Cultivator fender assembly and welding tool

A technology for assembling welding tooling and fenders, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of increasing processing costs, affecting welding accuracy, and low production efficiency, so as to save production and use costs and improve work efficiency. Efficiency and service life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

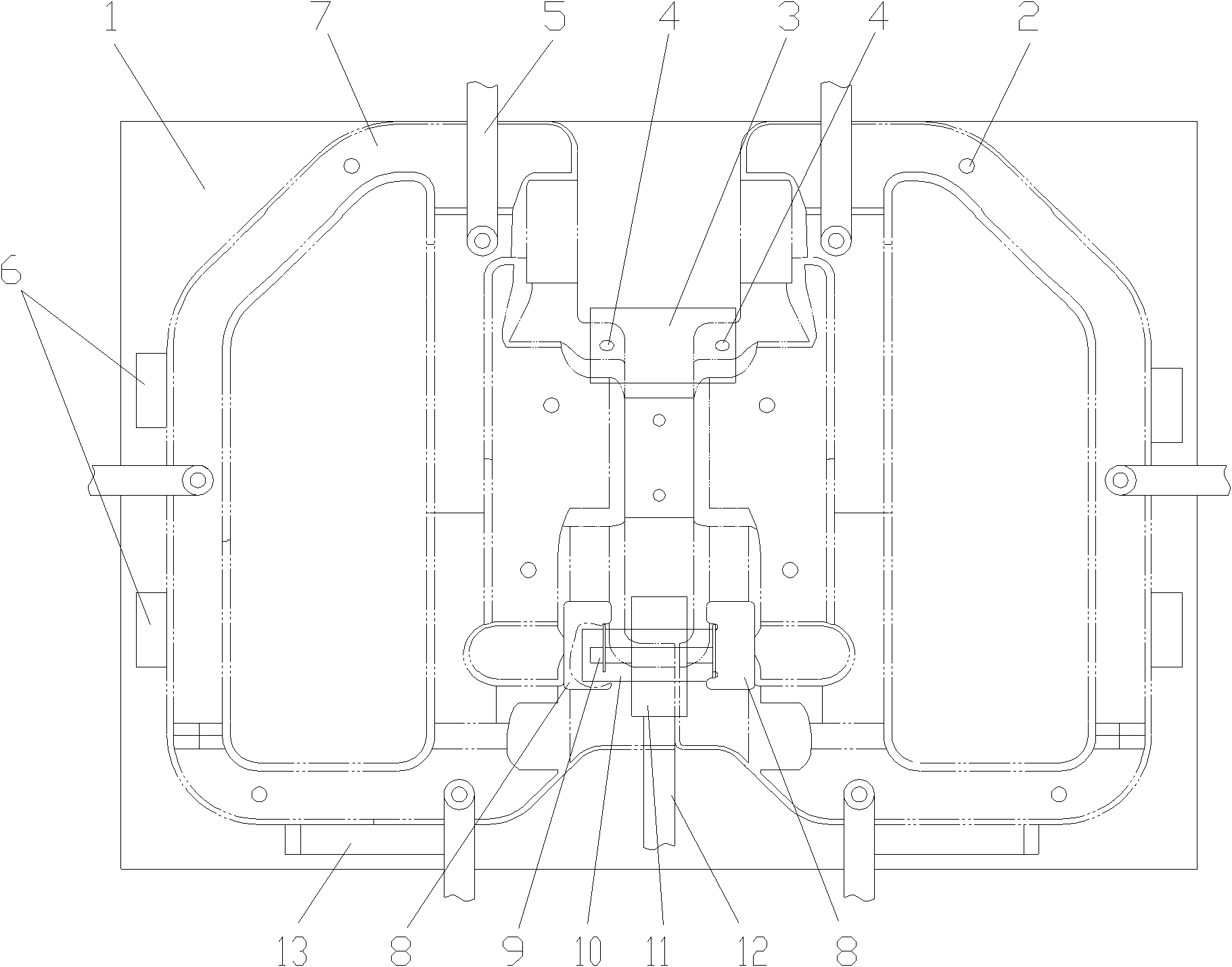

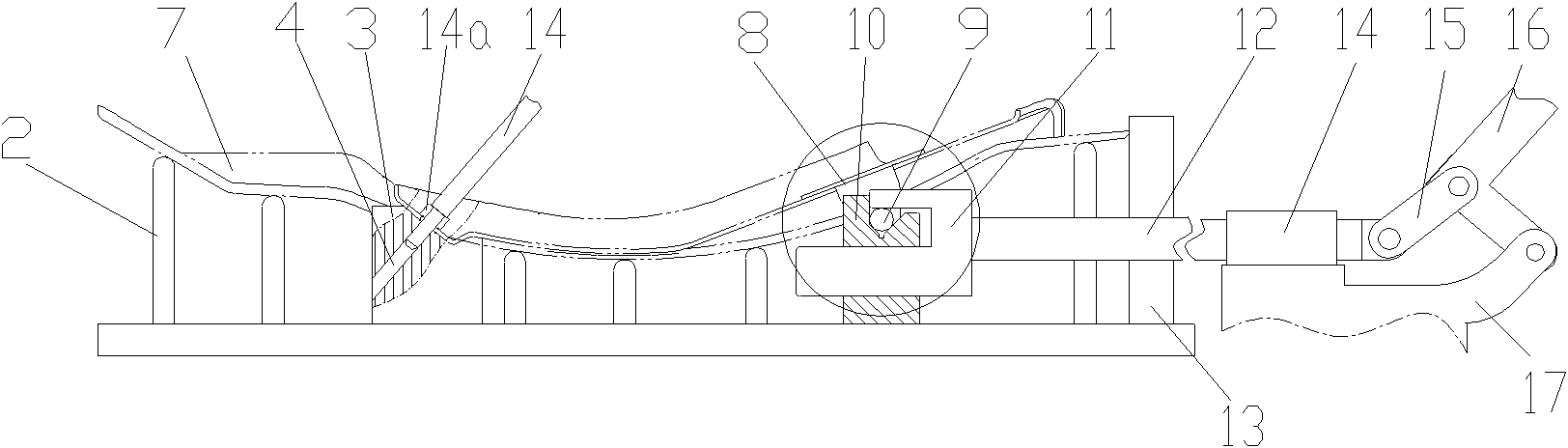

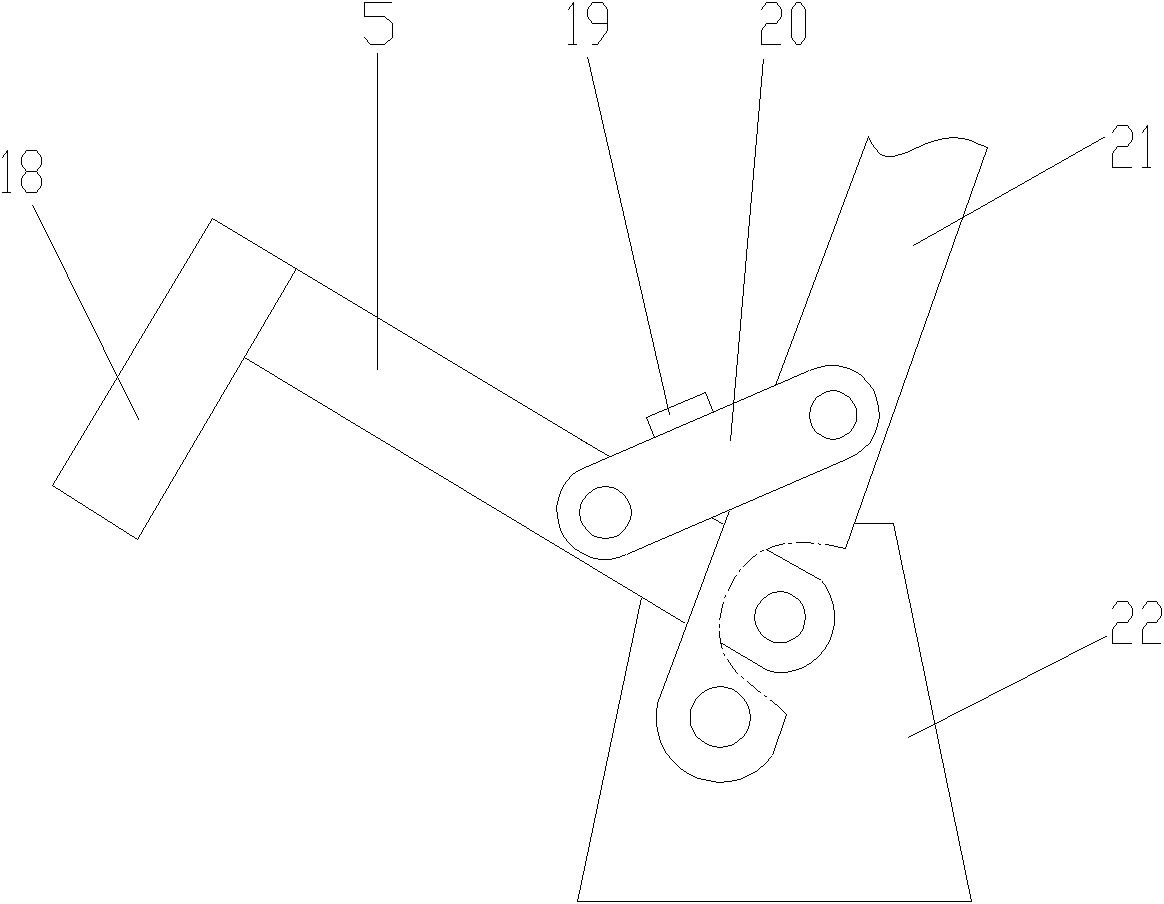

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along direction A, image 3 It is a schematic diagram of the structure of the compression drive device, Figure 4 It is a schematic diagram of the fixed block structure, Figure 5 for figure 2 The enlarged view at B of , as shown in the figure: the tiller fender assembly welding tooling of the present embodiment includes a base plate 1, a support column 2, a limit block 6, a limit block 13, a cushion block 3, a fixed block 10, The movable briquetting block 11 and the pressing device, the support column 2 is distributed on the bottom plate 1 in a height-adjustable manner to support the two parts of the fender 7 that need to be assembled and welded (that is, the left and right fenders that the fender needs to be welded to connect) ), the limit block 6 and the limit block 13 are located at the edges of the two parts of the fender 7 that need to be welded and fixedly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com