Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Good anti-slip and wear-resistant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-healing antiskid unvulcanizedrubber material and preparation method thereof

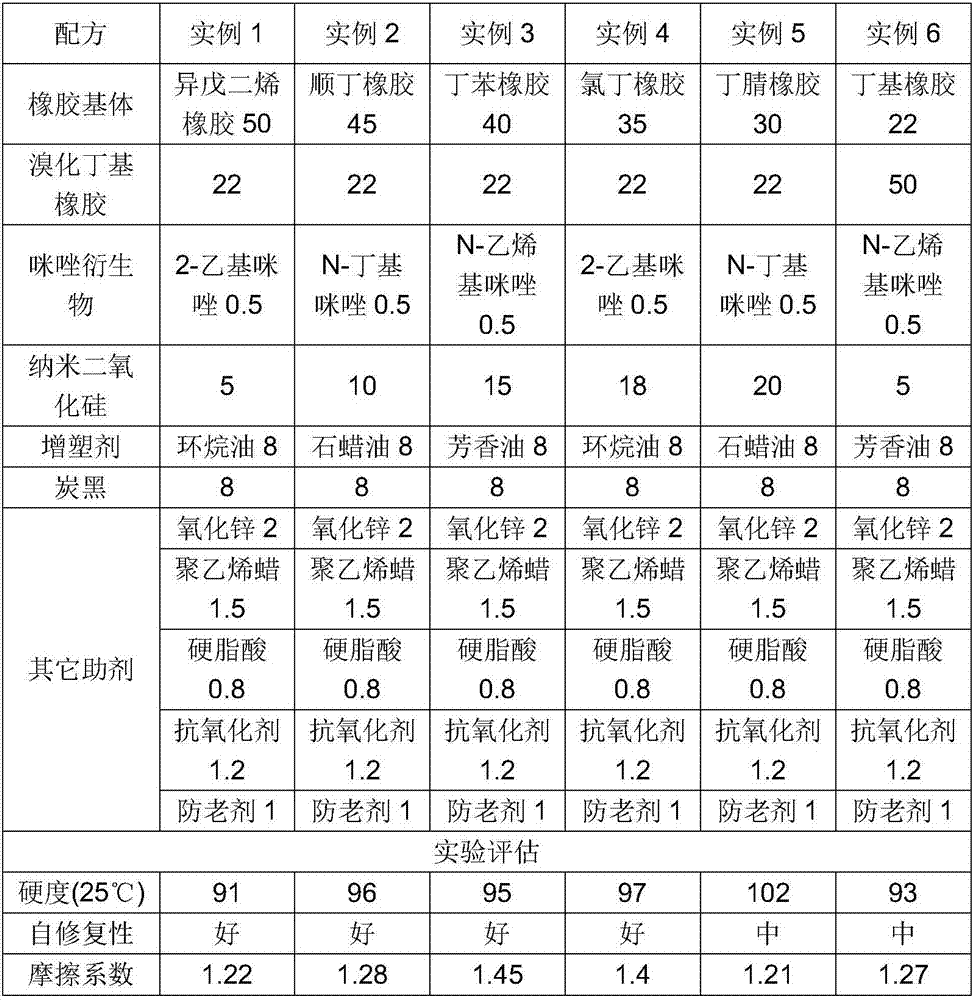

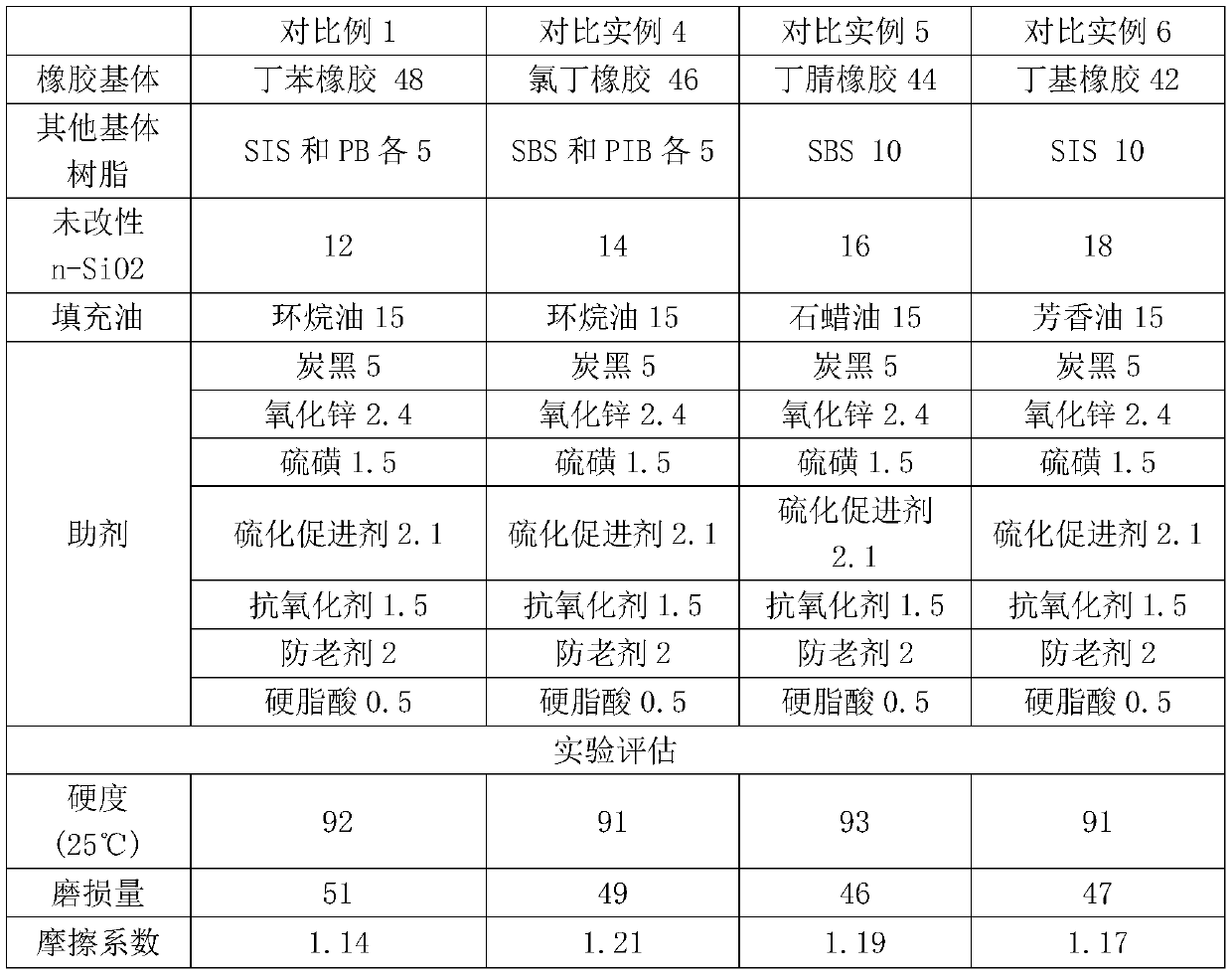

The invention discloses a self-healing antiskid unvulcanized rubber material comprising the following components in percentage by weight: 20-50wt% of a rubber matrix, 1-50wt% of brominated butyl rubber, 0.1-0.5wt% of an imidazole derivative, 5-25wt% of nano silicon dioxide, 5-20wt% of a plasticizer, 5-10wt% of carbon black, and 1-5wt% of an auxiliary agent. The invention also discloses a preparation method. The self-healing antiskid unvulcanized rubber material disclosed by the invention has excellent weathering resistance, water tightness and air tightness, has good resistance to chemicals, oils, solvents and the like, can be used for manufacturing a sole material, automobile tires, and antiskid wear-resistant materials in various aspects of processing and manufacturing, and can also be used as a sealing ring and a waterproof material.

Owner:成都微熵科技有限公司

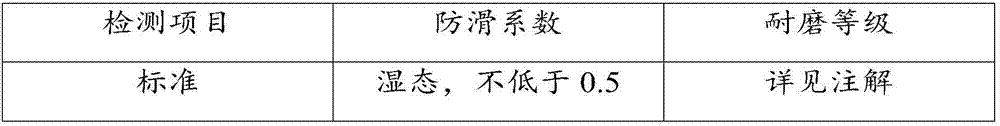

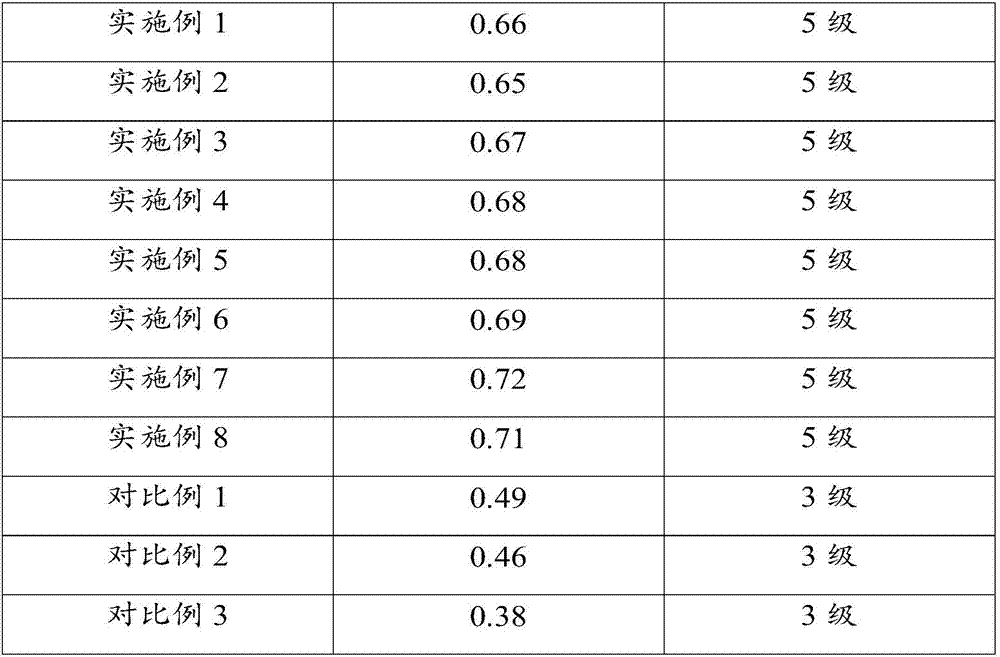

Rubber antiskid and abrasion-resistant shoe sole and preparation method thereof

InactiveCN106317493AGood anti-slip and wear-resistant effectGuaranteed wearing comfortSolesEpoxyPolymer science

The invention provides a rubber antiskid and abrasion-resistant shoe sole and a preparation method thereof. The rubber antiskid and abrasion-resistant shoe sole is prepared from, by weight, 20-30 parts of butadiene rubber, 40-55 parts of natural rubber, 1-2 parts of sulfur, 4.5-6.5 parts of nano-zinc oxide, 1-3 parts of stearic acid, 0.5-3 parts of vulcanization accelerator DM, 0.5-1.5 parts of nanometer silicon nitride, 40-50 parts of carbon black, 1-3 parts of antiager DNP, 6-10 parts of diethyl phthalate, 7-15 parts of modified benzoxazine resin, 5-15 parts of bicyclopentadiene dioxide epoxy resin, 5-10 parts of B205 ceramic sand, 3-8 parts of high-performance hollow glass beads and 7.5-12.5 parts of aramid fibers. The rubber antiskid and abrasion-resistant shoe sole is prepared through the steps of pre-mixing, mixing, cooling and vulcanizing. The formula and preparation method of shoe sole rubber are improved, the shoe sole rubber with the high anti-skid coefficient and abrasion resistance is obtained, the service life is prolonged, and the use comfort is improved.

Owner:张顺其

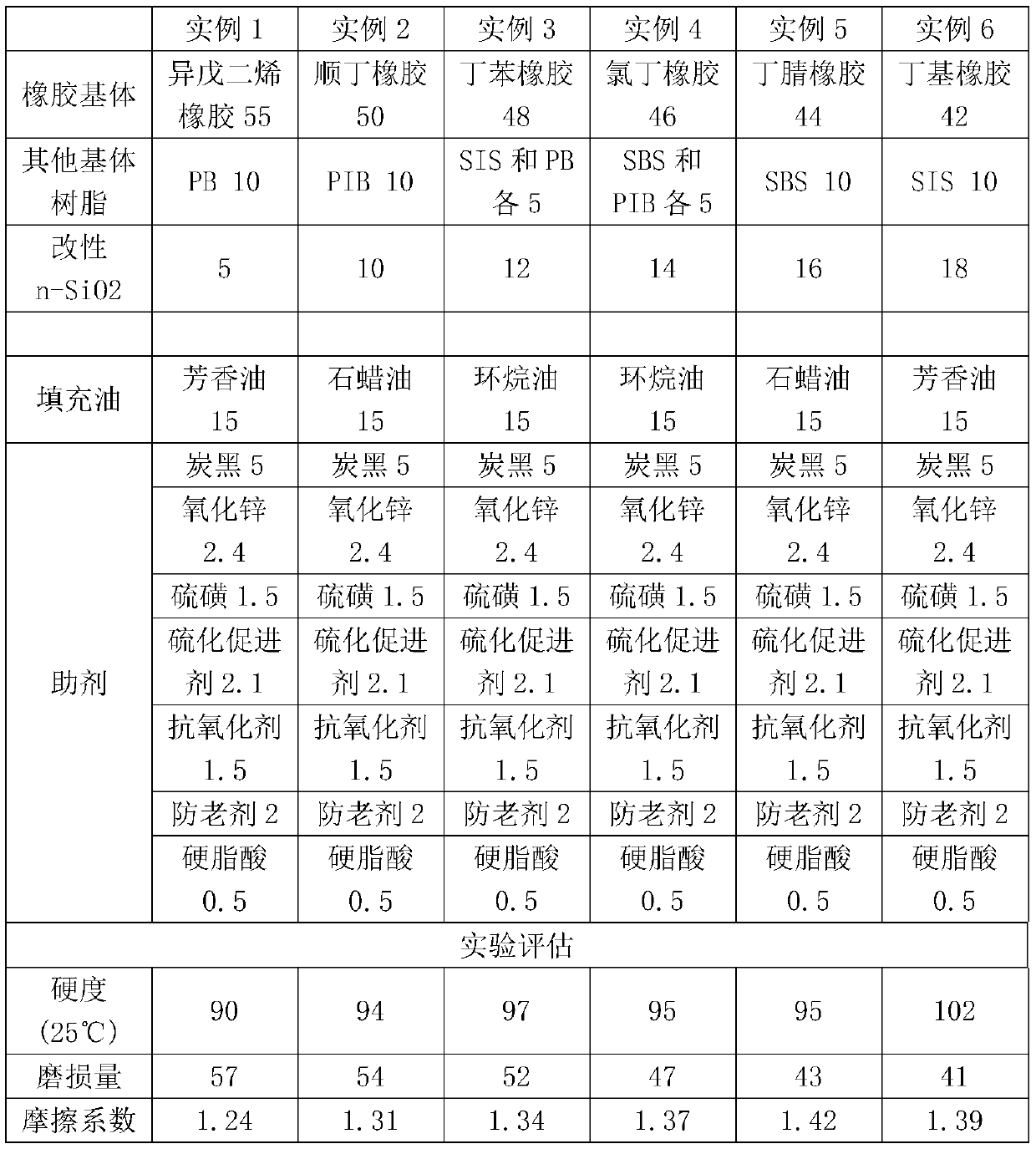

Antiskidding wear-resistant glaze and preparation method thereof

The invention relates to the field of ceramic glaze and particularly provides antiskidding wear-resistant glaze and a preparation method thereof. The antiskidding wear-resistant glaze is mainly prepared from the following raw materials in parts by mass: 90-110 parts of antiskidding wear-resistant particles, 90-110 parts of printing paste and 0.2-0.4 part of sodium tripolyphosphate, wherein the antiskidding wear-resistant particles are mainly prepared from the following ingredients in parts by mass: 60-70 parts of SiO2, 20-30 parts of Al2O3, 0.01-1 part of Fe2O3, 0.1-2 parts of TiO2, 1-5 parts of Na2O, 1-10 parts of K2O, 0.01-1 part of MgO, 0.1-5 parts of CaO and 0.1-2 parts of ignition loss. Through the reasonable matching of all the raw materials and all the ingredients of the antiskidding wear-resistant particles, the antiskidding wear-resistant glaze has a good antiskidding effect and a good wear-resisting effect.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

