Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Good anti-friction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for denaturing and breaking down friction-reducing polymer and for destroying other oil well contaminants

InactiveUS20070298979A1Onset of propertyIncreases hydrogen-bonding potentialOther chemical processesFluid removalOrganic compoundOxidizing agent

A composition and method for breaking down and denaturing friction-reducing compound introduced into the ground during the drilling of oil wells and for destroying other contaminants and biohazards naturally present within and artificially introduced into oil wells, which are formed as a result of the drilling and pumping processes. The composition comprises several species of oxidizing agent compounds that are effective in breaking down hydrogen sulfide produced by bacteria as well as the friction-reducing polymer used during drilling and several other organic compounds.

Owner:PERRY STEPHEN C +1

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

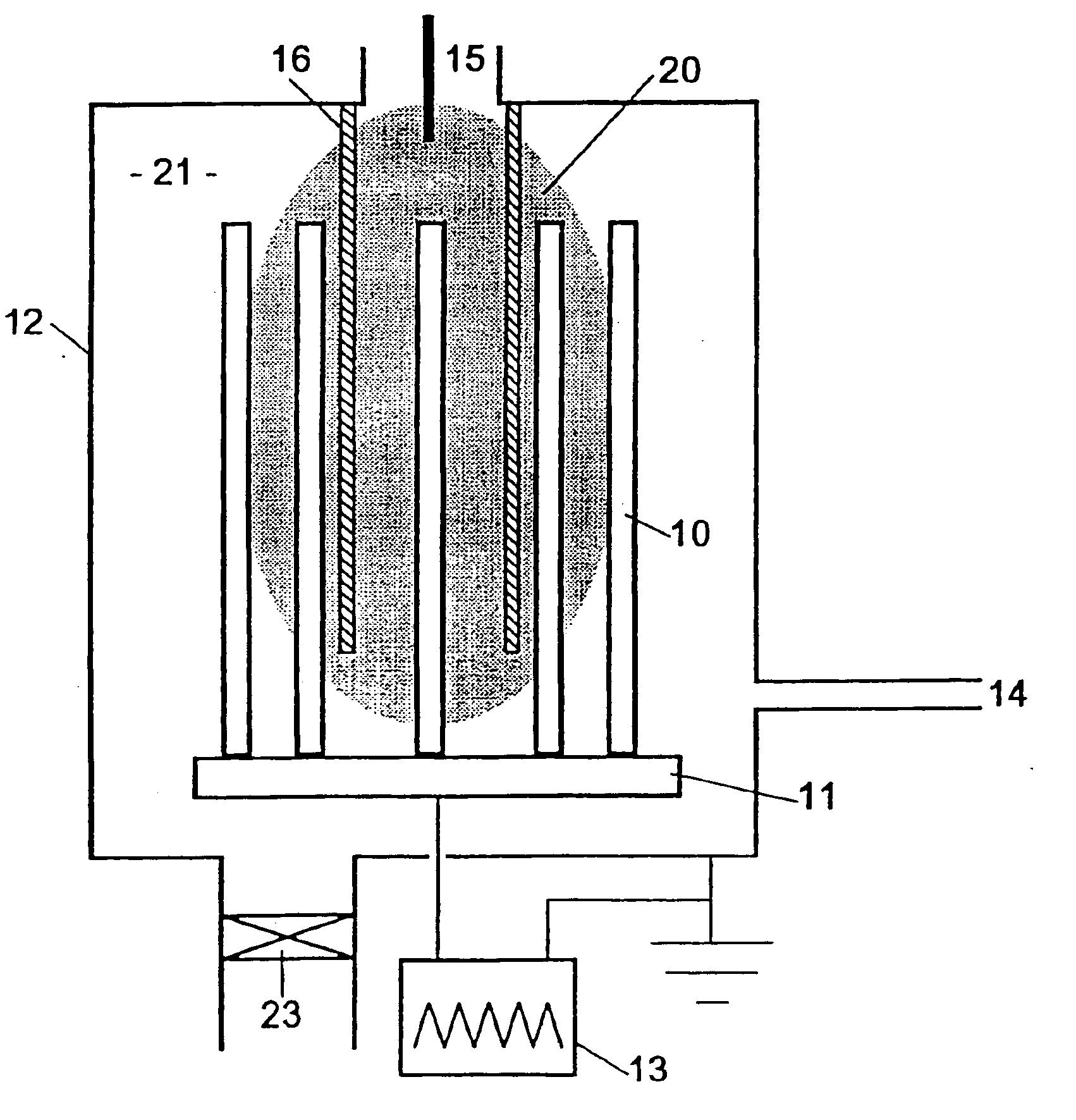

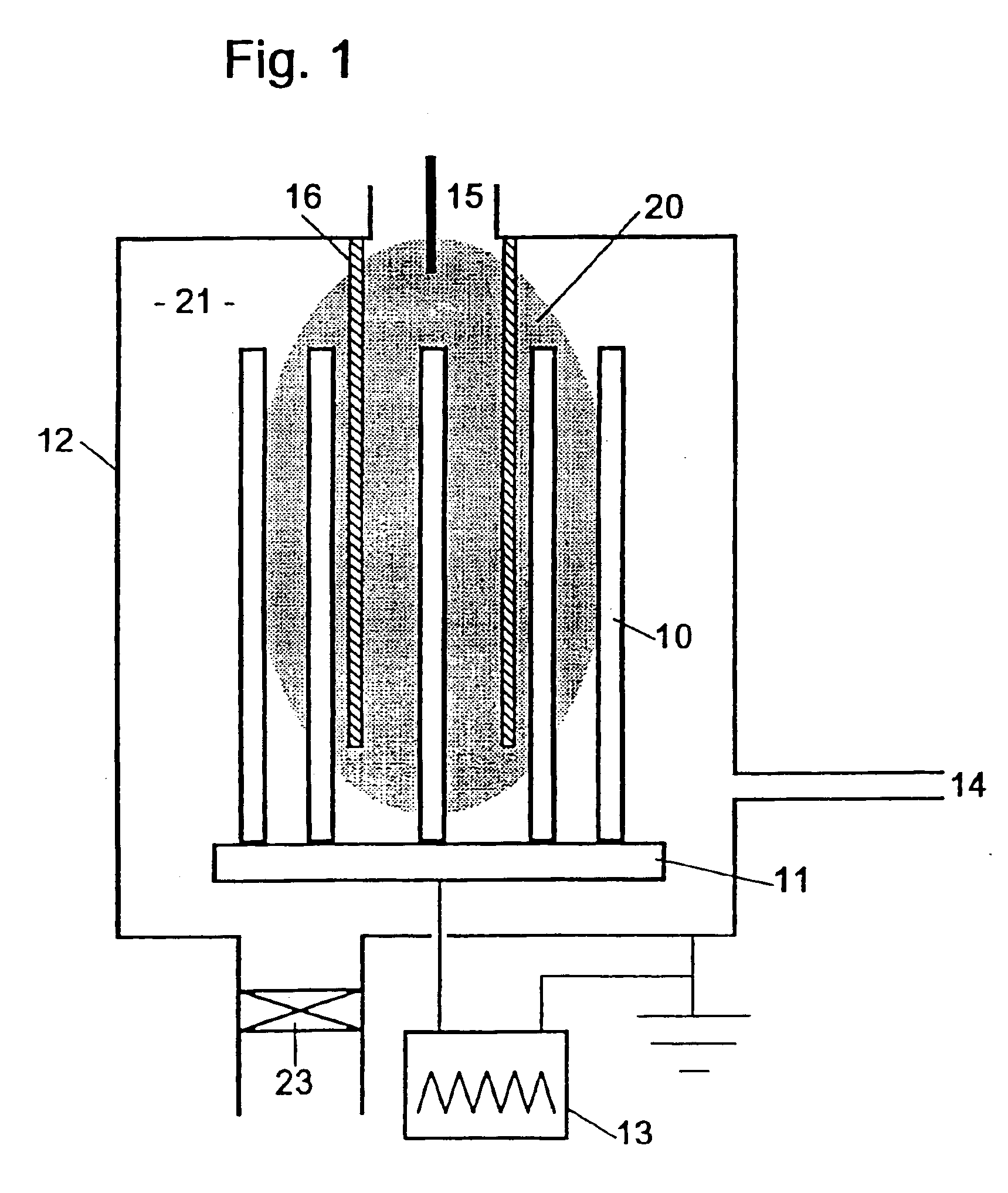

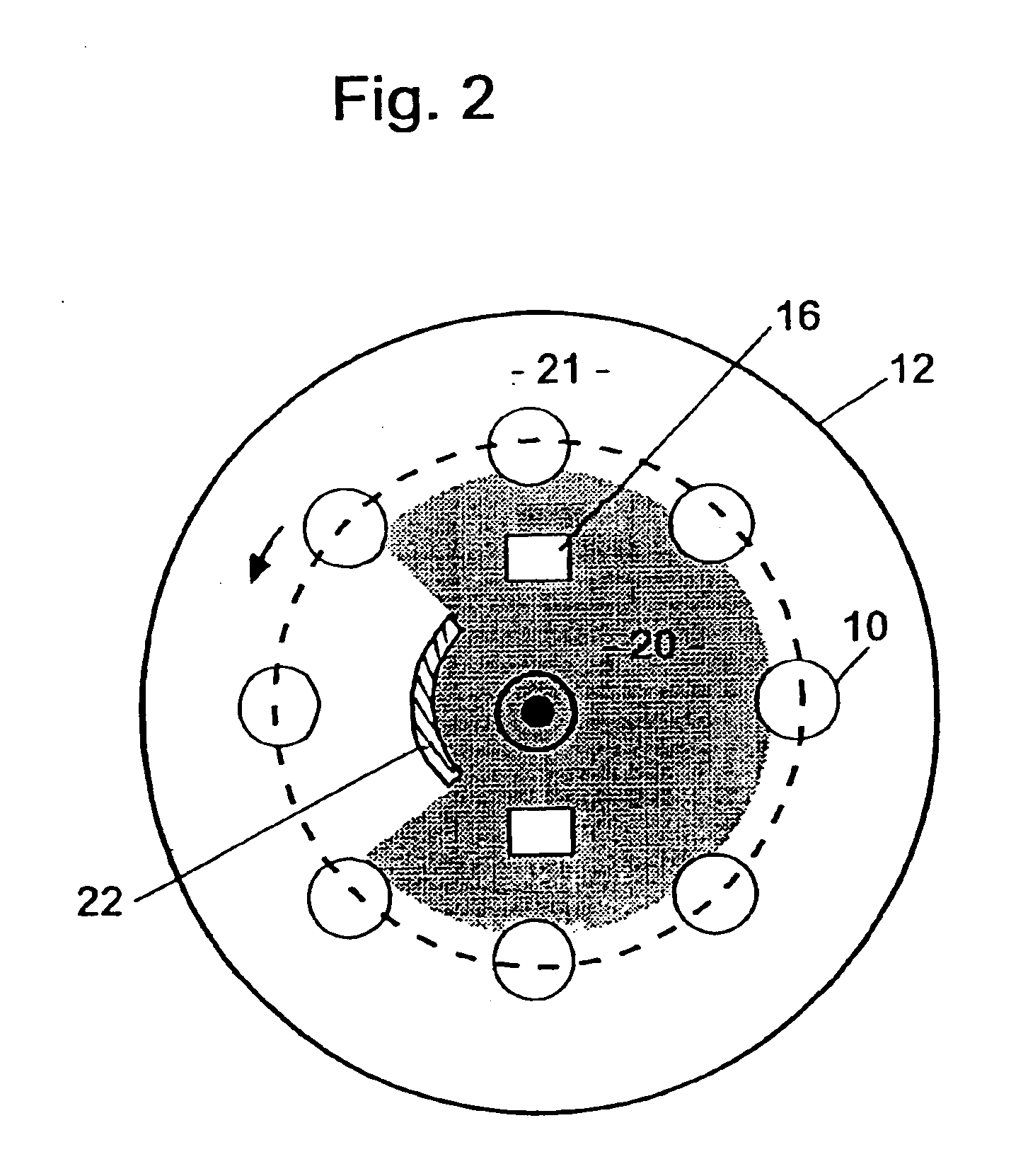

Method and device for vacuum-coating a substrate

InactiveUS6869676B2Increase chanceReduce frictionPigmenting treatmentVacuum evaporation coatingIon bombardmentWear resistant

A method is proposed for vacuum-coating a substrate using a plasma-CVD method. In order to control ion bombardment during the vacuum coating, a substrate voltage, produced independently from a coating plasma, is applied to the substrate. The substrate voltage is modified during the coating. The substrate voltage is a direct voltage that is pulsed in bipolar fashion with a frequency of 0.1 kHz to 10 MHz. A wear-resistant and friction-reducing multilayer structure of alternating hard material individual layers and carbon or silicon individual layers is proposed.

Owner:ROBERT BOSCH GMBH

Lubricating grease composition

Use of a lubricating grease composition comprising: (D) base oil selected from mineral oil, synthetic oil or mixtures thereof; (E) one or more urea compounds; and (F) one or more metal salts of a fatty acid wherein the metal is selected from the group consisting of aluminium, magnesium, zinc, calcium and mixtures thereof, in order to reduce fretting corrosion.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Method for producing compound thin film of phosphoric acid radicle silane-carbon nanotubes on the surface of single crystal silicon wafers

