of the mold is reduced, and the service life of the mold is also prolonged.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

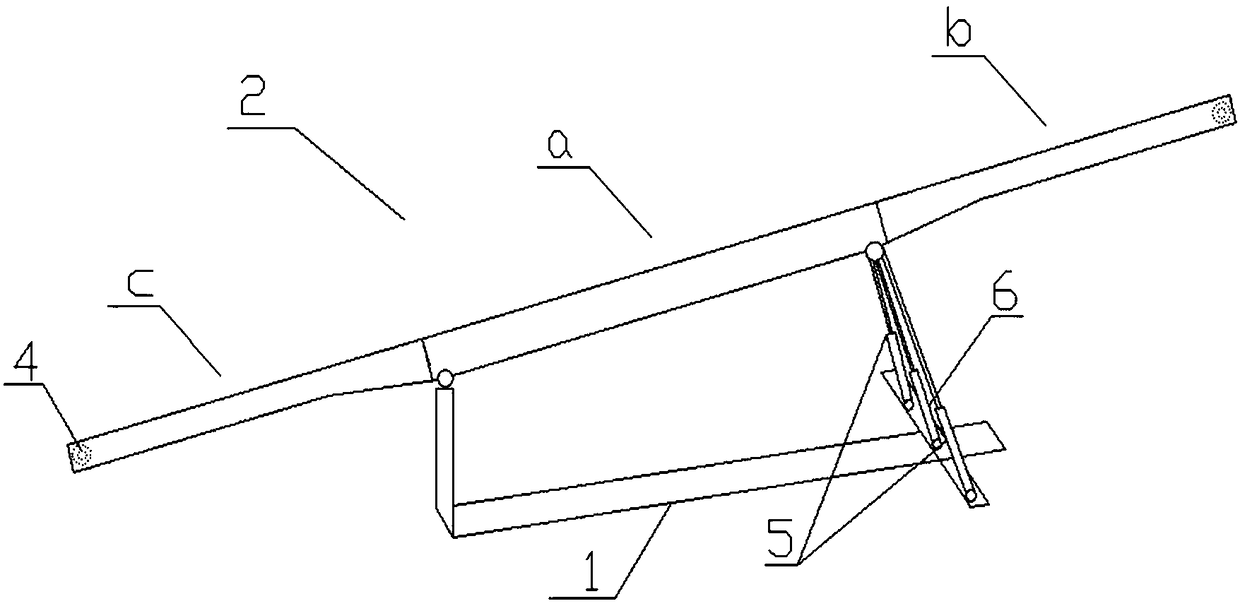

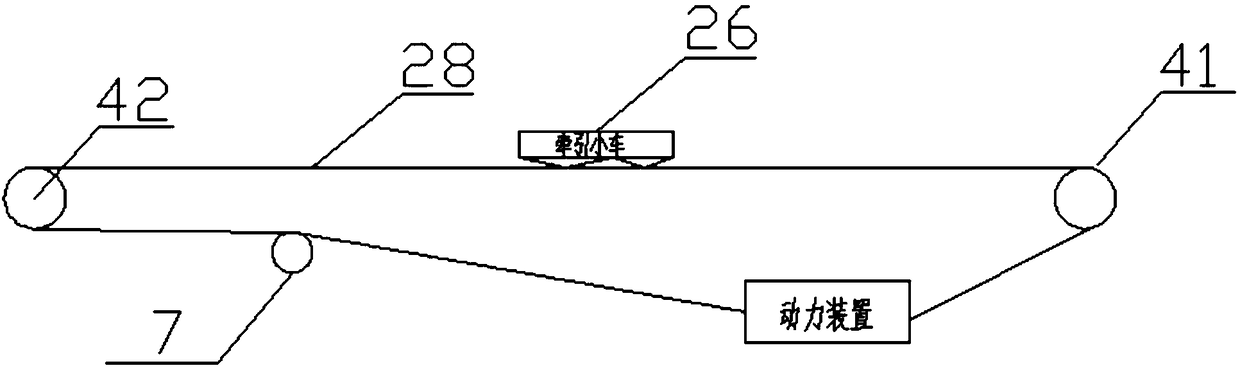

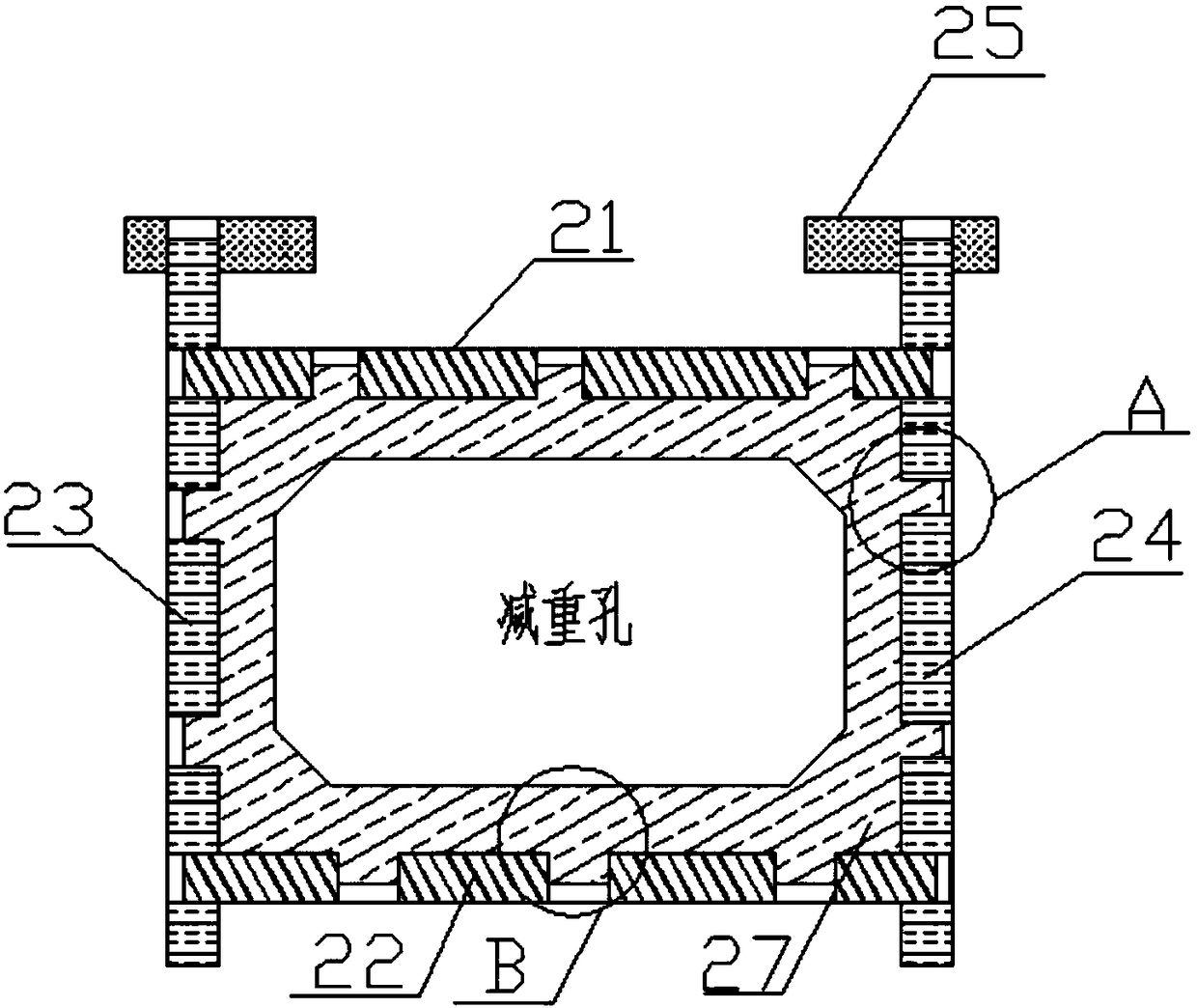

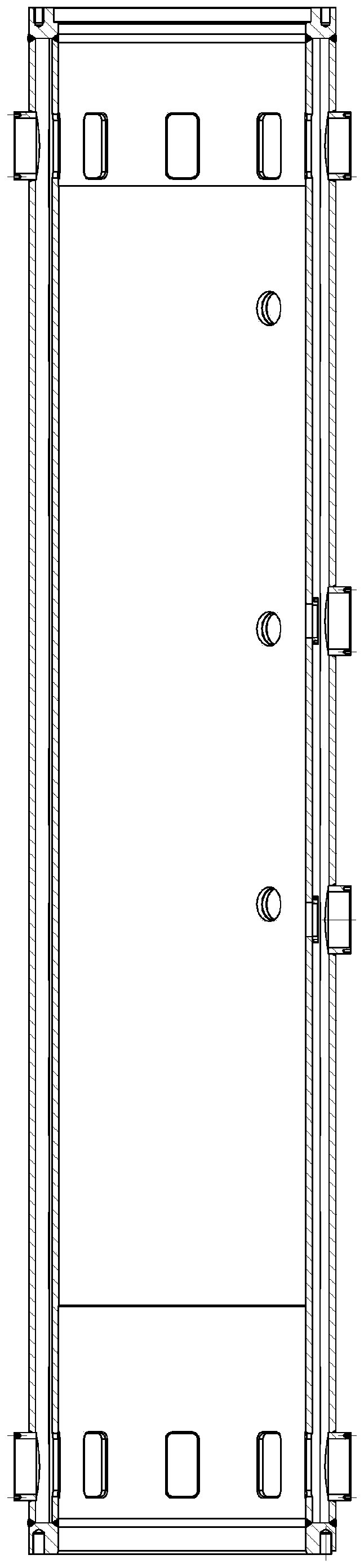

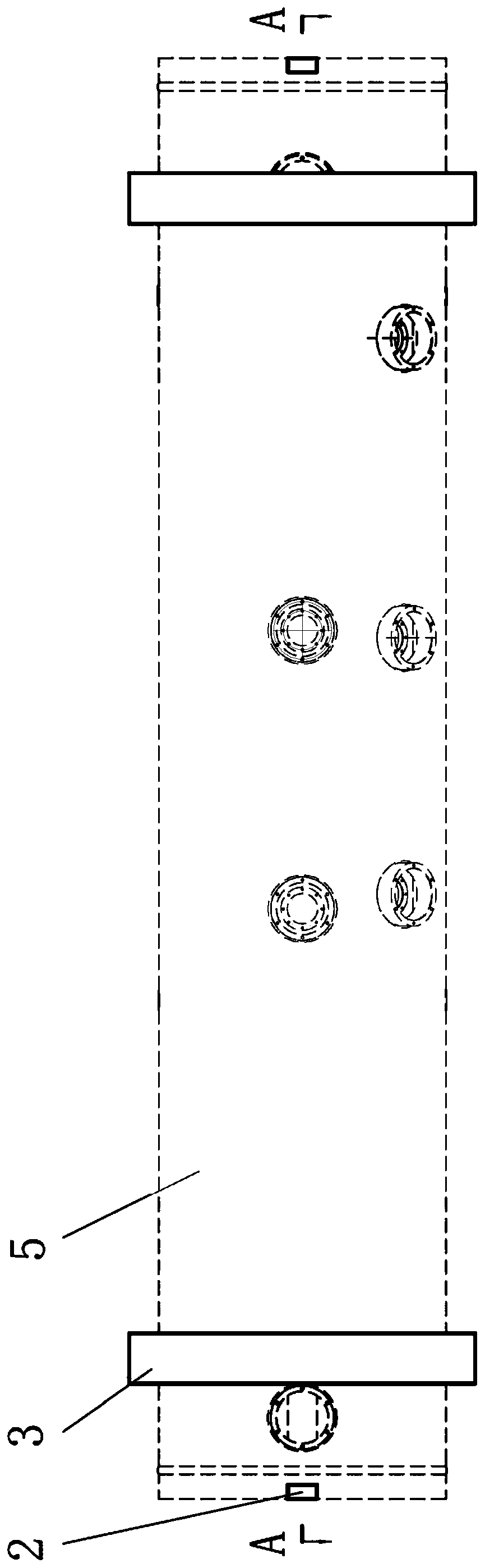

An ejection trajectory device of a launcher

PendingCN109018418AGuaranteed shape and position accuracyRapid Mass Production ManufacturingRocket launchersLaunching/towing gearHydraulic cylinderEngineering

The invention relates to the launching field of an unmanned aerial vehicle, which is an ejection trajectory device of a launcher. The device Comprises a base and a track located on the base, wherein the track can be assembled into one track or several tracks, and the tracks are folded and retracted laterally or vertically in a hinged manner in the track plane. The above-mentioned rails are mainlyinserted