Method for assembling underwater copper alloy perforated mesh of pasture type shallow sea fence farming facility

An assembly method and copper alloy technology, which are applied in fish farming, animal husbandry, applications, etc., can solve the problem of difficult offshore installation of rigid copper alloy tensile mesh structural parts, complicated connection between rigid meshes and meshes, and speeding up the mesh. Damage at mesh junctions, etc., to achieve the effects of reducing maintenance and mesh replacement costs, good water exchange, and stable mesh structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

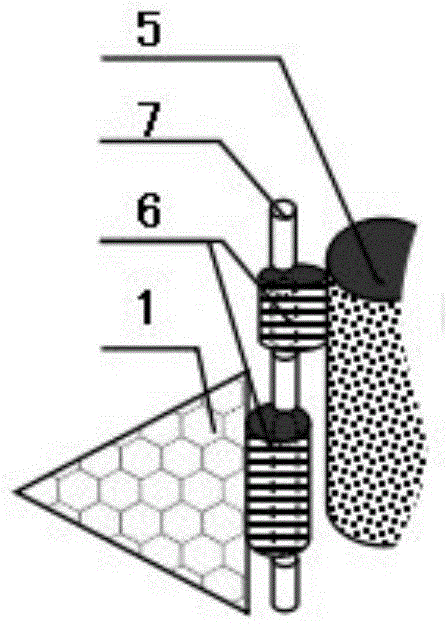

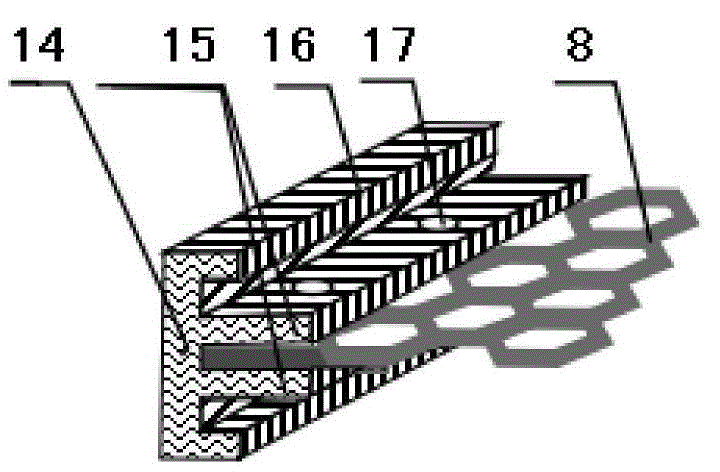

[0036] The embodiment of the present invention relates to a method for assembling underwater copper alloy perforated nets of pasture-type shallow sea fence fish farming facilities, such as figure 1 and figure 2 As shown, it uses the standard assembly 1 of the copper alloy perforated mesh sheet with the shape of an equilateral triangle and the standard assembly 2 of the copper alloy punched mesh sheet with the shape of a right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com