Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Guarantee quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

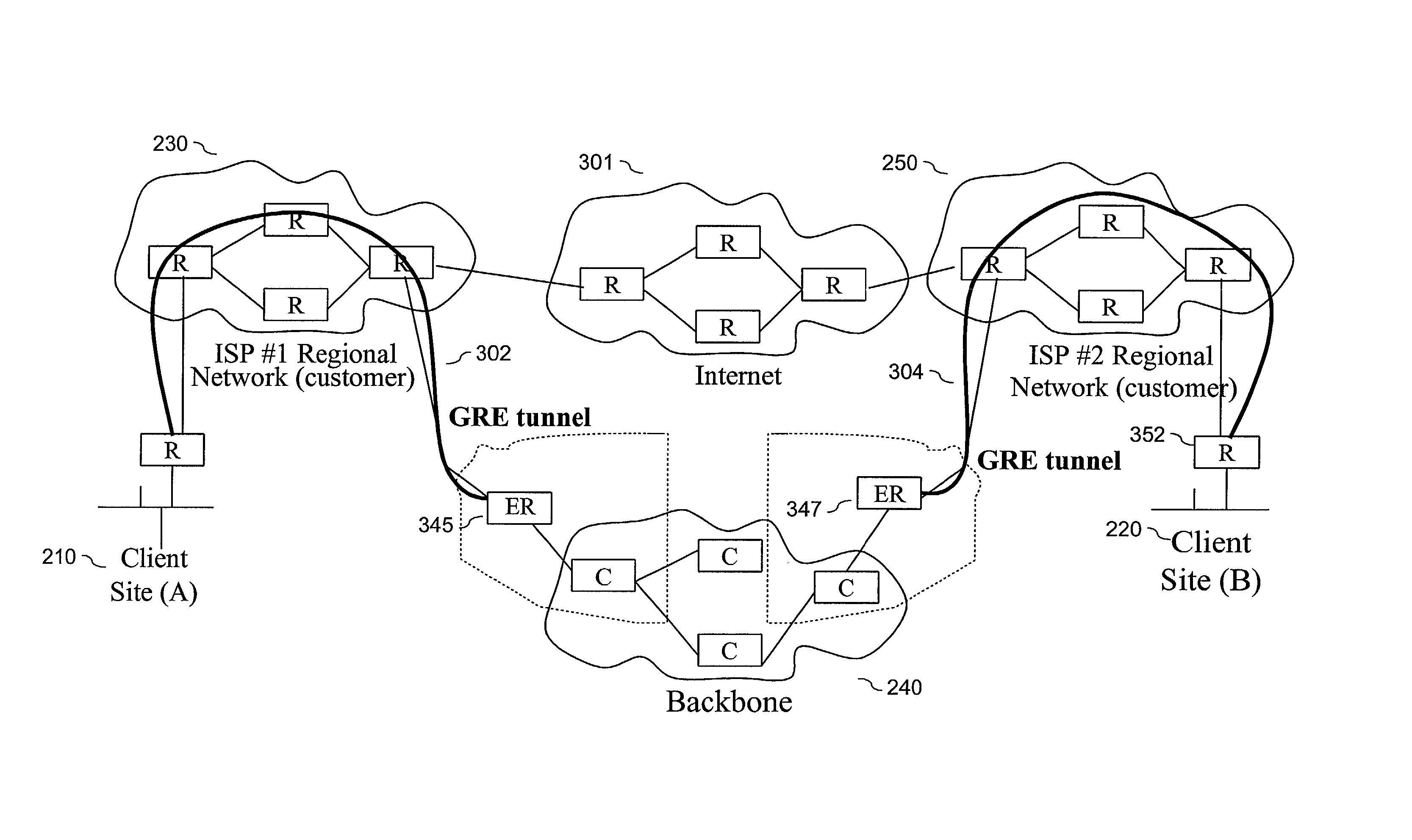

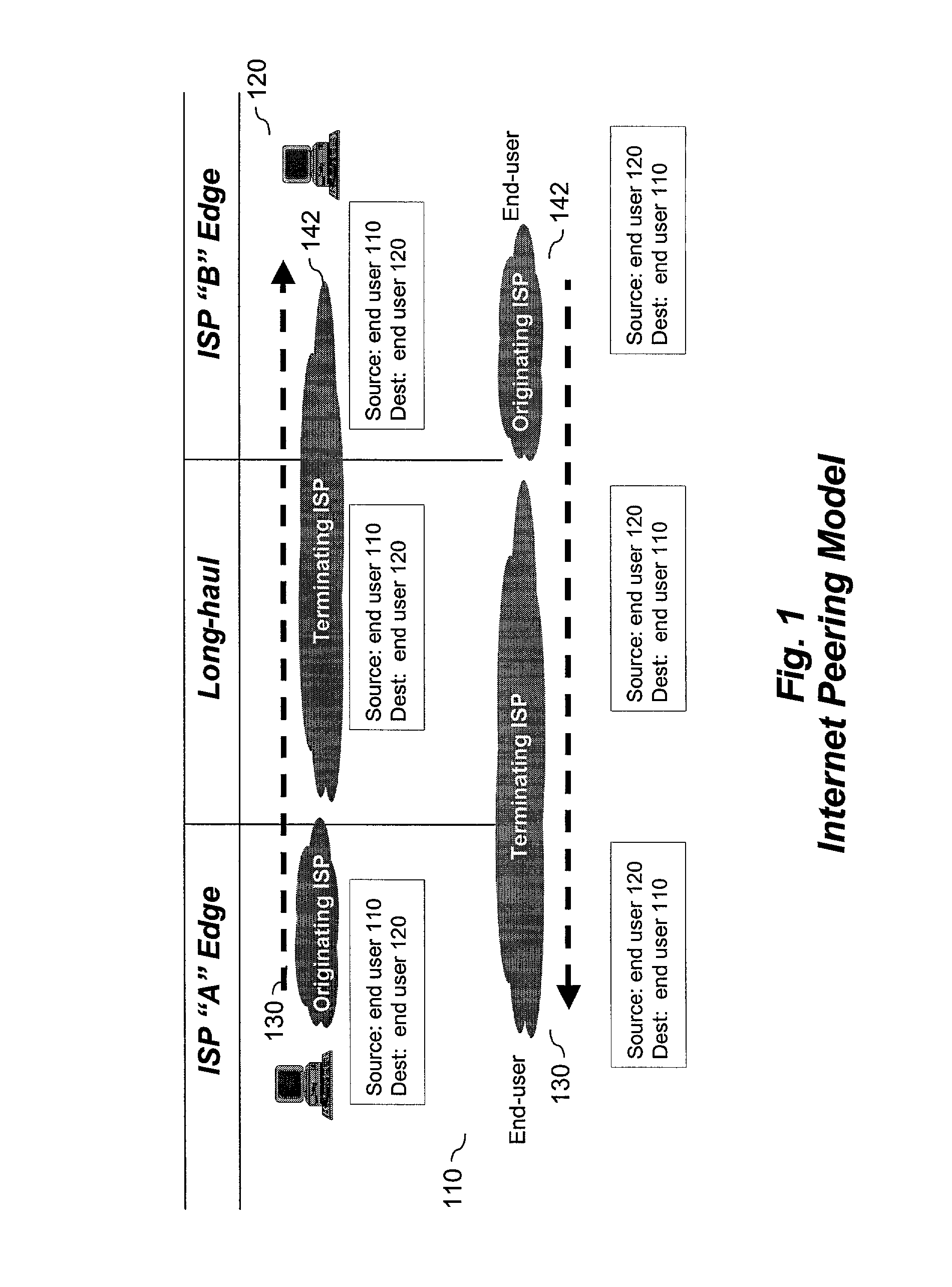

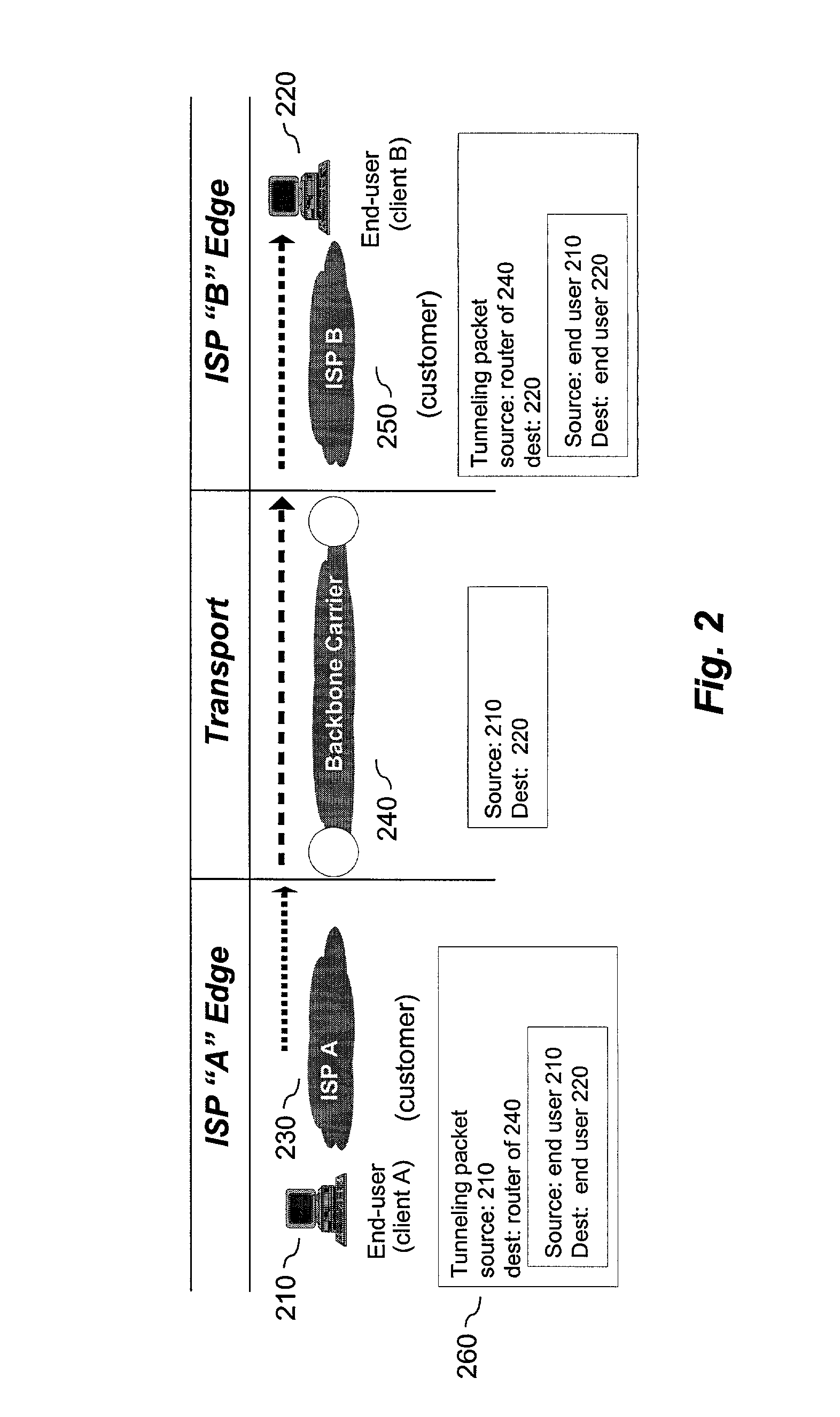

Method and system for sending information on an extranet

InactiveUS20020069292A1Guarantee qualityFew hopMetering/charging/biilling arrangementsTelephonic communicationDistributed computingExtranet

A method and system providing a single, symmetric path for forward and return traffic between two points on a network.

Owner:COREEXPRESS +2

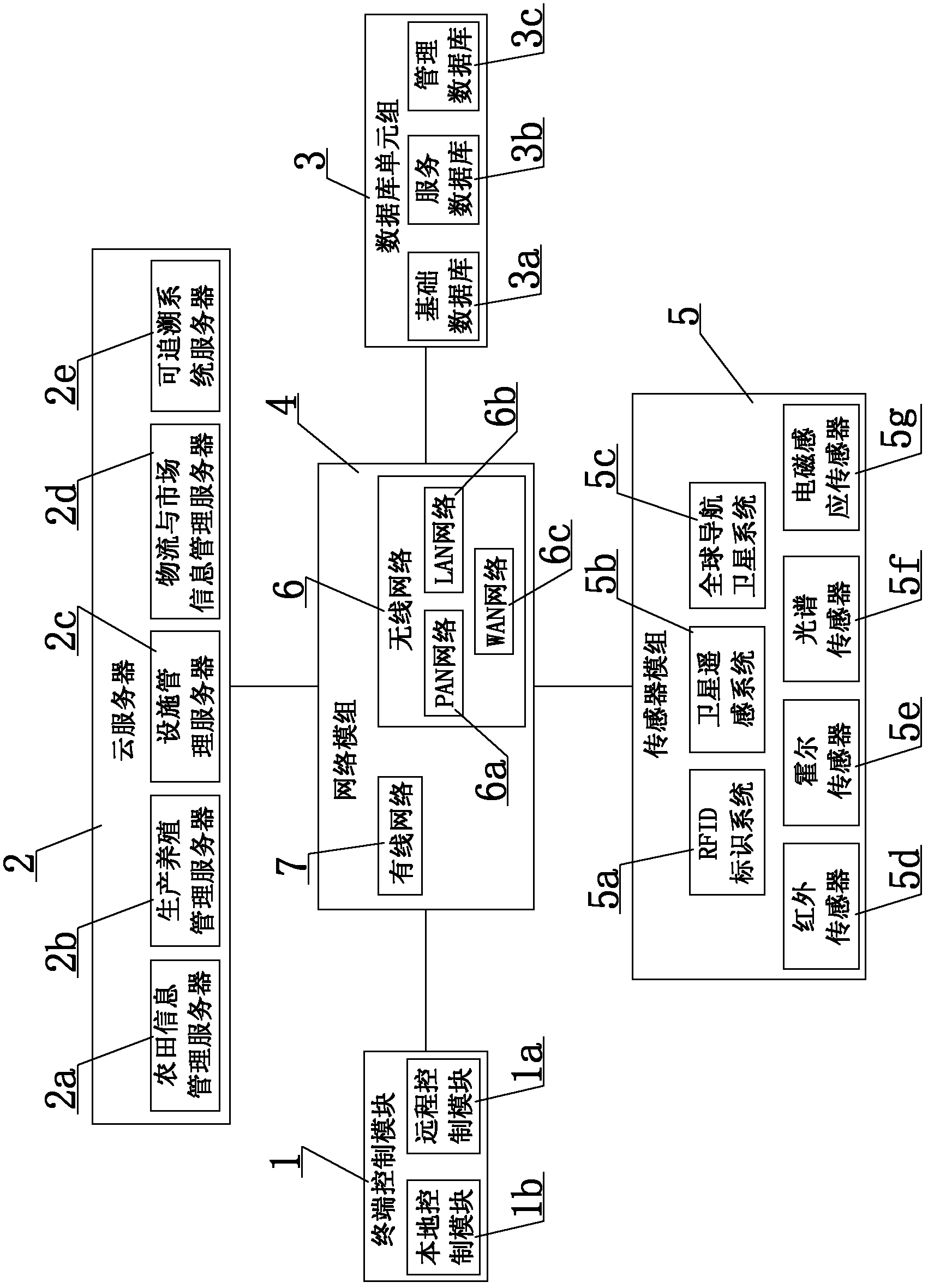

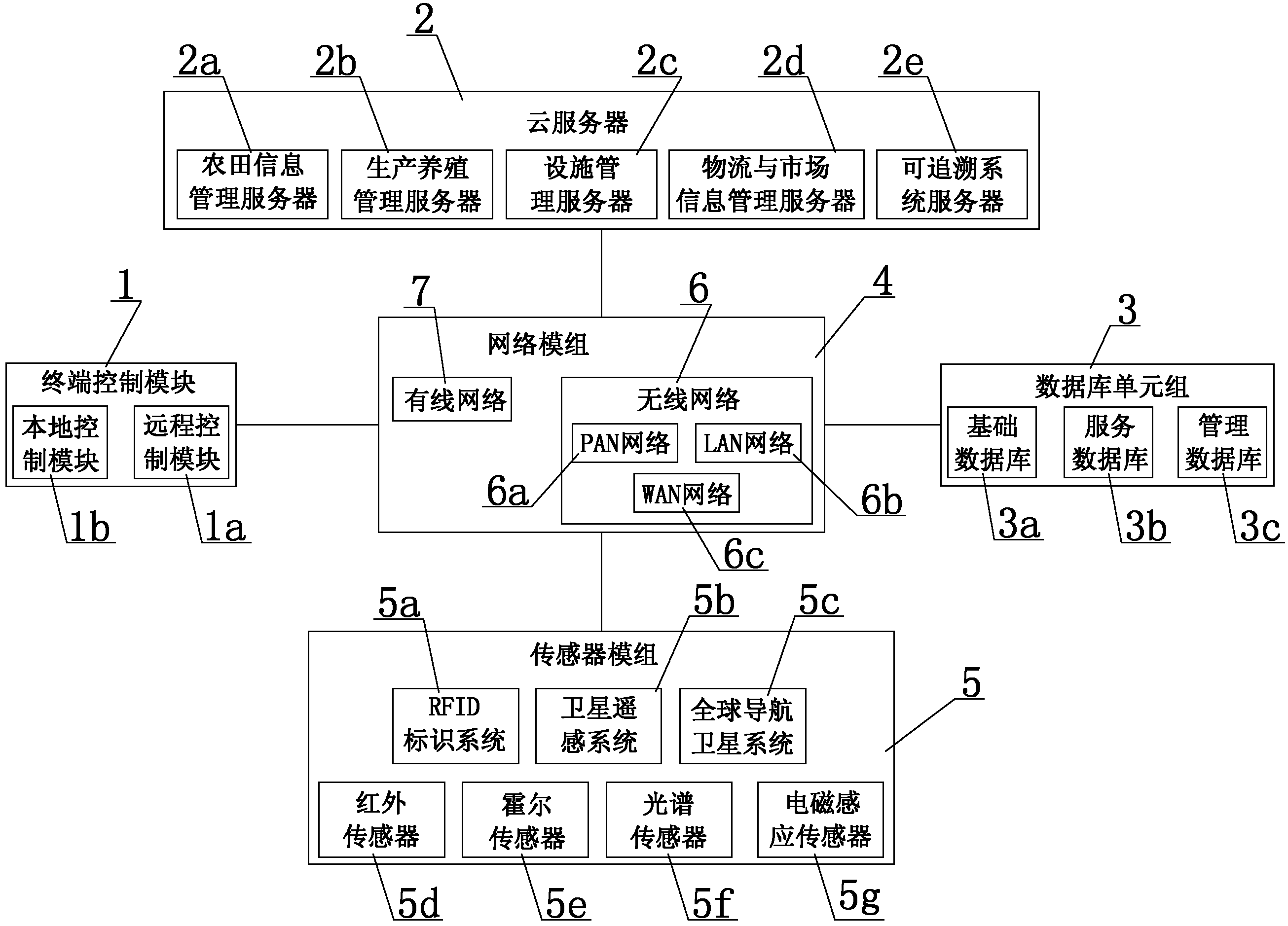

Internet-of-things-based intelligent management control system for agriculture and animal husbandry

The invention discloses an Internet-of-things-based intelligent management control system for agriculture and animal husbandry, which belongs to the technical field of management for the agriculture and the animal husbandry. The technical key points are that: the system comprises a terminal control module, a cloud server, a database unit group, a network module and a sensor module, wherein the terminal control module, the database unit group and the sensor module are connected with the cloud server by the network module. The Internet-of-things-based intelligent management control system for the agriculture and the animal husbandry is diverse and open, can realize intelligent identification, data acquisition, processing and management, and is used for intelligent management for the agriculture and the animal husbandry.

Owner:OUTRACE TECH

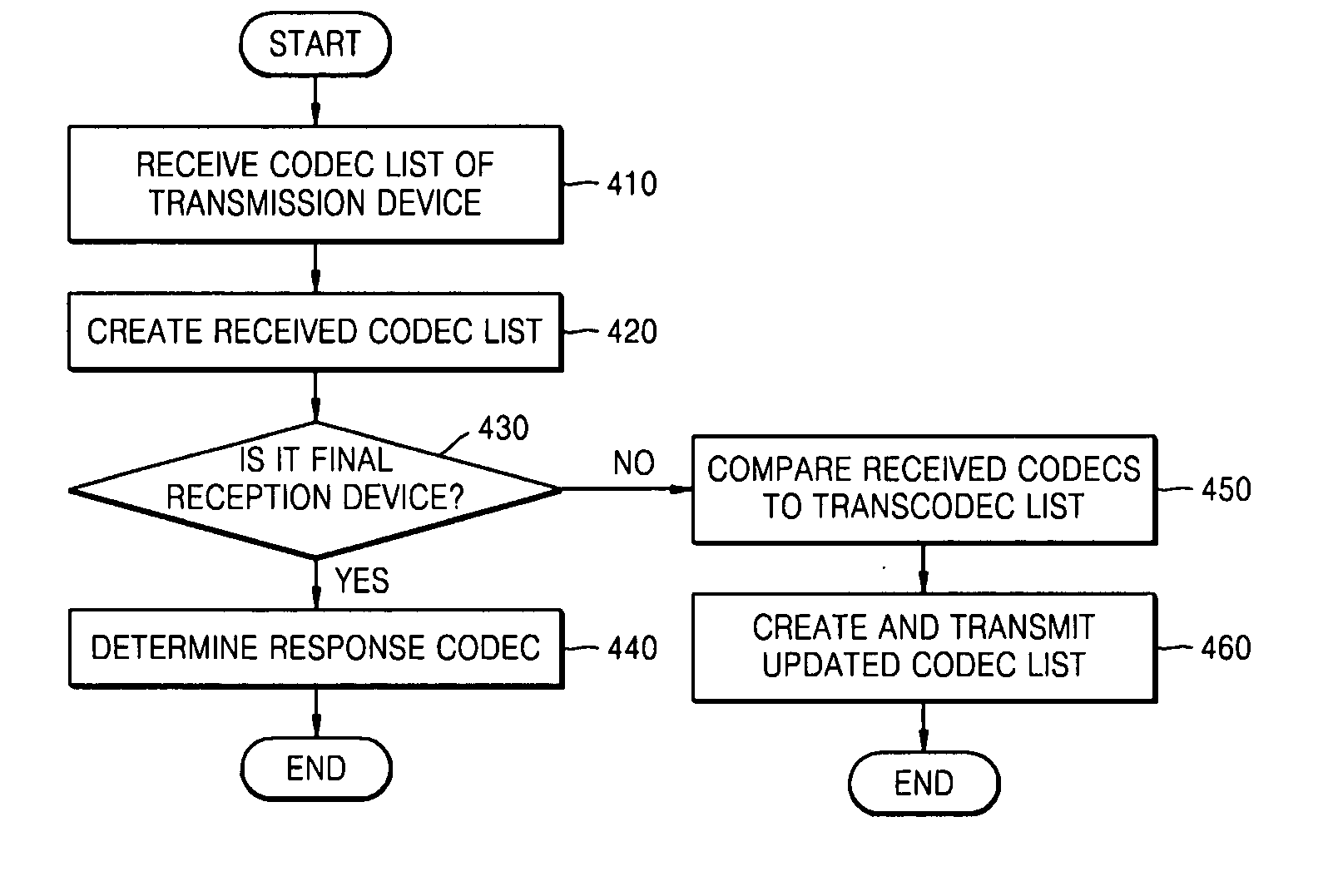

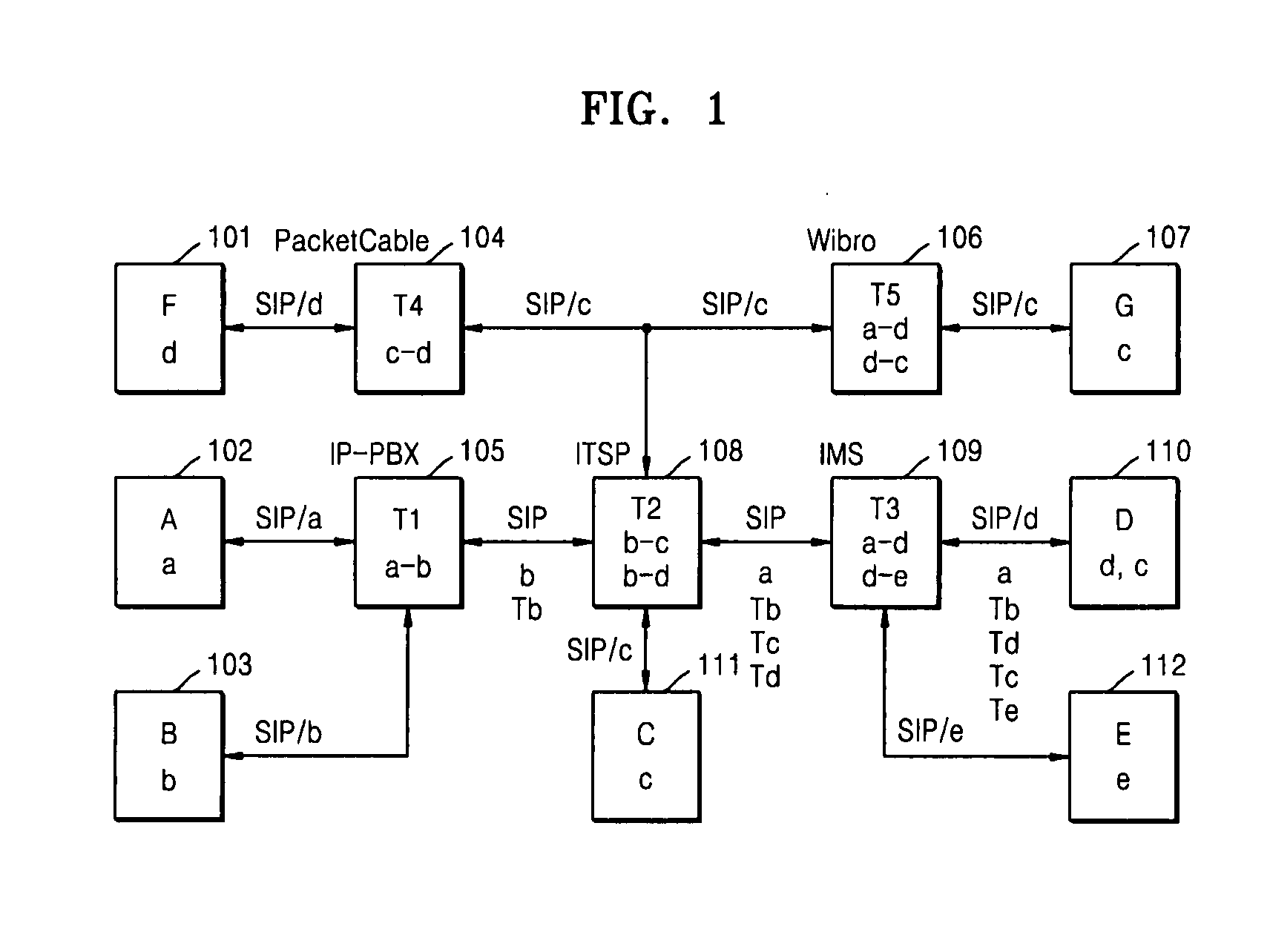

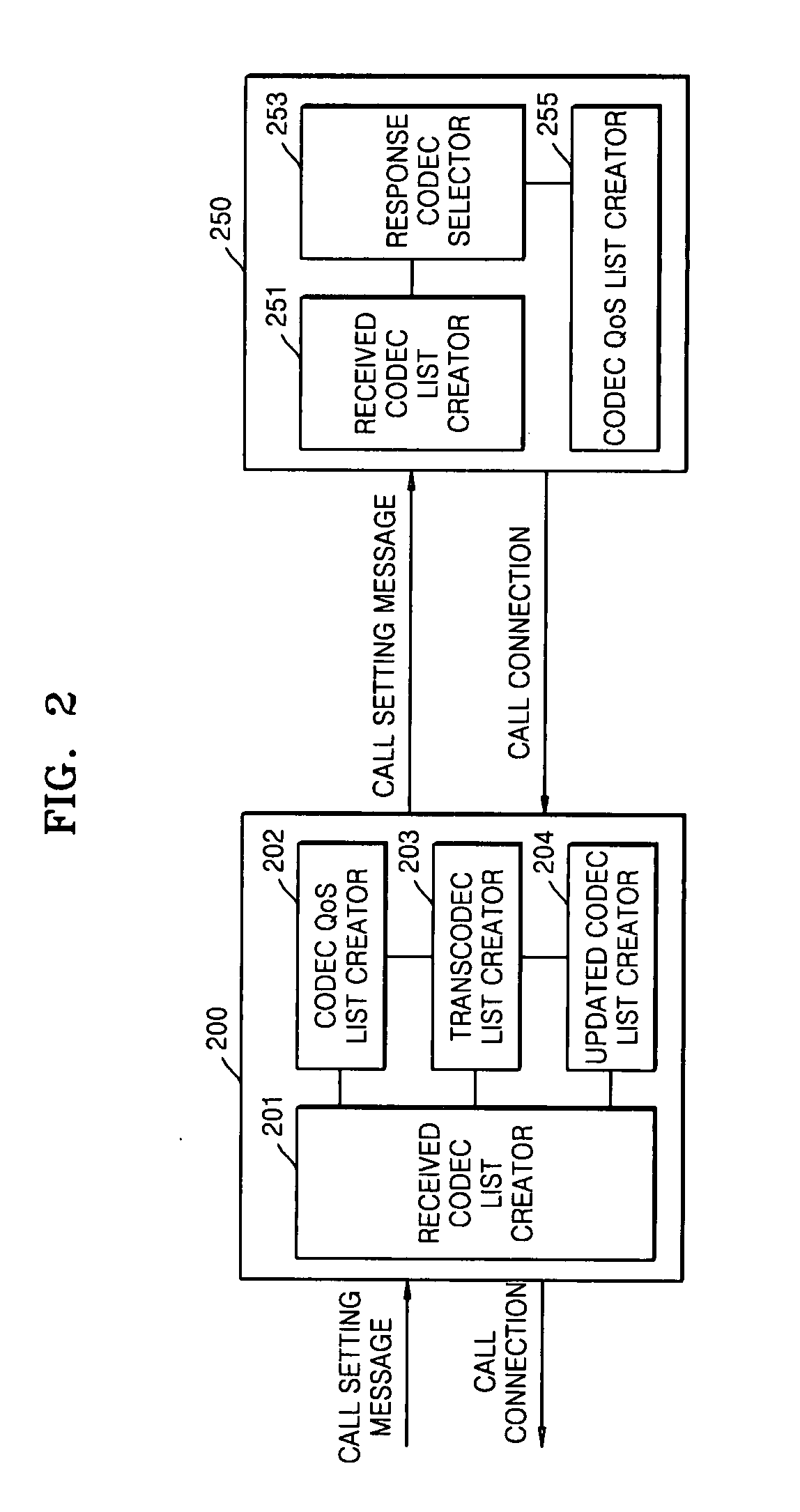

Apparatus and method for minimizing number of transcodings in multi-network multi-codec environment

InactiveUS20080081648A1Minimize numberGuarantee qualityInterconnection arrangementsNetwork traffic/resource managementQuality of serviceQuality information

Provided is a method and apparatus for minimizing the number of transcodings between network devices in a multi-network multi-codec environment. The method includes: creating a received codec list by receiving a transmit codec comprised in a call setting message from a transmission device and the number of transcodings of the transmit codec, which has been performed from a codec of an initial transmission device; creating a codec Quality of Service (QoS) list containing total codecs of the multi-network and quality information of each of the total codecs; creating a transcodec list containing internally providable transcodecs and quality information of the transcodecs based on the codec QoS list; and creating an updated codec list by adding codecs of the transcodec list matching codecs of the received codec list to the received codec list and adjusting codec priority according to the number of transcodings. Accordingly, since the number of transcodings can be minimized, a quality decrease of original media can be minimized.

