Stable-type phosphate plasticizer and preparing method thereof

A type of phosphoric acid ester and plasticizer technology, applied in the direction of phosphorus organic compounds, etc., can solve the problems of increasing acid value, easy to return to acid, poor stability, etc., achieve good low temperature softness, solve acid return, and good cold resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

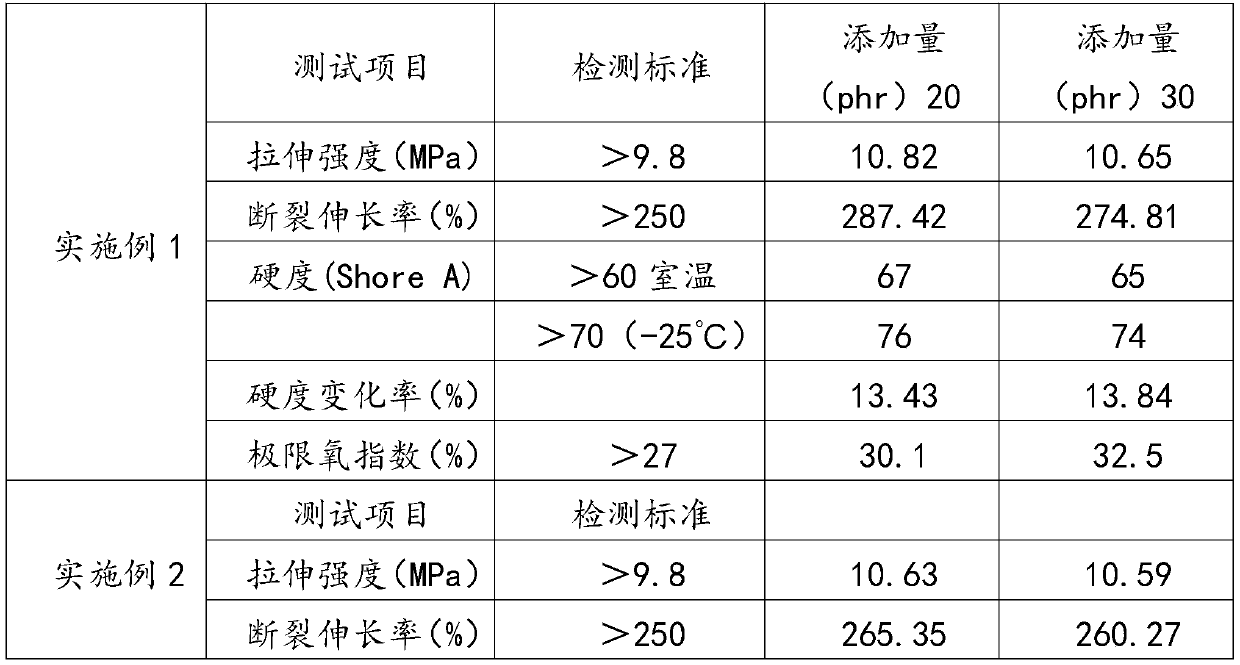

Embodiment 1

[0020] Embodiment 1: in the 2000ml four-necked bottle that is equipped with heating, stirring and vacuum device, add 1020.6g

[0021] (3.15mol) diethylene glycol butyl ether and 5g (5‰) strong acid ion exchange resin Amberlyst-15, join 153.5g (1mol) phosphorus oxychloride in the constant pressure dropping funnel, open vacuum pump, form vacuum Finally, the operator opens the cooling inlet and outlet valves of the four-necked bottle glass condenser in turn, starts stirring, and controls the pressure in the four-necked bottle to 80-98Kpa. After the pressure in the four-necked bottle is stable, turn on the electric heating mantle to heat, raise the temperature to 80°C, slowly turn on the switch of the constant pressure dropping funnel, slowly add phosphorus oxychloride into the four-necked bottle, and raise the temperature to 130-135°C After equilibrating for 5 hours, after the acid value is qualified, filter out the strong acid ion exchange resin. In normal operation, the strong ...

