Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Guaranteed basic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous glue, lithium battery applying the aqueous glue and manufacturing method for the lithium battery

ActiveCN101286563ALow costLow investment costElectrode manufacturing processesFinal product manufactureIonChemistry

The invention provides a water-base cement which consists of a main adhesion agent, an auxiliary adhesion agent and a defoaming agent which are mixed according to the weight ratio of 20-30:1-3:1-5, wherein, the main adhesion agent is a mixed liquor prepared by one or a plurality of polyethylene glycol oxide, sodium carboxymethyl cellulose or polyvinyl alcohol with de-ionized water, and the solid content thereof is between 1 percent and 10 percent; the auxiliary adhesion agent is the mixed liquor prepared by one or two of butadiene styrene rubber or polyfluortetraethylene with the de-ionized water, and the solid content thereof is between 30 percent and 70 percent; the defoaming agent is one or a plurality of ethanol, glycol or propanediol which are mixed for use. The water-base cement has low cost, is innoxious and environment-friendly. The invention also provides a lithium battery which uses the water-base cement and a manufacturing method for the lithium battery.

Owner:袁植良

Edible insect full-powder and the production process and application thereof

InactiveCN101116472ARich varietyIncrease the number ofAnimal proteins working-upAdditive ingredientInternational market

The present invention relates to a method to fabricate a full edible insect powder, with the main raw material as the edible insects with the represent of the flour weevil, the cicada, the cryptympana atrata, the locust and the silkworm pupa. The exploited products in both domestic and international markets at present include the specific animal feeds and the dishes of edible insects, as well as the animal feed made from a certain amount of raw materials of insects. The present invention aims to exploit a full edible insect powder as well as the fabrication method and application thereof to accomplish the industrialized production with a large scale. The technical proposal is that the insects which undergoes both elimination of foreign bodies, toxins and cleaning up in the latter phase of cultivation are killed, dehydrated, roasted, (or dried through refrigeration) dried and refrigerated in vacuum, and then smashed and filtrateed to be the final product. The effect of the present invention is that the full insect powder contains all nutritious elements thereof, including proteins, lipids, vitamins and various trace elements. The present invention has unique characteristic, safety without toxins, wide application fields, feasibility to be the nutrition of serious snacks, and feasibility to be the stuffing of food of various cakes and candies.

Owner:西安市轻工业研究所

Printed circuit board, design method thereof and terminal product main board

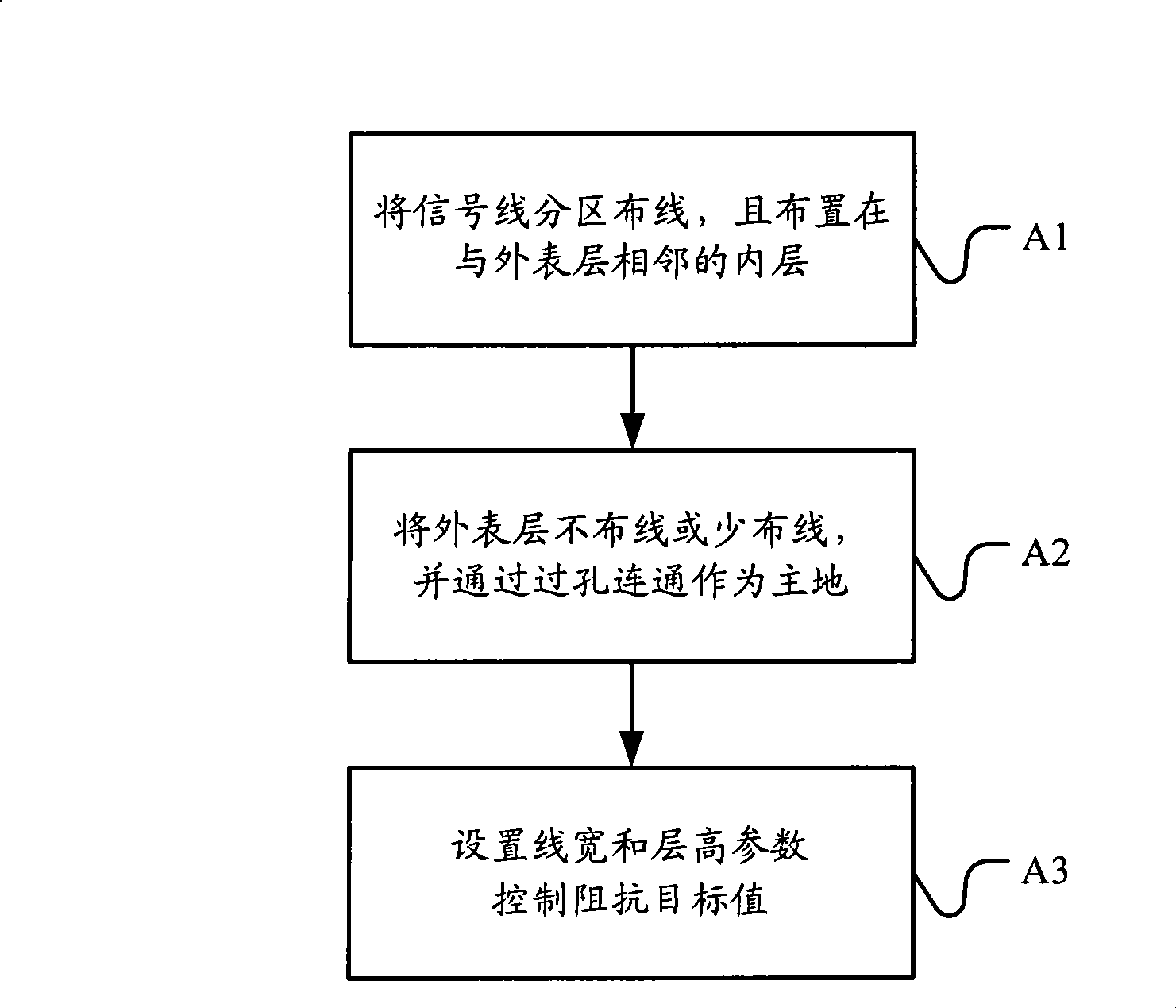

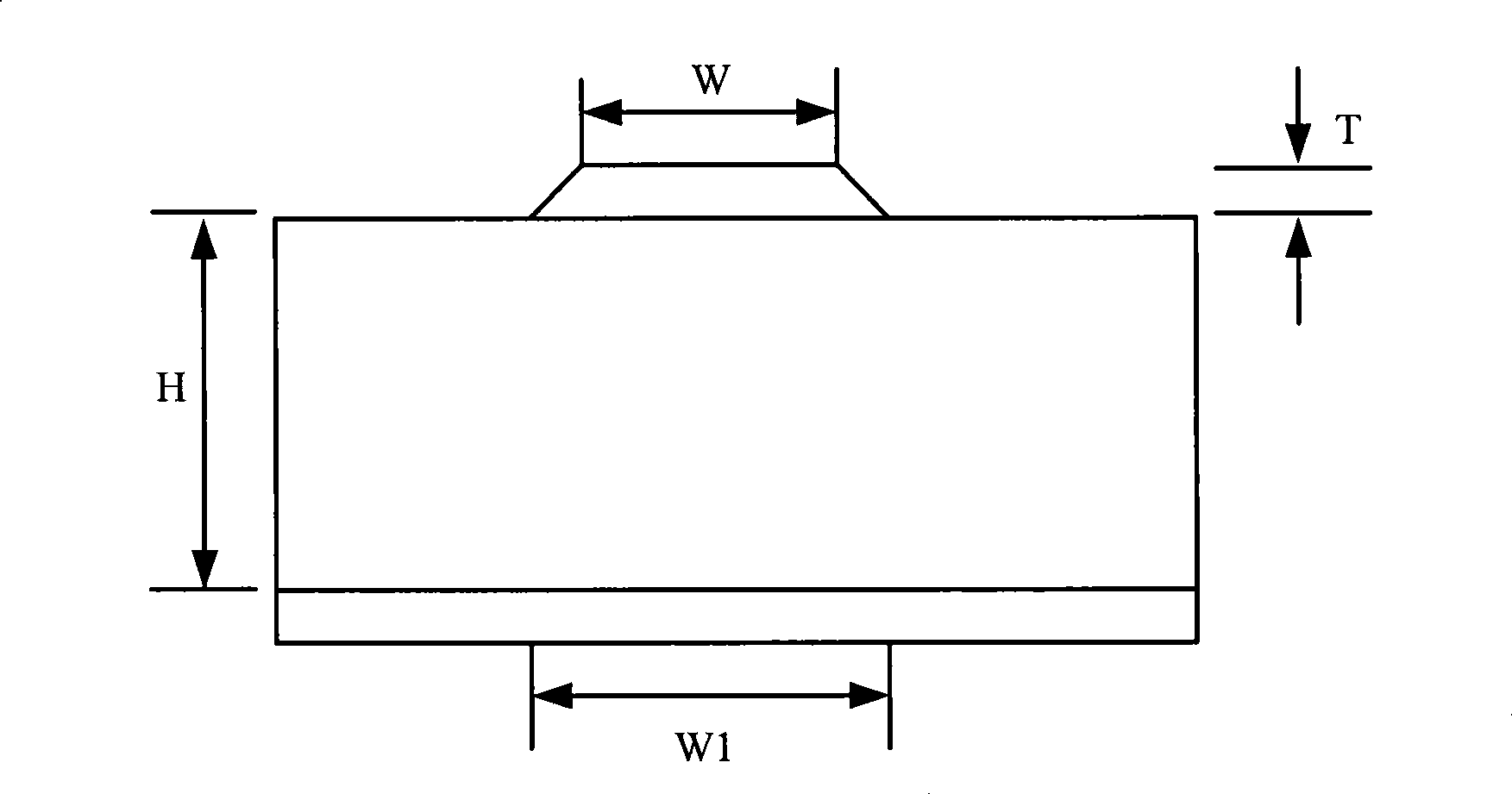

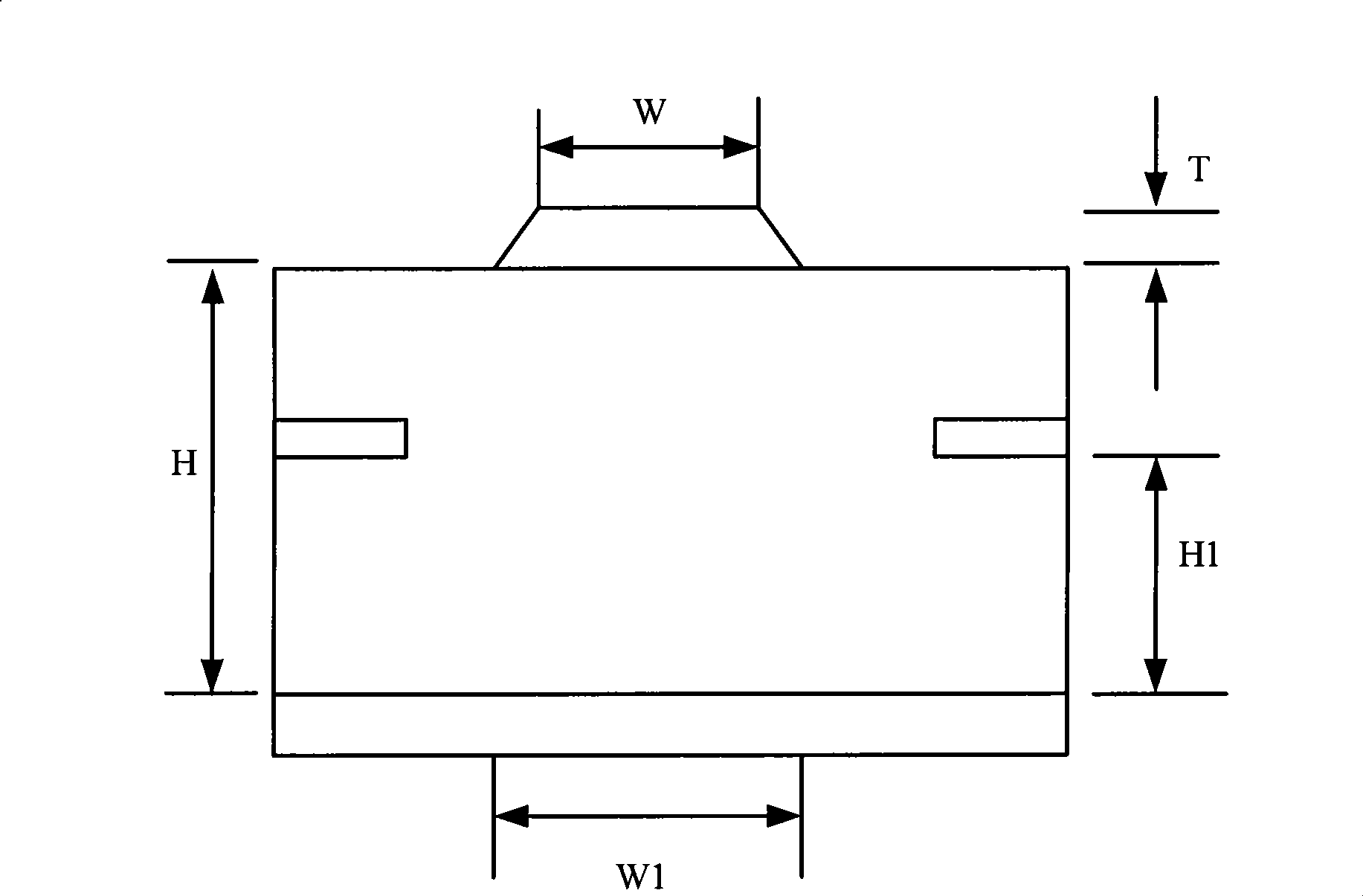

ActiveCN101365291AGuaranteed basic performanceGuaranteed performanceCross-talk/noise/interference reductionPrinted circuit aspectsWire widthSurface layer

The embodiment of the invention discloses a design method of a printed circuit board. The method comprises the following steps of laying a signal wire on inner layers next to an outer surface layer by zones; not wiring the outer surface layer or laying less wire on the outer surface layer which is used as a main area communicated through a hole; and setting wire width and layer height parameters to control an impedance target value. Correspondingly, the embodiment of the invention provides the printed circuit board, which comprises the out surface layer, and two inner layers positioned between the surface layers. The inner layers next to the out surface layer are used for laying signal wires by zones. Few wires or no wire is laid on the out surface layer and the outer surface layer is used as the main area communicated through the hole. The invention also discloses a terminal product main board using the printed circuit board. The technical proposal provided by the embodiment of the invention can reduce the cost and improve the reliability by layer reduction design under the condition that the basic properties of the original multi-layer printed circuit board is kept.

