Sealing strip cladding sizing material and preparation method thereof as well as car door sealing strip and preparation method thereof

A technology of sealing strip and coating glue, which is applied to the preparation of the sealing strip covering rubber, and the field of preparing the vehicle door sealing strip, can solve the problem that the density of the coating rubber product is difficult to continue to reduce, it is unfavorable for lightweight design, and the product density is high. and other problems, to avoid the rubber sticking to the mixing roller, shorten the mixing time, and achieve the effect of excellent foaming stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

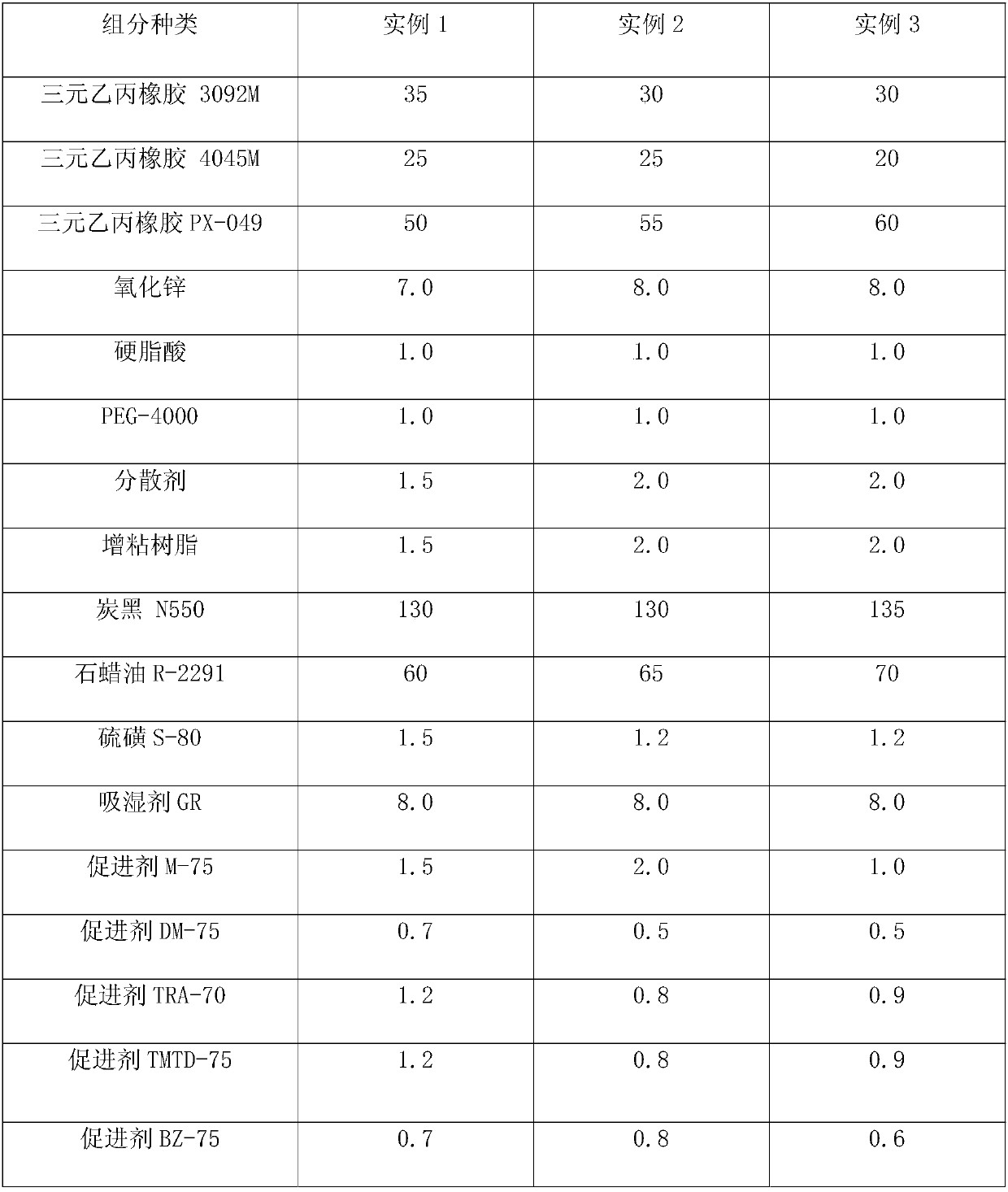

[0043] This embodiment relates to a rubber compound for sealing strips, which is specifically made of the following components by weight ratio: EPDM rubber 3092M: 20-40 parts, EPDM rubber: 4045M: 10-30 parts , EPDM rubber PX-049: 40-60 parts, zinc oxide: 6.0-8.0 parts, stearic acid: 0.5-1.5 parts, PEG-4000: 0.5-1.5 parts, dispersant: 1.0-2.0 parts, increase Viscose resin: 1.0-2.0 parts, paraffin oil R-2291: 50-70 parts, carbon black N550: 120-140 parts, sulfur S-80: 1.0-2.0 parts, hygroscopic agent GR: 6.0-10.0 parts, accelerator M -75: 1.0~2.0 parts, accelerator DM-75: 0.5~0.9 parts, accelerator TRA-70: 0.8~1.6 parts, accelerator TMTD-75: 0.8~1.6 parts, accelerator BZ-75: 0.5~0.9 parts Parts, accelerator ETU-80: 0.5-0.9 parts, microsphere foaming agent EWE-60GE: 4.5-5.0 parts.