Owner:ELECTRONICS & TELECOMM RES INST

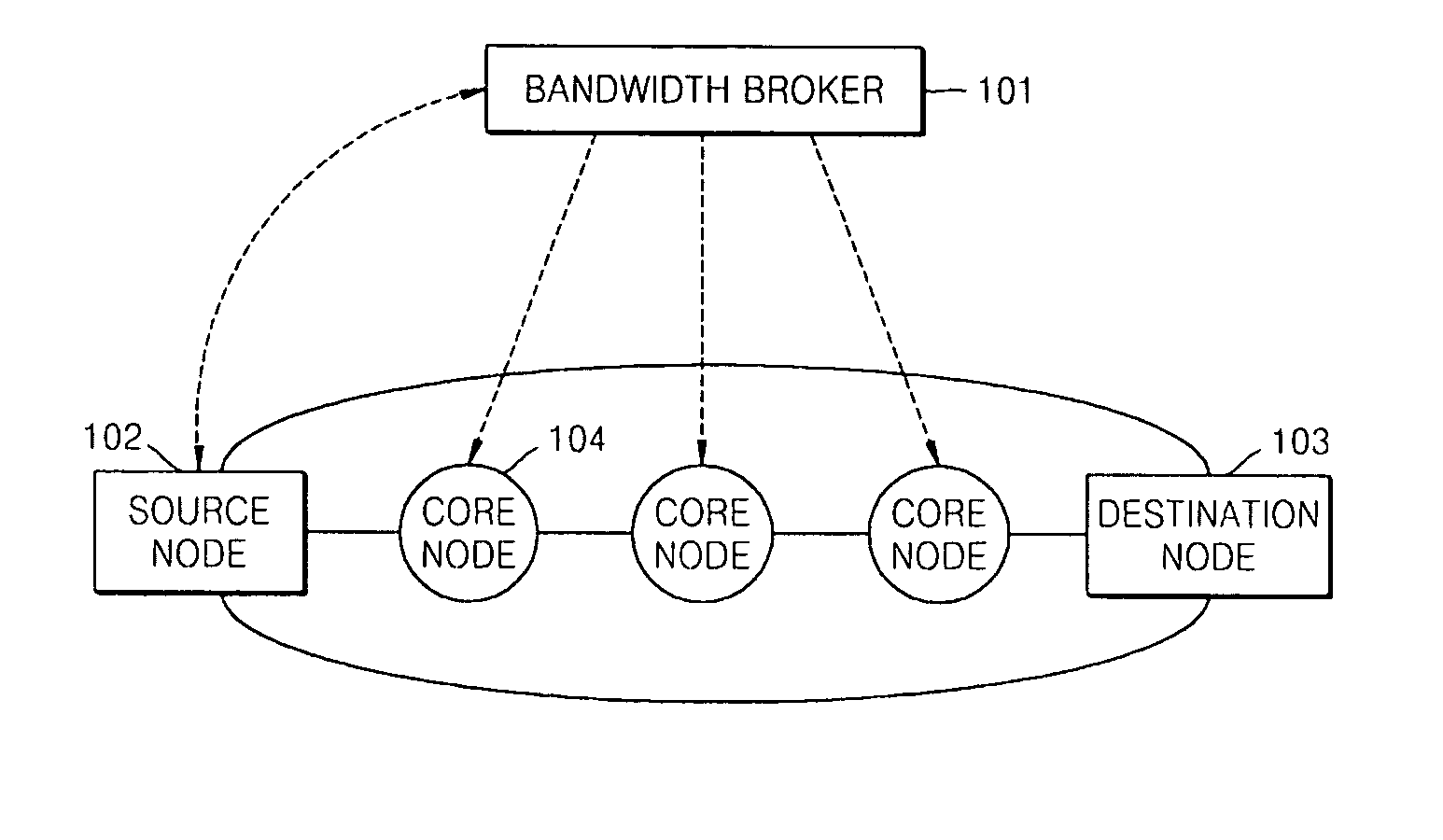

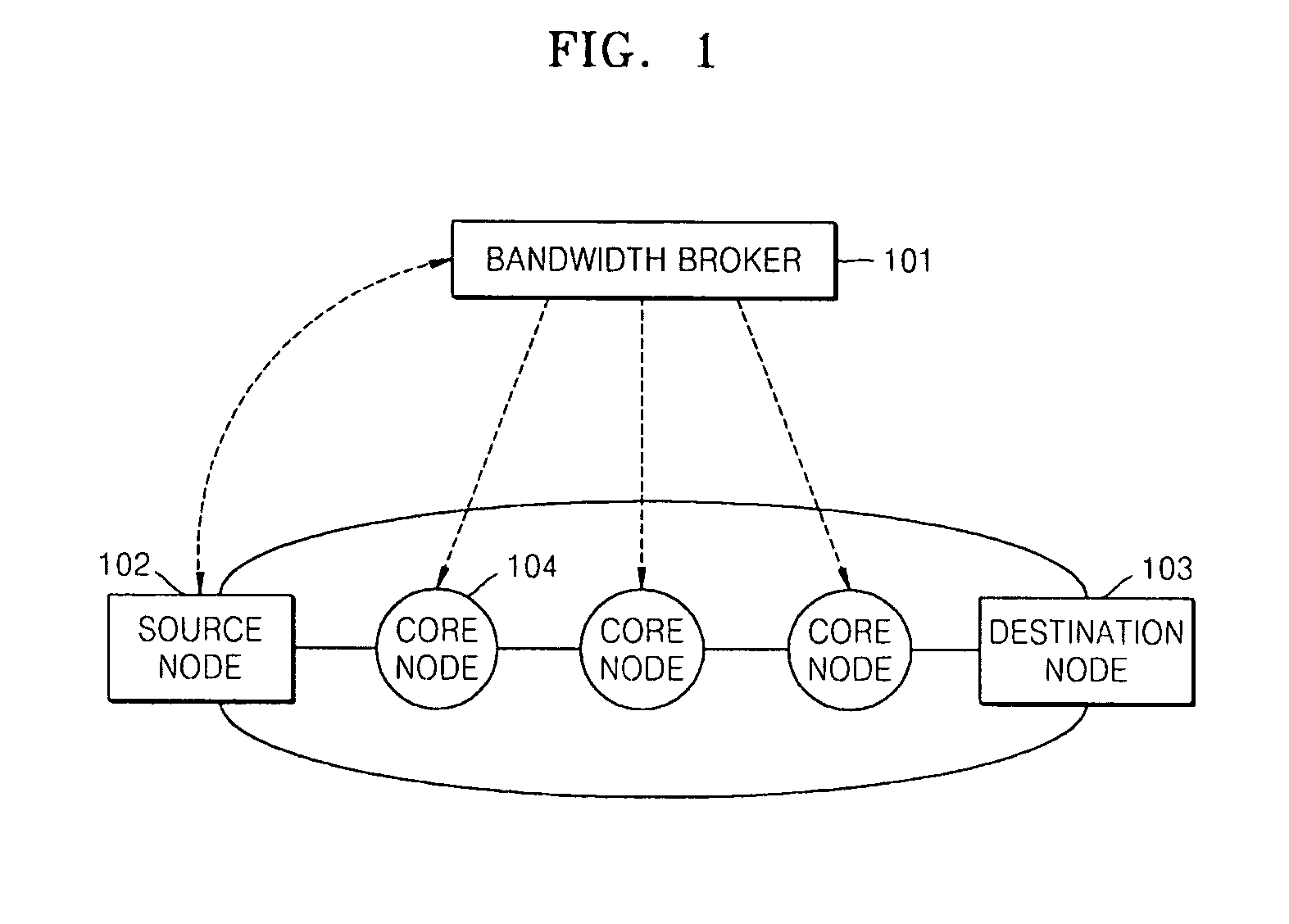

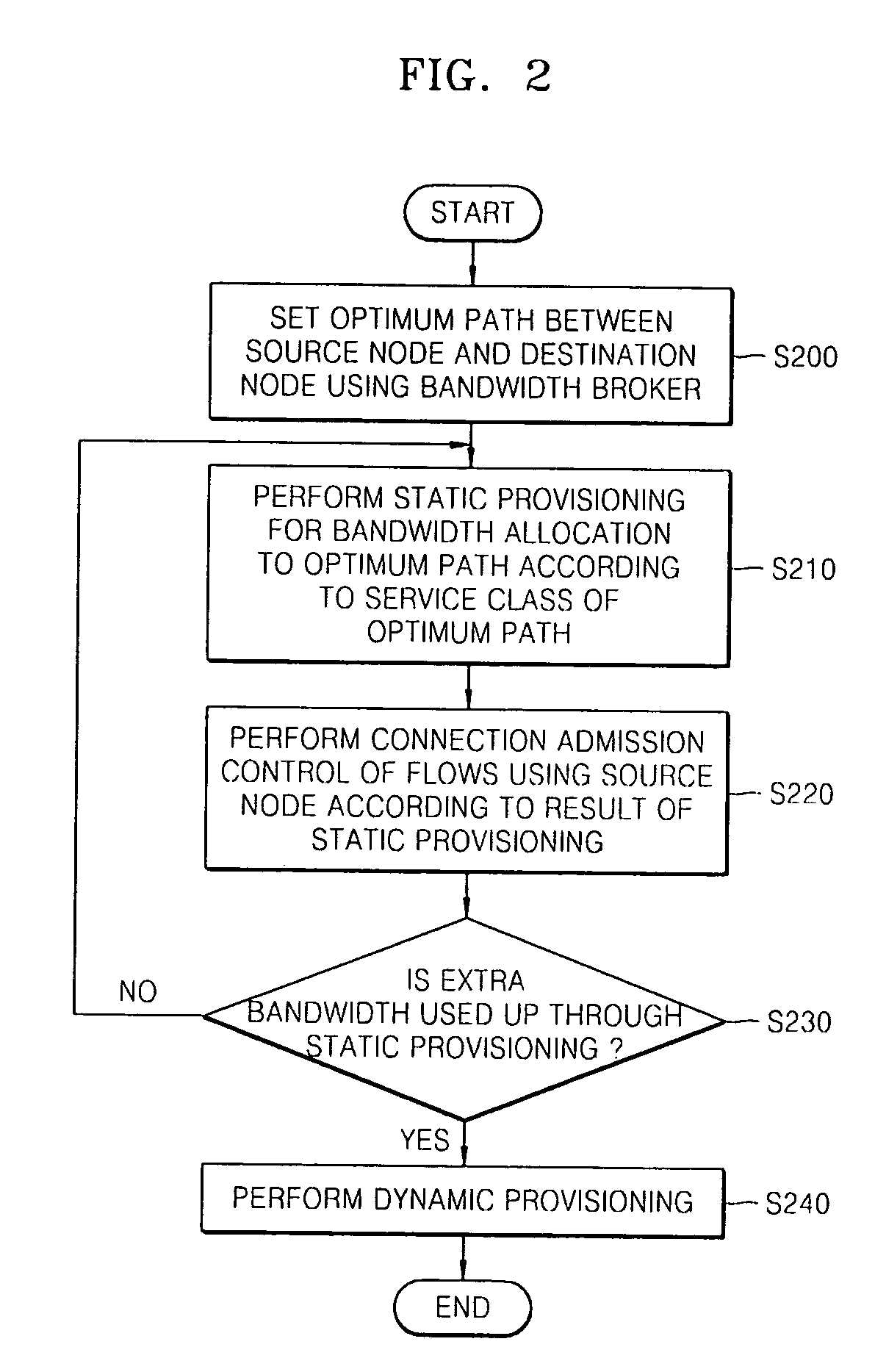

Network resource provisioning method for bandwidth guarantee per flow

InactiveUS20070118636A1Guarantee qualityGuaranteed service qualityError preventionTransmission systemsTraffic volumeBandwidth allocation

Provided is a network resource provisioning method for bandwidth guarantee per flow in a differentiated service Internet in which bandwidth needed for each flow is individually requested. The method comprises setting an optimum path between a source node and a destination node based on a request for traffic for a specific period of time; performing static provisioning in which bandwidth is allocated to the optimum path according to a service class thereof; determining whether all of the bandwidth allocated to the optimum path by performing static provisioning are used up, and accepting connection admission according to the determination result; and when connection admission is not accepted, performing dynamic provisioning in which additional bandwidth is allocated to the optimum path based on a request for traffic from a new incoming flow. Accordingly, it is possible to efficiently provide a quality-guaranteed service by accepting a request for bandwidth per flow.

Owner:ELECTRONICS & TELECOMM RES INST

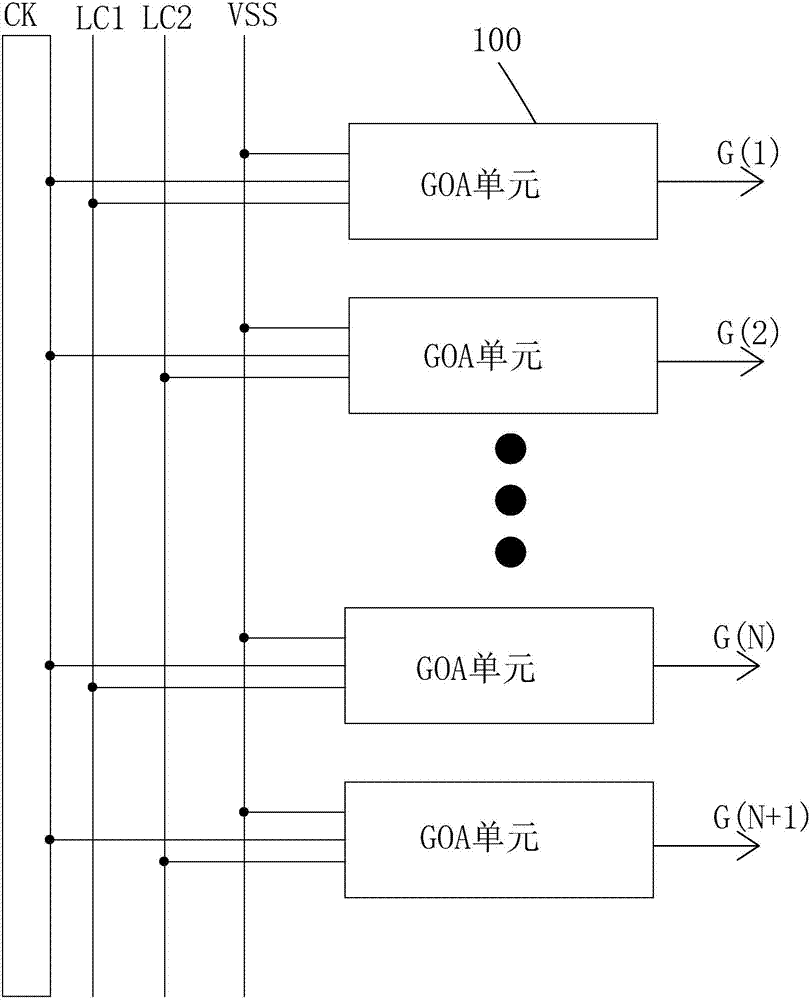

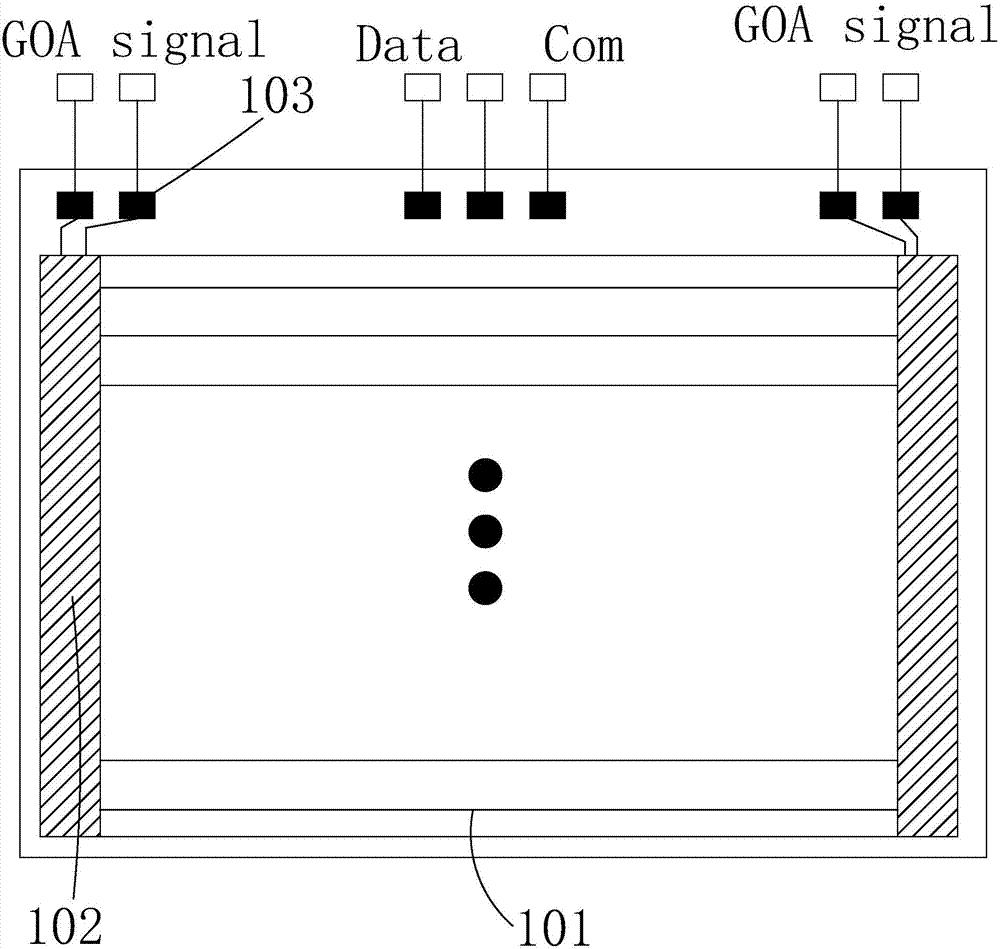

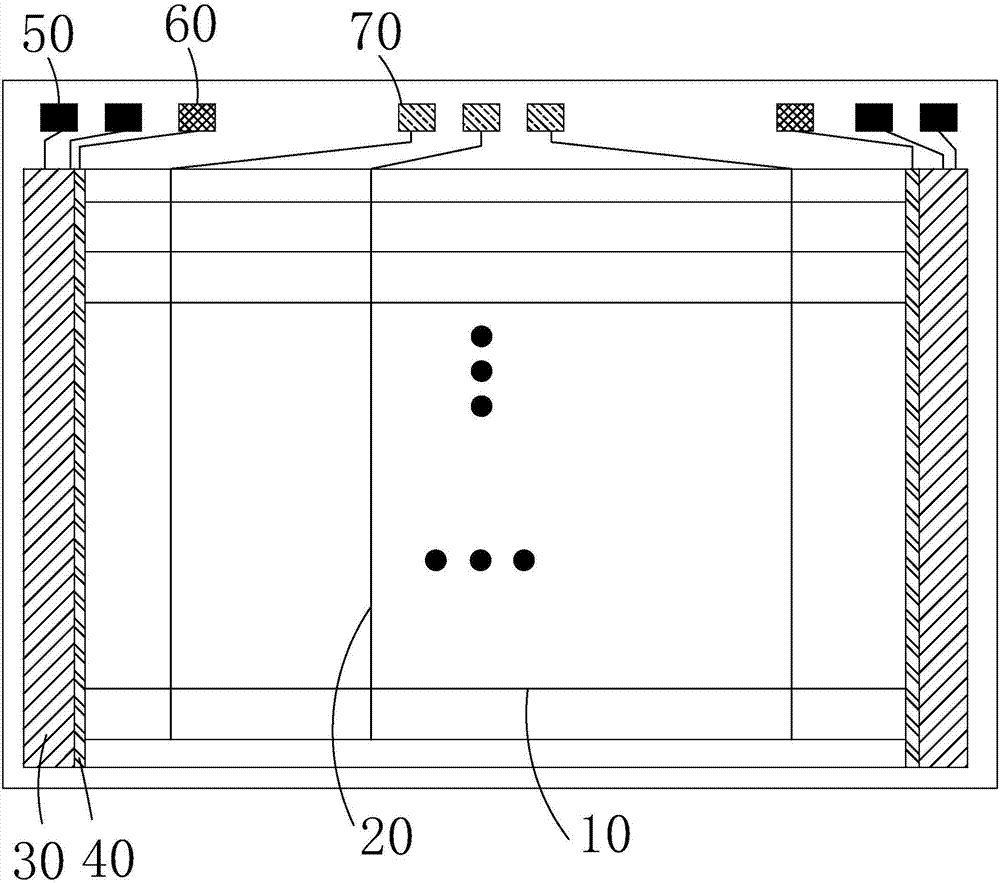

TFT substrate, test method thereof and method for eliminating shutdown residual image

InactiveCN107015408AImprove bad detection rateGuarantee qualityStatic indicating devicesNon-linear opticsLiquid-crystal displayIn plane

The invention provides a TFT substrate, a test method thereof and a method for eliminating a shutdown residual image. The TFT substrate is provided with an in-plane test circuit; the in-plane test circuit comprises a plurality of switch modules corresponding to a plurality of GOA units one to one and at least one switch control cabling line, each switch module comprises a control end, an input end and an output end, the control end and the input end are electrically connected with one switch control cabling line, the output end is electrically connected with scanning signal output ends of the GOA units corresponding to the switch control modules, each switch control cabling line is electrically connected with an in-plane test signal output point, an in-plane test signal is input to a scanning line through the switch control cabling lines and the switch modules so that fault detection can be conducted on the scanning line independently, and when a liquid crystal display device shuts down, a power discharge signal is input to the scanning line through the switch control cabling lines and the switch modules so that the shutdown residual image of the liquid crystal display device can be eliminated.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

