Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good resistance to seawater corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy tube resistant to seawater corrosion and preparation method thereof

ActiveCN102465221AImprove seawater corrosion resistanceGood resistance to seawater corrosionRigid pipesDistillationMulti effect

The invention relates to an aluminum alloy tube resistant to seawater corrosion, in particular to an aluminum alloy tube with high seawater corrosion resistance. The aluminum alloy tube is manufactured from magnesium, aluminum and other raw materials through the steps of: melting, stirring, in-furnace modification treatment, impurity removal, fining treatment, online argon refining, purification treatment, casting, homogenization treatment, extrusion, cold drawing and the like. The aluminum alloy tube has the advantages of good seawater corrosion resistance and long service life, is particularly suitable for equipment for low-temperature multi-effect seawater distillation and seawater desalination treatment.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

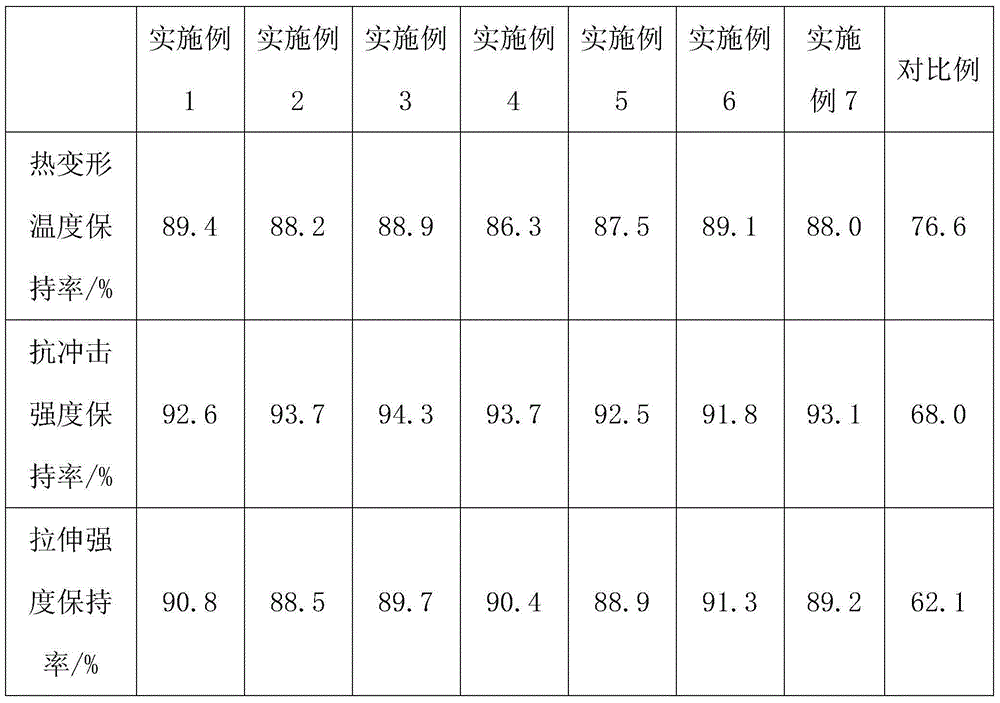

PE sheath material for submarine cable and preparation method thereof

ActiveCN104829919AGood resistance to seawater corrosionImprove seawater corrosion resistanceMicrobial corrosionElectric cables

The invention provides a PE sheath material for a submarine cable. The PE sheath material comprises, by weight, 100 parts of PE, 8-12 parts of modified hemp fibers, 6-10 parts of modified magnesium oxide, 0.2-0.3 parts of an anti-oxidant, 9-10 parts of EVA, 2-3 parts of carbon black, 3-4 parts of calcium carbonate, 0.1-0.2 parts of a stabilizing agent and 0.1 parts of a coupling agent. The invention also provides a preparation method of the PE sheath material. The PE sheath material for a submarine cable has good sea water corrosion resistance and microbiological corrosion resistance, can effectively reduce corrosion damage and has a long service life.

Owner:青岛宏信塑胶造粒有限公司

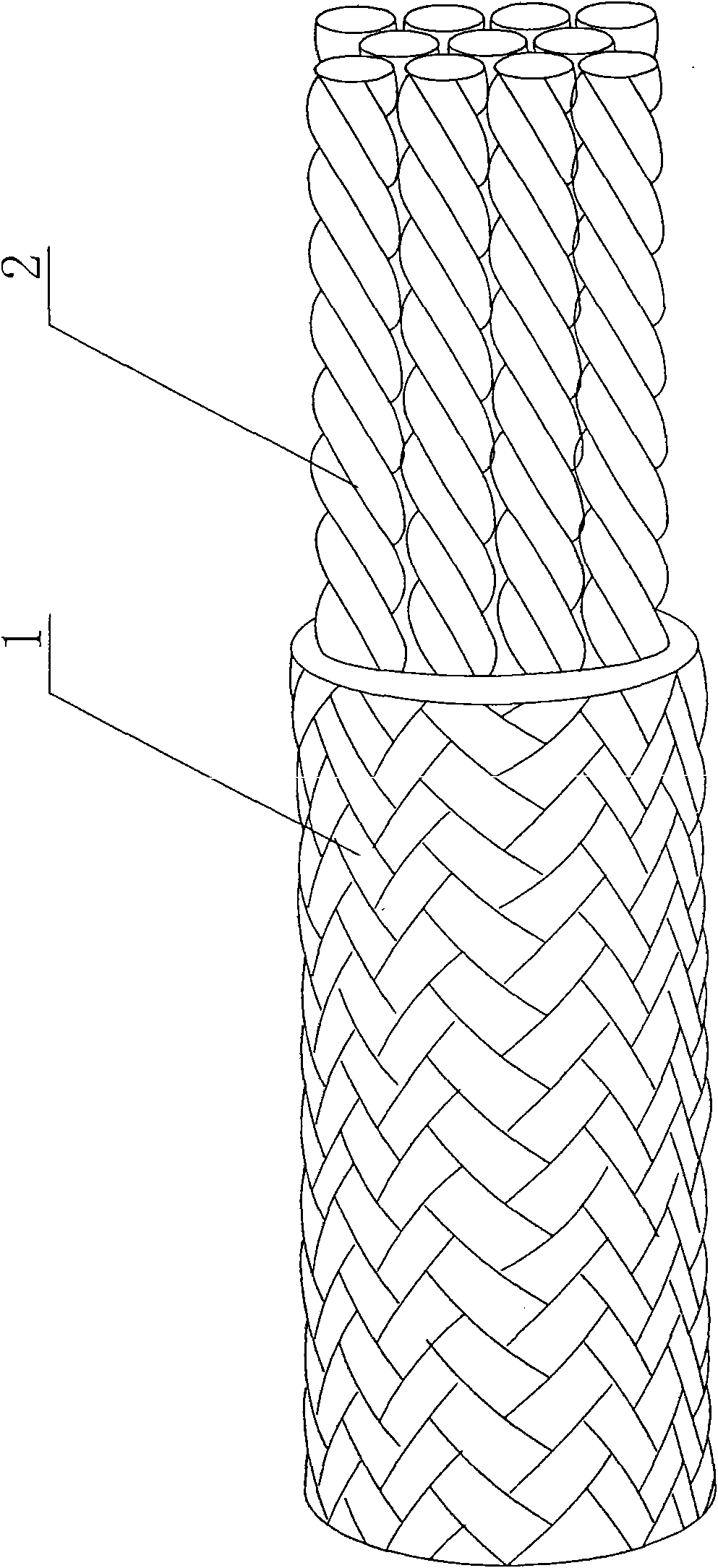

Deep sea cable

InactiveCN101638856AImprove wear resistanceGood resistance to seawater corrosionTextile cablesFiberWear resistant

The invention discloses a deep sea cable, which belongs to the technical field of cables. The deep sea cable comprises a cable core bundle consisting of a plurality of cable cores, wherein each cablecore is twisted by using three stands of high-strength high-modulus polyethylene fibers; and an outer coverage layer woven by 32 stands of high-strength polyamide multifilament is arranged on the periphery of the cable core bundle. The excellent wear and corrosion resistance of the high-strength polyamide multifilament ensures the excellent wear-resistance, sea water corrosion-resistance and ultraviolet radiation-resistance performance of the whole cable; the ultra high strength of the high-strength high-modulus polyethylene fibers increases the tensile strength of the cable and meets the requirements on ultra high strength of the deep sea cable; and the cable cores can be manufactured by a multi-length small-diameter connector-free ultra-long process that ensures that the whole cable is made long enough, avoids connectors and meets the requirements on the ultra high strength of the deep sea cable. The deep sea cable is high in strength, light in weight, wear resistant and corrosion resistant and can be applied to off-shore operation, in particular to oil exploration platforms.

