Mildew-proof cold-resistant nitrile rubber material and preparation method thereof

A technology of nitrile rubber and nitrile rubber, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of cold resistance, oil resistance, poor mildew resistance, and no mechanical properties of nitrile rubber materials, and achieve mildew resistance. Good, small compression set, the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

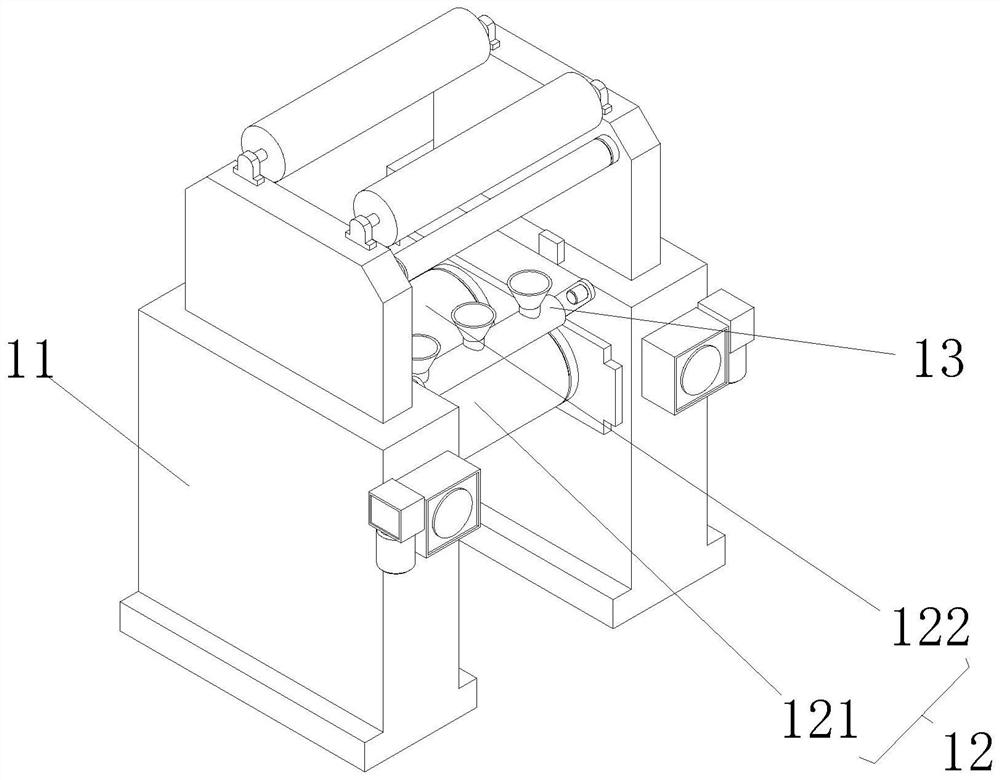

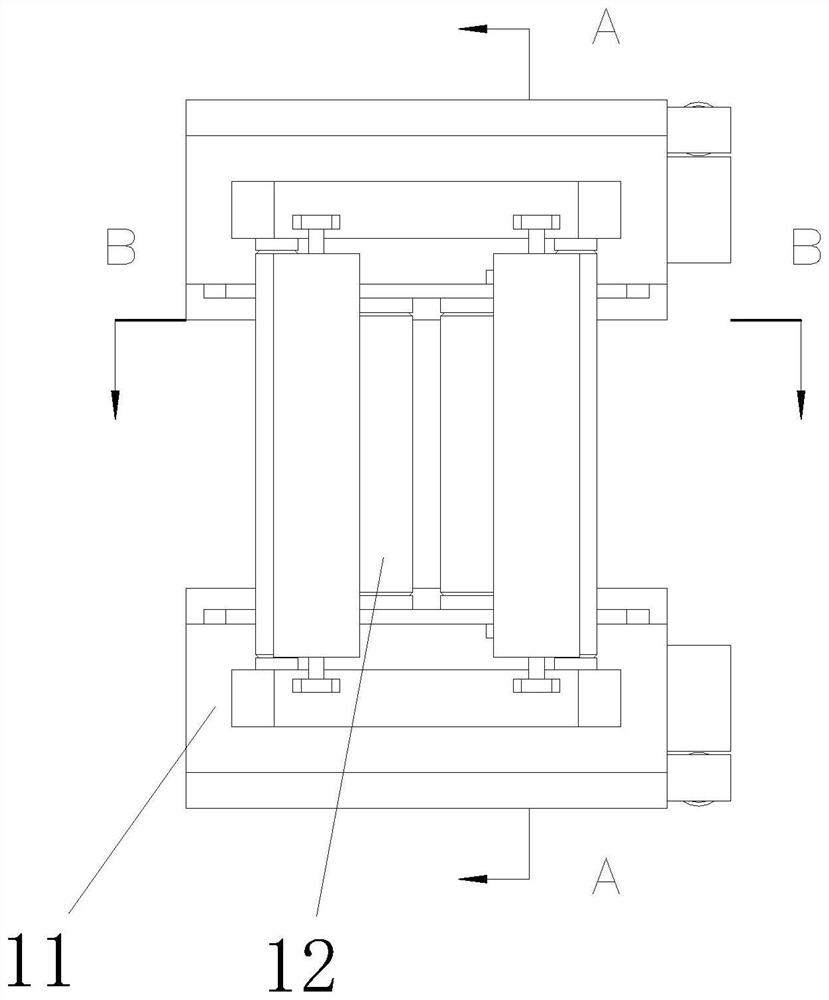

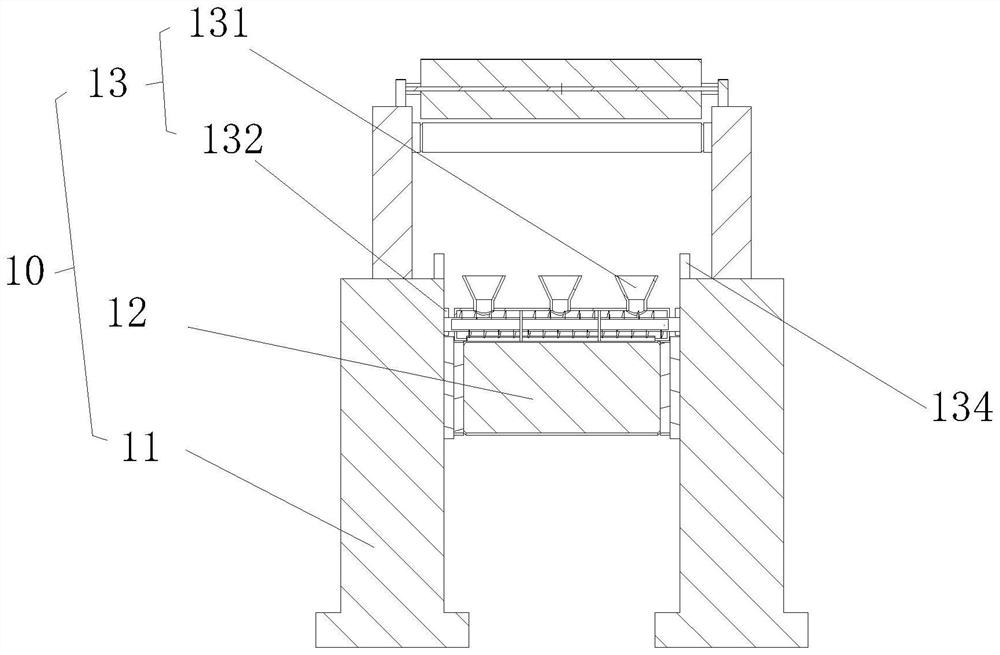

[0052] For example, please refer to the appendix Figure 1-8 , a mildew-proof and cold-resistant nitrile rubber material, comprising the following substances by weight:

[0053] No. 1 Nitrile rubber 65 parts

[0054] The second nitrile rubber 35 parts

[0055] 5 parts zinc oxide

[0056] 1 part stearic acid

[0057] Anti-aging agent 4020 3 parts

[0058] 23 parts of dibutyl sebacate

[0059] Spray carbon black 120 parts

[0060] Pre-dispersed sulfur 0.4 part

[0061] Accelerator TMTD 2 parts

[0062] Accelerator CZ 2 parts

[0063] 2 parts of mildew inhibitor;

[0064] It should be noted that, in this embodiment, the first NBR is made of NBR1704 NBR with acrylonitrile content of 17-20%, and the second NBR is made of NBR1704 with acrylonitrile content of 27-30%. NBR2707 nitrile rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com