Owner:HUAWEI TECH CO LTD

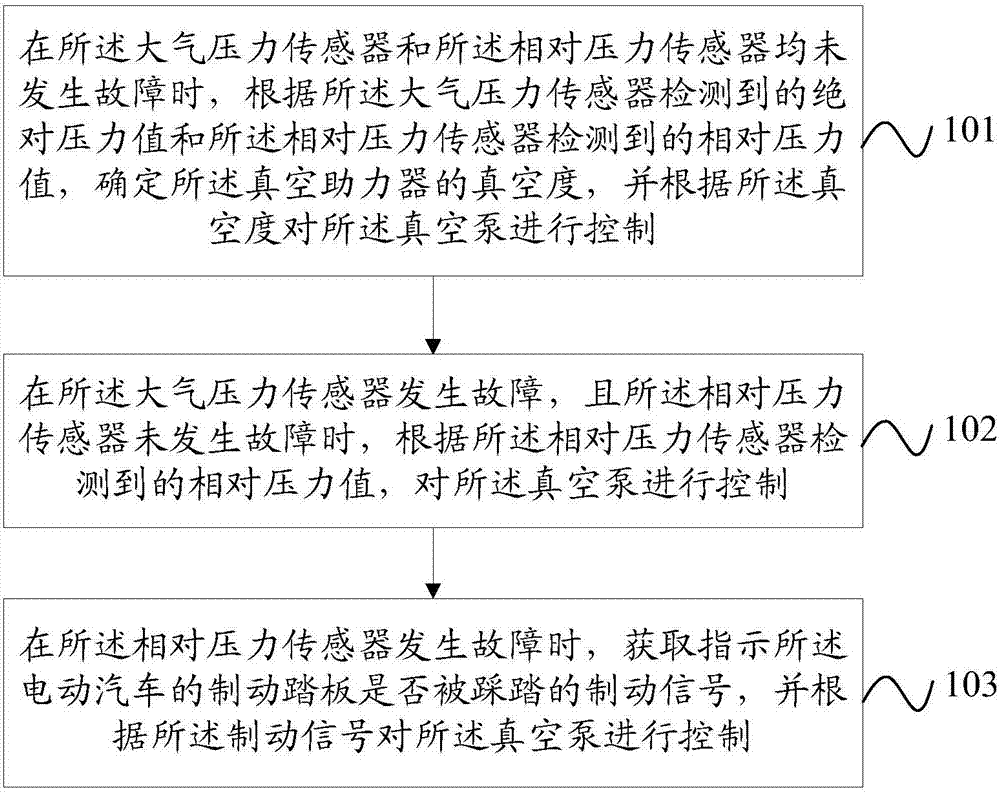

Vacuum pump control method and device and electric car

ActiveCN107097769AImprove reliabilityGuaranteed reliabilityBraking action transmissionPump/compressor arrangementsRelative pressureEngineering

The invention provides a vacuum pump control method and device and an electric car and relates to the field of electric car control. The problems that in the prior art, the property of a vacuum pump cannot be ensured, and reliability and safety are low are solved. The method is applied to a vacuum pump system which comprises an atmospheric pressure sensor and a relative pressure sensor. The method comprises the steps that when breakdowns do not occur to the two pressure sensors, the vacuum degree of a vacuum booster is determined according to an absolute pressure value detected through the atmospheric pressure sensor and a relative pressure value detected through the relative pressure sensor, and the vacuum pump is controlled according to the vacuum degree; when the breakdowns occur to the atmospheric pressure sensor and do not occur to the relative pressure sensor, the vacuum pump is controlled according to the relative pressure value; and when the breakdowns occur to the relative pressure sensor, the vacuum pump is controlled according to braking signals. According to the scheme of the vacuum pump control method and device and the electric car, effective control over the vacuum pump under different breakdown conditions is achieved, so that the property of the vacuum pump is ensured, and reliability and safety are improved.

Owner:BEIJING ELECTRIC VEHICLE

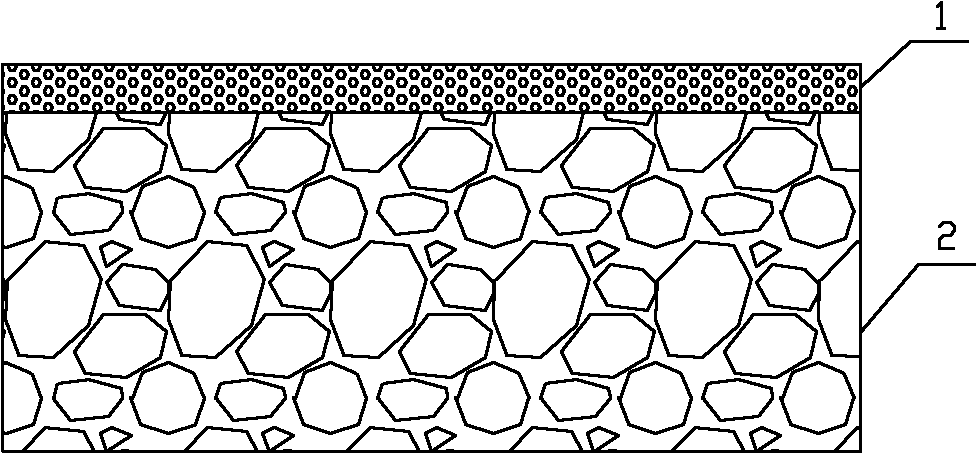

Water permeable brick capable of adsorbing heavy metal ions

ActiveCN102127891AGuaranteed basic performanceSolve the pollution treatment problems caused by urban traffic that cannot be solvedSolid waste managementSingle unit pavingsSurface layerBrick

The invention discloses a water permeable brick capable of adsorbing heavy metal ions, and belongs to the field of building materials. A paving brick has a double-layer structure, wherein the surface layer is made of ferroaluminate cement mortar, and the lower layer is made of ferroaluminate cement concrete; the ferroaluminate cement mortar of the surface layer comprises the following components in percentage by weight: 25 to 30 percent of ferroaluminate cement, 55 to 65 percent of sand and 10 to 15 percent of steel slag; and the ferroaluminate cement concrete of the lower layer comprises the following components in percentage by weight: 15 to 30 percent of ferroaluminate cement, 1 to 5 percent of zeolite, 50 to 60 percent of coarse aggregate and 20 to 30 percent of fine aggregate. Since the water permeable brick capable of adsorbing the heavy metal ions has the double-layer structure which is constructed by different materials, the heavy metal ions can be adsorbed on the basis of guaranteeing basic performance of the water permeable brick; and the problem of pollution treatment caused by urban traffic which cannot be solved by the conventional paving brick can be practically solved.

Owner:北京新奥混凝土集团有限公司

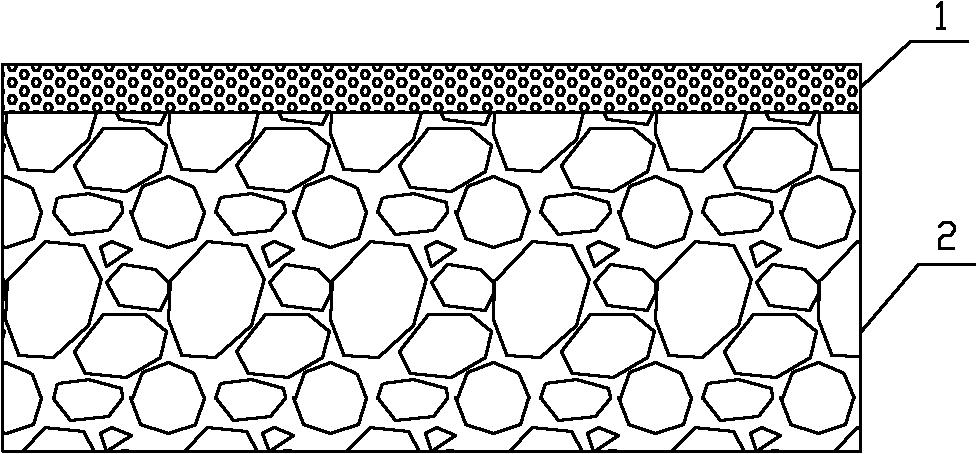

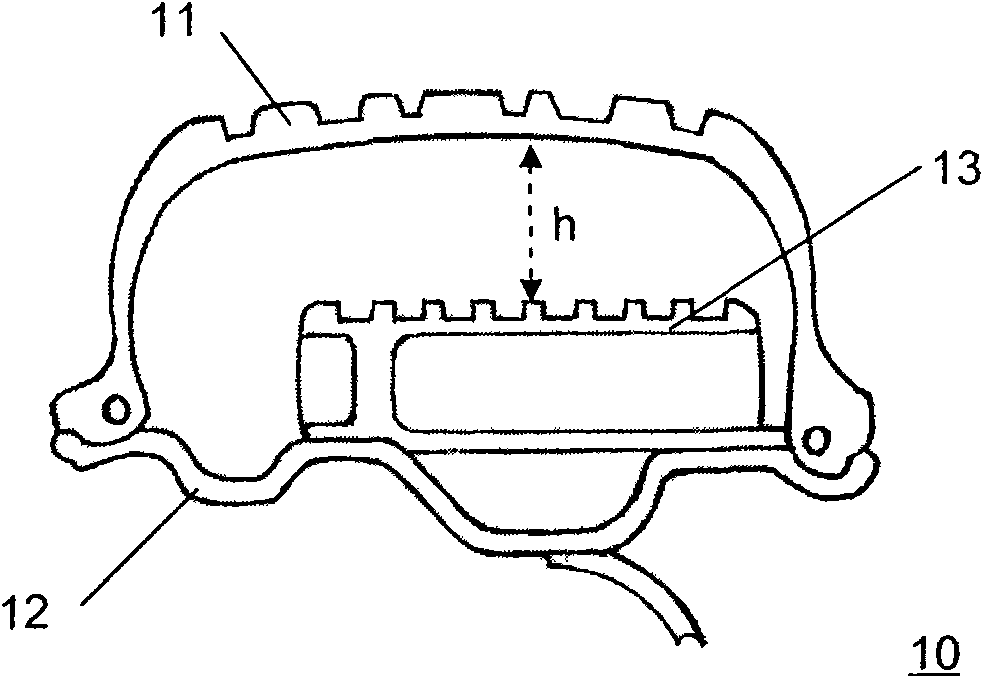

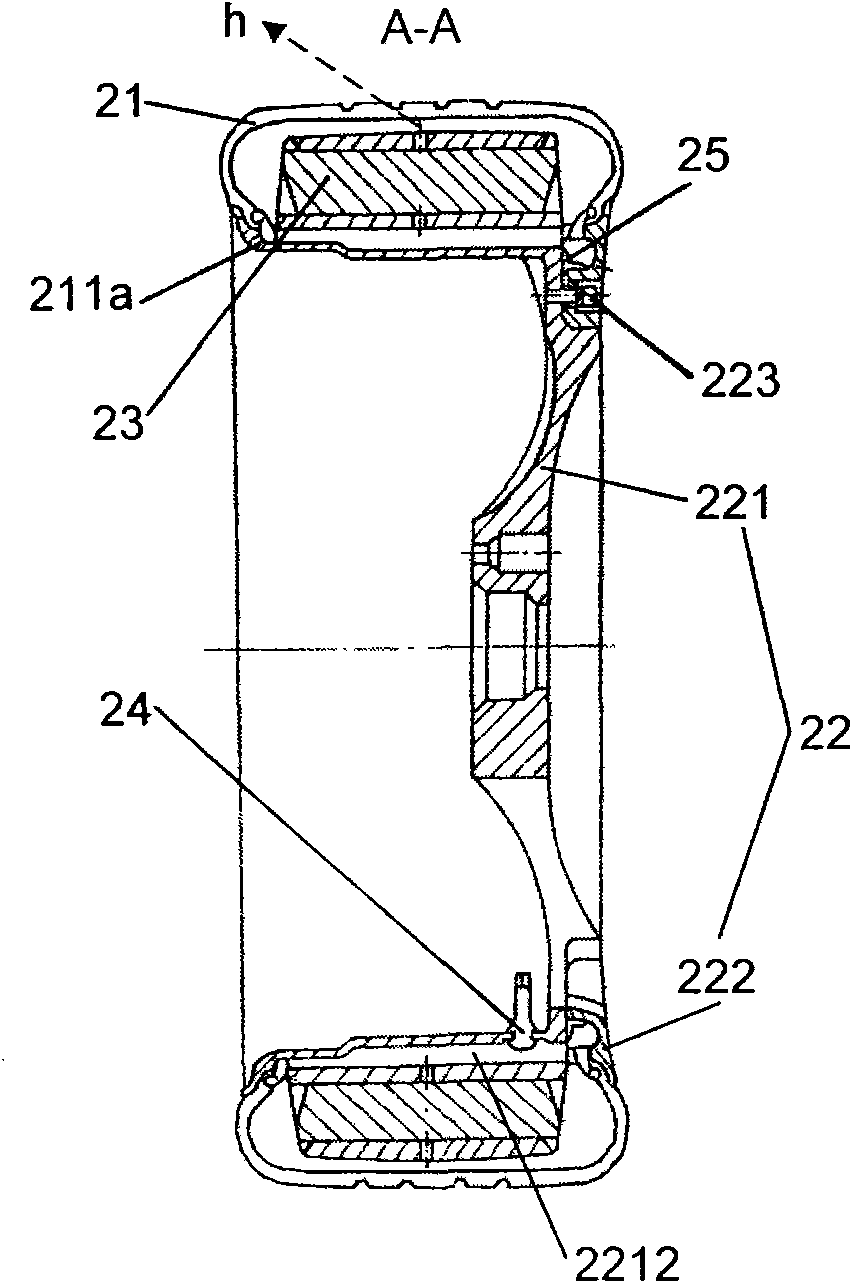

Explosion-proof safety tyre of vehicle

ActiveCN101596845AGuaranteed basic performanceReduce distanceRimsTyre measurementsEngineeringLarge size

The invention discloses an explosion-proof safety tyre of a vehicle. The tyre comprises an outer tyre, a split rim, an L-shaped sealing ring, a combined support loop and a valve core. The combined support loop comprises a plurality of layers of support rings, and a plurality of layers of support rings are sleeved layer upon layer and fixed with the rim. The size of the tyre can be increased through the combined support loop so as to furthest shorten the distance between the inner wall of the outer tyre and the outer wall of the support loop under normal tyre pressure; at tyre burst moment, the combined support loop can quickly and effectively support the outer tyre, and controls the change of the acting radius of the tyre in a smallest possible range so as to ensure the prior basic performance of the tyre, prevent accidents caused by sudden control loss of the running direction of the vehicle and avoid potential safety hazard; in addition, the split rim is favorable for mounting the large-size combined support loop by layering, and is greatly convenient for assembly and disassembly processes at the same time so that the maintenance and replacement of the tyre can be finished by adopting a common tool.

Owner:吴小寅 +1

Sirospun yarn and spinning method thereof

The invention discloses a sirospun yarn and a spinning method thereof. The yarn consists of 25-35 wt% of coffee carbon fiber, 25-35 wt% of bamboo-carbon fiber and 30-40 wt% of cotton fiber, wherein the fibers are spun into the yarn through a siro spinning process. The spinning method sequentially comprises a loose fiber dyeing process, a cotton carding process, a drawing process, a roving process, a fine yarn siro spinning process and a spooling process. The yarn is formed by blending various fibers, the characteristics of each fiber are highlighted by reasonably setting the weight proportion of each fiber, the advantages of various fibers are integrated, the basic performance of the yarn is kept, the propagation of bacteria is restrained, the release of odor ammonia is reduced, and peculiar smell of alcohol, tobacco and the like can also be effectively removed. Compared with the conventional spinning process, the sirospun yarn disclosed by the invention has less hairness than the ordinary ring spun yarn, particularly the long hairness longer than 3mm is well improved, the method has greater advantages in size dyeing, weaving, singeing and other processes, and the woven fabric has a good wear-resisting property, a good anti-pilling performance and better surface handfeel and softness.

