Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Good softness at low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent medical antibacterial polyvinyl chloride material and preparing method thereof

InactiveCN106117880AImprove antibacterial propertiesDurable and stable antibacterialPlasticizerPolyvinyl chloride

The invention relates to a transparent medical antibacterial polyvinyl chloride material and a preparing method thereof. The material comprises 100 weight parts of polyvinyl chloride resin serving as basic resin, an antibacterial agent, plasticizer and optional stabilizer. The antibacterial agent is directly added into the carrier material, by means of a blending method, the antibacterial agent is directly added into the carrier material, and the raw material obtains an antibacterial property. The polyvinyl chloride material has the greatest advantage of being easy to process and capable of ensuring durability, as the new antibacterial agent on the inner layer can be exposed even if the material surface is abraded, the antibacterial agent cannot be transferred, and the transparent medical antibacterial polyvinyl chloride material is particularly suitable for serving as a medical macromolecular material.

Owner:HENAN TUOREN MEDICAL DEVICE GRP

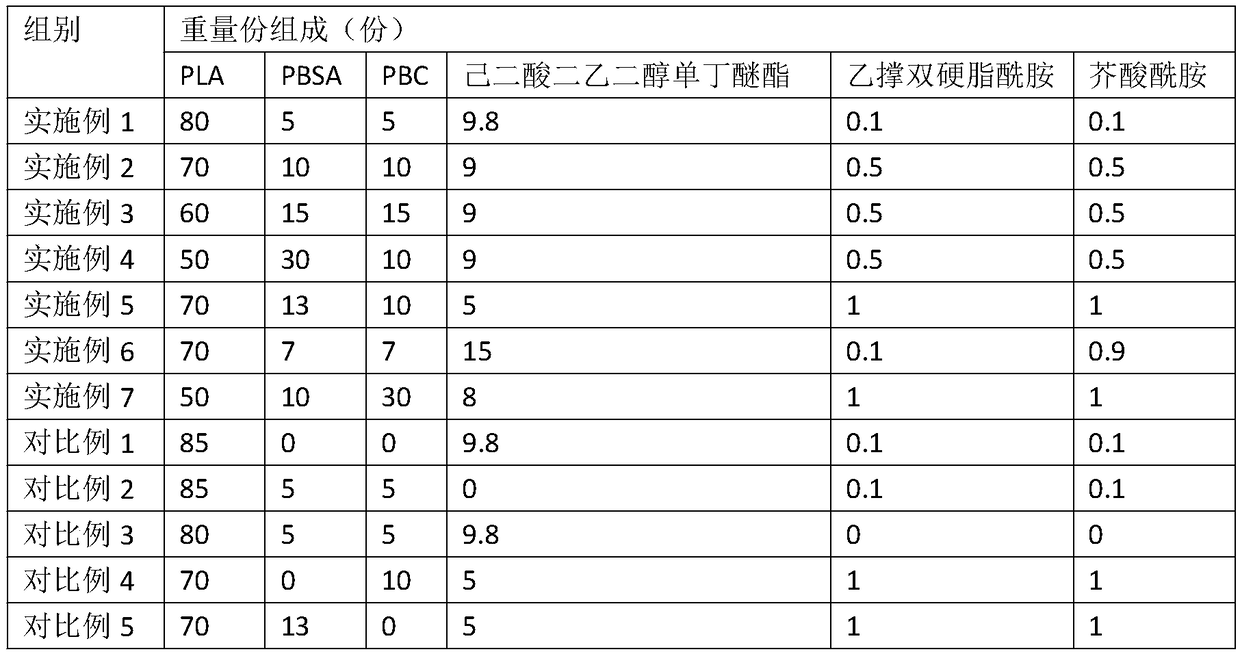

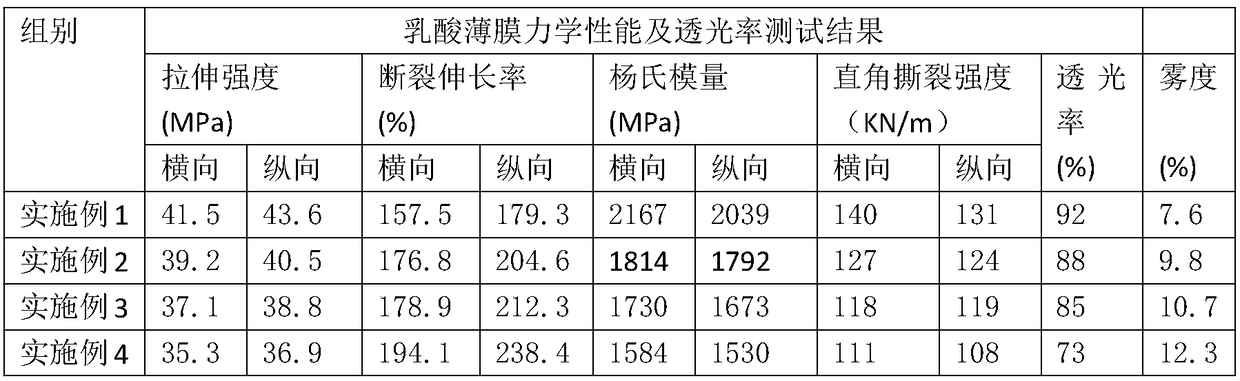

Completely-biodegradable polylactic acid-based blow molding thin film and preparation method thereof

The invention belongs to the field of polymer materials, and particularly relates to a PLA (polylactic acid) biodegradable thin film and a preparation method thereof. The PLA biodegradable thin film is prepared from the following components of PLA, PBSA (poly(butylene succinate-co-adipate)), PBC (polypropylene carbonate), a plasticizer, a lubricant and a pore forming agent. The preparation methodcomprises the following steps of mechanically mixing the PLA, the PBSA, the PBC, the lubricant and the pore forming agent; adding the mixed raw materials into a material hopper of a double-screw extruder; metering the plasticizer by a metering pump, adding via a liquid adding port of the extruder, starting the solid charge and liquid charge, smelting, extruding and granulating, so as to obtain thePLA resin material; performing blow molding and film forming on the PLA resin material, so as to obtain the PLA-based thin film. The PLA-based thin film has the advantages that the mechanical property is better, and the transparency is good; the complete biodegradable effect is realized; the PLA-based thin film can be used for replacing PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride) and the like to prepare thin films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

Polyurethane resin for high-density shoe leather and preparation method thereof

ActiveCN102181034ALow costGood softness at low temperatureTextiles and paperN dimethylformamidePolymer science

The invention relates to wet-process polyurethane resin for high-density shoe leather. The polyurethane resin is prepared from isocyanate, a polyether polyol mixture, a chain extender and N, N-dimethylformamide serving as an organic solvent. Polyoxytetramethylene-ethylene epoxide copolyether diol and polyoxypropylene diol are taken as macromolecular polylol raw materials for reacting, the raw materials have high hydrolysis resistance and the polyurethane resin can be endowed with high low-temperature flexibility and rebound resilience, so that the prepared high-density shoe leather has finer folds, high durability and high low-temperature adaptability, and recovers quickly. On the aspect of synthesis technology, a special process for stepwise reaction of two polyether polyols is designed,so that a macromolecular structure is more regular, and advantages of the two polyether polyols can be brought into play.

Owner:SHANGHAI HUIDE TECH CO LTD

Polyvinyl chloride/sulfonated cis-butadiene rubber and preparation method thereof

ActiveCN101704977AImprove cold resistanceGood softness at low temperaturePlastic/resin/waxes insulatorsPolymer scienceNitrile rubber

The invention relates to the field of electric wire and cable material manufacture, in particular to a polyvinyl chloride / sulfonated cis-butadiene rubber and a preparation method thereof. The polyvinyl chloride / sulfonated cis-butadiene rubber has excellent cold resistance and low temperature flexibility. In the method, the sulfonated cis-butadiene rubber is added to improve the cold resistance and the low temperature flexibility of polyvinyl chloride. The cis-butadiene rubber is the rubber with the best low temperature performance, the brittle point is 110 DEG C below zero which is far lower than that of 35 DEG C below zero of acrylonitrile-butadiene rubber, and the low temperature resilience of the cis-butadiene rubber is the best in conventional rubber. However, the cis-butadiene rubber is non-polar rubber and has poor intermiscibility with the polyvinyl chloride, and sulfonate polar groups are introduced into molecular chains after the sulfonation reaction of the cis-butadiene rubber, so the intermiscibility between the cis-butadiene rubber and the polyvinyl chloride is greatly improved to form an even blending system.

Owner:JIANGSU HENGFENG CABLE

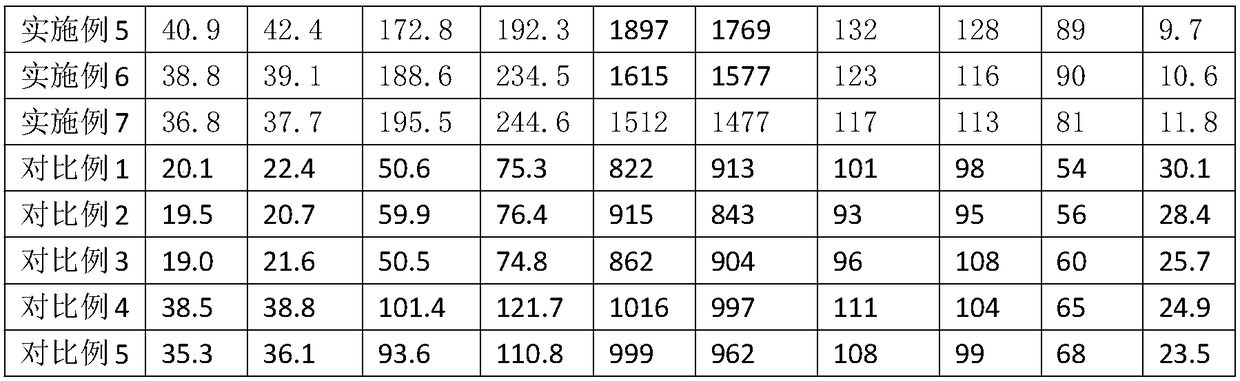

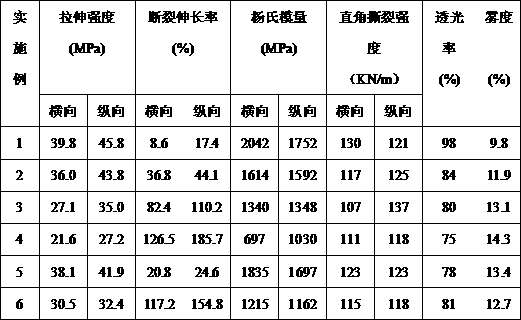

PLA-PBSA blown film and preparation method thereof

InactiveCN108017887AIncreased tensile elongation at breakHigh tear strengthFlat articlesDiethylene glycol monobutyl etherPolymer science

The invention provides a polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film and a preparation method thereof. The blown film comprises a mixture of PLA, PBSA, plasticizer diethylene glycol monobutyl ether adipate, a lubricant, a plastic lubricant and an antioxidant. The PLA, the PBSA, the lubricant, the plastic lubricant and the antioxidant are first mechanically mixed into a premix, the premix is added through a feeding port of a twin-screw extruder, meanwhile the plasticizer diethylene glycol monobutyl ether adipate is metered and added in through a liquid feeding port of the twin-screw extruder, modified polylactic acid blown film special resin is prepared by melt-extruding, water-cooling, pelletizing and drying, the modified polylactic acid blown film special resin is blown by a film blowing machine to form a transparent tear-resistant biodegradable film. The PBSA, the plasticizers, the lubricant, the plastic lubricant and the antioxidant can effectively increase the tensile elongation at break and tear strength of polylactic acid films, maintains the transparency of the polylactic acid, and solves the brittleness defects of the polylactic acid films. The polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and the like for preparation of films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

Single-component reaction-type polyurethane hot melt adhesive and preparation method thereof

ActiveCN109666441AHigh plasticizing efficiencyReduce volatilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerHot-melt adhesive

The invention discloses single-component reaction-type polyurethane hot melt adhesive. The single-component reaction-type polyurethane hot melt adhesive is prepared from the following raw materials: polyurethane prepolymer, a chain extender, tackifying resin, a latent curing agent and filler, wherein the polyurethane prepolymer is formed by polymerizing polyalcohol with a molecular weight of 500 to 3000, polyisocyanate and a catalyst; and the raw material composition also comprises a plasticizer, wherein the plasticizer is dioctyl phthalate and / or diethylene glycol dibenzoate. The components of the single-component reaction-type polyurethane hot melt adhesive of the invention are mixed with plasticizers, the plasticizers are dioctyl phthalate and / or diethylene glycol dibenzoate, the two substances have high plasticizing efficiency for the polyurethane and low volatility and have good low-temperature flexibility; and by adding the plasticizers, the interaction between polymer macromolecular chains can be weakened, the elasticity and flexibility of the polymer materials of the polyurethane hot melt adhesive can be improved, and the high-temperature and low-temperature resistance of the hot melt adhesive can be improved.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Low-temperature-resistant bidirectionally-stretched polypropylene thin film and preparation method of same

ActiveCN105235336AImprove low temperature resistanceLess crystal pointLamination ancillary operationsSynthetic resin layered productsMasterbatchPolymer science

The invention discloses a low-temperature-resistant bidirectionally-stretched polypropylene thin film and a preparation method of the same. The polypropylene thin film comprises, from exterior to interior, a low-temperature-resistant anti-adhesion layer, a low-temperature-resistant core layer and a low-temperature-resistant corona treatment layer. The low-temperature-resistant core layer is composed of 30-70% of homo-polypropylene, 10-40% of a thermoplastic elastic master batch, and 20-50% of a low-temperature-resistant master batch. The low-temperature-resistant anti-adhesion layer and the low-temperature-resistant corona treatment layer are both composed of 50-70% of copolymerized modified polypropylene, 25-40% of a low-temperature-resistant master batch and 2-10% of a SiO2 anti-adhesion agent. The polypropylene thin film has excellent low-temperature-resistant performance, has excellent use performance even at -30 DEG C, is soft, is excellent in printing performance, has excellent physical performance and is simple in preparation method.