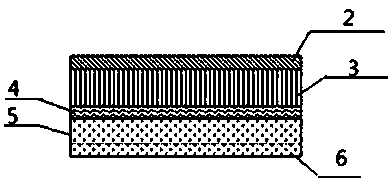

Iron-based composite structure high-temperature anti-corrosion and anti-skid coating and preparation method thereof

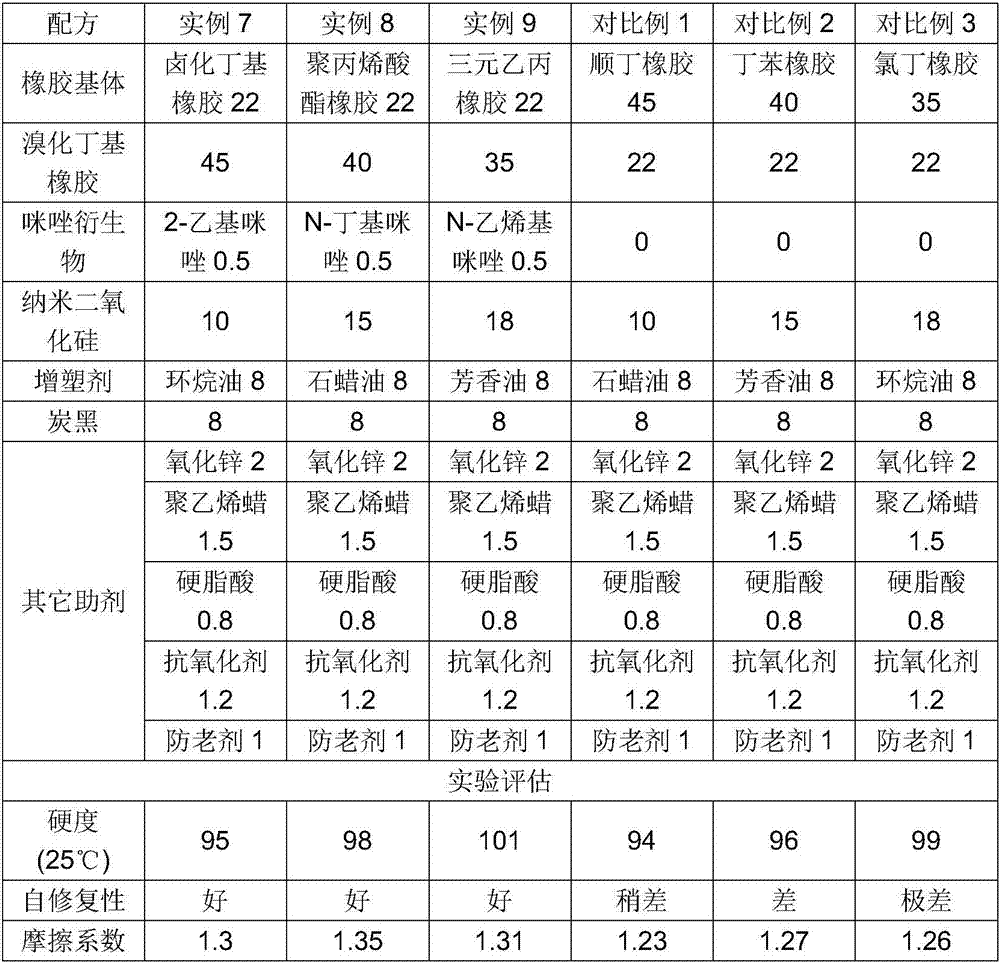

ActiveCN109504965AIncrease coefficient of frictionHigh bonding strength of coatingMetallic material coating processesBonding strengthBoron

The invention discloses an iron-based composite structure high-temperature anti-corrosion and anti-skid coating and a preparation method thereof. The coating comprises a SAM2X5 amorphous alloy anti-corrosion bottom layer (2) and an iron-based amorphous alloy / ceramic anti-skid top layer (1). The iron-based amorphous alloy / ceramic anti-skid top layer (1) is composed of alloy powder and ceramic powder. The alloy powder is prepared from, by mass percent, 31wt% of iron, 28wt% of chromium, 12wt% of boron, 11wt% of cobalt, 10wt% of nickel and 8wt% of silicon. The mass of the ceramic powder is 10%-70%of the total mass of the iron-based amorphous alloy / ceramic anti-skid top layer (1). The coating is high in friction coefficient, coating bonding strength and corrosion resistance.

Owner:MARINE CHEM RES INST +1

Wear-resisting antiskid plastic track and preparation method

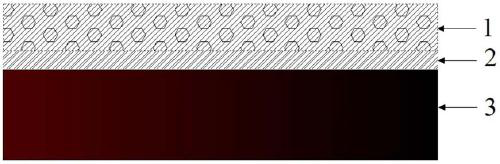

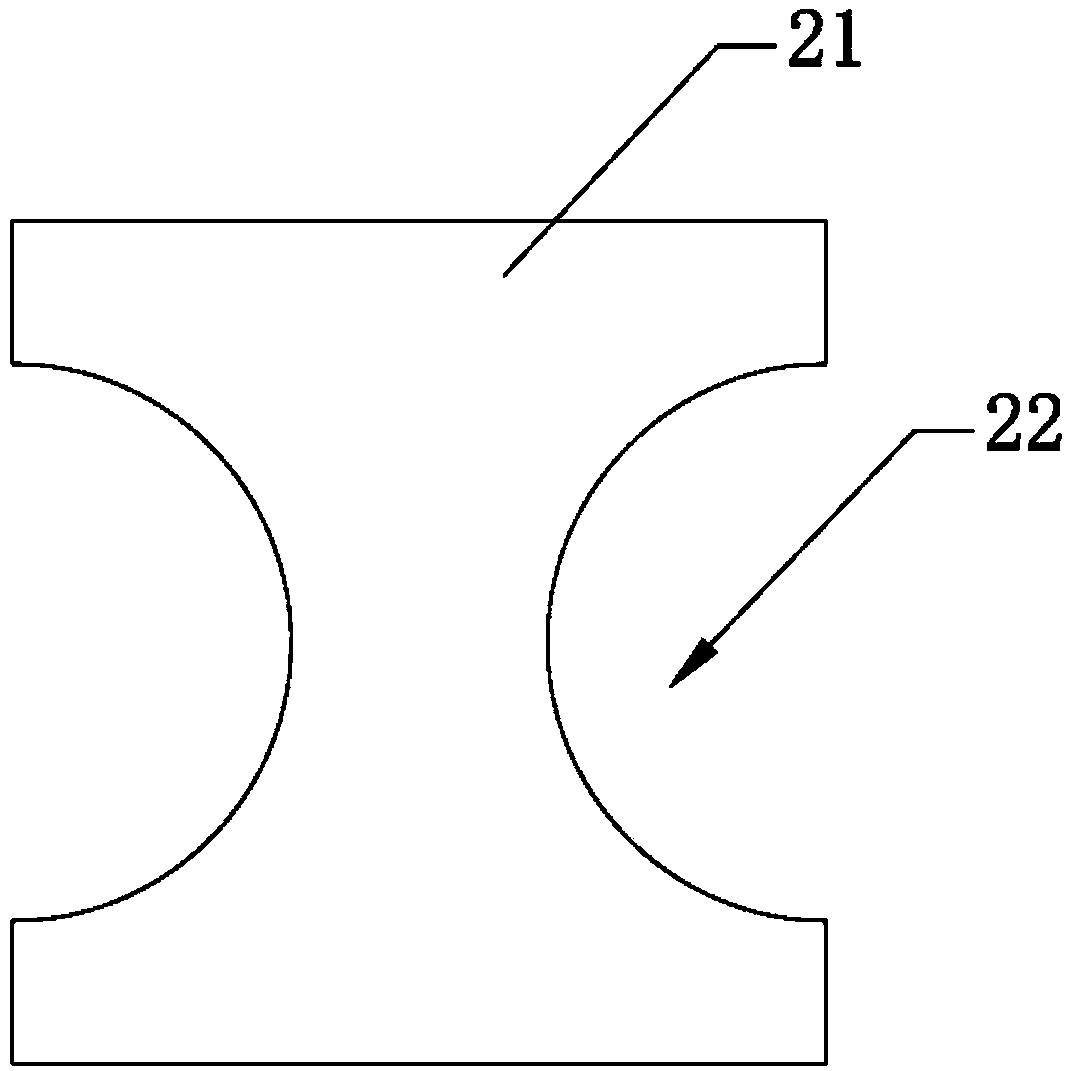

InactiveCN107090131AGood anti-slip and wear-resistant effectExtended service lifeNon-macromolecular adhesive additivesPaving gutters/kerbsAdhesiveToughness

The invention discloses a wear-resisting antiskid plastic track and a preparation method. The wear-resisting antiskid plastic track sequentially comprises an antiskid wear-resisting layer, a toughness reinforcing layer, a substrate layer and a cement powder stable layer from top to bottom, wherein a figure structure is arranged on the upper surface of the antiskid wear-resisting layer, and the antiskid wear-resisting layer and the toughness reinforcing layer are connected through an adhesive. The preparation method comprises the steps: firstly preparing the antiskid wear-resisting layer, the toughness reinforcing layer and the adhesive respectively; then laying the cement powder stable layer on a soil base layer, laying a self-adhesion SBS modified asphalt layer on the cement powder stable layer, then laying the toughness reinforcing layer on the surface of the asphalt layer, then coating the adhesive on the upper surface of the toughness reinforcing layer and adhering the antiskid wear-resisting layer to obtain the wear-resisting antiskid plastic track. The plastic track not only has better antiskid and wear-resisting performance, but also has better adhering firmness among all the layers; furthermore, the plastic track cannot release toxic gas, is safe and free of pollution and has better practical value.

Owner:合肥市晨雷思建筑材料科技有限公司

Wear-resistant powder coating

InactiveCN104356876AHigh surface resistanceGood wear resistancePowdery paintsEpoxy resin coatingsIron oxideCarbon black

The invention discloses a wear-resistant powder coating, which is composed of the following raw materials in parts by weight: 20-30 parts of bisphenol F epoxy resin, 40-50 parts of aliphatic glycidyl ether epoxy resin, 10-15 parts of poly (meth)acrylic resin with free carboxyl, 2-3 parts of magnesium carbonate, 5-9 parts of rubber powder, 10-15 parts of carbon black, 2-3 parts of aluminum powder, 3-5 parts of iron oxide red, 3-4 parts of a curing agent, 0.7-1.2 parts of a stabilizer, 3-4 parts of a flatting agent, and 30-40 parts of non-slip wear-resistant powder, wherein the non-slip wear-resistant powder is a mixture of emery, hollow ceramic micro-powder and colloidal graphite powder. The powder coating disclosed by the invention is moderate in volume resistance, high in surface resistance, and good in wear resistance.