Owner:JIANGNAN UNIV +1

Semi-worsted yarn and spinning method thereof

InactiveCN102719953AWide adaptability of raw materialsHigh or low spinning countYarnDyeingEngineering

The invention relates to a semi-worsted yarn and a spinning method thereof. The semi-worsted yarn is formed by blending, by weight, 25-35% of coffee carbon fibers, 25-35% of bamboo carbon fibers and 30-40% of cotton fibers and spinning the same by semi-worsted spinning process. The spinning method sequentially includes a dyeing step, a fiber combining step, a cotton carding step, a drawing step, a roving step, a yarn spinning step and a spooling step. The blended semi-worsted yarn is blended with various fibers. The advantages of each fiber, which are shown by reasonable arrangement of the fibers according to weight proportion, are integrated, and accordingly, basic performance of the yarn is kept while functions of suppressing bacterium breeding, reducing discharge of smelly ammonia and effectively removing peculiar smell of smoke and wine and the like are achieved. Besides, compared with the worsted process, the semi-worsted process is short in procedure. The semi-worsted yarn is looser and softer than worsted yarns and more uniform and lustrous than roving and is high in applicability to raw materials, widely popularized, low in equipment investment and small in occupation space in factories, and the count of the yarn can be adjustable.

Owner:JIANGNAN UNIV +1

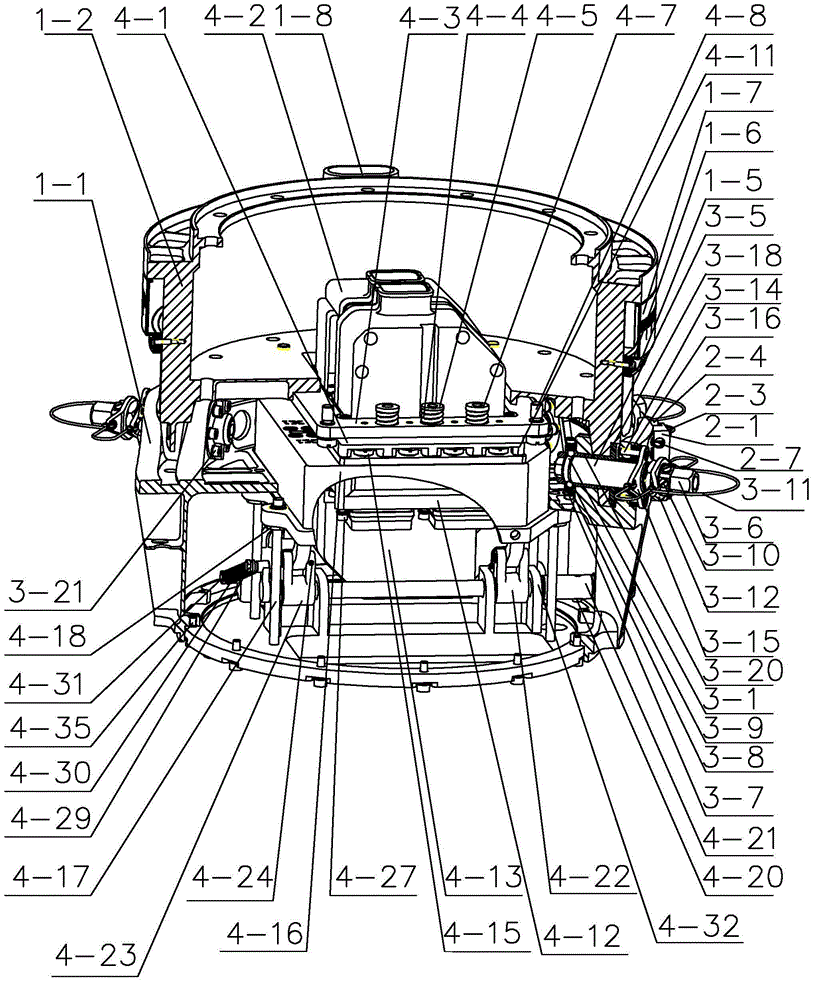

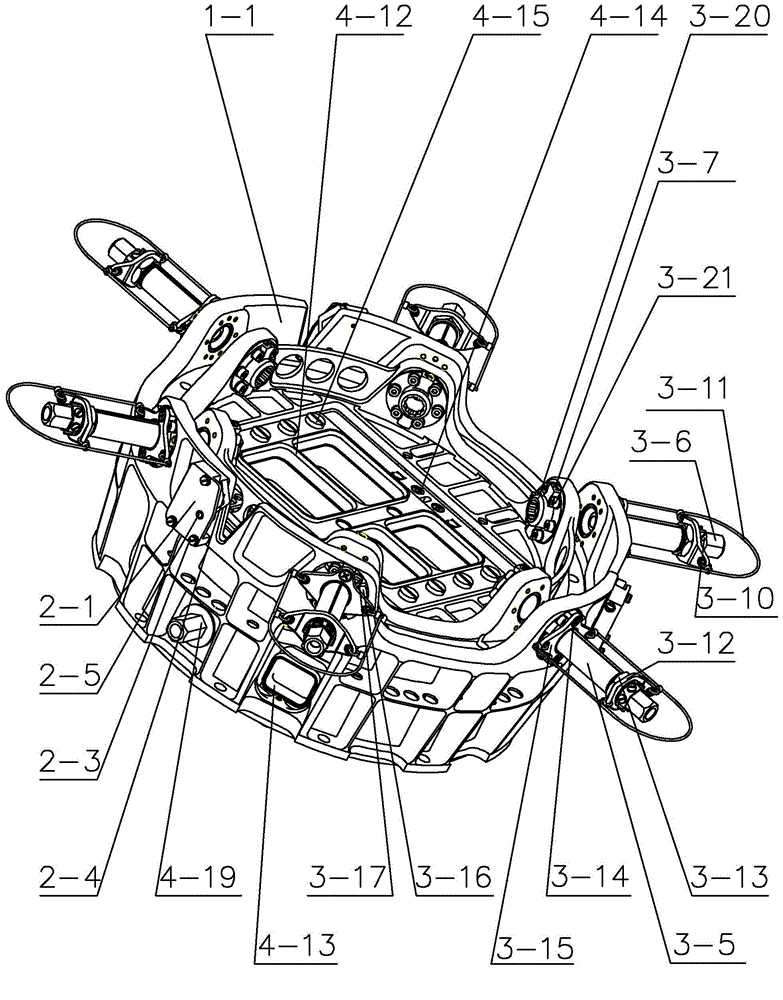

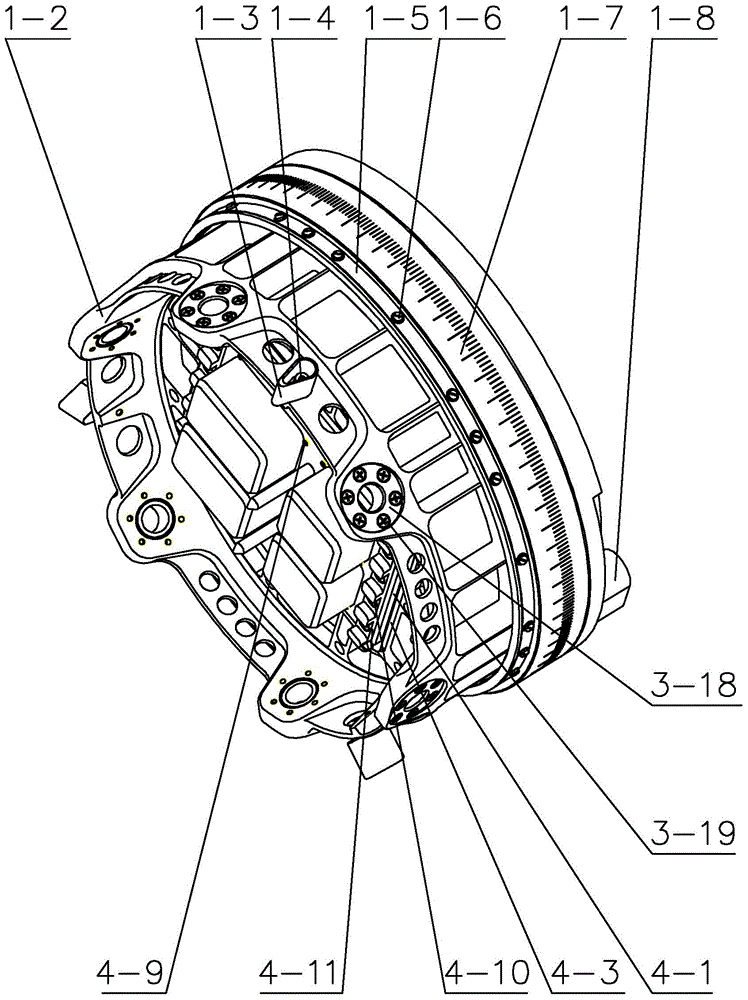

Robot arm joint quick-change interface system allowing on-rail replacement

InactiveCN104816311AWith overtravel buffer functionSo as not to damageJointsElectrical bondingSacroiliac joint

A robot arm joint quick-change interface system allowing on-rail replacement relates to a robot arm joint quick-change interface system. The robot arm joint quick-change interface system solves the problem that an electric connector of a conventional robot arm joint quick-change interface system is damaged due to overload, since the electric connector has no over travel buffering function. A tolerance guiding abutting apparatus comprises a recessed body and a protruding body matching with the recessed body structure, wherein the recessed body and the protruding body are detachably connected through a plurality sets of locking positioners and a plurality sets of mechanical connection and quick-detach apparatuses, the plurality sets of locking positioners are uniformly arranged between the recessed body and the protruding body, and the plurality sets of mechanical connection and quick-detach apparatuses are uniformly arranged between the recessed body and the protruding body. An electrical connecting device is arranged in a cavity formed by the recessed body and the protruding body. The robot arm joint quick-change interface system is used for spatial on-rail maintenance.

Owner:HARBIN INST OF TECH

Multi-fiber color-mixed semi-worsted antibacterial yarns and spinning technology thereof

InactiveCN103422211AGuaranteed basic performanceGuaranteed antibacterial functionYarnFiberCarbon fibers

The invention relates to multi-fiber color-mixed semi-worsted antibacterial yarns which are formed by spinning the following fibers in percentage by weight: 20-40 percent of coffee carbon fibers, 20-25 percent of porel fibers and 25-35 percent of modal fibers by a semi-worsted technology. A spinning technology sequentially comprises a cotton carding technology, a drawing technology, a roving technology, a spinning technology and a spooling technology. The multi-fiber color-mixed semi-worsted antibacterial yarns are formed by blending multiple fibers; characteristics of every type of fiber are highlighted by reasonably arranging the weight proportion of the fiber; the advantages of the fibers are integrated, so that the basic performance of the yarns is retained, and an antibacterial function is guaranteed. Compared with a worsted technology, the semi-worsted technology has the advantage of shorter flow process; semi-worsted yarns are looser and more flexible than worsted yarns and are more uniform and more bright than roved yarns; furthermore, the colored coffee fibers are blended into the semi-worsted yarns, so that dyeing is not needed in the whole flow process, and the whole flow process is environment-friendly and energy-saving.