Owner:ANHUI GUOFENG PLASTIC

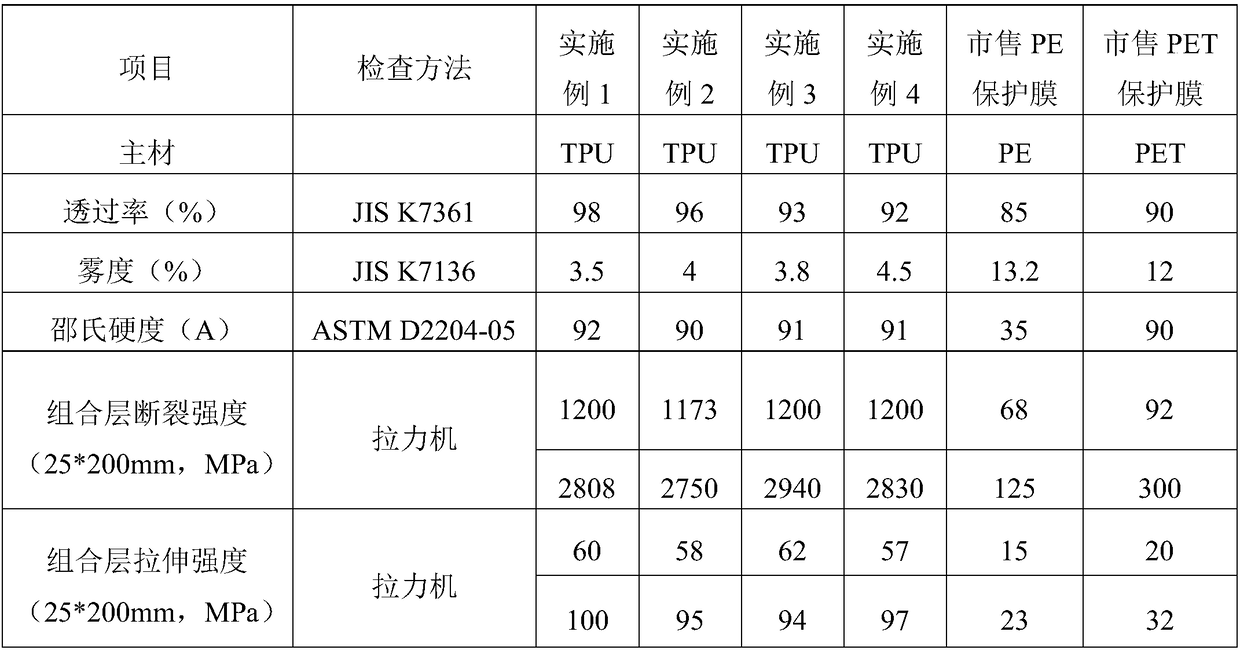

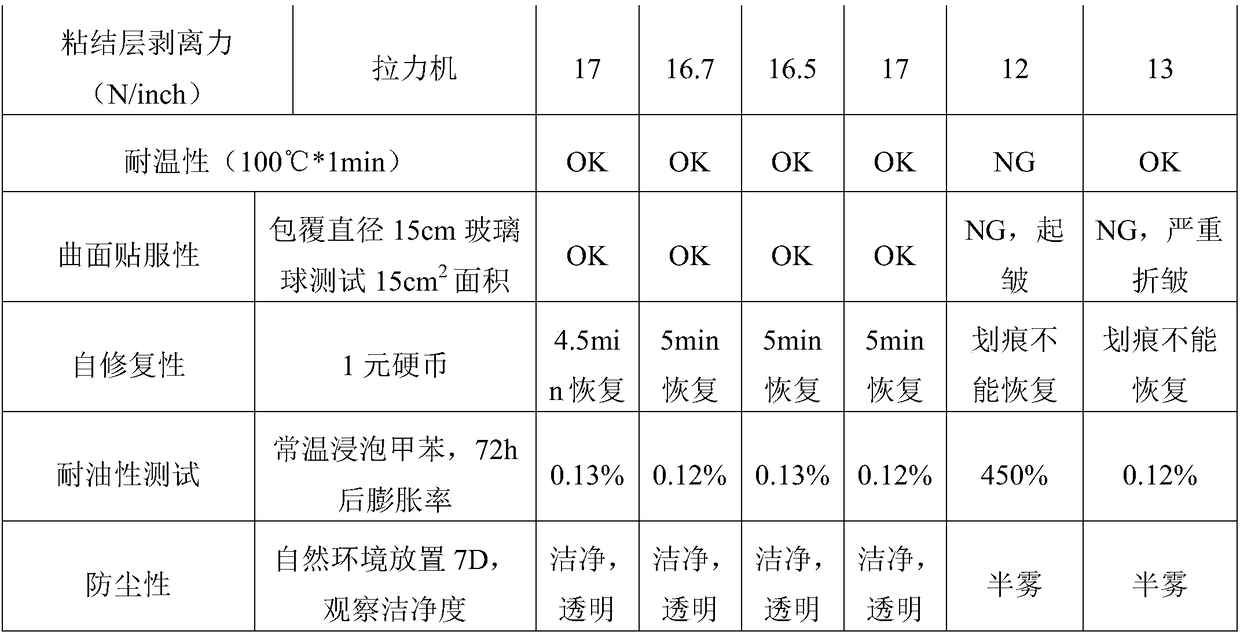

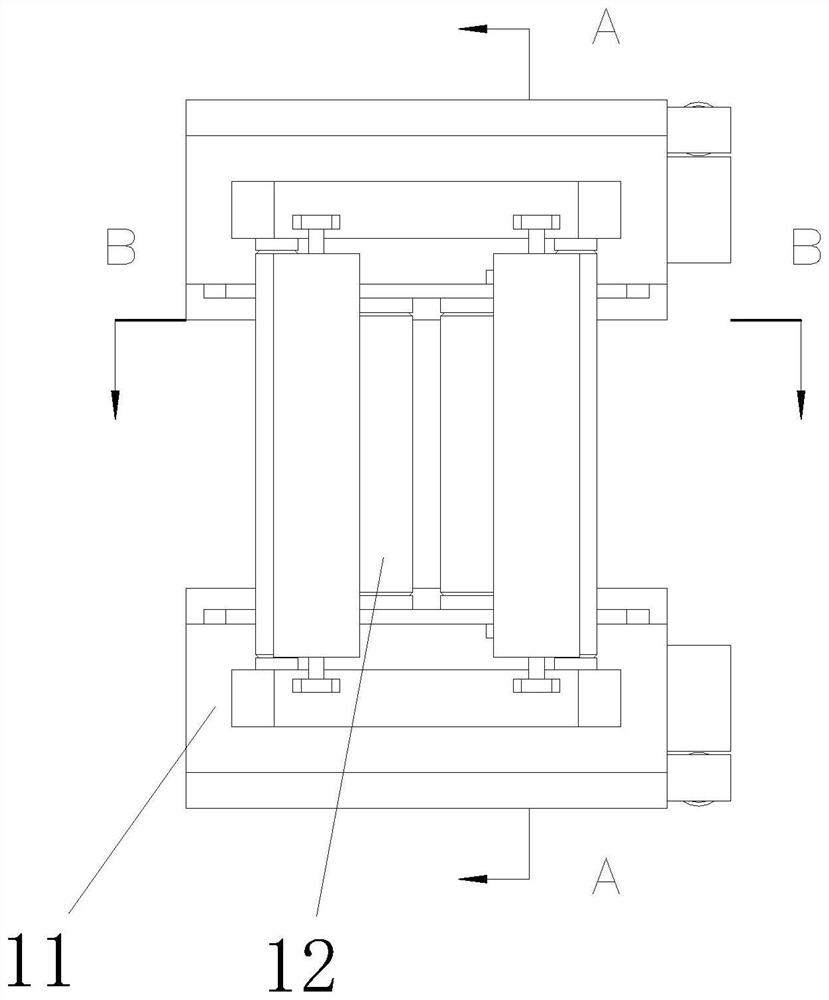

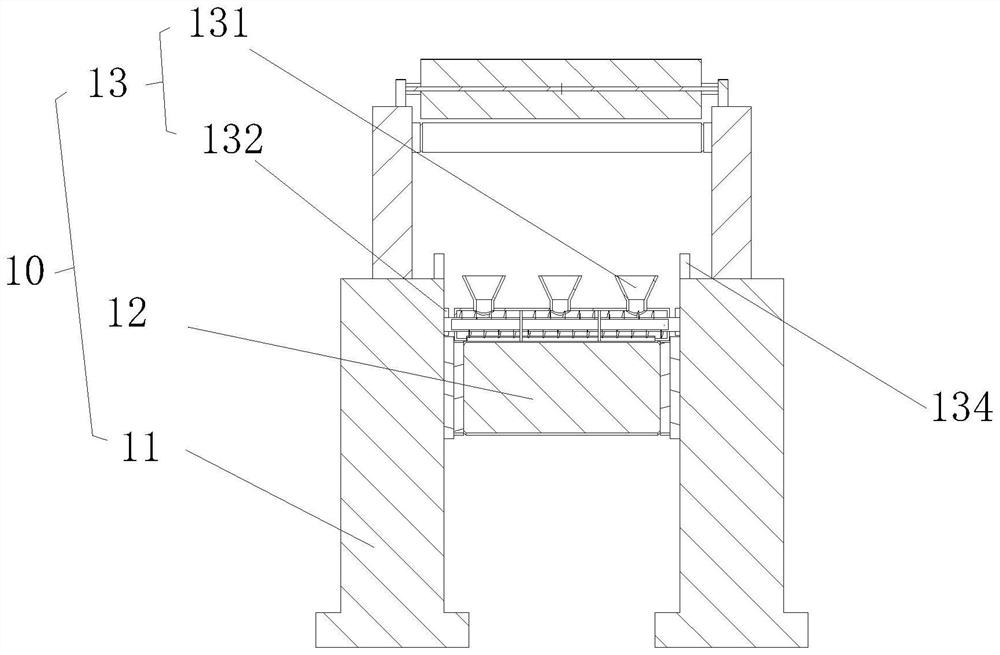

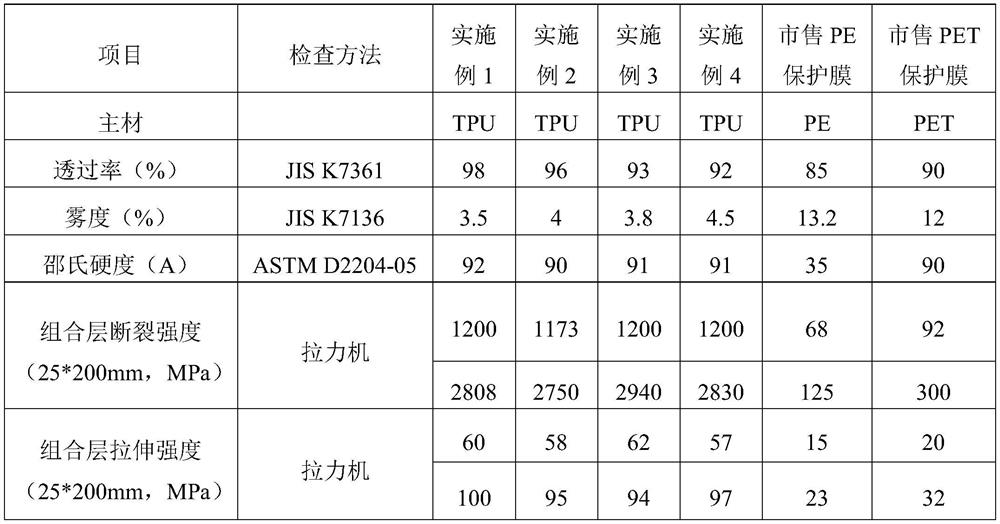

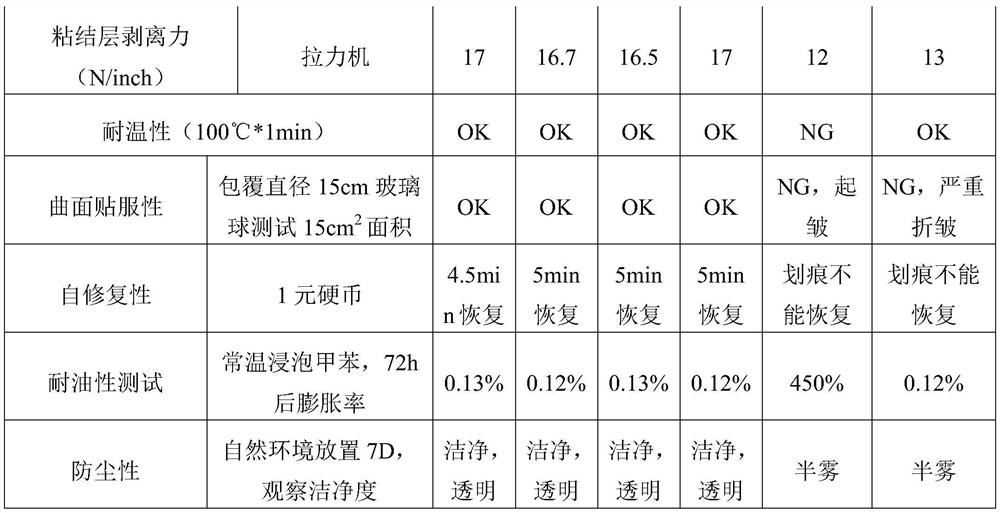

Protection film of curve surface element and preparation method thereof

ActiveCN108690516AHigh elongationHigh tensile strengthFilm/foil adhesivesTectorial membraneAdhesion force

The invention belongs to the field of a protection film, and discloses a protection film of a curve surface element. The protection film sequentially comprises a first macromolecular resin mixing layer, a second macromolecular resin mixing layer, a bonding layer and a release film from top to bottom, wherein through being metered in parts by weight, the first macromolecular resin mixing layer is prepared from 20 to 30 parts of TPU, 6 to 10 parts of filling agents, 5 to 10 parts of wear-resistant agents, 2 to 4 parts of dispersing agents, 4 to 8 parts of anti-static agents and 0.2 to 0.5 part of leveling agents; the second macromolecular resin mixing layer is prepared from 15 to 25 parts of TPU, 2 to 5 parts of filling agents, 1 to 2 parts of dispersing agents, 5 to 8 parts of adhesion force accelerators and 0.1 to 0.4 part of wetting agents. The invention also discloses a preparation method of the protection film. The protection film can be used on a plane and a display element with the curvature; the thin film is soft and has high extending rate; the protection film has good attachment performance on the curve surface; the stretch fracture deformation cannot easily occur through the film spreading and stretching; the protection film has good scratch-resistant performance, oil resistance, waterproof performance and dustproof performance.

Owner:HUIZHOU YIDU IMAGE TECH

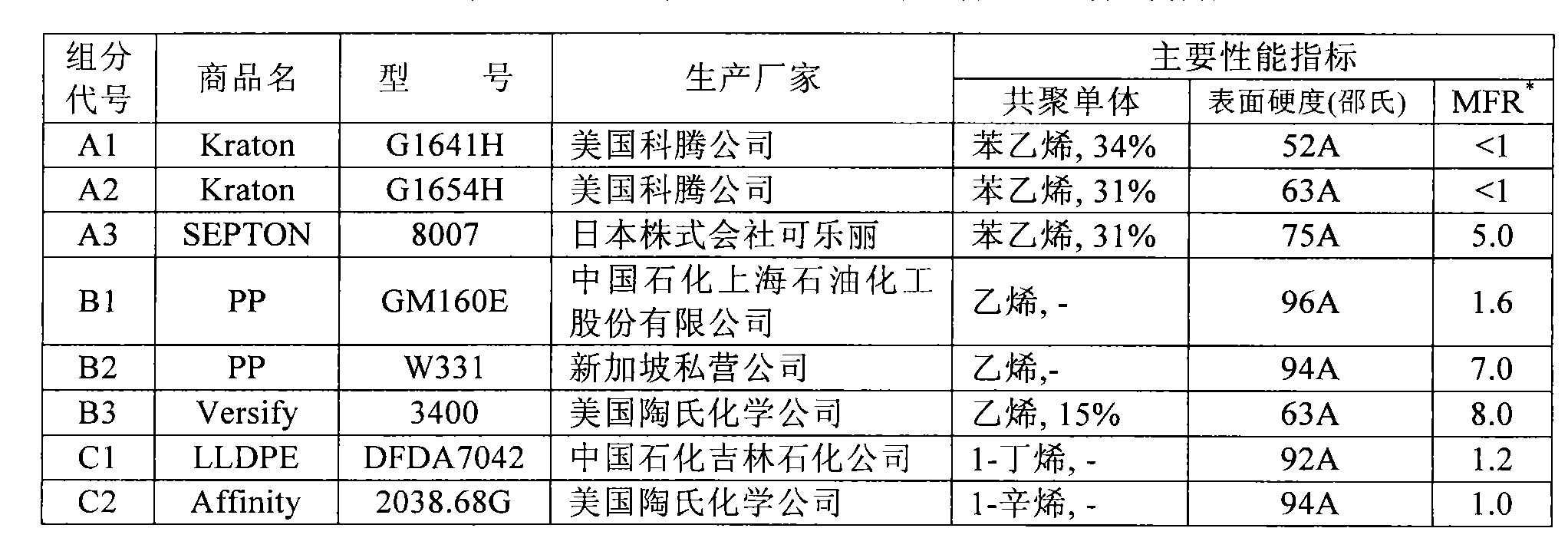

Polyolefin thermoplastic elastomer blending resin and preparation method thereof

The invention provides a polyolefin thermoplastic elastomer blended resin and a method for preparation the same. The resin is prepared through a melting and blending method and comprises the following compositions: (A) a segmented copolymer accounting for 60 to 80 percent of gross weight of which the middle part is an irregular copolymer chain segment of ethene and 1-butylene, and two ends are capped through styrene chain segments; (B) polypropylene resin accounting for 10 to 30 percent of gross weight; and (C) polyethylene resin accounting for 5 to 20 percent of gross weight. The blended resin has innocuity, does not need to add a plasticizer in processing, does not have dangers that a compound is precipitated out, pollutes medical liquid and enters human body, and can be used for manufacturing a vessel for storing human blood and blood compositions.

Owner:WEIGAO HLDG +1

High strength, anti-aging natural rubber/nitrile rubber cable material

The invention discloses a high strength, anti-aging natural rubber / nitrile rubber cable material. The raw material comprises the following components: natural rubber, nitrile rubber, precipitated silica, nano calcium carbonate, calcium sulfate whisker, zinc oxide, stearate, sulfur, 1,3-phenylene-di(1H-2,5-pyrrole-dione), 2-mercaptobenzothiazole thiazole parts, N-oxydisuccinic ethylenebis-2-benzothiazole sulfenamide, phthalate, di-n-octyl phthalate, dioctyl maleate, silane coupling agent and an antioxidant. The high strength, anti-aging natural rubber / nitrile rubber cable material disclosed by the invention is high in strength, and high in aging resistance, and the cable made from the material has good property and is long in service life, so that the cost is reduced.