Owner:JIULI ROPE

Rubber for ship sealing rings

The invention relates to high-molecular materials, especially to formula improvement of rubber for sealing rings in ship sealing equipment. Besides an allowable amount of trace impurities, the rubber for ship sealing rings comprises the following components by mass: 39.3-46% of nitrile-butadiene rubber N220, 8.73-11.35% of spray, 29.7-37.12% of high wear resistant carbon black 330, 6.55-8.73% of dibutyl phthalate, 0.65-0.87% of eleaostearic acid, 2.1-2.4% of zinc oxide, 1.22-1.53% of coumarone, 0.44-0.57% of paraffin, 0.153-0.24% of a promoter M, 0.044-0.065% of a promoter DM, 0.078-0.11% of a promoter D, 0.57-0.78% of an antioxidant D, and 0.44-0.66% of an antioxidant 4010. The rubber refined by the formula of the invention has good wear resistance, seawater corrosion resistance, oil resistance and high temperature resistance, thus satisfying ship operation better.

Owner:JIANGSU HUAYANG HEAVY IND +1

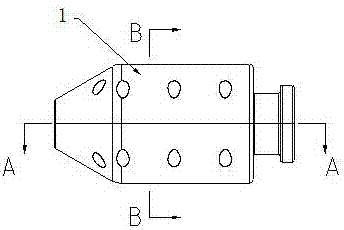

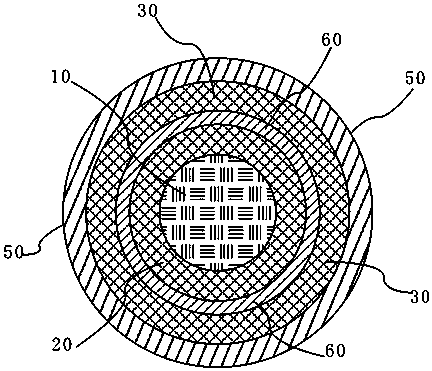

Method for assembling underwater copper alloy perforated mesh of pasture type shallow sea fence farming facility

ActiveCN104813966AStable structureExtended service lifeClimate change adaptationPisciculture and aquariaIsoetes triquetraRight triangle

The invention relates to a method for assembling an underwater copper alloy perforated mesh of a pasture type shallow sea fence farming facility. Basic components include standard assemblies of copper alloy perforated mesh plates with equilateral triangular profile and standard assemblies of copper alloy perforated mesh plates with right angled triangular profile. Assembly of standard assemblies of copper alloy perforated mesh plates is completed through ultrahigh molecular weight polyethylene extruded profiled lath connecting pieces and ultrahigh molecular weight polyethylene injection moulded corner-end connecting pieces. After the copper alloy perforated mesh plates are assembled, the copper alloy perforated mesh plates are hinged to reinforced concrete piles via endless tube section assembly parts prefabricated on the reinforced concrete pillar and ultrahigh molecular weight polyethylene bars. The method prevents adhesion of marine fouling organisms and retains excellent seawater flowing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

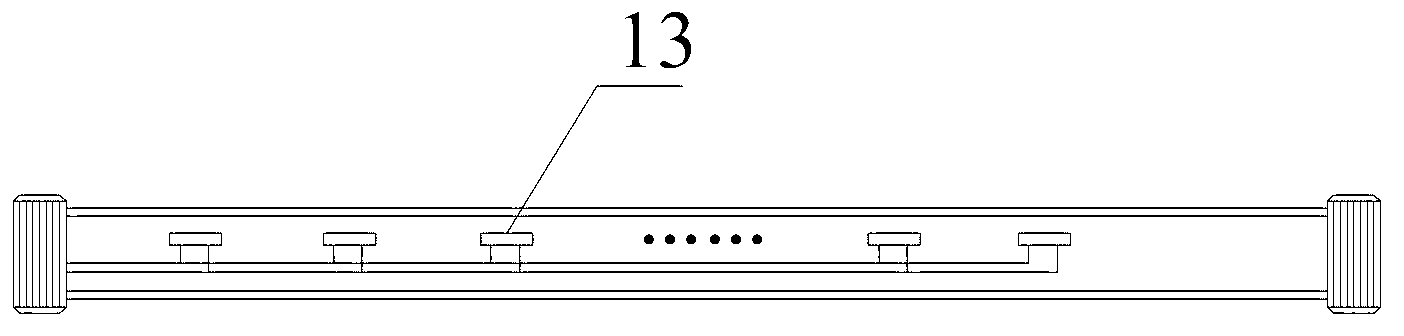

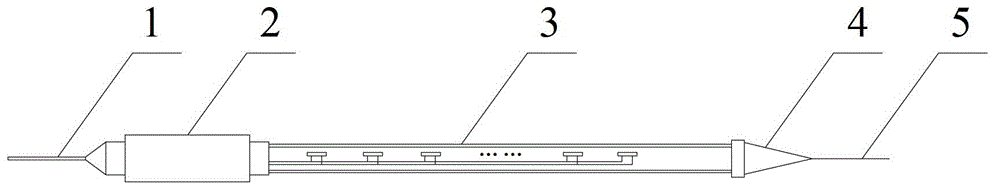

Marine seismic exploration towline equipment

ActiveCN103217717AReasonable structureClear Structure ImagingSeismology for water-covered areasLow noiseEngineering

The invention discloses marine seismic exploration towline equipment, which comprises a deck cable, a collection and transportation bag, a towing cable, a tail accessory and a current stabilization rope which are connected in sequence, wherein the deck cable is connected with a shipborne system; the collection and transportation bag is provided with a control board card; at least one detector is arranged in the towing cable; and the control board card controls data collected by the detector to be transmitted to the shipborne system. The marine seismic exploration towline equipment disclosed by the invention can be applied to the fields, such as marine seismic exploration, and has the characteristics of high tensile strength, good corrosion resistance and low noise interference, and seismic data with the high resolution ratio can be provided to obtain a clearer underground geologic structure image.