Owner:JIANGNAN UNIV +1

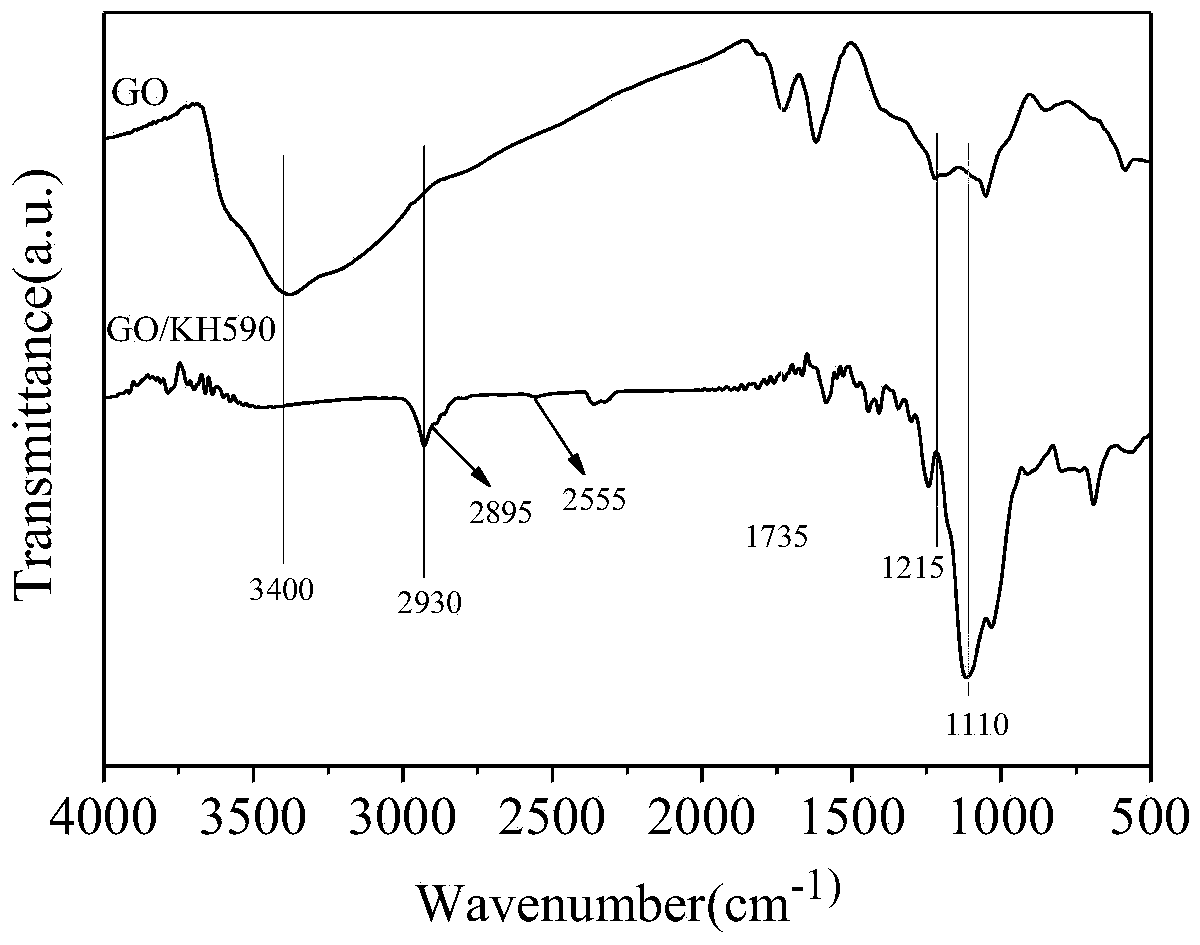

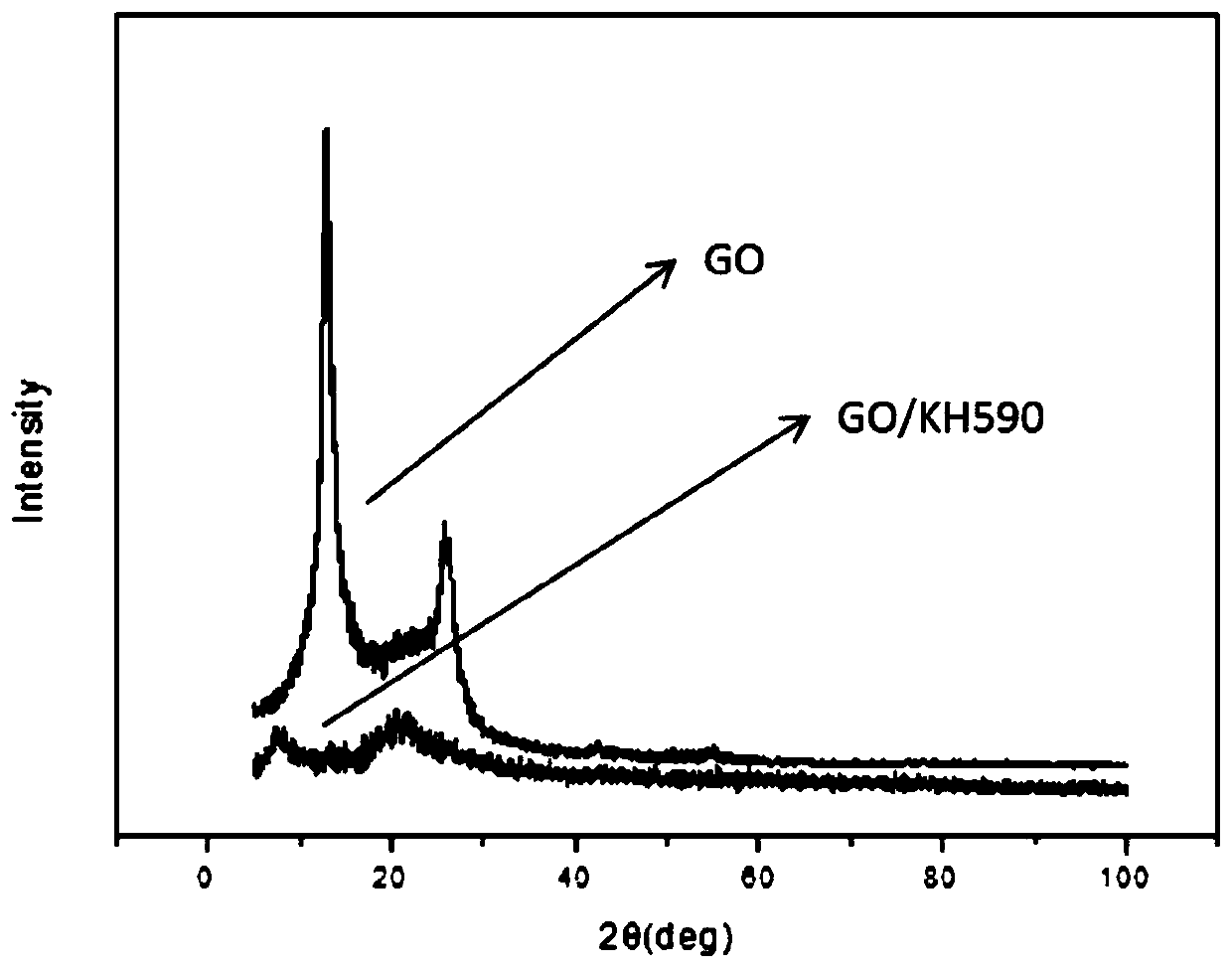

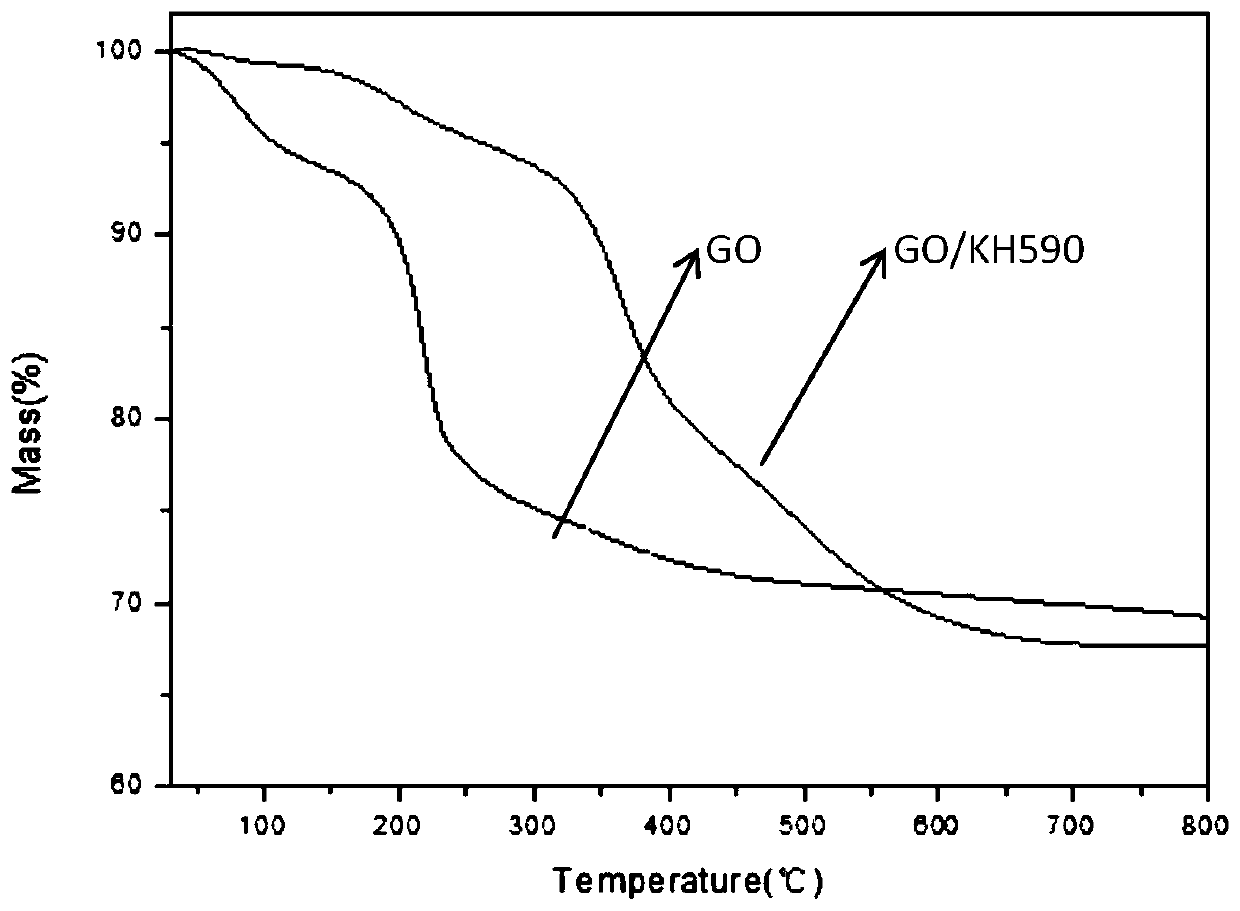

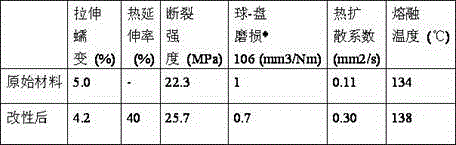

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

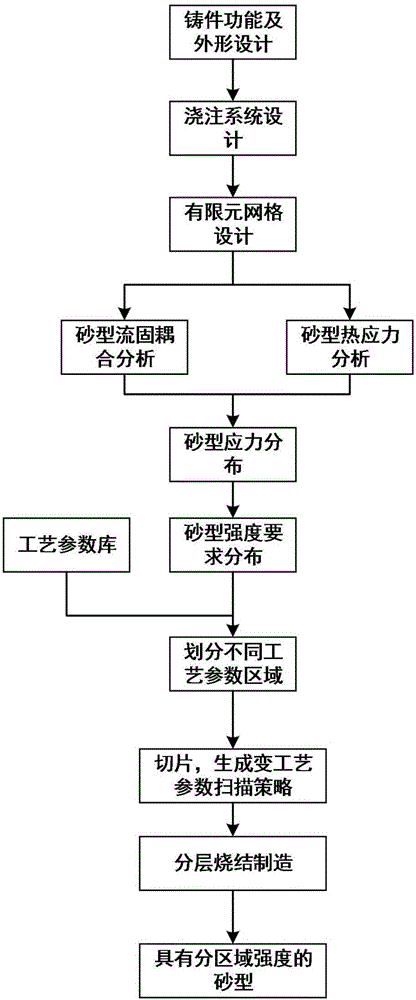

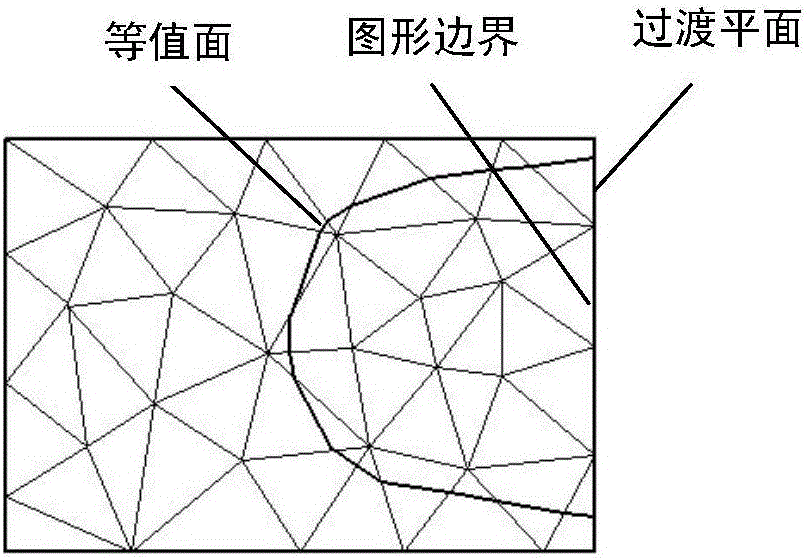

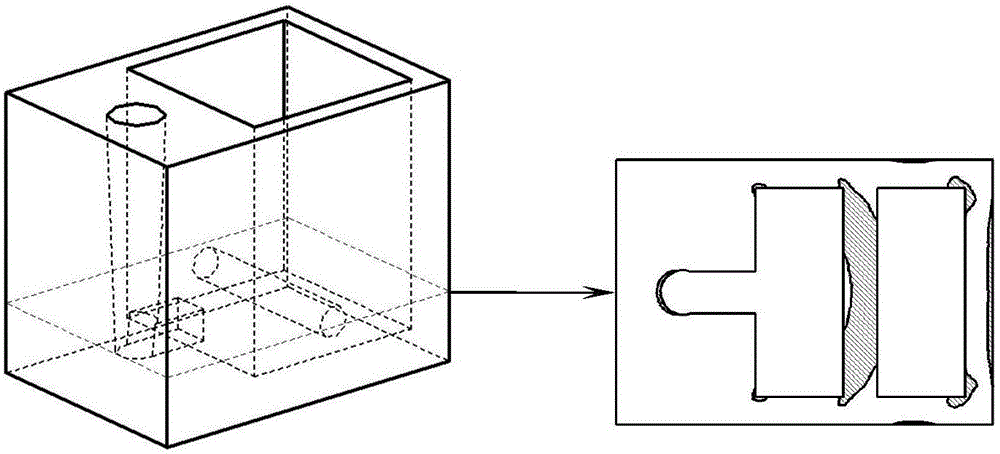

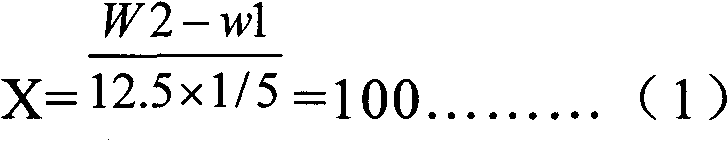

Design and manufacturing method used for selective laser sintering sand mould regional strength change

ActiveCN106682299AImprove adaptabilityGuaranteed basic performanceDesign optimisation/simulationSpecial data processing applicationsStress distributionSelective laser sintering

The invention provides a design and manufacturing method used for selective laser sintering sand mould regional strength change. Firstly, a belt casting system three-dimensional model is designed according to appearance characteristics of a cast part and divided into finite element meshes used for numerical simulation, fluid-solid coupling and thermal stress calculation are conducted on the finite element meshes, stress distribution of a sand mould in the filling and solidifying processes is obtained, the stress distribution is converted into equivalent stress according to a sand mould material strength standard, and strength required distribution of the sand mould is obtained; secondly, sintering efficiency is taken into consideration, process parameters meeting requirements are extracted from a process parameter library, and regions using different process parameters are divided out; thirdly, the sand mould model obtained after partition is sliced to generate a regional variable-process-parameter scanning strategy; fourthly, the regional variable-process-parameter scanning strategy is imported into a selective laser sintering device for layered sintering and manufacturing, and finally the sand mould with regional strength is obtained. The method is capable of improving efficiency of manufacturing the sand mould through the laser sintering technology and improving adaptability of the sand mould to the casting process.

Owner:XI AN JIAOTONG UNIV

Hemp fibre filter wire and preparation method thereof

InactiveCN101884859AUnique anti-mold and bactericidal functionGood inhibition effectFiltration separationVegetable materialChemical industryYarn

The invention relates to a filter material for water treatment, in particular discloses a hemp fibre filter wire and a preparation method thereof. The hemp fibre filter wire is characterized by being prepared by using hemp fibres as raw materials, spinning the hemp fibres into yarns through hemp spinning equipment and then degumming, bleaching, drying and forming. The invention is mainly used for the purification and the filtering of various liquids; a wire-wound filter core prepared by the hemp fibre filter wire is used for the precise filtering of the liquids in a petroleum industry, a chemical industry, an electron industry, a pharmaceuticals industry, a food industry, a domestic water industry, and the like; and in addition, the invention can bring new vitality for the water treatment industry due to excellent performance and complete green environmentally-friendly quality.

Owner:郭淼

High-energy lithium battery cathode slurry and preparation method thereof

InactiveCN109888264AGood dispersionHas ion conductivityElectrode manufacturing processesSecondary cellsElectrical batteryHigh energy

The invention discloses high-energy lithium battery cathode slurry, and relates to the technical field of lithium battery production. The slurry mainly aims at solving the problems that the existing cathode slurry has poor viscosity, has insufficiently uniform smearing, and has a direct influence on the performance of a battery. The slurry comprises the following raw materials: a cathode active substance, a conductive agent, an adhesive agent, a defoaming agent, a high-polymer additive, a dispersing additive, a thickening agent, a flame retardant, a buffer solution and the balance of solvent.The invention further discloses a preparation method of the high-energy lithium battery cathode slurry. The high-polymer additive has ionic conductivity, so that the ionic conductivity of a cathode material can be improved; the charge transfer resistance can be reduced; and the rate capability of a lithium ion battery can be improved. The thickening agent is added by combination, so that various components can fully exert effects; the thickening agent can keep the stability of a molecular structure in a long-time standing process, and can keep the performance of the slurry stable; and agglomeration and sedimentation can be avoided.