Owner:繁昌县菲德通讯材料设计有限公司

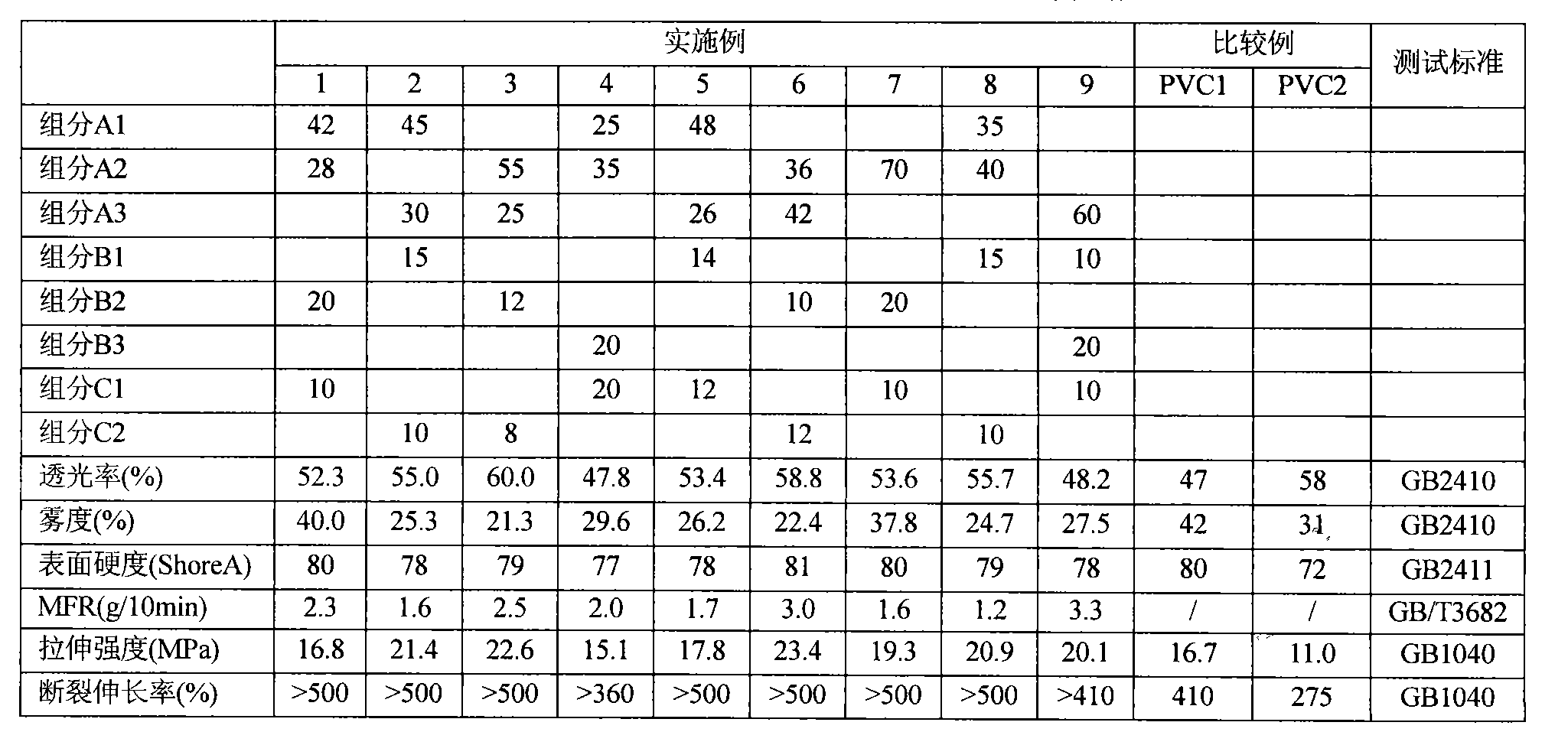

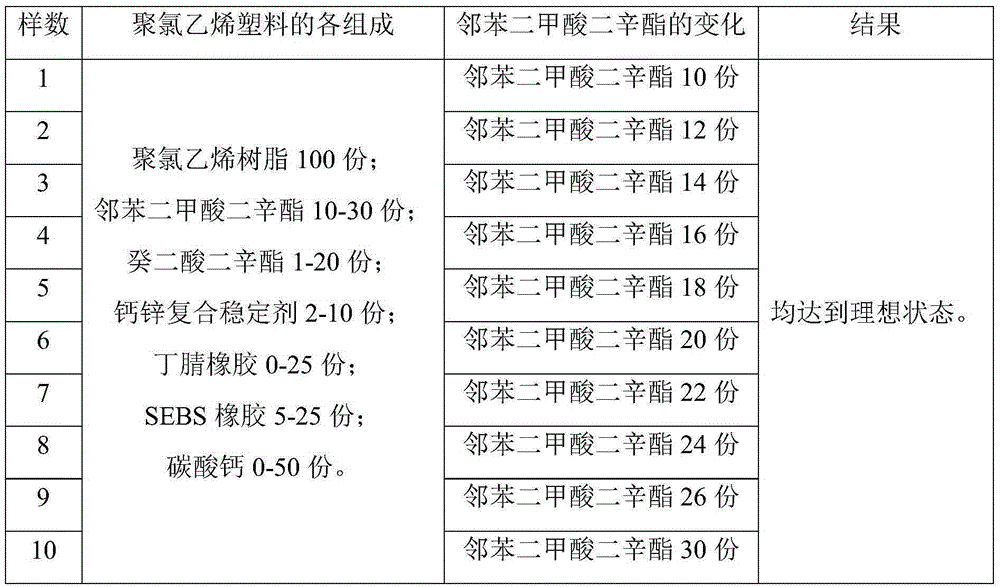

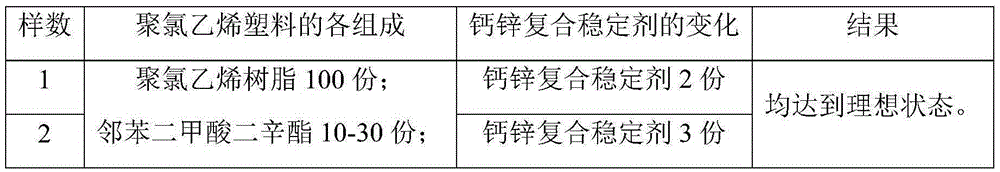

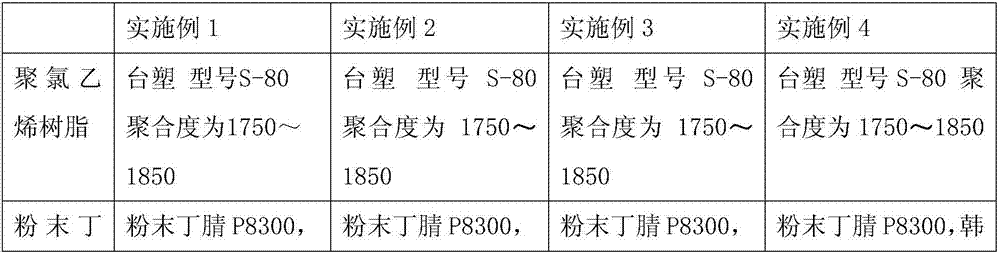

Making method of polyvinyl chloride plastic, and making method of charging pile connecting cable sheath material

InactiveCN105385066AGood weather resistanceImprove heat resistancePlastic/resin/waxes insulatorsNitrile rubberPlasticizer

The invention discloses a making method of a polyvinyl chloride plastic, and a making method of a charging pile connecting cable sheath material. The making method of the polyvinyl chloride plastic is characterized in that the polyvinyl chloride plastic adopts SEBS rubber and nitrile rubber as auxiliary plasticizers, and concretely comprises 100 parts of polyvinyl chloride resin, 10-30 parts of dicapryl phthalate, 1-20 parts of dioctyl sebacate, 2-10 parts of a calcium and zinc composite stabilizer, 0-25 parts of the nitrile rubber, 5-25 parts of the SEBS rubber and 0-50 parts of calcium carbonate. The SEBS rubber is a linear or star-shaped triblock copolymer with styrene as an end segment and an ethylene-butylene copolymer obtained after butadiene hydrogenation as a middle elastic copolymer. The nitrile rubber with the acrylonitrile content of 25-35% is used as a compatilizer in the making process of the polyvinyl chloride plastic. The invention also discloses a making method of the charging pile connecting cable sheath material made from the polyvinyl chloride plastic.

Owner:SUZHOU HENGLI COMM MATERIAL

Nitrile butadiene rubber sealant

The invention discloses a nitrile butadiene rubber sealant comprising the following raw materials by weight: 30-40 parts of nitrile butadiene rubber, 24-32 parts of styrene butadiene rubber, 20-30 parts of dioctyl phthalate, 45-55 parts of calcium carbonate, 8-12 parts of a curing agent, 8-12 parts of a modifier, 10-20 parts of fumed silica, 1-3 parts of dicyandiamide and 24-36 parts of epoxy resin; the nitrile butadiene rubber sealant is prepared by the following preparation process: the epoxy resin and the dicyandiamide are reacted for 50-60min at 150-180 DEG C to obtain mixed resin, wherein the reacted dicyandiamide accounts for 65-70wt% of the total amount of the dicyandiamide; the nitrile butadiene rubber, the styrene butadiene rubber and the remaining dicyandiamide are reacted for 80-100 min at 120-140 DEG C to obtain mixed rubber; the prepared mixed resin, mixed rubber and other components are added into a mixing container for even mixing, grinding and vacuum defoamation to obtain the nitrile butadiene rubber sealant. The nitrile butadiene rubber sealant ensures the adhesion ability and sealing effect, the raw materials are easily obtained, and the nitrile butadiene rubber sealant is simple to make.

Owner:TIANCHANG YONG TAI SEALING MATERIAL

Low-temperature-resistant protective sleeve for underground cable

PendingCN113201188AImprove heat resistanceAccelerated corrosionEthylene-propylene-diene-monomerPlasticizer

The invention discloses a low-temperature-resistant protective sleeve for underground cables, and belongs to the technical field of cable protection. The protective sleeve is prepared from the following raw materials by weight: 20-30 parts of silicone rubber, 35-45 parts of ethylene propylene diene monomer, 2.5-3.5 parts of white carbon black, 5-8 parts of a vulcanizing agent, 2-5 parts of an accelerator, 3-8 parts of a plasticizer, and 2-4.5 parts of a flame retardant. Compared with a traditional cable protective sleeve and a preparation process thereof, the elongation at break of the protective sleeve at normal temperature reaches 678% or above, the tensile strength reaches 28.6 Mpa or above, and the mechanical performance is excellent; the low-temperature retraction temperature TR10 is -24.5 DEG C or below, and the low-temperature-resistant protective sleeve can keep good elasticity under the low-temperature condition and is suitable for being used in the low-temperature environment; and the oxygen index reaches 48 or above, the flame retardant property is good, the use requirement of the underground cable can be met, the cable can be used in a low-temperature environment, and the service life of the underground cable is prolonged.

Owner:国网河南省电力公司镇平县供电公司

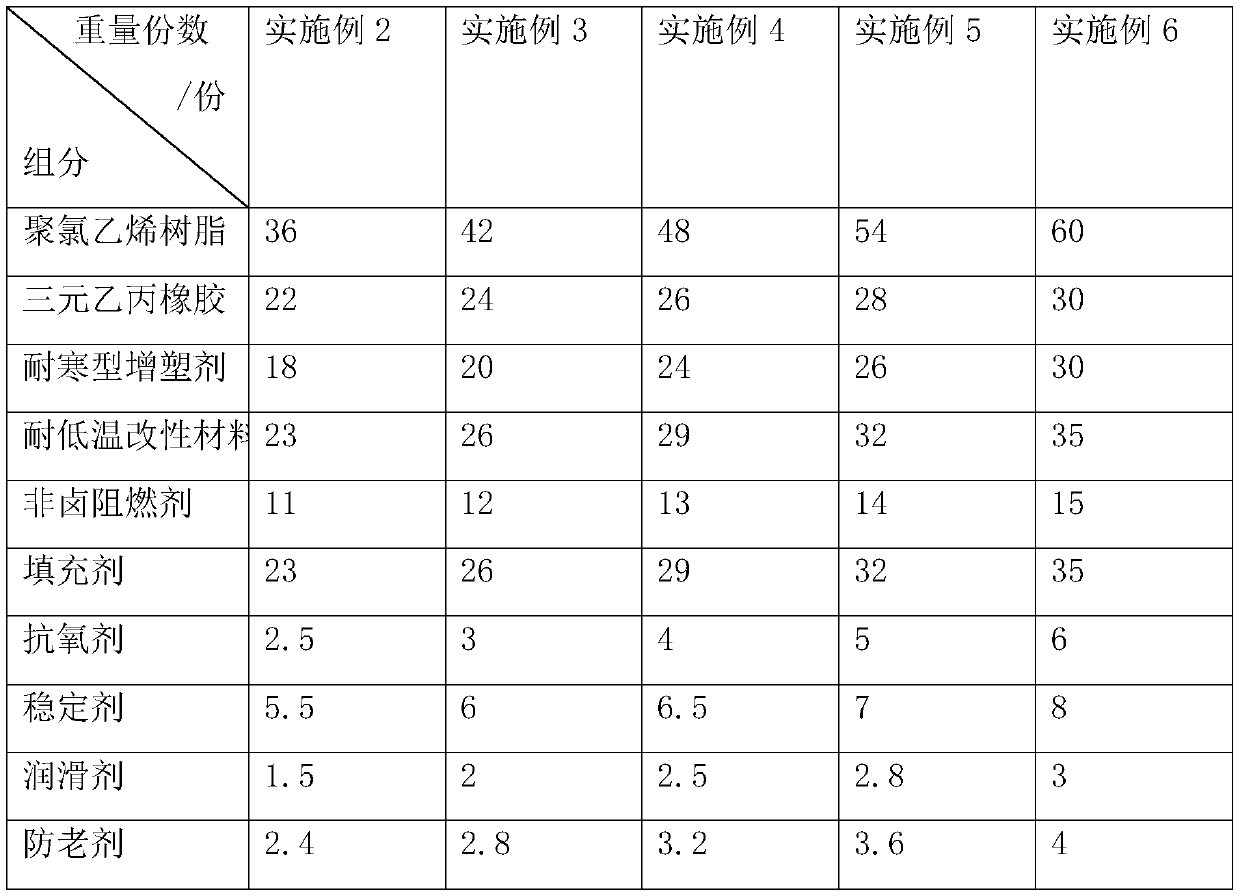

PVC/NBR cold-resistant oil-resistant flame retardant thermoplastic elastomer material for new energy automobile charging pile cable and preparation method thereof

InactiveCN107880442ABig price advantageImprove moisture resistancePlastic/resin/waxes insulatorsElastomerAntioxidant

The invention discloses a PVC / NBR cold-resistant oil-resistant flame retardant thermoplastic elastomer material for a new energy automobile charging pile cable and a preparation method thereof. The elastomer material is prepared from, by weight, 100 parts of polyvinyl chloride resin, 20-40 parts of powder butyronitrile, 30-40 parts of plasticizer A, 20-30 parts of plasticizer B, 20-30 parts of plasticizer C, 5-10 parts of stabilizer, 6-12 parts of flame retardant A, 6-12 parts of flame retardant B, 6-12 parts of flame retardant C, 0.5-1.5 parts of lubricant, 1-2 parts of antioxidant A, 1-2 parts of antioxidant B and 40-70 parts of inorganic filler. The elastomer material is high in mechanical property, good in hydrolysis resistance, strong in oil resistant property and cold resistant property and good in dispersion uniformity and low-temperature flexibility, and therefore the cable is not damaged in multiple times of tow dragging; the PVC / NBR cold-resistant oil-resistant flame retardant thermoplastic elastomer material is good in processing performance, free of particles and smooth in extrusion surface, low in cost, easy to prepare and operate, suitable for occasions on which the elastomer material needs to be frequently bent and scraped at low temperature with oil.