InactiveCN101036910ANo pollution in the processSimple processing methodSemi-permeable membranesCoatingsSilanesModified carbon

The invention relates to a preparation method for the monocrystalline silicon slice surface phospho silicane-carbon nanomater tube composite membrane, firstly dipping the monocrystalline silicon slice in the water, after being heated and cooled naturally to take out, repeatedly flushing using the deionized water and then drying, and then dipping into the well prepared amino silane solution, assembling the amino silane film on the surface of the substrate, then putting into the cyanidation methane solution containing the phosphorus oxychloride and the 2,3,5-trimethyl pyridine. The phospho group is assembled on the film surface, then the substrate is inputted in the modified carbon nanomater tube suspension liquid, for standing 2-24 hours in 30-90 DEG, then taking out to flush using plenty of deionized water, and drying using nitrogen gas, thereby obtaining an improved monocrystalline silicon slice of the carbon nanomater tube composite membrane deposited on the surface. The invention has simple technology, low cost, no pollution to the environment, and the carbon nanomater tube composite membrane has evident anti friction function and good resistance to wear.

Owner:ZHEJIANG QIXIN NEW ENERGY TECH

Composition for denaturing and breaking down friction-reducing polymer and for destroying other oil well contaminants

InactiveUS7615518B2Onset of propertyIncreases hydrogen-bonding potentialOther chemical processesFluid removalOrganic compoundOxidizing agent

A composition and method for breaking down and denaturing friction-reducing compound introduced into the ground during the drilling of oil wells and for destroying other contaminants and biohazards naturally present within and artificially introduced into oil wells, which are formed as a result of the drilling and pumping processes. The composition comprises several species of oxidizing agent compounds that are effective in breaking down hydrogen sulfide produced by bacteria as well as the friction-reducing polymer used during drilling and several other organic compounds.