Owner:山东高质新能源检测有限公司

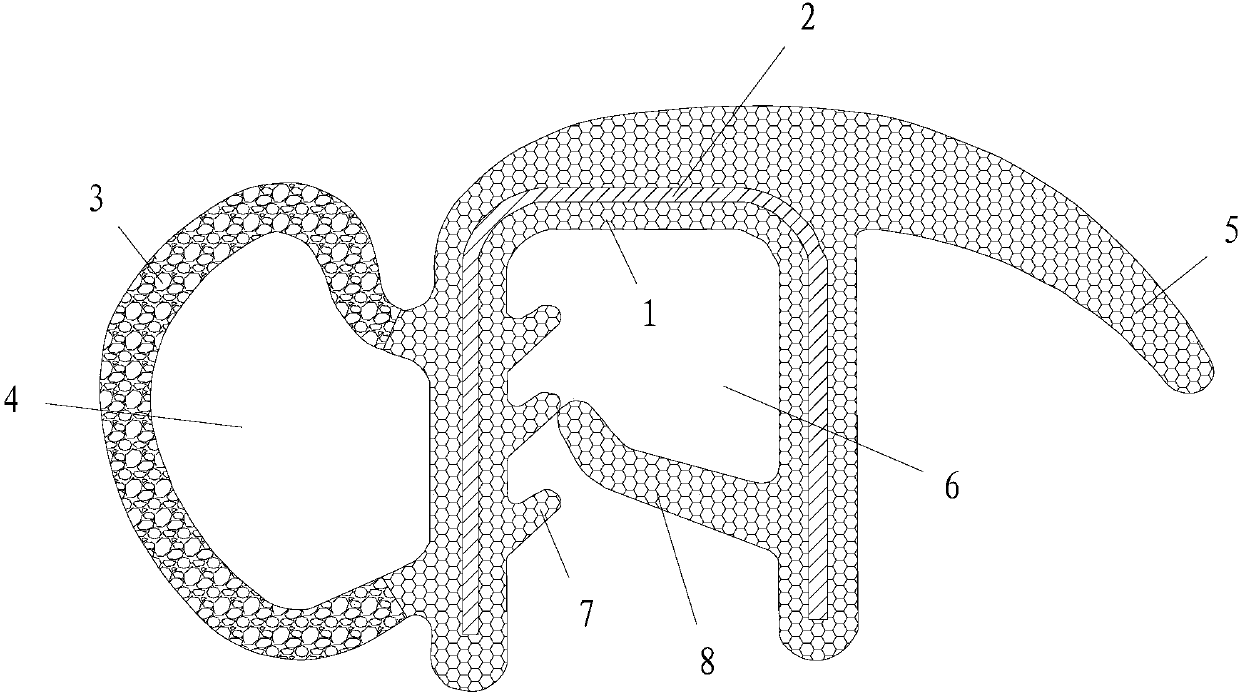

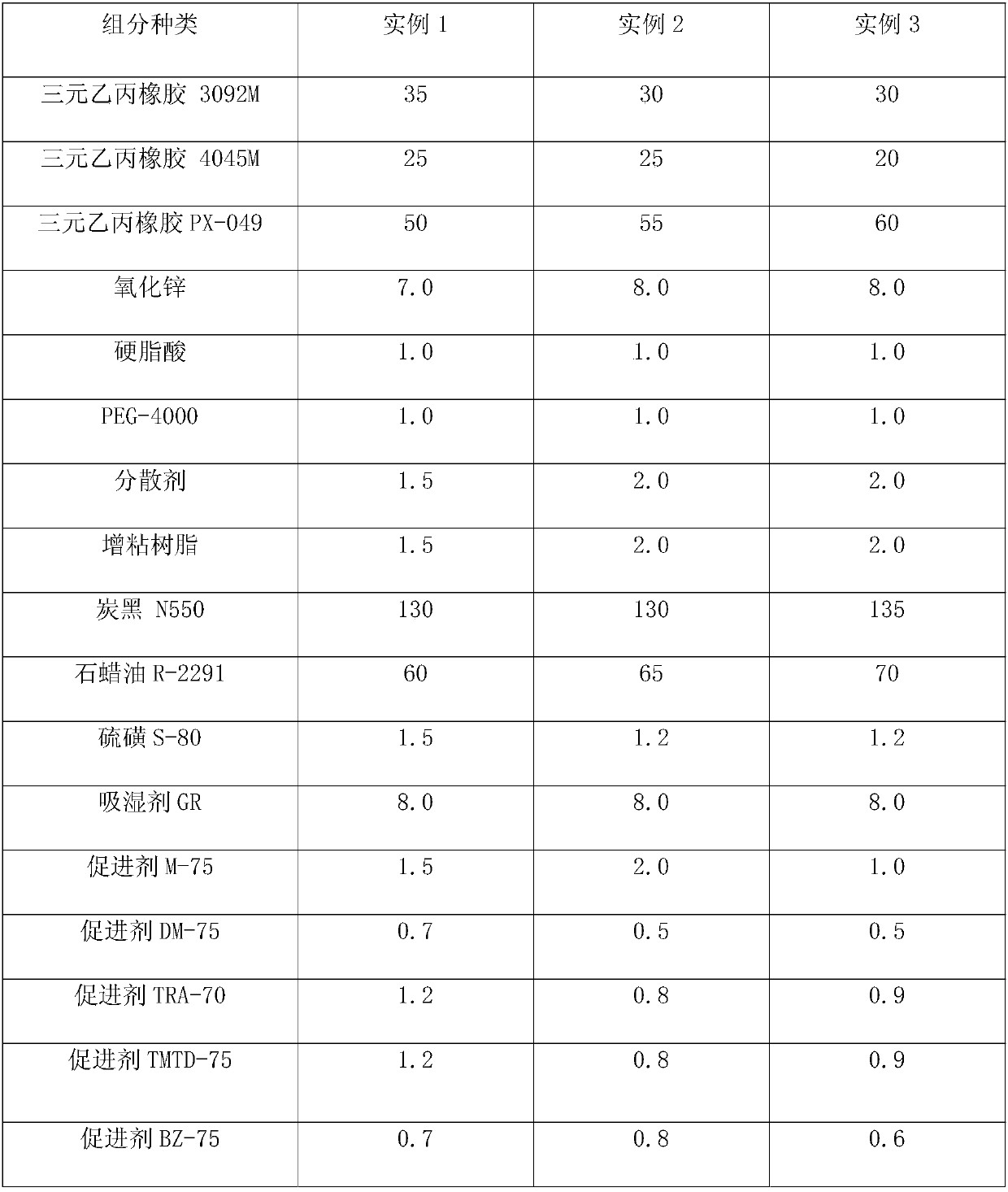

Sealing strip cladding sizing material and preparation method thereof as well as car door sealing strip and preparation method thereof

The invention provides a sealing strip cladding sizing material and a preparation method thereof as well as a car door sealing strip and a preparation method thereof. The sealing strip cladding sizingmaterial of the invention is prepared from the following components: EPDM (Ethylene-Propylene-Diene Monomer) 3092M, EPDM 4045M, EPDM PX-049, zinc oxide, stearic acid, PEG-4000, a dispersing agent, tackifying resin, paraffin oil R-2291, carbon black N550, sulfur S-80, a moisture absorbent GR, an accelerant M-75, an accelerant DM-75, an accelerant TRA-70, an accelerant TMTD-75, an accelerant BZ-75,an accelerant ETU-80, and a microsphere foaming agent EWE-60GE. The sealing strip cladding sizing material of the invention can implement the light-weight design of a sealing strip product, also hasrelatively good physical properties such as processability and surface quality, and can improve the quality of a sealing strip utilizing the sealing strip cladding sizing material.

Owner:NUOBO RUBBER PRODION

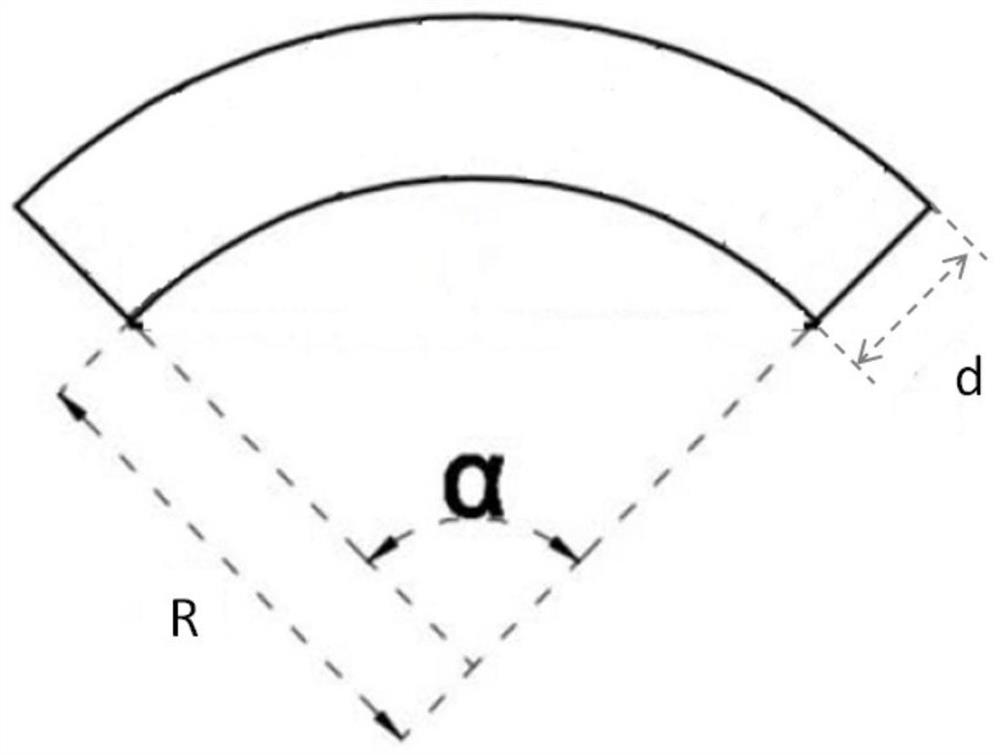

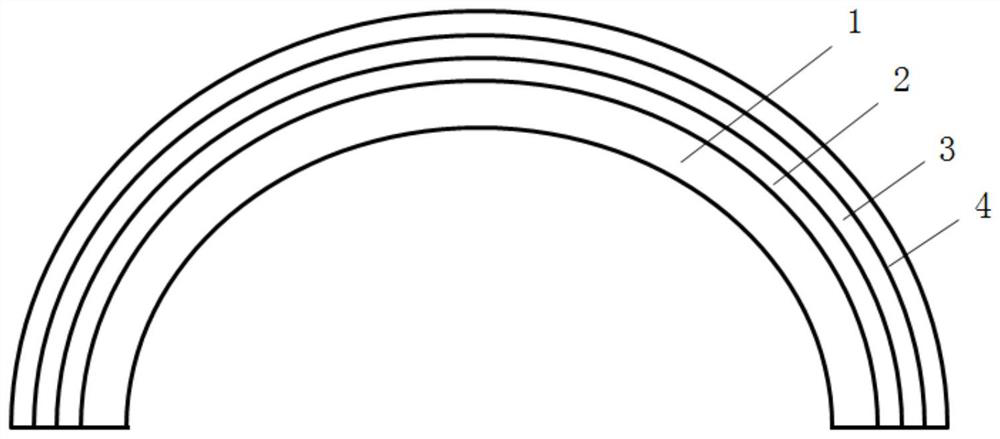

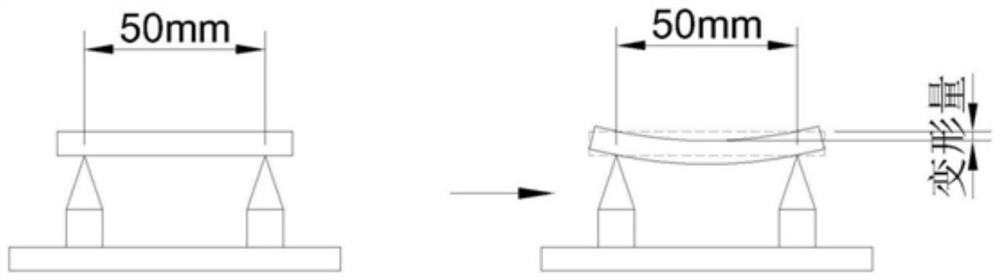

High-curvature wide-color-gamut ceramic curved surface rock plate and preparation method and application thereof

ActiveCN113979738AGuaranteed basic performanceReduce contentCovering/liningsSolid waste managementCelluloseGlaze

The invention discloses a high-bending-degree wide-color-gamut ceramic curved surface rock plate and a preparation method and application thereof. The thickness of the curved surface rock plate is 3-6 mm, the curvature radius is larger than or equal to 100 mm, and the arc center angle is 0-180 DEG C. The curved surface rock plate comprises a glaze layer, and the glaze layer comprises a ground glaze layer and a cover glaze layer arranged on the upper portion of the ground glaze layer. The ground glaze layer is prepared from the following raw materials in parts by weight: 81-90 parts of EN-1 frit, 8-12 parts of kaolin, 2-7 parts of quartz, 0.3-0.5 part of sodium tripolyphosphate and 0.15-0.22 part of sodium carboxymethyl cellulose; the cover glaze layer is prepared from the following raw materials in parts by weight: 30-45 parts of 7 # transparent frit, 8 parts of kaolin, 0-7 parts of quartz, 0-40 parts of albite, 0-15 parts of potassium feldspar, 0-5 parts of dolomite, 0-5 parts of calcite, 0-6 parts of barium carbonate, 0.3-0.5 part of sodium tripolyphosphate and 0.15-0.22 part of sodium carboxymethyl cellulose. According to the ground glaze formula adopted by the curved surface rock plate, after hot bending and re-burning, glaze cracks of the bottom surface glaze are not generated, the phenomena of matt recrystallization and glaze layer devitrification are avoided, and the color gamut range is widened.

Owner:广东东唯新材料有限公司 +4

Novel environment-friendly phase change plastering putty

ActiveCN101514267AGuaranteed basic performanceAutomatic temperature adjustmentFilling pastesPhase changePhase-change material

The invention discloses a novel environment-friendly phase change plastering putty, which comprises the following components in percentage by weight: 0.1 to 8 percent of modifier, 0.5 to 25 percent of phase change material, 0.3 to 1 percent of water retention agent, 0.01 to 0.2 percent of bonding agent, 0.1 to 2 percent of intensifier, and the balance of construction gypsum. Because the phase change having the characteristics of energy storage is added, and the modifier, the intensifier and the like are also added, the novel environment-friendly phase change plastering putty has the characteristics of ensuring the basic performances of the plastering putty, simultaneously automatically adjusting the ambient temperature in the room and making an indoor air-conditioning system operate smoothly, and meeting the requirements of modern people on the high-quality living environment.

Owner:北新建材(苏州)有限公司

Washable anti-pilling process of knitted cashmere sweater maker

The invention discloses a washable anti-pilling process of a knitted cashmere sweater maker. The process includes the step: weaving on a Shima Seiki 16-needle computerized flat knitting machine by 40 2-strand roves for the first time. The basic anti-pilling performance is ensured by transverse density and walewise density while cashmere comfort is retained. Woven is naturally formed by a knitting process and cannot shrink or deform after being repeatedly washed by a washing machine, and the problems of fuzzing and pilling are solved and deformation caused by machine washing is avoided as the yarn twist is tightened during spinning, knitting density is increased in flat knitting, and a steel wire frame is used for natural setting in ironing.