Owner:李永志

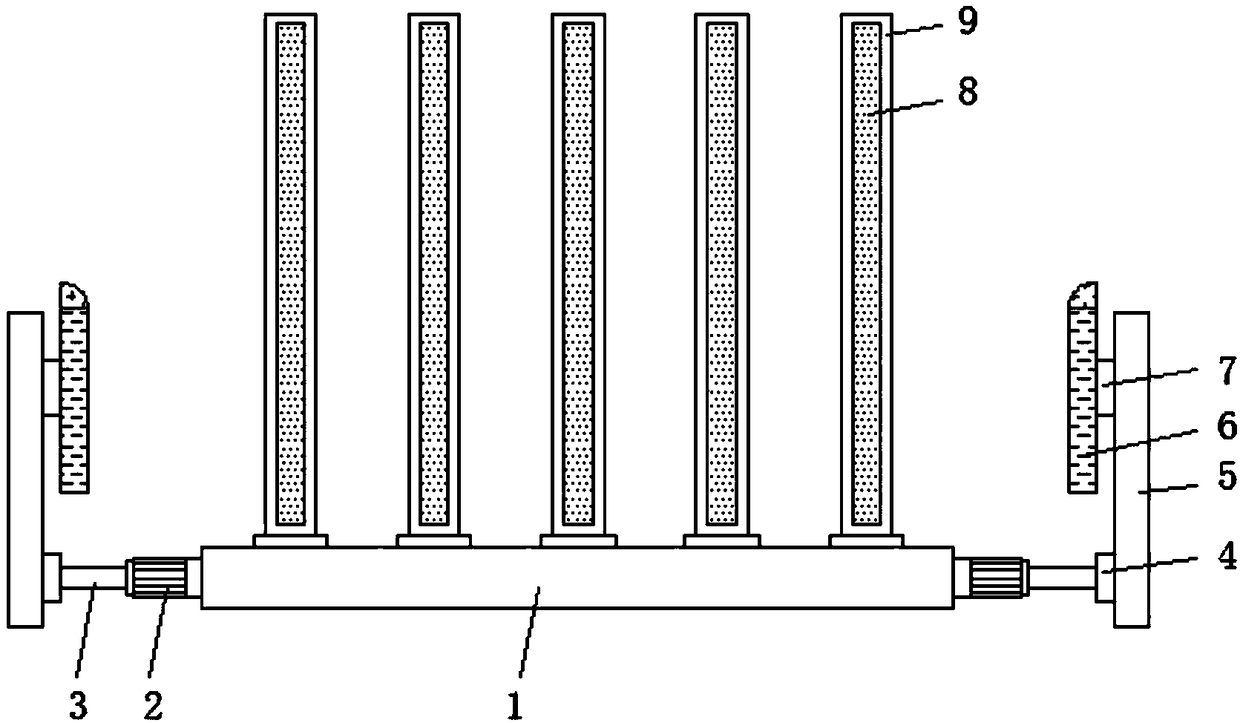

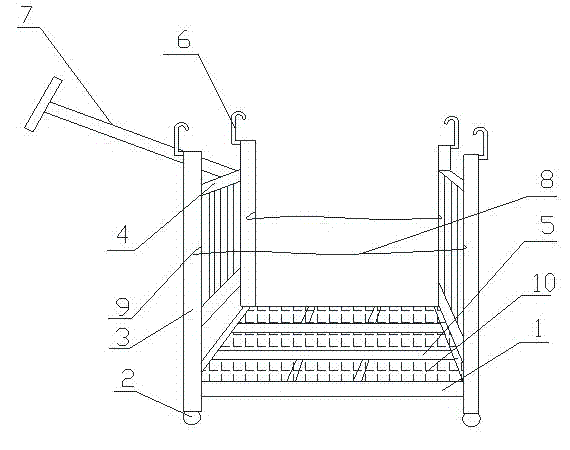

Forklift pallet fork with high practicability

InactiveCN108910785AAvoid side slippingImprove stabilityLifting devicesHydraulic cylinderEngineering

The invention discloses a forklift pallet fork with high practicability. The forklift pallet fork comprises a fixed iron plate, welding pieces and locking bolts. Hydraulic cylinders are both fixed tothe centers of the two end faces of the fixed iron plate. The output ends of the hydraulic cylinders are both connected with hydraulic telescopic rods. One end of each hydraulic telescopic rod is connected with a fixed iron rod. Side plates are arranged on the surfaces of the corresponding fixed iron rods, and the fixed iron rods and the side plates are firmly connected through two locking bolts.Guide plates are fixed to one ends of the side plates. Supporting plates are fixed to the bottom ends of the fixed iron plates, and the number of the supporting plates is five altogether. The spaces between the adjacent supporting plates are the same. According to the forklift pallet fork with high practicability, the two hydraulic cylinders can drive the hydraulic telescopic rods to achieve telescoping, so that the two side plates are at suitable positions. When the pallet fork is used for bearing a packing box, the two side plates can play a good limiting effect, the side slippage phenomenonof the packing box can be avoided, the stability of the packing box is improved and the practicability is made higher.

Owner:合肥瀚鹏新能源有限公司

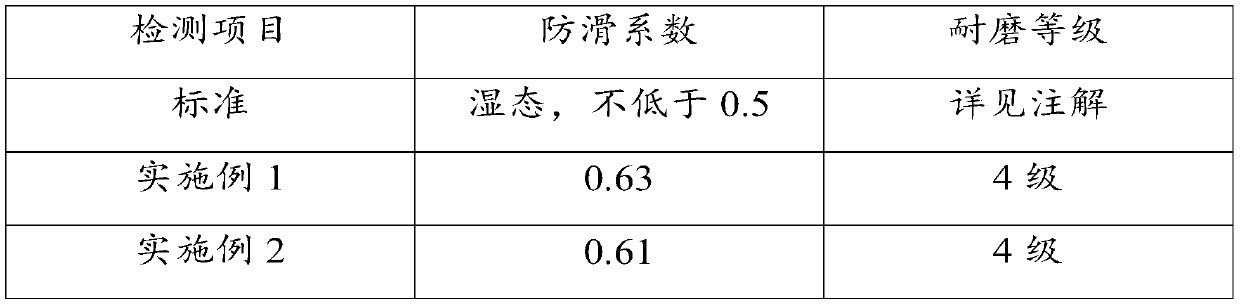

Anti-slip wear-resistant ceramic tile preparation method

The invention relate to the field of ceramic tiles, in particular to an anti-slip wear-resistant ceramic tile preparation method. The method mainly includes the steps of a), preparing a green-body layer; b), spreading anti-slip wear-resistant glaze on the green-body layer to form an anti-slip wear-resistant layer; c), performing sintering. The anti-slip wear-resistant glaze is mainly prepared from anti-slip wear-resistant particles, printing paste and sodium tripolyphosphate; the anti-slip wear-resistant particles are mainly composed of SiO2, Al2O3, Fe2O3, TiO2, Na2O, K2O, MgO, CaO and ignition loss. The method is simple in operation, scientific and reasonable in process, easy to implement and low in cost, and the anti-slip wear-resistant ceramic tile is good in anti-slip and wear-resistant effects, high in product quality, durable and safe and reliable.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

SPC solid wood composite floor

InactiveCN108019028ARaw materials are easy to obtainNot easy to crack and deformFlooringSolid woodWax

The invention provides an SPC solid wood composite floor comprising a PVC board and a solid wood board skin. The PVC board and the solid wood board skin are glued and fixed into a whole; the PVC boardcomprises, by weight, 80-130 parts of PVC resin, 260-350 parts of calcium carbonate powder, 1-1.5 parts of PE wax, 5.5-8 parts of a calcium and zinc stabilizer, 6-12 parts of ACR-401, and 3-4.5 partsof stearic acid. The SPC solid wood composite floor is attractive and generous, safe and environmentally friendly, and not only are the natural wood grain, texture, and foot feeling of solid wood floor obtained, but also the SPC solid wood composite floor has suitable elasticity and is not prone to being deformed and cracked, and has excellent performance in water and moisture resistance, impactresistance, corrosion resistance, and anti-skid and wear-resistance.

Owner:ANHUI TIANRUN PLASTIC IND

Anti-skid and abrasion-resistant coating for surface of ship deck and preparation method thereof

ActiveCN107868576AGood anti-slip and wear-resistant effectReduce wear ratePolyamide coatingsEpoxy resin coatingsFiberEpoxy

The invention discloses an anti-skid and abrasion-resistant coating for surface of a ship deck and a preparation method thereof. The anti-skid and abrasion-resistant coating is mainly prepared from the following components of epoxy resin, graphene, paeonol, carbon fiber powder, dibutyl phthalate, silicon dioxide, titanium dioxide, silicon carbide, polyamide and the like. The preparation method comprises the following steps of ball milling, dispersing, rolling and brushing and the like. The anti-skid and abrasion-resistant coating has the advantages that the good anti-skid and abrasion-resistant effects are realized, the stability is strong, the preparation technology is simple and convenient, the cost is lower, and the good application prospect is realized.

Owner:HEFEI UNIV OF TECH

Goods shelf used for warehousing transferring

Owner:SUZHOU FUSHIDE LOGISTICS FACILITIES

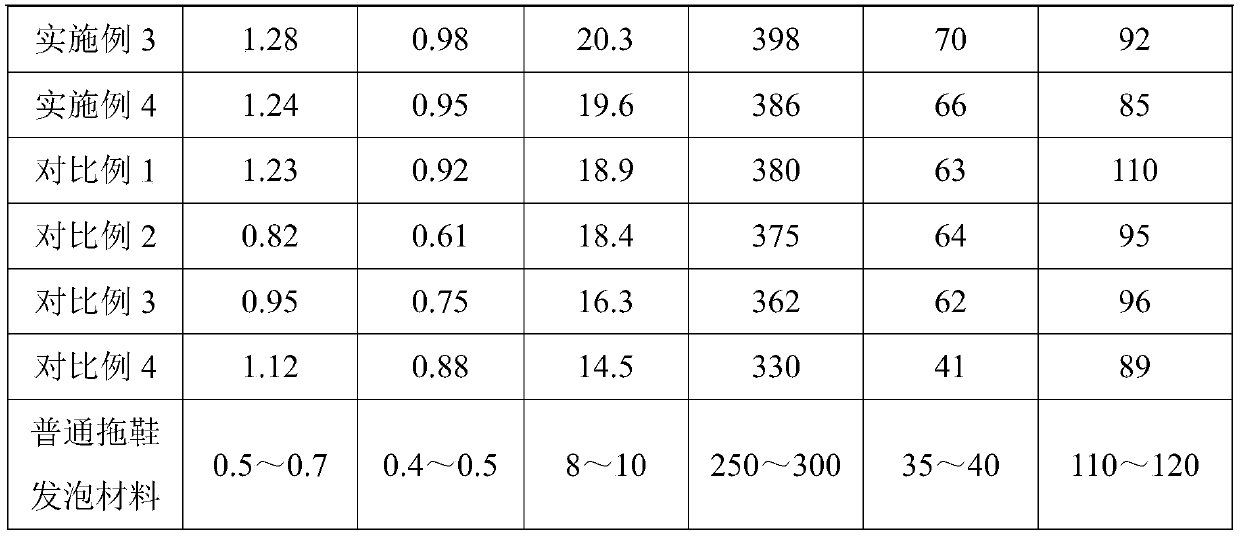

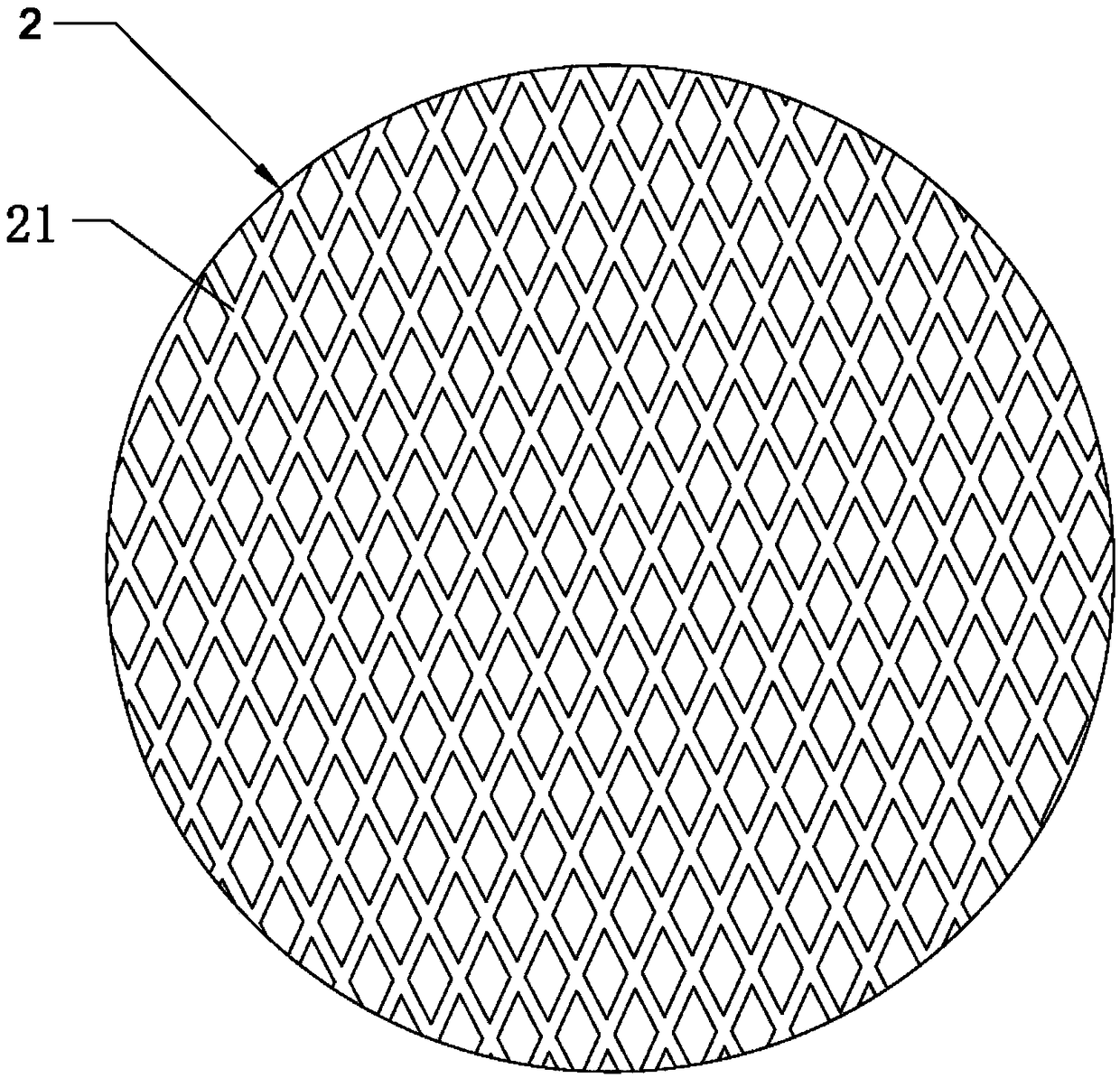

Non-slip slipper foaming material and preparation method thereof

The invention discloses a non-slip slipper foaming material and a preparation method thereof. The non-slip slipper foaming material is prepared from the following raw materials in parts by weight: 20-30 parts of natural rubber, 35-50 parts of butadiene rubber, 40-55 parts of butadiene rubber, 8-15 parts of high-wear-resistance carbon black, 6-8 parts of a polybutylene elastomer, 5-12 parts of an anti-skid agent, 5-10 parts of a short fiber, 5-10 parts of zinc oxide, 0.7-5 parts of zinc stearate, 1-5 parts of stearic acid, 1-4 parts of a cross-linking agent, 2-10 parts of an expanding agent and0.5-5 parts of a foaming agent. According to the non-slip slipper foaming material disclosed by the invention, through carefully selecting the raw material composition, the content of each raw material is optimized and a proper proportion is selected, the respective advantages are fully exerted, mutual complementation and mutual promotion are realized, the prepared non-slip slipper foaming material has the excellent anti-slip performance, and the cushioning performance and the tensile strength are both improved.

