Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Facilitated catalytic cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for promoting heavy oil catalytic pyrolysis and improving propylene yield and selectivity

InactiveCN101892067AFacilitated catalytic crackingHigh yieldCatalytic crackingCatalytic pyrolysisAlcohol

The invention relates to a method for promoting heavy oil catalytic pyrolysis and improving propylene yield and selectivity. The method is mainly characterized in that one or a mixture in a small amount of methanol, ethanol, propyl alcohol, butyl alcohol and other small-molecule alcohol is fed with heavy oil, so that the conversion rate of the heavy oil can be obviously promoted, and the yield of liquefied gas and propylene can be improved. Compared with other technologies for increasing the production of propylene by heavy oil catalytic cracking or catalytic pyrolysis, the invention improves the yield and selectivity of propylene generated by catalytic pyrolysis by introducing a small amount of alcohols, thereby having the advantages of convenient implementation, obvious effect, prominent economic benefit and the like. For dry gas hydrogen-producing enterprises, the hydrogen content of the dry gas can be obviously increased after the introduction of alcohols, and therefore, the invention is beneficial to improving the hydrogen yield of a dry gas hydrogen-producing device.

Owner:PETROCHINA CO LTD +1

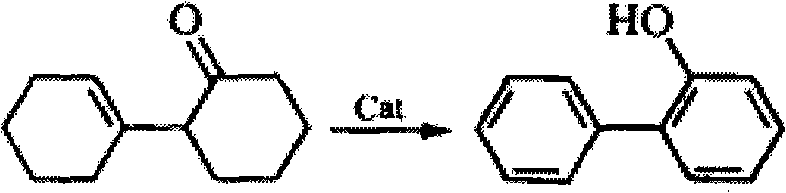

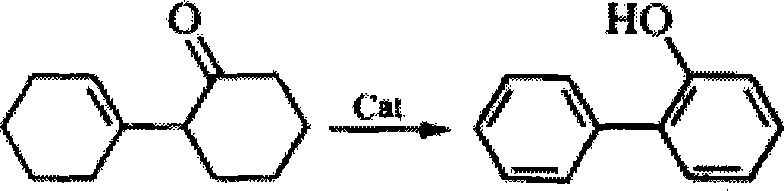

Method for preparing catalyst for use in production of o-phenylphenol

ActiveCN101524643AImprove stabilityStable structureOrganic chemistryOrganic compound preparationO-PhenylphenolHigh activity

The invention provides a method for preparing a catalyst for use in the production of o-phenylphenol. The method prepares the catalyst for use in the production of the o-phenylphenol through processes of carrier pretreatment, immersion, drying and activation, assistant addition, roasting and the like. The catalyst has high activity, selectivity and stability at high temperature.