Owner:杭州琪利琪羊绒服饰有限公司

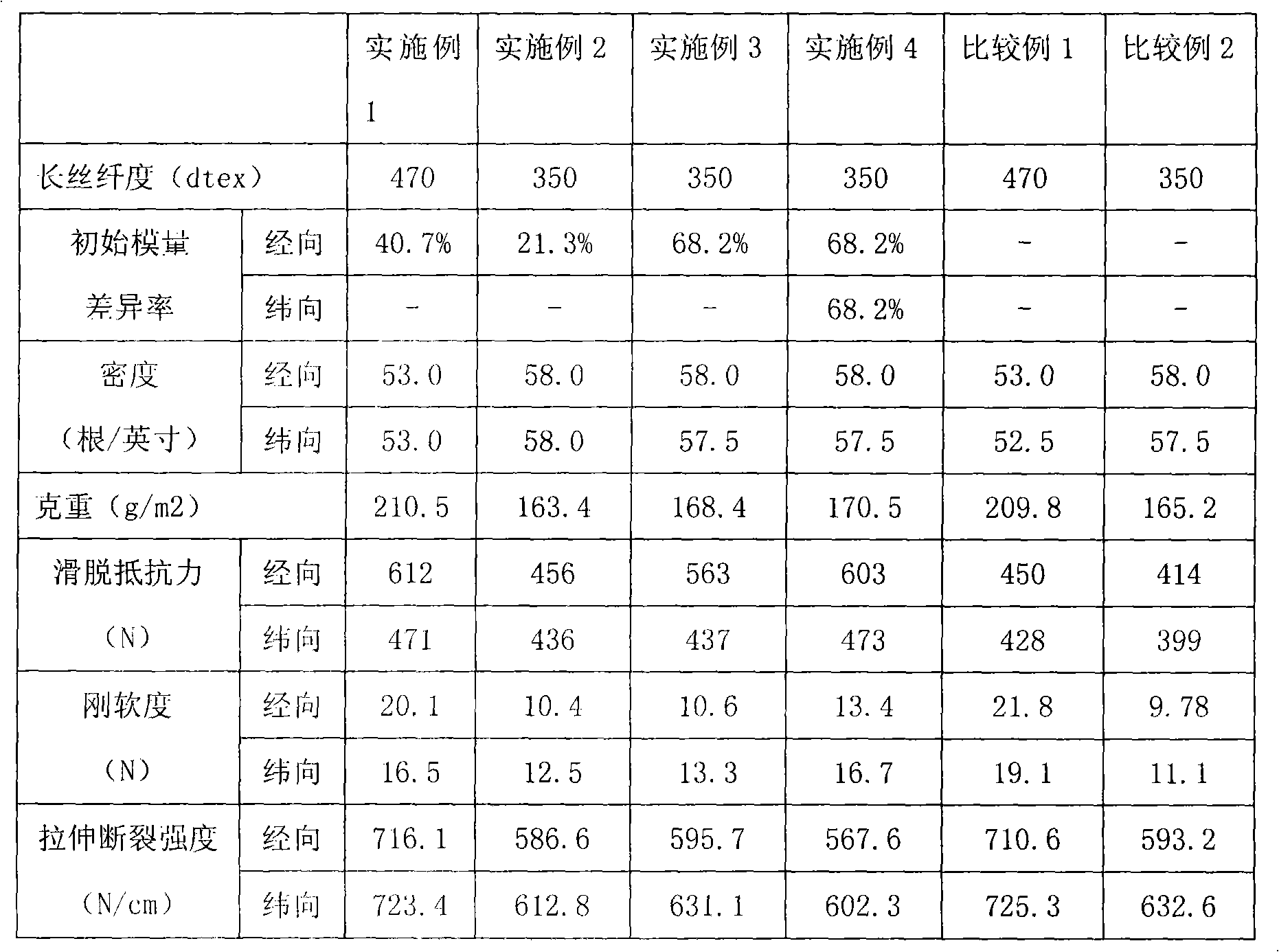

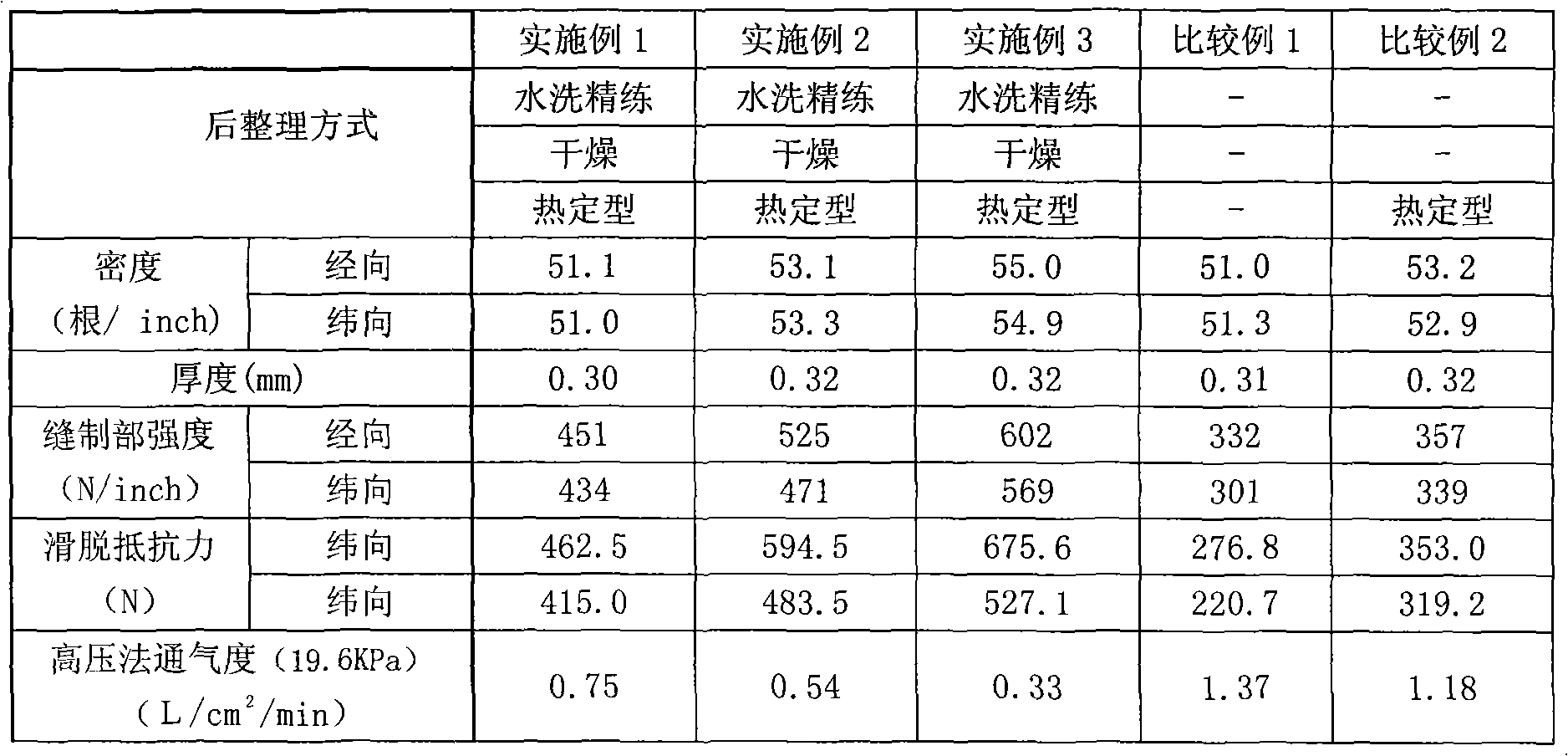

Fabric for safety air bag

InactiveCN101666007AImprove slip resistanceModerate stiffnessPedestrian/occupant safety arrangementWoven fabricsEngineeringAirbag

Owner:TORAY FIBER RES INST(CHINA) CO LTD

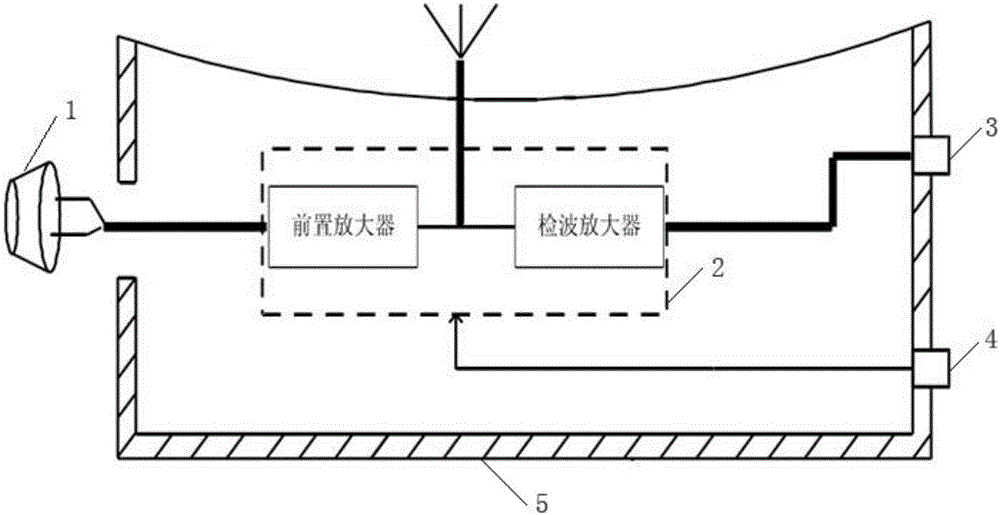

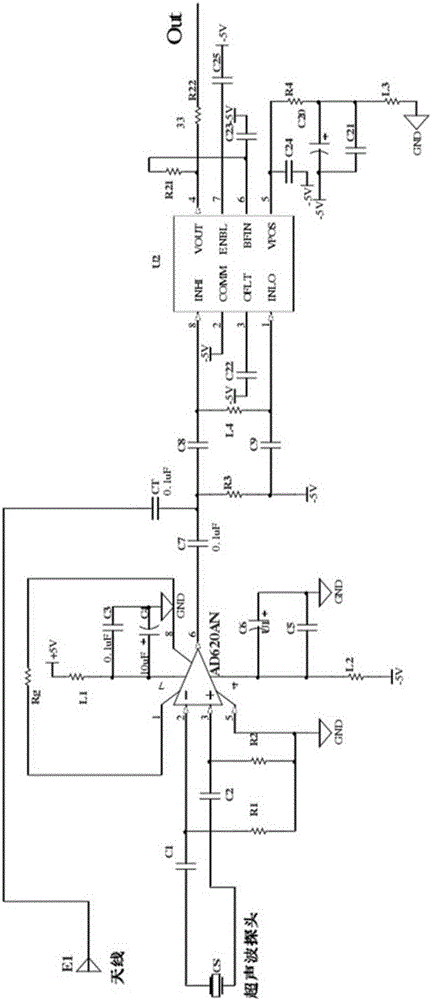

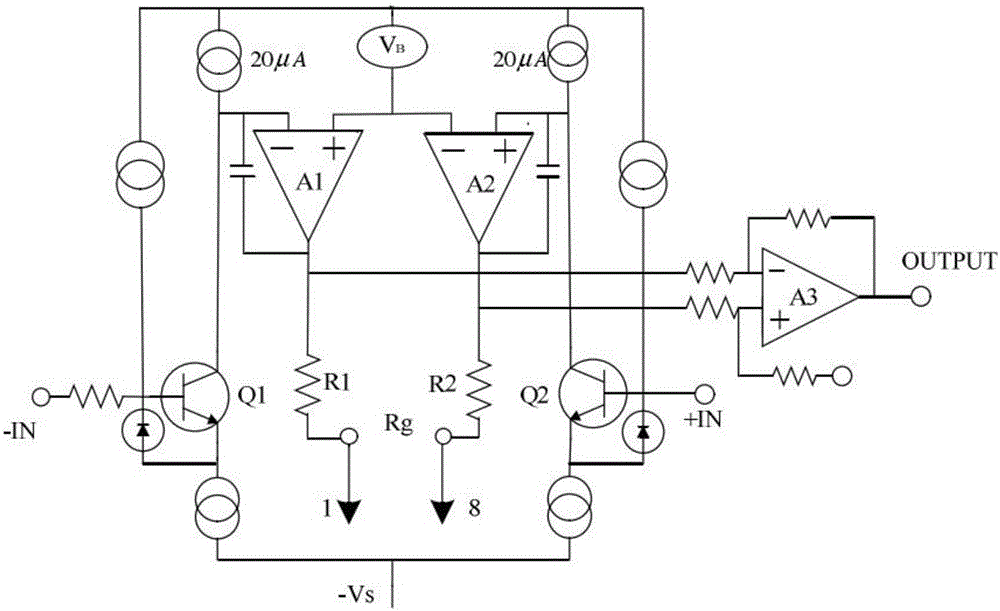

GIS local discharging detecting system and method based on sound-electricity integration sensor

InactiveCN106324459AGuaranteed basic performanceReduce the numberTesting using acoustic measurementsTesting circuitsElectricityComputer module

The invention discloses a GIS local discharging detecting system and method based on sound-electricity integration sensor,comprising sound-electricity integration sensor, BP neural network fusion module, DS decision module and display module; the sound-electricity integration sensor is used for simultaneous detection of ultrasonic wave and ultra-high frequency signal generated from local discharging ; BP neural network fusion module filters and fuses the discharging information detected by sound-electricity integration sensor and transmits such information to DS decision module;according to the obtained discharging information, the DS decision module uses the D-S evidence theory to perform the decision fusion for fault type determination results and transmits the decision fusion to display module; the display module is used for display after analysis and processing of obtained data. The system and method are used for GIS local discharging detection by new sound-electricity integration sensor and detecting whether local positioning is performed while local discharging occurs.