Owner:福建省超然科技发展有限公司

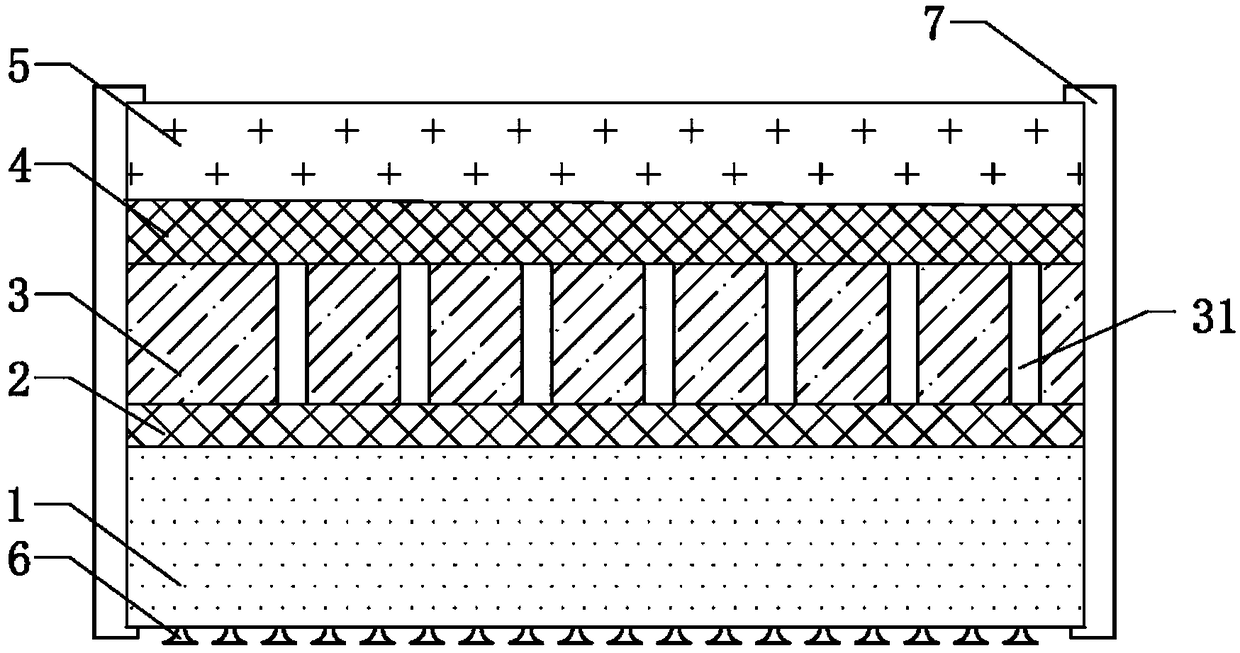

Carpet with silencing and denoising functions and preparation method of carpet

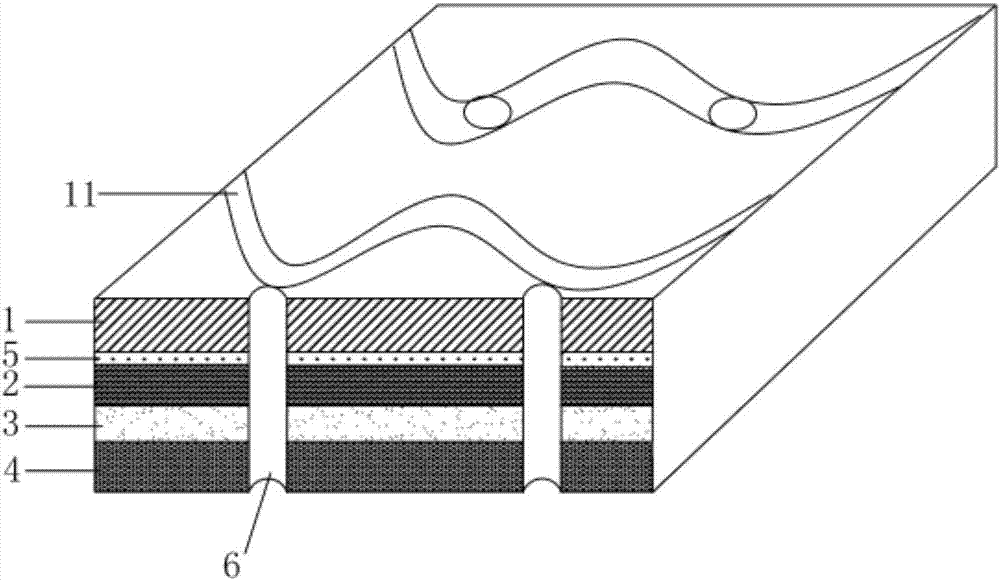

InactiveCN109393917AImprove the noise reduction effectGood anti-slip and wear-resistant effectPolyureas/polyurethane adhesivesFloor carpetsPolyesterFiber

The invention relates to the technical field of carpets, and in particular relates to a carpet with silencing and denoising functions and a preparation method of the carpet. The carpet with silencingand denoising functions comprises a wear-resistant layer, a first hot melt adhesive net layer, a sound absorbing layer, a second hot melt adhesive net layer and a weaving layer which are arranged in the sequence from bottom to top, wherein a plurality of anti-skidding bulge parts distributed at intervals are arranged below the wear-resistant layer, the upper ends of the anti-skidding bulge parts are connected with the lower surface of the wear-resistant layer, the weaving layer is formed by weaving warp weaving yarns and weft weaving yarns, and the sound absorbing layer is a polyester fiber sound absorbing layer. For the carpet with the silencing and denoising functions provided by the invention, through the compounding of the wear-resistant layer, the first hot melt adhesive net layer, the sound absorbing layer, the second hot melt adhesive net layer and the weaving layer, the prepared carpet has good silencing and denoising effects, through the wear-resistant layer and the anti-skidding bulge parts, the skid resistance and wear resistance of the carpet are improved, in addition, the connection among all the layers is stable, so that the service life of the carpet is long, moreover, the preparation method is simple and efficient, the operation process is easy to control, the industrial production is benefited, and the prepared product is stable in quality.

Owner:广东雅丽斯佳新材料有限公司

Epoxy road surface antiskid cladding layer and preparation method thereof

InactiveCN106396487AReduce dead loadImprove water resistanceIn situ pavingsPaving detailsEpoxyPorosity

The invention discloses an epoxy road surface antiskid cladding layer including a component A, a component B and a component C; the epoxy road surface antiskid cladding layer is characterized in that the component A comprises epoxy resin and a diluent, the component B comprises a curing agent and a toughening agent, and the component C comprises aggregates with different particle sizes. A preparation method of the epoxy road surface antiskid cladding layer comprises the following steps: S1, mixing and stirring; S2, preparing the curing agent; S3, testing the performance of a mixed liquid; S4, using; and S5, laying for a second time. The epoxy road surface antiskid cladding layer has a thin laying layer, is only 5-7 mm thick, and cannot increase the dead load of a bridge surface; the curing time is short, and thus the traffic influence is small; the bonding strength is high, and compared with a traditional asphalt material, the bonding properties of the cladding layer with the cement concrete bridge surface is more excellent; the water resistance and the chemical corrosion resistance are excellent, the chlorine ion erosion can be effectively prevented, while an asphalt mixture has a certain porosity and has poor water resistance; and the high and low temperature performance is good.

Owner:CARBON COMPOSITESTIANJIN CO LTD

Preparation method of anti-slip wear-resistant ceramic tile

The invention relates to the field of ceramic bricks, in particular, it provides a preparation method of anti-slip and wear-resistant ceramic bricks. The preparation method of the anti-slip and wear-resistant ceramic brick mainly includes the following steps: (a) preparing a green body layer; (b) spreading an anti-slip and wear-resistant glaze on the green body layer to form an anti-slip and wear-resistant layer; (c) sintering; Grinding glaze is mainly prepared from the following raw materials: anti-slip and wear-resistant particles, printing paste and sodium tripolyphosphate; the anti-slip and wear-resistant particles are mainly composed of the following components: SiO 2 、Al 2 o 3 , Fe 2 o 3 、TiO 2 、Na 2 O, K 2 O, MgO, CaO and loss on ignition. The method is simple in operation, scientific and reasonable in process steps, easy to implement, and low in cost. The anti-skid and wear-resistant ceramic tiles prepared by the method have excellent anti-skid and wear-resistant effects, and the product is high in quality, durable, safe and reliable.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Construction process for ceramic sand floor

ActiveCN109853906AImprove the decorative effectGood anti-slip and wear-resistant effectFlooringSurface layerRoad surface

The invention discloses a construction process for a ceramic sand floor. The construction process includes the following steps: (1) a road surface is cleaned and dried; (2) after clear water is addedto a self-leveling cement powder body for stirring and uniformly mixing, obtained self-leveling cement mortar is poured on the road surface; and (3) after the self-leveling cement mortar is levelled and before its surface is dried and cured, ceramic sand particles are uniformly sprayed on the surface of the self-leveling cement mortar as a surface layer, and the dosage ratio of the ceramic sand particles to the self-leveling cement mortar is 1.5-2 .5:1. The construction process for the ceramic sand floor provided by the invention enables ceramic sand to be sprayed on the surface of the self-leveling cement mortar according to a certain filling ratio, the obtained floor is good in skid resistance and wear resistance performance; and a whole construction process has only two steps, the self-leveling cement mortar does not need to be completely dried, the second step can be carried out, an operation method is simple, a construction period can be obviously shortened, and the construction efficiency is improved.

Owner:HUBEI QILI NEW MATERIAL CO LTD

Screw adjustable in hoof

InactiveCN103671430AImprove shock absorptionGood anti-slip and wear-resistant effectScrewsWear resistantEngineering

The invention discloses a screw adjustable in hoof. The screw comprises a metal supporting disc, an antiskid rubber pad, an extensible screw, a first nut and a second nut, a threaded hole is arranged at the center of the metal supporting disc, the metal supporting disc is connected with the extensible screw through the central threaded hole, the antiskid rubber pad is embedded in the metal supporting disc, the first nut is arranged at the lower end of the extensible rod, and the second nut is arranged at the upper end of the extensible rod. The screw has the advantages of good shock-absorbing performance, high antiskid and wear-resistant performance, great convenience in height adjusting and wide application range.

Owner:朱立花

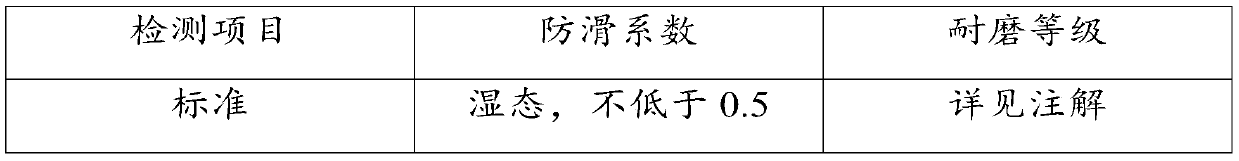

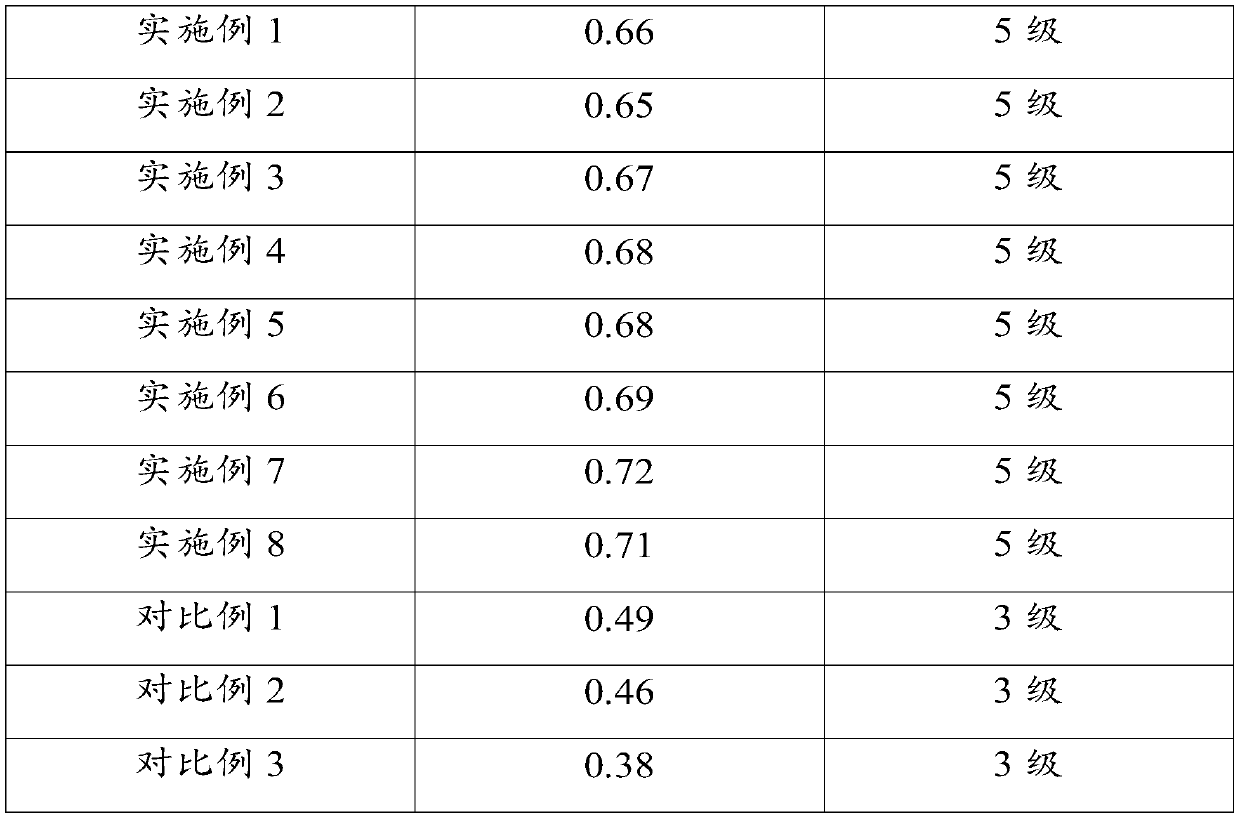

A kind of hydrophobic silicon dioxide modified rubber and its preparation method

The invention discloses a hydrophobic silicon dioxide used for modifying rubber. The formula and ratio are as follows: 40-60wt% of rubber matrix, 1-10wt% of other matrix resins, 5-25wt% of modified nano-silica, and 5% of filler oil ‑15wt%, additives 3‑15wt%. The invention also discloses a preparation method. The modified rubber material of the present invention improves the interface between silica and rubber, and plays a good reinforcing role. The nano-effect of silica makes the modified rubber have excellent wear resistance and high friction coefficient , has excellent anti-skid performance on water film interface or oil film interface, and can be used in anti-skid fields such as rubber tires and shoe sole materials.