Owner:PERRY STEPHEN C +1

Method of manufacturing carbon nano tube composite film on glass substrate surface

The invention discloses a making method of carbon nanometer pipe composite film on the glass base surface, which comprises the following steps: immersing glass base in the Pirahan solution to dispose for 1h at 90 deg.c; cleaning; drying; immersing in the mercapto silicane solution; stewing 6-8h; washing; blowing through nitrogen; placing in the nitric acid solution; obtaining the glass base with sulfosilicane film on the surface; placing base into carbon nanometer suspension liquid modified by rare earth; stewing for 4-20h under 20-80 deg.c; fetching; washing through large amount of deionized water; blowing through nitrogen; obtaining the product.

Owner:SHANGHAI JIAO TONG UNIV

Porous oil-containing composite lubricating material and preparation method thereof

The invention relates to a porous oil-containing composite lubricating material and a preparation method thereof. The composite lubricating material based on porous oil-containing particle filling phases is prepared from components as follows: porous particles, a lubricating agent and a porous matrix. Compared with an existing porous oil-containing material technology, three oil-containing particle filling phases with the porous structure are prepared and dispersed in a porous polymer or a metallic matrix with a certain method, and one novel porous oil-containing lubricating material is formed. The lubricating agent is effectively prevented from overflowing from the porous matrix automatically by the aid of the porous oil-containing particles, so that timeliness of the self-lubricating material is improved; meanwhile, mechanical performance of the porous matrix can be compensated to a certain degree by the porous oil-containing particles, and therefore, the material has quite broad application prospect.

Owner:TSINGHUA UNIV

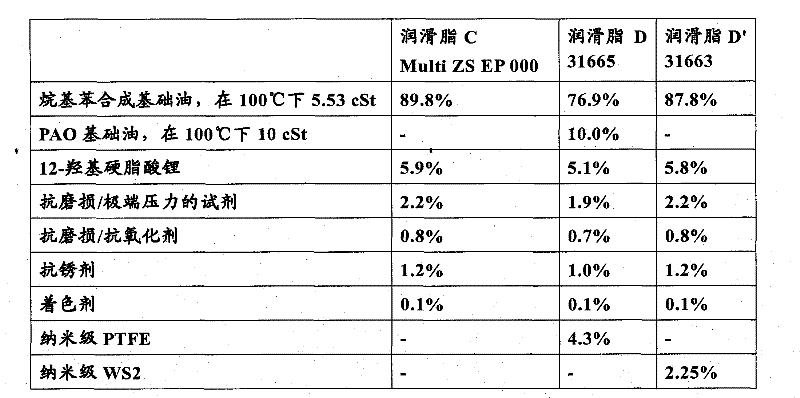

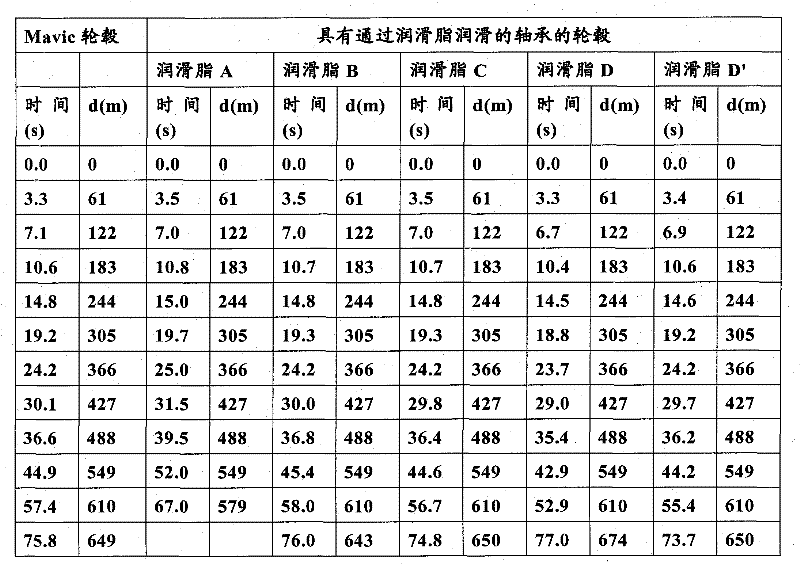

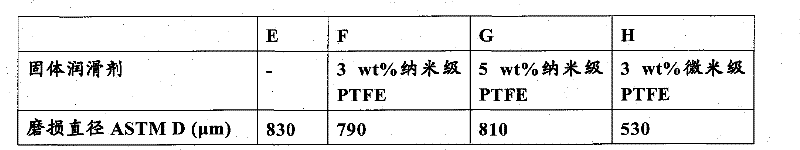

Grease composition

InactiveCN102348790AReduce coefficient of frictionIncrease incomeShaftsBearing componentsNanoparticleBase oil

The invention relates to a grease composition, including: (A) a synthetic base oil mainly consisting of alkylaromatic compound(s) (A1); (B) a thickener mainly consisting at least one fatty acid metal soap; (C) a solid lubricant mainly consisting of nanoparticulate polytetrafluoroethylene, at least 85% of the particles of which are smaller than one micron.