Owner:CHINA PETROCHEMICAL CORP

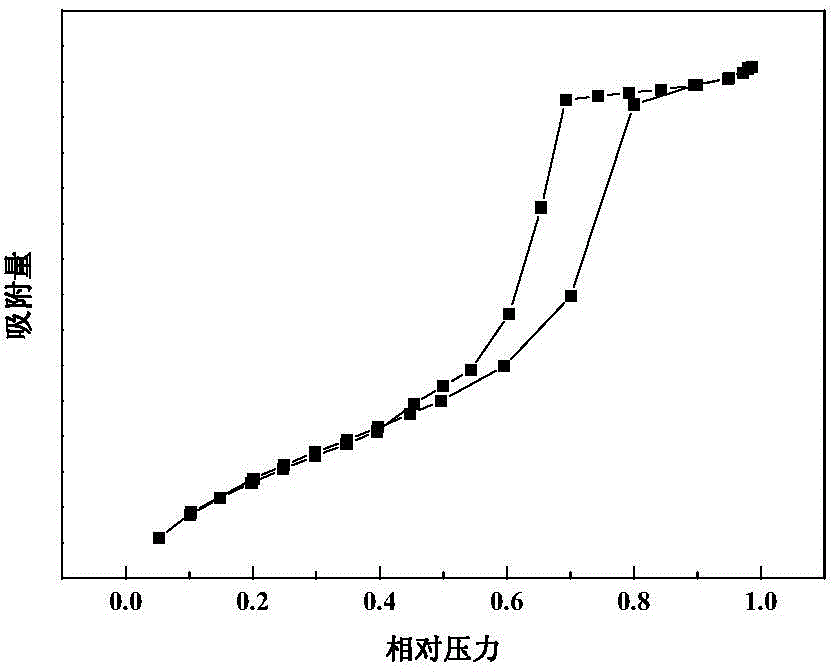

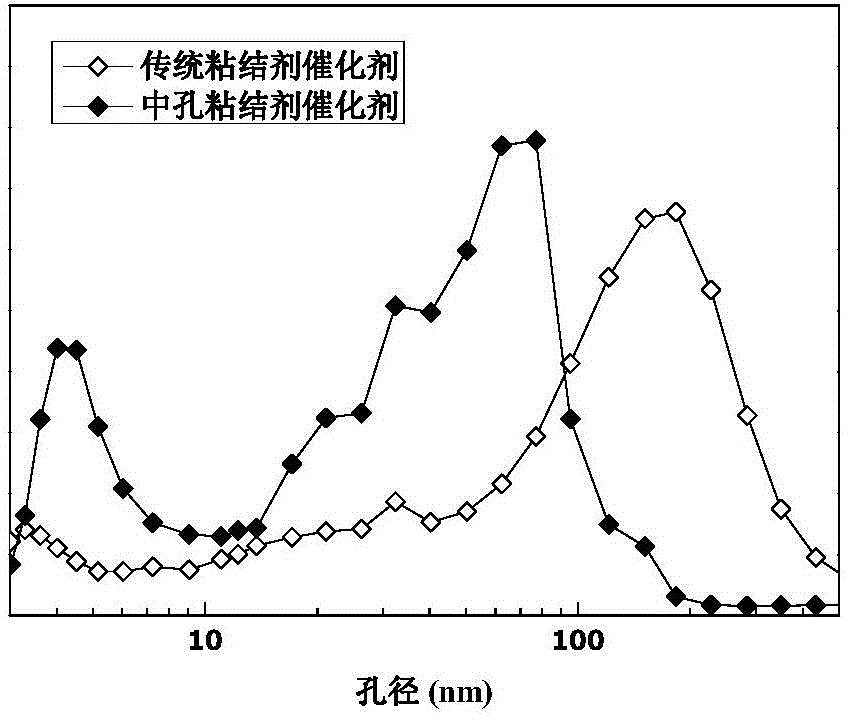

Preparation method of mesoporous aluminum oxide binder, and application thereof in heavy oil catalytic-cracking catalyst

ActiveCN105983400AFacilitated catalytic crackingIncrease the areaCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention relates to a preparation method of a mesoporous aluminum oxide binder, and an application thereof in a heavy oil catalytic-cracking catalyst. In the method, a mesoporous aluminum oxide molecular sieve is employed as an aluminum source to prepare a glue solution of the mesoporous aluminum oxide binder through acidifying peptization, wherein the binder can replace a conventional binder in preparation of the heavy oil catalytic-cracking catalyst. Compared with the conventional binder, the mesoporous aluminum oxide binder has a mesoporous structure, large specific surface area and high pore volume. The catalyst, compared with a catalyst prepared with the conventional binder, prepared through the mesoporous aluminum oxide binder is increased in heavy oil conversion rate and light oil yield, is reduced in coke yield and heavy oil yield, and has a better heavy oil catalytic-cracking performance.

Owner:PETROCHINA CO LTD

Method for preparing catalyst for use in production of o-phenylphenol

ActiveCN101524643BImprove stabilityStable structureOrganic chemistryOrganic compound preparationO-PhenylphenolBiological activation

The invention provides a method for preparing a catalyst for use in the production of o-phenylphenol. The method prepares the catalyst for use in the production of the o-phenylphenol through processes of carrier pretreatment, immersion, drying and activation, assistant addition, roasting and the like. The catalyst has high activity, selectivity and stability at high temperature.

