Polyolefin thermoplastic elastomer blending resin and preparation method thereof

A thermoplastic elastomer, polyethylene resin technology, applied in the field of polyolefin blend resin, can solve problems such as reduced air permeability, and achieve the effects of easy handling, avoiding toxicity problems, and good low-temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

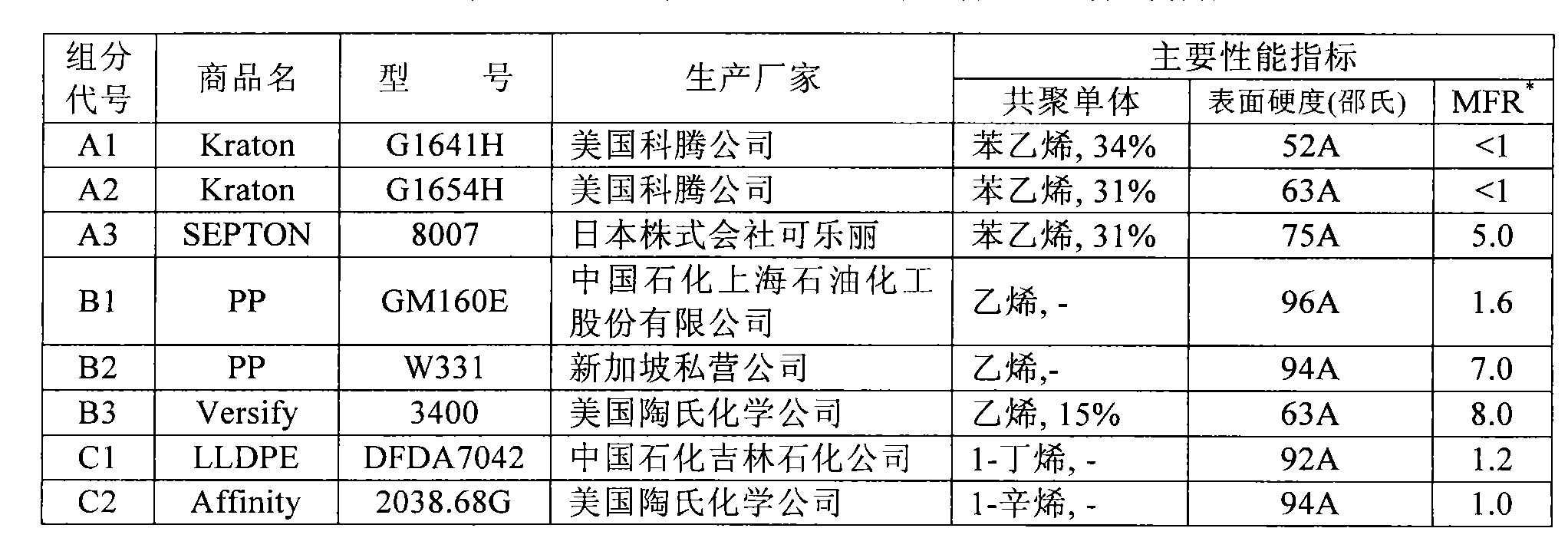

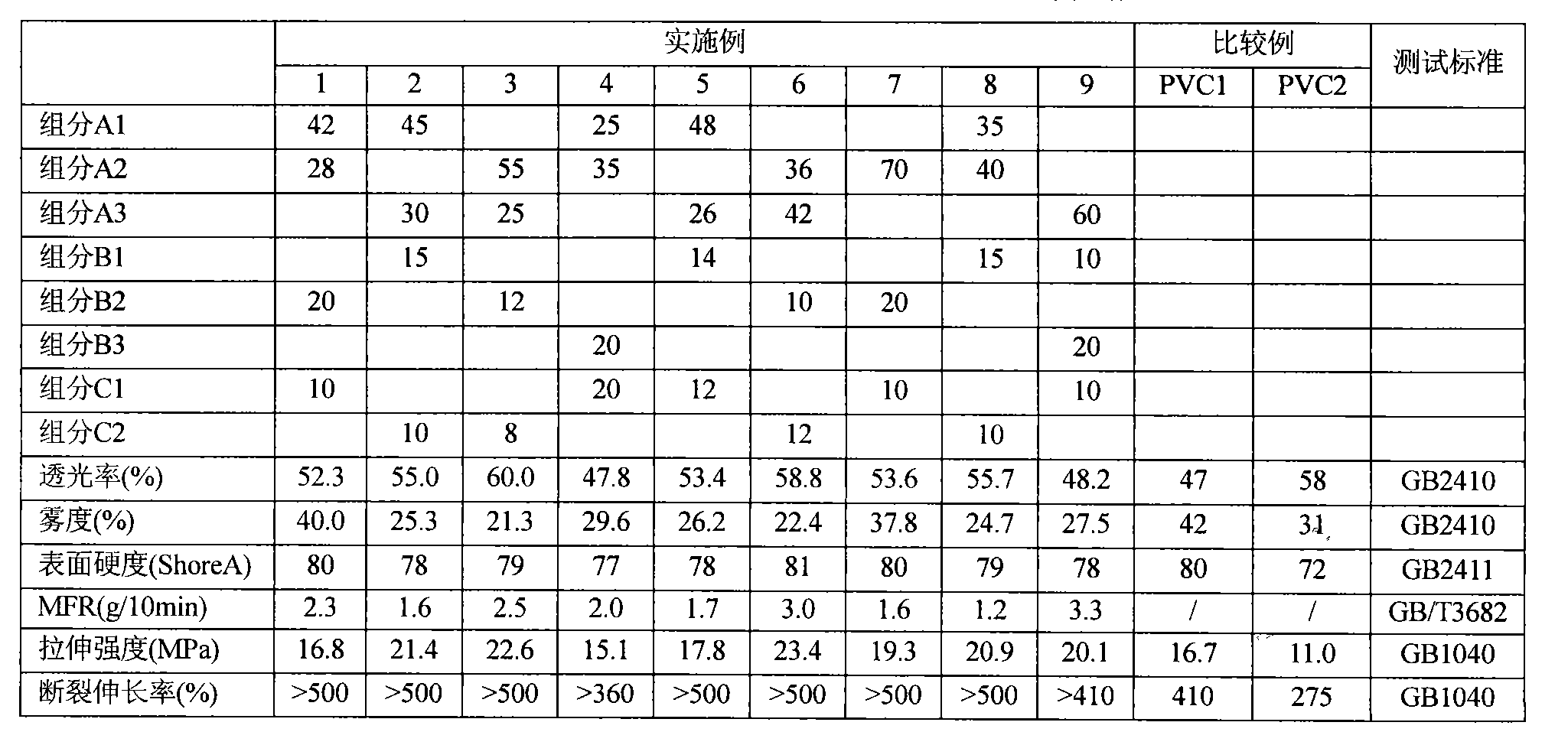

[0015] Example 1 According to the weight ratio of 42 / 28 / 20 / 10, the components A1, A2, B2 and C1 were formulated into a blended resin, and mixed in a high-speed mixer for 5 minutes to obtain a premix. The above-mentioned premixed material is transported to a reactive twin-screw extruder. The screw diameter of the extruder is 40mm, and the aspect ratio is 36. The temperature of the extruder along the feeding port to the die is set at 140-230°C. The die temperature was 220°C. The blend was extruded through a die, cooled, and pelletized to obtain a blended resin, and the melt flow rate was tested. The blended resin was molded into a standard sample of 0.5 mm to test its light transmittance and haze; the blended resin was injected into a standard sample to test the surface hardness and mechanical properties. The test results are summarized in Table 2.

Embodiment 2

[0016] Example 2 According to the weight ratio of 45 / 30 / 15 / 10, the components A1, A3, B1 and C2 are formulated into a blended resin, except that the temperature of the extruder along the feeding port to the die is set at 150-240 °C and Except that the die temperature was set at 230°C, the equipment, processing conditions and steps used were the same as in Example 1, and the same method as in Example 1 was used for sample preparation, and the corresponding performance indicators were tested. The results are listed in Table 2 middle.

Embodiment 3

[0017] Embodiment 3 Components A2, A3, B2 and C2 are formulated into blended resins according to the weight ratio of 55 / 25 / 12 / 8. The equipment, processing conditions and steps used are all the same as in Example 2. The same method as Example 1 was used for sample preparation, and the corresponding performance indicators were tested. The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com