Owner:JIANGSUSNGSHANG CABLE GROUP

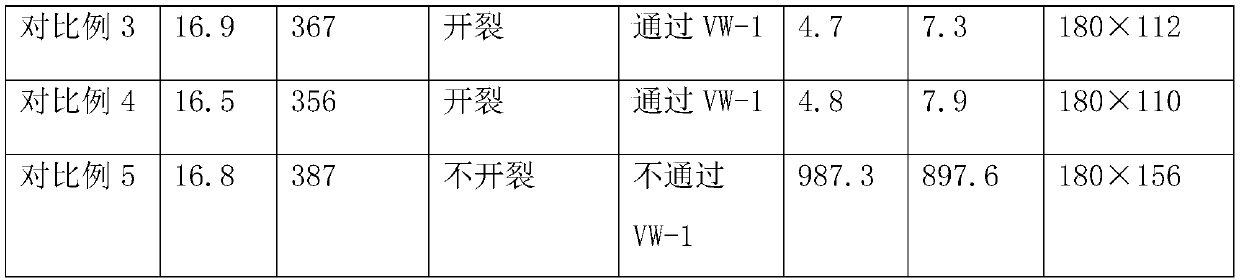

Fireproof blocking material for cables

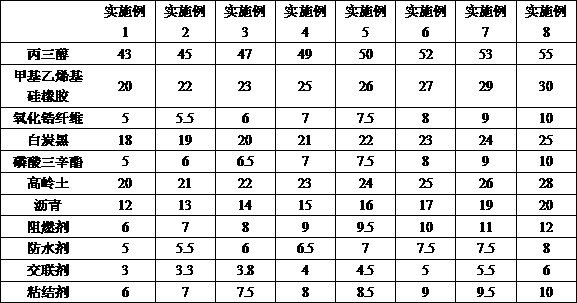

InactiveCN110079096AImprove fire performanceExtended service lifeBuilding insulationsCarbon blackGlycerol

The invention discloses a fireproof blocking material for cables and belongs to the technical field of cable blocking materials. The fireproof blocking material is prepared from raw materials in partsby weight as follows: 43-55 parts of glycerol, 20-30 parts of methyl vinyl silicone rubber, 5-10 parts of zirconium oxide fiber, 18-25 parts of white carbon black, 5-10 parts of trioctyl phosphate, 20-28 parts of kaolin, 12-20 parts of asphalt, 6-12 parts of a flame retardant, 5-8 parts of a waterproof agent, 3-6 parts of a crosslinking agent and 6-10 parts of an adhesive. The fireproof blockingmaterial has good comprehensive properties; the vertical combustion level of the material reaches level V-1 and V-2, the fireproof level is level 2 and even level 3, and the material has excellent flame retardance and fire resistance and good fireproof effects; after a water resistance test, the material has a complete surface after being soaked for 3 days, does not swell or crack and has excellent waterproof performance; after a freezing and thawing resistance test, the surface of a specimen does not crack and is not pulverized. The material is long in service life, fireproof, water-resistantand resistant to freezing and thawing erosion, can be used in the low-temperature environment for a long time and has a blocking effect.

Owner:国网河南省电力公司邓州市供电公司

Irradiation crosslinking modified ECTFE (ethylene chlorotrifluoroethylene) heat shrinkable sleeve and preparation method thereof

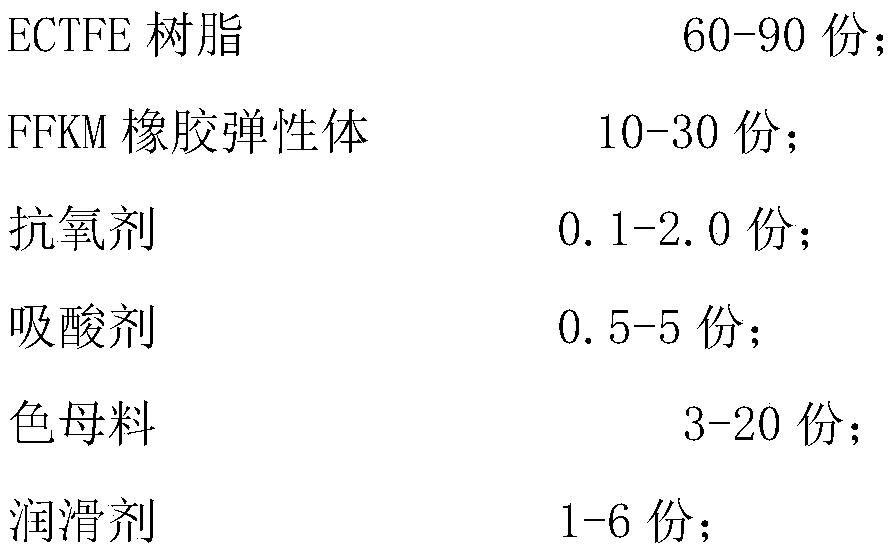

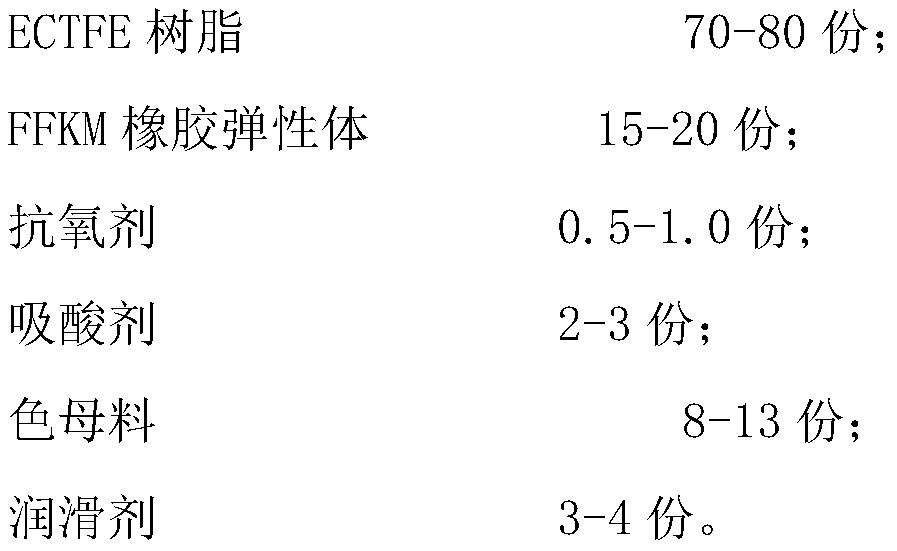

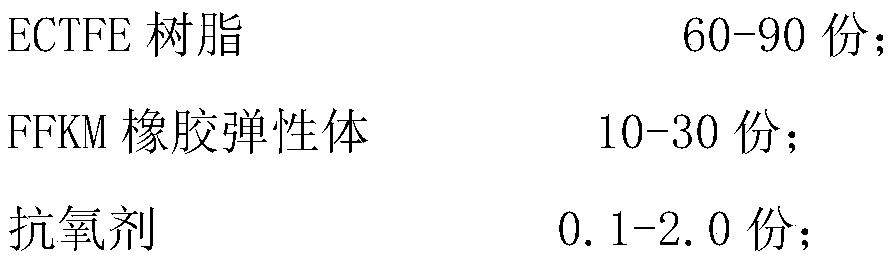

InactiveCN110256762AImprove performanceOvercome product performanceTubular articlesHeat-shrinkable sleeveElastomer

An irradiation crosslinking modified ECTFE (ethylene chlorotrifluoroethylene) heat shrinkable sleeve comprises, by weight, 60-90 parts of ECTFE resin, 10-30 parts of FFKM rubber elastomers, 0.1-2.0 parts of antioxidants, 0.5-5 parts of acid absorbers, 3-20 parts of color masterbatches and 1-6 parts of lubricants. The irradiation crosslinking modified ECTFE heat shrinkable sleeve has outstanding properties of resistance to high temperature, oil, chemical solvents, ageing, mechanical damage and corrosion, can meet requirements for long-term use at the temperature of minus 55 DEG C to 200 DEG C, and can be applicable to the fields such as military projects, automobiles, ships, high-speed trains and aerospace.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Trapezia fresh-keeping packaging bag special for single spiked vine

The present invention relates to a trapezoidal preserving packaging bag, which is exclusively used for an odd-fringe grape and is made of plastic film. The appearance of the utility model is an isosceles trapezoid which is suitable for the appearance of the odd-fringe grape. The packaging bag comprises a front and a rear trapezoid-shaped plastic films which are in the same size. The two trapezoid-shaped plastic films are overlapped together. Two shorter upper lines of the two same-size and overlapped trapezoid-shaped plastic film thermally combined together; two longer bottom lines are not thermally sealed; so the trapezoidal odd-fringe grape exclusive preserving packaging bag with the bottom lines open is formed. The same intermittent slots or lunules are regularly and evenly distributed on the front and the rear trapezoid-shaped plastic films. So the preserving is even and good; the grape extruding and damaging caused by being piled up in a box are avoided; the preserving time limit of the odd-fringe grape is easily controlled at the same time; the transforming and marketing can be well-planed; partly rotting is avoided; and the marketing cost is reduced.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Root-resisting TPO (thermoplastic polyolefin) waterproof coating and preparation process thereof

The invention discloses a root-resisting TPO (thermoplastic polyolefin) waterproof coating and a preparation process thereof. The root-resisting TPO waterproof coating comprises the following components in percentage by weight: 30-50 percent of TPO (thermoplastic polyolefin), 10-30 percent of EPPE (Easy Processing Polythene), 4-8 percent of root resisting agent, 5-15 percent of active calcium, 1-5 percent of anti-aging agent, 10-35 percent of aromatic hydrocarbon oil and 1-4 percent of plasticizer DOP (Dioctyl-Phthalate). The root-resisting TPO waterproof coating has the advantages of convenient construction, good aging resistance, high tensile strength, large elongation, no need of a protection layer during exposure, and low cracking rate of a coating layer after the coating is cured; and a good waterproof effect can be kept for a long time.