Owner:CHINA NAT OFFSHORE OIL CORP +1

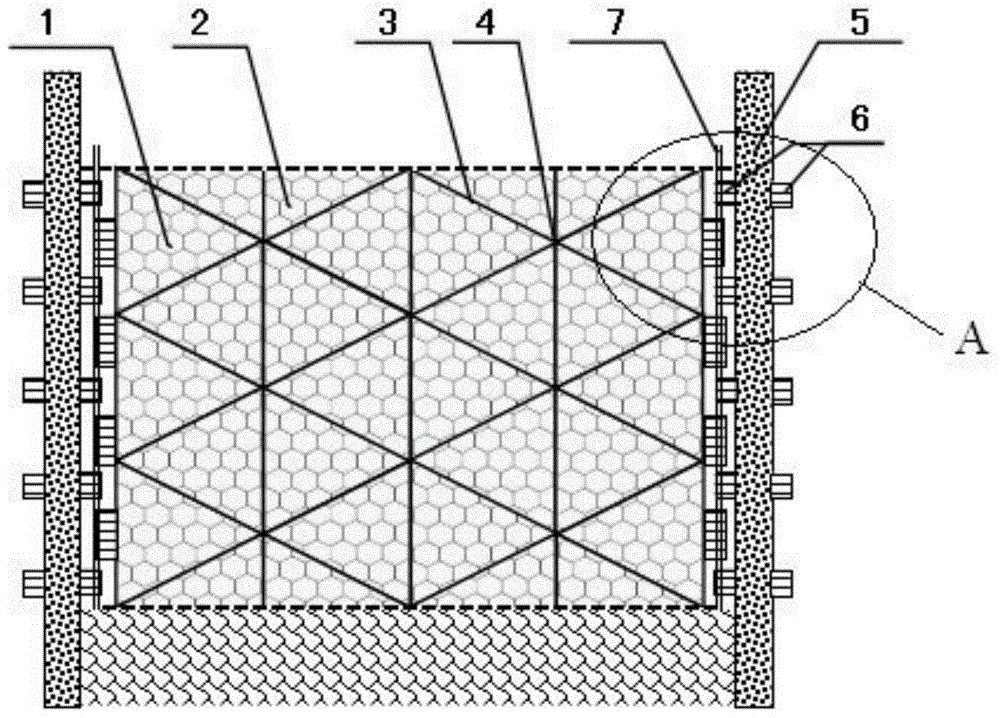

Corrosion resistant coating layer with self-repair capacity and preparation method thereof

ActiveCN106048529ALong corrosion lifeIncrease deposition rateVacuum evaporation coatingSputtering coatingStress processOxygen

The invention discloses a corrosion resistant coating layer with self-repair capacity. The coating layer is compounded by two phases of crystalline state Al and amorphous state Al2O3, and is represented as Al1-xOx, wherein x is 0.25-0.62, x is the atomic ratio, and the density of the coating layer is 3.0-3.4 g / cm3. The invention further discloses a preparation method of the corrosion resistant coating layer with self-repair capacity; and the preparation method comprises the steps of: (1) cleaning of a basal body; and (2) deposition of the coating layer: the cleaned basal body is put in a vacuum chamber; when the vacuum degree of a cavity is 1*10-5-5*10-5 Pa, argon and oxygen are introduced; the flow ratio of argon to oxygen is 2: 1; the sputtering air pressure is controlled as 0.25-0.4 Pa; the sputtering power density of a target is adjusted as 7.0-9.5 W / cm2; then, oxygen is gradually introduced; and when the voltage of the target reaches the lowest value, a sample baffle plate is opened for depositing the surface of the basal body to obtain the corrosion resistant coating layer with self-repair capacity. The prepared coating layer uses an Al corrosion product as a repair element for repairing through holes generated in later stress process of the coating layer to improve the corrosion resistance of the coating layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of marine corrosion-preventing non-woven fabric

InactiveCN104213330AImprove fatigue strengthGood wear resistanceNon-woven fabricsWoven fabricRough surface

The invention provides a preparation method of marine corrosion-preventing non-woven fabric, which belongs to the technical field of function non-woven materials. The marine corrosion-preventing non-woven fabric is prepared by the flowing steps of opening and scotching polyformaldehyde (POM) fiber, carding to form a web, mechanical laying, needling reinforcement, and hot rolling. One side is a smooth and clean surface (a compact layer), the other side is a rough surface (an adhesive layer), and the thickness of the compact layer is 5 percent and 25 percent of the thickness of the whole non-woven protective layer; the smooth and clean surface (the compact layer) is in direct contact with sea water, so that the sea water can be prevented from permeating; the rough surface (the adhesive layer) is in direct contact with the protected part, and is tightly attached with the protected part. The marine corrosion-preventing non-woven fabric is strong in seawater corrosion resistance, has excellent water-repellency performance and flexibility, and can meet the requirement of practical application.