Owner:TOTAL RAFFINAGE MARKETING

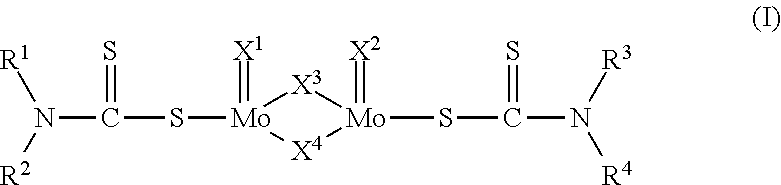

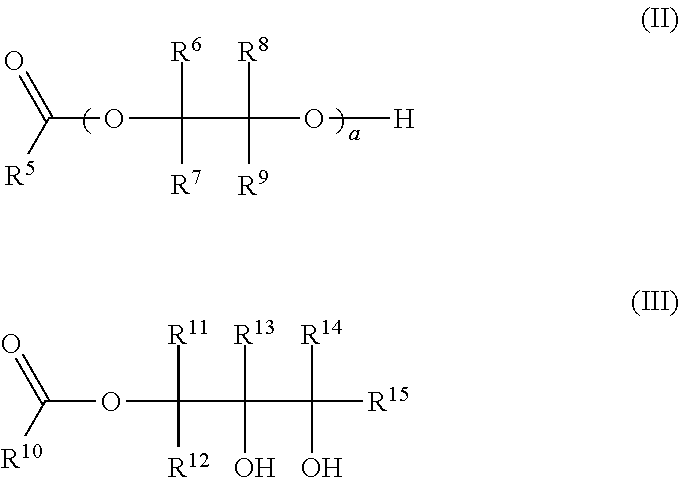

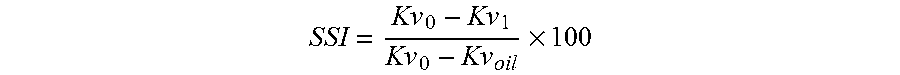

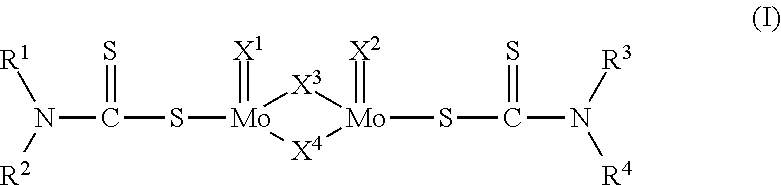

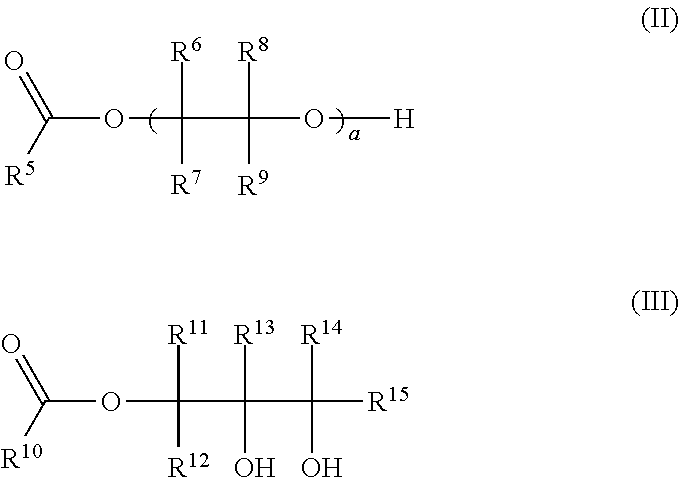

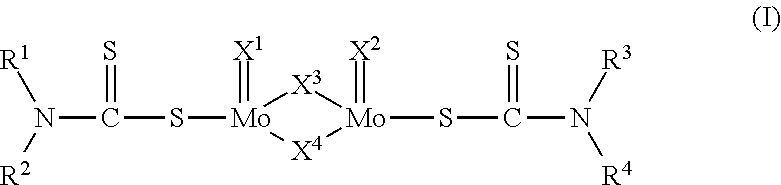

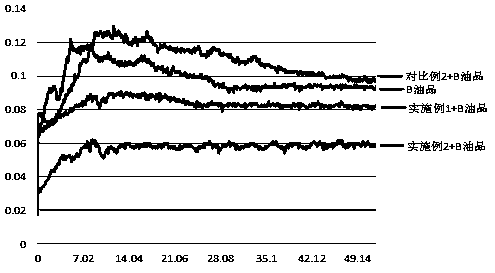

Lubricating oil composition and method for reducing friction in internal combustion engines

ActiveUS20170130158A1Good anti-friction effectEnhance fuel consumption reducing propertyAdditivesCombustionChemical composition

A lubricating oil composition that hardly generates precipitation attributable to a molybdenum compound under the low temperature environment and is excellent in a friction-reducing effect under the low temperature environment is provided.The lubricating oil composition is one including (A) a lubricating base oil, (B) a molybdenum-based compound, (C) a metal-based detergent, and (D) an ester compound having one or more hydroxyl groups in a molecule thereof, wherein the metal-based detergent (C) includes (C1) a calcium detergent and (C2) a magnesium detergent, and a content of the ester compound (D) having one or more hydroxyl groups in a molecule thereof is 0.03 to 1.20 mass % on a basis of the total amount of the lubricating oil composition.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil composition

One lube oil compound with the quality of oxidation resistance, abrasive resistance, and anti-attrition, based on total weight of the compound, includes the following components: (a) zinc salt, ntoquita nantokite, magnesium salts, calcium salt and barium salt of dialkyl phosphorodithioic acid, the content is 0.1-3.5%; (b) compound antioxidant of amine antioxidant and phenolic ester antioxidant, the content is 0.2-3.0%; (c) molybdenum salt of dialkyl dithioic organic acid, the content is 0.05-1.5%; (d) monohydric or polyhydric alcohol ester with abrasive resistance and anti-attrition produced by monohydric alcohol or diatomic alcohol and alkyl, arene or alkyl phenol in place of carboxylic acid, the content is 0.05-1.5%; (e) zinc salt, sodium salt, magnesium salts, calcium salt and barium salt dialkyl dithiocarbamate or dialkyl dithiobenzoic acid, the content is 0.05-1.5%; (f) grease oil, the residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of manufacturing phosphate group silicane-carbon nano tube composite film on glass substrate surface

The invention discloses a making method of phosphate group silicane-carbon nanometer pipe composite film on the glass base surface, which comprises the following steps: adopting glass base with surface disposed by hydroxy as base material; immersing base into amino silicane solution; assembling amino silicane film on the surface; placing the base in the solution with phosphorus oxytrichloride and 2, 3, 5-trimethylpyridine acetonitrile; stewing for a while; assembling phosphate group on the film surface; placing base into carbon nanometer pipe suspension modified by rare earth; stewing under 20-60 deg.c for 4-16h; washing through large amount of deionized water; blowing through nitrogen; obtaining the product.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of self-assembled sulfonic acid group silane-titanium dioxide composite film on monocrystalline silicon substrate surface

InactiveCN101555629AThe process method is simpleLow costPolycrystalline material growthAfter-treatment detailsChemistryNitrogen gas

The invention relates to a preparation method of self-assembled sulfonic acid group silane-titanium dioxide composite film on monocrystalline silicon substrate surface. The invention is characterized in that the monocrystalline silicon piece is treated in advance and is immersed in prepared hydrosulphonyl silane solution, after holding for 8 hours, the monocrystalline silicon piece is taken out and washed by acetone, chloroform and deionized water, and the nitrogen is used for drying the monocrystalline silicon piece, after being dried, the monocrystalline silicon piece is put into the nitric acid with finite concentration for 2 hours under 80 DEG C, and then the sulfonic acid group silane-titanium dioxide self-assembled nano film is obtained. The preparation method has the advantages of simple process, low cost and no environment pollution and the obtained titanium dioxide nano film is well-distributed and compactly with evident antifriction effect. Furthermore the titanium dioxide self-assembled nano film has the advantage of good abrasion resistance property.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

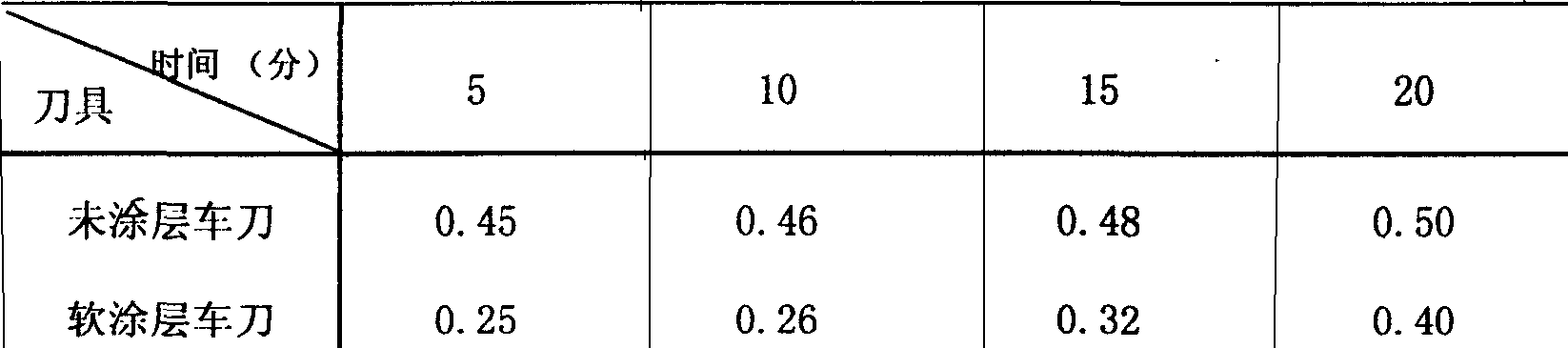

Solid lubricating flexible coating of high speed steel fool and its preparation method

InactiveCN1786129AImprove anti-friction effectGood anti-friction effectBase-materialsLubricationBlack lead

