Protection film of curve surface element and preparation method thereof

A technology of protective film and components, which is applied in the field of protective film of curved surface components and its preparation, can solve the problems of high price, and achieve the effect of good conformability of curved surface, wide application range, and not easy to stretch, break and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

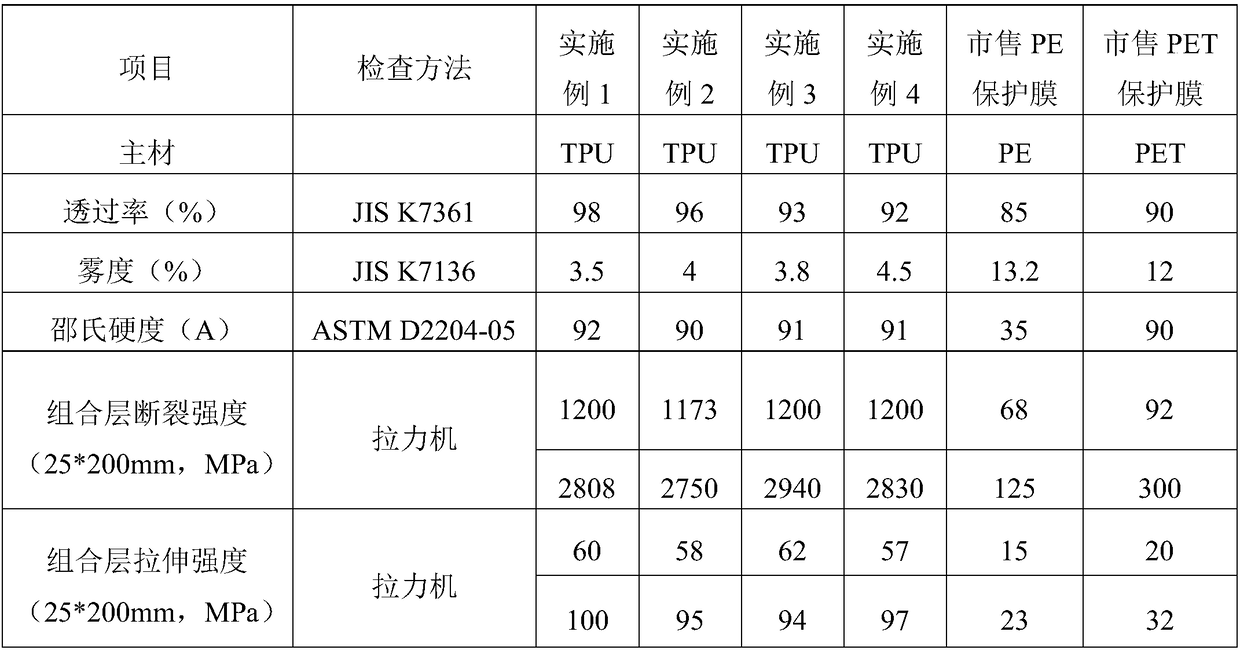

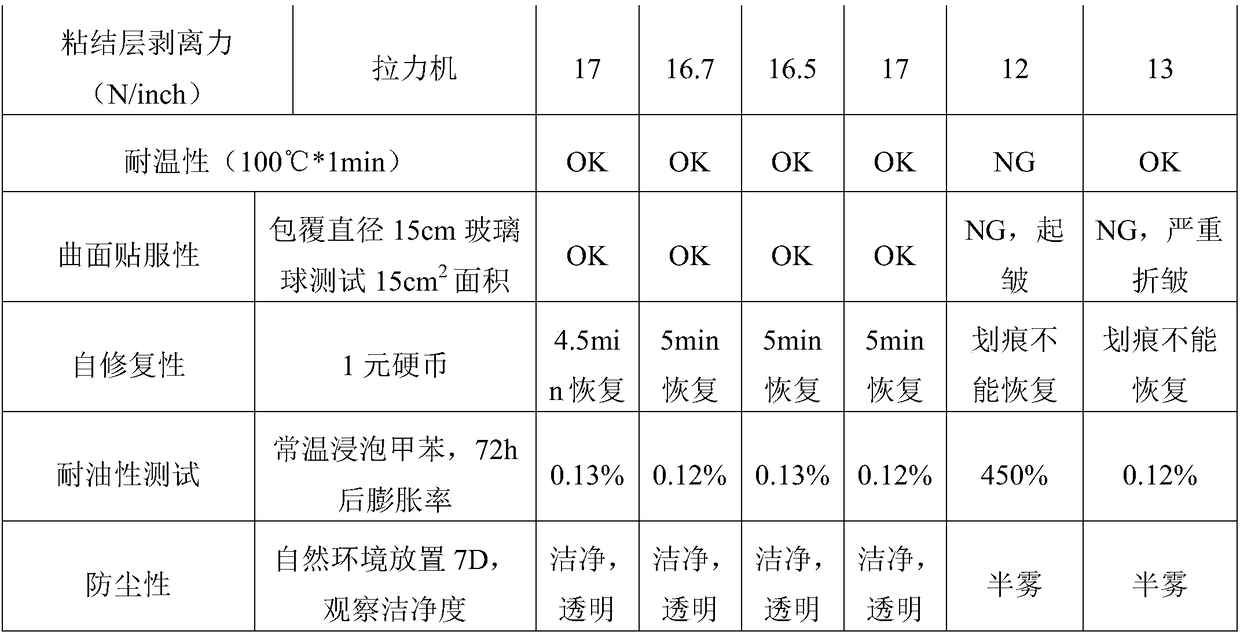

Examples

Embodiment 1

[0037] The protective film of curved surface components, from top to bottom, is the first polymer resin mixed layer with a thickness of 50 μm, the second polymer resin mixed layer with a thickness of 30 μm, the adhesive layer with a thickness of 10 μm, and the release film with a thickness of 20 μm , The composition of the first polymer resin mixed layer is: 24.4 parts of TPU, 8.54 parts of filler (polymethylurea resin), 7.21 parts of anti-wear agent, 2.44 parts of dispersant, 6.71 parts of antistatic agent, 0.32 parts of leveling agent ; The composition of the second polymer resin mixed layer is: 18.4 parts of TPU, 2.76 parts of filler (polymethylurea resin), 1.84 parts of dispersant, 6.44 parts of adhesion promoter, 0.29 parts of wetting agent. The adhesive layer is an acrylic pressure-sensitive adhesive layer, and the release film is a transparent PET film.

[0038] Follow the steps below to prepare a protective film:

[0039] 1. Prepare the first polymer resin mixed layer...

Embodiment 2