and welded by the alignment of the upper, lower, left and right panels and the rib panels between them. The rear part of the rail is hinged on the base, the two sides of the front part of therail are coaxially hinged with a pair of balancing hydraulic cylinders, and the other ends of the pair of balancing hydraulic cylinders are also coaxially hinged on the two sides of the base. The lifting hydraulic cylinder is hinged on the rail and the base, and the hinge axis of the lifting hydraulic cylinder can be coaxial with or parallel to the hinge axis of the balancing hydraulic cylinder.The invention has the advantages of scientific and reasonable design, assembly, high manufacturing accuracy, light weight, high strength, good stability, low construction cost and easy mass production, and is a technical revolution in the field.

Owner:QIHANG LAUNCHING TECH CO LTD

Machining device and method for double-thrust sliding bearing in finish machining stage

PendingCN113976926AGuaranteed shape and position accuracyQuality assuranceAuxillary equipmentTurning machinesSlider bearingEngineering

The invention discloses a machining device and method for a double-thrust sliding bearing in the finish machining stage. The device comprises two sets of pressing plate combinations; a bearing alloy end face F is placed on a base positioning working face to be reliably attached to the base positioning working face; after a bearing is aligned, the first set of pressing plate combination penetrates through an inner hole to tightly press a bearing alloy end face E for finish machining of an outer circle and the second set of pressing plate combination is used for pressing the side face of an outer circular ring groove from the outer portion of the bearing, so that finish machining of an inner hole and an alloy end face E is conducted; then the bearing is turned over, positioning and pressing are conducted through a positioning cylindrical pin and the second set of pressing plate combination, and finish machining of the alloy end face F is conducted. The clamping force layout is reasonable; automatic centering is achieved when the bearing is turned over, and alignment is not needed; the problem that the form and location tolerance cannot meet the design requirement due to the fact that an existing machining device clamps the outer circle of the bearing and the quality problem that a machined alloy end face is prone to being scratched are solved, and the form and location precision and the product quality of a double-thrust sliding bearing are guaranteed.

Owner:CSIC NO 12 RES INST

Large thin-wall double-layer cylinder deep hole machining device and machining method thereof

ActiveCN111097942ASmall cylinder deformationIncrease stiffnessBoring/drilling machinesAttachable boring/drilling devicesManufacturing engineeringDeep hole