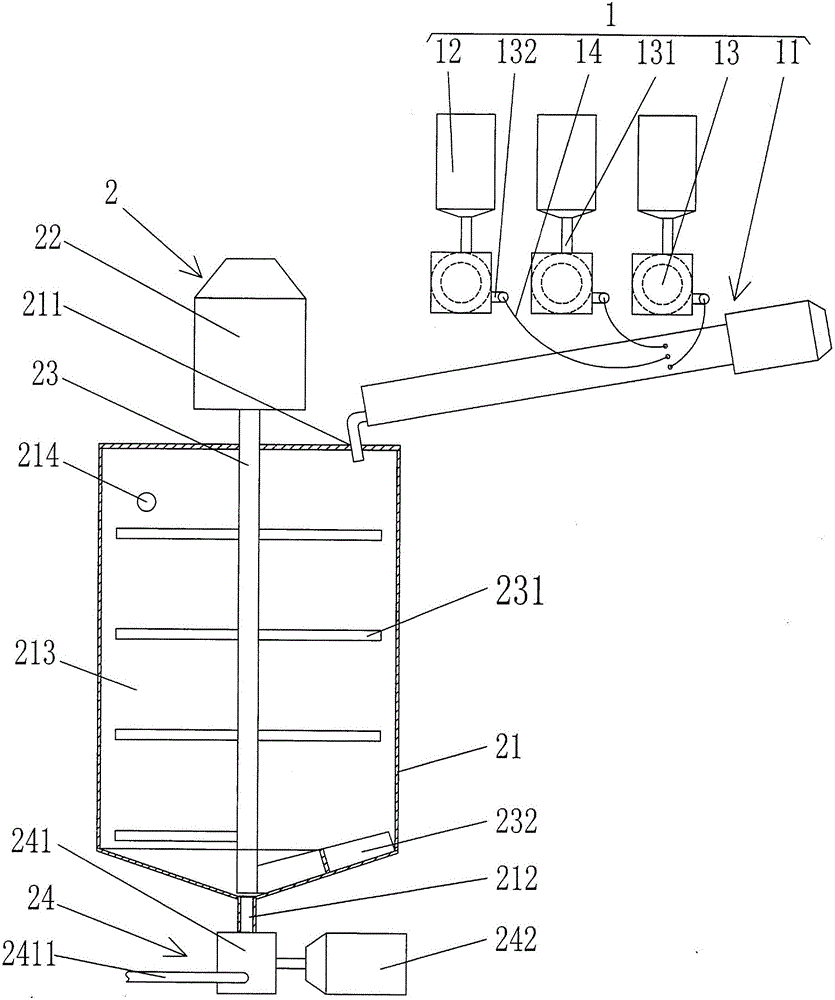

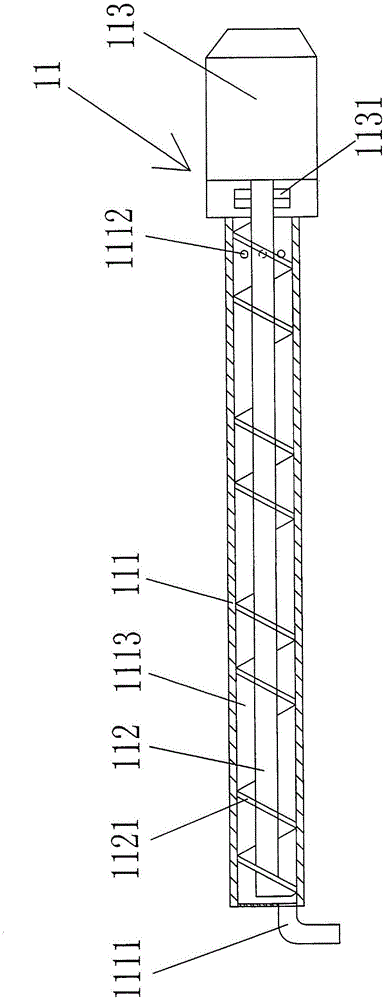

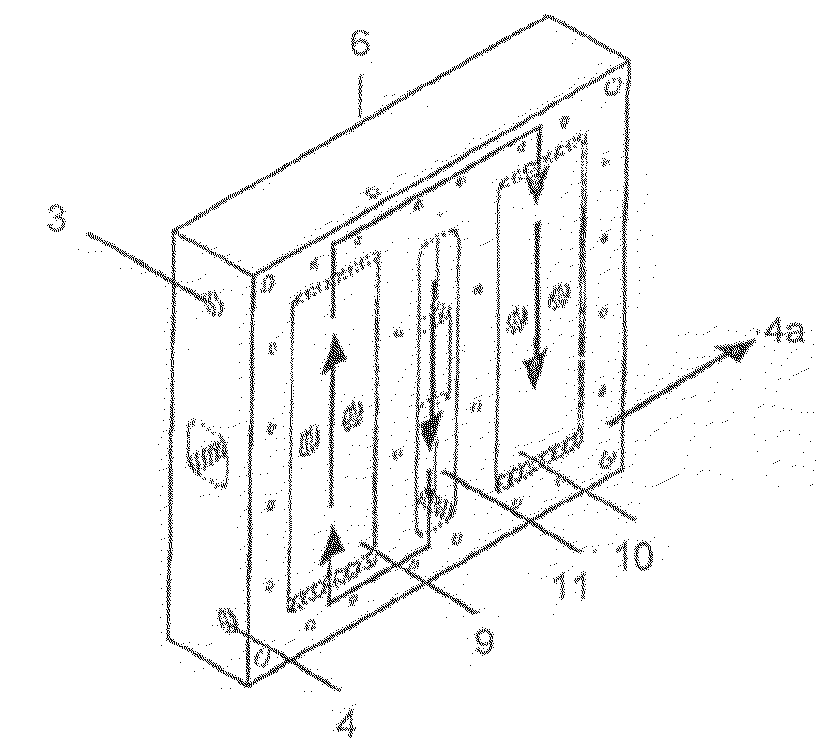

Color paste stirring device

PendingCN106362622AExcellent uniform mixing effectGuarantee qualityRotary stirring mixersTransportation and packagingYarnAssistive device/technology

The invention relates to a color paste stirring device, belonging to the technical field of auxiliary equipment for melt-spun color yarns. The color paste stirring device comprises a color blending and conveying mechanism and a color paste mixing mechanism, wherein the color blending and conveying mechanism comprises a spiral conveyor, a color paste tank and a color paste metering pump; the spiral conveyor is connected with the color paste mixing mechanism; the color paste tank is connected with a feeding hole of the color paste metering pump, and a discharge hole connecting pipe is connected between a discharge hole of the color paste metering pump and the spiral conveyor; the color paste mixing mechanism comprises a stirring tank, a stirring motor, a stirring shaft and a mixed slurry output device; a stirring tank feeding hole is formed in the top of the stirring tank, and a stirring tank discharge hole is formed in the center of the bottom of the stirring tank; the stirring shaft is arranged in a cavity of the stirring tank; the upper end of the stirring shaft is supported on the top of the stirring tank, and the lower end of the stirring shaft is supported at the bottom of the stirring tank; a stirring rod is arranged on the stirring shaft; the stirring motor is connected with the upper end of the stirring shaft; the mixed slurry output device is connected with the stirring tank; the spiral conveyor is connected with the stirring tank. The color paste stirring device is ideal in color blending efficiency and uniform in mixing effect, and can guarantee the quality of the spun color yarns.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Flexible porous metal foil and preparation method therefor

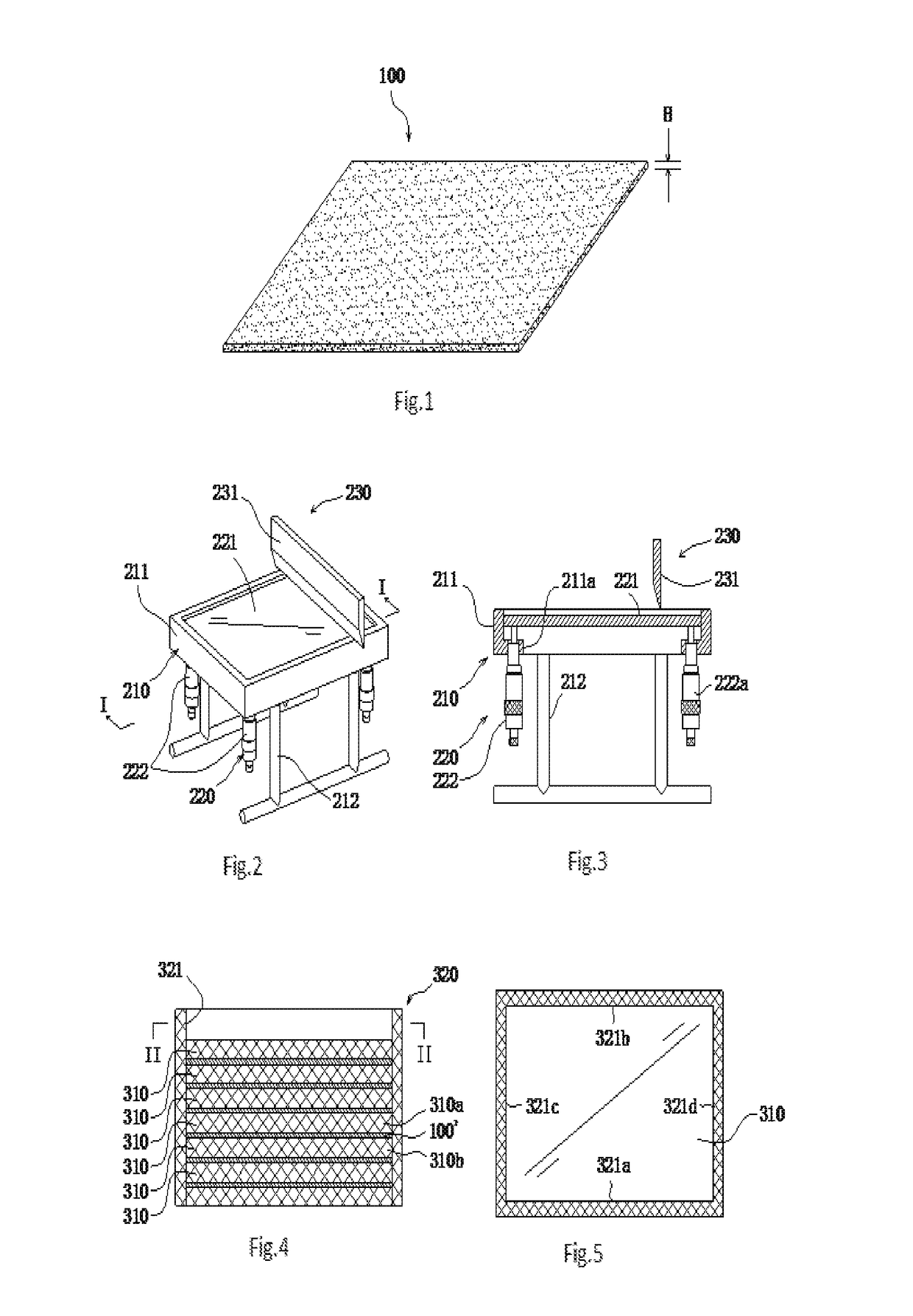

ActiveUS20170333992A1Easily manufactureGuarantee qualityTransportation and packagingMetal-working apparatusMicrometerPorous metal

A piece of flexible porous metal foil is a sheet made of porous metal material using solid solution alloy, face-centered cubic metal simple substance or body-centered cubic metal simple substance as matrix phase. The thickness of the sheet is 5 to 200 micrometers, the average aperture thereof is 0.05 to 100 micrometers, the porosity thereof is 15-70%, and the sheet is made by sintering a homogeneous film. The preparation method for the flexible porous metal foil comprises: (1) preparing thick turbid liquid with raw material powder forming the metal porous material by using dispersing agent and binding agent; (2) injecting the turbid liquid into a mold cavity of a film manufacturing fixture, and drying the turbid liquid to form a piece of homogeneous film; (3) putting the film into a sintering manufacturing fixture matching with the film in shape, then sintering the film, and taking the film out after sintering and obtaining the flexible porous metal foil. The flexible porous metal foil made by the above method can be used in many fields, and have ideal performance in flexible and chemical stability.

Owner:CHENGDU INTERMENT TECH

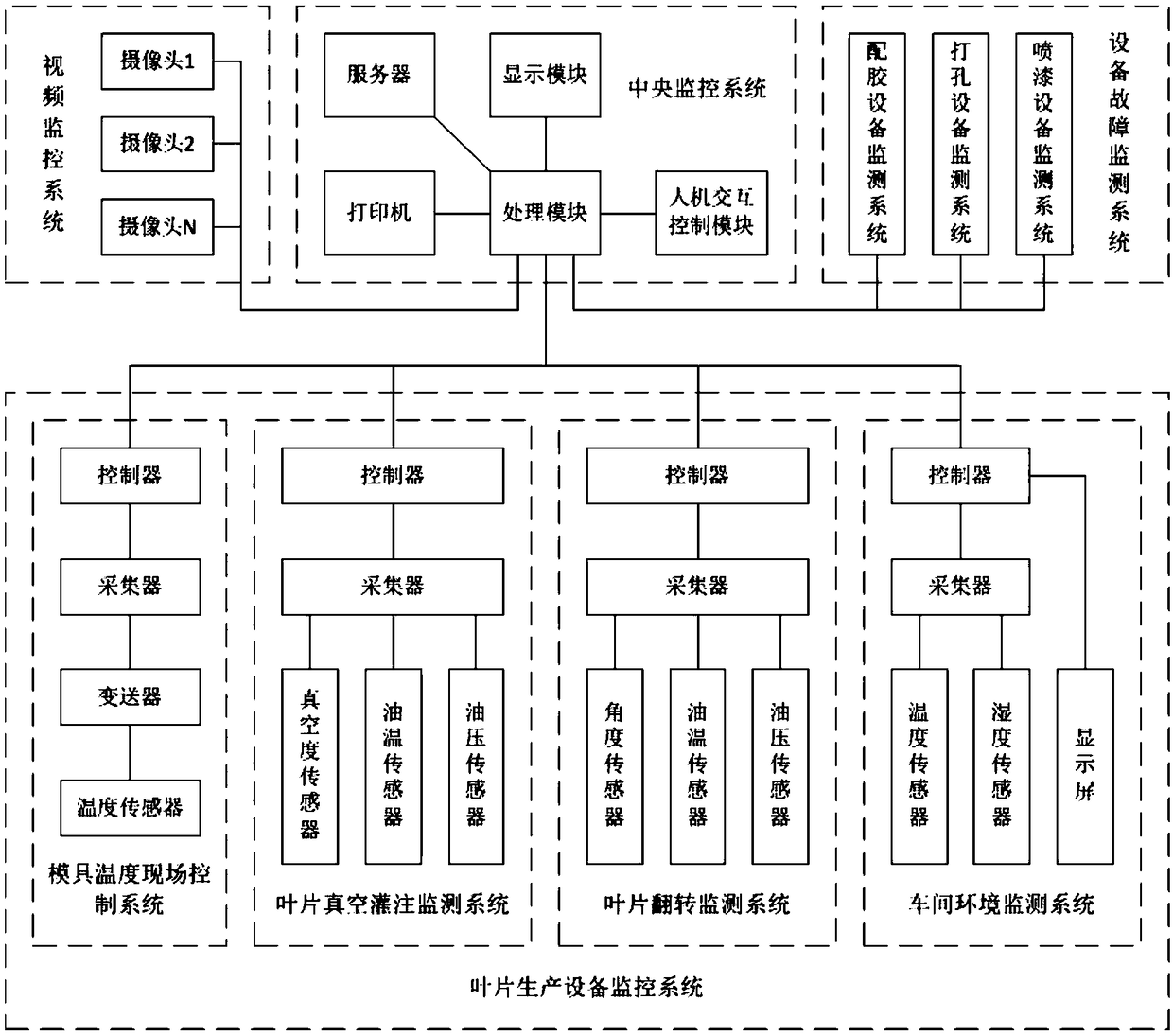

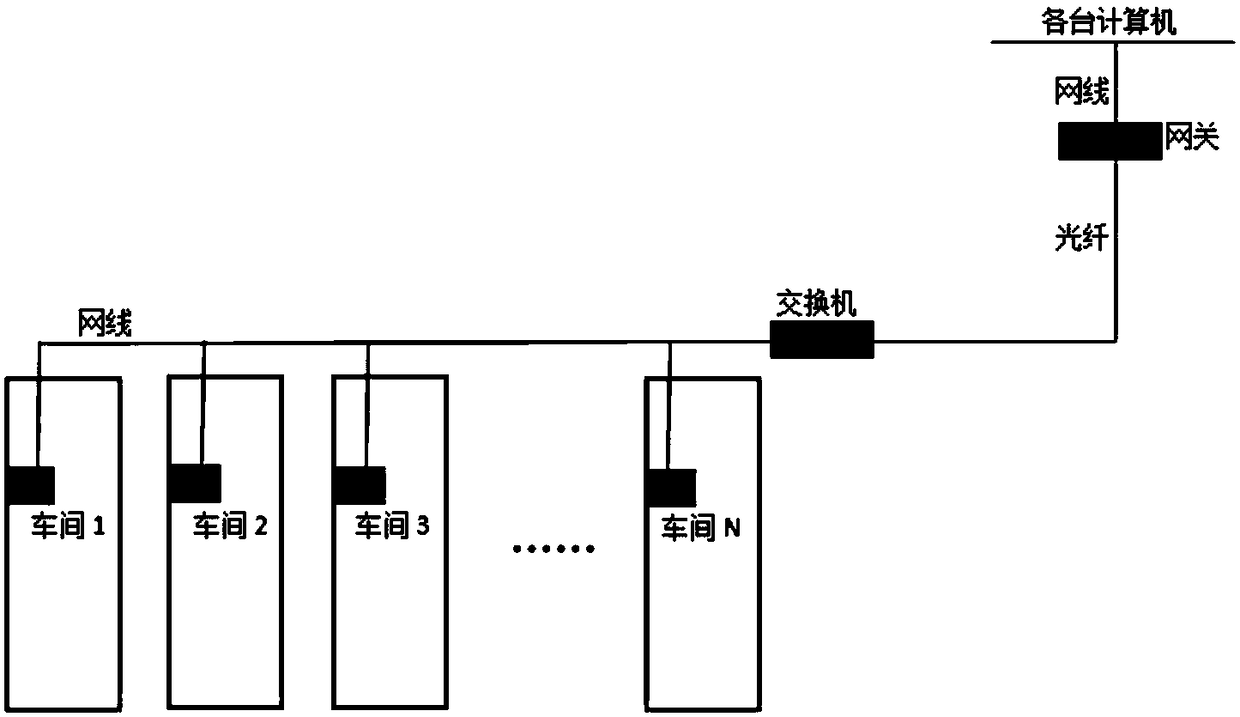

Intelligent control system for large wind power blade production process

ActiveCN109189015AGuarantee qualityQuality assuranceTotal factory controlProgramme total factory controlIntelligent control systemElectricity

The invention discloses an intelligent control system for the large wind power blade production process. The intelligent control system comprises a center control system, a video monitoring system, ablade production system and an equipment fault detection system. The center control system is respectively connected with the video control system, the blade production system and the equipment faultdetection system. The blade production system comprises a mold temperature in-situ control system, a blade vacuum filling control system, a blade overturning control system and a workshop environmentmonitoring system. The equipment fault detection system comprises a glue distributing equipment monitoring system, a drilling equipment monitoring system and a paint spraying equipment monitoring system. The intelligent control system has the beneficial effects that through monitoring and collecting to functional data, running conditions of all equipment can be centralized and monitored, and the problems of delayed feedback, inaccurate measuring and non-prewarning caused by relying on manual operation and dispersion of monitoring equipment are solved.

Owner:GUODIAN UNITED POWER TECH LIANYUNGANG CO LTD

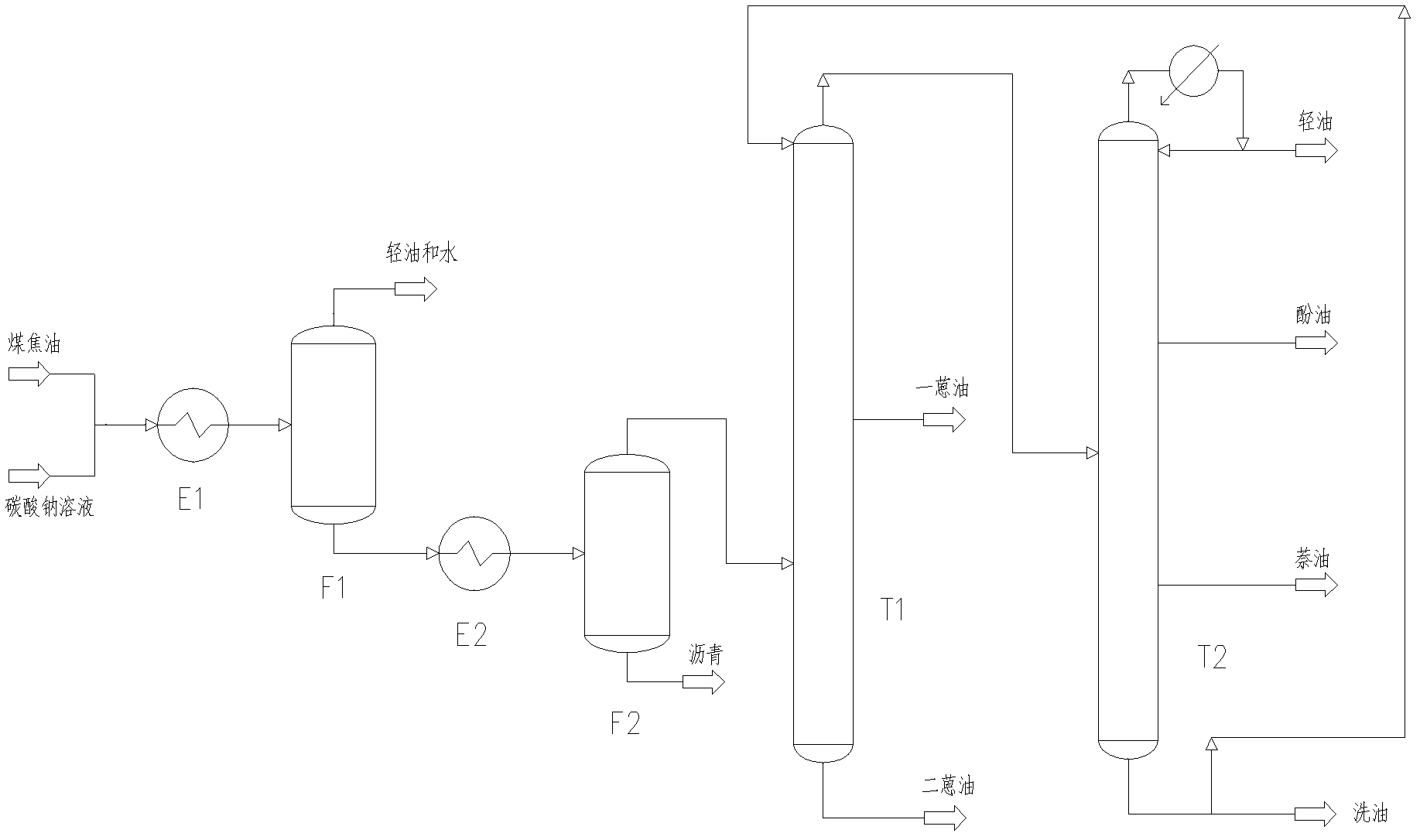

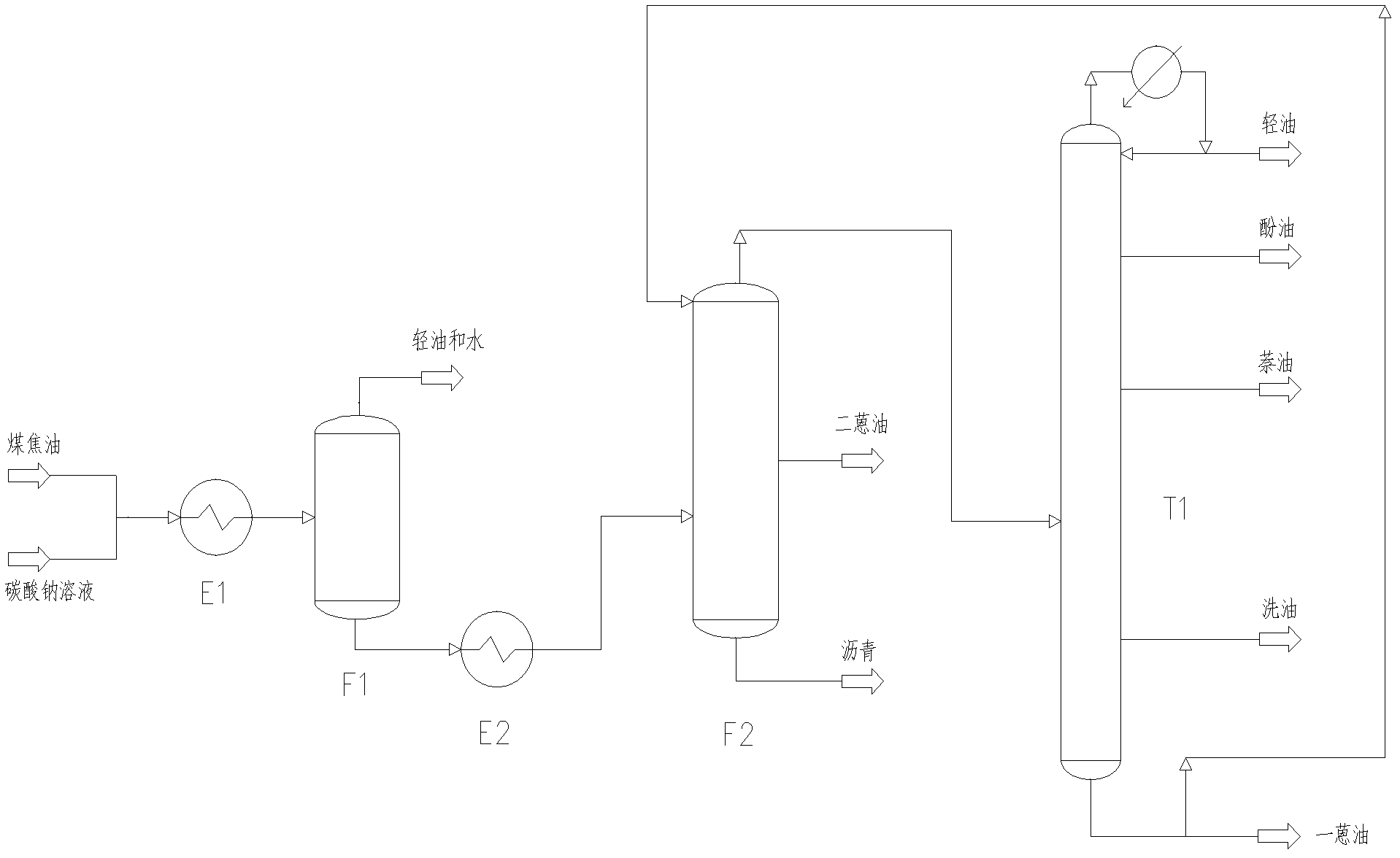

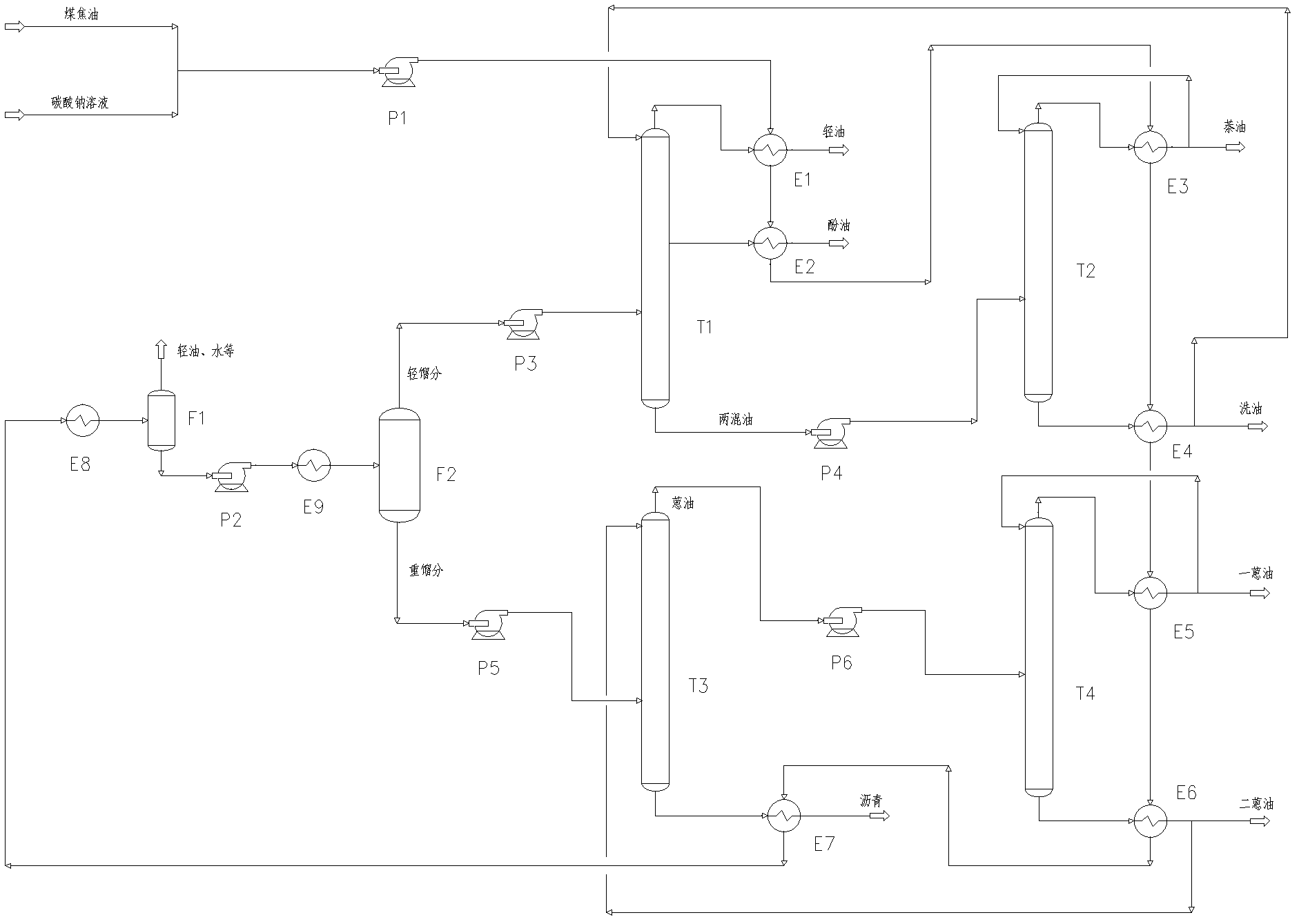

Coal tar treatment method

ActiveCN103013547AReduce energy consumptionGuarantee qualityTar working-up by distillationTarChemistry

The present invention provides a coal tar treatment method, which comprises: carrying out mixing heating on coal tar and a sodium carbonate solution, and conveying the obtained mixed solution to a first section evaporator to carry out dehydration, such that the tar component is discharged from the bottom; conveying the tar component into a second section evaporator to carry out distillation, such that a light fraction with a boiling point of lower than 300 DEG C is discharged from the top, and a heavy fraction containing anthracene oil and asphalt is discharged from the bottom; conveying the light fraction with a boiling point of lower than 300 DEG C into a light fraction tower to carry out rectification, wherein a light oil fraction is recovered from the top of the tower, a phenol oil fraction is recovered from the side stream, and a two oil mixing fraction is recovered from the bottom of the tower; conveying the two oil mixing fraction into a two oil mixing tower to carry out rectification, wherein a naphthalene oil fraction is recovered from the top of the tower, and a wash oil fraction is recovered from the bottom of the tower; conveying the heavy fraction containing anthracene oil and asphalt into a heavy fraction tower to carry out rectification, wherein an anthracene oil fraction is recovered from the top of the tower, and an asphalt fraction is recovered from the bottom of the tower; and conveying the anthracene oil fraction into an anthracene oil tower to carry out rectification, wherein an anthracene oil fraction 1 is recovered from the top of the tower, and an anthracene oil fraction 2 is recovered from the bottom of the tower. With the treatment method, energy source consumption is low, and a key component concentration degree is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-yield eggplant planting method

The invention belongs to the technical field of tree planting and relates to a high-yield eggplant planting method, in particular to an eggplant planting method which is perfect and can accelerate growth of eggplants. The high-yield eggplant planting method comprises steps as follows: 1, seed treatment: seeds are placed in warm water with the temperature ranging from 55 DEG C to 60 DEG C, stirred continuously until the temperature is reduced to 30 DEG C, soaked for 2 hours and placed in a gibberellin solution with the concentration of 200 mg / kg to be soaked for 24 hours, and then, germination is accelerated; 2, sowing on beddings: the flat and fine beddings which are 1 m wide and have edges on two sides are made, and disinfected and soaked seeds subjected to germination acceleration are mixed with sand to be sown after water penetration; 3, seedling management: weeds should be timely and manually pulled out once the weeds are found; 4, field arrangement: sandy loam with higher terrain should be selected for cultivation due to the fact that high-temperature and rainy days come soon after field planting of eggplants in summer and the eggplants are not tolerant to waterlogging; 5, field planting: the field planting period for the eggplants generally lasts from the first ten days of June to the first ten days of July after wheat harvest, and fielding planting should be performed early but not too late, so that rooting and tillering before midsummer are facilitated.