[0043] The protective film of curved surface components, from top to bottom, is the first polymer resin mixed layer with a thickness of 42 μm, the second polymer resin mixed layer with a thickness of 35 μm, an adhesive layer with a thickness of 8 μm, and a release film with a thickness of 12 μm , The composition of the first polymer resin mixed layer is: 20 parts of TPU, 6 parts of filler (polymethylurea resin), 5 parts of wear-resistant agent, 3 parts of dispersant, 5 parts of antistatic agent, 0.4 part of leveling agent ; The composition of the second polymer resin mixed layer is: 15 parts of TPU, 2 parts of filler (polymethylurea resin), 1 part of dispersant, 7 parts of adhesion promoter, and 0.3 part of wetting agent. The adhesive layer is a silicone pressure-sensitive adhesive layer, and the release film is a transparent PET film.

[0044] Follow the steps below to prepare a protective film:

[0045] 1. Prepare the first polymer resin mixed layer glue: weigh various raw ...

Embodiment 3

[0049] The protective film of curved surface components, from top to bottom, is the first polymer resin mixed layer with a thickness of 60 μm, the second polymer resin mixed layer with a thickness of 24 μm, an adhesive layer with a thickness of 15 μm, and a release film with a thickness of 30 μm , the composition of the first polymer resin mixed layer is: 30 parts of TPU, 10 parts of filler (silicon dioxide), 10 parts of wear-resistant agent, 4 parts of dispersant, 8 parts of antistatic agent, 0.5 part of leveling agent; The composition of the two-polymer resin mixed layer is: 25 parts of TPU, 5 parts of filler (silicon dioxide), 2 parts of dispersant, 5 parts of adhesion promoter, and 0.1 part of wetting agent. The bonding layer is a polyurethane system pressure-sensitive adhesive layer, and the release film is milky white PET film.

[0050] Follow the steps below to prepare a protective film:

[0051] 1. Prepare the first polymer resin mixed layer glue: weigh various raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com