Owner:STATE GRID CORP OF CHINA +1

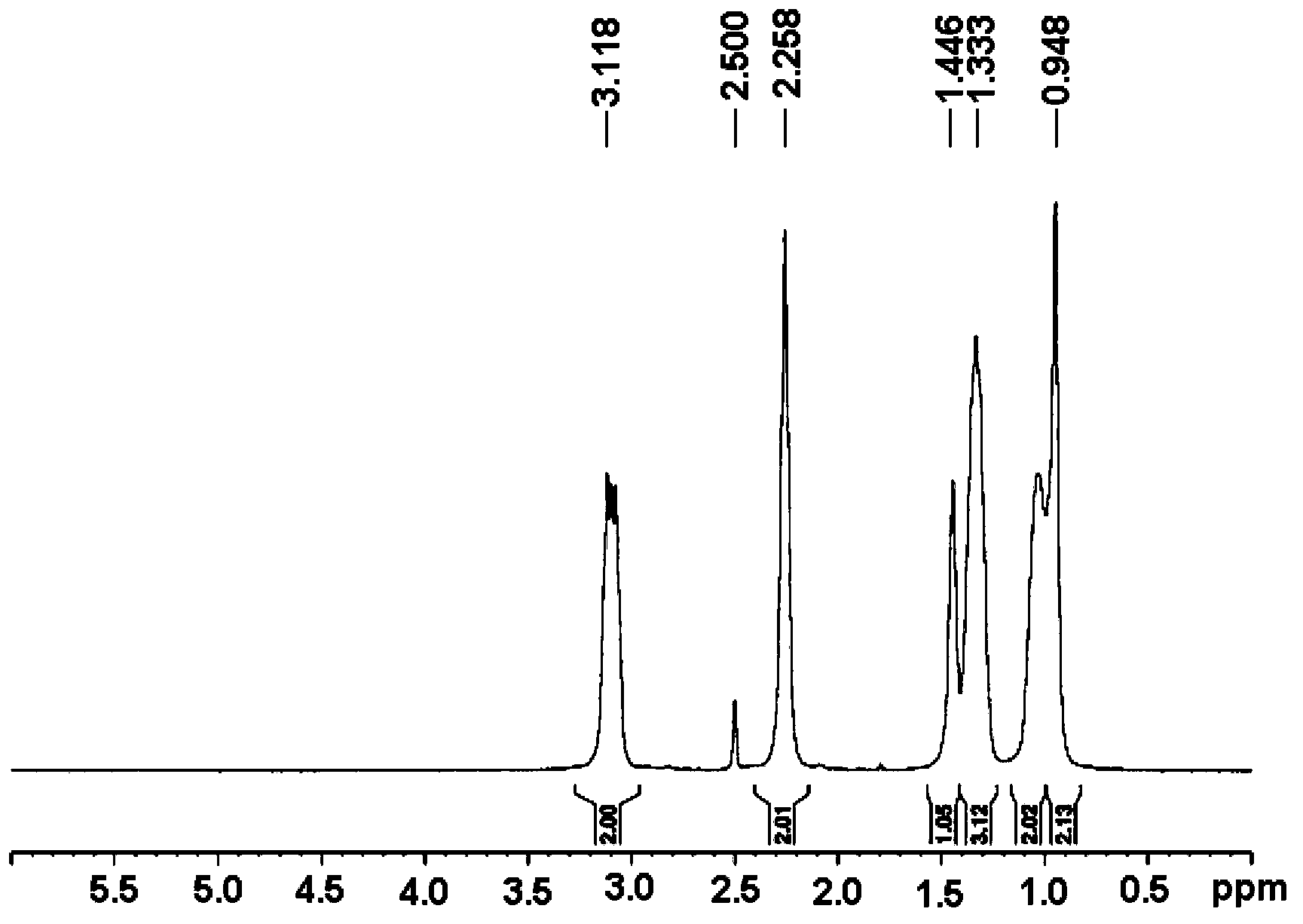

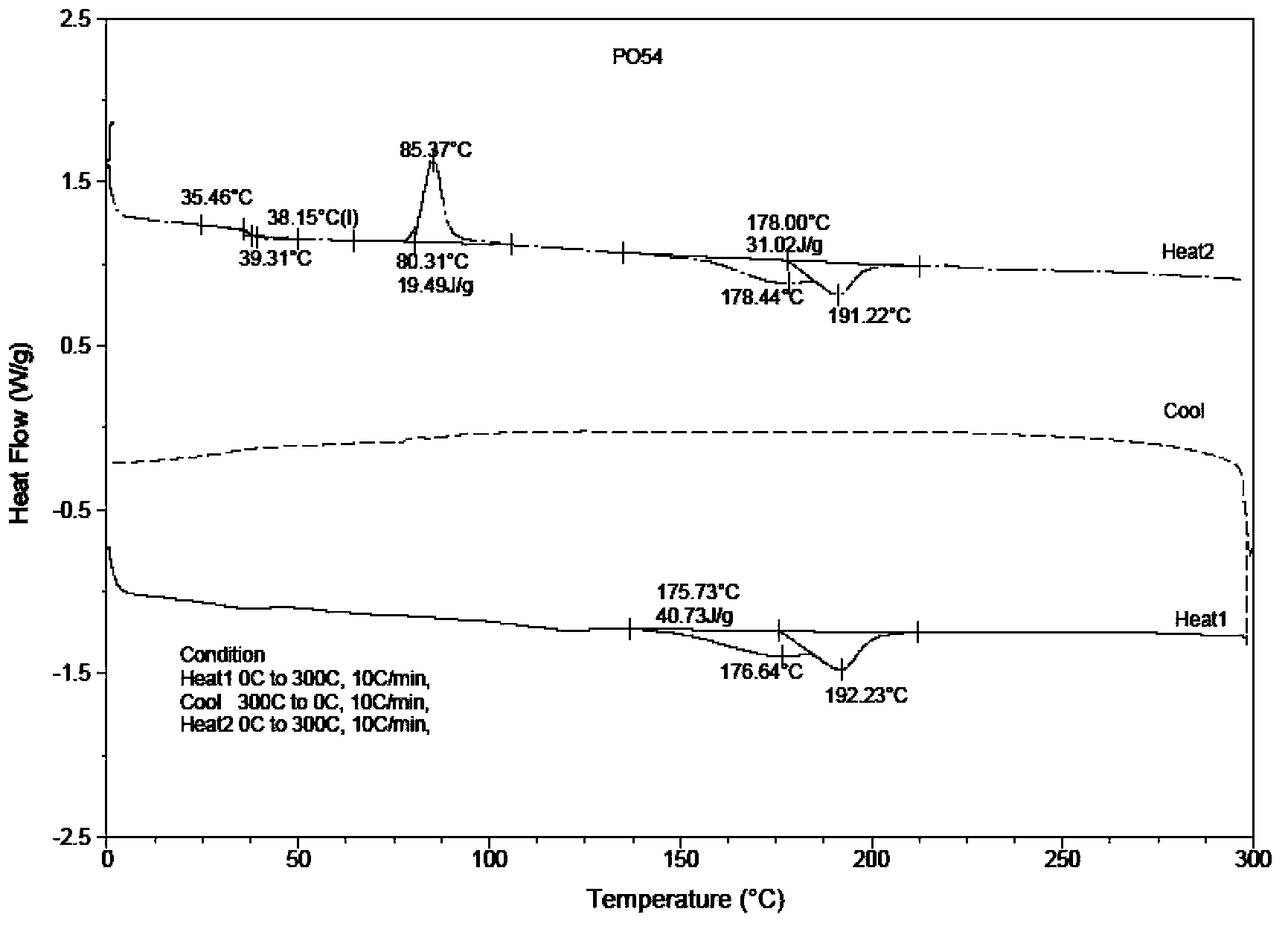

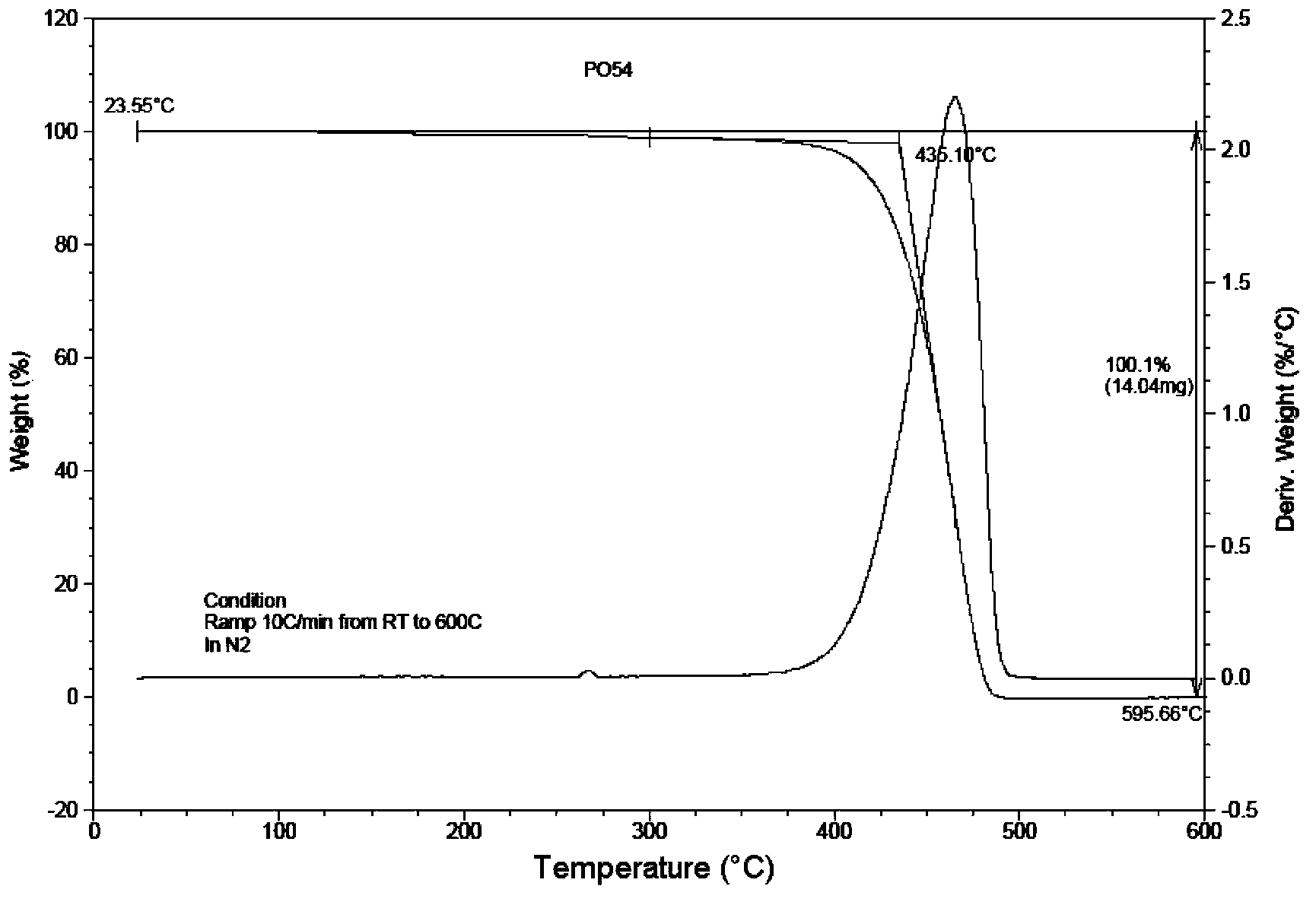

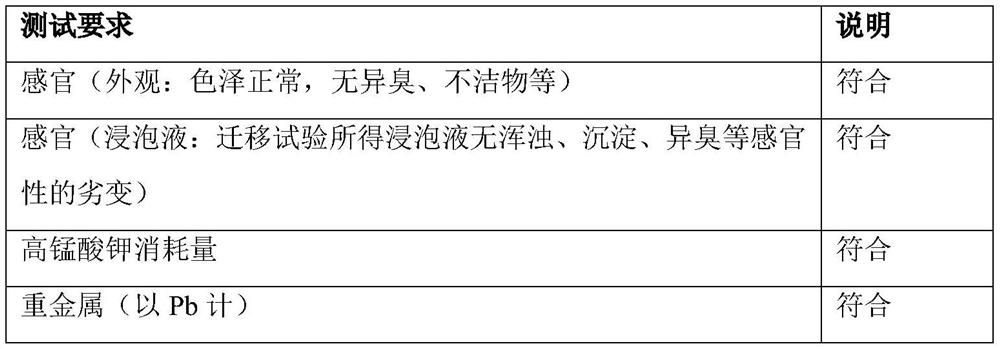

Polyamide and production method and application thereof

The invention provides polyamide and a production method and application thereof. The polyamide is shown as -[(NH-R1-NH)-(OC-R2-CO / OC-R3-CO)]m-, wherein R1 is preferably straight chain alkyl having 3-8 carbon atoms; R2 is preferably straight chain alkyl having 4-8 carbon atoms; and R3 is preferably straight chain alkyl having 6-20 carbon atoms. The polyamide provided by the invention does not need to form transparency by means of addition and modification, so that the problems of sensitivity to the content of additives, aging and migration occurring after a long time, and the like are solved.

Owner:CATHAY R&D CENT CO LTD +2

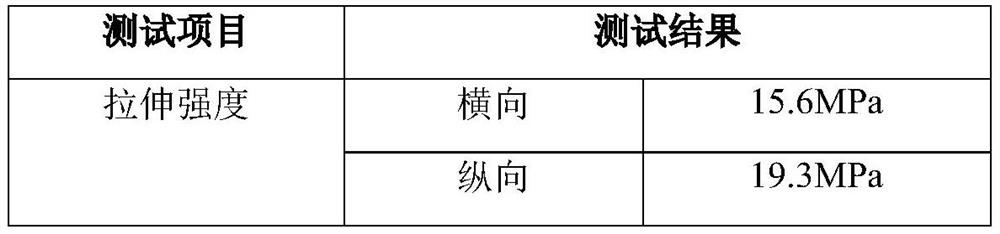

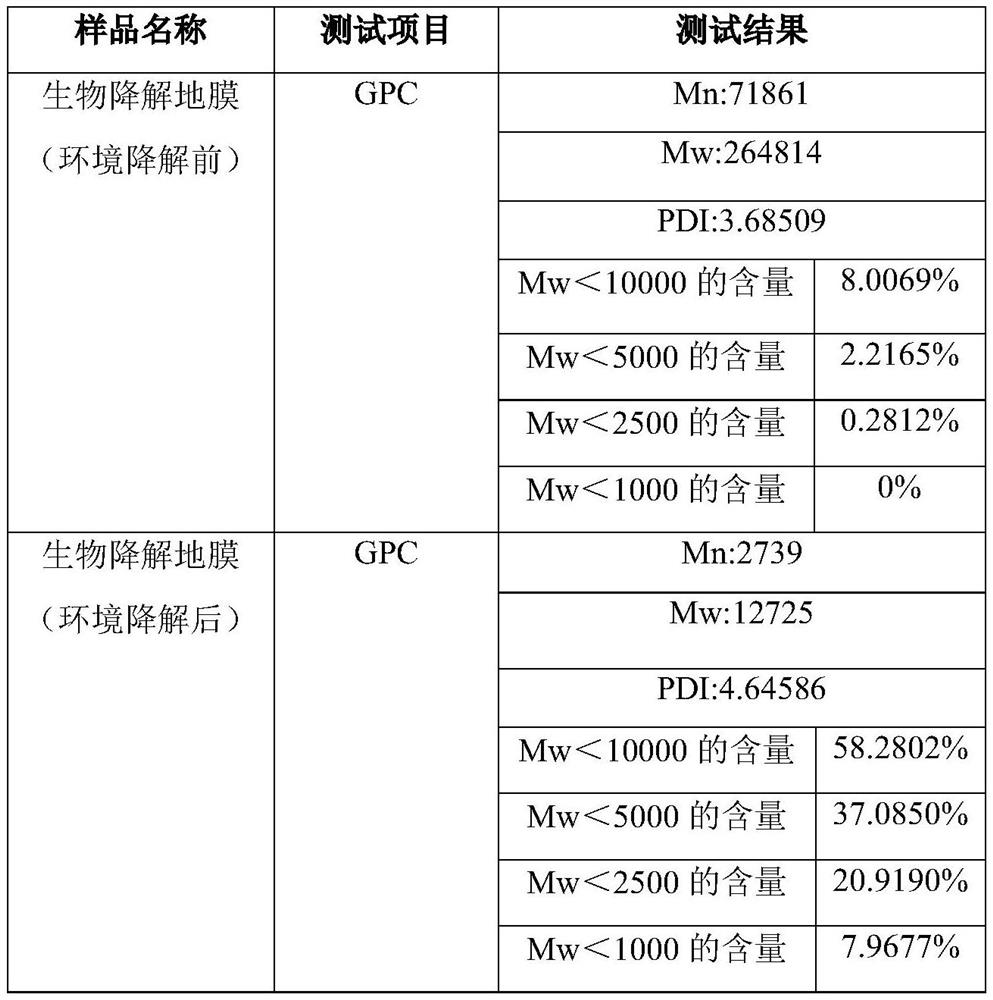

Biodegradable film material

The invention belongs to the technical field of biodegradable materials, and relates to a biodegradable film material. The film material comprises 60 to 90 parts of PBAT, 5 to 15 parts of PLA / PBS, 3 to 8 parts of modified starch, 10 to 30 parts of modified biological calcium powder, 2 to 10 parts of EAA, 0.1 to 1 part of a dispersant, 0.1 to 1 part of a chain extender, 0.1 to 1 part of erucyl amide, 0.1 to 1 part of a surfactant and 1 to 5 parts of glycerin / silicone oil. The film material is green, environmentally friendly, degradable, capable of reducing pollution to the environment, high inbiological decomposition rate, high in strength and low in cost.

