High-curvature wide-color-gamut ceramic curved surface rock plate and preparation method and application thereof

A technology with wide color gamut and curvature, which is applied in the field of high curvature and wide color gamut ceramic curved rock slabs and its preparation, can solve the problems of glaze cracks on the bottom glaze and narrow color gamut, so as to avoid pattern discoloration and tone, The effect of avoiding gloss deviation and widening the color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] In parts by weight, 25 parts of ball clay, 5 parts of zirconium silicate, 5 parts of zirconium white frit, 15 parts of wollastonite, 20 parts of polishing slag, 5 parts of albite, 15 parts of quartz, 0.6 part of water glass, 0.2 part of sodium tripolyphosphate, 1 part of reinforcing agent CMC, 0.5 part of sodium lignosulfonate, and 0.3 part of sodium hexametaphosphate are added to a ball mill and mixed evenly, and then sieved to remove iron, stale, impurity, and spray-dried to obtain Powder, and then the powder is pressed into shape, and after being dried in a drying kiln, a ceramic green body (green body layer) is obtained;

[0105] In parts by weight, 90 parts of EN-1 frit, 8 parts of kaolin, 2 parts of quartz, 0.5 part of sodium tripolyphosphate, and 0.22 parts of CMC (wherein, by weight, the chemical composition of EN-1 frit for SiO 2 63 copies, Al 2 o 3 4 copies, K 2 O 6.0 parts, Na 2 0.8 parts of O, 6 parts of CaO, 2 parts of MgO, 6.8 parts of ZnO, 5 parts of...

Embodiment 2

[0130]In parts by weight, 30 parts of ball clay, 8 parts of zirconium silicate, 21 parts of wollastonite, 11 parts of polishing slag, 5 parts of albite feldspar, 25 parts of quartz, 0.6 part of water glass, 0.2 part of sodium tripolyphosphate, Add 1 part of green body enhancer CMC, 0.5 part of sodium lignosulfonate, and 0.6 part of sodium hexametaphosphate into a ball mill and mix them evenly, then sieve and remove iron, stale, remove impurities, and spray dry to obtain powder, and then powder The material is pressed and formed, and after being dried in a drying kiln, a ceramic green body (green body layer) is obtained;

[0131] In parts by weight, 81 parts of EN-1 frit, 12 parts of kaolin, 7 parts of quartz, 0.5 part of sodium tripolyphosphate, and 0.22 part of CMC (wherein, by weight, the composition of EN-1 frit is SiO 2 62.8 parts, Al 2 o 3 6.93 copies, K 2 O 6 parts, Na 2 O 1 part, CaO 6.88 parts, MgO 2 parts, ZnO 10 parts, BaO 3.08 parts, TiO 2 7.52 parts, Fe 2 ...

Embodiment 3

[0140] In parts by weight, 30 parts of ball clay, 3 parts of zirconium silicate, 21 parts of wollastonite, 17 parts of polishing slag, 9 parts of potassium feldspar, 20 parts of quartz, 1.0 part of sodium lignosulfonate body strengthening agent, Add 1.0 part of water glass and 0.3 part of sodium tripolyphosphate into a ball mill and mix them evenly, then sieve and remove iron, stale, impurity, and spray dry to obtain powder, then press the powder into shape, and dry it in a kiln , to obtain a ceramic green body (green body layer);

[0141] In parts by weight, 90 parts of EN-1 frit, 8 parts of kaolin, and 2 parts of quartz, (wherein the composition of EN-1 frit is SiO 2 55.2 parts, Al 2 o 3 6.93 copies, K 2 O 1.36 parts, Na 2 O 0.56 parts, CaO 7.36 parts, MgO 3.6 parts, ZnO 5.08 parts, BaO 3.08 parts, TiO 2 5.53 parts, Fe 2 o 3 0.2 parts, ZrO 2 1.05 copies, B 2 o 3 7.39 parts) after mixing, join in the ball mill and carry out ball milling, after sieving and remov...

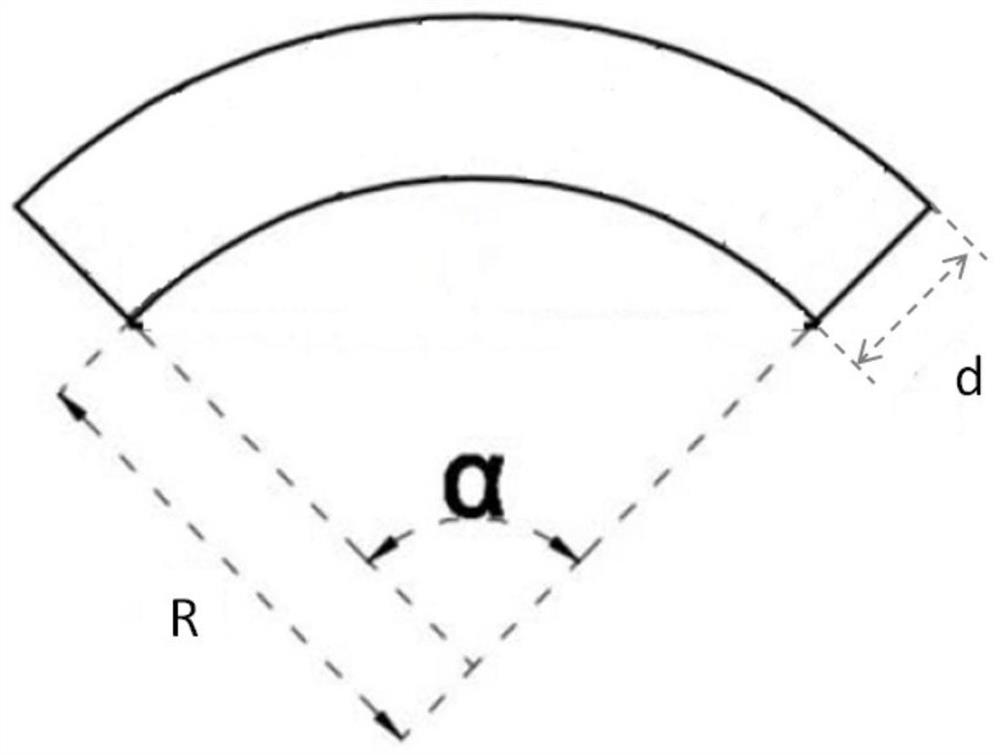

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com