Anti-skid wear-resistant container bottom plate and preparation method thereof

A container floor, anti-skid technology, applied in chemical instruments and methods, lamination devices, wood layer products, etc., can solve problems such as reducing the mechanical properties of the container floor and affecting the service life of the container floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

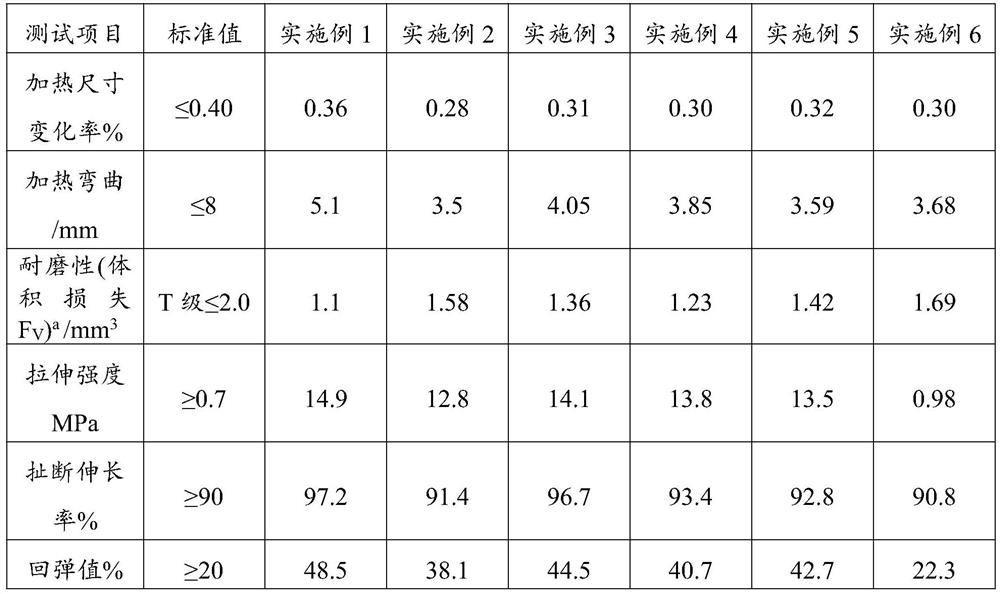

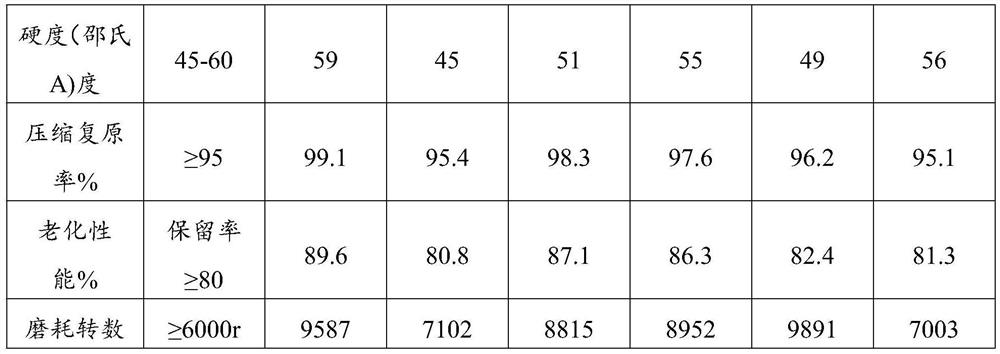

Examples

preparation example Construction

[0030] In the present invention, the bottom layer is preferably a bamboo-wood composite board. The source of the bamboo-wood board is not particularly limited in the present invention. It can be purchased directly or made by yourself. In the embodiment of the present invention, the bamboo-wood composite board It is preferably obtained by a self-made method, and the preparation method of the bamboo-wood composite board preferably includes the following steps: processing moso bamboo into bamboo strips, drying and dipping in order to obtain a bamboo curtain, and forming a bamboo curtain and a wood veneer, The bamboo-wood composite board slab is obtained; the bamboo-wood composite board slab is pre-pressed, hot-pressed and edge-sawed sequentially to obtain the bamboo-wood composite board. In the present invention, the thickness of the wood veneer is preferably 1.0 to 2.0 mm, more preferably 1.5 to 1.7 mm; in the present invention, the surface of the wood veneer is preferably coated...

Embodiment 1

[0067] 60 parts of thermoplastic polyurethane elastomer, 60 parts of calcium carbonate, 2 parts of zinc calcium stabilizer, 1 part of polyethylene wax, 0.5 part of Al with a particle size of 460 mesh 2 o 3 , 2 parts of SiO with a particle size of 450 mesh 2 , 1.5 parts of stearic acid and 0.5 parts of silicone oil are mixed and placed in a three-layer co-extruded closed rubber mixer, mixed for 5 minutes at 165 ° C to obtain a surface wear-resistant layer, and the surface is wear-resistant by a three-roll calender The layer is discharged and calendered to obtain a wear-resistant sheet with a thickness of 0.05mm; the temperature of the pressing roller is 180°C±2°C, and the gap between the pressing rollers is 0.05mm, and the wear-resistant sheet is cooled to 45°C for standby;

[0068] 50 parts of polyvinyl chloride, 100 parts of calcium carbonate, 10 parts of palm oil, 1 part of 138 rosin resin, 1 part of zinc calcium stabilizer, 0.3 part of carbon black and 5.0 parts of SiO wit...

Embodiment 2

[0072] 80 parts of thermoplastic polyurethane elastomer, 65 parts of calcium carbonate, 1.5 parts of zinc calcium stabilizer, 1 part of polyethylene wax, 1 part of Al with a particle size of 400 mesh 2 o 3 , 1.5 parts of SiO with a particle size of 430 mesh 2 , 1 part of stearic acid and 0.5 part of silicone oil are mixed and put into a three-layer co-extruded closed rubber mixer, and mixed at 150 ° C for 6 minutes to obtain the surface wear-resistant layer. The material is discharged and calendered to obtain a wear-resistant sheet with a thickness of 0.1mm; the temperature of the pressing roller is 180°C±2°C, the gap between the pressing rollers is 0.1mm, and the wear-resistant sheet is cooled to 45°C for later use;

[0073] 60 parts of polyvinyl chloride, 150 parts of calcium carbonate, 15 parts of linseed oil, 1.5 parts of C9 petroleum resin, 1.5 parts of zinc calcium stabilizer, 0.2 parts of carbon black and 3 parts of SiO with a particle size of 250 mesh 2 After mixing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com