Owner:王勇

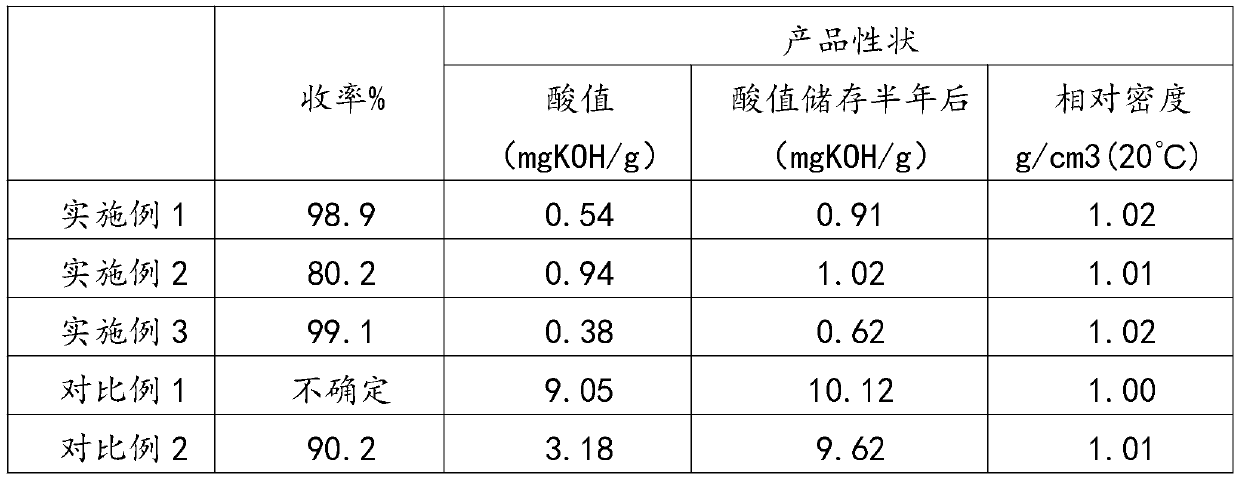

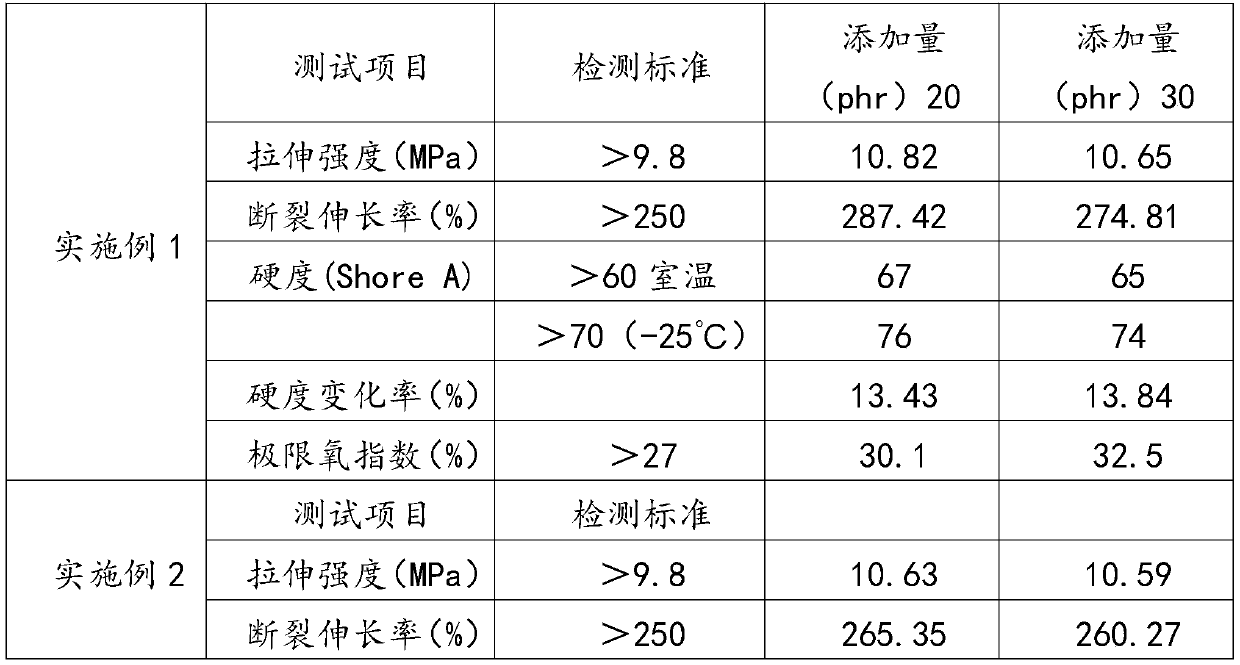

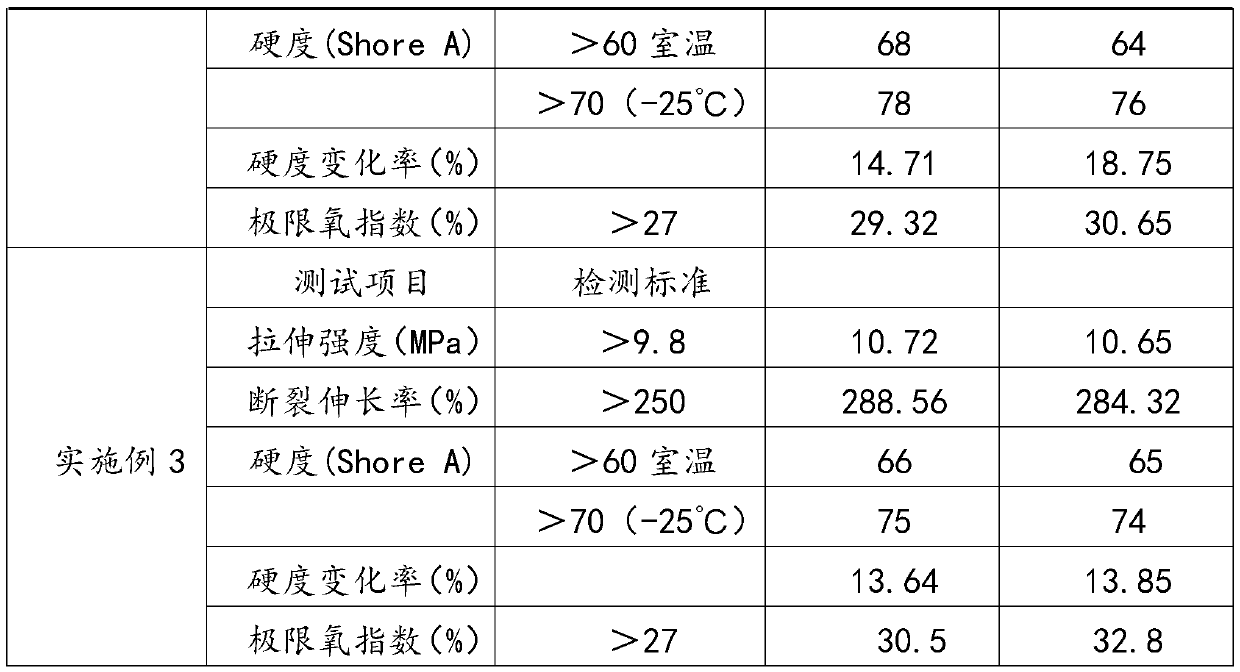

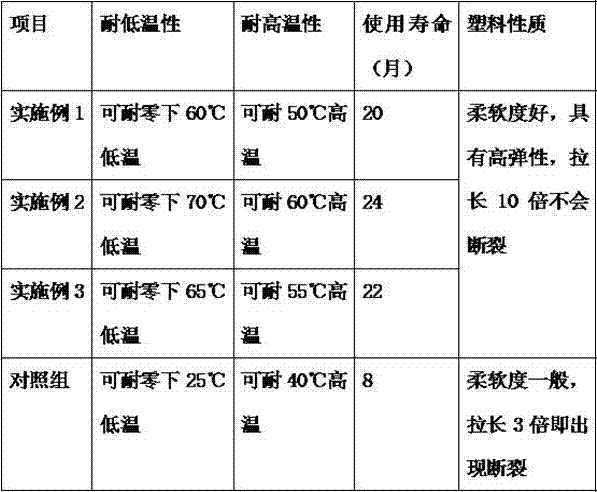

Stable-type phosphate plasticizer and preparing method thereof

InactiveCN109796627AGood softness at low temperatureImprove cold resistancePhosphorus organic compoundsCelluloseStrong acids

The invention belongs to the technical field of chemical auxiliaries, and particularly relates to a stable-type phosphate plasticizer and a preparing method thereof. The preparing method comprises thefollowing steps of 1, filtering out strong-acid-type ion exchange resin after phosphorus oxychloride and alcohol ether are subjected to an esterfication reaction to obtain a crude phosphate plasticizer; 2, adding a stabilizer into the obtained crude phosphate plasticizer, wherein the addition amount of the stabilizer accounts for 0.05-3% of the dry weight of phosphate. The prepared stable-type phosphate plasticizer has high contents of oxygen and phosphorus, has flame-retardant and plasticizing effects on polyurethane rubber, cellulose, engineering plastics and the like, and has good cold tolerance, so that products are endowed with higher low-temperature softness; meanwhile, the phosphate product into which the stabilizer is added can still have the acidity smaller than 1 mg KOH / g afterbeing stored for half a year; the problem of acid reflux of the phosphate product in the storage process is solved.

Owner:天津利海石化有限公司

Durable PVC (polyvinyl chloride) bionic bait

The invention relates to the technical field of research, development and processing of fishing gear and discloses durable PVC (polyvinyl chloride) bionic bait. The bait is prepared from the components as follows: PVC, DHP (dihexyl phthalate), dibutyl sebacate, epoxidized soybean oil, tricresyl phosphate, citrate, diol fatty acid ester, dipentaerythritol, diol benzoate, zinc stearate, calcium stearate, ash calcium powder, talcum powder, an aluminate coupling agent, titanium dioxide and an antibacterial agent, the PVC is used as the main material, the rest components are added to enhance the performance of PVC, the PVC has excellent low-temperature resistance, the brittle temperature of a product can be decreased to subzero 70 DEG C-subzero 30 DEG C, the low-temperature softness is better, the heat resistance and weather resistance are higher, the service life of the bionic bait can be prolonged, the recycling rate is high, and the used inorganic antibacterial agent can be dispersed uniformly in the biotic bait and can play the antibacterial role for a long term.

Owner:界首市汇珠渔具有限公司

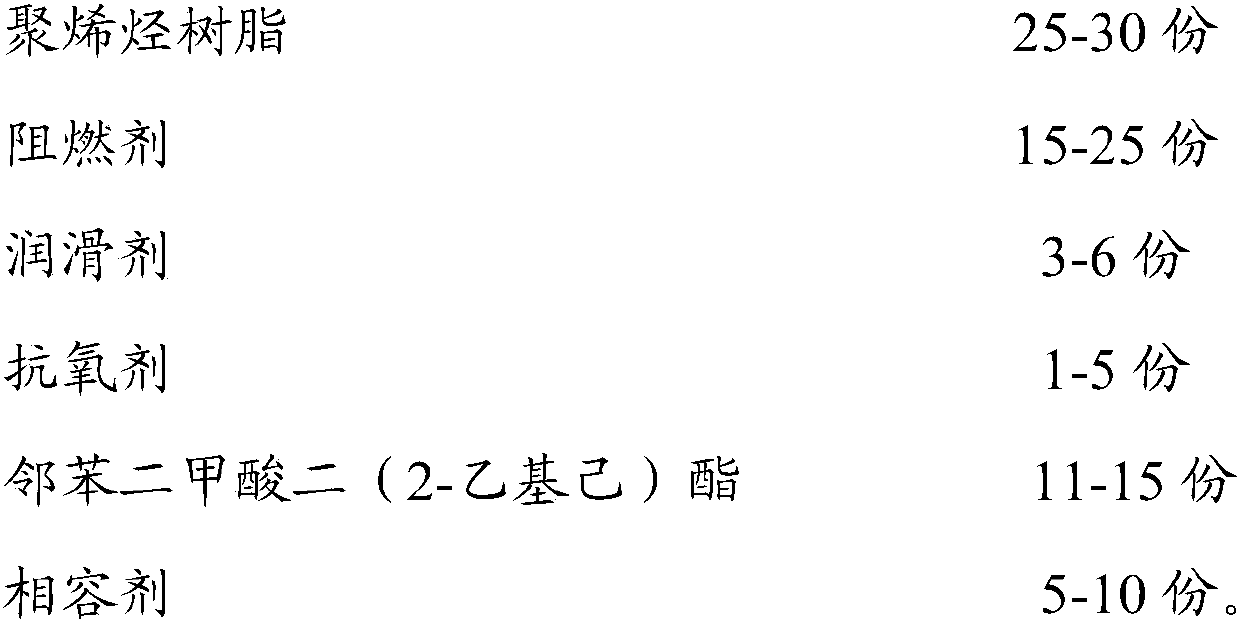

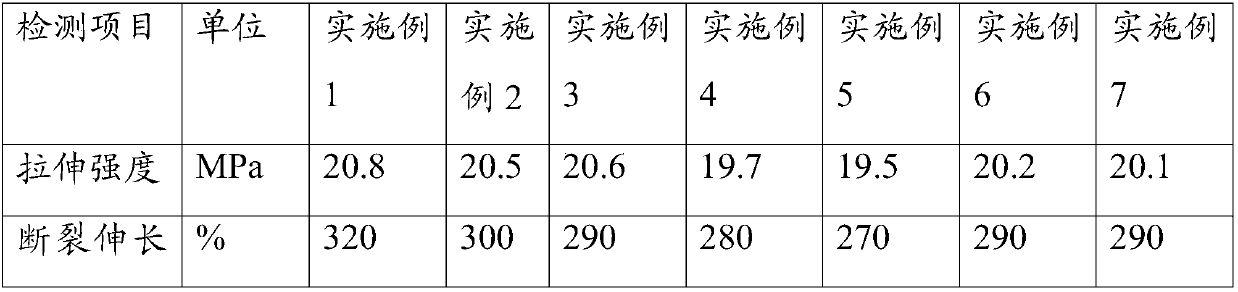

Flame-retardant cable material and preparation method thereof

InactiveCN110564031AHigh impact strengthImprove flex resistancePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a flame-retardant cable material which comprises the following components in parts by weight: 25-30 parts of polyolefin resin, 15-25 parts of a flame retardant, 3-6 parts of alubricant, 1-5 parts of an antioxidant, 11-15 parts of phthalic acid di(2-ethylhexyl) ester and 5-10 parts of a compatilizer. The cable material prepared by using a preparation method disclosed by theinvention has good effects of flame retardancy and fire resistance, high temperature resistance and electric insulation.

