Viscoelastic anticorrosive material as well as preparation method and application thereof

A kind of anti-corrosion material and viscoelastic technology, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc. It can solve the problem that the balance between ductility and high and low temperature resistance needs to be improved, and high temperature resistance poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

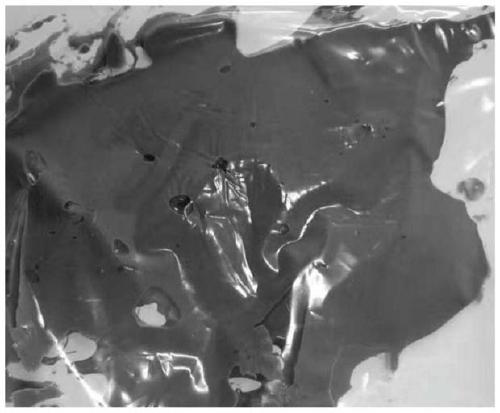

Image

Examples

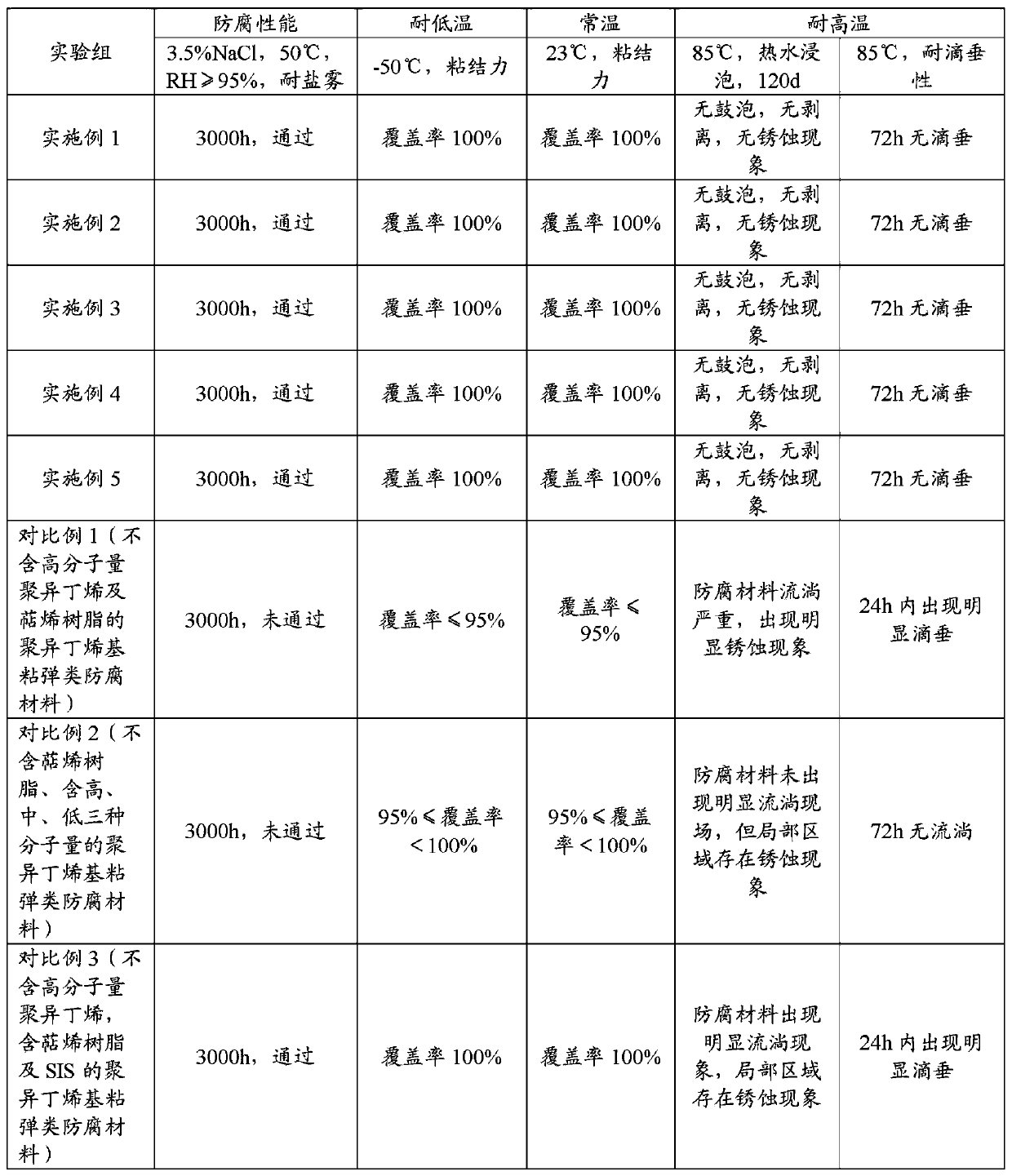

Embodiment 1

[0052] The preparation method steps of the viscoelastic anticorrosion material of the present embodiment are as follows:

[0053] In the first step, each raw material is prepared in parts by weight of the following viscoelastic anticorrosion;

[0054]Specifically, the raw materials include: 3 parts of high-molecular polyisobutene, 20 parts of medium-molecular polyisobutene, 12 parts of low-molecular polyisobutene, 60 parts of inorganic filler (30 parts of titanium dioxide (rutile type), 30 parts of wollastonite powder), terpene 3 parts of resin, 1.9 parts of styrene-isoprene-styrene (SIS, full name Styrene-Isoprene-Styrene), 0.1 part of phthalocyanine green.

[0055] Wherein, the molecular weight of the high-molecular polyisobutene is 200,000-1,000,000; the molecular weight of the middle-molecular polyisobutene is 40,000-85,000; Macromolecular polyisobutylene is one or more mixing in OppanolB30, OppanolB50, OppanolB80 and OppanolB100 of BASF company; Described medium molecula...

Embodiment 2

[0060] In the first step, each raw material is prepared in parts by weight of the following viscoelastic anticorrosion;