Owner:李志刚

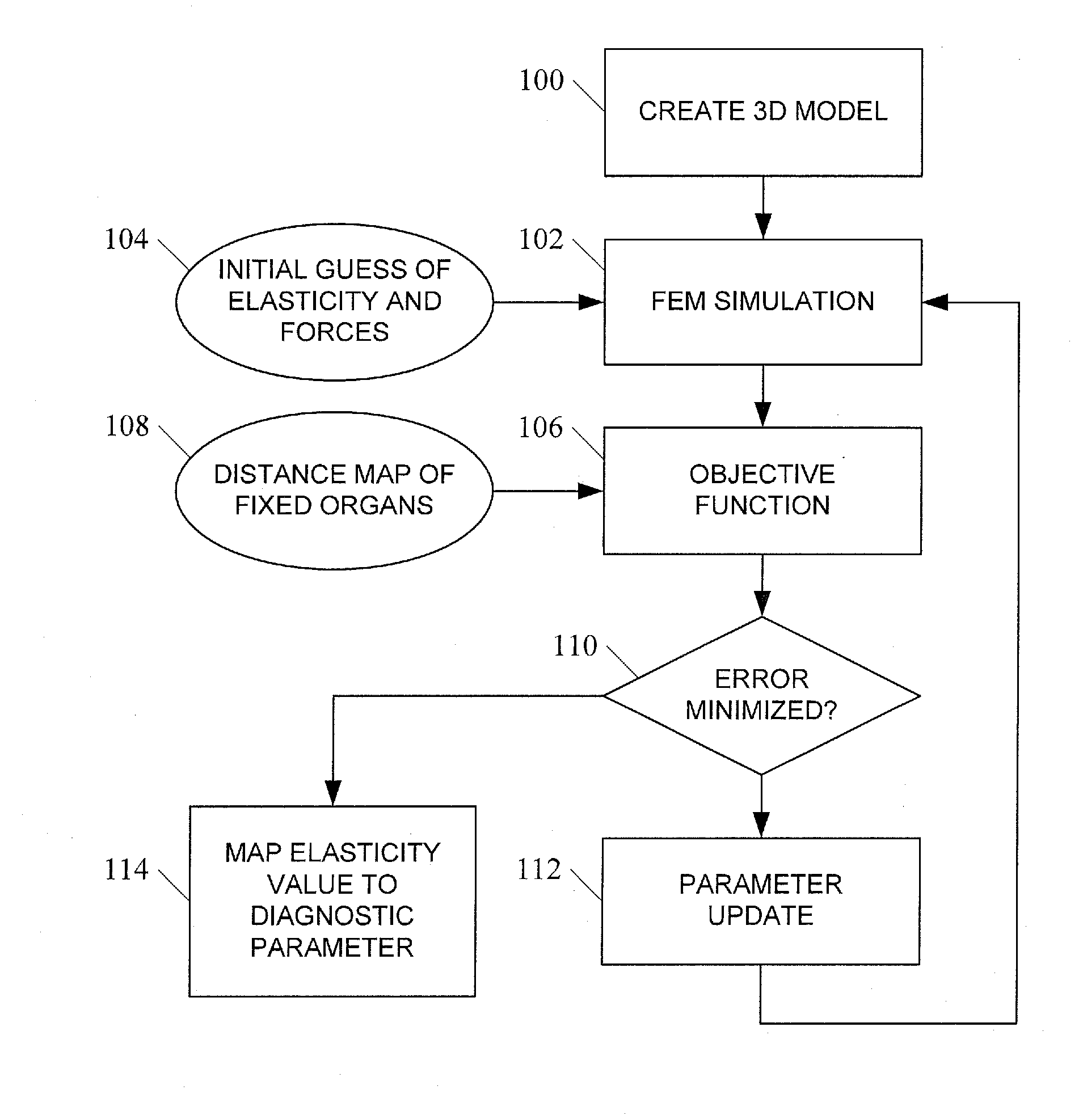

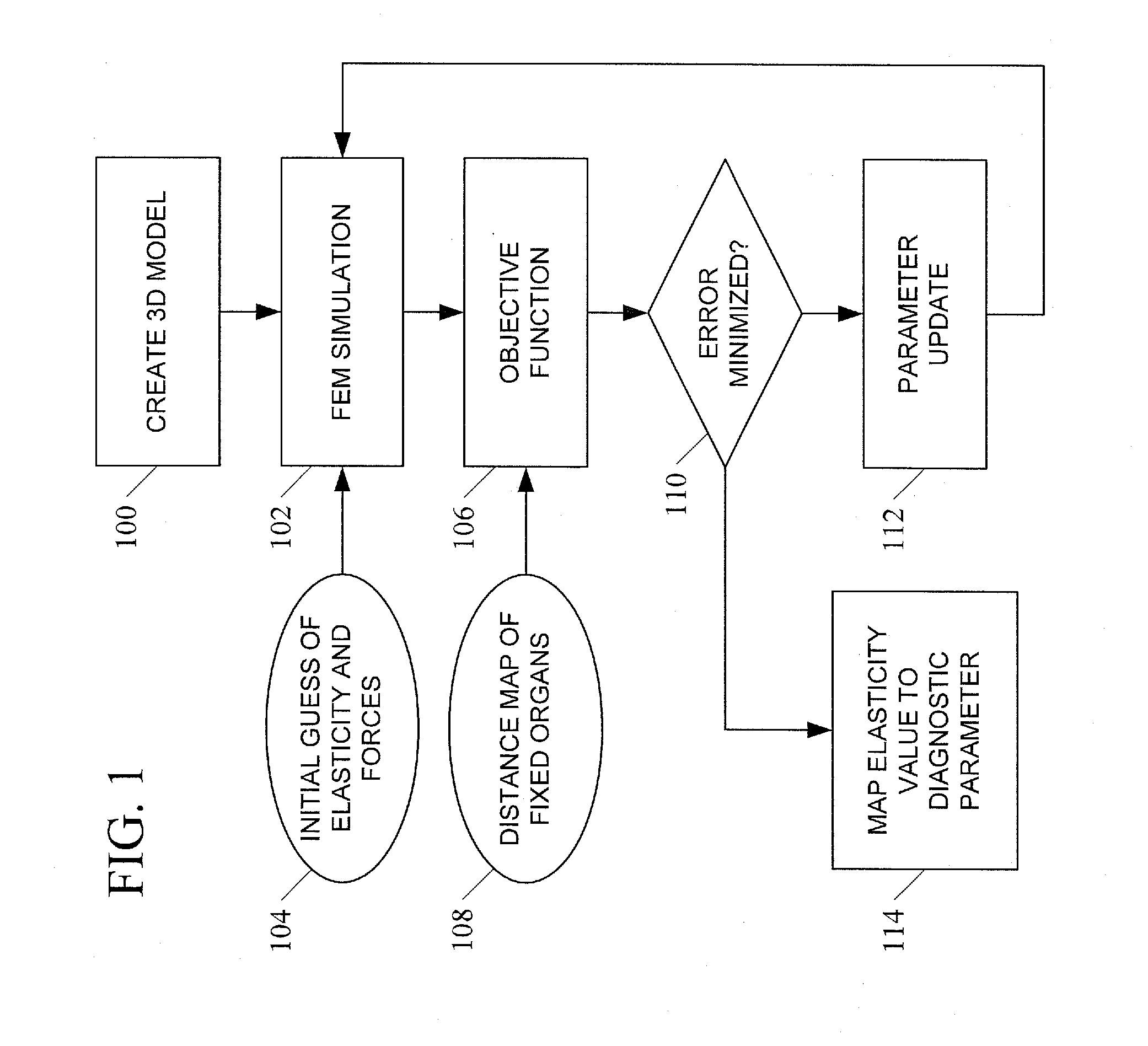

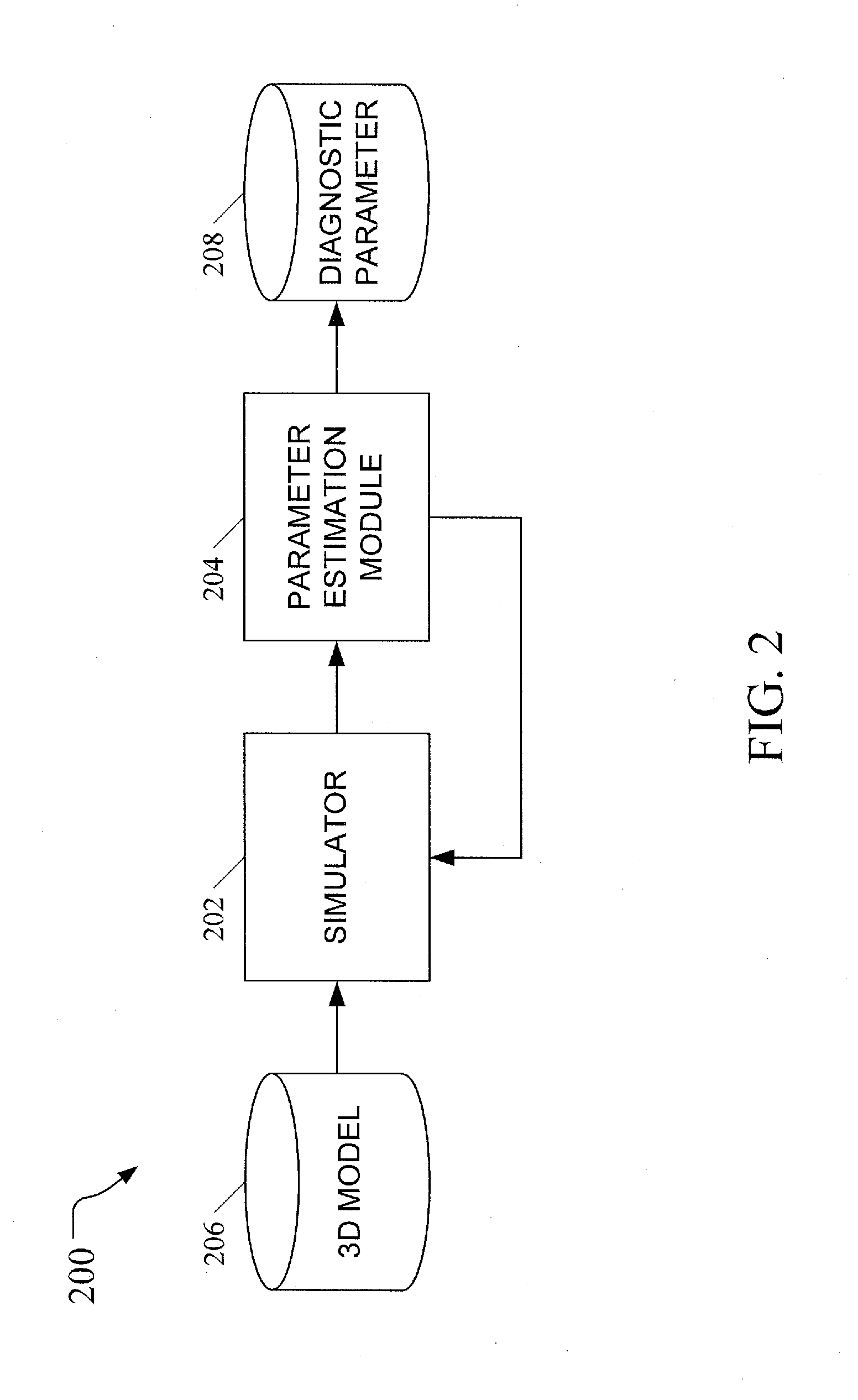

Simulation-based estimation of elasticity parameters and use of same for non-invasive cancer detection and cancer staging

ActiveUS20150216496A1Guarantee qualityImage enhancementImage analysisCancer detectionBiological tissue

Simulation-based estimation of elasticity parameters and use of same for non-invasive cancer detection and cancer staging are disclosed. According to one aspect, a method for simulation-based estimation of elasticity parameters includes constructing a 3D model of an object comprising biological tissue, the model having a first shape and an elasticity value. A simulation iteration is then performed, which includes simulating the application of an external force to the model, causing the model to have a second shape, measuring the difference between the second shape and a target shape, and determining whether the measured difference between the second shape and the target shape is within a threshold of error. If the measured difference is not within the threshold of error, the process performs additional iterations using adjusted elasticity or force values until the measured difference is within the threshold of error, at which time the final elasticity and force values are reported. In one embodiment, the elasticity value is mapped to a diagnostic parameter, such as an indication of the possibility, presence, or stage of cancer.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

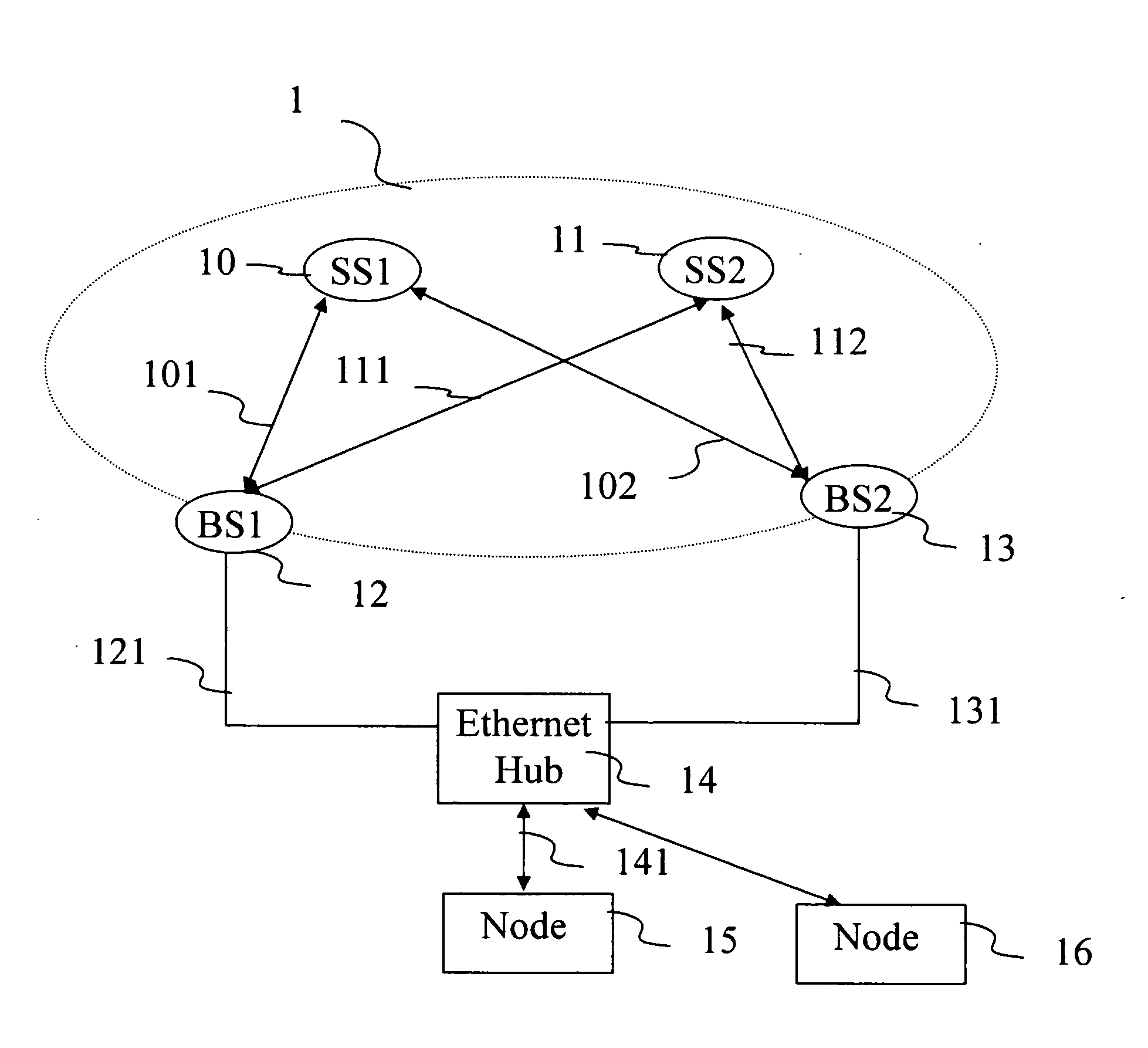

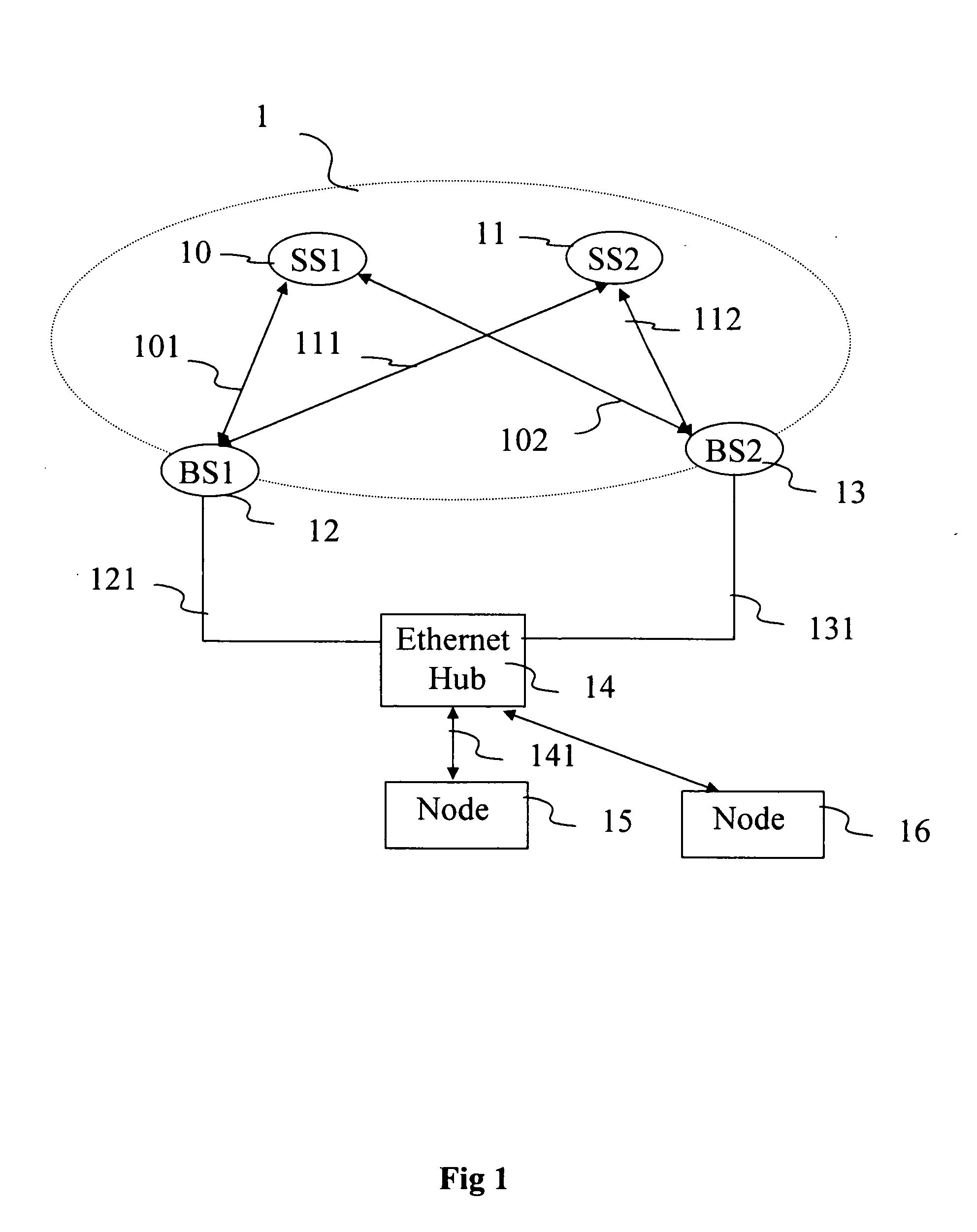

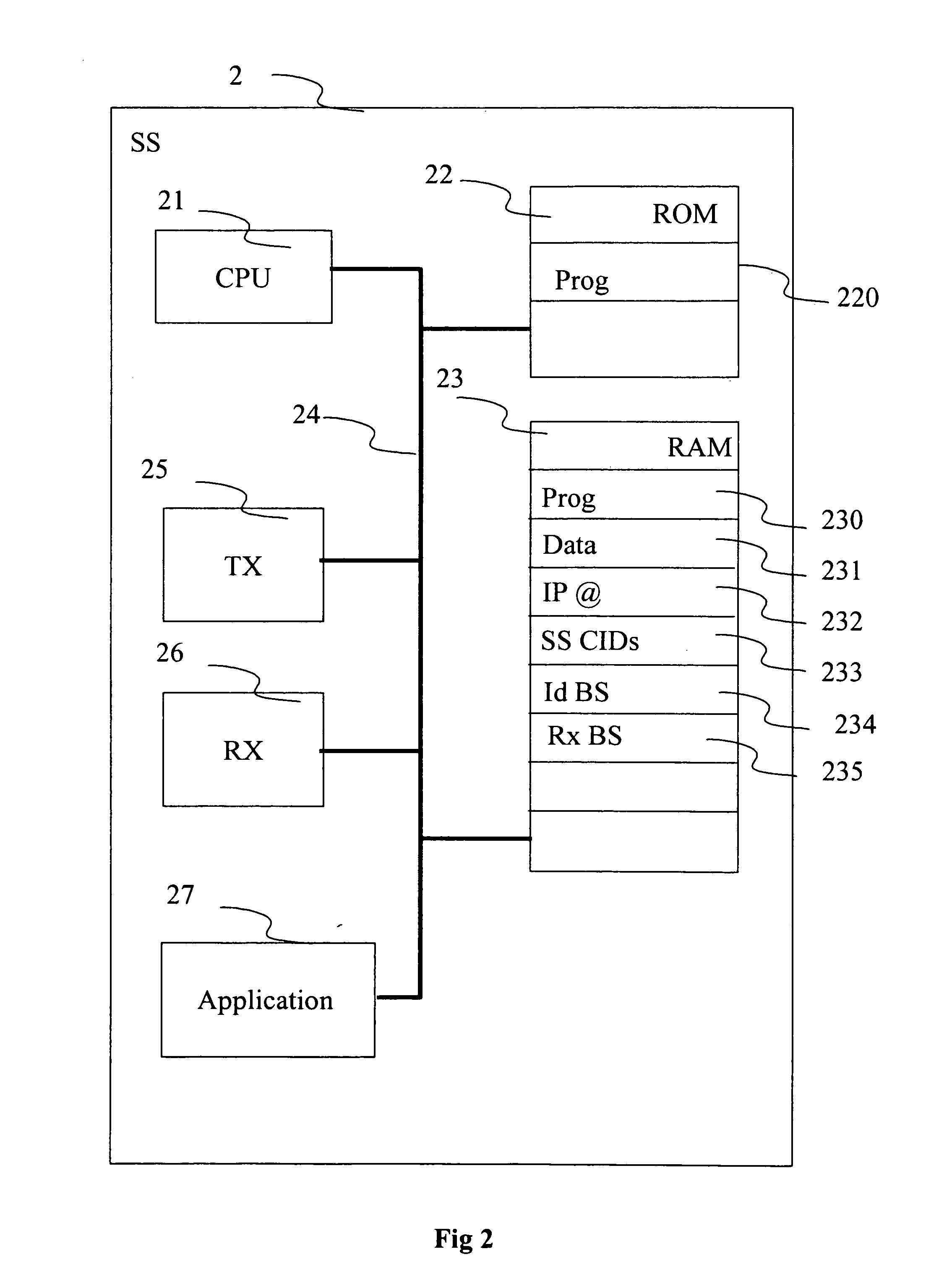

Communication method between at least one subscriber station and at least two base stations

InactiveUS20080225794A1Guarantee qualityNo loss of packets sentNetwork topologiesRadio/inductive link selection arrangementsTelecommunications linkBase station

Communication method implementing at least one subscriber station and at least two base stations synchronised and connected to each other by a communication link.In order to prevent breaks in communication, the method comprises a time resource allocation step for the transmission and / or reception of packets by at least one subscriber station, the time resource being specific to each subscriber station and being able to be used with all the base stations.