Owner:成都纵横创新科技有限公司

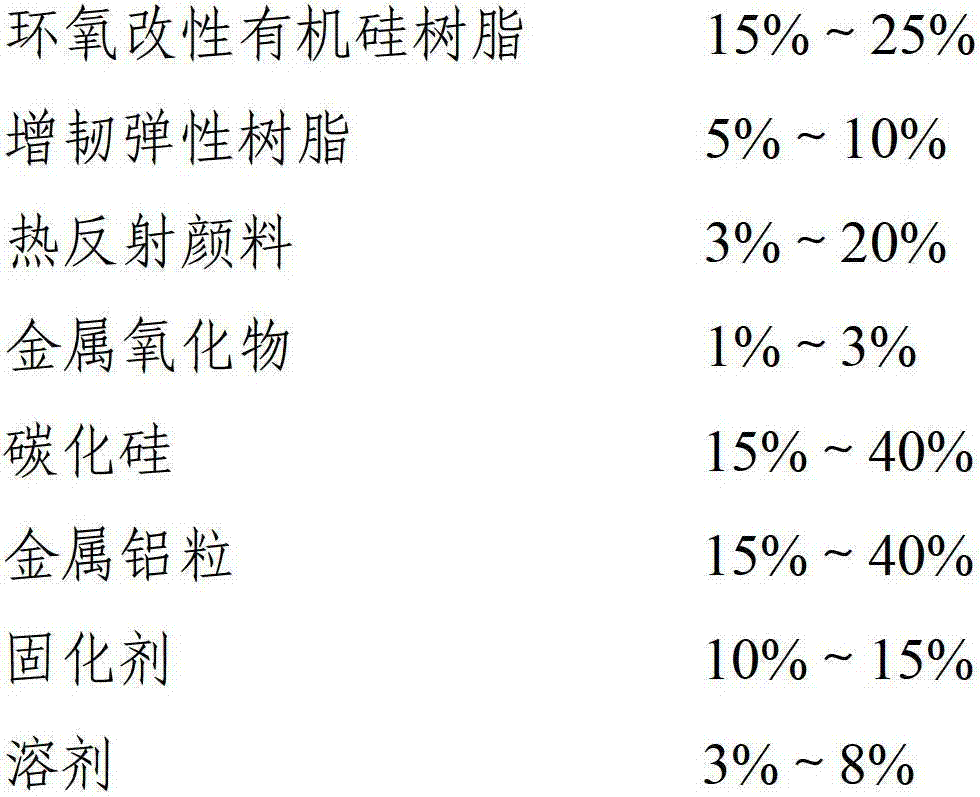

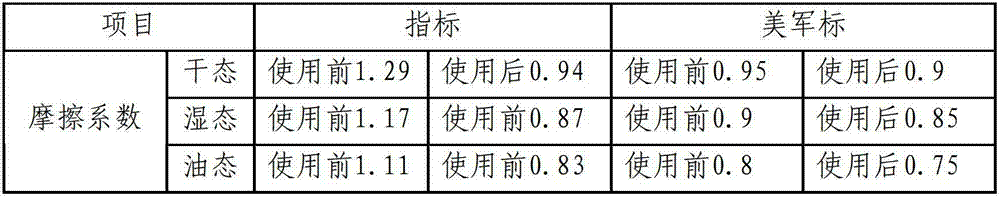

Roller-coating type high-durability multifunctional flight deck skid-resistant coating

The invention discloses a roller-coating type high-durability multifunctional flight deck skid-resistant coating. The roller-coating type high-durability multifunctional flight deck skid-resistant coating comprises epoxy modified organic silicon resin, toughened elastic resin, heat reflection pigment, metal oxide, silicon carbide, metal aluminum particle, a curing agent and a solvent. The coating can be applied to more base materials, has excellent adhesion to various base materials, and is particularly suitable for iron, aluminum alloy, thermal spraying metal and ceramic surface; moreover, the coating has excellent flexibility, skid-resistant abrasive resistance, salt spray resistance, ultraviolet ray resistance, fire prevention, high-temperature resistance, and resistance to various chemical solvents and oils; meanwhile, the coating has important performances of cooling by heat reflection, absorbing radar waves, reducing the heavy wear of the cable, and the like. The coating can be directly rolled, and can be used for simply and conveniently carrying out single-pass coating construction and repair; besides, the high and low temperature resistance is good, the construction is convenient and the requirements on the construction environment are low.

Owner:江阴市大阪涂料有限公司

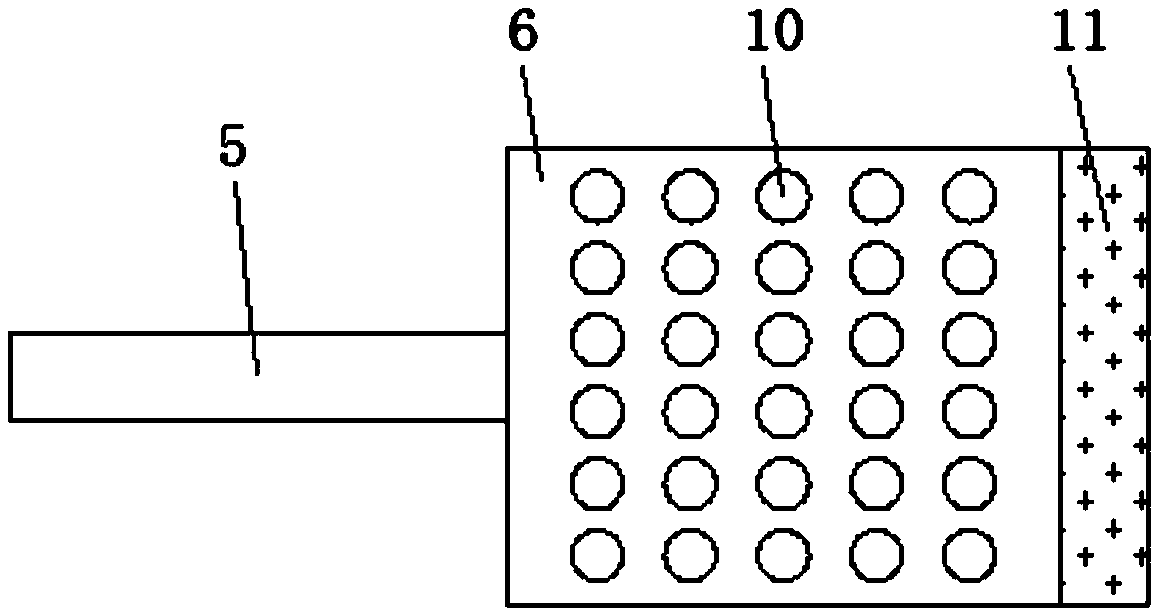

Non-slip wear-resistant ceramic tiles

The invention relates to the field of ceramic tiles, and particularly provides an anti-slip wear-resistant ceramic tile. The anti-slip wear-resistant ceramic tile comprises a green body layer and an anti-slip wear-resistant layer formed after the surface of the green body layer is coated with anti-slip wear-resistant glaze, wherein the anti-slip wear-resistant glaze is mainly prepared from the following raw materials in parts by mass: 90 to 110 parts of anti-slip wear-resistant particles, 90 to 110 parts of printing paste and 0.2 to 0.4 part of sodium tripolyphosphate; the anti-slip wear-resistant particles are mainly prepared from the following components in parts by mass: 60 to 70 parts of SiO2, 20 to 30 parts of Al2O3, 0.01 to 1 part of Fe2O3, 0.1 to 2 parts of TiO2, 1 to 5 parts of Na2O, 1 to 10 parts of K2O, 0.01 to 1 part of MgO, 0.1 to 5 parts of CaO and 0.1 to 2 parts of loss on ignition. The anti-slip wear-resistant ceramic tile has an excellent anti-slip effect and an excellent wear-resistant effect, has high product quality, and is durable, safe and reliable.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Water-based PRT colored pavement

The invention discloses a water-based PRT colored pavement which mainly comprises a water-based emulsion, a curing agent and composite powder in a ratio of 3: 1: 12. The coating does not contain an organic solvent, has no pungent smell, has no harm to the working environment and the health of constructors, and is more environment-friendly and safer in the transportation process; by adopting the mode that spraying is matched with traditional construction and the corresponding proportion of materials, the opening time on the pavement is long, drying and curing are rapid, the binding force with the pavement is higher, and by spraying colored paint, the water-based perfluoroethylene transparent cover face and the anti-skid layer, the color vividness, the skid resistance, the wear resistance and other performance are further enhanced.

Owner:朱广清

Anti-skid wear-resistant container bottom plate and preparation method thereof

PendingCN113665192AGood anti-slip and wear-resistant effectEasy to prepareSynthetic resin layered productsLaminationWear resistanceMechanical engineering

