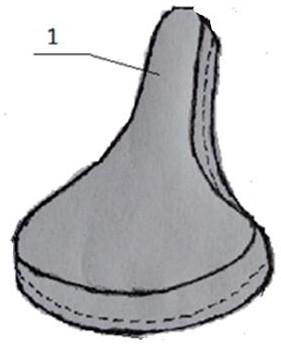

Bicycle seat cushion cover and preparation method thereof

A technology for bicycles and seat cushions, applied in the field of bicycle seat cushion covers and their preparation, can solve the problems of difficult to realize related products, complicated production process, difficult to realize, etc., and can reduce bumps, increase wear resistance, and improve wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

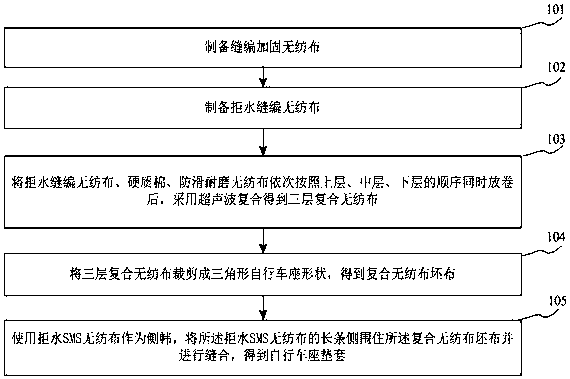

Method used

Image

Examples

Embodiment 1

[0038] 1) PET fiber is used to prepare stitch-bonded reinforced non-woven fabric.

[0039] 2) Water-repellent treatment is performed on the stitch-bonded reinforced non-woven fabric to obtain a water-repellent stitch-bonded non-woven fabric.

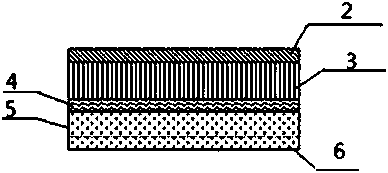

[0040] 3) Unwind the water-repellent stitch-bonded non-woven fabric, hard cotton and non-slip and wear-resistant non-woven fabric simultaneously in the order of the upper layer, the middle layer, and the lower layer, and stack them together to form a three-layer composite non-woven fabric web. When unwinding, the non-slip and wear-resistant surface of the non-slip and wear-resistant non-woven fabric faces outward, and the three-layer fabric composed of the water-repellent stitch-bonded non-woven fabric, the hard cotton and the non-slip and wear-resistant non-woven fabric is The composite non-woven fiber web is fed together into an ultrasonic composite machine for a composite reinforcement process to obtain a three-layer composite non-wov...

Embodiment 2

[0044] 1) Select polyester fibers with a length of 51-65mm and a fineness of 1.5-3D, and obtain a semi-finished product of stitch-bonded reinforced non-woven fabric after opening, mixing, carding and cross-lapping processes.

[0045] 2) Send the semi-finished product of stitch-bonded reinforced non-woven fabric into machine number 22-25 needles / (25mm) -1 The double-bar stitch-bonding machine is used for stitch-bonding reinforcement, and the grammage is 80-100 g / m 2 Stitch-bonded reinforced non-woven fabric, the stitch-bonded reinforcement process uses high-strength polyester filaments as the stitch-bonded reinforced yarn, the fineness of the stitch-bonded reinforced yarn is one of 150D / 2 and 150D / 3, and the stitched The stitch length of the braided reinforcing yarn is 0.9-1.8 mm, and the head speed of the double-bar stitch-bonding machine is 1000-1200 rpm / min.

[0046] 3) Configure the water repellent solution: use an environmentally friendly fluorine-based water repellent ag...

Embodiment 3

[0057] 1) Preparation of stitch-bonded reinforced non-woven fabric

[0058] (1) Select polyester fibers with a length of 65 mm and a fineness of 3D, and obtain a semi-finished product of stitch-bonded reinforced non-woven fabric after opening, mixing, carding and cross-lapping processes.

[0059] (2) Send the semi-finished product of stitch-bonded reinforced non-woven fabric into machine number 25 needles / (25mm) -1 The double-bar stitch-bonding machine is used for stitch-bonding reinforcement, using high-strength polyester filament as the stitch-bonding reinforcement yarn, the fineness of the stitch-bonding reinforcement yarn is 150D / 3, and the stitch length of the stitch-bonding reinforcement yarn is 1.8 mm , the head speed of the double-bar stitch-bonding machine is 1000rpm / min, and the grammage is 100 g / m 2 Stitch-bonded reinforced non-woven fabric.

[0060] 2) Preparation of water-repellent stitch-bonded non-woven fabric

[0061] (1) Configure the water repellent soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com