Automobile engine protective agent and preparation method thereof

A technology of automobile engine and protective agent, which is applied in the direction of additives, petroleum industry, lubricating composition, etc. It can solve the problems of poor bending precision and complex structure, and achieve the goal of improving service life, prolonging oil change interval, and reducing hard impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

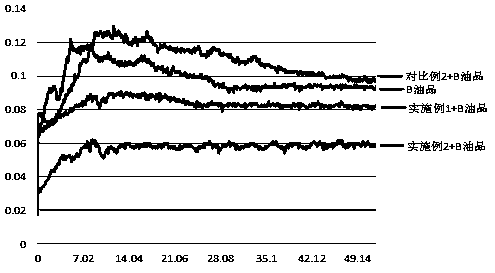

Image

Examples

Embodiment 1

[0026] The preparation method of embodiment 1 automobile engine protective agent

[0027] S 1 1. Heat 70 parts by weight of paraffinic base oil to 50°C, continue to heat up 4.5 parts by weight of base oil to 110-130°C, keep the remaining 65.5 parts by weight of base oil at 50°C, add 0.5 parts by weight of thickener into the 110°C base oil, stirred and dissolved, then cooled to 50°C, and finally stirred and mixed with the remaining 65.5 parts by weight of the heat-insulating base oil to obtain a base mixed oil;

[0028] S 2 , with 1 part by weight of phenolic antioxidant, 1 part by weight of dispersant dialkyl dithiophosphate, 1 part by weight of friction reducer molybdenum dialkyl dithiocarbamate and glyceryl monooleate, 0.1 part by weight The pour point depressant polymethacrylate is gradually added to the base mixed oil, stirred for 1 hour, and mixed evenly;

[0029] S 3 , Cool down to 40°C, and after sampling and testing pass, filter and fill to obtain the finished prot...

Embodiment 2

[0031] The preparation method of embodiment 2 automobile engine protective agent

[0032] S 1 1. Raise the temperature of 90 parts by weight of base oil polyalphaolefin oil and ester oil polyol ester to 60°C, continue to heat up 9 parts by weight of base oil to 130°C, keep the remaining 81 parts by weight of base oil at 60°C, and heat 1 A thickener in parts by weight is added to the base oil at 130°C, stirred and dissolved, then cooled to 60°C, and finally mixed with the remaining 81 parts by weight of the heat-insulating base oil to obtain a base mixed oil;

[0033] S 2 , with 5 parts by weight of amine antioxidant, 5 parts by weight of dispersant dialkyl dithiophosphate, 5 parts by weight of friction reducer dialkyl molybdenum dithiophosphate and borate, 0.8 parts by weight of pour point depressant The polyalphaolefin is gradually added to the base mixed oil, stirred for 1 hour, and mixed evenly;

[0034] S 3 , Cool down to 45°C, and after sampling and testing pass, filt...

Embodiment 3

[0036] The preparation method of embodiment 3 automobile engine protective agent

[0037] S 1 1. Heat up 80 parts by weight of base oil polyester and polyol ester to 55°C, continue to heat up 6.3 parts by weight of base oil to 120°C, keep the remaining 73.7 parts by weight of base oil at 55°C, add 0.7 parts by weight of The thickener was added to the 120°C base oil, stirred and dissolved, then cooled to 55°C, and finally mixed with the remaining 73.7 parts by weight of the heat-insulating base oil to obtain a base mixed oil;

[0038] S 2 , with 3 parts by weight of phenolic antioxidant, 3 parts by weight of dispersant dialkyl dithiophosphate, 3 parts by weight of friction reducer molybdenum dialkyldithiophosphate and glyceryl monooleate, 0.45 parts by weight of The coagulant polymethacrylate is gradually added to the basic mixture, stirred for 1 hour, and mixed evenly;

[0039] S 3 , Cool down to 42°C, and after sampling and testing pass, filter and fill to obtain the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com