The invention discloses a large thin-wall double-layer cylinder deep hole machining device and a machining method thereof. The device comprises a lathe, a fixing mechanism, a supporting mechanism anda guiding floating boring head, wherein the fixing mechanism is mounted on the end portion of a cylinder body, located on the outer side of a flange, and is used for fixing the cylinder body to a lathe flower disc of the lathe; the supporting mechanism comprises a supporting ring, the supporting ring fixedly sleeves the outer side of the cylinder body and is used for supporting the cylinder body by carrier rollers, and the guiding floating boring head is detachably mounted on a lathe boring rod of the lathe and is used for machining an inner hole of the cylinder body. According to the large-scale thin-wall double-layer cylinder deep hole machining device and the machining method thereof, the cylinder body is fixedly clamped on the lathe flower disc through the fixing mechanism, and the cylinder body deformation caused by clamping can be reduced; the cylinder body is supported by the carrier rollers of the supporting mechanism, the rigidity of a shell on the outer side of the cylinder body can be increased, and the cylinder body deformation caused by the supporting of the carrier rollers can be reduced; and meanwhile, the inner hole of the cylinder body can be machined through the guide floating boring head, so that the size precision, the shape bit precision and the surface roughness requirement of the inner hole machining can be guaranteed.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

Machining method for compressor impeller of ZR series superchargers

ActiveCN113020899AIncrease productivityImprove processing qualityInternal combustion piston enginesImpellerStructural engineering

The invention discloses a machining method for a compressor impeller of ZR series superchargers, which can improve the machining precision. The machining method comprises the following steps: S1, roughly turning one end of a workpiece through a common lathe, and drilling a center hole; S2, carrying out heat treatment; S3, roughly turning the other end of the workpiece through a numerical lathe; S4, roughly turning one end of the workpiece, and the two ends of the workpiece are leveled; S5, carrying out inspection; S6, roughly turning the outer meridian plane through the common lathe, and reserving a clamping section at the end; S7, semi-finish turning the large end and the inner hole of the workpiece through the common lathe; S8, semi-finish turning the outer meridian plane of the workpiece through the common lathe, and finish turning the air inlet surface; S9, milling U-shaped grooves in the two sides of the large end of the workpiece; S10, milling blades and a runner of the workpiece; S11, finish turning the outer circle of the large end of the workpiece through the common lathe; S12, finish turning the large end face and the inner hole of the workpiece through the common lathe; and S13, finish turning the small end face and the meridian plane of the workpiece through the common lathe.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Grinding device and method for boron carbide gas bearing

ActiveCN105269456AAchieve precision grindingImprove shape and position accuracyRevolution surface grinding machinesGrinding work supportsBoron carbideEngineering

The invention particularly relates to a precision grinding device and method for a boron carbide gas bearing. The grinding device comprises a positioning seat, a compression nut, a positioning ring and an elastic check ring. A limiting protrusion used for being clamped on a grinding machine chuck and an external thread which is used for being connected with the compression nut are arranged on the outer wall of the positioning seat. A positioning ring bearing assembly is mounted in an inner hole of the positioning seat. A circular groove is arranged in the inner hole of the positioning seat. The elastic check ring is mounted in the circular groove. The boron carbide gas bearing to be machined is mounted on the inner wall of the positioning ring, and the two end faces of the positioning ring are in close fit with the elastic check ring and the compression nut respectively. The method of the grinding device comprises the steps of first mounting, second inner hole grinding of parts to be machined, third online repairing of an inner hole grinding diamond grinding wheel, fourth end face grinding of the parts to be machined, fifth online repairing of end face grinding diamond grinding wheels, and sixth disassembling after part machining. When the grinding device and method are used for machining boron carbide materials, the machining precision is high, and operation is convenient.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

