Machining method of perpendicularly intersected hole system of speed reducer body

A vertical intersection and processing method technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing accuracy, inability to ensure shape and position accuracy, and large adjustment workload, etc., to achieve the release of welding residual stress , to ensure stability and reduce processing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

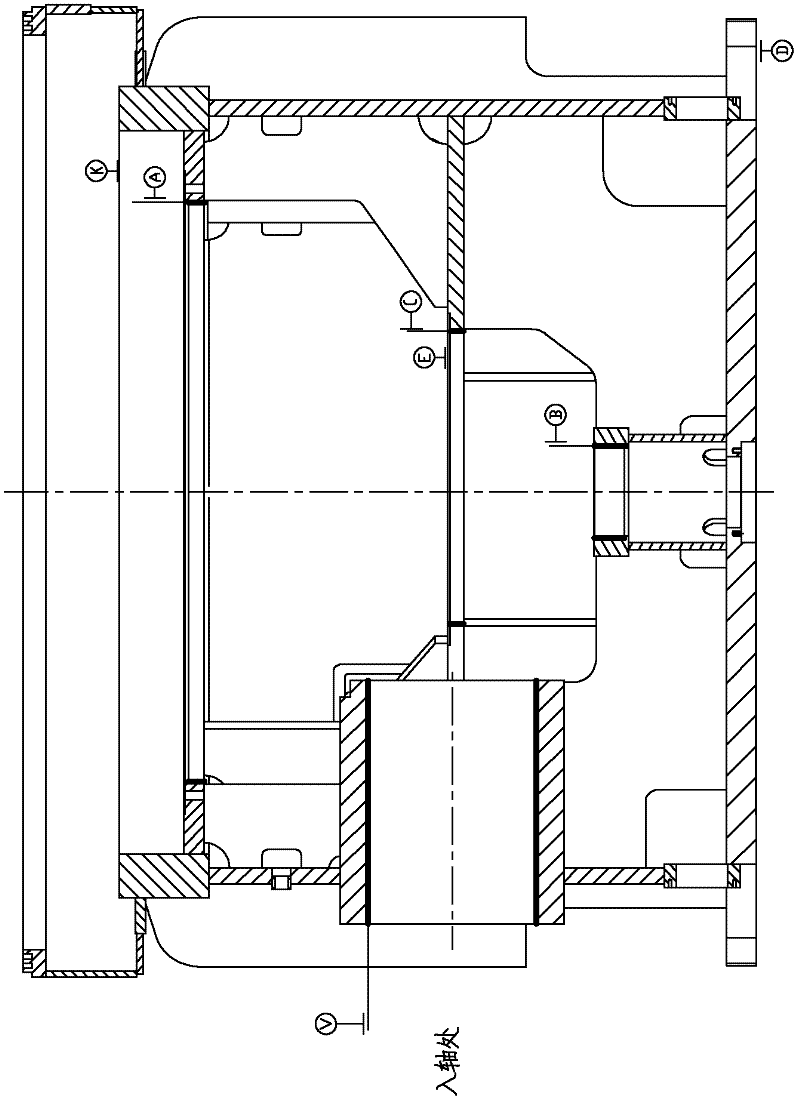

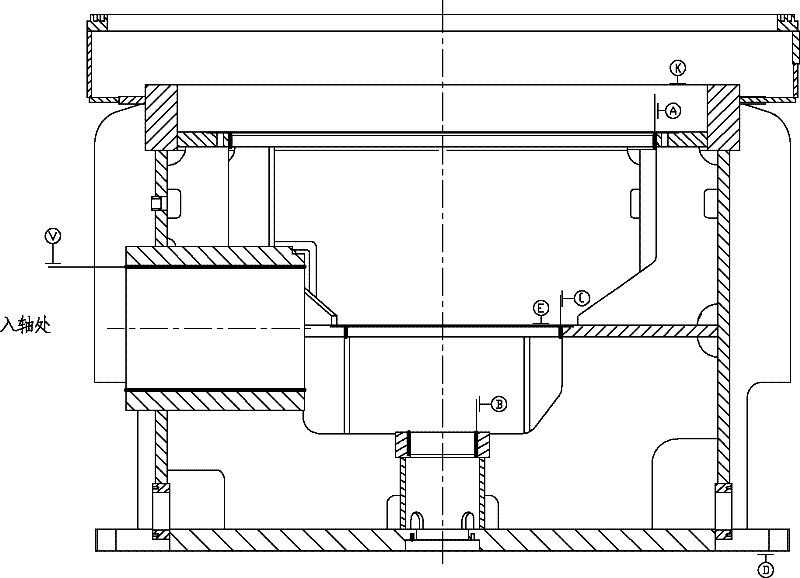

[0044] combine figure 1 , the main requirements of the vertical intersecting hole system on the body of the machined power 4800-5300KW vertical mill reducer:

[0045] 1. The dimensional accuracy of each fit of the body is 6-7 grades.

[0046] 2. The shape and position accuracy between the holes and surfaces of the machine body is 4-6 grades.

[0047] 3. The mating surface roughness of relative movement is Ra3.2.

[0048] The application of the vertical intersecting hole system processing method of the large vertical mill reducer body of the present invention is as follows:

[0049] 1. If figure 2 , the body is welded and annealed after welding to eliminate welding stress;

[0050] 2. Scribe to check the machining allowance of each part of the welding body, draw the center line of the vertical hole system A-B, and the horizontal hole V, and ensure that the two center lines intersect vertically;

[0051] 3. Select the KY-64 vertical lathe with P-level precision for roughin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com