Owner:INTERDIGITAL CE PATENT HLDG

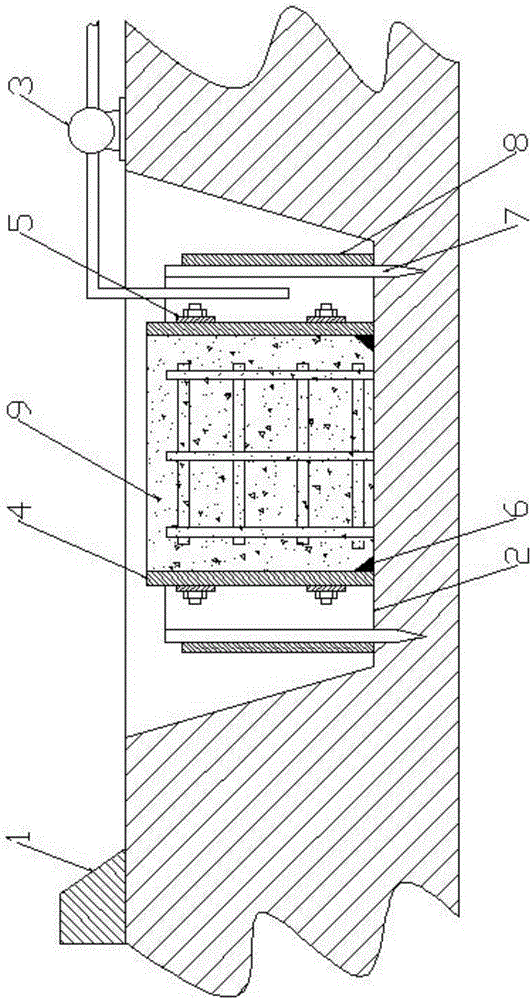

Tower foundation negative-pressure construction method for river channel

The invention provides a tower foundation negative-pressure construction method for a river channel. The quality of a tower foundation can be improved, and a tower can be stable and safe in the use process. The method comprises steps as follows: a dam is constructed on the upstream of a place where the river channel is to be constructed for drainage; construction is performed in the place where the river channel is to be constructed in a natural sloping heavy-excavation manner, and a water pump is used for draining river water seeping into a foundation pit to the downstream of the foundation pit in the excavation process; a square die formed by splicing four templates two by two is put in the center of the bottom surface of the foundation pit; the water pump is used for draining the water in the die and discharging the water to the downstream of the foundation pit; high-grade concrete is applied to the inner bottom surface of the die for blocking; a water pumping pipe of the water pump is put in the foundation pit outside the die, so that river water seeping into the foundation pit outside the die can be continuously discharged to the downstream of the foundation pit, and the water pumping port is located in the position 1 / 3-1 / 2 of the height of the die; the concrete is directly cast into the die after a steel reinforcement cage is put into the die and vibrated with a vibrator; the concrete is cured.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

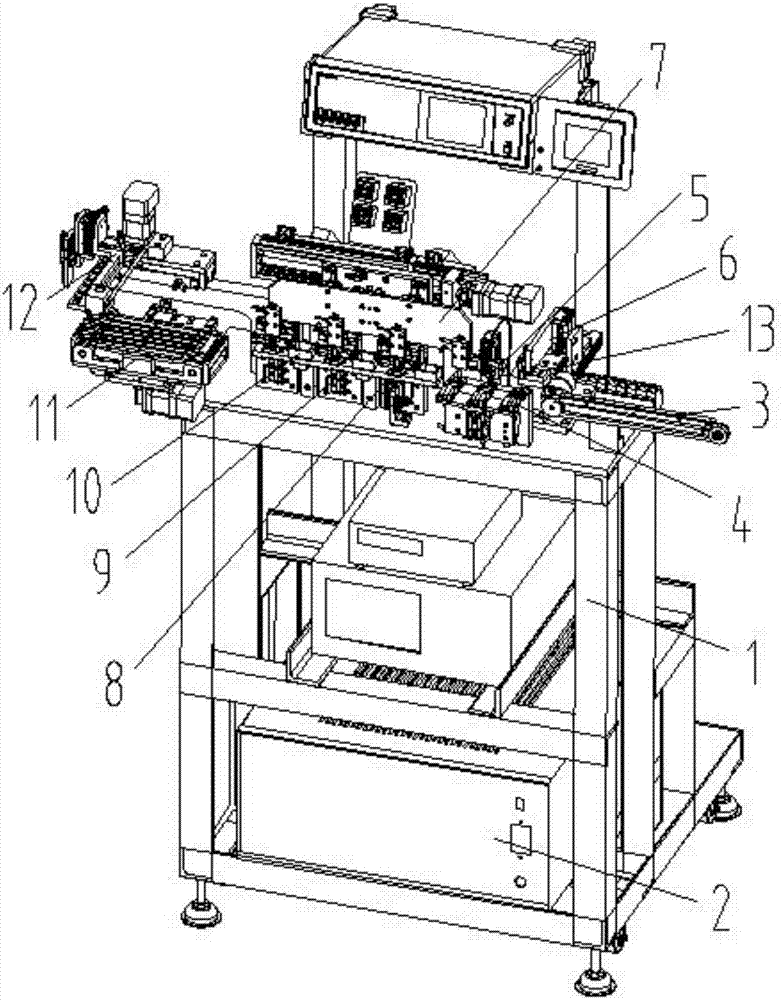

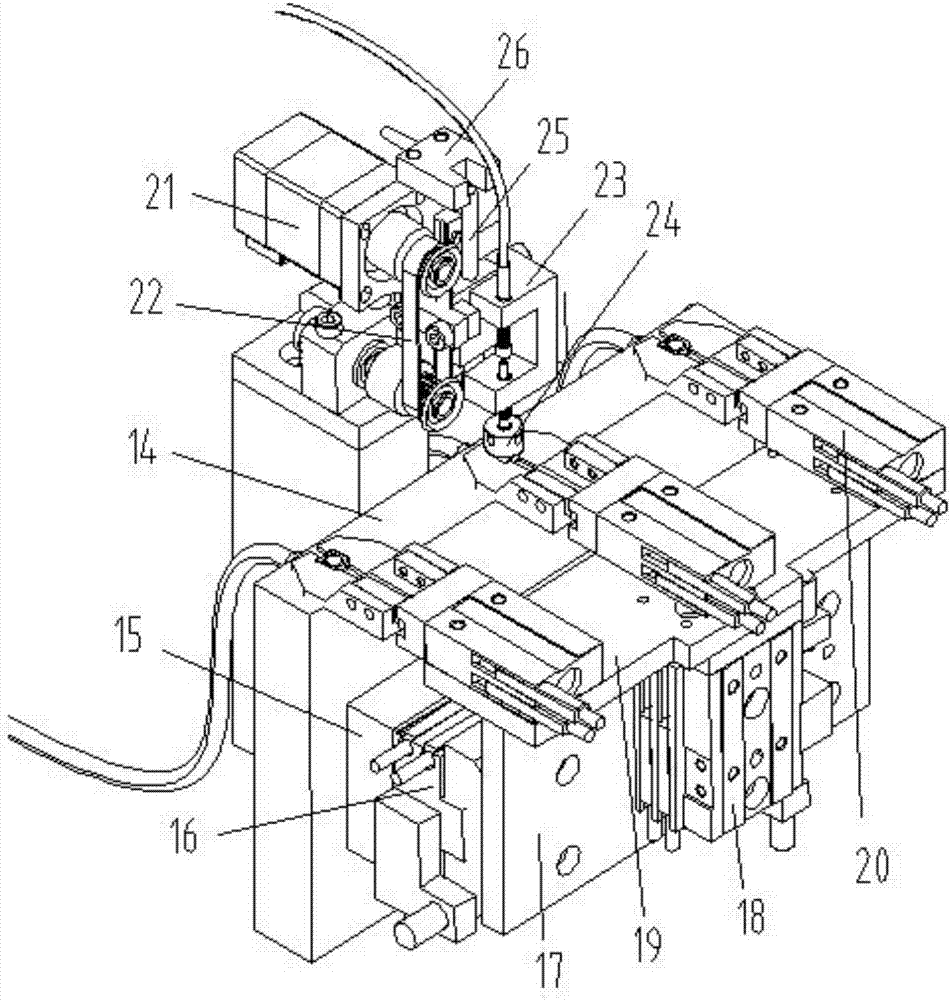

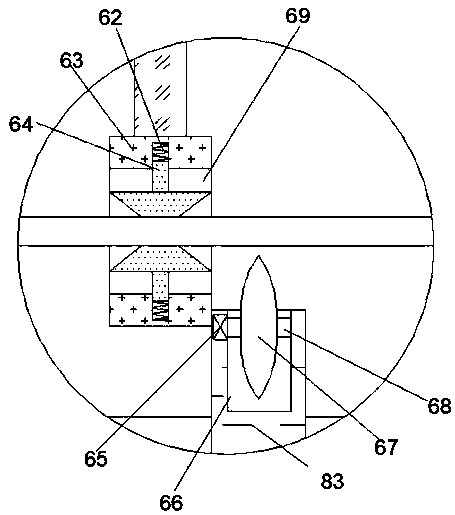

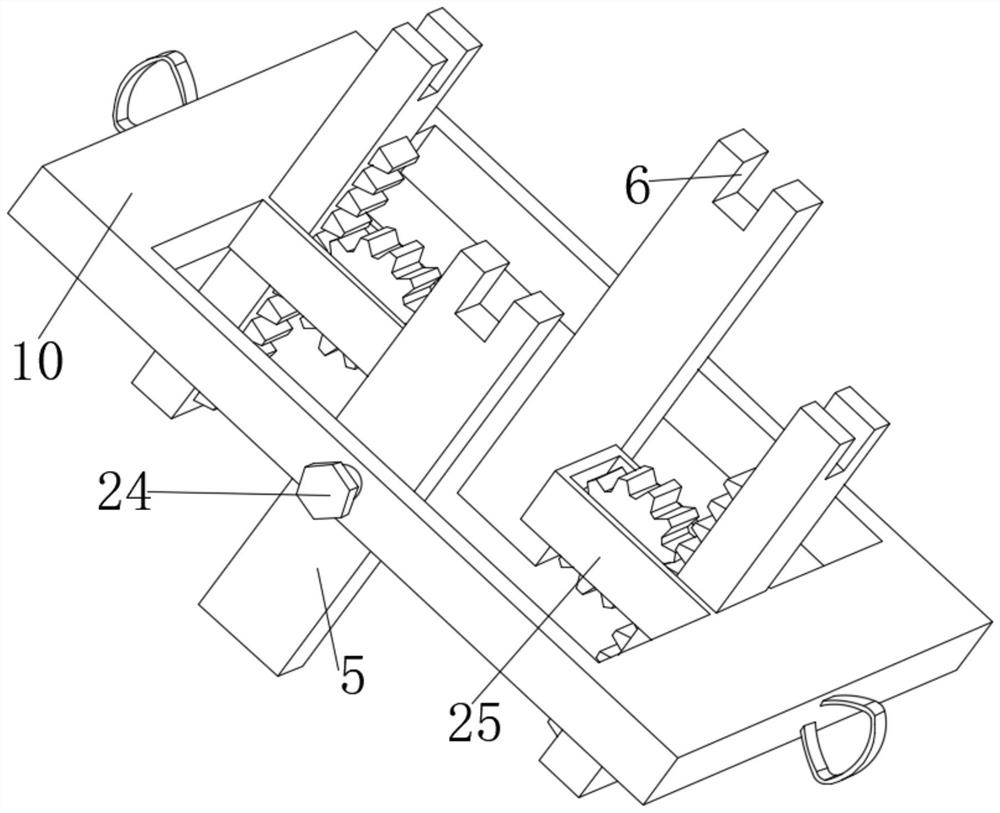

Chip resistor detecting sorting machine

ActiveCN106862101AGuaranteed accuracyGuarantee qualityElectrical testingSortingDistribution controlChip resistor

The invention relates to a chip resistor detecting sorting machine. The chip resistor detecting sorting machine comprises a machine frame and a power distribution control cabinet, wherein a feeding conveying device, an upper part detecting seat and a lower part detecting seat are sequentially arranged on the machine frame from right to left; the feeding conveying device and the upper part detecting seat are matched through an upper part detecting and taking device; the upper part detecting seat and the lower part detecting seat are matched through a lower part detecting and taking device; an upper part detecting device which is matched with products is arranged on the upper part detecting seat, wherein a CCD detecting head is used as a detecting component of the upper part detecting device; a lower part detecting device matched with the lower parts of the products is arranged on the lower part detecting seat; the lower part detecting device comprises a detecting and discharging seat arranged on the lower part detecting seat; an LCR detecting probe penetrating through the lower part of the detecting and discharging seat is arranged at the lower part of the detecting and discharging seat; and a first unqualified product collecting box is arranged at the lower part detecting seat. According to the chip resistor detecting sorting machine disclosed by the invention, automatic and integral detection for two sides of chip resistors is realized, so that the detecting accuracy is guaranteed, and the quality of subsequent finished products is guaranteed; and besides, the detecting efficiency is improved.

Owner:SHENZHEN MESTEK ELECTRONICS CO LTD

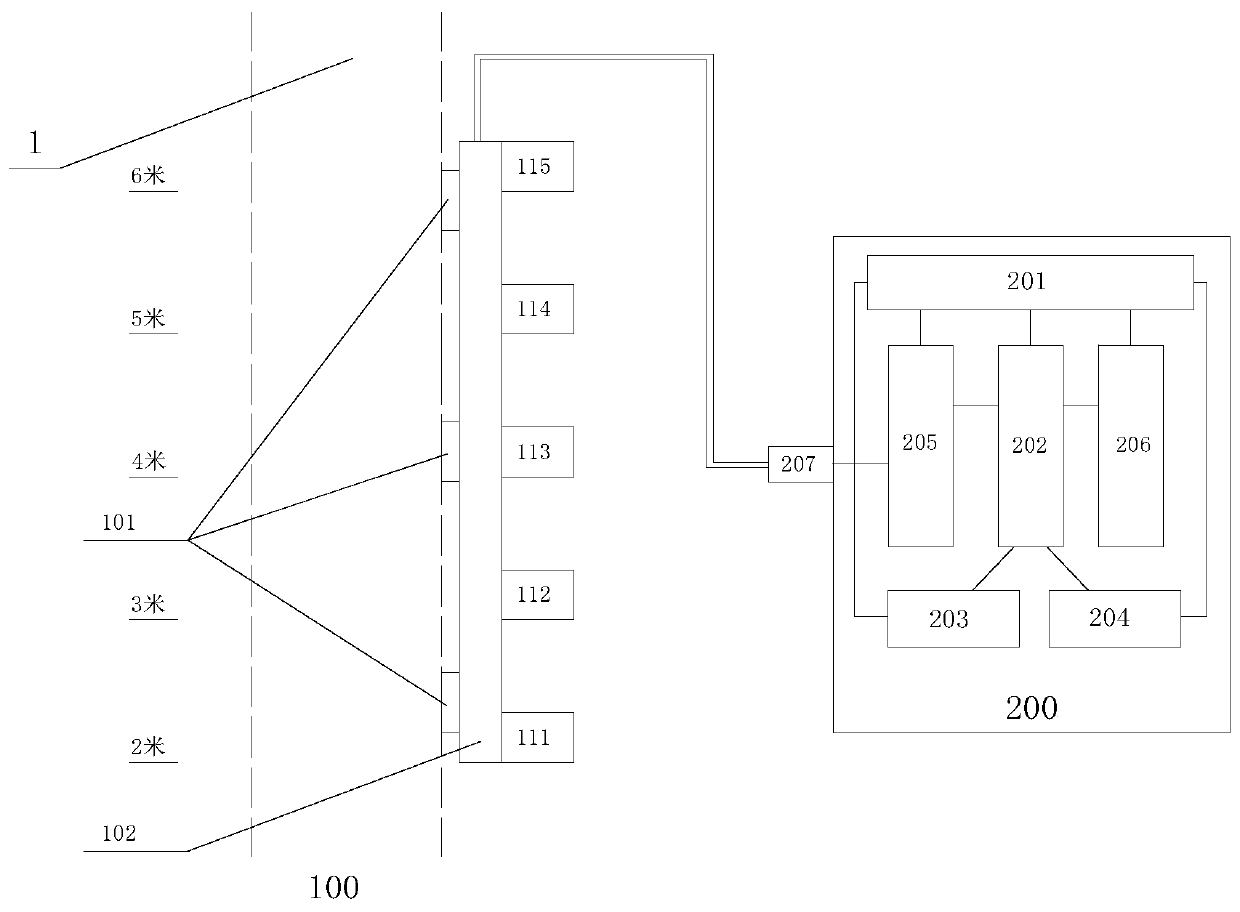

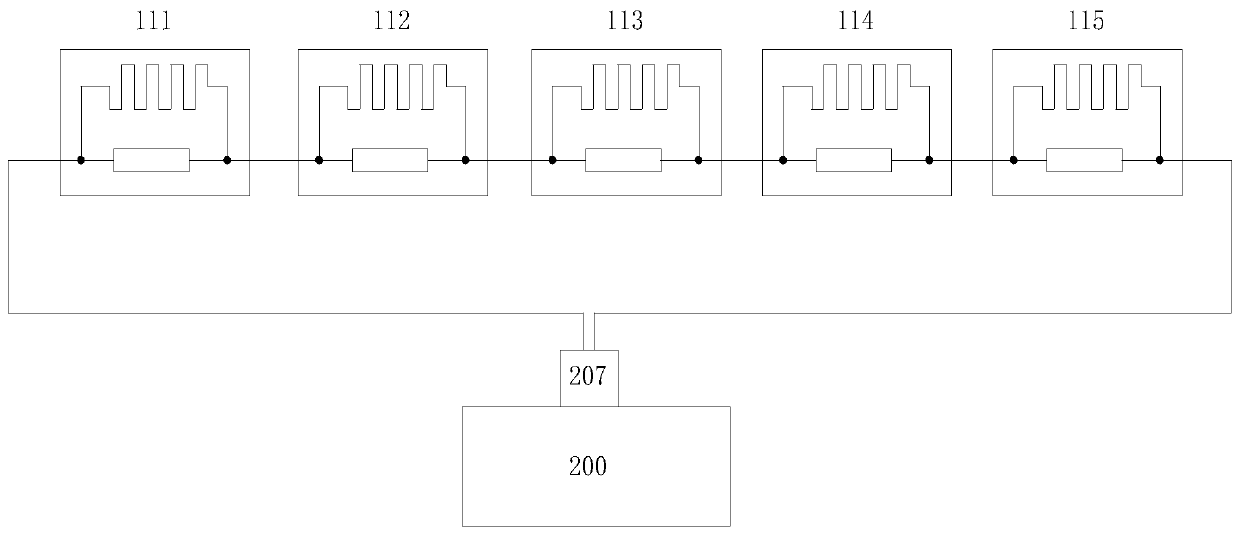

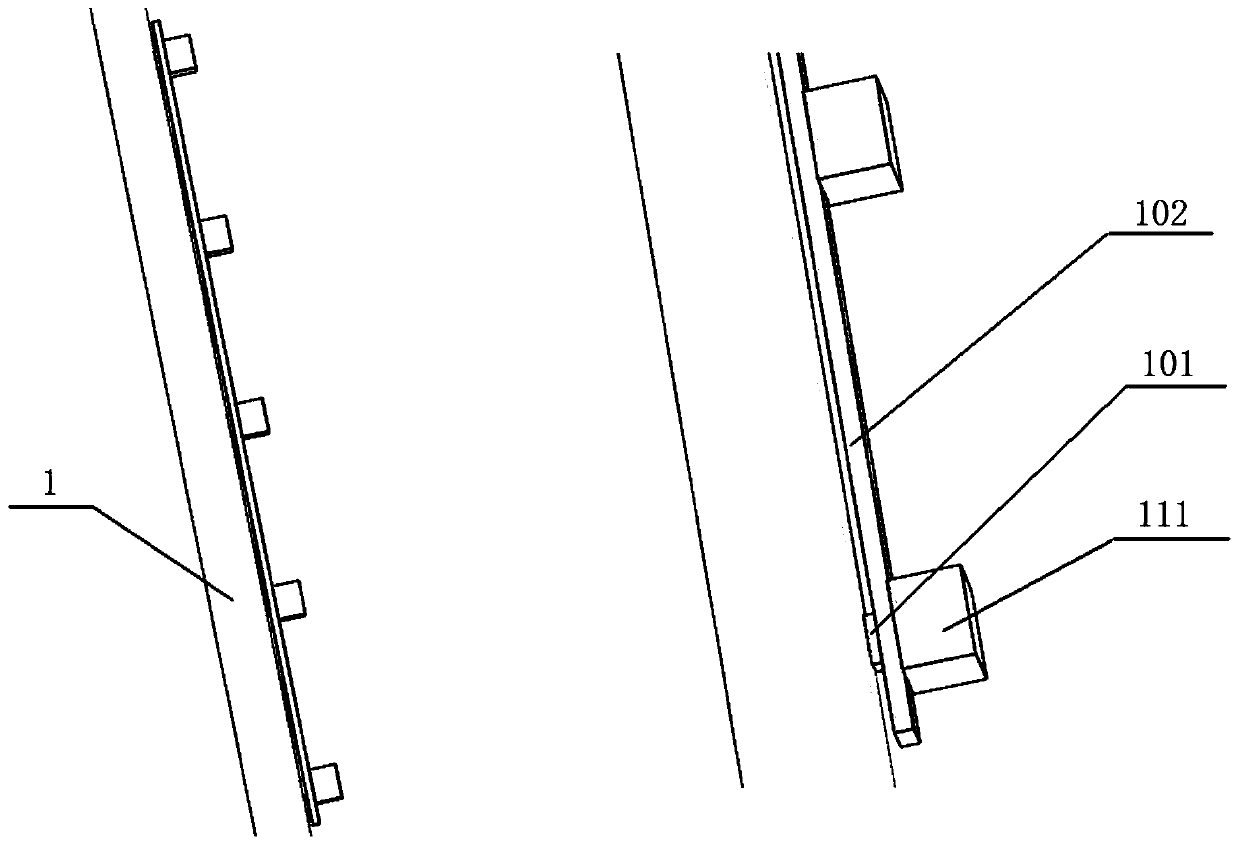

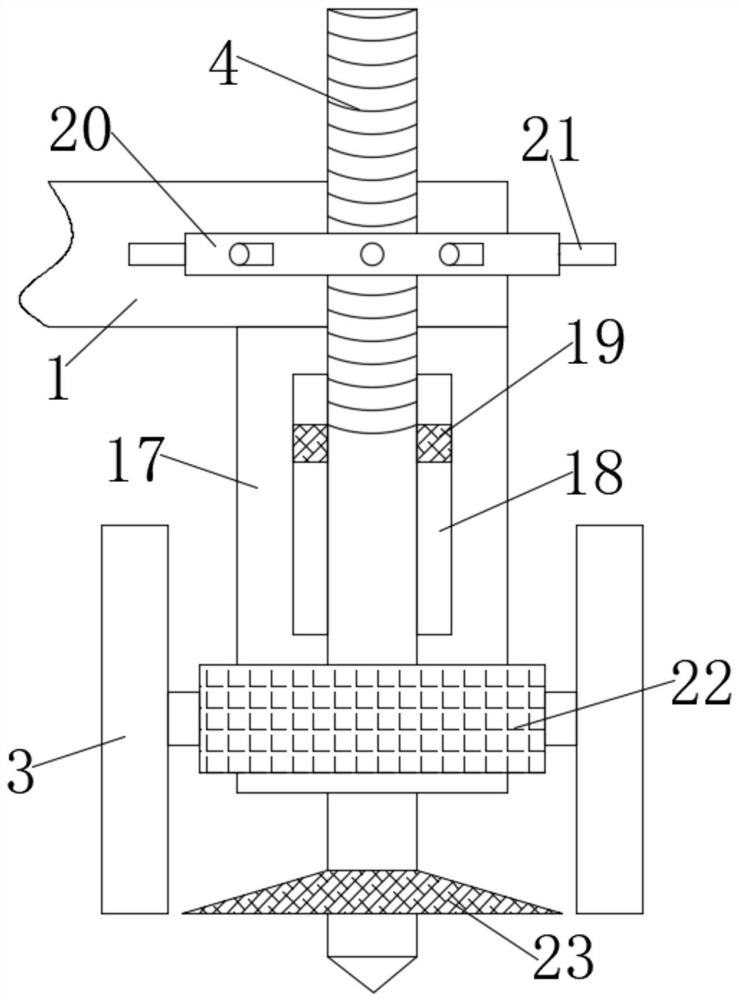

Concrete feed delivery pipe position measuring device for underwater filling pile construction

InactiveCN109972672AGuarantee qualityAvoid construction accidentsFoundation testingEngineeringSurface pressure

The invention discloses a concrete feed delivery pipe position measuring device for underwater filling pile construction. The concrete feed delivery pipe position measuring device includes a sensing unit and a display control unit; the sensing unit includes a plurality of surface pressure sensors, wherein the surface pressure sensors are mounted on a mounting frame in a fixed-spaced mode from thebottom to the top, the mounting frame is fixedly connected to two or more welding blocks through bolts, and the welding blocks are welded to the outer wall above a discharging hole of the concrete feed delivery pipe from the bottom to the top; and the surface pressure sensors are connected in series and then connected to the display control unit. The concrete feed delivery pipe position measuringdevice has the beneficial effects that in the operation process of the underwater concrete filling pile, operators in the site can be effectively guided to complete lowering and lifting operation of the concrete feed delivery pipe, and the actions that quality is ensured, and construction accidents are avoided are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

