Coextrusion reinforced polyethylene antibacterial composite pipe

A composite pipe and polyethylene technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of unsightly appearance and large bending degree, and achieve the effect of ensuring quality and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing, the present invention will be further described:

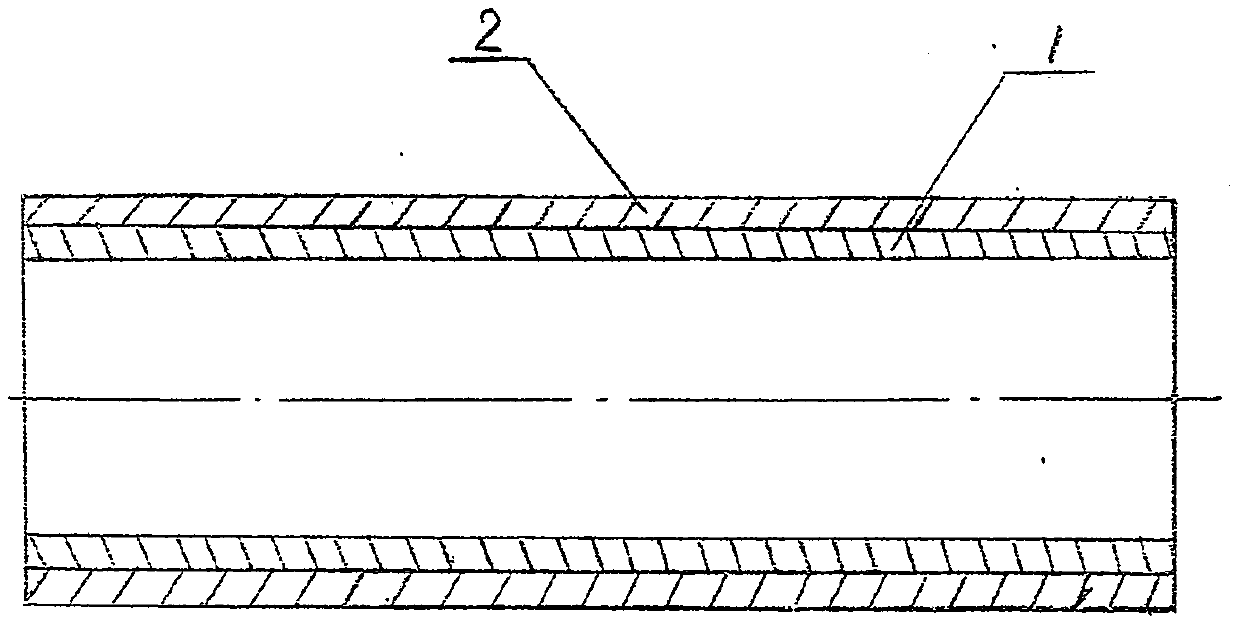

[0009] See attached figure 1 The inner layer 1 is an antibacterial material mixed with 10% inorganic antibacterial agent and 90% polyethylene, and the outer layer 2 is reinforced polyethylene mixed with 85% polyethylene and 15% glass fiber with a length of 10mm. The co-extrusion process forms a double-layer structure in which the inner layer 1 and the outer layer 2 are combined.

[0010] See attached figure 1 , firstly, the antibacterial material mixed with 10% inorganic antibacterial agent and 90% polyethylene is fed into the barrel of the extruder,

[0011] Again, 85% polyethylene and 15% glass fibers with a length of 10 mm were mixed and fed into another extruder barrel.

[0012] The two different materials are fed into their respective extruders, heated and smelted, and compounded by co-extrusion to form a double-layer structure of the inner layer 1 and the outer la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com