Owner:宁夏中原塑业科技有限公司

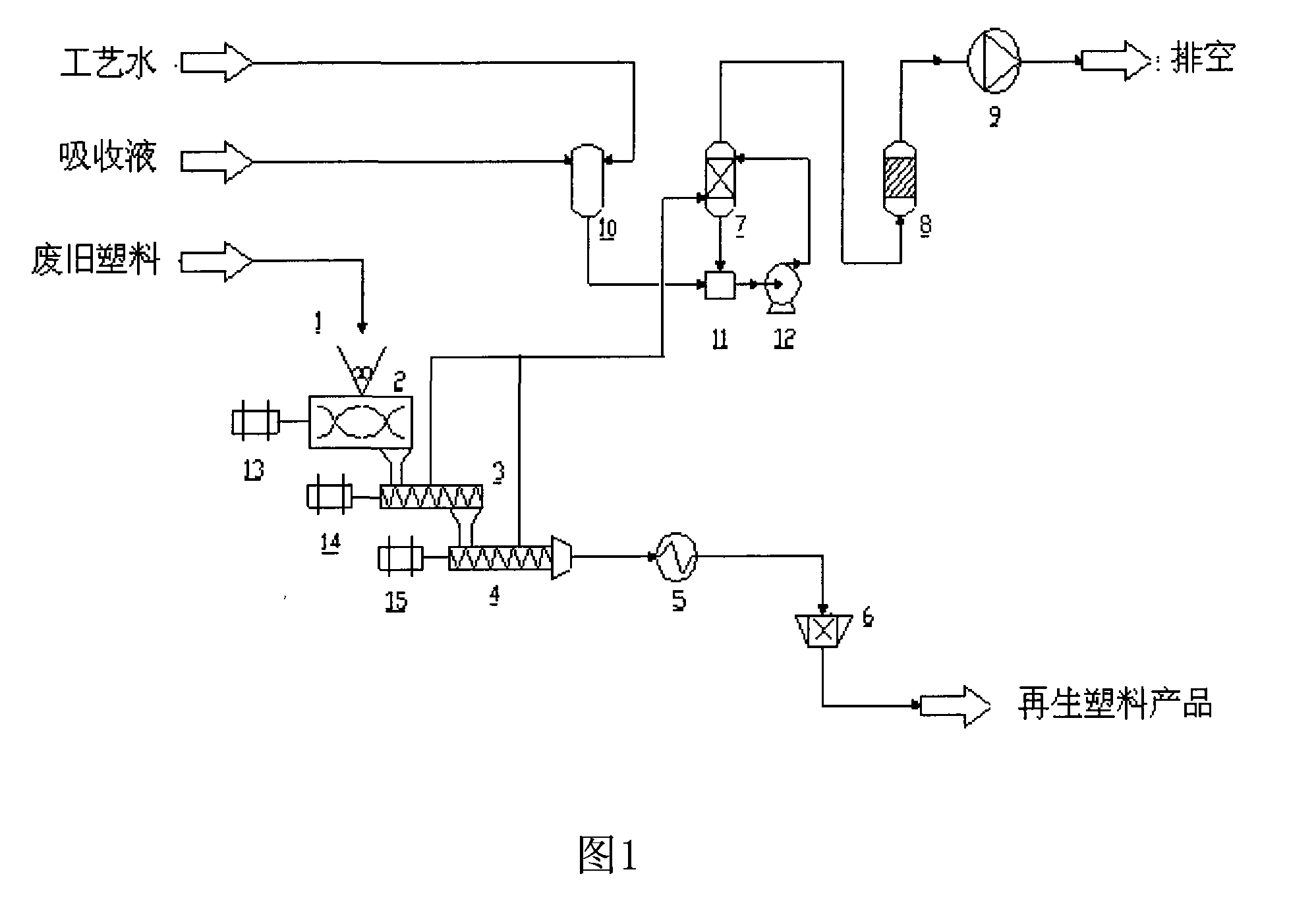

Apparatus and method for dehalogenation regeneration of waste and old electric plastics

InactiveCN101220173AEasy to separateReduce viscosityPlastic recyclingEnvironmental engineeringPre treatment

The invention discloses a device used for dehalogenation and regeneration of waste and old electronic plastic and a method thereof. The device comprises a dehalogenation and regeneration system of the waste and old electronic plastic and a two-step tail gas purification and treatment system, wherein, the dehalogenation and regeneration system of the waste and old electronic plastic consists of a feeder, a preprocessor, a dehalogenation reactor, a regenerator, a regenerating plastic cooler and a granulator that are connected in sequence; an absorption liquid collecting tank of the two-step tail gas purification and treatment system is connected with a tail gas absorption tower by an absorption liquid circulating pump, and the tail gas absorption tower is further connected with the absorption liquid collecting tank; the dehalogenation reactor is connected with an inlet arranged at the lower end of the tail gas absorption tower through an air guide pipeline. The method comprises steps of preprocessing of the waste and old electronic plastic, vacuum dehalogenation, treatment of the tail gas from dehalogenation, modification of fused mass, plasticity repairing, cooling, solidification and molding of the fused mass and granulation, etc. The invention is applicable to regeneration of the waste and old electronic material represented by TV shells and other high-bittern containing waste and old plastic and is characterized by being environment friendly.

Owner:SOUTH CHINA UNIV OF TECH

Novel environment-friendly fireproof sealing gypsum

The invention discloses an environment-friendly fireproof sealing gypsum, which comprises the following components in percentage by weight: 0.2 to 8 percent of non-metallic mineral fireproof material, 0.1 to 5 percent of modifier, 0.01 to 0.8 percent of water retention thickening agent, 0.01 to 0.2 percent of bonding agent, 0.01 to 0.5 percent of retarder, 0.1 to 2 percent of intensifier, and the balance of construction gypsum. Because the non-metallic mineral fireproof materials such as mica powder or vermiculite and the like are added, and the modifier, the intensifier and the like are also added, the environment-friendly fireproof sealing gypsum can ensure the basic performances of the sealing gypsum and simultaneously has the characteristics of fire resistance, crack resistance, environmental protection, no toxin, no irritation, and the like.

Owner:北新建材(苏州)有限公司

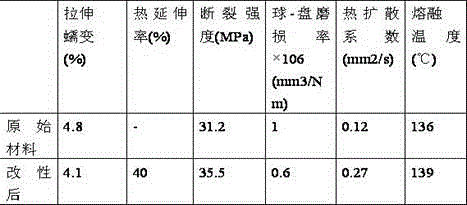

Preparation method of wear-resistant heat-conducting irradiation-crosslinking ultra-high molecular weight polyethylene

InactiveCN106633287AImprove thermal conductivityImprove wear resistanceWear resistantHeat conducting

The invention discloses a preparation method of wear-resistant heat-conducting irradiation-crosslinking ultra-high molecular weight polyethylene. The preparation method comprises the following steps: adding ultra-high molecular weight polyethylene granules with the molecular weight of 2 million or so into 8 wt% of heat-conducting filler, boron nitride, 0.5 wt% of wear-resistant filler, carbon nanotubes, 1 wt% of crosslinking accelerator and 0.1 wt% of antioxidant to form a mixture; sufficiently mixing the mixture, sending the mixture into an extruder, melting by heating, and extruding by an extruder, wherein in the heating process, the temperature and pressure of the raw materials are controlled, and the thickness of the extruded material is kept at 1-10mm; and irradiating the obtained sample by gamma-rays of a cobalt source in air with the irradiation dose of 50-180 kGy, and putting the irradiation sample into a drying oven under vacuum conditions. On the premise of keeping the inherent properties of the ultra-high molecular weight polyethylene material stable, the method further enhances the wear resistance, heat-conducting property, temperature resistance and mechanical strength of the ultra-high molecular weight polyethylene material.

Owner:中广核高新核材科技(苏州)有限公司

A solvent-free environment-friendly type mica tape and a preparation method thereof

The invention discloses a solvent-free environment-friendly type mica tape comprising a piece of mica paper, enhanced materials and adhesive which are recombined. The adhesive is composed of the following substances according to parts by weight: 40-60 parts of epoxy resin, 10-20 parts of maleic anhydrides, 1-5 parts of dioctyl phthalic acid, 10-20 parts of nonsaturated polyesterimide resin and 5-10 parts of modified organic silicone resion. The enhanced materials are one kind among glass fibre cloths, polyimide films or polyester fibre non-woven fabrics. The mica tape prepared in the invention has relatively good binding manufacturability and insulating properties. While basic performance of the mica tape is guaranteed, and the usage of an organic solvent is substantially reduced. The mica tape prepared in the invention facilitates atmosphere environmental protection.

Owner:平江县岳峰云母新材料有限公司

Fabrics for air pocket and production method thereof

InactiveCN101858005AGuaranteed basic performanceReduce slipHeating/cooling textile fabricsWoven fabricsEngineeringHeat setting

The invention discloses fabrics for an air pocket and a production method thereof. According to the standard of JISL-1093, the strength of a sewing part of the fabrics for the air pocket is over 400 N / inch. The production method comprises the following steps of: weaving synthetic fiber filaments through a water-jet loom to form the fabrics for the air pocket, and performing aftertreatment including washing refining at the temperature of between 30 and 90 DEG C, heat setting and drying. The invention can provide fabrics of which the slippage of the sewing part is little when air bags are unfolded.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Synthetic resin tile and preparation method thereof

PendingCN109591414ADelay resin agingExtended service lifeSynthetic resin layered productsConstructions elementsWeather resistanceChemistry

The invention discloses a synthetic resin tile and a preparation method thereof, belonging to the technical field of resin tiles. According to the preparation method, chopped alkali-free glass fibersare added into a polyvinyl chloride resin base material so as to form a network skeleton structure in the base material, so that the aging of the resin is delayed, and the service life of the synthetic resin tile is prolonged. Meanwhile, the synthetic resin tile is divided into three layers, namely an upper surface layer, a middle layer and a lower surface layer which have different effects, so that the resin tile has multiple properties of weather resistance, ultraviolet resistance and the like further has relatively high practicability and high product quality on the basis that basic properties (lightness, high strength, good tenacity, corrosion resistance and the like) of the resin tile are guaranteed.

Owner:LESHAN JIACHENG BUILDING MATERIAL

A lithium battery separator in a high-strength fiber structure and a preparation method and application thereof

InactiveCN109585751AProcess stabilityHigh mechanical strengthCell seperators/membranes/diaphragms/spacersElectrospinningNanofiber

The invention discloses a lithium battery in a high-strength fiber structure and a preparation method thereof. According to the invention, micro fibers are uniformly dispersed into a nano fiber spinning solution, and the micro fibers are insoluble in the nano fiber spinning solution and can stably exist. The separator is prepared by an ectrospinning method. The separator produced by the inventionhas good ion transfer performance, puncture resistance and tensile strength performance; the separator can withstand the puncture strength of more than 300 g, and the tensile strengths in both the transverse and longitudinal directions are more than 50 MPa, thereby effectively improving the charge and discharge performance and safety performance of the battery. The production technology is simple;the efficiency is high; and the lithium battery separator is suitable for scale production.

Owner:DONGGUAN UNIV OF TECH +1

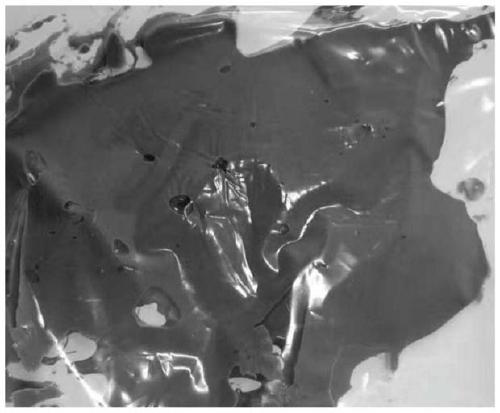

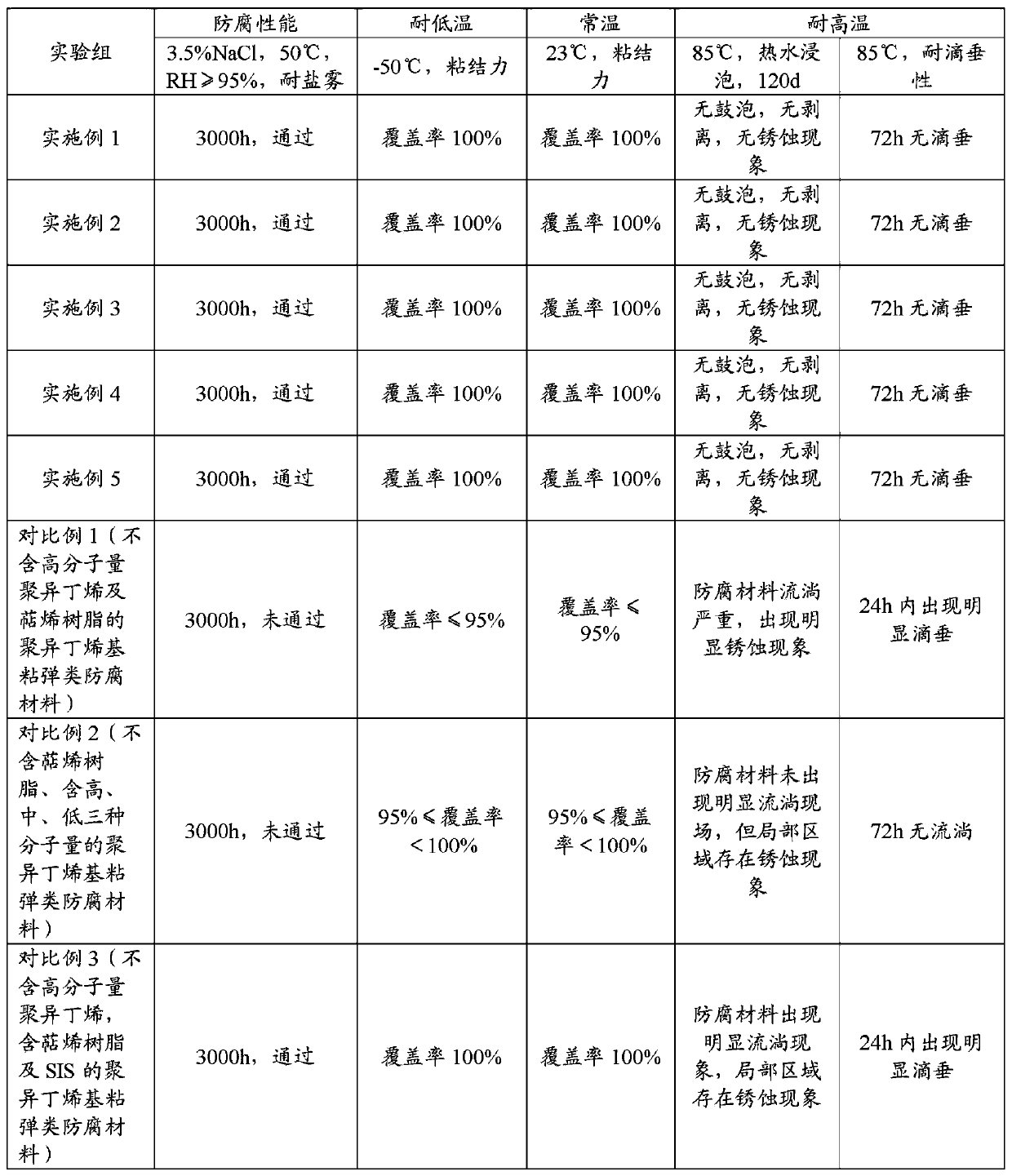

Viscoelastic anticorrosive material as well as preparation method and application thereof

InactiveCN111394020AEasy to processGood high and low temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolymer chemistry

The invention relates to a viscoelastic anticorrosive material which comprises the following components in parts by weight: 3-8 parts of high-molecular polyisobutene, 20-33 parts of medium-molecular polyisobutene, 10-20 parts of low-molecular polyisobutene, 45-60 parts of inorganic filler, 3-12 parts of terpene resin, 1.5-5 parts of styrene-isoprene-styrene and 0.1-0.5 parts of phthalocyanine green. The weight fraction ratio of the inorganic filler to the high-molecular polyisobutene, the medium-molecular polyisobutene and the low-molecular polyisobutene is increased, the filler and the polyisobutene are fully combined through intermolecular interaction in the mixing process, so that the high and low temperature resistance of the viscoelastic anticorrosive material is improved on the basisthat the viscoelastic anti-corrosion material maintains the good ductility of a polyisobutene-based material. By adding the rest components, the basic performance of the viscoelastic anticorrosive material is guaranteed. Therefore, the comprehensive performance of the anticorrosive material is further improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com