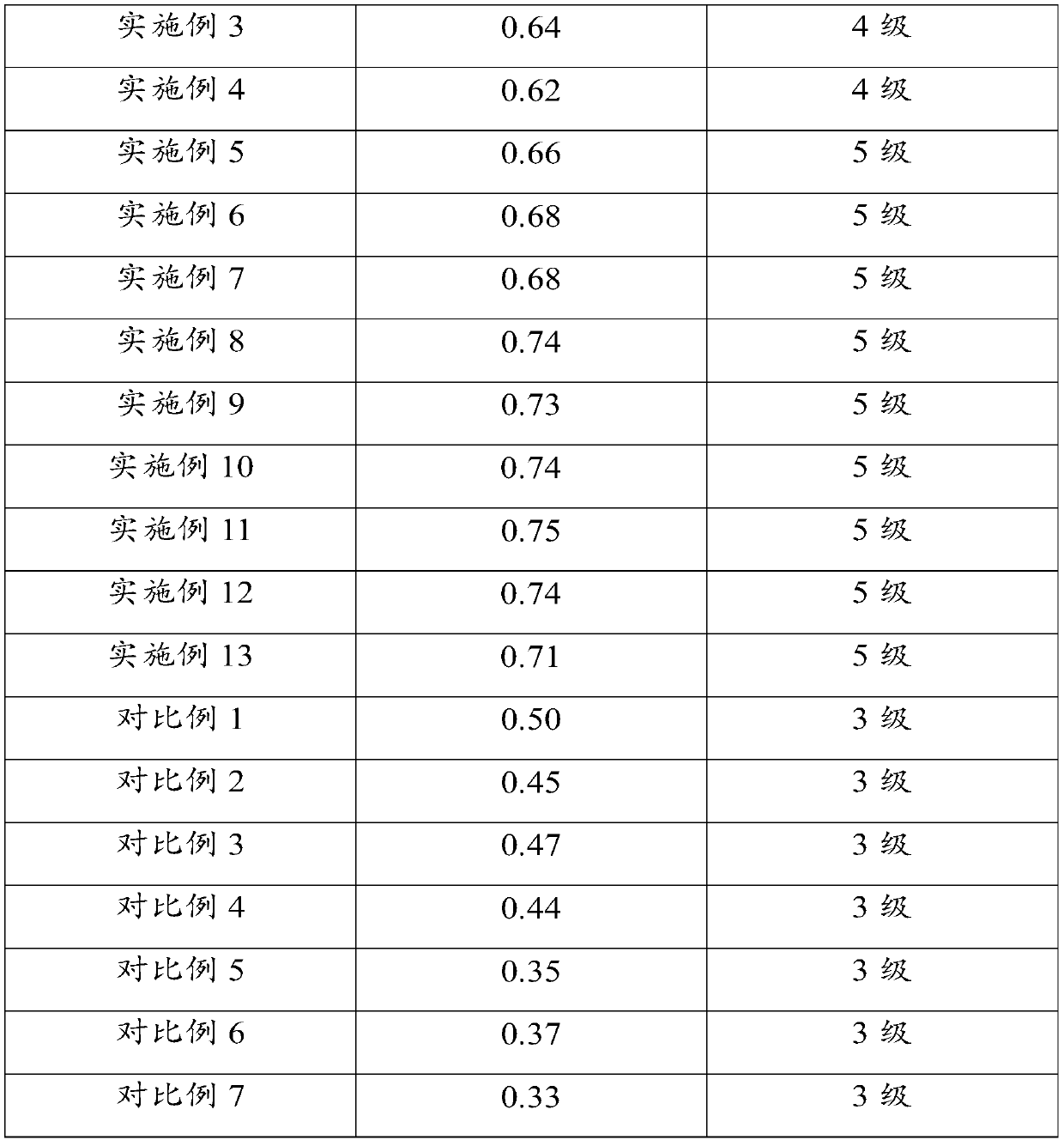

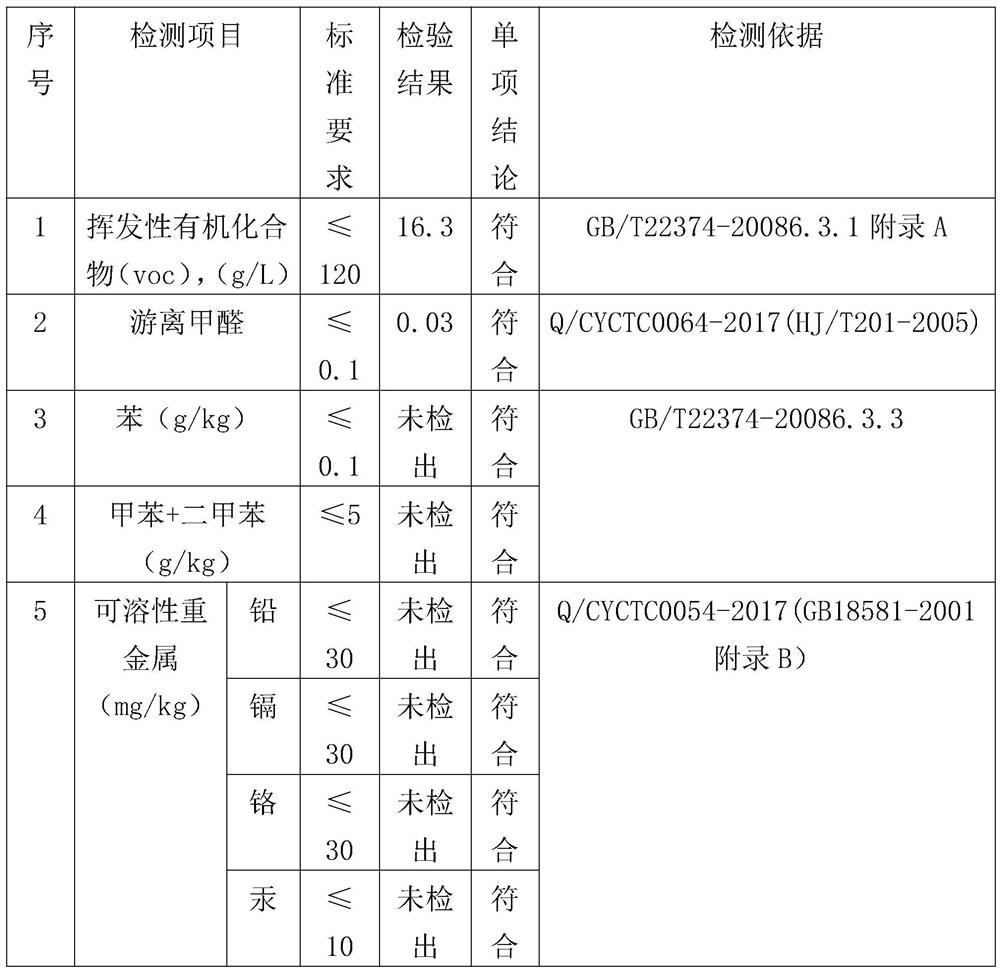

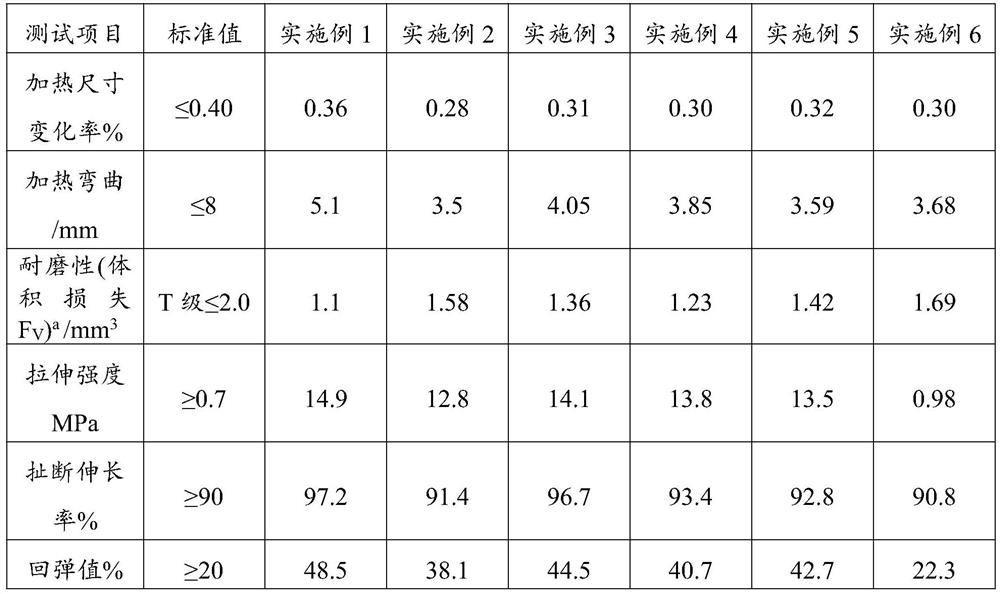

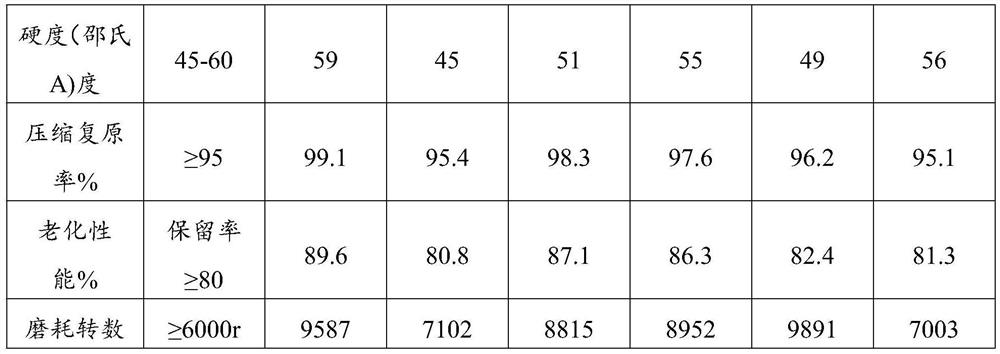

The invention belongs to the technical field of container bottom plates, and particularly relates to an anti-skid wear-resistant container bottom plate and a preparation method thereof. The invention provides the anti-skid wear-resistant container bottom plate. The anti-skid wear-resistant container bottom plate sequentially comprises a bottom layer, a middle elastic layer and a surface wear-resistant layer from bottom to top, and the surface wear-resistant layer comprises a wear-resistant sheet or a wear-resistant paint layer. The invention further provides a preparation method of the anti-skid wear-resistant container bottom plate. According to the result of the embodiment, the anti-skid and wear-resistant container bottom plate has high anti-skid and wear-resistant performance, the wear resistance (volume loss FV) a of the anti-skid and wear-resistant container bottom plate ranges from 1.1 mm<3> to 1.69 mm<3>, the number of abrasion revolutions ranges from 7003 revolutions to 9891 revolutions, and the retention rate of aging performance ranges from 80.8% to 89.6%.

Owner:FUJIAN HEQIZU FORESTRY SCI & TECH CO LTD

Anti-slip and wear-resistant coating on ship deck surface and preparation method thereof

ActiveCN107868576BGood anti-slip and wear-resistant effectReduce wear ratePolyamide coatingsEpoxy resin coatingsEpoxyFiber

The invention discloses an anti-skid and abrasion-resistant coating for surface of a ship deck and a preparation method thereof. The anti-skid and abrasion-resistant coating is mainly prepared from the following components of epoxy resin, graphene, paeonol, carbon fiber powder, dibutyl phthalate, silicon dioxide, titanium dioxide, silicon carbide, polyamide and the like. The preparation method comprises the following steps of ball milling, dispersing, rolling and brushing and the like. The anti-skid and abrasion-resistant coating has the advantages that the good anti-skid and abrasion-resistant effects are realized, the stability is strong, the preparation technology is simple and convenient, the cost is lower, and the good application prospect is realized.

Owner:HEFEI UNIV OF TECH

Method for grafting and activating powder rubber for modifying to pavement asphalt

InactiveCN100523065CLarge specific surface areaEasy to cutIn situ pavingsPlastic recyclingPolymer scienceTar

The invention discloses a synthetic utilizing method of waste rubber product to obtain grafted active modified tar, which comprises the following steps: grinding waste rubber product into 30-order powder rubber; blending 4-8% softening agent, 0.2-0.5% coking-proof agent, 0.3-0.6% heat stabilizer, 0.5-0.9% activator and 90-95% powder rubber to break chain through high-cutting equipment; obtaining activated powder rubber; stirring the compound of 10-25% activated powder rubber, 60-90% tar, 5-8% dissolving-increasing agent and 8-10% grafting agent through high-speed stirrer; obtaining the product.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