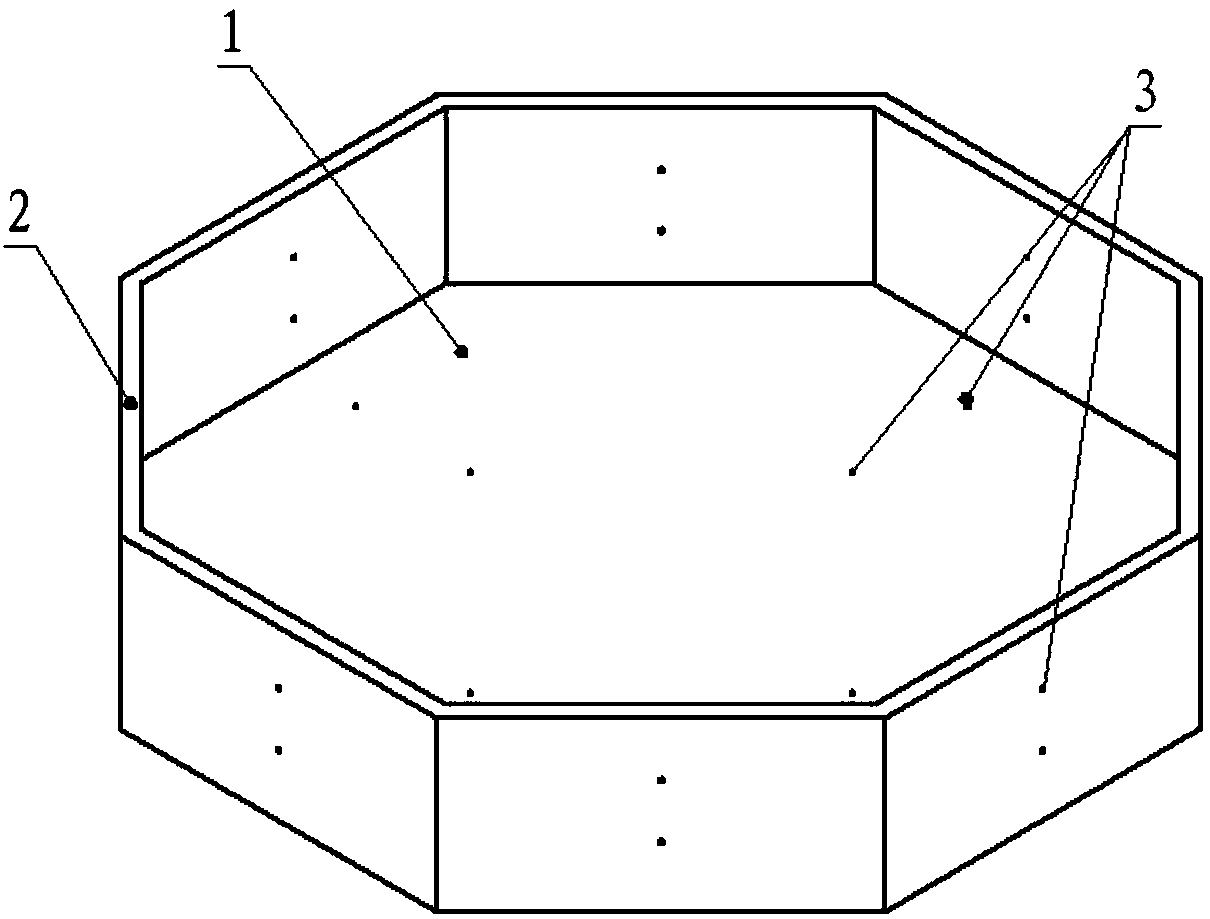

Curing forming tool and method for honeycomb sandwich structure

ActiveCN109291518AEffective protectionCoordinating CTE DifferencesPaper/cardboard articlesAluminum honeycombThermal expansion

The invention relates to a curing forming tool and method for a honeycomb sandwich structure, particularly relates to the curing forming tool and method for a polygonal box-shaped composite material skin-aluminum honeycomb sandwich structure, and belongs to the technical field of curing forming of composite material honeycomb sandwich structures. A forming template is assembled by using compositematerial skin-aluminum honeycomb sandwich structure plates, the problem of large difference in the thermal expansion coefficient between the forming template and service products thereof is solved, and the risk of damage in the product manufacturing process is reduced. The forming template is formed by assembling split forming bottom plates and forming vertical plates, the configuration is simple,the manufacturing cost is low, and the split forming template is easier to separate from the products, so that the risk of damage is reduced when the products are separated from the curing forming tool. The split forming template can be provided with corresponding positioning openings and connecting openings according to different configurations and connecting opening layouts of a honeycomb sandwich structure to be formed, and is assembled and formed, so that recycle of the tool is facilitated.

Owner:BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com