Electrically-driven self-adjusting pressure control method and device, program and storage medium

A pressure control and self-adjusting technology, applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problems of unstable yarn contact pressure and unqualified spinning quality, so as to save manpower and reduce labor costs , the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

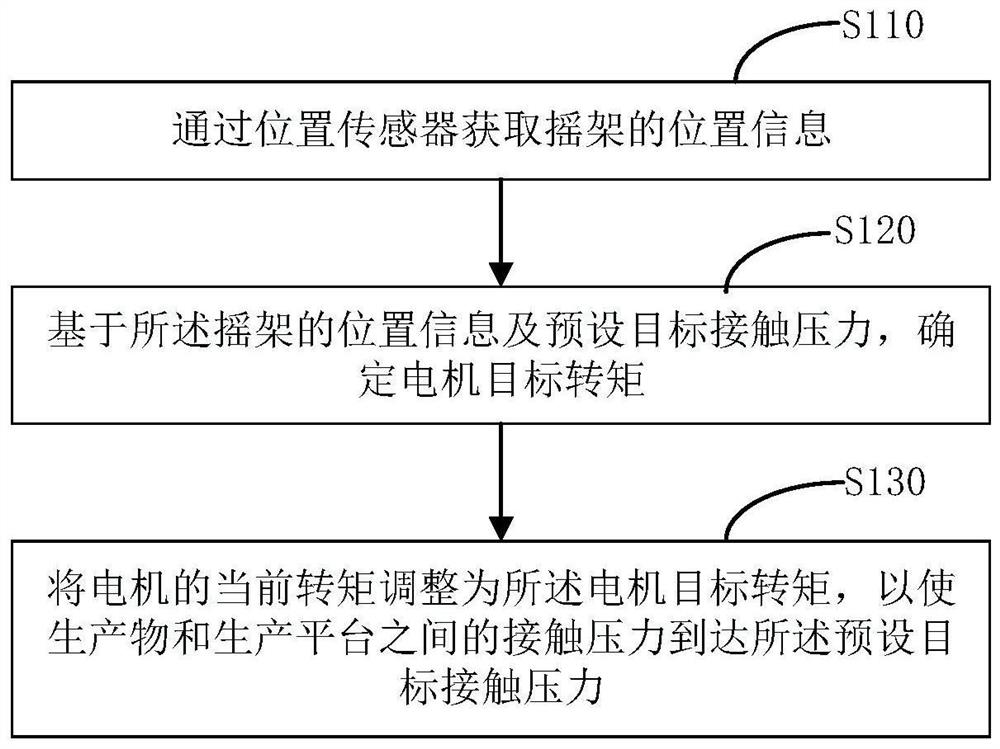

[0070] refer to Figure 4 , Figure 4 It is the second embodiment of the electric drive self-regulating pressure control method of the present application, the method further includes:

[0071] Step S210: Obtain the position information of the cradle through the position sensor.

[0072] Step S220: Determine the target torque of the motor based on the position information of the cradle and the preset target contact pressure.

[0073] Step S230: Adjust the current torque of the motor to the target torque of the motor, so that the contact pressure between the product and the production platform reaches the preset target contact pressure.

[0074] Step S240: Obtain current information of the motor through a current sensor.

[0075] Specifically, a current sensor is a detection device that can sense the information of the measured current, and can transform the information sensed by the detection into an electrical signal that meets certain standards or other required forms of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com