The invention relates to a high-speed steel cutter solid lubrication soft coating and its making method. The boiling coating compound solid lubrication material component and weight percentage are glycerol and water, 80-90; MoS2: 5-10; black lead, 1-5; Al2O3: 1-5. The dipping coating are epoxy resin, firming agent, 15-25; thinner, 50-60; MoS2:10-15; black lead, 3-5; Al2O3: 3-5. The manufacturing method of the soft coating includes the following steps: adopting boiling coating method that the pretreated cutter is put into the boiling coating fluid; and it does heating in water bath; the superficial of the cutter is adsorbed one layer compound solid lubrication; adopting dipping coating method that the cutter is put into the pretreated dipping coating fluid to solidify, make into cutter soft coating. The invention not only can realize dry cutting, but also has good cutting effect.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing carbon nano-tube coextruded film on single-crystal silicon slice surface

InactiveCN101012562ANo pollution in the processSimple processing methodLiquid surface applicatorsSuperimposed coating processComposite filmSilanes

The invention discloses a making method of composite film of carbon nanometer pipe on the surface of single-crystal silicon chip, which comprises the following steps: immersing base in the chloroazotic acid to heat 5-6h; washing through deionized water; placing in the hydroxylating solution; disposing for 1h under indoor temperature; cleaning; drying; immersing in the mercapto silane solution; stewing 6-8h; blowing through nitrogen; oxidizing mercapto into sulfonic group; placing base in the suspension of modified carbon nanometer pipe; stewing 2-24h under 20-60 deg.c for 2-24h; washing; drying through nitrogen; obtaining the product.

Owner:SHANGHAI JIAO TONG UNIV

Process for preparing single crystal silicon substrate surface self-assembly rare earth nano-film

InactiveCN1544690ASimple configurationNo pollution in the processLiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingEthylene diamine tetra aceticAlcohol

The invention is an on-monocrystalline silicon rare-earth nano-film self-composing preparing method, firstly preprocessing monocrystalline silicon slice, then dipping it in prepared rare-earth modifier, placing for 8 hours, take it out and wash by deionized water, airing it at room temperature and then placing in an oven, preserving heat at 120 deg.C for 1 hour, and obtaining the rare-earth self-composing film; where, the components of the rare-earth modifier in weight percent: rare-earth compound 3.5%-7%, alcohol 65%-85%, ethylene diamine tetra acetic acid 1%-4%, ammonium chloride 2%-5%, urea 10%-25%, and thick HCl 0.5%-1.5%. It has simple process, low cost, no environmental pollution, uniformly distributed rare-earth nano film, compact film formation, and obvious frication reducing action. Besides, the self-composing film has good wearability.

Owner:SHANGHAI JIAO TONG UNIV

Lubricating oil composition and method for reducing friction in internal combustion engines

ActiveUS10155915B2Improve suppression propertiesGood anti-friction effectAdditivesPhysical chemistryMolybdenum compounds

A lubricating oil composition that hardly generates precipitation attributable to a molybdenum compound under the low temperature environment and is excellent in a friction-reducing effect under the low temperature environment is provided.The lubricating oil composition is one including (A) a lubricating base oil, (B) a molybdenum-based compound, (C) a metal-based detergent, and (D) an ester compound having one or more hydroxyl groups in a molecule thereof, wherein the metal-based detergent (C) includes (C1) a calcium detergent and (C2) a magnesium detergent, and a content of the ester compound (D) having one or more hydroxyl groups in a molecule thereof is 0.03 to 1.20 mass % on a basis of the total amount of the lubricating oil composition.

Owner:IDEMITSU KOSAN CO LTD

Preparation method of surface phosphate silane-CdSe composite film of monocrystalline silicon piece

InactiveCN101671849ANo pollution in the processImprove wear resistanceAfter-treatment detailsPretreated surfacesFriction reductionComposite film

The invention relates to a preparation method of a surface phosphate silane-CdSe composite film of a monocrystalline silicon piece, which comprises: firstly, a monocrystalline silicon piece is immersed in chloroazotic acid, taken out after being heated and naturally cooled, dried after being repeatedly rinsed by deionized water, and immersed into a prepared amino silane solution, and an amino silane film is formed on the surface of a basal piece; the basal piece is placed into a methane cyanide solution containing phosphorus oxychloride and 2,3,5-collidine to react for 20 minutes, the basal piece is rinsed by deionized water after being taken out, and the film basal piece with phosphate groups on the surface is obtained; and the basal piece is placed into CdSe suspending liquid, allowed tostand for 2 to 24 hours at 30 to 90 DEG C, rinsed by a large amount of deionized water after being taken out, and dried by the blowing of nitrogen, and thus the monocrystalline silicon piece with a CdSe composite film deposited on the surface is obtained. The invention has simple technology, low cost and no environmental pollution, and the prepared CdSe composite film has obvious function of friction reduction and excellent abrasion resistance and adhesion resistance properties.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for preparing sulfonic silane-rare earth nanometer compound membrane on single crystal silicon sheet surface

InactiveCN1670248ANo pollution in the processSimple processing methodMetallic material coating processesSilanesRare earth

A method is for making sulfonic acid radical silicane-tombarthitenanometer coextruded film on the surface of a monocryst a self-assemblage process on the surface to make said film, which comprises the following steps: putting the monocrystalline silicon chip into aqua regia to heating it for 5-6 hours, cooling it at the room temperature, washing and drying it, and immersing it into the mercaptosilicane solution for 6-8 hours, after the flush process, weathering it with nitrogen, then putting it into the aquacare to reacting, for oxygenating the end mercapto group to sulfonic group, and adding the chip into the tombarthite self-assemblage solution with tombarthite compound, ethanol, ethylene diamine tetraacetic acid, chlor ammonia, aquacare and aquacare to assemble, and then getting the sulfonic acid radical silicane-tombarthite self-assemblage nanometer coextruded film. The invention provides an easy technique, and the tombarthite self-assemblage film made on the surface of the monocrystalline silicon chip can lower friction and improve wear-resistance dramatically.

Owner:SHANGHAI JIAO TONG UNIV

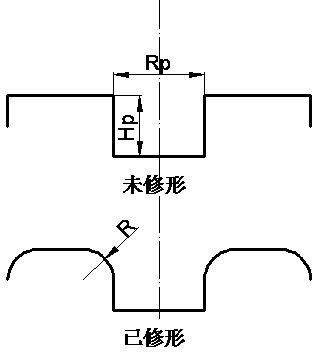

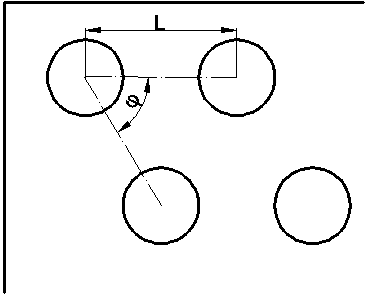

Surface pit texture subjected to edge profile modification and processing method thereof

ActiveCN104044016AReduce edge effectsGood anti-friction effectVacuum evaporation coatingSputtering coatingCrystallographyWear particle

The invention relates to a surface pit texture subjected to edge profile modification and a processing method thereof. The number of pits in an effective contact area of the surface texture is no less than 3, the diameter of each pit is not smaller than 30 micrometers, the depth of each pit is not smaller than 10 micrometers, the area duty ratio is 5-30%, the edges of the pits can be in continuous curved surface change through edge profile modification, i.e., relatively gentle curved surfaces inside the pits and relatively gentle curved surfaces outside the pits are connected, and no sharp edges exist. The method comprises the steps of selecting a base material; manufacturing pits; performing edge profile modification and cleaning. The surface pit texture subjected to edge profile modification can lower the aggressivity of the surface of the texture on a dual and is suitable for various working conditions, such as point contact, linear contact, surface contact, dry friction and boundary lubrication, and under the lubrication state, while lubricating liquid storage, impurity collection and granulating function are realized, a lubricating film can be facilitated to be formed since the edges of the pits subjected to profile modification in the contact area are in wedge contact, so that frictional wear is reduced.