Embodiment 2

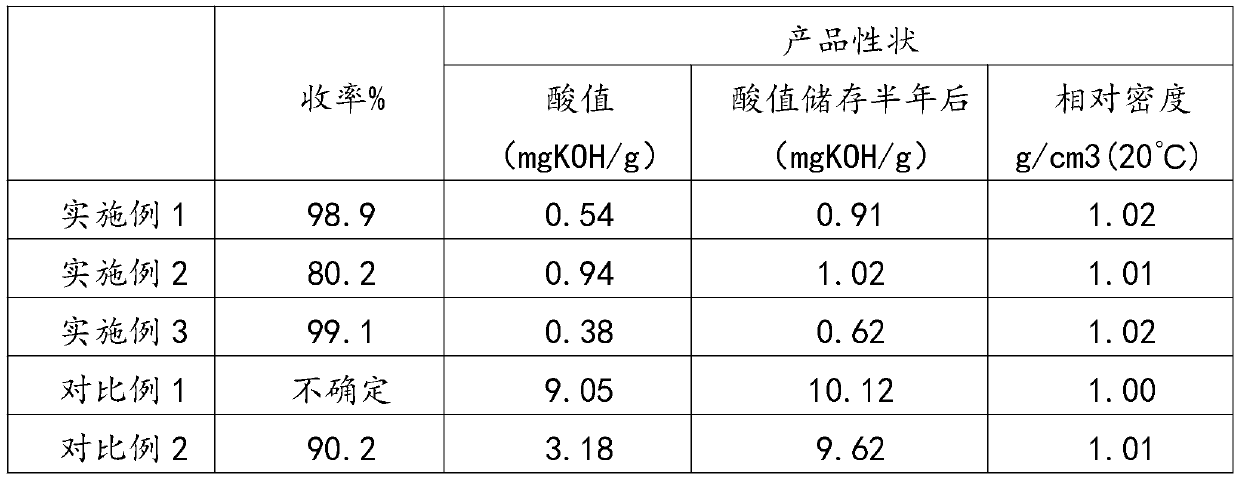

[0022] Embodiment 2: the operating steps of embodiment 2 and embodiment 1 are basically the same, and the only difference is that alcohol ether is diethylene glycol butyl ether, and the addition of catalyst is 3‰ of alcohol ether, phosphorus oxychloride and alcohol ether The molar ratio is 1:2.5. The temperature is 110-120°C. Neutralization was carried out with 0.05% 1-butyl-2,3-dimethylimidazolium hydroxide on the dry weight of the phosphate ester. The product properties are as shown in Table 1:

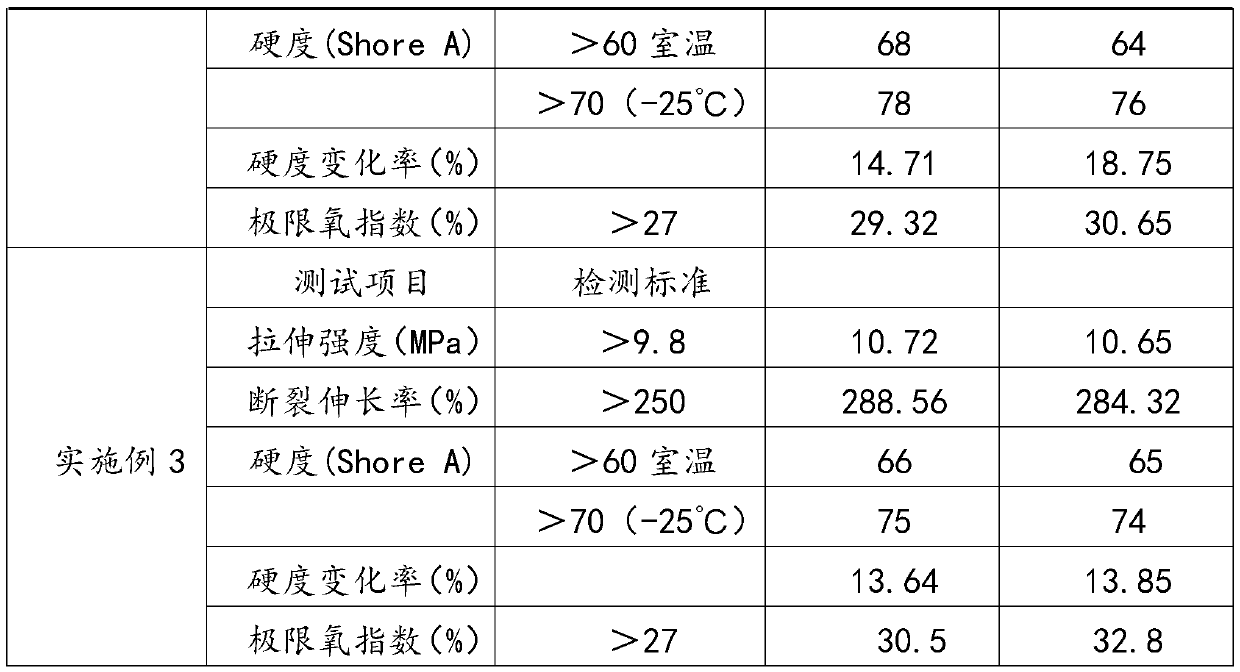

Embodiment 3

[0023] Embodiment 3: the operating steps of embodiment 3 are basically the same as embodiment 1, the only difference is that the alcohol ether is dipropylene glycol butyl ether, and the addition of the catalyst is 10‰ of the alcohol ether; the catalyst is NKC-9, phosphorus oxychloride The molar ratio with alcohol ether is 1:3.5. The temperature is 140-150°C. Neutralization was carried out with 3% 1-butyl-2,3-dimethylimidazolium hydroxide on the dry weight of the phosphate ester. The traits are shown in Table 1:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com