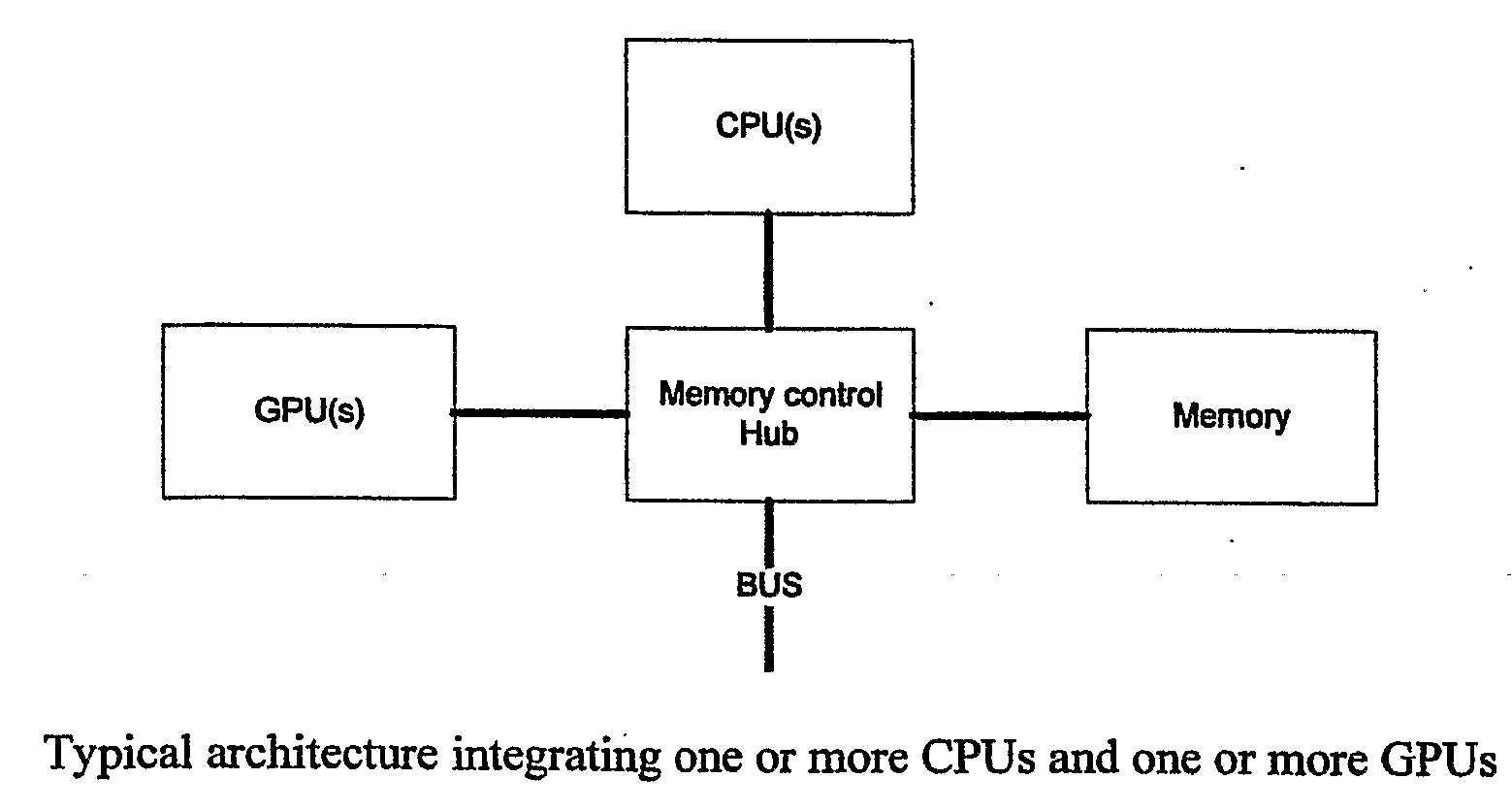

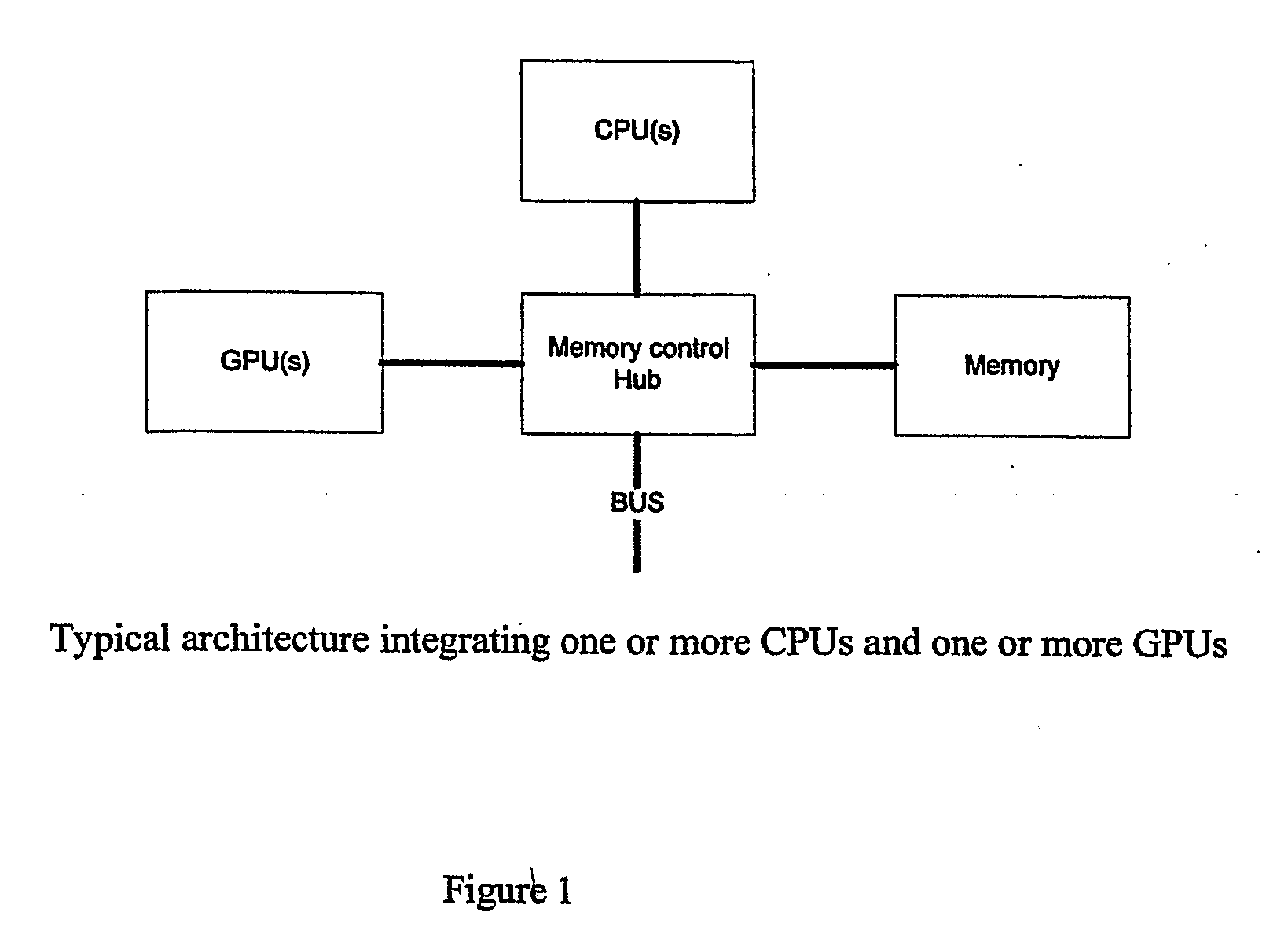

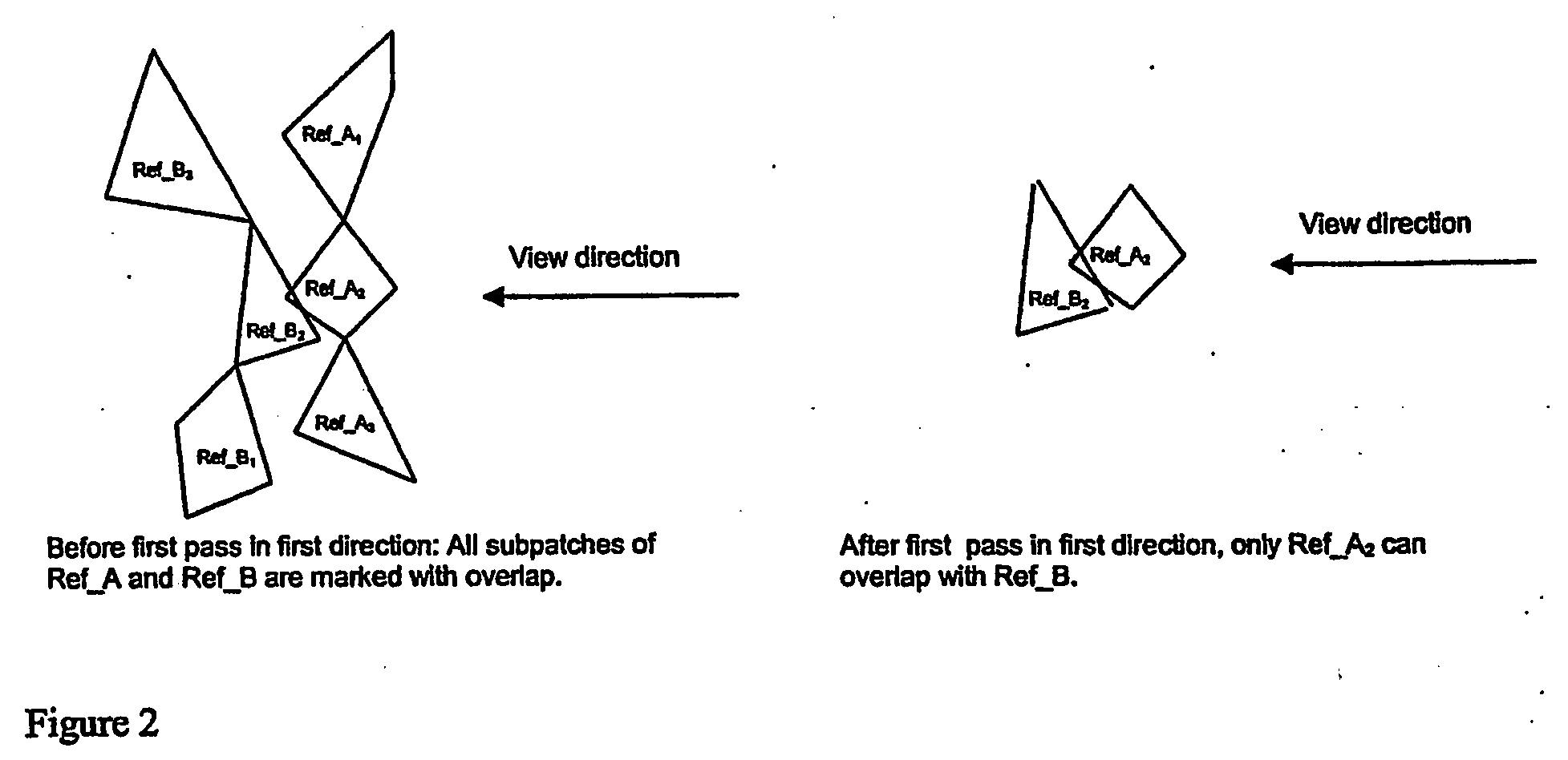

Apparatus and Method for Determining Intersections

InactiveUS20080259078A1Increase speedGuarantee qualityMultiple digital computer combinationsImage data processing detailsNormal fieldCriss-cross algorithm

In a data processing system for determining intersections between geometric objects, the work is split between a CPU and a stream processor. The intersection determination is controlled by the CPU. Data processing intensive parts of intersection algorithms, such as checking possible overlap of objects, checking overlap of normal fields of objects, approximating the extent of an object, approximating the normal fields of an object, or making conjectures for intersection topology and / or geometry between objects, are run on the stream processor. The results of the algorithmic parts run on the stream processor are used by the part of the algorithms run on the CPU. In cases where conjectures for the computational result are processed on the stream processor, the conjectures are checked for correctness by algorithms run on the CPU. If the correctness check shows that the result found is incomplete or wrong, additional parts of the algorithm are run on the CPU and possibly on the stream processor.

Owner:SINVENT AS

Manufacturing method for PCB electroplated with thick-gold partially

ActiveCN105682380AGuarantee qualityReduce thickness differenceMultilayer circuit manufactureCopper platingTin can

Owner:JIANGMEN SUNTAK CIRCUIT TECH

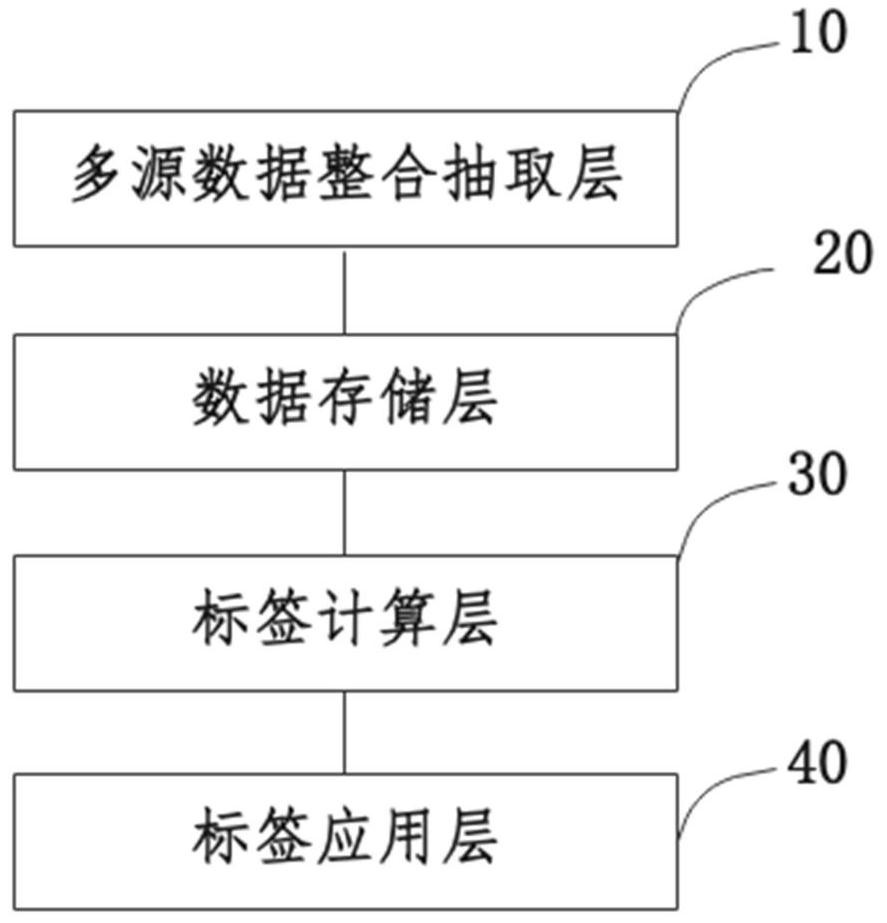

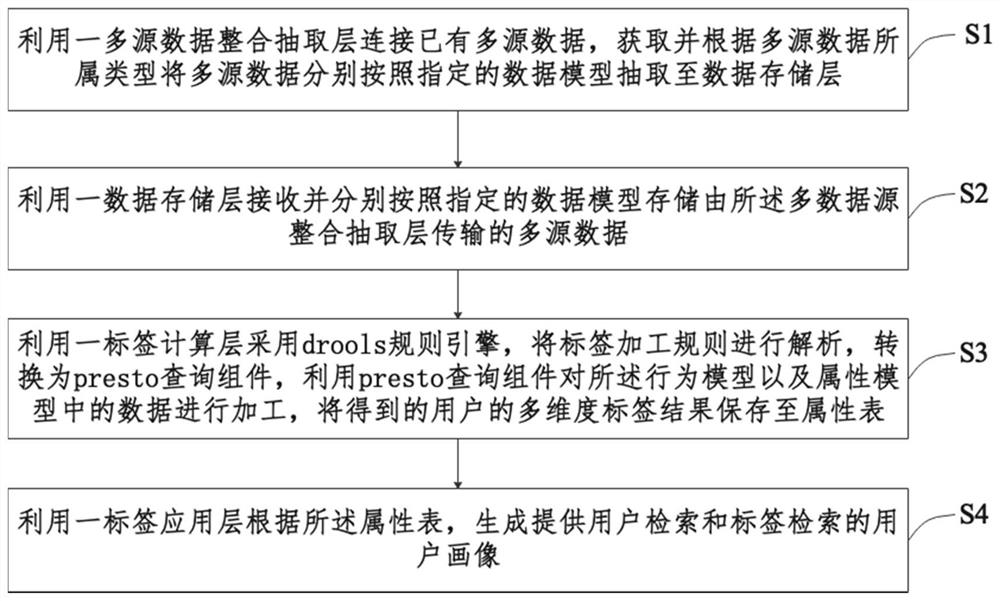

Portrait generation system and method, electronic equipment and storage medium

PendingCN112287015AGuarantee qualityReduce difficultyDatabase management systemsVisual data miningSource dataEngineering

The embodiment of the invention provides a portrait generation system and method, electronic equipment and a storage medium. The portrait generation system comprises: a multi-source data integration and extraction layer that is used for acquiring multi-source data and extracting the multi-source data to the data storage layer respectively according to a specified data model based on the type of the multi-source data; the data storage layer that is used for receiving and storing the multi-source data transmitted by the multi-data-source integration extraction layer according to a specified datamodel; the label calculation layer that is used for analyzing label processing rules by adopting a drools rule engine, converting the label processing rules into a presto query component, processingdata by utilizing the presto query component, and storing an obtained multi-dimensional label result of a user into an attribute table; and the label application layer that is used for generating a user portrait for providing user retrieval and label retrieval according to the attribute table. Through the embodiment of the invention, the difficulty of unifying multiple data sources of the user portrait can be reduced, the accuracy of data integration is improved, and the quality of the finally produced portrait data is ensured.

Owner:北京易观数智科技股份有限公司

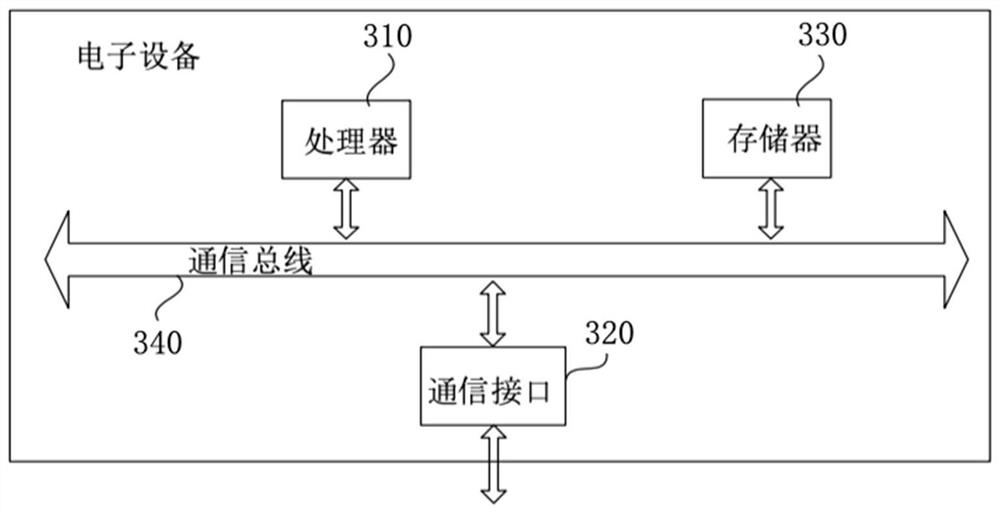

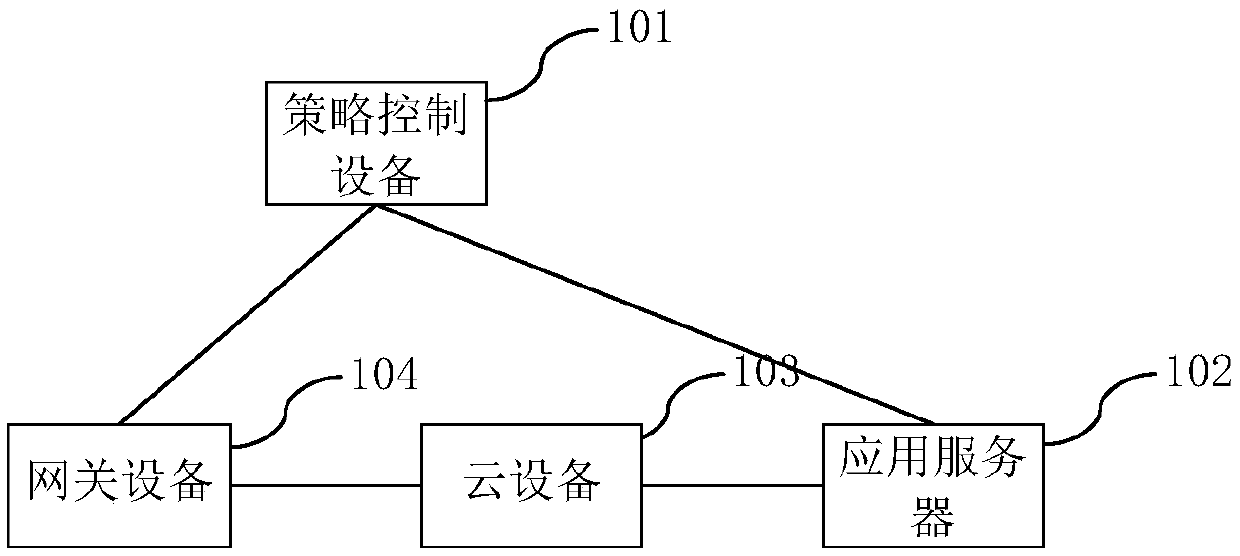

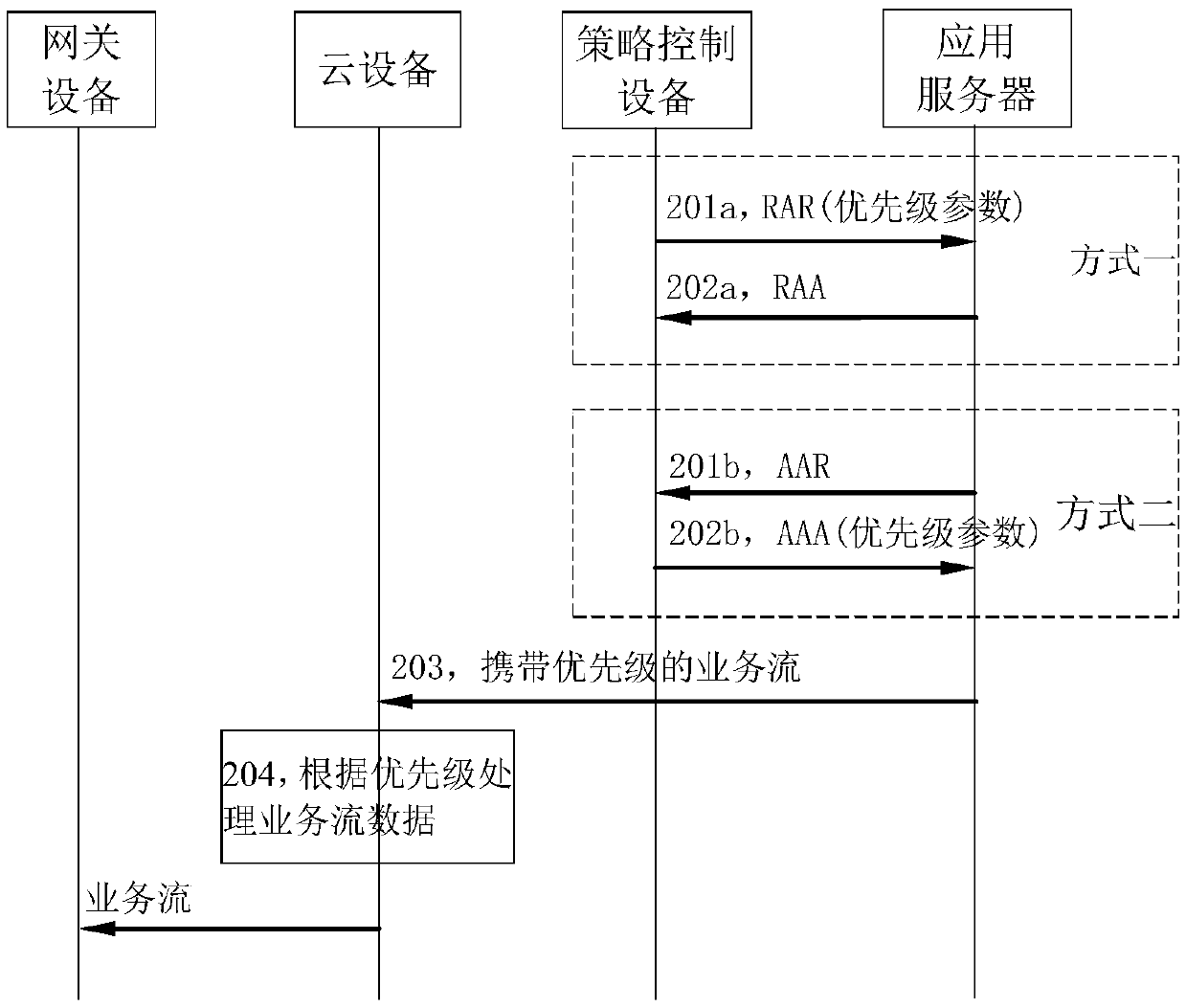

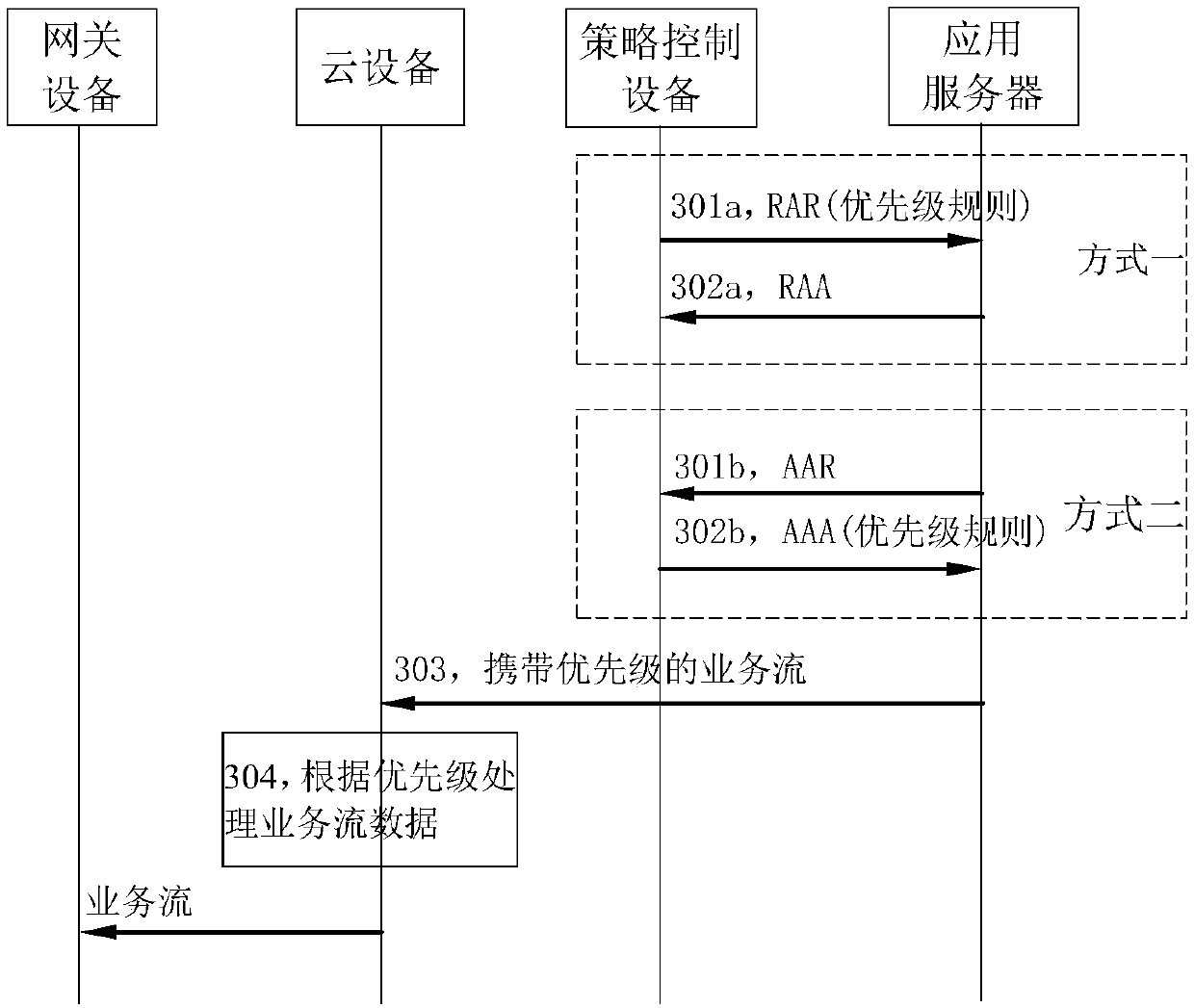

A method and apparatus for service flow transmission

PendingCN110391998AGuarantee qualityImprove reliabilityHome automation networksApplication serverService quality

Owner:HUAWEI TECH CO LTD

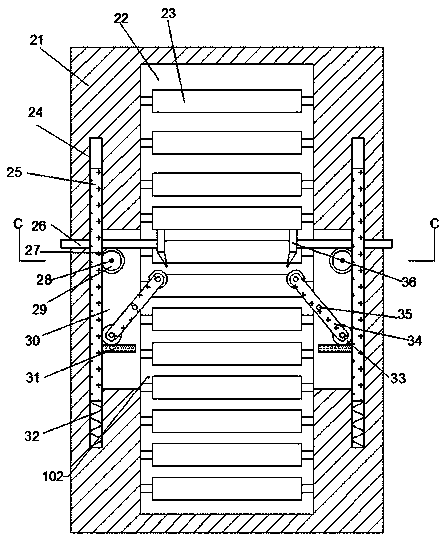

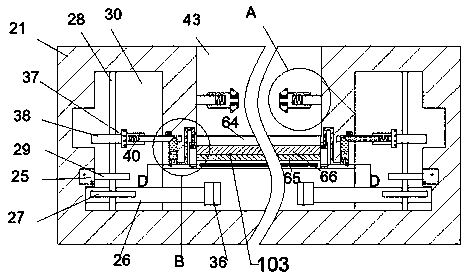

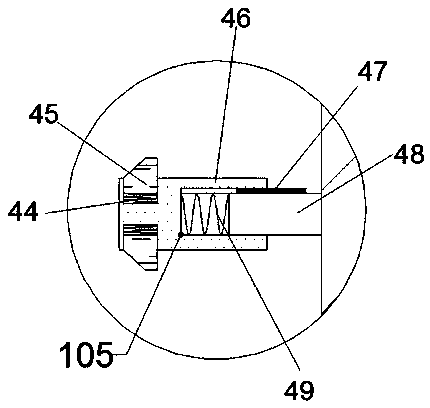

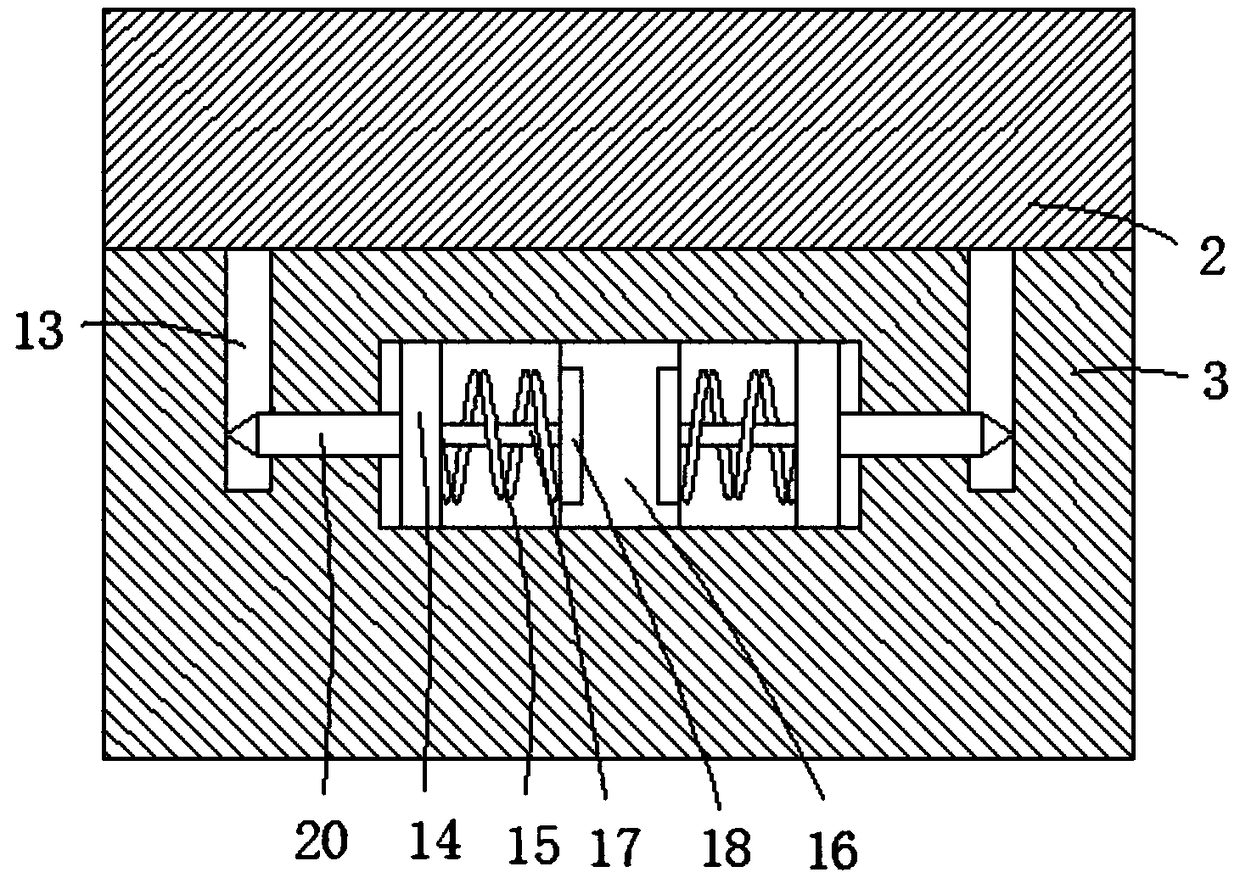

Automatic glass laminating machine based on safety protection

ActiveCN110253875AImprove film application efficiencyGuarantee qualityEngineeringElectrical and Electronics engineering

The invention discloses an automatic glass laminating machine based on safety protection. The automatic glass laminating machine comprises a machine body, wherein a transmission cavity is arranged in the machine body; driving cavities are symmetrically arranged on the left side wall and the right side wall of the transmission cavity; and transmission devices capable of transmitting glass according to the width of the glass are arranged in the driving cavities and the transmission cavity. A sleeve is pushed to the left side and the right side by hand, then the sleeve in the center of a film is inserted onto the sleeve on one side, and film pasting on glass can be automatically completed, so that the safety of people is prevented from being threatened when the glass is broken, and the broken glass firmly adheres to a film pasting; and compared with a traditional manual film pasting mode, the film pasting efficiency of the device can be greatly improved, and the quality of the film pasting can be guaranteed.