Owner:SHANGHAI UNIV

Preparation method of phosphate silane-carbon nanotube composite film on surface of quartz substrate

InactiveCN102092957ASimple configurationSignificant anti-friction effectN dimethylformamideComposite film

The invention relates to a preparation method of a phosphate silane-carbon nanotube composite film on the surface of a quartz substrate, belonging to the technical field of nanometer composite films. The method comprises the following steps: pretreating the quartz substrate through hydroxylation treatment; soaking carbon nanotubes in rare earth modifier at the room temperature for 2-6 hours, filtering, drying; placing 0.05-0.15mg / ml of the obtained carbon nanotubes in N,N-dimethylformamide dispersant, performing ultrasonic dispersion for 2-6 hours to obtain stable suspension; soaking the film substrate assembled with phosphate groups on the surface in the prepared carbon nanotube suspension, standing at 20-60 DEG C for 4-16 hours, taking out the phosphate to wash with a lot of deionized water, and drying with nitrogen after washing to obtain the quartz substrate with the modified carbon nanotube composite film on the surface. The process method in the invention is simple and the carbon nanotube composite film prepared on the surface of the quartz substrate has good optical properties.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing Co3O4 composite film on surface of single crystal silicon chip and use thereof

InactiveCN101665933ANo pollution problemReduce coefficient of frictionSolid/suspension decomposition chemical coatingComposite filmPolyethylene glycol

The invention discloses a method for preparing a Co3O4 composite film on the surface of a single crystal silicon chip, comprising the steps of: putting the single crystal silicon chip into Pirahan solution to be processed at 90 DEG C for 1 hour; ultrasonically cleaning with deionized water; putting into a dustproof oven to be dried; dipping into cobalt nitrate solution and sodium hydroxide solution; leading the mixture and high-temperature and high-pressure water to flow into a reactor synchronously, wherein the reaction temperature is 300 DEG C; putting Co(NO3)2.6H2O into a beaker and addingwater solution for dissolving; magnetically stirring and adding polyethylene glycol solution and buffer solution with the PH value of 10; and adding H2O2 and stirring for 30 minutes. The method further comprises the steps of: filling the mixture into stainless steel high-pressure reaction kettle which is internally provided with polyfluortetraethylene and sealing the kettle, reacting at 200 DEG Cfor 20 minutes; centrifugally separating the reactant from the mixture; washing; and drying to obtain the single crystal silicon chip, the surface of which is attached with the Co3O4 film. The methodis used for the scale production of the module surfaces of the micro complex components, thereby improving abrasion-resistant performance.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for preparing sulfonic silane-rare earth nanometer composite film on glass substrate surface

The method to prepare sulfo radical silicane-rare earth nano composite thin membrane on glass substrate surface comprises, preparing sulfo radical silicane thin membrane with self-assemblt method and then rare-earth-element thin membrane with sol-gel method on hydroxylated substrate surface; dipping the substrate into Pirahan solution for one hour at 90Deg temperature; after clearing and drying, dipping it into mercaptoalkyl solution for 6-8h; clearing, blowing with nitrogen and putting into hitric acid to obtain the substrate with surface adsorbed sulfo radical silicane thin membrane; following, dipping the substrate into peptization solution composed of rare earth compounds, titanate, alcohol, diethyl ethanolamine and dimethyl formamide, drawing, drying, or repeating said operation to prepare multilayer thin membrane; putting sample in muffle furnace, heating slowly to 500Deg; then, cooling naturally to room temperature and obtain the product.

