Furnace pressure detection control system for high-boron glass total oxygen furnace

A detection and control system, high boron glass technology, applied in glass manufacturing equipment, glass furnace equipment, pressure difference measurement between multiple valves, etc. Realize problems such as post-maintenance, and achieve the effect of ensuring authenticity, quality, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

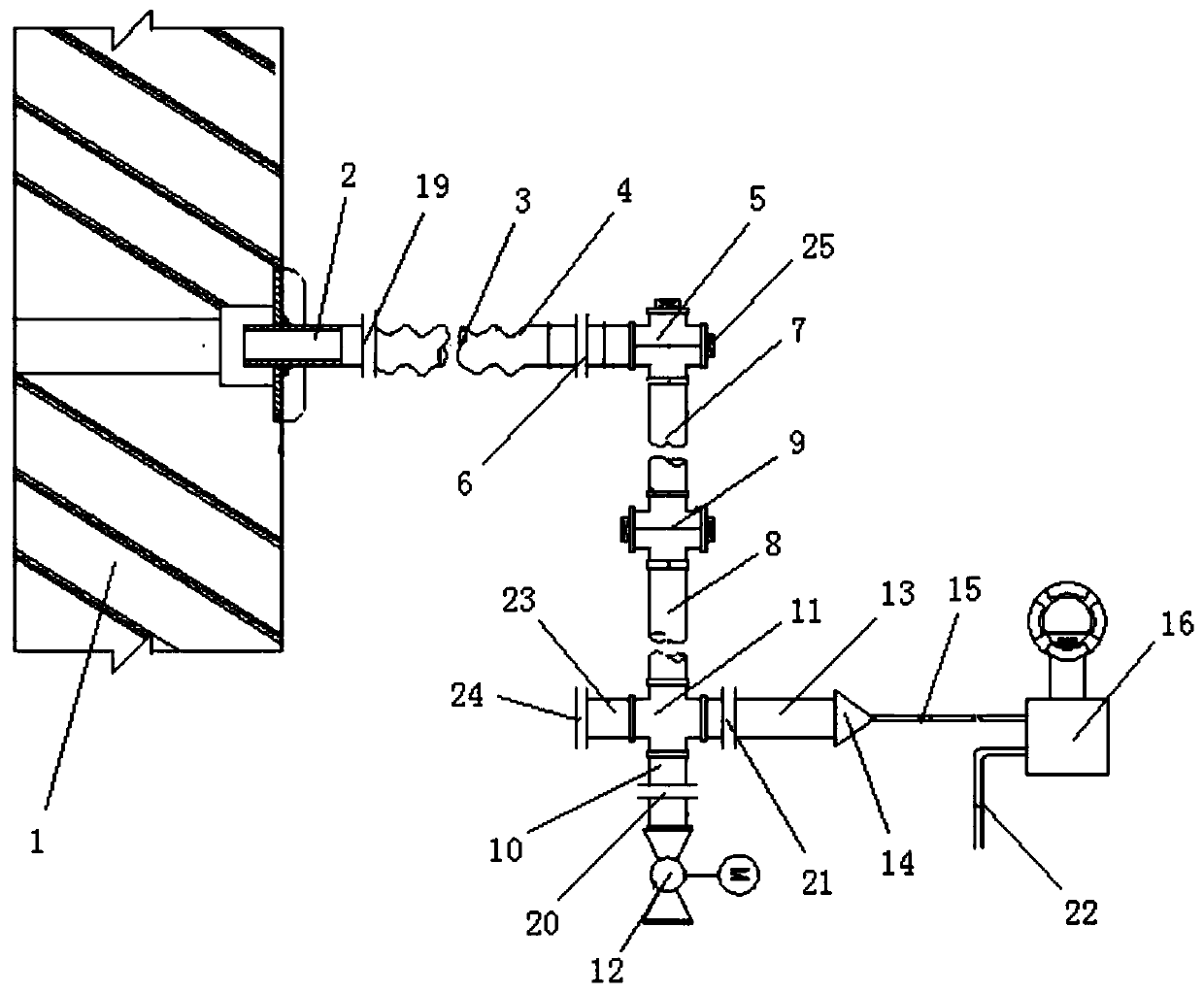

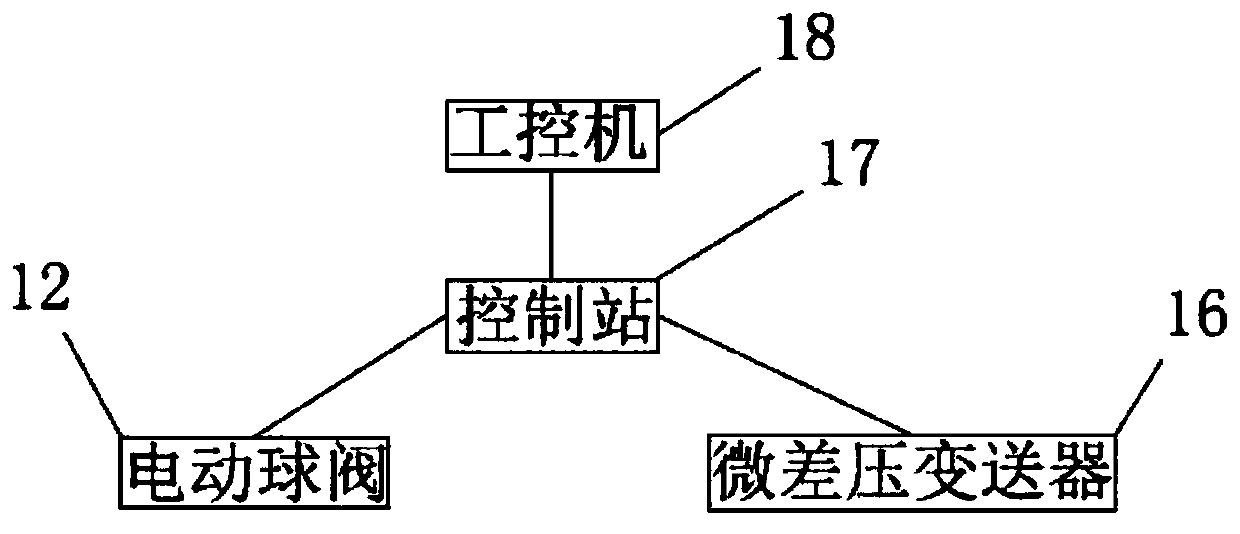

[0039] figure 1 It is a structural sectional view of the high boron glass all-oxygen kiln kiln pressure detection and control system of the present invention, figure 2 It is the control flow chart of the high boron glass all-oxygen kiln kiln pressure detection and control system of the present invention, please refer to Figure 1 to Figure 2 As shown, a preferred embodiment is shown. The kiln pressure detection and control system of a high boron glass all-oxygen kiln includes a melting furnace (not shown in the figure), the melting furnace has a melting furnace breast wall, and the melting furnace There are pressure induction positions on the breast wall, including:

[0040] The steel plate 1, the steel plate 1 is arranged on the pressure introduction position.

[0041] The first pressure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com