Intelligent control system for large wind power blade production process

An intelligent control system and wind power blade technology, applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the hidden danger of product quality, unable to realize automatic start and stop, unable to realize data and other problems, to achieve the quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

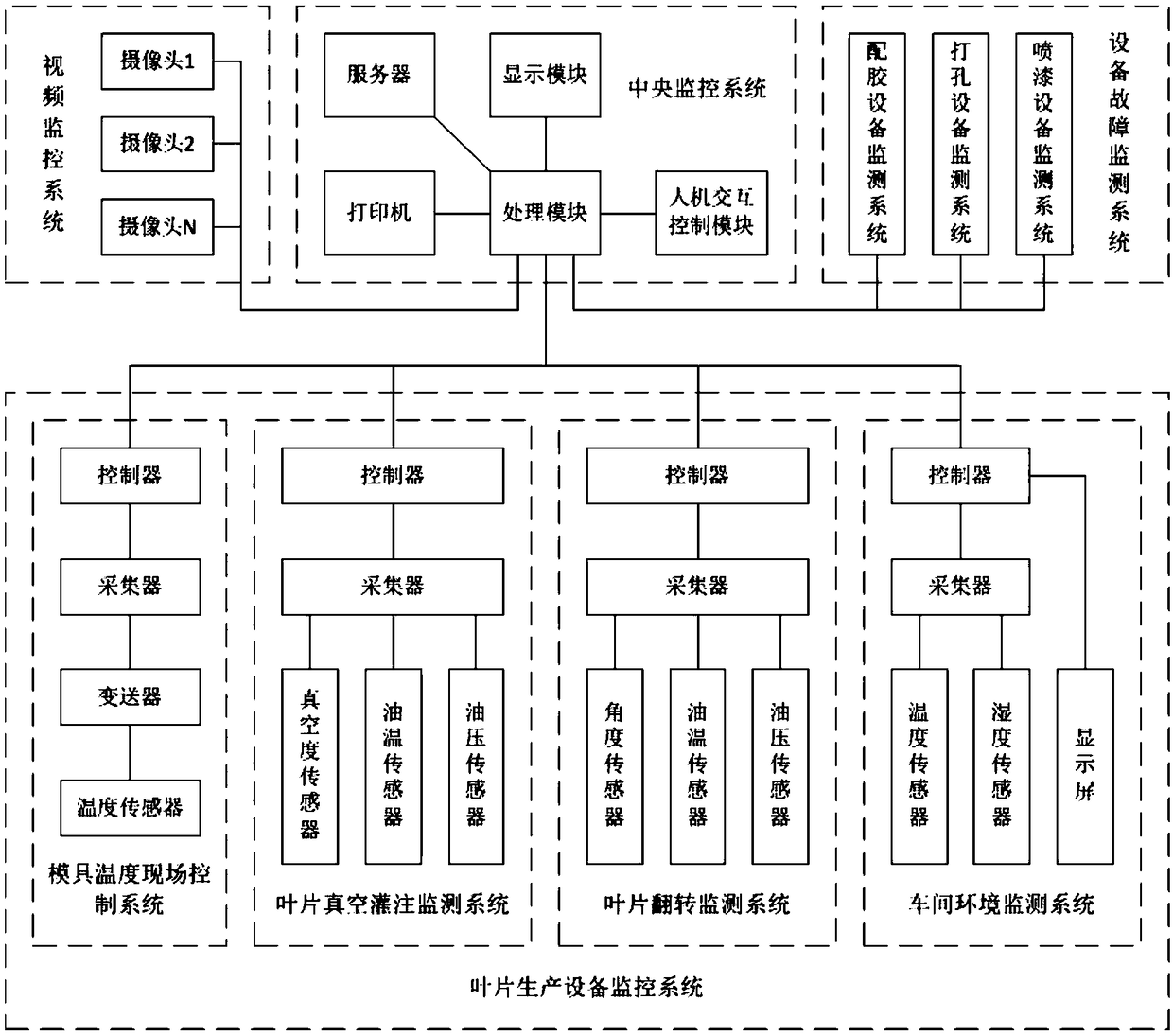

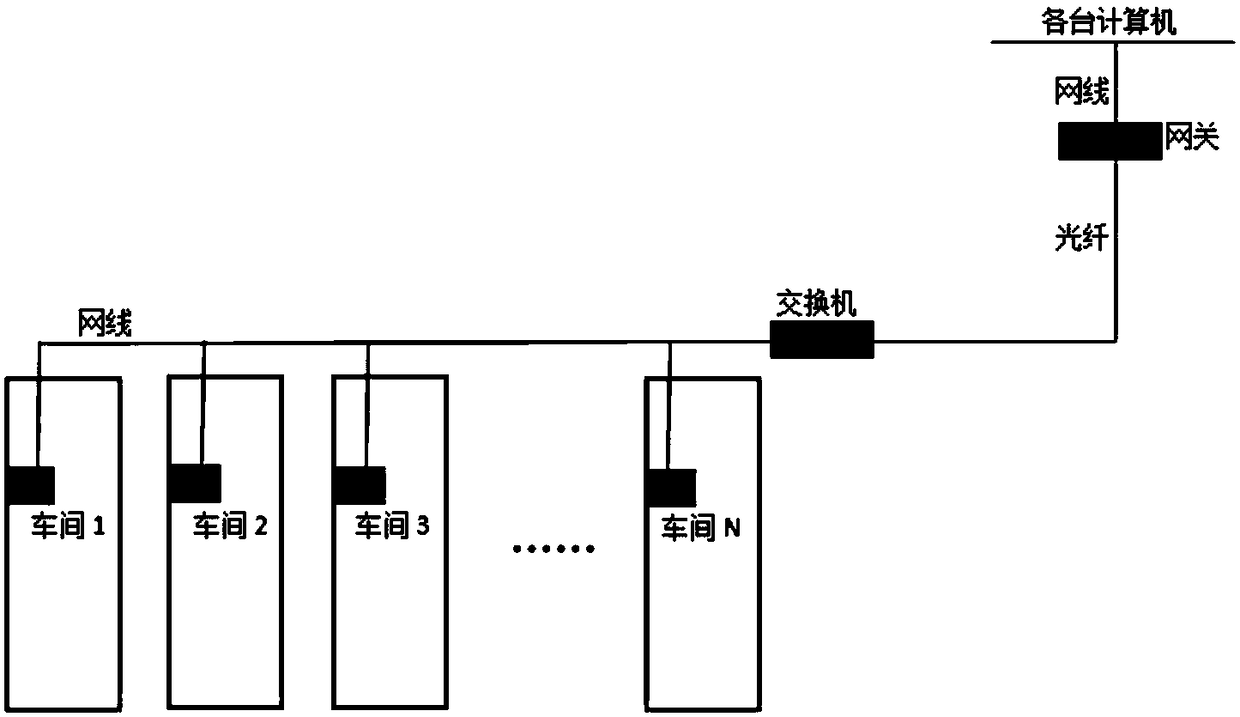

[0034] Such as figure 1 As shown, a large-scale wind power blade production process intelligent control system includes a central monitoring system, a video monitoring system, a blade production line monitoring system, and an equipment failure monitoring system. The blade production line monitoring system includes a mold temperature field control system and a blade vacuum perfusion monitoring system. , Blade turnover monitoring system and workshop environment monitoring system, equipment failure monitoring system includes glue dispensing equipment monitoring system, punching equipment monitoring system and painting equipment monitoring system.

[0035] The central monitoring system includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com