Roller-coating type high-durability multifunctional flight deck skid-resistant coating

A technology for flight decks and anti-skid coatings, applied in coatings and other directions, can solve problems such as poor weather resistance, harsh construction environment requirements, and long cycle times, and achieve excellent resistance to various chemical solvents and oils, low construction environment requirements, and high durability. Good high and low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

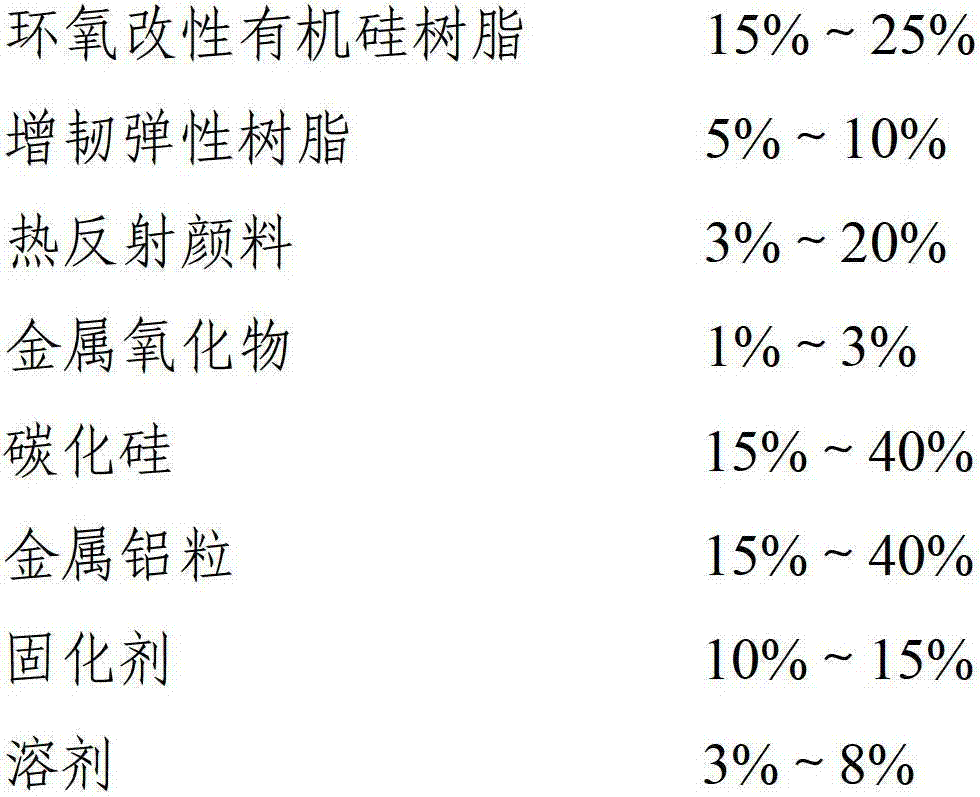

Method used

Image

Examples

Embodiment 1

[0023] Proportionally mix 15kg of epoxy-modified silicone resin, 10kg of toughened elastic resin, and 8kg of solvent for 10min, then add 2kg of dispersant, 10kg of heat-reflecting pigment, 3kg of metal oxide, and 2kg of thixotropic agent and stir at high speed for 40min, then add 10kg of curing agent, 15kg of silicon carbide and 25kg of metal aluminum particles were stirred for 5 minutes to obtain a roller-coated high-durability multifunctional anti-skid coating for flight decks;

[0024] Metal oxides are composed of CaO, MgO and ZrO 2 Composition of the mixture, the mass percentage of each component in the mixture is: 30%CaO, 30%MgO and 40%ZrO 2 .

[0025] Silicon carbide is formed by mixing silicon carbide particles with a particle size of 15-20 mesh and 30-40 mesh respectively, and the mass percentage of silicon carbide particles with a particle size of 15-20 mesh in the silicon carbide anti-skid particles is 50%;

[0026] The particle size of metal aluminum particles is ...

Embodiment 2

[0030] Proportionally mix 25kg of epoxy-modified silicone resin, 5kg of toughened elastic resin, and 3kg of solvent for 10 minutes, then add 1kg of dispersant, 5kg of heat-reflecting pigment, 1kg of metal oxide, and 5kg of thixotropic agent and stir at high speed for 40 minutes, then add 10kg of curing agent, 30kg of silicon carbide and 15kg of metal aluminum particles were stirred for 5 minutes to obtain a roller-coated high-durability multi-functional anti-skid coating for flight decks;

[0031] The composition of the thixotropic agent is: 50% polyamide wax, 50% fumed silica;

[0032] The mass percent of polyamide curing agent in curing agent is 55%;

[0033] All the other components are composed the same as in Example 1.

Embodiment 3

[0035] Proportionally mix 20kg of epoxy-modified silicone resin, 7kg of toughened elastic resin, and 4kg of solvent for 10 minutes, then add 2kg of dispersant, 12kg of heat-reflecting pigment, 2kg of metal oxide, and 1kg of thixotropic agent and stir at high speed for 40 minutes, then add 15kg of curing agent, 22kg of silicon carbide and 15kg of metal aluminum particles, stirred for 5 minutes to obtain a roller-coated high-durability multi-functional anti-skid coating for flight decks;

[0036] The composition of the thixotropic agent is: 50% polyamide wax, 50% fumed silica;

[0037] The mass percentage of polyamide curing agent in curing agent is 50%;

[0038] All the other components are composed the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com