Owner:湖南明意湖智能科技股份有限公司

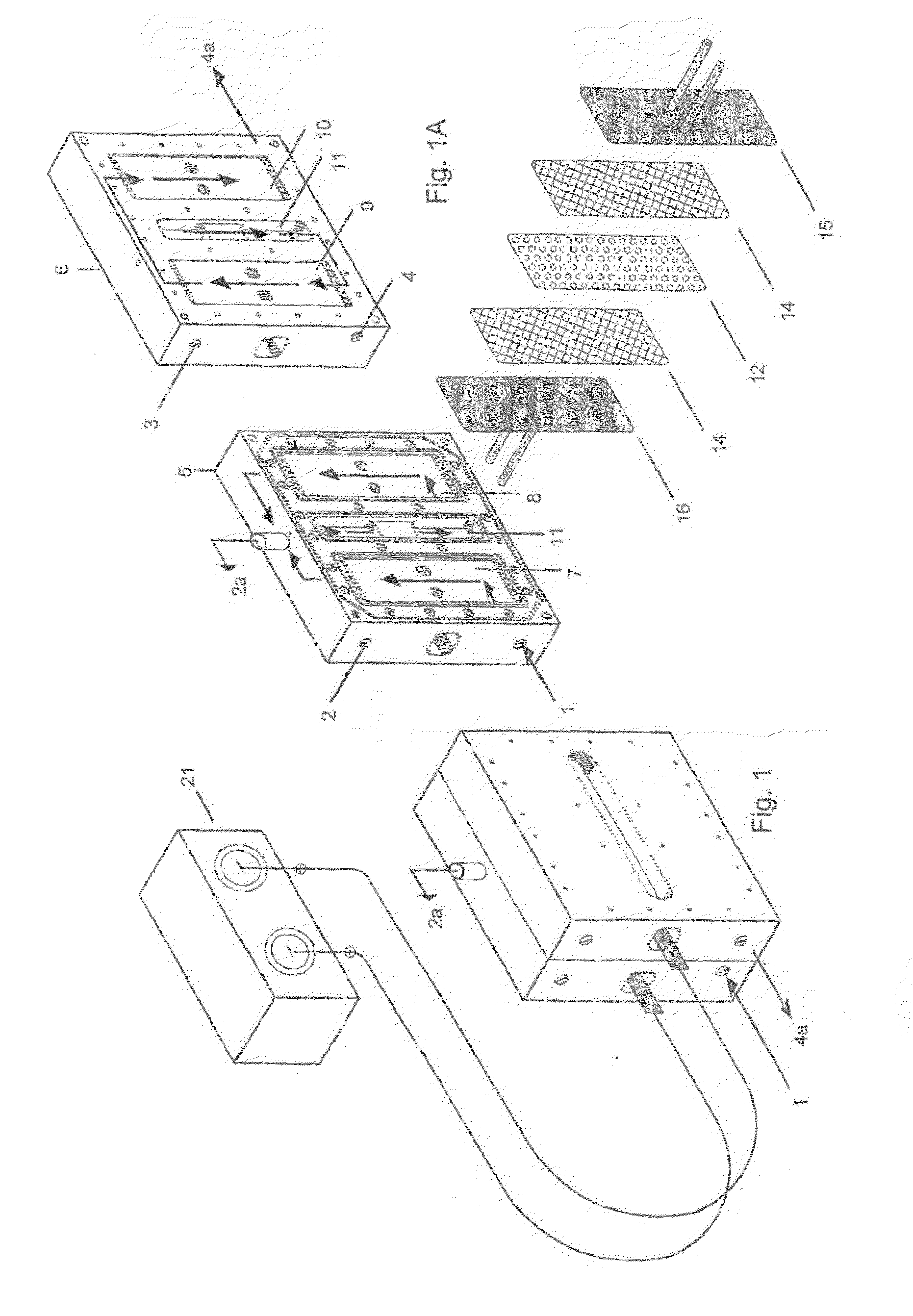

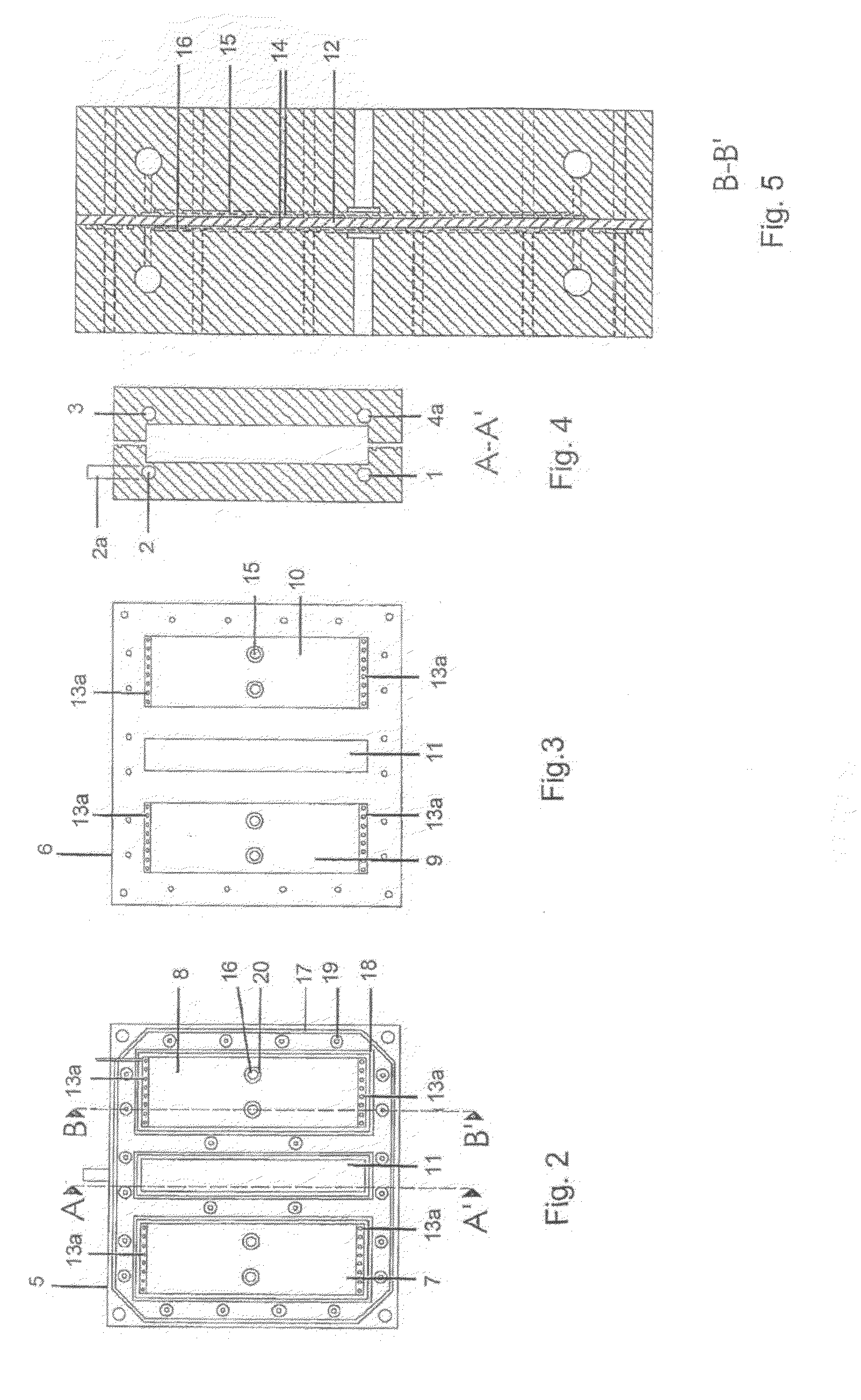

Membrane electrolytic reactors system with four chambers

InactiveUS20100065421A1Guarantee qualityCellsWater/sewage treatment apparatusEngineeringReactor system

Owner:E C A S

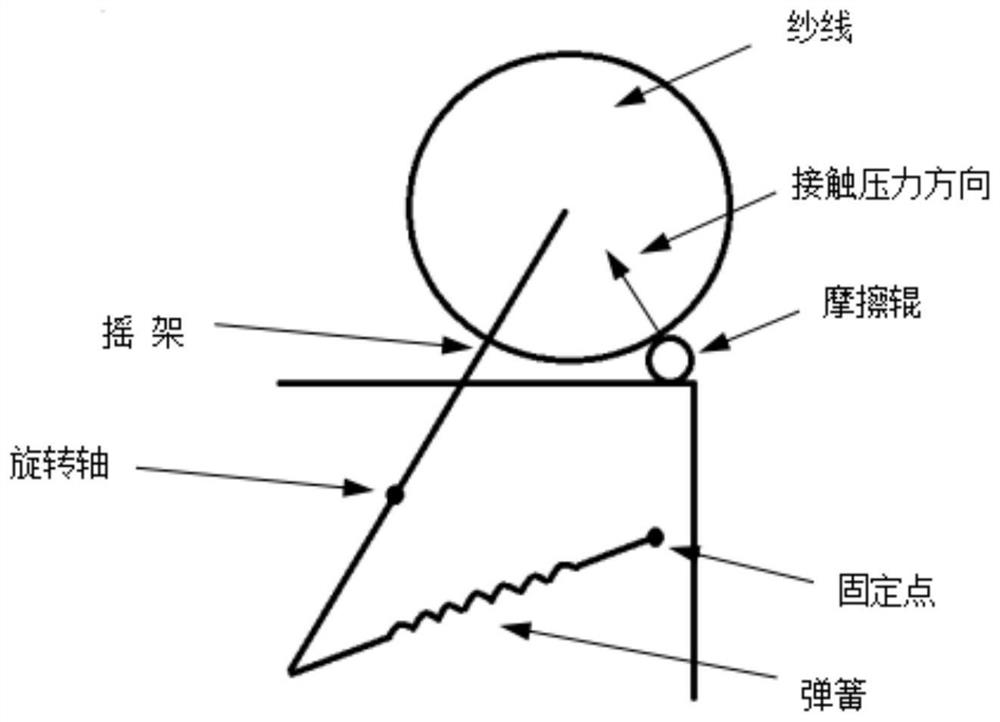

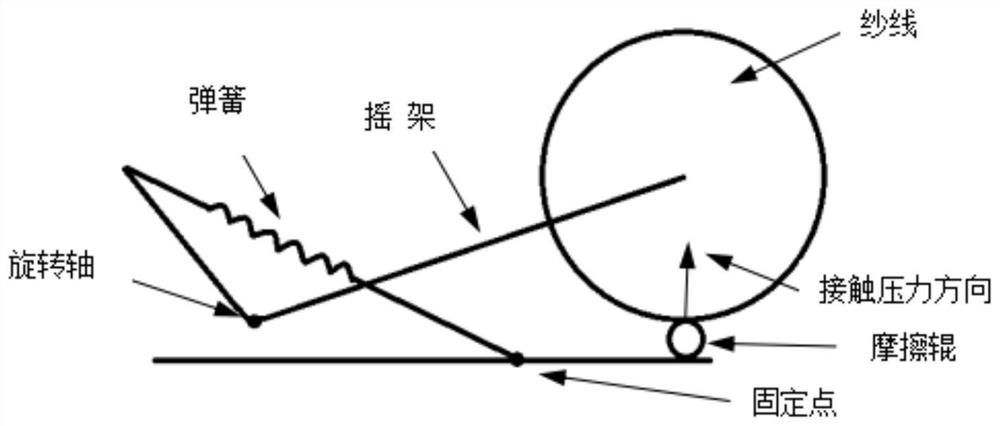

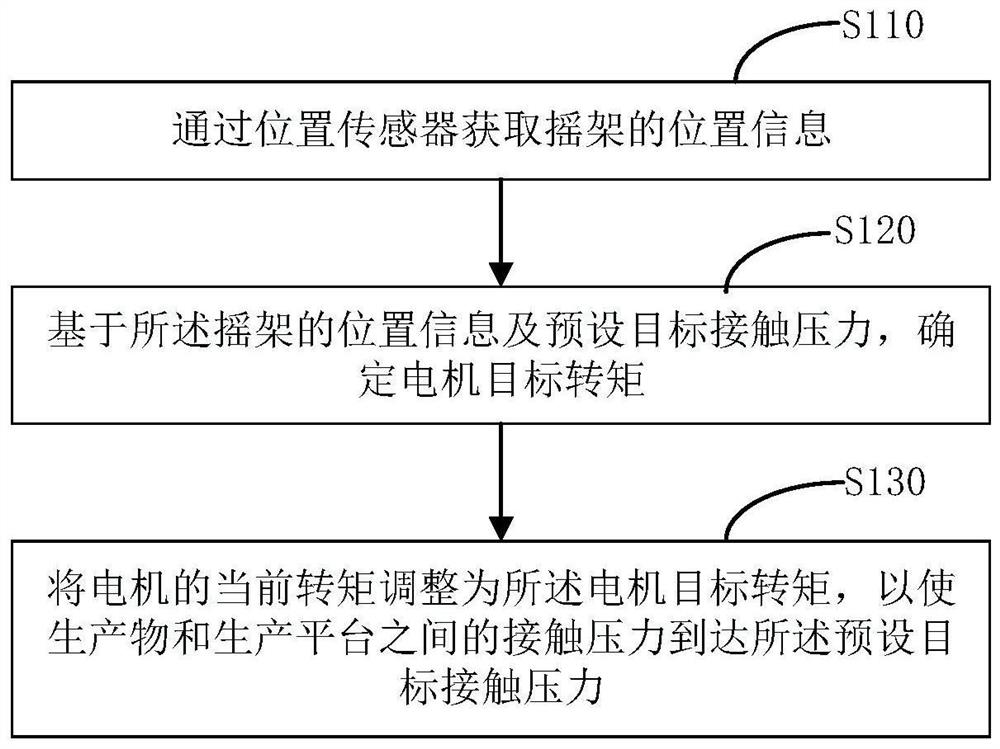

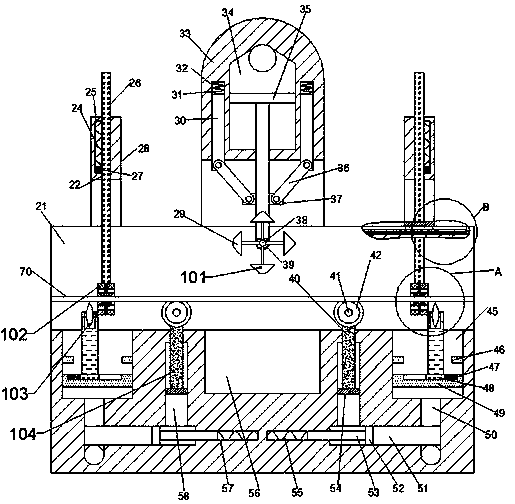

Electrically-driven self-adjusting pressure control method and device, program and storage medium

PendingCN113512785AReduce labor costsGuarantee qualityDrafting machinesElectric driveProcess engineering

The invention discloses an electrically-driven self-adjusting pressure control method and device, a program and a storage medium. The method comprises the following steps that position information of a cradle is obtained through a position sensor; a motor target torque is determined based on the position information of the cradle and a preset target contact pressure; the current torque of the motor is adjusted to be the target torque of the motor, so that a contact pressure between a production object and a production platform reaches the preset target contact pressure. According to the electrically-driven self-adjusting pressure control method and device, the program and the storage medium, the problems that a yarn contact pressure is inaccurate and spinning quality is unqualified due to the fact that production equipment is manually adjusted to control the yarn contact pressure are solved, the contact pressure borne by the production object is automatically and accurately adjusted according to requirements, manpower is saved, and the spinning production quality is guaranteed.

Owner:SUZHOU INOVANCE CONTROL TECH CO LTD

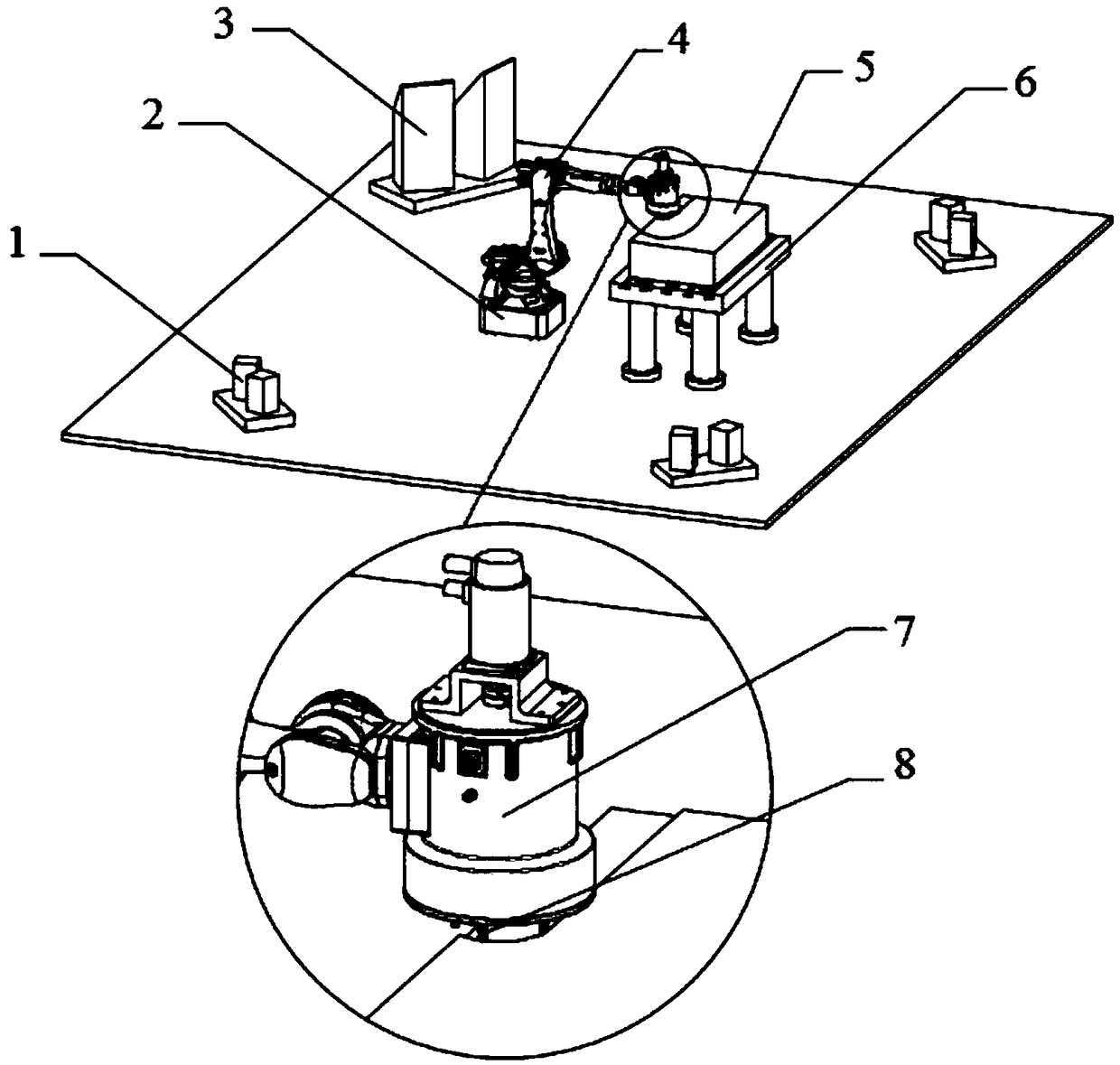

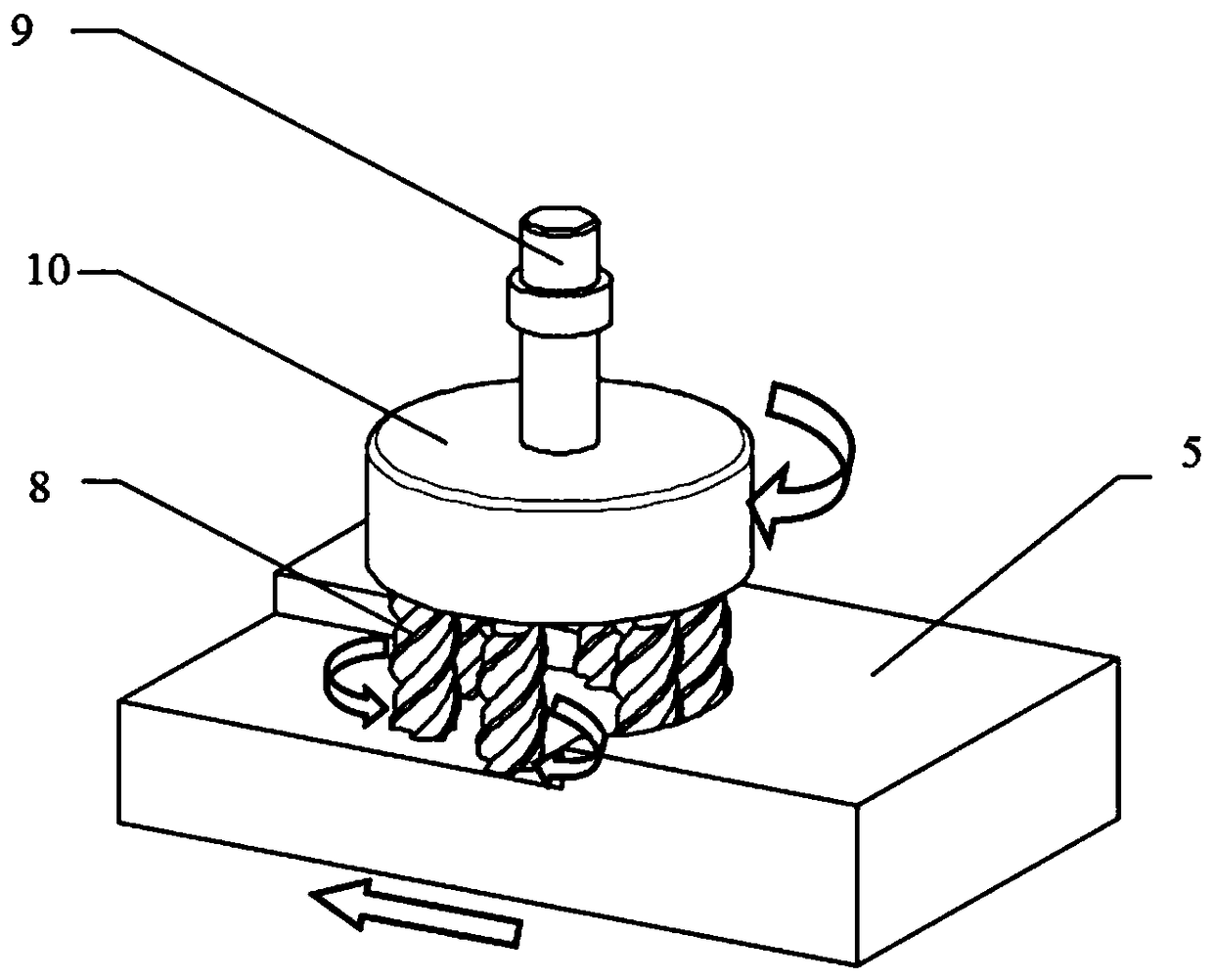

High-flexibility machining system and method based on milling-milling combined machining principle

InactiveCN108746783AGuarantee qualityExtended processing spaceMeasurement/indication equipmentsMilling equipment detailsEngineeringCutting force

The invention discloses a high-flexibility machining system and method based on the milling-milling combined machining principle. The high-flexibility machining system based on the milling-milling combined machining principle comprises a supporting feeding mechanism, a control mechanism, an auxiliary machining mechanism and a power head mechanism. The supporting feeding mechanism adopts an industrial robot. A power head is installed at the tail end of a mechanical arm through an adapter plate. The auxiliary machining mechanism comprises an indexable workbench. A workpiece to be machined is placed on the indexable workbench. The industrial robot, the indexable workbench and the power head mechanism are in signal connection with a numerical control module in the control mechanism. Multiple end mills are fixed to a cutter head of the power head and evenly distributed in the circumferential direction. Each end mill rotates around the axis of the cutter head and also rotates around own axisat the same time. The rotation directions of every two adjacent planetary end mills are opposite. The high-flexibility machining system and method based on the milling-milling combined machining principle have the advantages that the cutting force is small, the cutting temperature is low, cutting vibration is small, the wear of cutters is little, the service lives of the cutters are long, and themachining efficiency is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

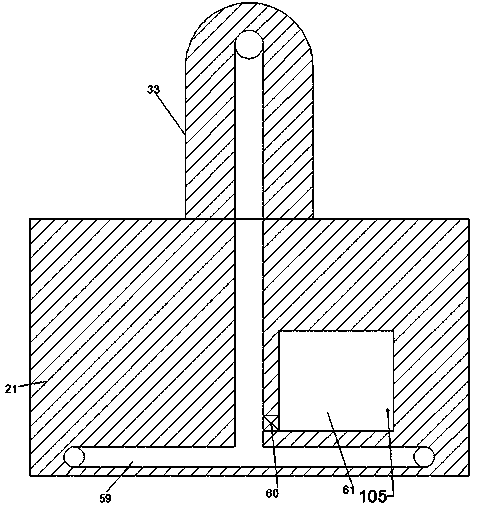

Steel bar bending machine used at construction site

The invention discloses a steel bar bending machine used at a construction site. The steel bar bending machine comprises a machine body, a top pressing box is fixedly arranged on the top surface of the machine body, a hydraulic cavity is arranged in the top pressing box, the hydraulic cavity is provided with a top pressing device capable of adjusting the bending radian and bending the steel bar, when the steel bar needs to be sheared, a selection motor is opened first, so that a selection motor shaft and bending blocks are driven to select one suitable bending block to face downwards, and thenthe selection motor is turned off. The steel bar bending machine can automatically bend the steel bar, compared with a traditional steel bar bending machine, the steel bar bending machine can selectthe bending radian according to the thickness degree of the steel bar, therefore, it is guaranteed that the steel bar is not easily broken when being bent, so that the quality of the later house is guaranteed, the potential safety hazard of the house is reduced, and meanwhile, the steel bar bending machine can bend any one of the positions of the steel bar.