Owner:TIANJIN POLYTECHNIC UNIV

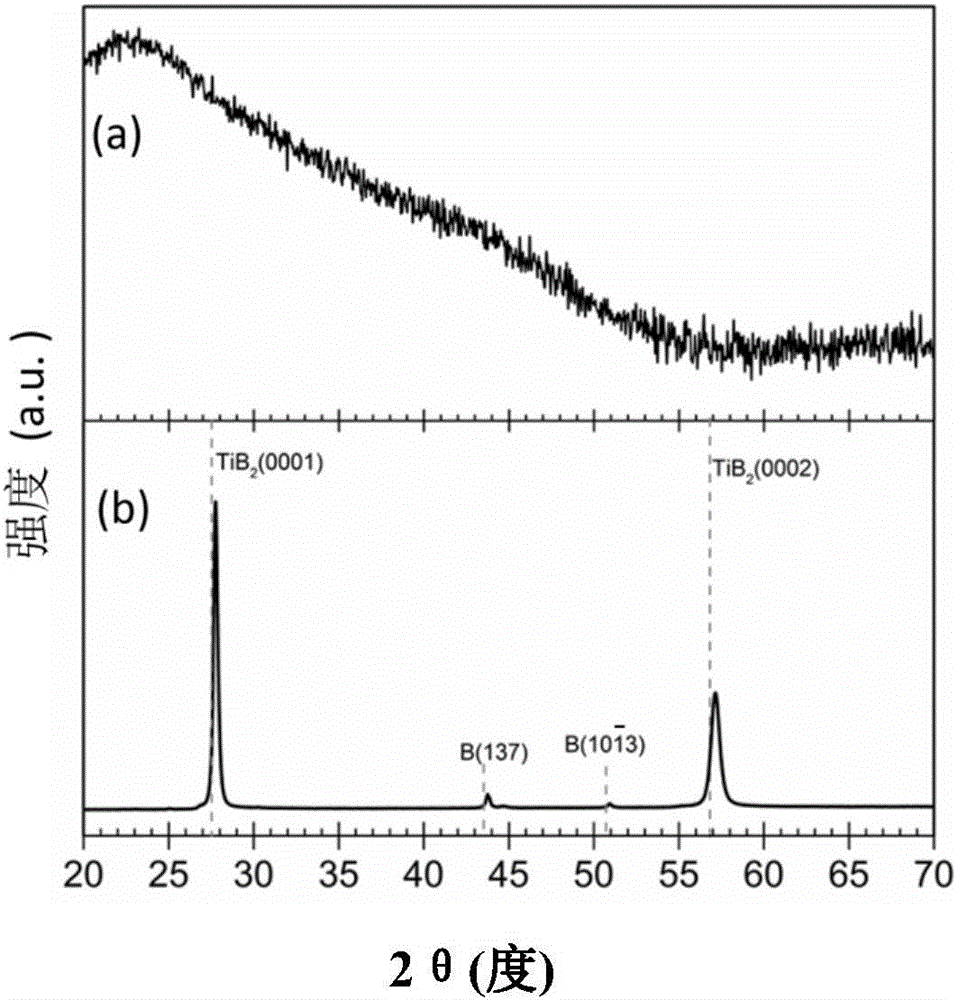

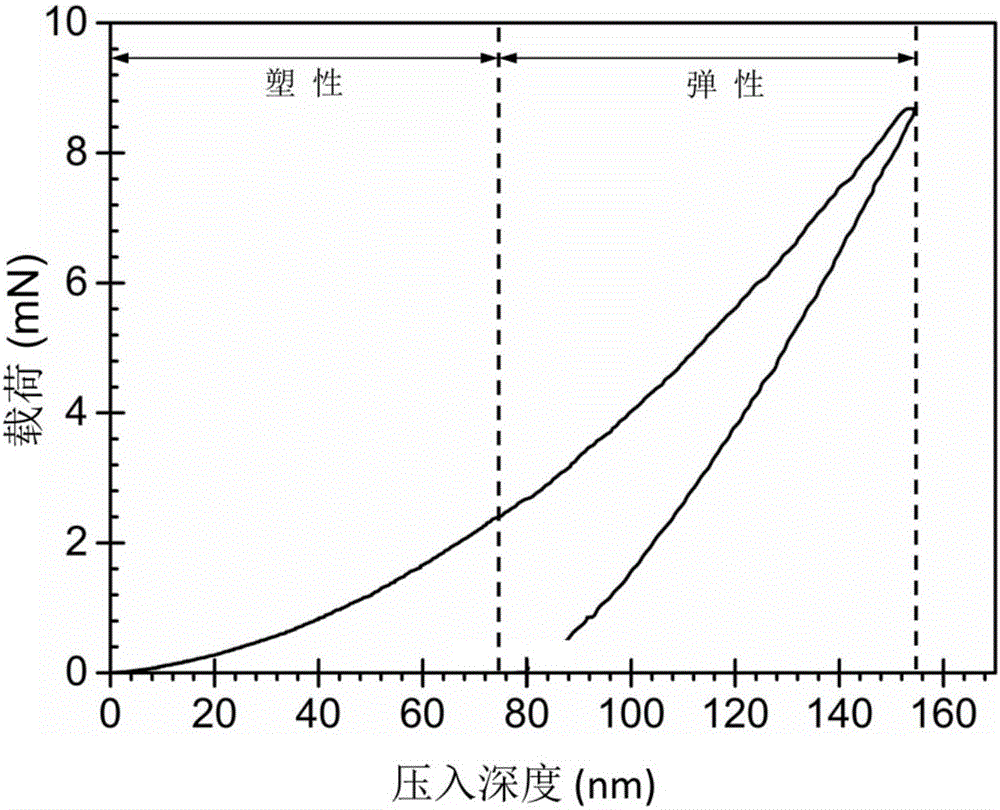

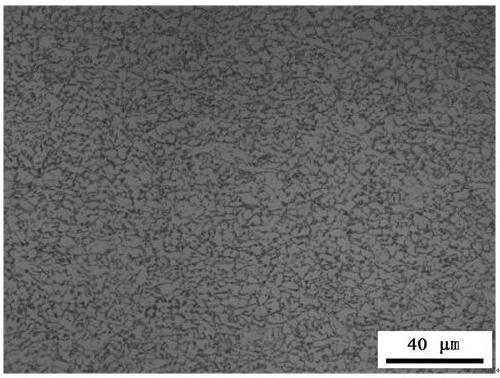

Seawater-corrosion-resistant hard coating and preparation method thereof

ActiveCN105755440AImprove corrosion resistanceExtended service lifeVacuum evaporation coatingSputtering coatingHardnessSeawater

The invention discloses a seawater-corrosion-resistant hard coating.The hard coating is composed of Ti100-xBx, wherein x is equal to 50-60 and refers to atom ratio.The hard coating is of an amorphous structure is compact, and density is 4.6-5.1 g / cm3.The invention further discloses a preparation method of the hard coating.The hard coating with the special structure is obtained by adopting a magnetron sputtering method and accurately controlling process parameters.The hard coating has excellent resistance to seawater corrosion and high tenacity and hardness, and can be used for improving corrosion resistance of the surface of each stressed part in ocean equipment and prolonging service life of each part.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Seawater-corrosion-resistant bituminous pavement material and preparation method thereof