[0061] Specifically, the raw materials include: 5 parts of high molecular polyisobutylene, 20 parts of medium molecular polyisobutylene, 13 parts of low molecular polyisobutylene, 51 parts of inorganic filler (26 parts of calcium carbonate, 25 parts of hydrotalcite), 7 parts of terpene resin, benzene Ethylene-isoprene-styrene (SIS, full name Styrene-Isoprene-Styrene) 3.5 parts, phthalocyanine green 0.5 parts, antibacterial agent 2 parts.

[0062] Wherein, the molecular weight of the high-molecular polyisobutene is 200,000-1,000,000; the molecular weight of the middle-molecular polyisobutene is 40,000-85,000; Macromolecular polyisobutylene is one or more mixing in OppanolB30, OppanolB50, OppanolB80 and OppanolB100 of BASF company; Described medium molecular polyisobutene is one or more mixing in OppanolB10, OppanolB12 and OppanolB15 of BASF company; The low...

Embodiment 3

[0067] In the first step, each raw material is prepared in parts by weight of the following viscoelastic anticorrosion;

[0068] Specifically, the raw materials include: 4 parts of high molecular polyisobutylene, 25 parts of medium molecular polyisobutylene, 17 parts of low molecular polyisobutylene, 42 parts of inorganic filler (20 parts of barium sulfate, 22 parts of mica powder), 6 parts of terpene resin, benzene Ethylene-isoprene-styrene (SIS, full name Styrene-Isoprene-Styrene) 5 parts, phthalocyanine green 0.3 part, antioxidant 0.7 part.

[0069] Wherein, the molecular weight of the high-molecular polyisobutene is 200,000-1,000,000; the molecular weight of the middle-molecular polyisobutene is 40,000-85,000; Macromolecular polyisobutylene is one or more mixing in OppanolB30, OppanolB50, OppanolB80 and OppanolB100 of BASF company; Described medium molecular polyisobutene is one or more mixing in OppanolB10, OppanolB12 and OppanolB15 of BASF company; The low-molecular pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com