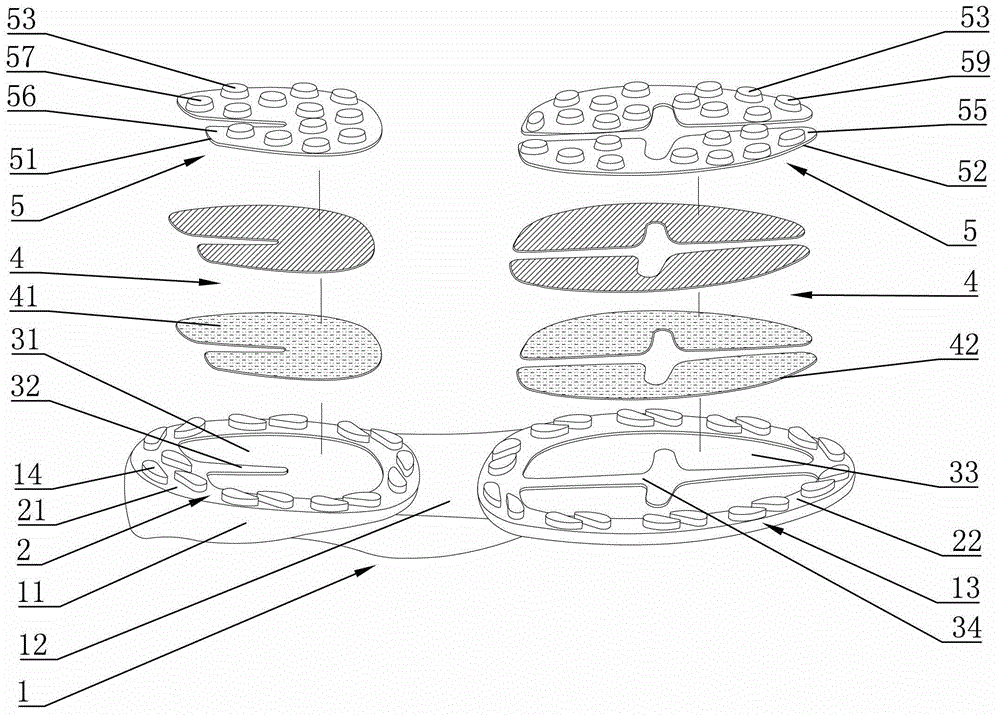

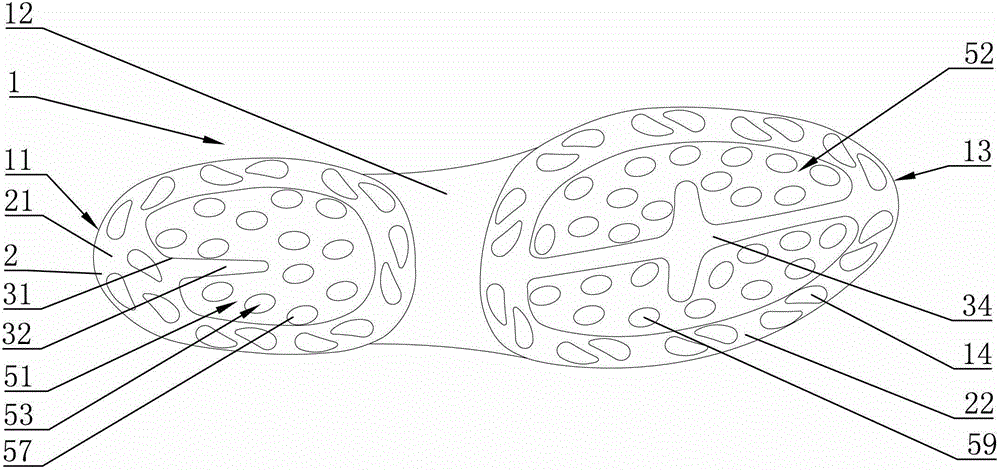

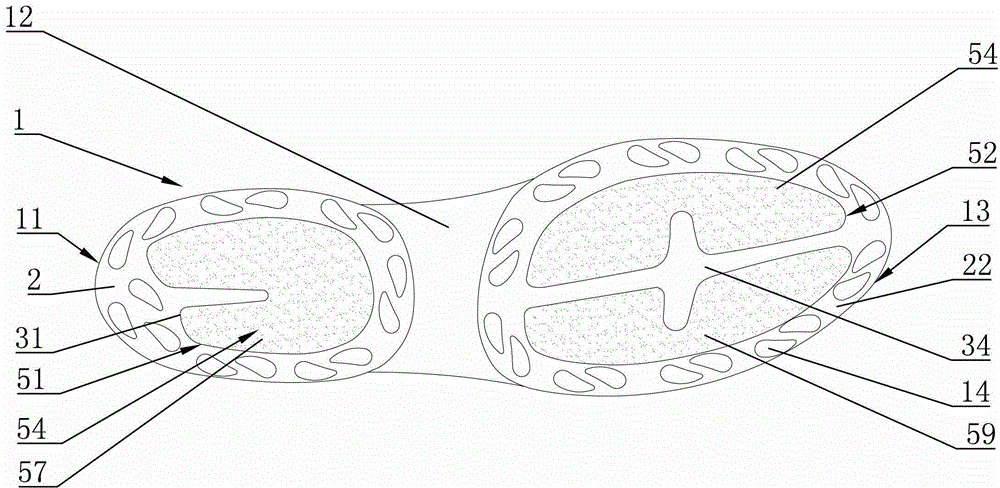

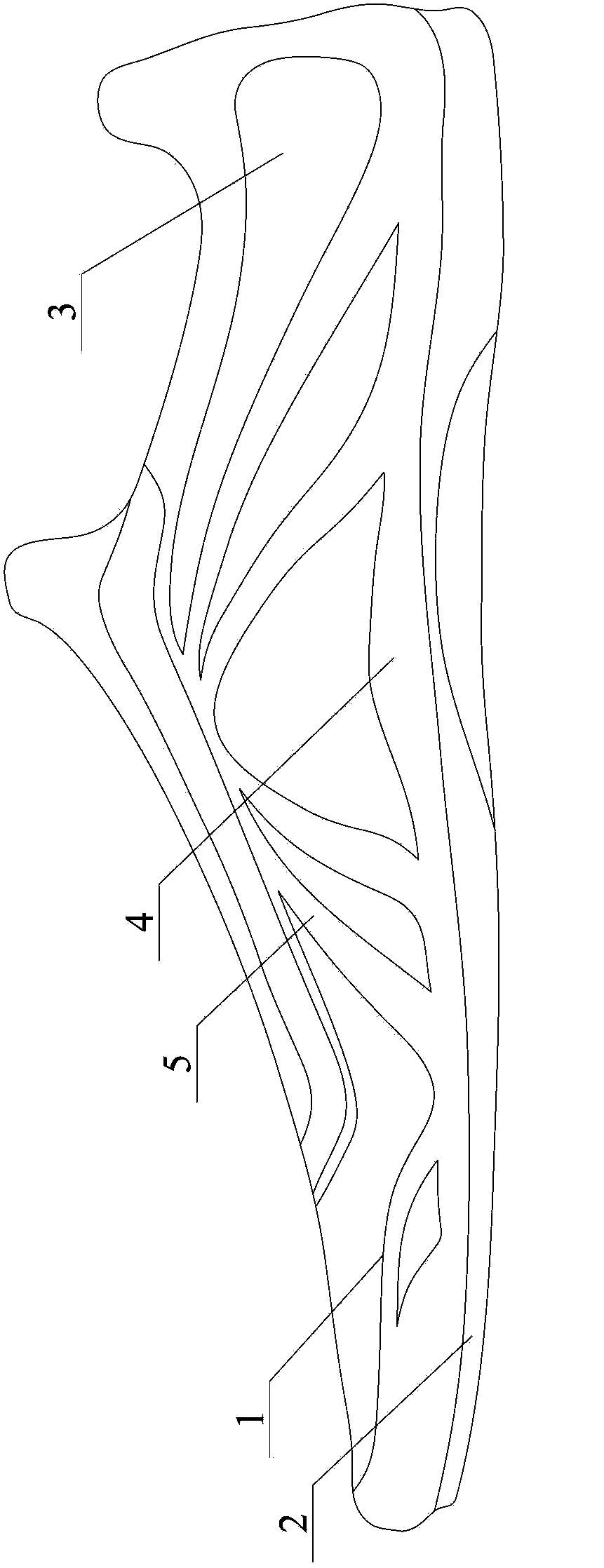

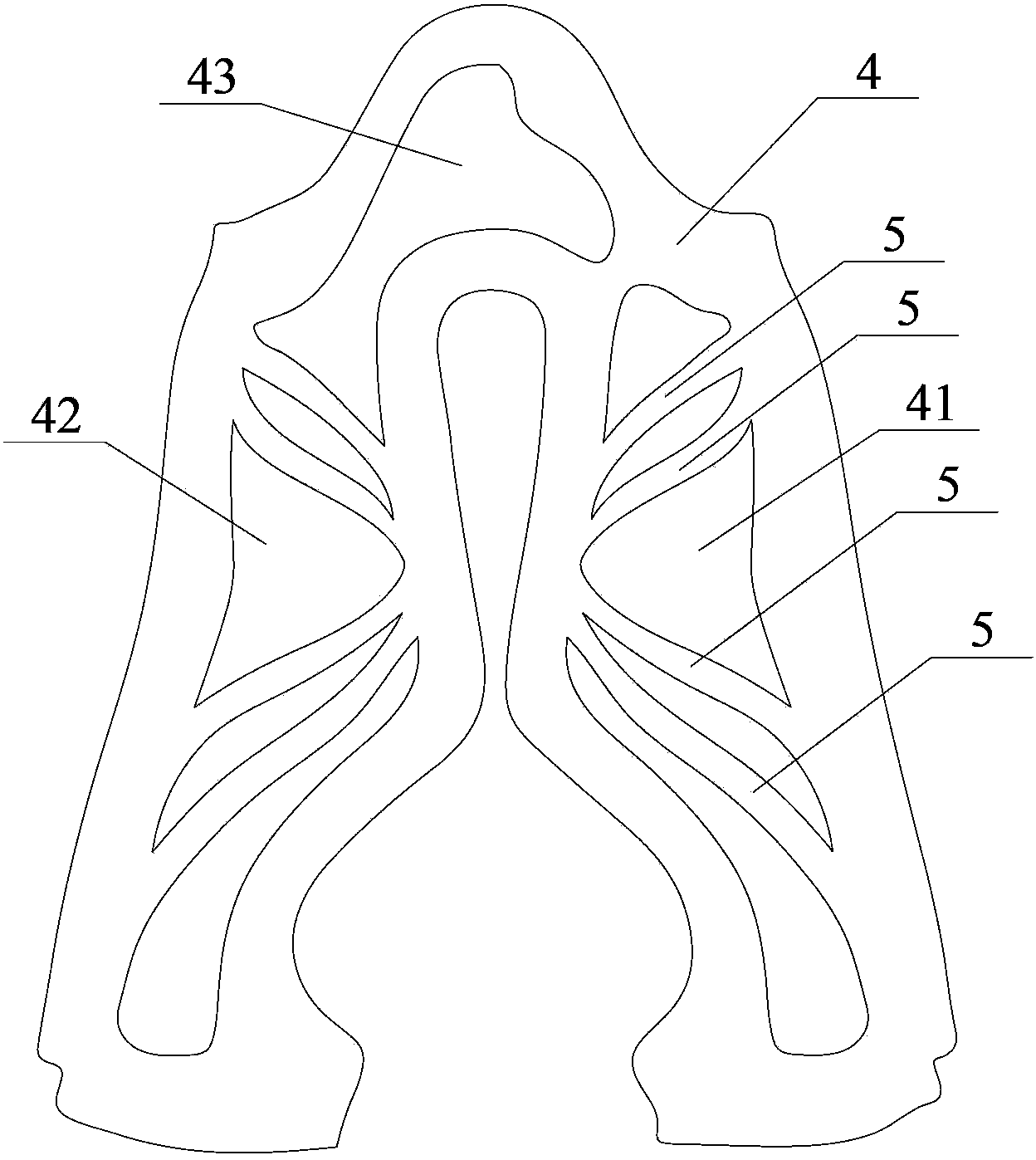

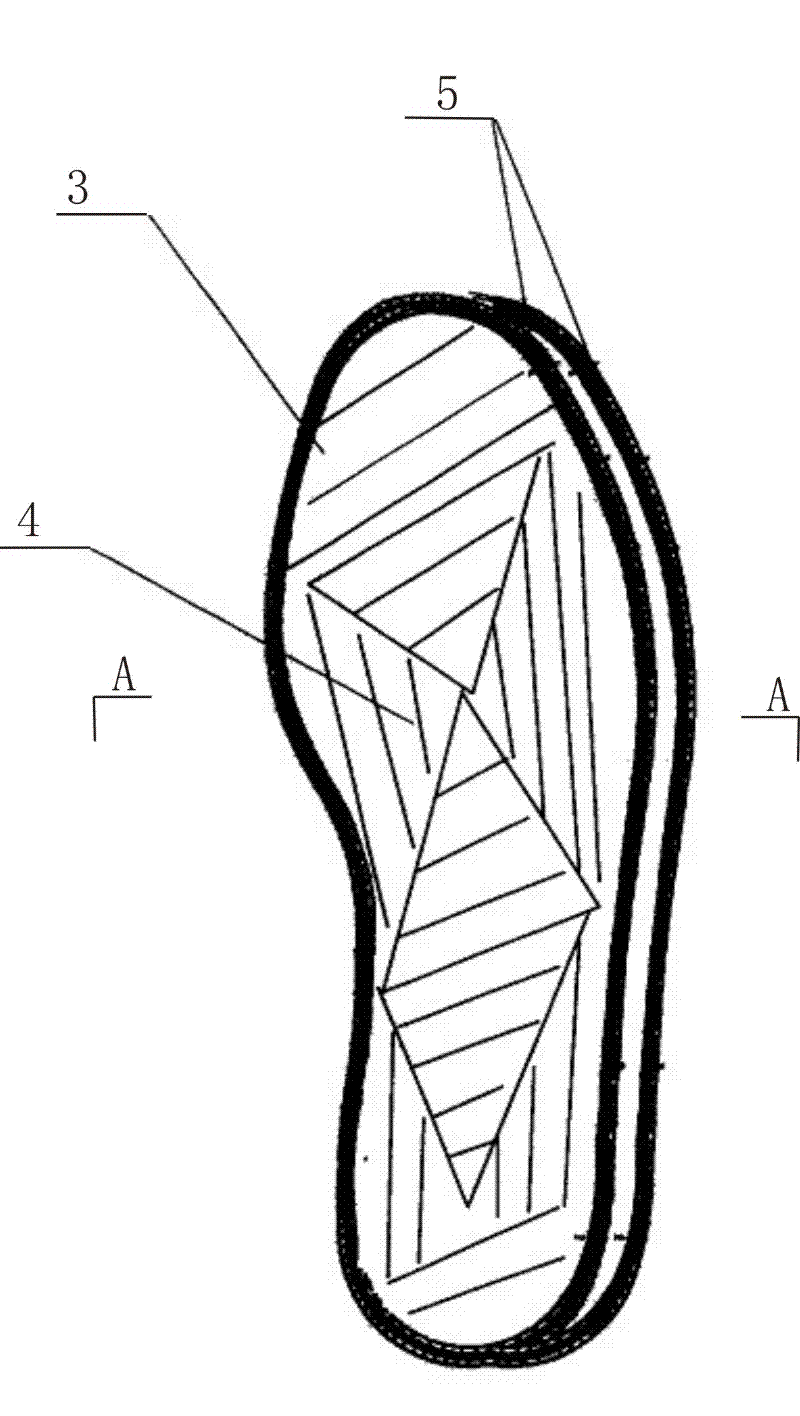

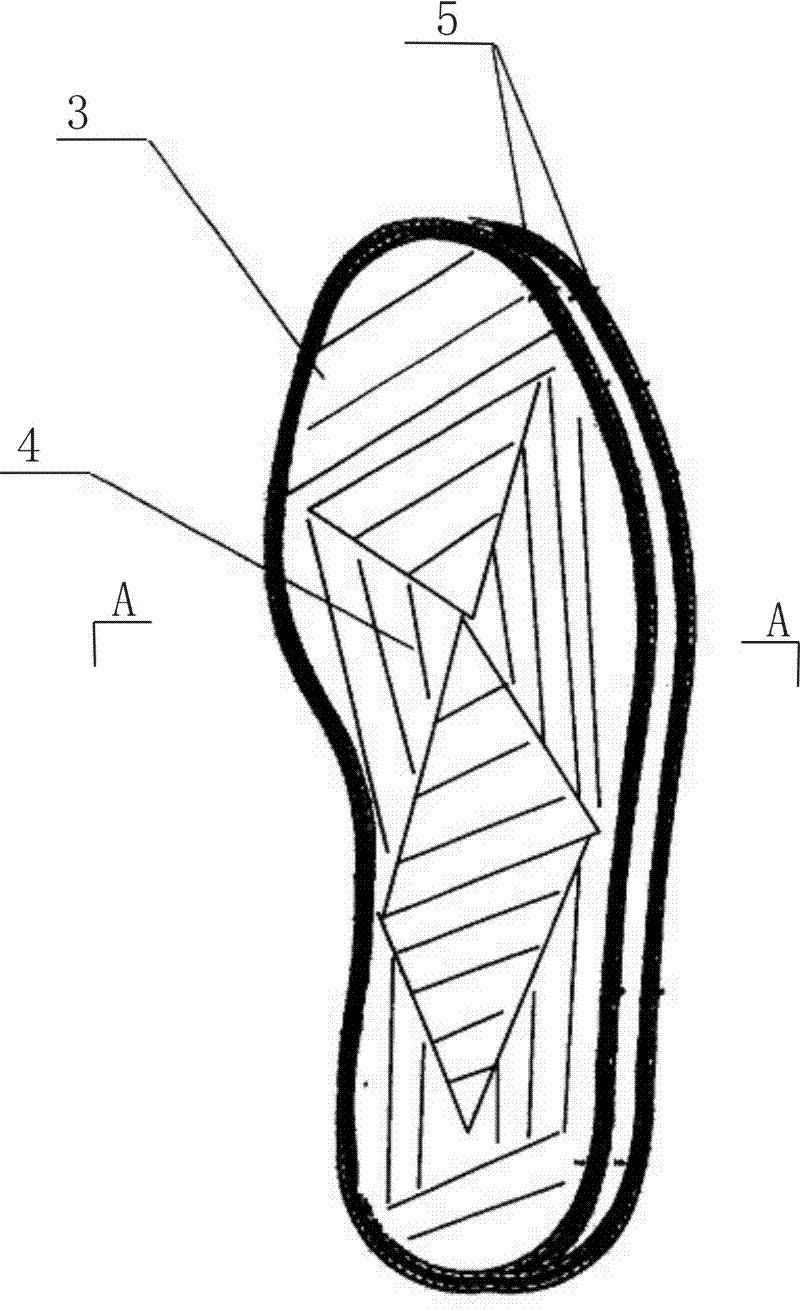

A shoe sole with replaceable sole and shoes using the shoe sole

ActiveCN103230125BIncrease frictionGood anti-slip and wear-resistant effectSolesGround contactEngineering

Disclosed are soles with replaceable bottom pattern pieces and shoes using the soles. Each of the soles comprises a large sole body and bottom pattern pieces. The large sole bodies comprise foot sole portions, foot arch portions and heel portions which are connected successively. The foot arch portions and the heel portions protrude outwards relative to the foot arch portions to form ground touching platforms respectively. A plurality of accommodation cavities with openings outward, in which the bottom pattern pieces can be embedded to be fixed, are arranged internally on the ground touching surfaces of the ground contacting platforms respectively, and shapes of accommodation cavity bottoms are matched with the bottom pattern pieces; and a plurality of rows of large sole body anti-skidding particles are arranged at positions close to edges of the ground touching surfaces. The bottom pattern pieces are attached to bottom surfaces of the accommodation cavities through Velcro, a plurality of bottom pattern piece anti-skidding particles are arranged on the surfaces of the grounding touching surfaces of the bottom pattern pieces, and planar shapes of the Velcro are matched with the bottom pattern pieces. Different bottom pattern pieces can be replaced according to different requirements of places or surroundings, so that the soles are practical and convenient to carry.