Owner:河北北方公路工程建设集团有限公司

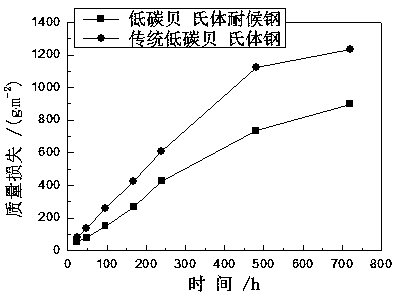

A kind of low-carbon bainitic weathering steel and its production method

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

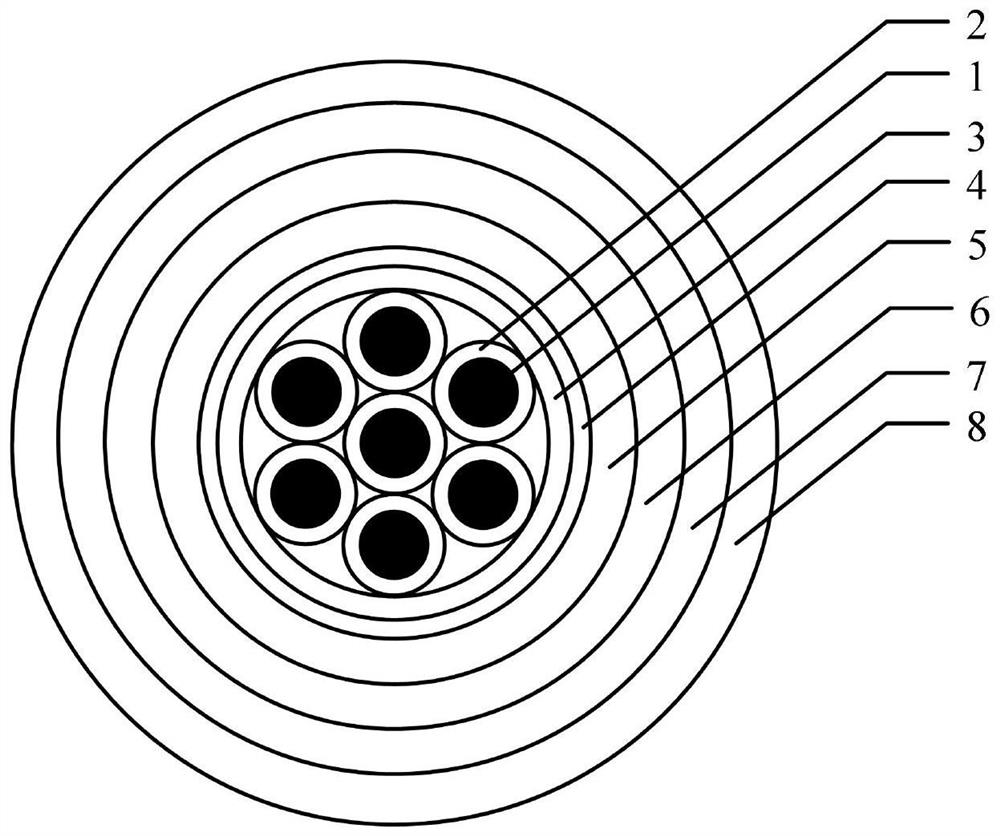

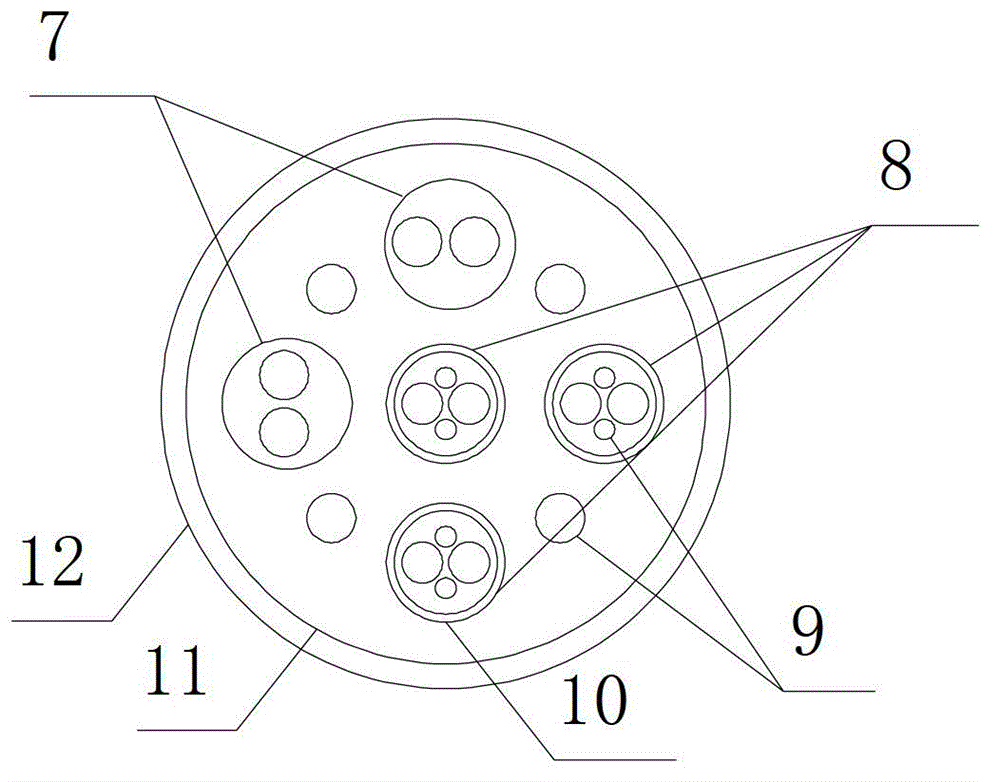

Degaussing cable for ship

InactiveCN112309622AGood resistance to seawater corrosionImprove wear resistanceSubmarine cablesFlexible cablesElectrical conductorMarine engineering

The invention discloses a degaussing cable for a ship. The degaussing cable for the ship comprises a reinforcing core, a conductor, an isolation belt, an insulating layer, an inner sheath layer, a filling layer, an armor layer and an outer sheath layer. The plurality of first conductors and the plurality of second conductors are stranded into a stranded wire, the plurality of stranded wires are stranded into a flexible conductor, the stranded wire is coated with the isolation belt, the insulating layer is coated with an internal sheath layer, and the internal sheath layer is sequentially coated with a filling layer, an armor layer and an external sheath layer. The seawater corrosion resistance of the cable is enhanced, the tensile strength of the cable is improved, and the bending performance of the cable is improved.

Owner:新亚特电缆股份有限公司

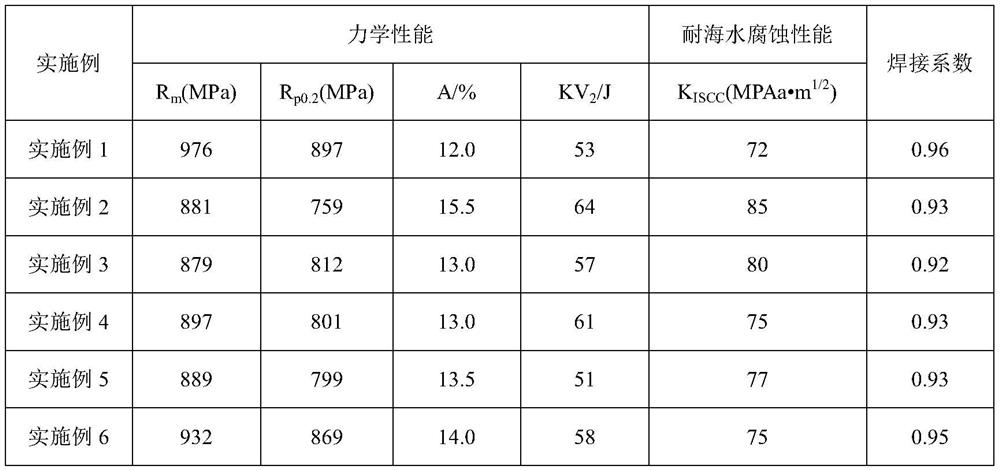

A kind of 3D printing marine titanium alloy and its preparation method

ActiveCN111411260BImprove mechanical propertiesHigh strengthAdditive manufacturing apparatusIncreasing energy efficiency3d printMetallurgy

The invention belongs to the field of titanium alloy materials, and discloses a 3D printing marine titanium alloy, the composition of which is: Al 4.0-8.0%, Mo 0.3-2.0%, Nb 1.0-4.0%, Zr 0.5-3.0%, Y 0.01-0.03 %, O 0.03~0.12%, the balance is Ti. The preparation method is as follows: batching according to the composition of the titanium alloy, melting the raw materials, casting ingots, and processing the ingots into rods after billeting and forging; processing the rods into powder, and sieving the powder to obtain 3D printing marine titanium Alloy powder: 3D printing marine titanium alloy powder is used as raw material, and 3D printing technology is used to prepare titanium alloy components. The strength and toughness of the 3D printing marine titanium alloy of the present invention are well matched, and has excellent 3D printing laser forming performance, and can be prepared into complex titanium alloy components through 3D printing; meanwhile, it also has excellent seawater corrosion resistance and welding performance.

Owner:XINXIANG UNIV

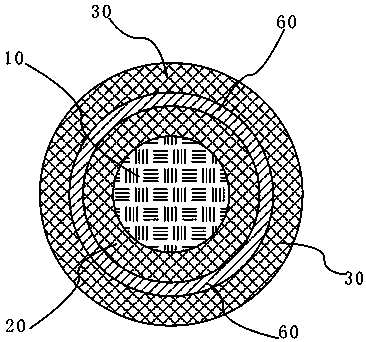

Integrated submarine cable protection device

InactiveCN110932218AGood fatigue resistance and bending resistanceGood resistance to seawater corrosionCable installations on groundCable installations in underground tubesEnvironmental geologyStructural engineering

The invention discloses an integrated submarine cable protection device. The device is installed in combination with the platform and the base, the platform is mounted on the base, the base is installed on a seabed surface, the integrated submarine cable protection device comprises a plurality of I-shaped pipes and a plurality of flexible protection pipes, the I-shaped pipes are attached to the base, the top ends of the I-shaped pipes are in butt joint with the platform, the flexible protection pipes are connected with the bottom ends of the I-shaped pipes, and the flexible protection pipes are sequentially connected end to end and extend to be laid on the seabed surface, and the flexible protection pipes at the joint of the base and the seabed surface are bent. The integrated structure isgood in fatigue resistance and bending resistance, so that the submarine cable can be protected more effectively; the flexible protection pipe made of a composite material is good in seawater corrosion resistance and longer in service life; installation is simple and rapid, and rapid laying of submarine cables is facilitated.

Owner:ZHONGTIAN TECH MARINE SYST CO LTD

Waterproof material that resists seawater erosion

ActiveCN108999051AGood resistance to seawater corrosionReduce the amount addedIn situ pavingsSeawaterPolyester

The invention discloses water-proof material resistant to seawater erosion, which comprises a matrix, an asphalt layer dipped on the matrix and a polyester film in turn from the inside to the outside,wherein the matrix is graphene composite ultrafine glass fiber cotton. The material is magnetic graphene oxide nanocomposite composite ultra-fine glass fiber, which has very good seawater corrosion resistance. At the same time, it can play a long-term effect of seawater corrosion resistance by adding a synergistic configuration of asphalt layer. In the preparation process of graphene composite ultra-fine glass fiber wool, In order to achieve the effect of industrial production, a small amount of Fe2O3 was added into the ultrafine glass fiber and the magnetism of magnetic graphene oxide nanocomposites was utilized to achieve a very good composite effect and efficiency, meanwhile, the addition amount of magnetic graphene oxide nanocomposites was reduced, and the cost was reduced. The invention also adjusts the addition amount of 10 # asphalt, so as to improve the hardness of the asphalt layer, thereby improving the composite effect with the matrix.

