Thin-walled shifting fork turning clamp

A fixture and forklift technology, which is applied in the field of thin-walled fork turning fixtures, can solve the problems of difficult to guarantee the processing process, complex structure, difficult clamping and calibration, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

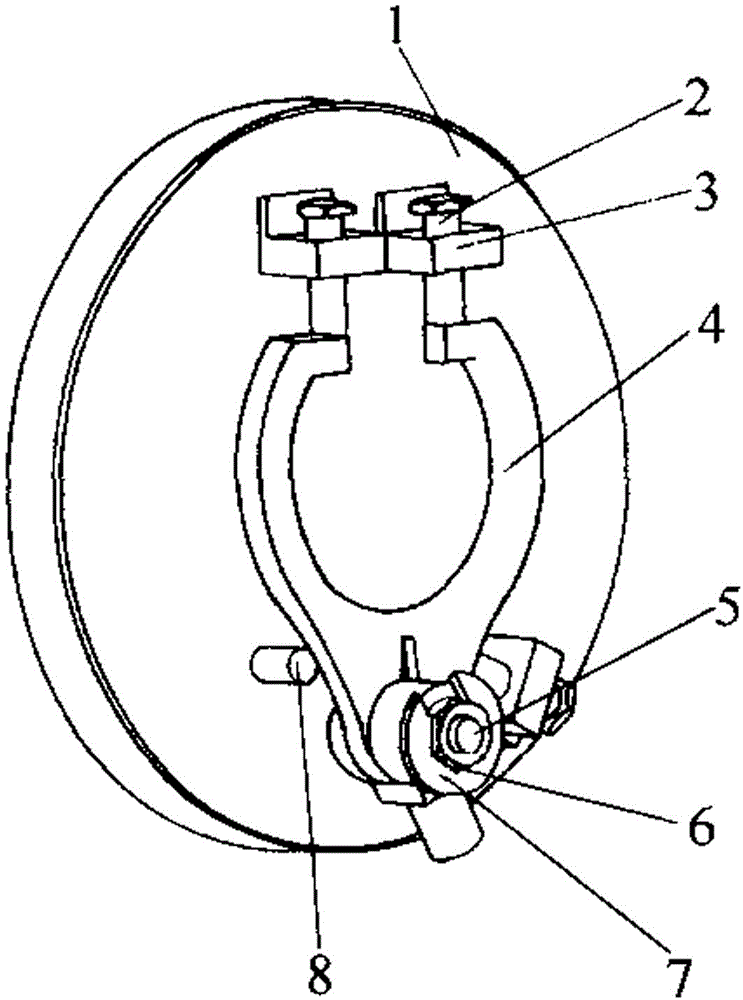

[0010] The thin-wall shift fork turning fixture of the present invention includes a fixture main body 1, the fixture main body 1 is a cylindrical circular platform, and a plurality of stoppers 3 are arranged on one end surface of the fixture main body 1, wherein two stoppers 3 are arranged side by side on the fixture main body 1 Above, the stoppers 3 are connected with compression bolts 2 through threaded holes, and two cylindrical pins are also arranged on the fixture main body 1, which are respectively a central positioning pin 5 and a limit pin 8, and the central positioning pin 5 and the Blocks 3 arranged side by side are located on the circumference of the same circle, and the center of the circle coincides with the center of the end surface of the clamp body 1 . The top of the central positioning pin 5 is threaded and connected with a nut 6 . There are three stoppers 3, and the angle between another stopper 3 and two parallel stoppers 3 is greater than 90° and less than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com