Owner:SHANGHAI JIAO TONG UNIV

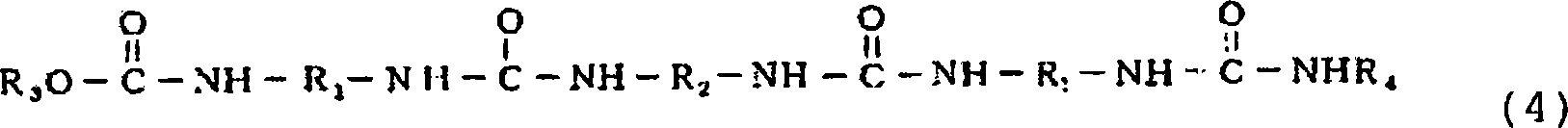

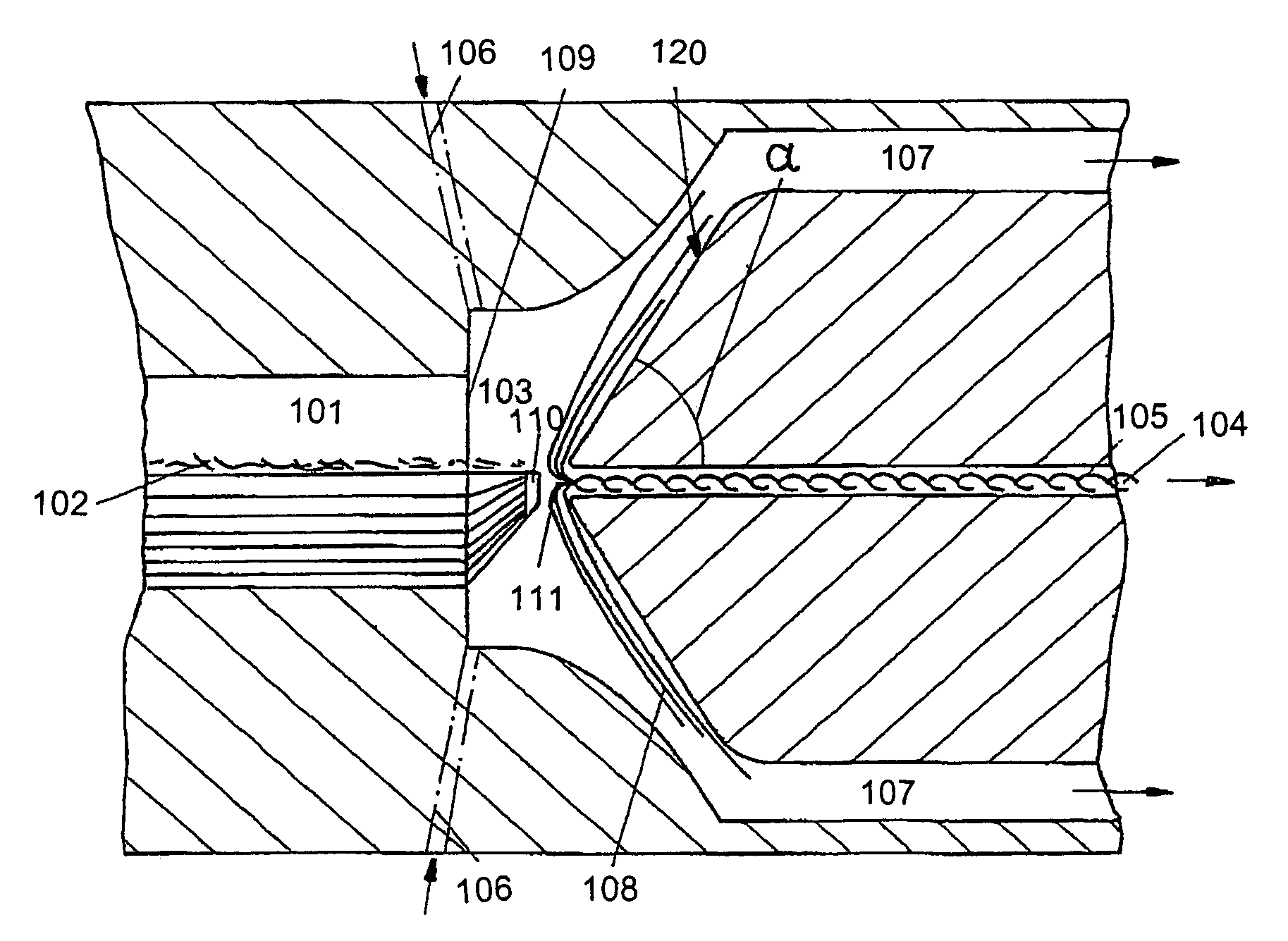

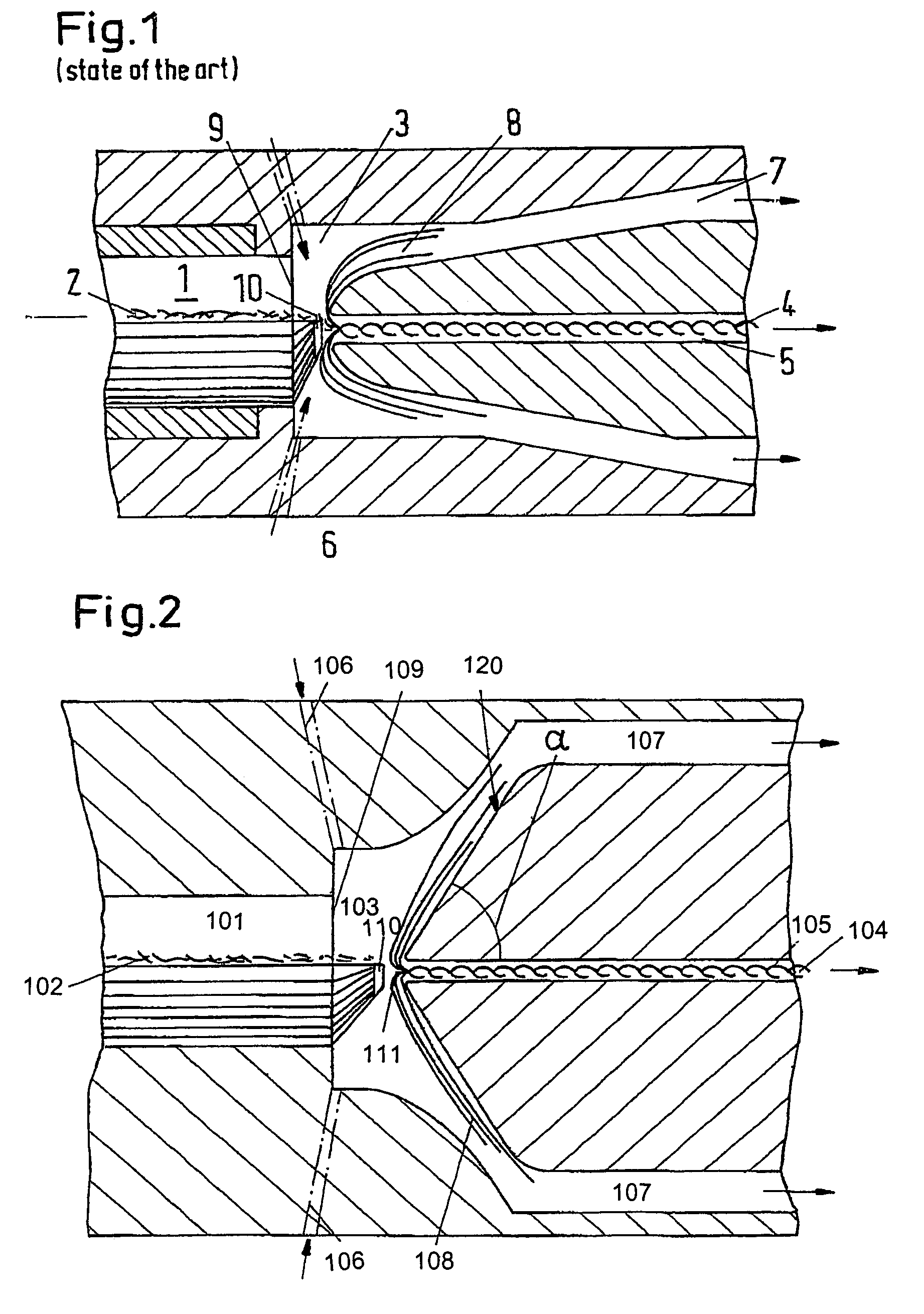

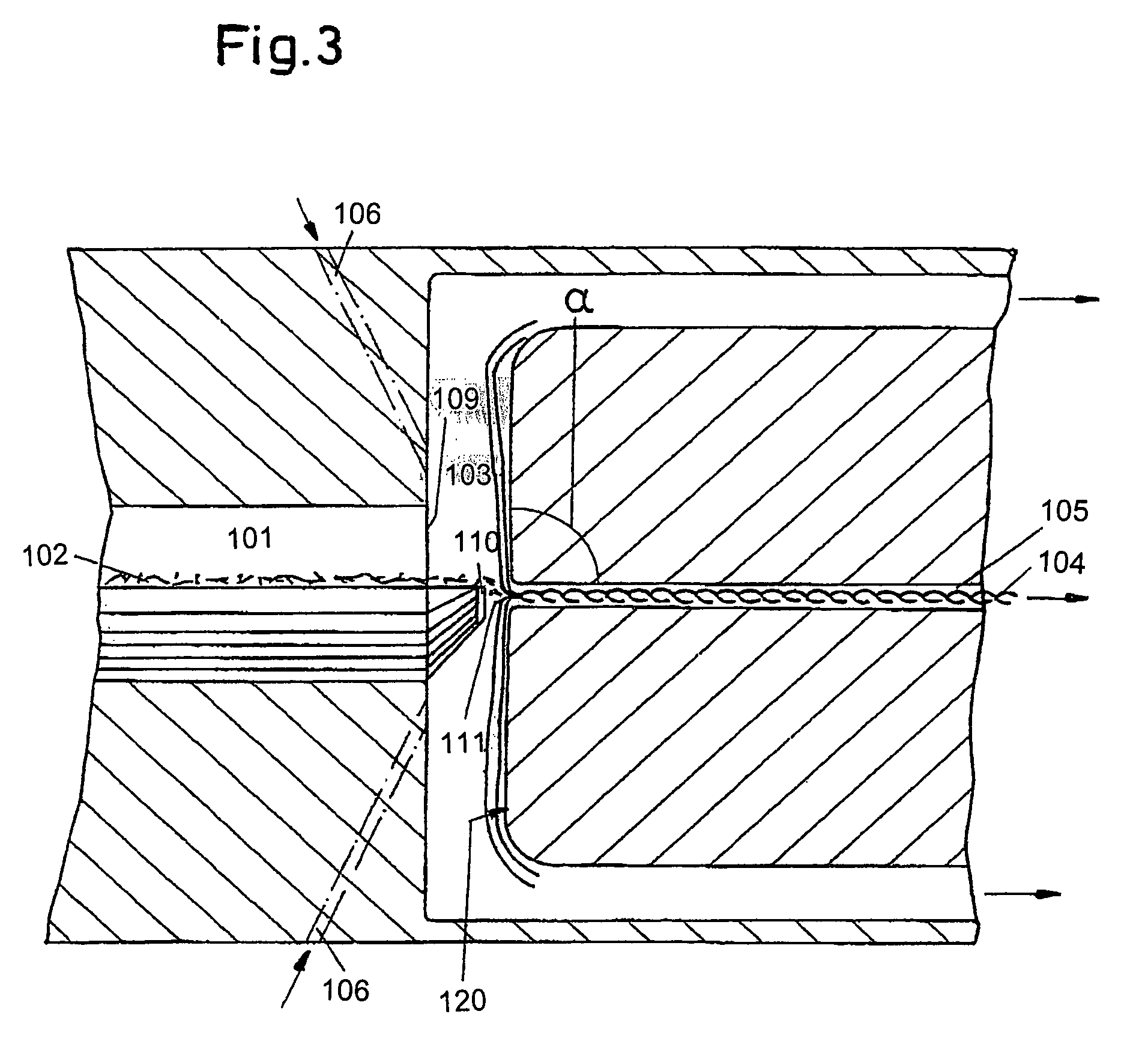

Device for producing a spun yarn

InactiveUS7043893B2Avoid frictionReduce frictionDrafting machinesContinuous wound-up machinesFiber structureYarn