Owner:浙江伟伦建材科技有限公司

Salt-corrosion-resistant torsion-resistant control cable for ocean wind power

PendingCN112442230AImprove heat aging resistanceGood resistance to salt spray corrosionPlastic/resin/waxes insulatorsEngineeringFire retardant

The invention relates to the technical field of cable materials, in particular to a salt-corrosion-resistant torsion-resistant control cable for ocean wind power and a preparation method of the salt-corrosion-resistant torsion-resistant control cable. The cable is composed of an ethylene copolymer, maleic anhydride grafted EVA, magnesium oxide, a reinforcing agent, a silane coupling agent, a lubricant, a flame retardant and modified potassium hexatitanate whiskers. The cable provided by the invention has relatively good performances in the aspects of thermal aging resistance, salt spray corrosion resistance, seawater corrosion resistance and the like, and can well adapt to a complex climate environment where an ocean wind power facility is located. The cable has excellent torsion resistance, the number of times of torsion resistance is higher than 2500, and torsion at normal temperature or low temperature has no obvious influence on the material of the cable.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

A waterproof material resistant to seawater erosion

ActiveCN108999051BGood resistance to seawater corrosionReduce the amount addedIn situ pavingsGlass fiberPolyester

Owner:浙江伟伦建材科技有限公司

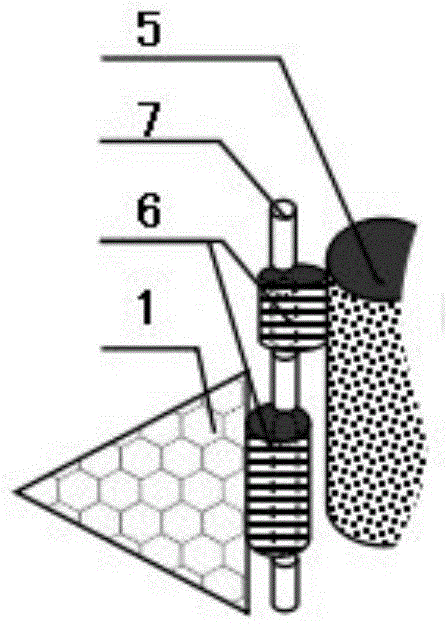

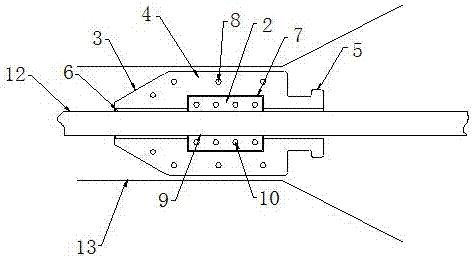

A submarine cable center positioning protection device

ActiveCN105305359BStrong penetrating powerPenetration guaranteeCable installations on groundEngineeringBolt connection

The invention discloses a centralized positioning protector of a submarine cable, which comprises a shell body and a clamp, wherein the shell body comprises two symmetrical parts, the head part is a conical structure, the middle part is a cylindrical section, and an installation raised part is disposed on the tail part; a center hole A is disposed inside the shell body, an installation groove is disposed inside the cylindrical section, and a plurality of bolt holes A are disposed in side faces of the two symmetrical parts of the shell body; the clamp comprises two symmetrical parts with a semi-cylindrical structure, the clamp is embedded in the installation groove of the shell body, and a center hole B is disposed inside the clamp; bolt holes B are disposed in two symmetrical side faces of the clamp, and the two symmetrical parts of the clamp are connected by bolts in the bolt holes B; and installation clearance is disposed between the semi-cylindrical structures of the two symmetrical parts of the clamp. The centralized positioning protector of the submarine cable disclosed by the invention can limit the submarine cable of a lower port section of a protective tube at the center of the protective tube, can effectively control swaying of the submarine cable in the protective tube, can prevent collision between the submarine cable and the rigid protective tube, and can avoid a fatigue failure of the submarine cable generated from long-term effects of ocean currents. The centralized positioning protector of the submarine cable is simple in structure, convenient in installation, high in reliability and long in service life.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

A marine seismic exploration streamer equipment

ActiveCN103217717BGood resistance to seawater corrosionReduced tail swingSeismology for water-covered areasLow noiseEngineering

The invention discloses marine seismic exploration towline equipment, which comprises a deck cable, a collection and transportation bag, a towing cable, a tail accessory and a current stabilization rope which are connected in sequence, wherein the deck cable is connected with a shipborne system; the collection and transportation bag is provided with a control board card; at least one detector is arranged in the towing cable; and the control board card controls data collected by the detector to be transmitted to the shipborne system. The marine seismic exploration towline equipment disclosed by the invention can be applied to the fields, such as marine seismic exploration, and has the characteristics of high tensile strength, good corrosion resistance and low noise interference, and seismic data with the high resolution ratio can be provided to obtain a clearer underground geologic structure image.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A kind of luminous rope and its preparation method

ActiveCN106120413BExtended service lifeImprove luminous performanceCoatingsTextile cablesYarnLight guide

The invention specifically discloses a luminescence rope and a preparation method thereof; the luminescence rope comprises a rope core, a rope sheath wrapping the rope core, a lighting assembly and a light guide fiber; the rope core braids and wraps the light guide fiber; the lighting assembly comprises a lighting body arranged relative to one end of the light guide fiber and used for providing light source for the light guide fiber; the rope sheath comprises Kevlar fibers, nylon yarns, light storing yarns and reflection filaments compositely intersecting and braiding; the rope sheath and the rope core are fixedly connected through a double-face thermosetting viscose glue net. The lighting system combines photoinduced passive luminescence with active luminescence; the light guide fiber, the light storing yarns and the reflection filaments can mutually cooperate with an enhanced effect, thus greatly enhancing the lighting effect, and providing very well safety caution effect and energy saving effect; in addition, the rope sheath comprises the Kevlar fibers and nylon yarns, so the luminescence rope is excellent in heatproof flame resistance, good in wear resistance and anti-tearing effect, flexible and light resistant, very high in tension and impact resistance effect, and long in service life.

Owner:中国人民武装警察部队警官学院 +1

A solvent-free heavy-duty anti-corrosion coating composition capable of wet coating and its preparation method and application

ActiveCN112760006BLow viscosityLow VOC contentAnti-corrosive paintsEpoxy resin coatingsCrack resistanceSolvent free

The invention discloses a solvent-free heavy-duty anti-corrosion coating composition capable of wet coating, its preparation method and application. The coating composition includes a first component and a second component that cooperate with each other; wherein, the first component includes a composite epoxy resin and a reactive diluent, and the composite epoxy resin includes two or more The epoxy resin; the second component includes cardanol modified phenalkamine, complex amine curing agent and non-reactive diluent. The composition of the present invention uses reactive diluents and non-reactive diluents to completely replace the organic volatile components to obtain a solvent-free coating composition. The thickness of the coating can reach 1200 microns once, and the cured coating has high hardness, Good toughness, excellent crack resistance, cathodic disbonding resistance and long-term salt spray resistance, it can provide long-term and effective protection for marine environment, industrial corrosion environment or buried metal structural components.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Assembling method of underwater copper alloy perforated net for pasture-style shallow sea fence fish farming facilities