Owner:MAOTAI FUJIAN SOLES CO LTD

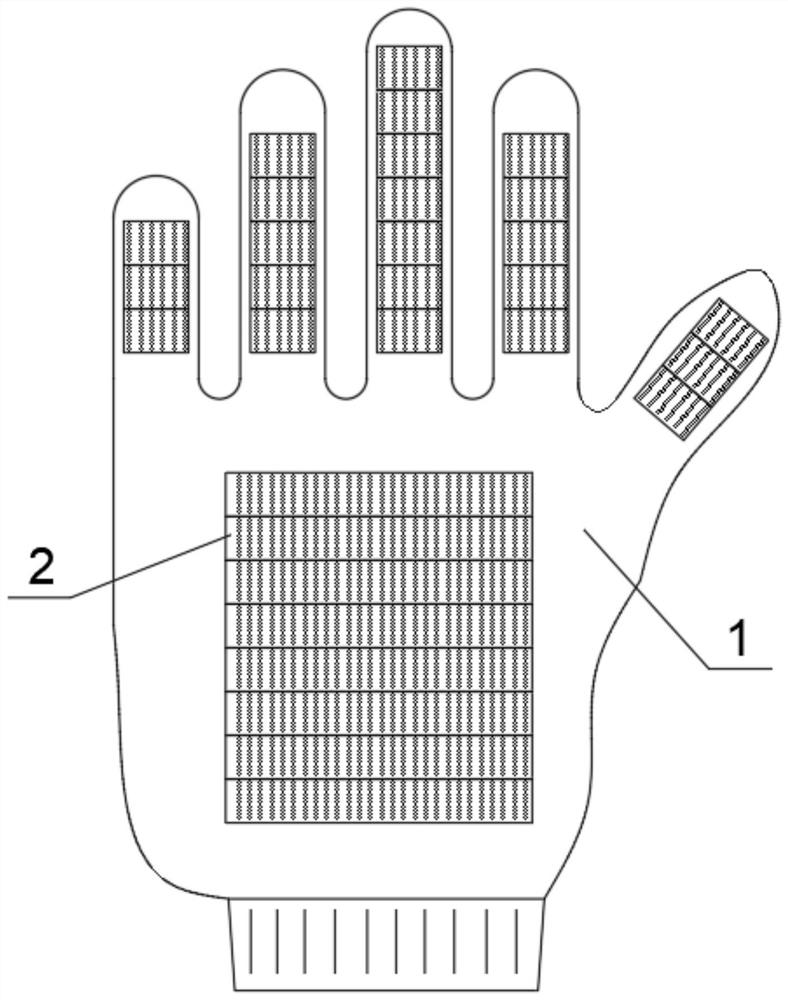

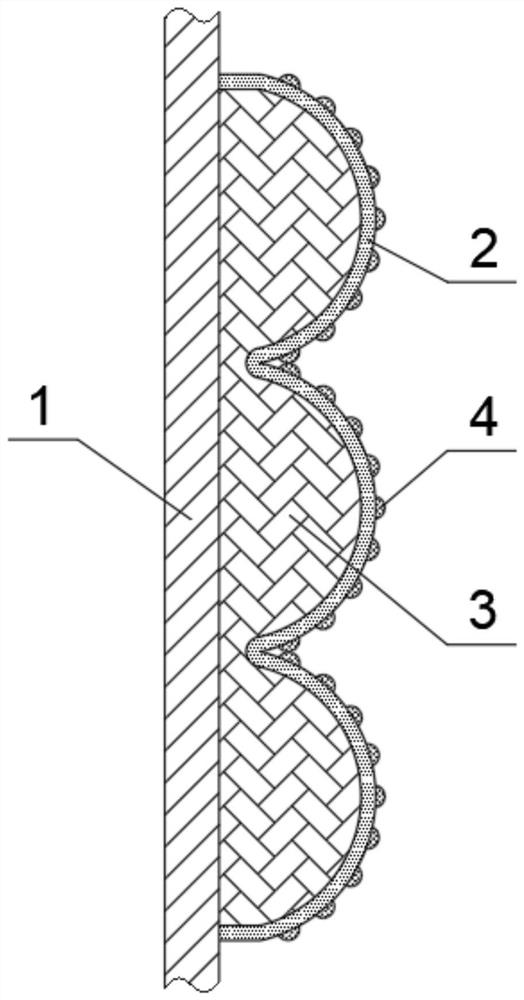

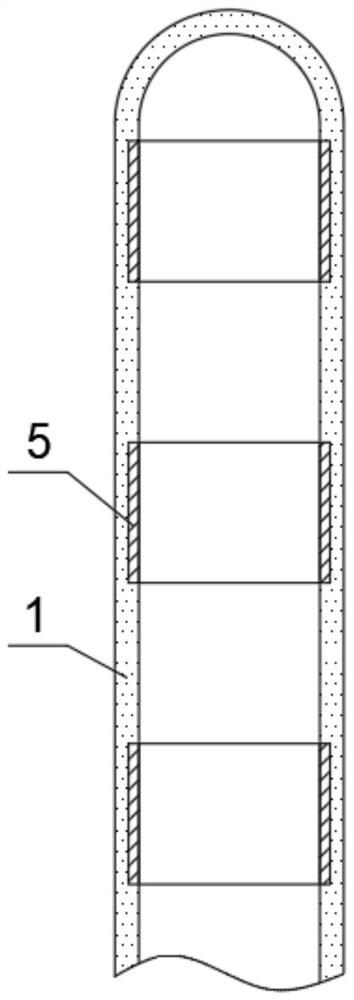

Antiskid wear-resistant protective rubber glove

PendingCN112205695AImprove skid resistanceImprove wear resistanceGlovesProtective garmentComposite materialMechanical engineering

The invention discloses an antiskid wear-resistant protective rubber glove which comprises a glove body, thickening sleeves of corrugated structures are fixedly connected to fingers and the palm center of the glove body, sponge is arranged among the thickening sleeves and the glove body, and a plurality of antiskid protruding points are fixedly connected to the outer end faces of the thickening sleeves at equal intervals in an annular mode. And a plurality of reinforcing rings are fixedly connected to the inner sides of the fingers of the glove body. According to the invention, by means of thecontact area between the thickening sleeves of the corrugated structures and an object needing to be held and the arrangement of the thickening sleeves and the anti-skid protruding points at the positions of the fingers and the palm center in the glove body, the wear-resisting performance of the frequently-worn position is improved, and therefore the anti-skid and wear-resisting performance of the glove is improved; reinforcing rings are fixedly connected to the inner sides of the fingers of the glove body, so that the protection performance of the glove on the fingers is improved, the shockabsorption effect on the hand is improved through the arrangement of the sponge, and the protection performance on the hand of a user is further improved.

Owner:TOP GLOVE XINGHUA CO LTD

Running shoe

Owner:FUJIAN HONGXING ERKE SPORTING GOODS CO LTD

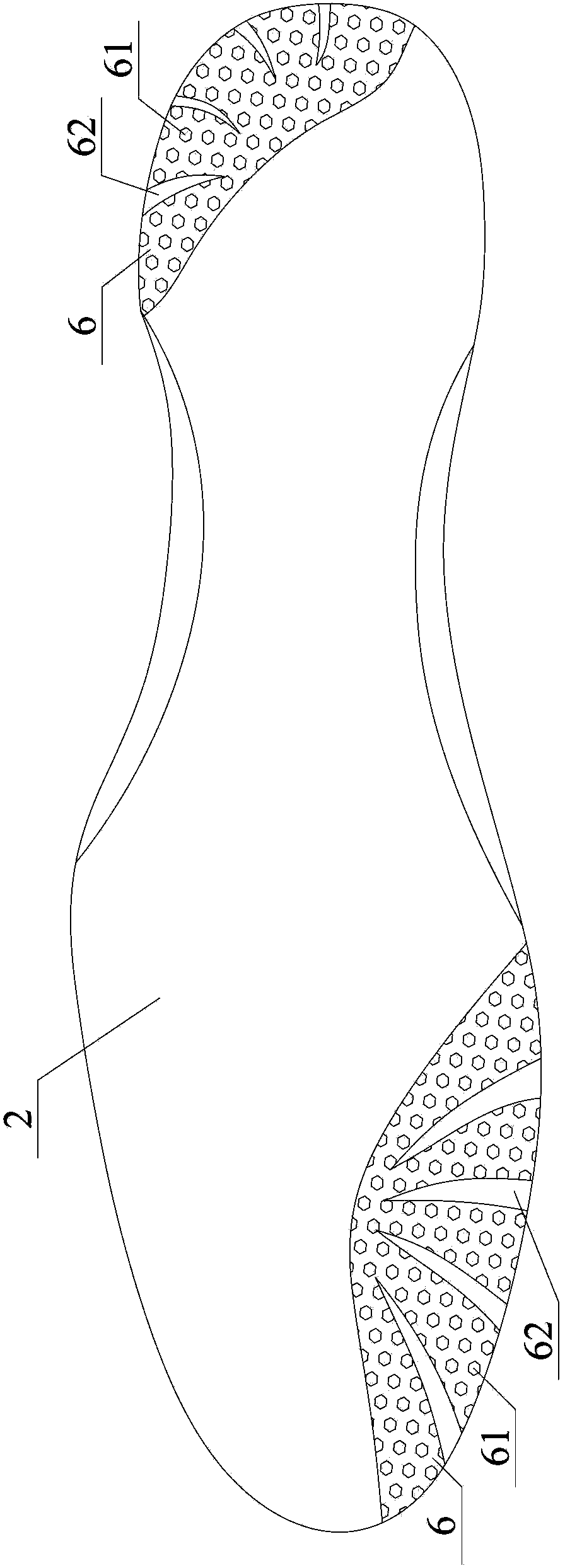

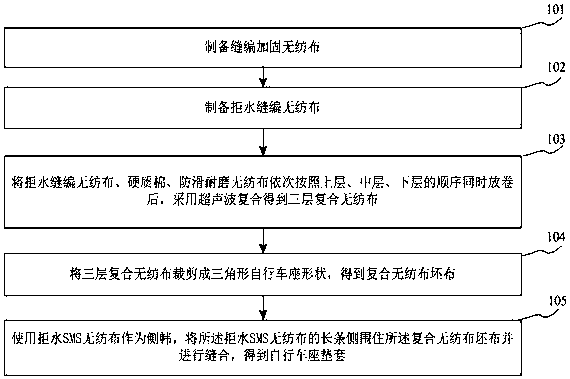

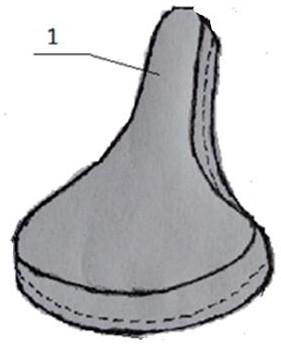

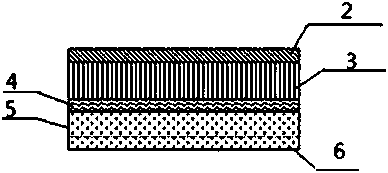

Bicycle seat cushion cover and preparation method thereof

ActiveCN107856374BGood warmth retentionHigh hardnessLamination ancillary operationsSynthetic resin layered productsEngineeringNonwoven fabric

Owner:JIAXING UNIV

Wear-resisting comfortable cloth shoe soles

The invention provides a pair of wear-resisting comfortable cloth shoe soles. Each shoe sloe is sewed of a sole bottom and a shoe outsole, a sole framework layer which is a cattail braided fabric layer is arranged between the sole bottom and the sole bottom, the shoe outsole is provided with a wear-resisting anti-skidding layer with patterns, and reinforcing ribs are arranged around the shoe outer sole, and the reinforcing ribs, the sole bottom and the shoe outsole are sewed together in a serging manner. The pair of wear-resisting comfortable cloth shoe soles, provided by the invention, has the advantages that sewed parts of the sole bottoms and the shoe outsoles are not easy to break and the firm and durable purpose is achieved; the shoe soles have good anti-skidding wear-resisting effect because of the wear-resisting anti-skidding layers with patterns, and the service life of the cloth shoe soles is prolonged; and since each sole framework layer is a cattail braided fabric layer, the firmness of the whole shoe soles is improved, moreover, the softness, air permeability and moisture absorption of the whole shoe soles are also increased, and the shoe soles can protect feet against cold in winter and cool feet in summer and are comfortable to wear.

Owner:枝江市步步升布艺有限公司

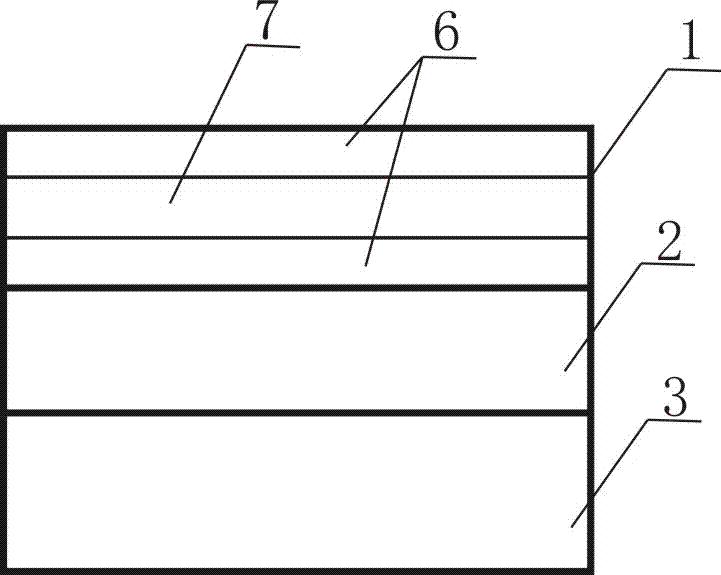

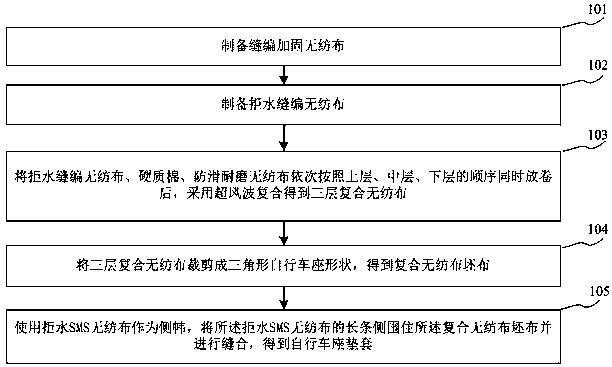

Bicycle saddle cover and preparation method thereof

ActiveCN107856374AGood warmth retentionHigh hardnessLamination ancillary operationsSynthetic resin layered productsWear resistantEngineering

The invention discloses a bicycle saddle cover and a preparation method thereof, and relates to the field of bicycle products. The bicycle saddle cover consists of three-layer composite non-woven fabrics and side cover. The method comprises the following steps: preparing a water-repellent stitch-knitted reinforced non-woven fabric by using PET fibers; preparing a water-repellent stitch-knitted non-woven fabric; unwinding the water-repellent stitch-knitted non-woven fabric, hard cotton and an anti-skid wear-resistant non-woven fabric in sequence according to a sequence of an upper layer, an middle layer and an lower layer at a same time, and adopting ultrasonic combination to obtain a three-layer combined non-woven fabric; cutting the three-layer combined non-woven fabric into a triangularbicycle-saddle shape, so as to obtain a combined non-woven fabric grey cloth; using a water-repellent SMS non-woven fabric as the side cover; surrounding the combined non-woven fabric grey cloth witha strip-shaped side of the water-repellent SMS non-woven fabric and carrying out sewing, so as to obtain the bicycle saddle cover. The bicycle saddle cover provided by the invention is prepared by using the hard cotton, the water-repellent stitch-knitted non-woven fabric, a PP spunbond non-woven point plastic cloth, and an ultrasonic reinforcing mode for carrying out a point composite process, sothat the bicycle saddle cover has the advantages of skid resistance, wear resistance, collision buffering, process simplification and the like.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com