Owner:天龙伟业线缆有限公司

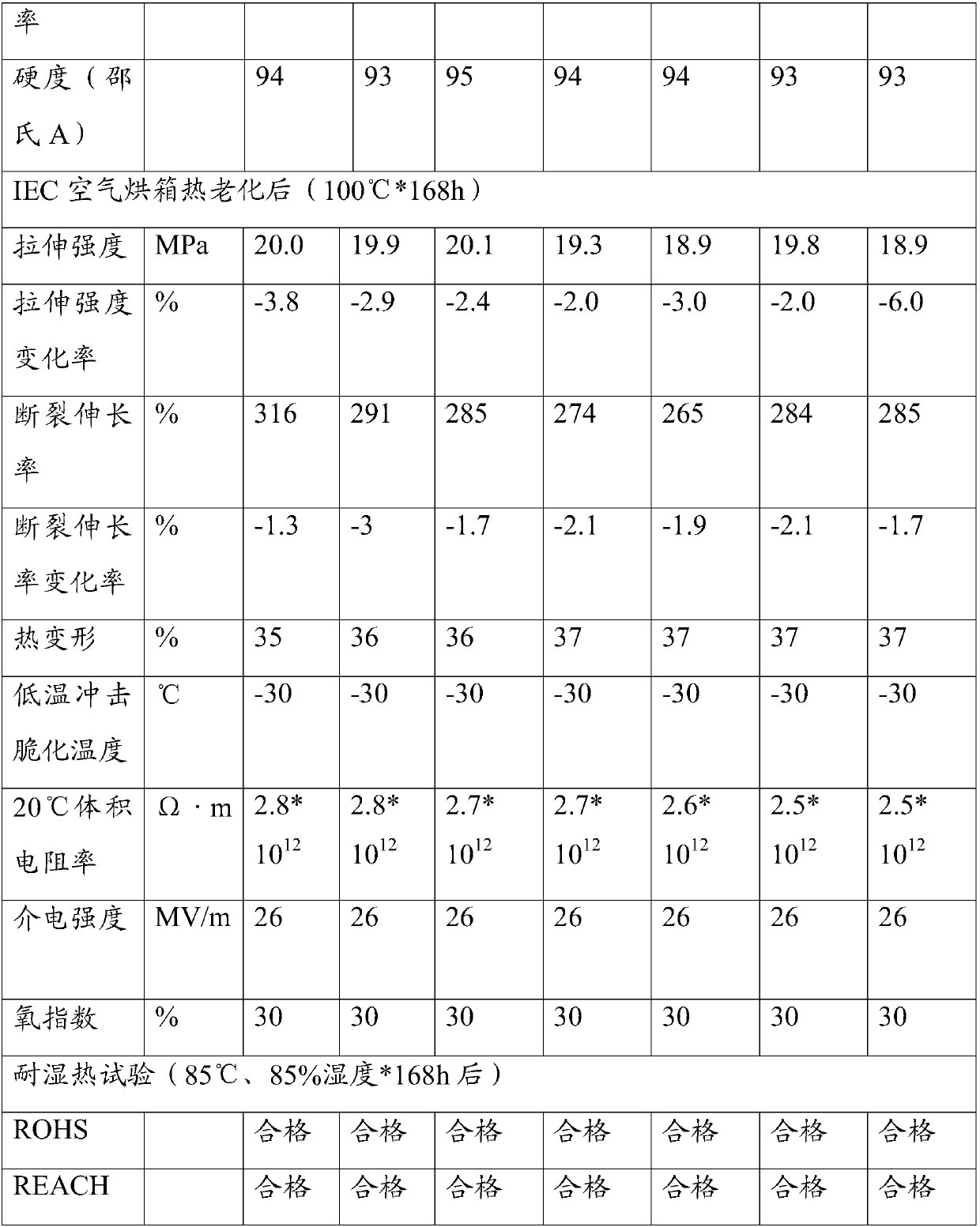

Polycarbonate diol composition

PendingCN114555670AGood softness at low temperatureExcellent heat and humidity resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceCarbonate ester

A polycarbonate diol composition containing a polycarbonate diol having a structure represented by general formula (I) and a polycarbonate structure represented by general formula (II), the polycarbonate diol composition having a melt viscosity at 50 DEG C of 1000-10000 mPa * s, and the average value of the number of repetitions (n11) in general formula (I) being 12 or more.

Owner:ASAHI KASEI KK

Polyurethane resin for high-density shoe leather and preparation method thereof

ActiveCN102181034BLow costGood softness at low temperatureTextiles and paperN dimethylformamidePolymer science

The invention relates to wet-process polyurethane resin for high-density shoe leather. The polyurethane resin is prepared from isocyanate, a polyether polyol mixture, a chain extender and N, N-dimethylformamide serving as an organic solvent. Polyoxytetramethylene-ethylene epoxide copolyether diol and polyoxypropylene diol are taken as macromolecular polylol raw materials for reacting, the raw materials have high hydrolysis resistance and the polyurethane resin can be endowed with high low-temperature flexibility and rebound resilience, so that the prepared high-density shoe leather has finer folds, high durability and high low-temperature adaptability, and recovers quickly. On the aspect of synthesis technology, a special process for stepwise reaction of two polyether polyols is designed,so that a macromolecular structure is more regular, and advantages of the two polyether polyols can be brought into play.