ActiveCN104813966BStable structureExtended service lifeClimate change adaptationPisciculture and aquariaIsoetes triquetraOcean sea

The invention relates to a method for assembling an underwater copper alloy perforated mesh of a pasture type shallow sea fence farming facility. Basic components include standard assemblies of copper alloy perforated mesh plates with equilateral triangular profile and standard assemblies of copper alloy perforated mesh plates with right angled triangular profile. Assembly of standard assemblies of copper alloy perforated mesh plates is completed through ultrahigh molecular weight polyethylene extruded profiled lath connecting pieces and ultrahigh molecular weight polyethylene injection moulded corner-end connecting pieces. After the copper alloy perforated mesh plates are assembled, the copper alloy perforated mesh plates are hinged to reinforced concrete piles via endless tube section assembly parts prefabricated on the reinforced concrete pillar and ultrahigh molecular weight polyethylene bars. The method prevents adhesion of marine fouling organisms and retains excellent seawater flowing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A kind of corrosion-resistant coating with self-healing ability and preparation method thereof

ActiveCN106048529BLong corrosion lifeGood resistance to seawater corrosionVacuum evaporation coatingSputtering coatingStress processVolumetric Mass Density

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Alloy material for chip processing system of marine drilling platform and preparation method of alloy material

The invention provides an alloy material for a chip processing system of a marine drilling platform and a preparation method of the alloy material. The alloy material comprises components of raw materials as follows: C, Mn, Si, S, P, Cr, Ni, Mo, Cu, Ir, Mg, Al, V, W, Pb, Nb, Sn, Zn, Ho, Lu and the balance Fe. The preparation method comprises steps as follows: metal raw materials and nonmetal raw materials are sintered under the vacuum condition at the temperature of 950-1,000 DEG C, the sintered raw materials are cooled to 700 DEG C under the condition of inert gas pressurization for tempering, then are heated to 750 DEG C for annealing and are cooled finally, and a finished product of the material for the chip processing system of the marine drilling platform is obtained. The alloy material has antirust performance, antimagnetic performance, pressure resistance and seawater corrosion resistance and is not prone to deformation.

Owner:QUANZHOU HUIAN MINTOU TRADING CO LTD

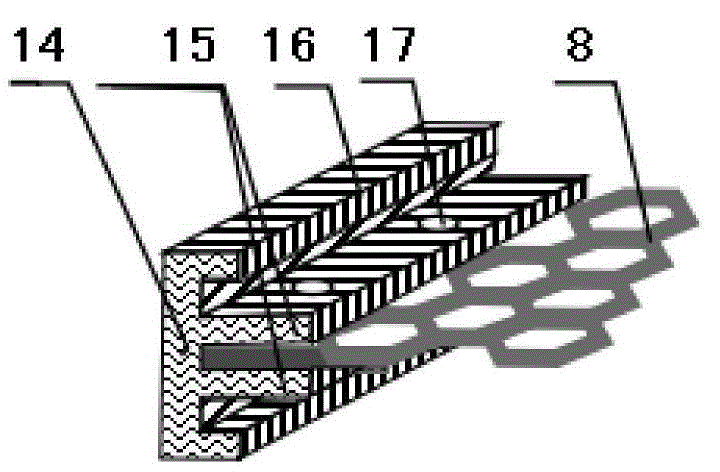

Pultrusion resin for producing frame structure for shallow sea culture

PendingCN113087853AGood resistance to seawater corrosionImprove bending strengthTert butylMethyl palmoxirate

The invention relates to pultrusion resin for producing a frame structure for shallow sea culture. The pultrusion resin is prepared from the following raw materials in a first step: 20 to 40 parts of neopentyl glycol, 10 to 20 parts of isophthalic acid, 10 to 20 parts of tetrahydrophthalic anhydride and 0.05 to 0.15 part of tetrabutyl titanate, and raw materials in a second step: 15 to 30 parts of methylpropanediol, 30 to 40 parts of fumaric acid, 0.01 to 0.05 part of benzenediol and 0.01 to 0.05 part of 2, 6-di-tert-butyl-4-cresol. The preparation method comprises the steps of detecting the selected raw materials, and feeding according to a formula sheet after the selected raw materials are confirmed to be qualified; after feeding is finished, carrying out operation strictly according to the determined manufacturing process; after the first central control acid value of a semi-finished product meets the requirement, performing decompression (nitrogen filling) dehydration; after the second central control acid value meets the requirement, cooling and diluting; and after dilution is finished, detecting the acid value, viscosity and gelation time of a finished product , conducting fine adjustment according to detection results and product requirement indexes, and conducting packaging till all the indexes are qualified. The pultrusion resin meets the performance requirements of seawater corrosion resistance and high bending strength, and the production cost is low.

Owner:宜兴市兴合树脂有限公司

A kind of marine pressure vessel bottle and production method thereof

ActiveCN109058753BGuaranteed tightnessReduce weightVessel manufacturingPressure vesselsCarbon fibersGas cylinder

The invention discloses a pressure container bottle for maritime work and a production method of the pressure container bottle, and belongs to the technical field of pressure container production. A seamless superaustenitic stainless steel pipe with the diameter larger than or equal to 400 mm is manufactured firstly, then, the seamless superaustenitic stainless steel pipe is used for manufacturinga seamless superaustenitic stainless steel pressure container bottle inner container, then, a carbon fiber rope is adopted, winding, dipping and curing are conducted on the outer surface of the seamless superaustenitic stainless steel pressure container bottle inner container, a carbon fiber winding resin strengthened layer is formed, and a pressure container in which the outer surface of the inner container is provided with the strengthened layer is obtained. The product is light and high in strength, fatigue resistance and corrosion resistance, and has the advantages of being resistant to seawater corrosion, free of welding lines, resistant to the high pressure, small in mass, high in fatigue filling performance and the like.

Owner:YANGZHOU CHENGDE STEEL PIPE

Waterproof material suitable for high-temperature and high-humidity environment

ActiveCN109263178AGood seawater corrosion resistanceComposite effect is goodFibre treatmentSynthetic resin layered productsCvd grapheneSeawater

The invention discloses a waterproof material suitable for a high-temperature and high-humidity environment. The waterproof material sequentially comprises a matrix, a thermal insulating layer, a high-temperature-resistant asphalt layer and a polyester film, wherein the matrix is graphene composite ultrafine glass fiber cotton. The waterproof material is magnetic graphene oxide nanocomposite composite ultrafine glass fiber and has very good seawater corrosion resistance, and meanwhile, the high-temperature-resistant asphalt layer which is cooperatively arranged is added, so that the effect ofresisting seawater corrosion for a long time can be achieved; in the preparation process of the graphene composite ultrafine glass fiber cotton, in order to achieve the effect of industrial production, a small amount of Fe2O3 is added into the ultrafine glass fiber, the magnetism of magnetic graphene oxide nanocomposites is utilized, so that a very good composite effect and efficiency are achieved, meanwhile, the addition amount of the magnetic graphene oxide nanocomposites is decreased, and therefore the cost is lowered; and the addition amount of 10# asphalt is also adjusted, so that the purpose of improving the hardness of the high-temperature-resistant asphalt layer is achieved, and therefore the composite effect of the high-temperature-resistant asphalt layer and the matrix is improved.

