Flame-retardant cable material and preparation method thereof

A technology of flame-retardant cable materials and fillers, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of high production cost, large bending radius, complex process, etc., and increase heat resistance and weather resistance Good performance, increase impact strength, low temperature softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

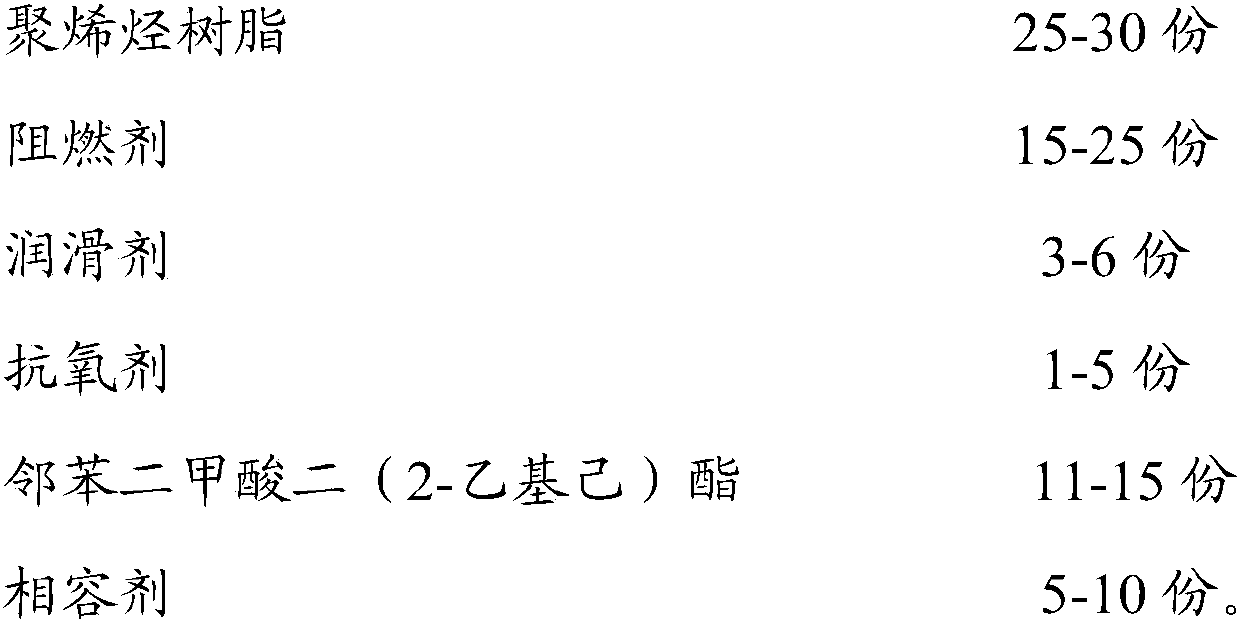

[0026] Flame retardant cable material: 25g of low-density polyethylene, 15g of magnesium hydroxide, 3g of stearic acid, 1g of antioxidant CA, 11g of bis(2-ethylhexyl) phthalate, ethylene-propylene copolymer grafted maleic acid Anhydride copolymer 5g, calcium carbonate 2g.

[0027] The above-mentioned preparation method is as follows: Step (1): Take the above-mentioned raw materials, divide the ethylene-propylene copolymer grafted maleic anhydride copolymer into two parts, the first part is 3g, and the second part is 2g;

[0028] Step (2): low-density polyethylene and the first part of ethylene-propylene copolymer grafted maleic anhydride copolymer are added in the mixer and stirred at 250r / min for 10min;

[0029] Step (3): Add calcium carbonate, magnesium hydroxide, stearic acid, antioxidant CA, bis(2-ethylhexyl) phthalate and the second part of ethylene in the mixer in step (2) -Propylene copolymer grafted maleic anhydride copolymer was stirred at 370r / min for 10min to obtai...

Embodiment 2

[0032] Flame-retardant cable material: 30g of low-density polyethylene, 25g of magnesium hydroxide, 6g of stearic acid, 5 parts of antioxidant CA, 15 parts of bis(2-ethylhexyl) phthalate, grafted ethylene-propylene copolymer Maleic anhydride copolymer 10 parts, calcium carbonate 6g.

[0033] The above-mentioned preparation method is as follows: Step (1): Take the above-mentioned raw materials, divide the ethylene-propylene copolymer grafted maleic anhydride copolymer into two parts, the first part is 3g, and the second part is 2g;

[0034] Step (2): Add low-density polyethylene and the first part of ethylene-propylene copolymer graft maleic anhydride copolymerization into the mixer and stir for 10min at 250r / min;

[0035] Step (3): Add calcium carbonate, magnesium hydroxide, stearic acid, antioxidant CA, bis(2-ethylhexyl) phthalate and the second part of ethylene in the mixer in step (2) -Propylene copolymer grafted maleic anhydride copolymer was stirred at 370r / min for 10min...

Embodiment 3

[0038] Flame-retardant cable material: 27g of low-density polyethylene, 20g of magnesium hydroxide, 4g of stearic acid, 3 parts of antioxidant CA, 13 parts of bis(2-ethylhexyl) phthalate, grafted ethylene-propylene copolymer 7 parts of maleic anhydride copolymer, 4 g of calcium carbonate.

[0039] The above-mentioned preparation method is as follows: Step (1): Take the above-mentioned raw materials, divide the ethylene-propylene copolymer grafted maleic anhydride copolymer into two parts, the first part is 4.2g, and the second part is 2.8g;

[0040] Step (2): Add low-density polyethylene and the first part of ethylene-propylene copolymer graft maleic anhydride copolymerization into the mixer and stir for 10min at 250r / min;

[0041] Step (3): Add calcium carbonate, magnesium hydroxide, stearic acid, antioxidant CA, bis(2-ethylhexyl) phthalate and the second part of ethylene in the mixer in step (2) -Propylene copolymer grafted maleic anhydride copolymer was stirred at 370r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com