Owner:SHANGHAI HUIDE TECH CO LTD

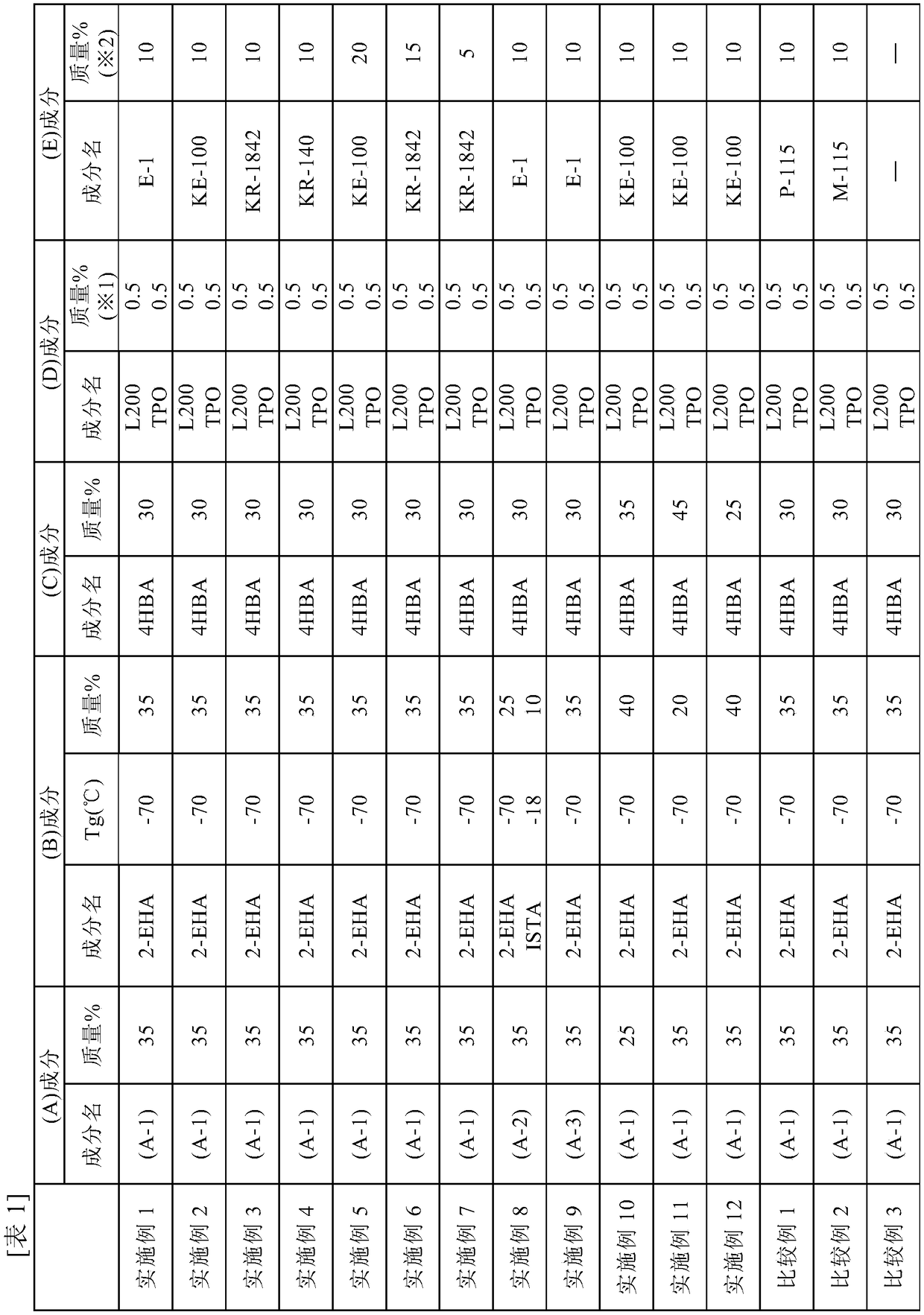

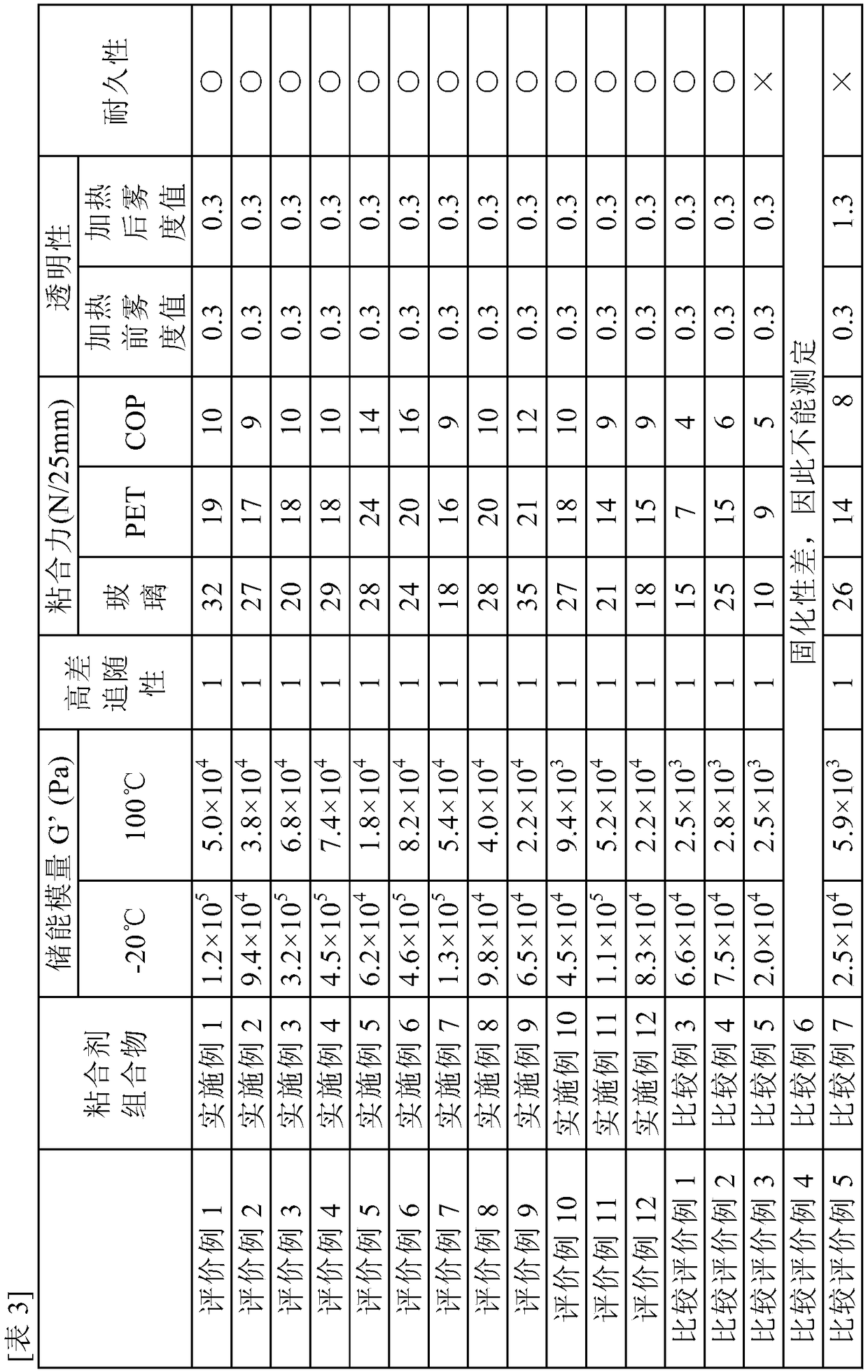

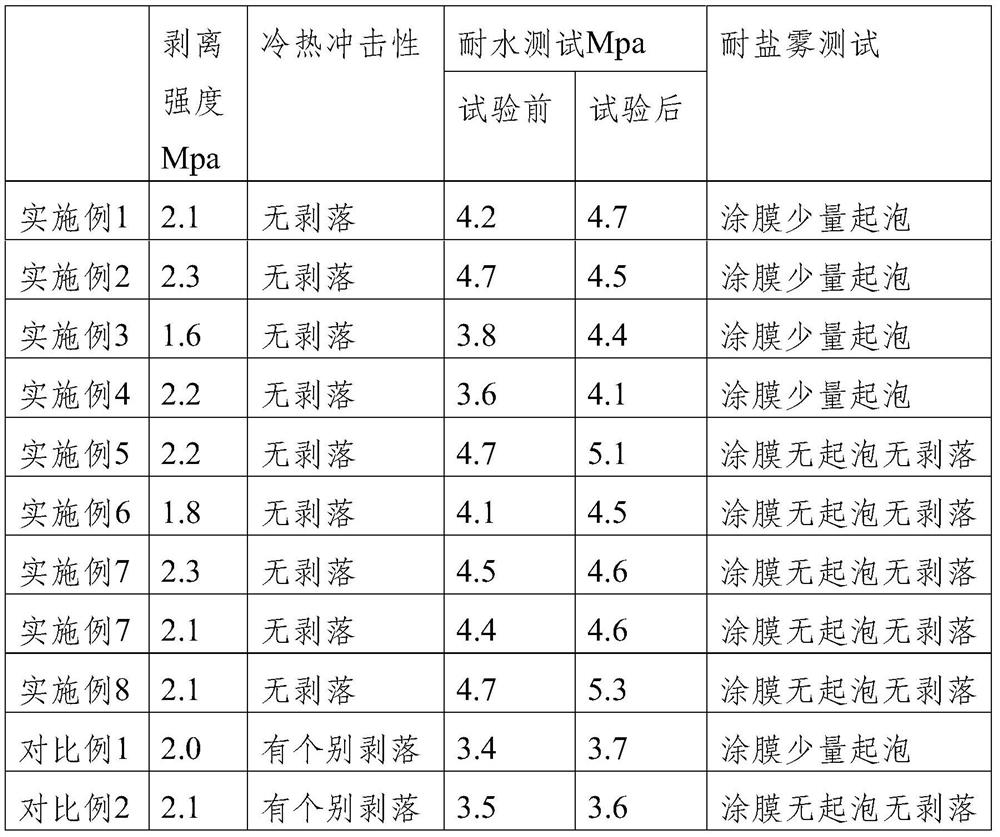

Ultraviolet ray-curable adhesive agent, cured product, and adhesive sheet

ActiveCN109294509AIncreased durabilityImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveUltraviolet

The invention relates to an ultraviolet ray-curable adhesive agent, a cured product, and an adhesive sheet. An ultraviolet ray-curable adhesive agent having no solvent in nature is provided. Even if asingle adhesive layer has good flexibility under lower temperature and indoor temperature, and has good adhesiveness to base material like COP with low polarity. The adhesive comprises polyether polyol (a1), polyisocyanate (a2), monomethyl acrylate (a3) containing hydroxyl or polyurethane (methyl) acrylate (A) having reactant of monomethyl acrylate containing isocyanate group, polymer monomer (B)having no hydroxyl group whose vitrification conversion temperature is above -70 DC and lower than 0DC at the time of forming homopolymer, monomethyl acrylate (C) having hydroxyl group, photopolymerization initiator (D), and viscosity resin (E) which is selected from at least one of petroleum resin having hydroxy group, dismuted rosin resin and hydrogenated rosin resin with softening point being100-150 DC.

Owner:ARAKAWA CHEM IND LTD

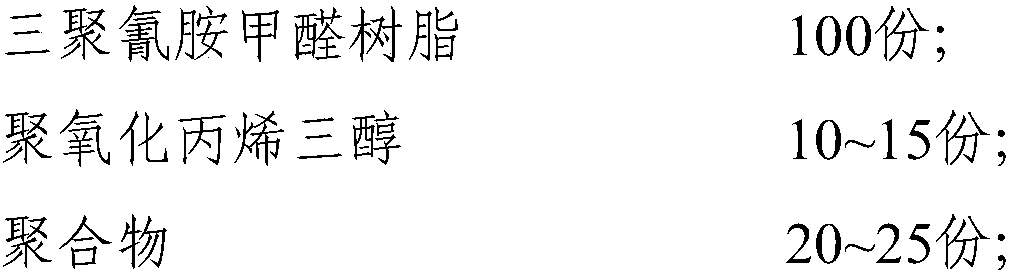

A kind of clear water anti-seepage glue and its preparation method and application

ActiveCN106009506BGood softness at low temperatureHigh ability to adapt to deformationPolymer scienceAdhesive

The invention relates to the field of organic high-polymer materials, and particularly provides a low-temperature-resistant high-ductility anti-seepage adhesive, and a preparation method and application thereof. The preparation method comprises the following steps: by using a melamine formaldehyde resin as a main material and polyoxypropylene triol as an NCO prepolymer, carrying out reaction with a polymer (TDI (toluene diisocyanate) and / or MDI (methylenediphenyl diisocyanate)) under the action of a thixotropic agent (silicon dioxide) and a tin catalyst in the presence of polypropylene glycol to form a uniform high-polymer flexible material, and mixing with a filler to obtain the anti-seepage adhesive which has the advantages of no pollution, low specific gravity, high ductility, high deformation adaptability, favorable corrosion resistance, favorable low-temperature resistance, favorable freezing resistance and no water permeability. The anti-seepage adhesive has the characteristics of favorable low-temperature flexibility, no crack at -30 DEG C, no water permeability, high stretching resistance (3.10 MPa) and high elongation percentage (1211%). The anti-seepage adhesive can effectively obstruct seepage of earthfill dams, earth water passages and the like, and is a novel synthetic soil engineering anti-seepage material with wide market prospects.

Owner:江西合盛安泰新材料有限公司

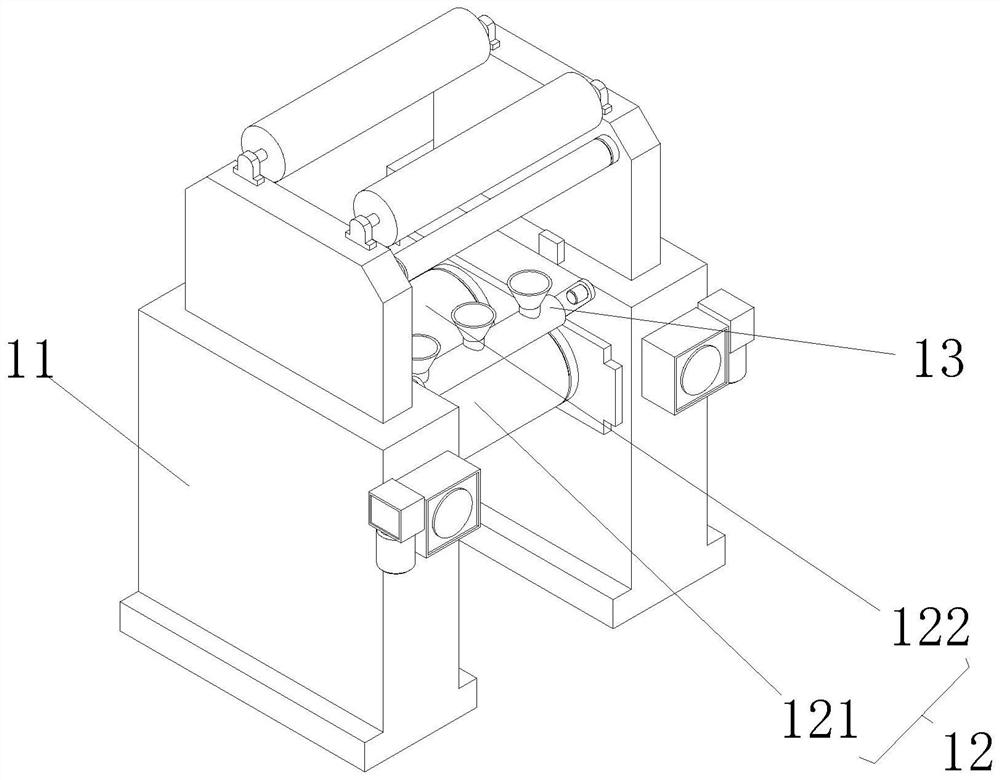

Ultra-low temperature resistant environment-friendly flexible cable and preparation method thereof

InactiveCN109360682BImprove cold resistanceGood softness at low temperaturePlastic/resin/waxes insulatorsClimate change adaptationCopper conductorPolyvinyl chloride

Owner:青岛长城巨龙电缆有限公司

A kind of one-component reactive polyurethane hot melt adhesive and preparation method thereof

ActiveCN109666441BHigh plasticizing efficiencyReduce volatilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a one-component reactive polyurethane hot-melt adhesive. The raw material composition includes a polyurethane prepolymer, a chain extender, a tackifying resin, a latent curing agent, and a filler. The polyurethane prepolymer has a molecular weight of 500- 3000 polyol, polyisocyanate and catalyst are polymerized; the raw material composition also includes a plasticizer, and the plasticizer is dioctyl phthalate and / or diethylene glycol dibenzoate. In the component of one-component reactive polyurethane hot-melt adhesive of the present invention, by adding plasticizer, plasticizer is dioctyl phthalate and / or diethylene glycol dibenzoate, and above-mentioned two kinds of materials are for polyurethane The plasticizing efficiency is high, the volatility is low, and it has good low-temperature flexibility. The addition of plasticizers weakens the interaction between the polymer chains and improves the elasticity and flexibility of the polymer material. , Improve the high and low temperature resistance of hot melt adhesives.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Mildew-proof cold-resistant nitrile rubber material and preparation method thereof