To manufacture a spun yarn from a loose fiber structure, devices are used in which a swirl chamber is provided between a fiber delivery channel and a yarn extraction channel. A fluid is blown into the swirl chamber. This device exhibits in the swirl chamber a guide surface, which delimits the swirl chamber downstream for the purpose of guiding fibers or fiber sectors that are swirling in the swirl chamber, the surface extending in collar fashion around the inlet aperture of the yarn extraction channel. The guide surface may form an angle of at least 30° with the axis of the yarn extraction channel in the yarn extraction direction, and outer areas of this guide surface are at a distance interval from the inlet aperture of the yarn extraction channel that corresponds to at least one tenth of the effective staple length of the fibers that are to be processed.

Owner:MASCHINENFABRIK RIETER AG

Method for preparing sulfhydryl silane-rare earth self-lubricating composite film on glass substrate surface

The method to prepare sulfo radical silicane-rare earth self-lubricating composite thin membrane on glass substrate surface comprises, preparing sulfo radical silicane thin membrane with self-assemblt method and then rare-earth-element thin membrane with sol-gel method on hydroxylated substrate surface; dipping the substrate into Pirahan solution for one hour at 90Deg temperature; after clearing and drying, dipping it into mercaptoalkyl solution for 6-8h; clearing, blowing with nitrogen and putting into peptization solution composed of rare earth compounds, titanate, alcohol water solution, diethyl ethanolamine and dimethyl formamide, drawing, drying, or repeating said operation to prepare multilayer thin membrane; putting sample in muffle furnace, heating slowly to 500Deg; then, cooling naturally to room temperature and obtain the product. This invention can decrease thefriction coefficienct from 0.8 to 0.1.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing sulfhydryl silane-rare earth nanometer compound membrane on single crystal silicon sheet surface

InactiveCN1670247ANo pollution in the processSimple processing methodMetallic material coating processesSilanesRare earth

A method is for making mercaptosilicane-tombarthitenanometer coextruded film on the surface of a monocrystalline silicon chip, in which base material is a single-crystal chip with surface treated, employing a self-assemblage process on the surface to make said film, which comprises the following steps: putting the monocrystalline silicon chip into chloroazotic acid, pretreating the chip, washing and drying it, and immersing it into the mercaptosilicane solution for 8 hours, after the flush process, weathering it with nitrogen, then putting it into the self-assemblage solution with tombarthite compound, ethanol, ethylene diamine tetraacetic acid, chlor ammonia, aquacare and aquacare to assemble, and then getting the mercaptosilicane-tombarthite self-assemblage nanometer coextruded film. The invention provides an easy technique, and the tombarthite self-assemblage film made on the surface of the monocrystalline silicon chip can reduce friction and increase wear-resistance dramatically.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing bismuth vanadate compound film on glass substrate surface

The invention discloses a method for preparing a bismuth vanadate composite film on the surface of a glass substrate, which comprises the following steps that: a sulfonic silane film is prepared on the surface of a hydroxylated glass substrate by a self-assembly method, then the glass substrate is placed into a N, N-dimethylformamide bismuth vanadate dispersion liquid, and bismuth vanadate is deposited on the surface of the glass substrate. Firstly, the glass substrate is dipped into a Pirahan solution, treated for 1 hour at the temperature of 90 DEG C, cleaned and dried, then dipped into a mercapto silane solution, kept stand for 6 to 8 hours, then taken out for washing, blow-dried by nitrogen, and then placed into a nitric acid solution to obtain the glass substrate of which the surface is attached with the sulfonic silane film; and then the glass substrate is placed into a bismuth vanadate suspension, is kept stand for 4 to 20 hours at a temperature of between 20 and 80 DEG C, is taken out to be washed by a large amount of deionized water, and is blow-dried by nitrogen after the washing, thus the glass substrate of which the surface is deposited with a modified bismuth vanadate composite film is obtained. The method can reduce the friction coefficient from 0.8 (no film exists) to 0.1, and has obvious antifriction effect.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for preparing TiO2 compound film on surface of glass substrate

The invention relates to a method for preparing a TiO2 composite film on a surface of a glass substrate. The method comprises the following steps: soaking the glass substrate in a solution containing H2SO4 and H2O2 according to volume ratio of 70 to 30, treating the glass substrate for 1 hour at a temperature of 90 DEG C, after cleaning and drying the glass substrate, soaking the glass substrate in a benzene solution containing hydrosulfuryl silane the concentration of which is between 0.1 and 2.0 mmol per liter, standing for 6 to 8 hours, taking out and washing the glass substrate, drying the glass substrate by blowing nitrogen, placing the glass substrate in 30-60 mass percent nitric acid, reacting for 1 hour at a temperature of between 50 and 80 DEG C, taking out and washing the glass substrate, and obtaining the glass substrate the surface of which is adhered with a sulfonic silane film; and placing the substrate in TiO2 suspension, standing for 4 to 20 hours at a temperature of between 20 and 80 DEG C; and taking out and washing the glass substrate by a large amount of deionized water, drying the washed glass substrate by blowing the nitrogen, and obtaining the glass substrate the surface of which is deposited with a modified TiO2 composite film. The method has short film forming period, can reduce frictional coefficient from 0.8 to 0.1 without a film, and has quite remarkable antifriction function.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Automobile engine protective agent and preparation method thereof

The invention belongs to the field of automobile engine lubricating protective agents, discloses an automobile engine protective agent, a preparation method thereof. The protective agent comprises thefollowing components in parts by weight: 70-90 parts of base oil, 0.5-1 part of a thickening agent, 1-5 parts of an antioxidant, 1-5 parts of a dispersing agent, 1-5 parts of a friction reducing agent and 0.1-0.8 part of a pour point depressant, the friction reducing agent is a mixture of an organic molybdenum compound and an ester compound, wherein the organic molybdenum compound is molybdenum dialkyldithiocarbamate or molybdenum dialkyldithiophosphate, the ester compound is glyceryl monooleate or boric acid ester. The protective agent has an excellent friction reducing effect and has an unexpected effect of repairing existing abrasive spots, hard impact during cold start can be effectively reduced, raw materials are easy to purchase, and the process is relatively simple.

Owner:青岛康普顿石油化工有限公司

Method for preparing sulfonic silicane-rare earth nano composite film on the surface of glass substrate

The self-assembling process of preparing nanometer level sulfo silane-RE film on the hydroxylated surface of glass substrate includes first soaking glass substrate inside Pirahan solution for processing at room temperature for 1 hr, cleaning, drying, soaking inside hydroxy silane solution for 6-8 hr, flushing, blowing to dry with nitrogen, reaction in nitric acid solution to in-situ oxidize terminal mercapto radical into sulfo radical, and self assembling via setting the substrate with sulfo silane film on the surface inside self-assembling RE solution comprising RE compound, ethanol, EDTA, ammonium chloride, urea and nitric acid to form the self-assembled nanometer level sulfo silane-RE film. The present invention has simple process, and the prepared self-assembled nanometer level sulfo silane-RE film on the surface of glass substrate has obvious friction reducing and anti-wear effects.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com