Owner:浙江伟伦建材科技有限公司

A seawater corrosion-resistant asphalt pavement material and preparation method thereof

Owner:河北北方公路工程建设集团有限公司

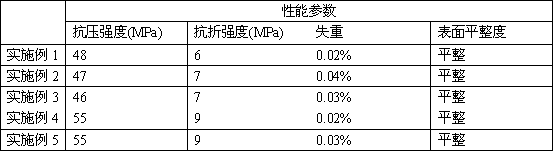

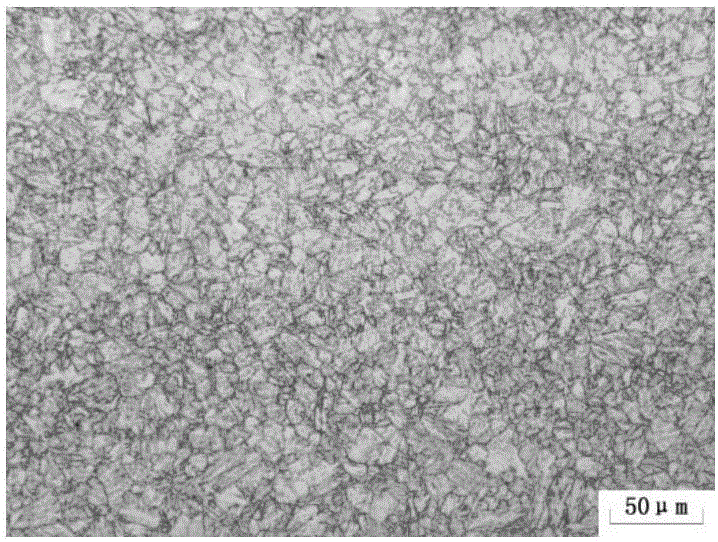

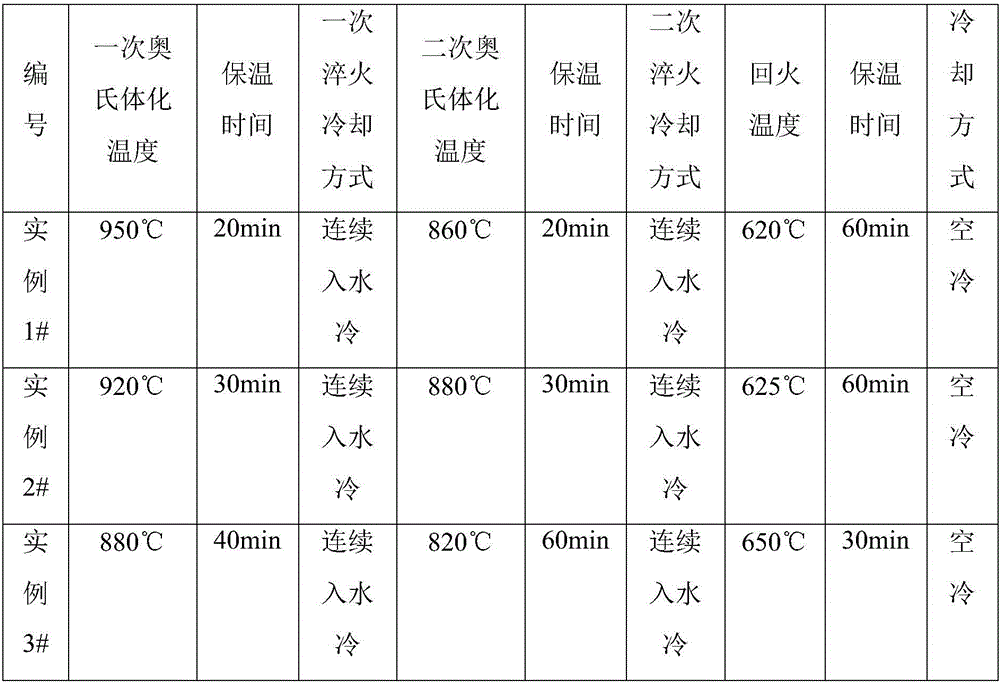

Steel for high-strength, high-toughness, corrosion-resistant chains and heat treatment method thereof

ActiveCN106521356BImprove uniform refinementGood resistance to seawater corrosionFurnace typesHeat treatment furnacesHeating furnaceMartensite

The invention discloses high-strength high-toughness corrosion-resistant chain steel. The steel comprises, by weight, 0.06-0.11wt.% of C, 0.15-0.35wt.% of Si, 0.30-0.50wt.% of Mn, 1.00-3.00wt.% of Cr, 2.00-4.00wt.% of Ni, 0.30-0.60wt.% of Mo, 0.02-0.06wt.% of Nb, 0.03-0.09wt.% of V, 0-0.015wt.% of P, 0-0.015wt.% of S, and the balance Fe and inevitable impurities. A vertical continuous heat treatment furnace and the double-quenching heat treatment and one-time tempering heat treatment processing mode are adopted in heat treatment of a chain. The chain sequentially passes through an A austenitizing heating furnace, an A quenching tank, a B austenitizing heating furnace, a B quenching tank and a C tempering heating furnace. A lath martensite structure with the lath block width being 0.3-5 microns can be obtained by means of heat treatment, and granular cementite with the diameter being 0.2-0.8 micron and the volume fraction being 0.15%-0.35% and MC phase particles with the diameter being 5-15nm and the volume fraction being 0.02%-0.08% are distributed between laths and inside the laths in a dispersed mode. The tensile strength of the chain reaches 1000MPa level after heat treatment, the loop back and welded joint KV2(-60 DEG C) can reach 100 or above, and seawater corrosion resistance is good.

Owner:CENT IRON & STEEL RES INST +1

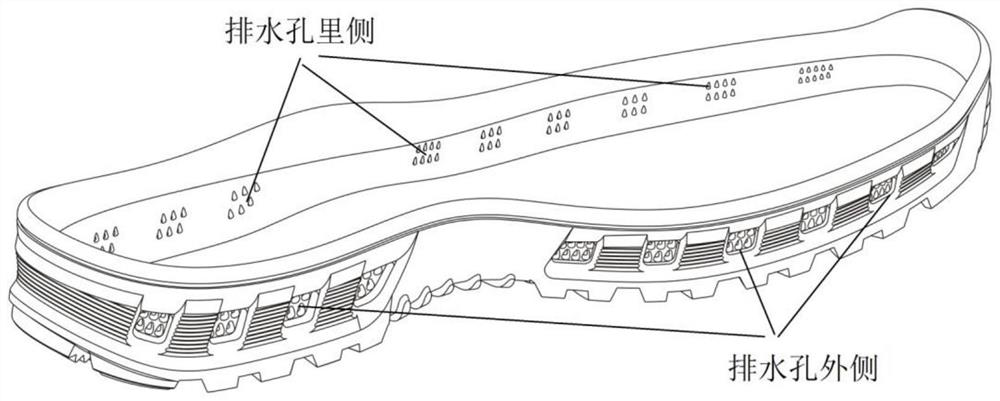

Seawater corrosion and aging resistant rubber outsole and preparation method thereof

ActiveCN111825889AGood resistance to seawater corrosionImprove heat aging resistanceSolesClimate change adaptationSoil sciencePlasticizer

The invention discloses a seawater corrosion and aging resistant rubber outsole and a preparation method thereof. The seawater corrosion and aging resistant outsole is prepared from the following rawmaterials in parts by mass: 100 phr of raw rubber; 40 to 50 phr of a reinforcing agent; 8-12 phr of a plasticizer; 3.0 to 5.0 phr of an active agent; 1.5 to 2.0 phr of a vulcanization accelerator; 1.0to 2.5 phr of an anti-aging agent; and 1.5 to 2.0 phr of a vulcanizing agent. The outsole resistant to seawater corrosion and aging has the following beneficial effects that 1, the rubber formula hasgood seawater corrosion resistance and hot sun aging resistance, and it is ensured that shoes prepared from the outsole have good durability; 2, the drainage holes are designed in the side wall of the sole, so that the probability of gravel particle blockage can be reduced, and the drainage effect is prevented from being influenced.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com