PendingCN114854105AGood extensibilityIncrease forceRolling resistance optimizationPolymer scienceDibutyl sebacate

The invention provides a mildewproof cold-resistant nitrile rubber material and a preparation method thereof. The mildewproof cold-resistant nitrile rubber material comprises the following substances in parts by weight: 65 parts of first nitrile rubber, 35 parts of second nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 203 parts of an anti-aging agent 403, 23 parts of dibutyl sebacate, 120 parts of spray carbon black, 0.4 part of pre-dispersed sulfur, 2 parts of an accelerant TMTD, 2 parts of an accelerant CZ and 2 parts of a mildewproof agent. The nitrile rubber material has mechanical properties, cold resistance, oil resistance and mildew resistance at the same time.

Owner:SHENYANG RUBBER RES & DESIGN INST CO LTD

A kind of protective film of curved surface element and preparation method thereof

ActiveCN108690516BHigh elongationHigh tensile strengthFilm/foil adhesivesPolymer sciencePolymer resin

The invention belongs to the field of protective films, and discloses a protective film for curved surface elements, which comprises a first polymer resin mixed layer, a second polymer resin mixed layer, an adhesive layer, and a release film from top to bottom, in parts by weight The composition of the first polymer resin mixed layer is: 20-30 parts of TPU, 6-10 parts of filler, 5-10 parts of anti-wear agent, 2-4 parts of dispersant, 4-8 parts of antistatic agent , 0.2 to 0.5 parts of leveling agent; the composition of the second polymer resin mixed layer is: 15 to 25 parts of TPU, 2 to 5 parts of filler, 1 to 2 parts of dispersant, 5 to 8 parts of adhesion promoter , 0.1 to 0.4 parts of wetting agent. The invention also discloses a preparation method of the protective film. The protective film of the present invention can be used on flat and curved display elements, the film is soft, has high elongation, the protective film has good conformability to curved surfaces, and the stretched film is not easy to be stretched, broken and deformed; the protective film is scratch-resistant Good performance, oil resistance, waterproof and dustproof.

Owner:HUIZHOU YIDU IMAGE TECH

Polyvinyl chloride/sulfonated cis-butadiene rubber and preparation method thereof

ActiveCN101704977BImprove cold resistanceGood softness at low temperaturePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl chloride

The invention relates to the field of electric wire and cable material manufacture, in particular to a polyvinyl chloride / sulfonated cis-butadiene rubber and a preparation method thereof. The polyvinyl chloride / sulfonated cis-butadiene rubber has excellent cold resistance and low temperature flexibility. In the method, the sulfonated cis-butadiene rubber is added to improve the cold resistance and the low temperature flexibility of polyvinyl chloride. The cis-butadiene rubber is the rubber with the best low temperature performance, the brittle point is 110 DEG C below zero which is far lower than that of 35 DEG C below zero of acrylonitrile-butadiene rubber, and the low temperature resilience of the cis-butadiene rubber is the best in conventional rubber. However, the cis-butadiene rubberis non-polar rubber and has poor intermiscibility with the polyvinyl chloride, and sulfonate polar groups are introduced into molecular chains after the sulfonation reaction of the cis-butadiene rubber, so the intermiscibility between the cis-butadiene rubber and the polyvinyl chloride is greatly improved to form an even blending system.

Owner:JIANGSU HENGFENG CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com