[0044] Wherein, the above-mentioned dispersant is specifically dispersant L-TP, and the tackifying resin is specifically tackifying resin ST505.

[0045] When preparing the rubber compound for seali...

Embodiment 2

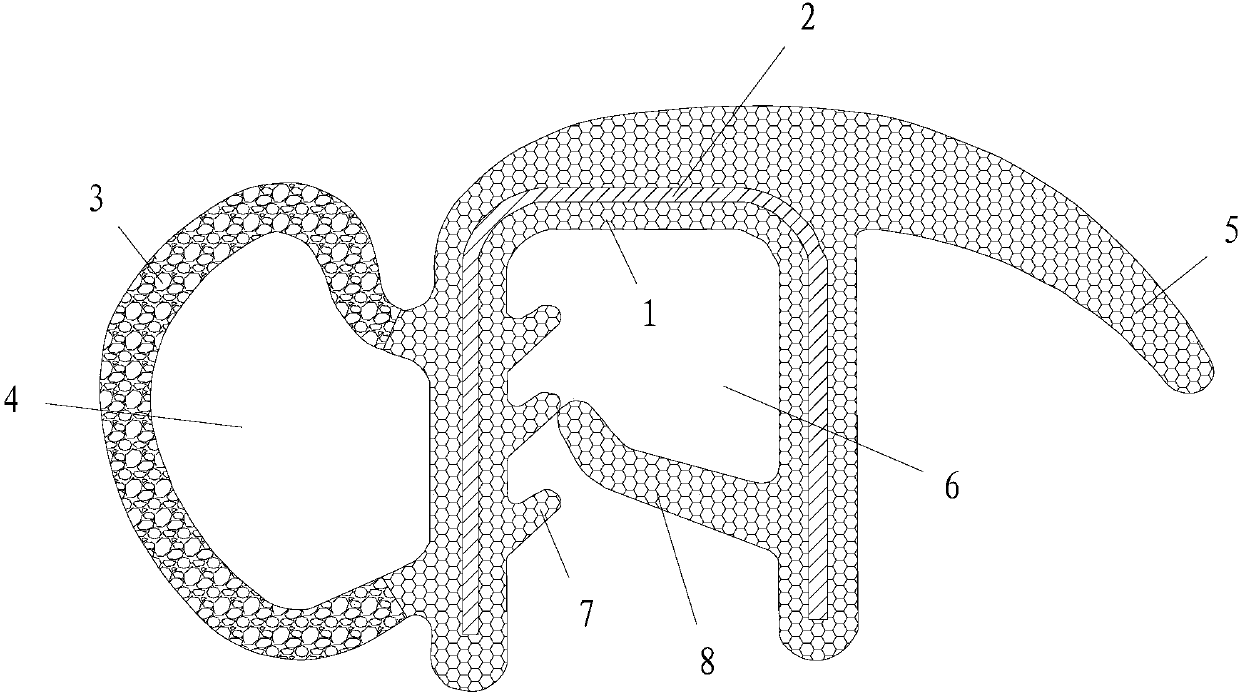

[0052] This embodiment relates to a kind of door sealing strip, such as figure 1 As shown in , the door weather strip includes an installation part 1 made of the sealing strip coating compound prepared in Example 1, a steel belt 2 is built in the installation part 1, and a A lip 5 extending toward one side of the installation part 1, and opposite to the lip 5, a sealing part 3 made of sponge foam rubber is also provided on the other side of the installation part 1 .

[0053] In this embodiment, in order to ensure the tightness of the sealing part 3 , a cavity 4 is formed between the sealing part 3 and the installation part 1 . In addition, in terms of specific structure, the mounting part 1 of this embodiment is also bent into a "U" shape, so that a mounting slot 6 is formed at the mounting part 1, and at the same time, on one end surface of the mounting slot 6 A tooth-shaped portion 7 is also formed. Relative to the tooth-shaped portion 7 , a tongue portion 8 protruding towa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com