Owner:天津奉壹科技有限公司

Production raw material of thiabendazole and preparation technology of production raw material

InactiveCN110041321AGuaranteed PH valueGuarantee qualityOrganic chemistryBrominePotassium permanganate

The invention provides a production raw material of thiabendazole. The production raw material mainly comprises components as follows: lactic acid, o-phenylenediamine, acetone, inorganic acid, potassium permanganate, bromine, ethyl acetate, formamide and phosphorus pentasulfide, wherein the mole ratio of lactic acid to o-phenylenediamine is 1:1.17; the ratio of ethyl acetate, formamide and phosphorus pentasulfide is 2:1:1. The raw material ratio is sophisticated, the adjusting range of PH value is narrowed in a preparation process, the conversation rate of a product is increased, and the quality of the product is improved.

Owner:孟宪锋

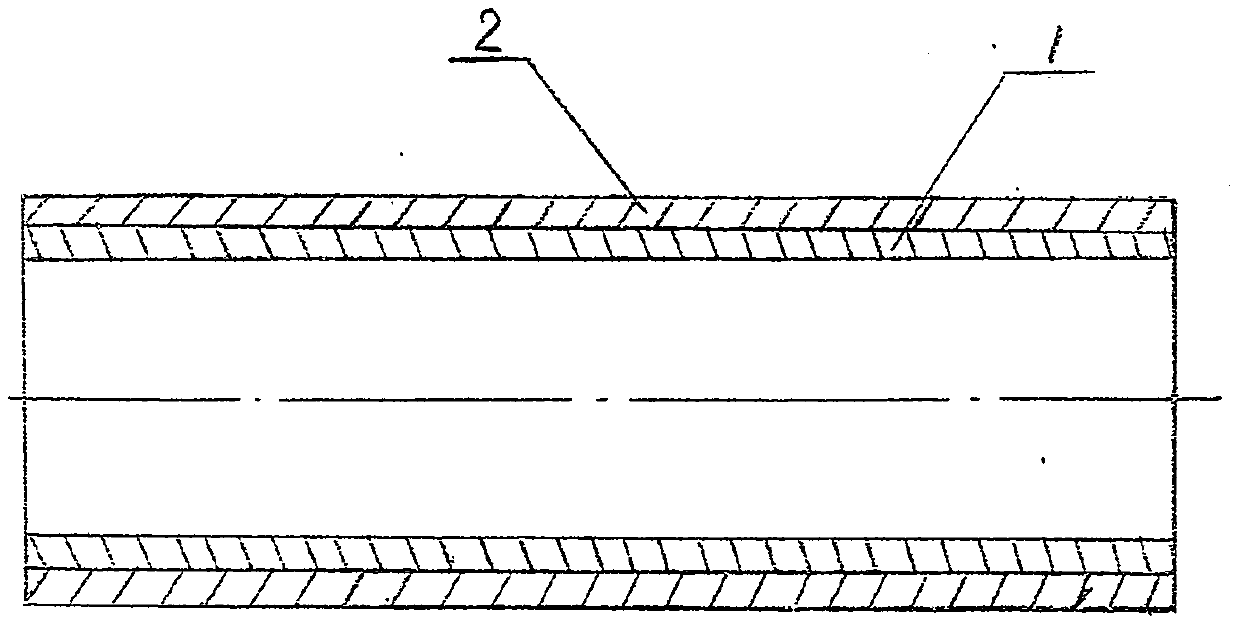

Coextrusion reinforced polyethylene antibacterial composite pipe

The invention discloses a coextrusion reinforced polyethylene antibacterial composite pipe. The coextrusion reinforced polyethylene antibacterial composite pipe is characterized in that an inner layeris made of an antibacterial material mixed by 10 % inorganic antibacterial agent and 90 % polyethylene, an outer layer is reinforced polyethylene mixed by 85 % polyethylene and 15 % glass fiber witha length of 10 mm, and a composite double-layer structure of the inner layer and the outer layer is formed by a coextrusion process method. Firstly, the relatively soft defect of the material is overcome, the rigidity is increased, thus the same effect of laying an open pipe and a concealed pipe is achieved, meanwhile a composite pipe with an antibacterial effect is formed by coextrusion, and thequality of water supply is effectively ensured.

Owner:SHANGHAI JIUTONG PLASTIC PROD

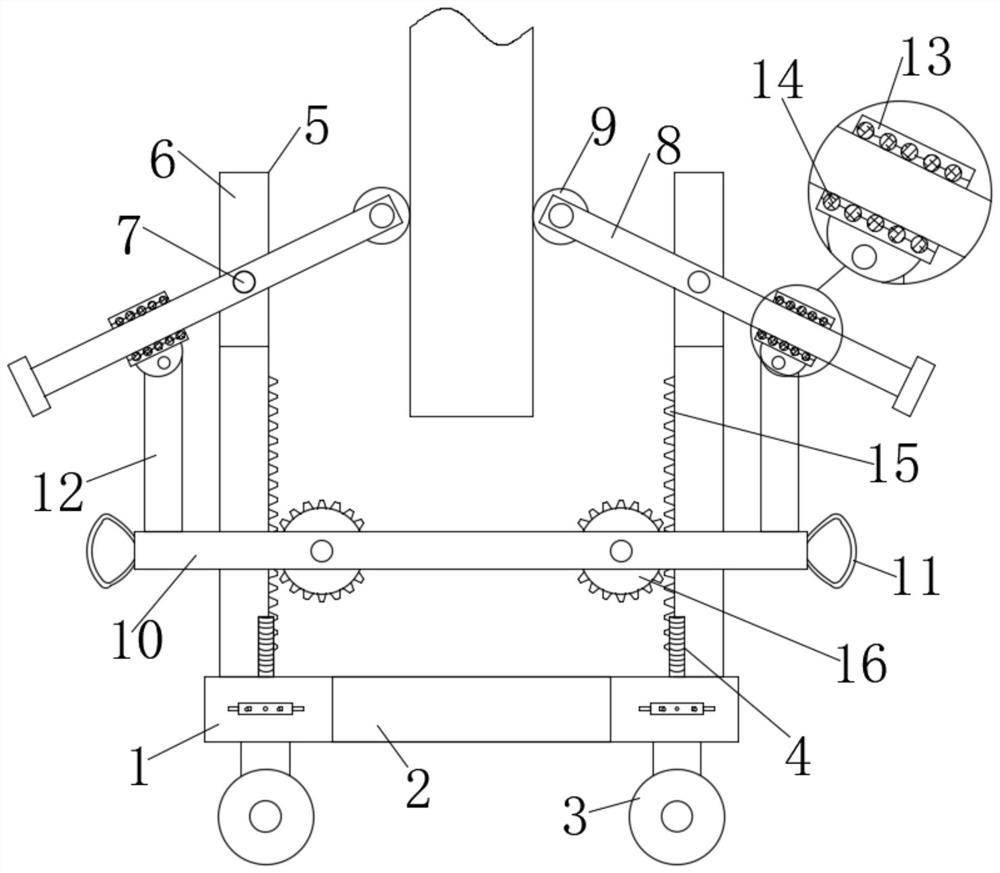

Guiding device for concrete pipe pile construction

The invention discloses a guiding device for concrete pipe pile construction. The guiding device comprises a base, wherein an opening is formed in the middle of the base; supporting plates are fixedly connected to the positions, located on the four side edges, of the base; an adjusting frame is in sliding connection to the outer sides of the four supporting plates; top plates are fixedly connected to the positions, located on the four side edges, of the upper end of the adjusting frame; connecting grooves are formed in the upper sides of the supporting plates; guiding plates are arranged at the positions, located in the connecting grooves, of the supporting plates; connecting columns are fixedly connected to the positions, located on the four corners of the bottom, of the base; wheels are arranged on the two sides of each connecting column; fixing columns are arranged at the positions, right opposite to the wheels, of the base; sliding grooves are formed in the positions, located on the two sides of the fixing columns, of the middles of the connecting columns; adjusting rings are rotationally connected to the four corners of the base; and holding handles are annularly arranged at the side ends of the adjusting rings. Positioning guiding can be carried out before concrete pipe pile piling, meanwhile, concrete pipe pile inclination can be avoided during piling, and the construction quality is effectively guaranteed.

Owner:CHINA CONSTR EIGHTH ENG DIV

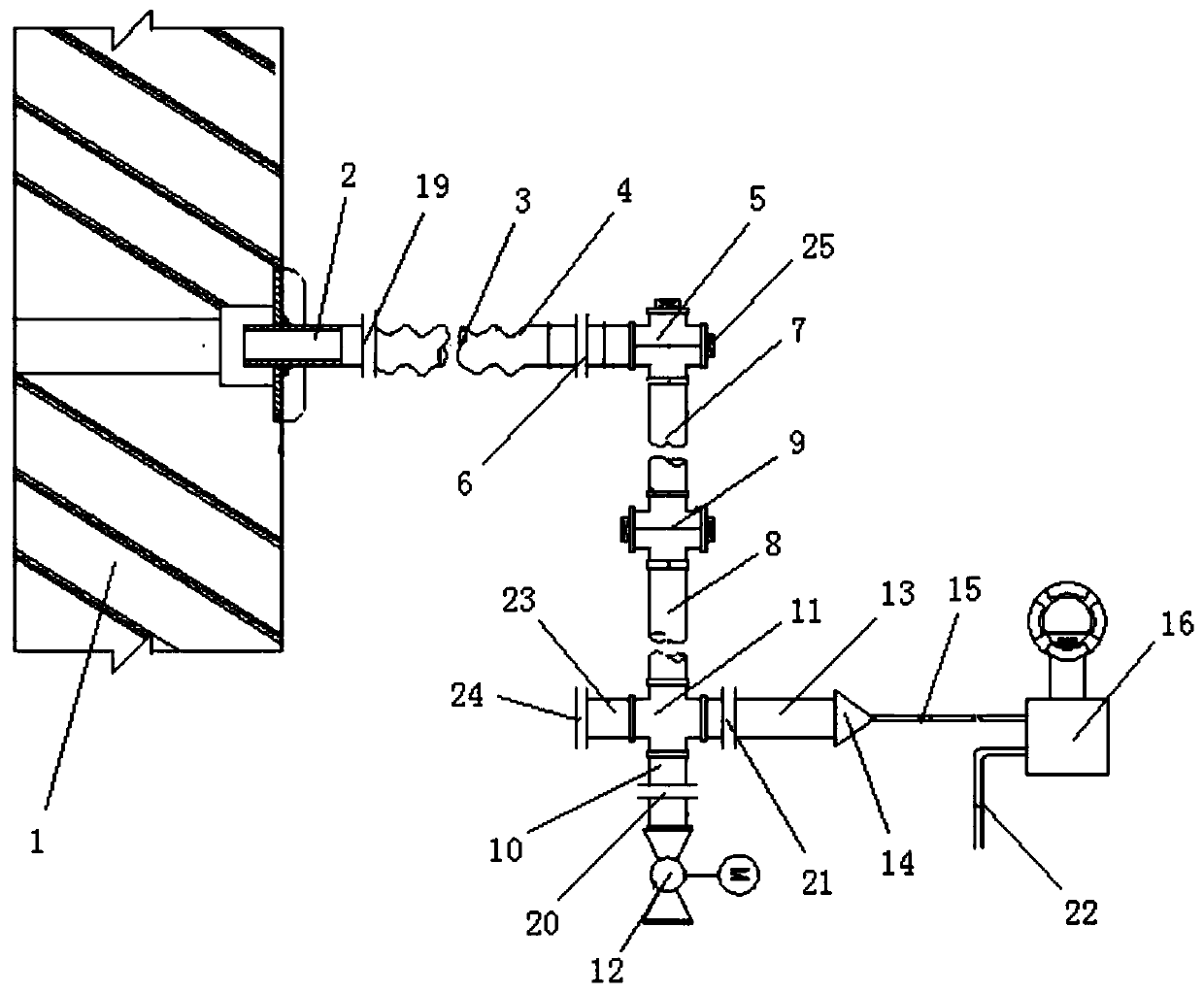

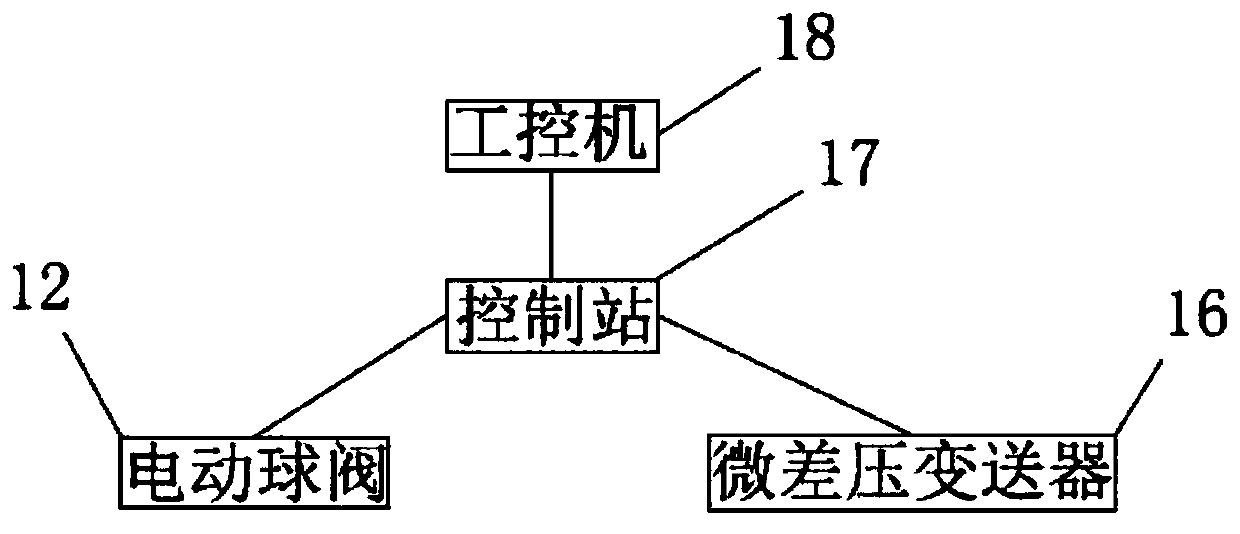

Furnace pressure detection control system for high-boron glass total oxygen furnace

InactiveCN111056730AGuarantee authenticityGuarantee qualityGlass furnace apparatusPressure difference measurement between multiple valvesBall valveGlass manufacturing

The invention discloses a furnace pressure detection control system for a high-boron glass total oxygen furnace, and relates to the technical field of glass manufacturing equipment. The system comprises a melting furnace, the melting furnace is provided with a melting furnace breast wall, a pressure leading position is arranged on the melting furnace breast wall, and the system further comprises asteel plate, a first pressure guide pipe, a heat-resistant metal hose, a second pressure guide pipe, a first heat-resistant four-way pipe fitting, a heat-resistant movable flange, a third pressure guide pipe, a fourth pressure guide pipe, a second heat-resistant four-way pipe fitting, a fifth pressure guide pipe, a four-way pipe fitting, an electric ball valve, a sixth pressure guide pipe, a reducer pipe, a stainless steel seamless pipe, a micro differential pressure transmitter, a control station and an industrial personnel computer. The control and detection of the electric ball valve and the micro differential pressure transmitter are collected through the control, collected signals are transmitted to the industrial personal computer, the whole detection process is full-automatic, useis convenient, and the measurement precision is high.

Owner:CHINA TRIUMPH INT ENG

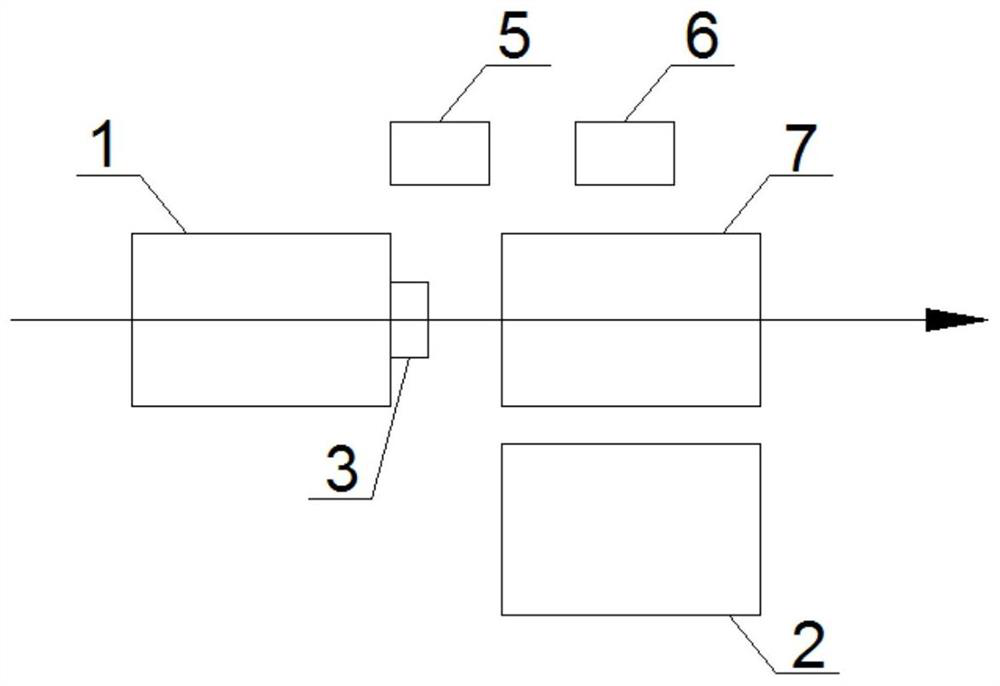

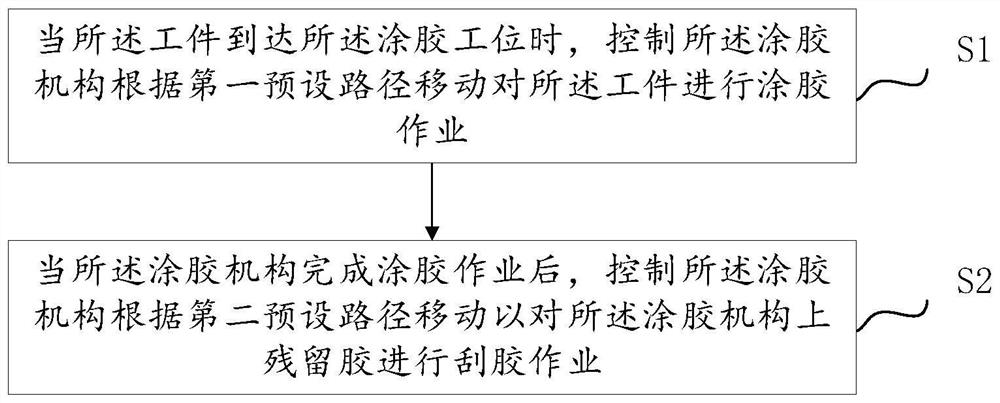

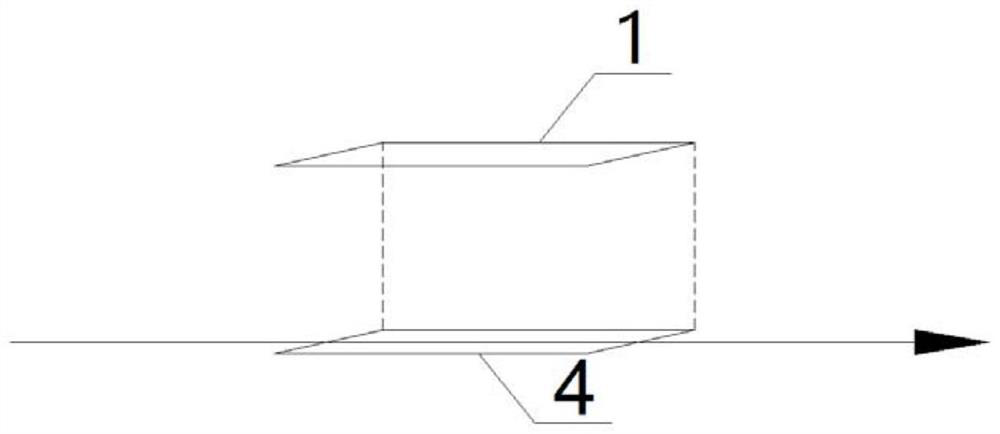

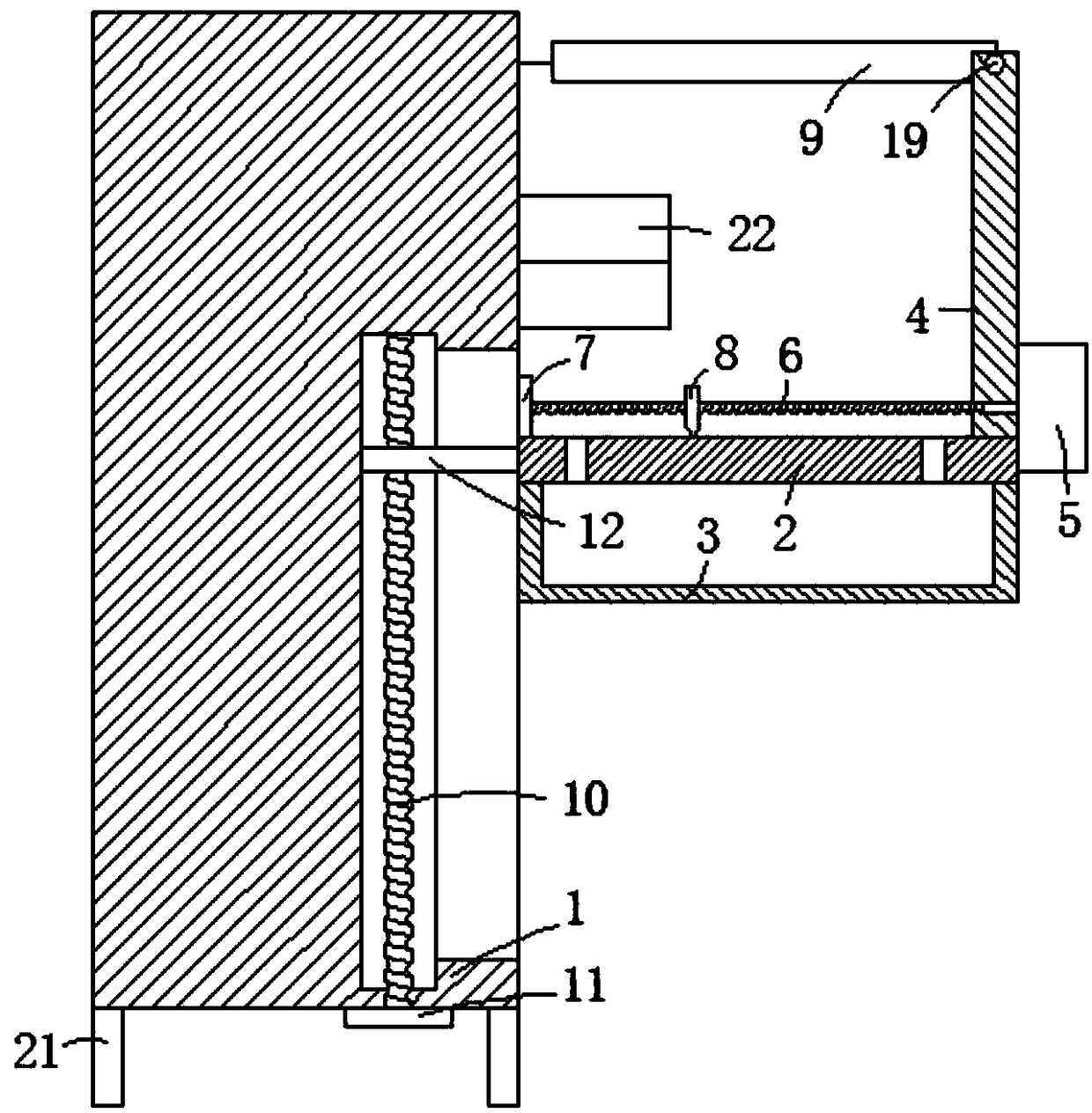

Gluing control method and system

PendingCN114011661AImprove work efficiencyGuarantee qualityLiquid surface applicatorsSpraying apparatusAssembly lineManufacturing engineering

The invention discloses a gluing control method and system which is suitable for an automatic gluing device. The gluing control method is achieved through the cooperation of a gluing mechanism in the automatic gluing device and a workpiece, and comprises the steps of, when the workpiece reaches a gluing station, controlling the gluing mechanism to move according to a first preset path to glue the workpiece; and after the gluing mechanism completes the gluing operation, controlling the gluing mechanism to move according to a second preset path so as to scrape the residual glue on the gluing mechanism. By controlling the workpiece and the gluing mechanism, the gluing operation of an automatic assembly line on the workpiece is realized, the working efficiency of gluing can be effectively improved, and the quality of a glued workpiece finished product is ensured. And meanwhile, after the gluing operation is completed, the gluing mechanism is controlled to conduct glue scraping operation so as to scrape off the residual glue at a glue outlet of the gluing mechanism, so that the situation that the next gluing operation is affected due to the fact that the residual glue is dried up, is avoided, and the gluing operation quality and efficiency are improved.

Owner:SHANGHAI HUIDA MFG +1

Protection device for aluminum alloy die-casting machine

The invention discloses a protection device for an aluminum alloy die-casting machine. The protection device for the aluminum alloy die-casting machine comprises a machine body, a die and multiple support rods. The support rods are fixedly connected to the lower surface of the machine body; the die is fixedly connected onto a side wall of the machine body; a sliding plate is slidably connected onto a side wall of the machine body and is located on the lower side of the die; a lifting mechanism is fixedly connected onto the sliding plate and is located in the machine body; two discharging holesare formed in the sliding plate; a rectangular barrel is arranged on the lower side of the sliding plate and is fixedly connected to the lower surface of the sliding plate through a locking mechanism; and a U-shaped plate is fixedly connected to the upper surface of the sliding plate. According to the protection device for the aluminum alloy die-casting machine provided by the invention, the height of the protection device and the distance between the protection device and the die can be adjusted according to the demands, and partial molten aluminum stained on the protection device can be scraped in time, so that the follow-up use quality of the protection device is ensured, and the service life of the protection device is prolonged to a certain extent.

Owner:NANJING JIAMING DIE CASTING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com