Owner:CHINA PETROCHEMICAL CORP

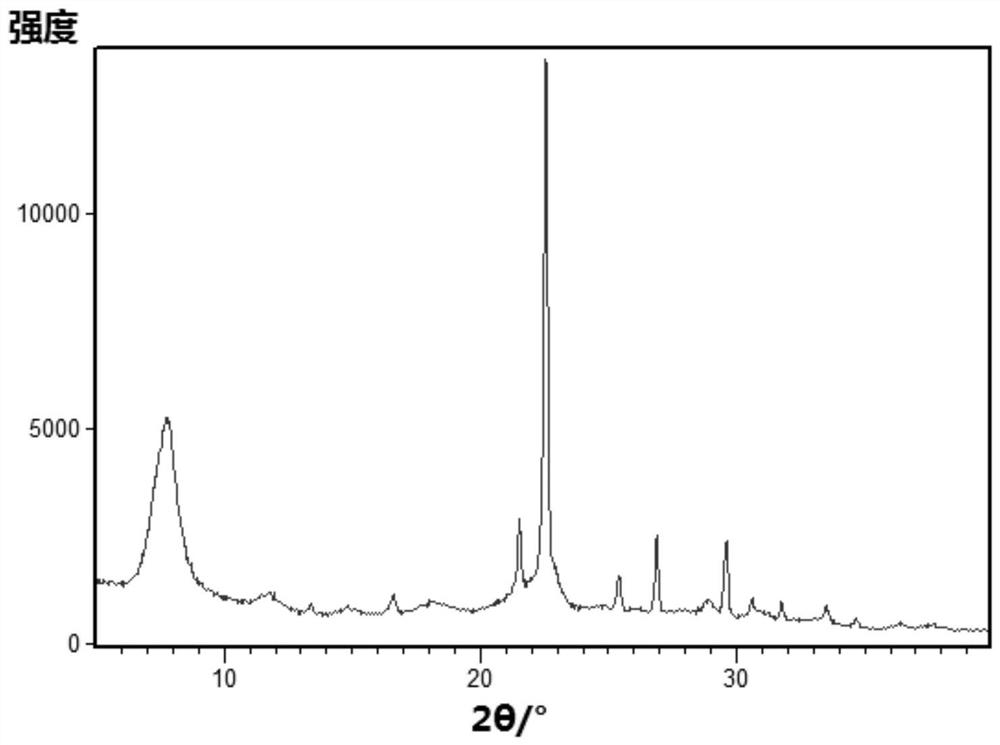

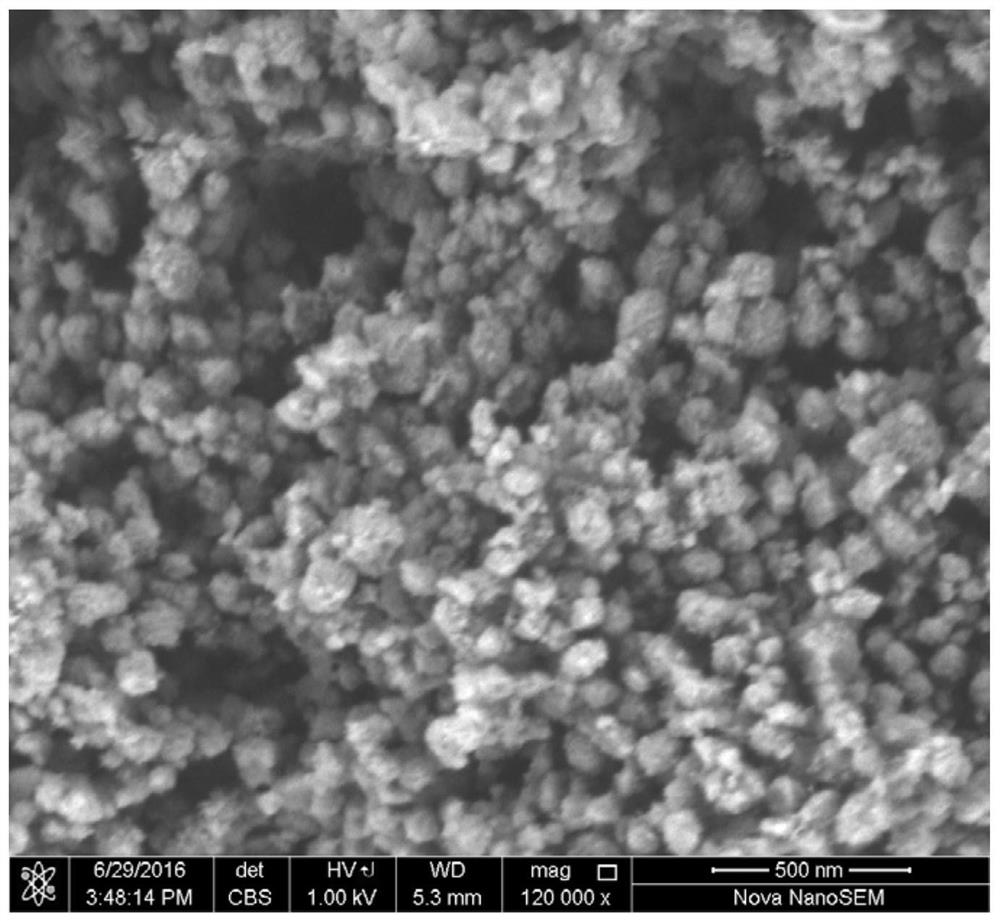

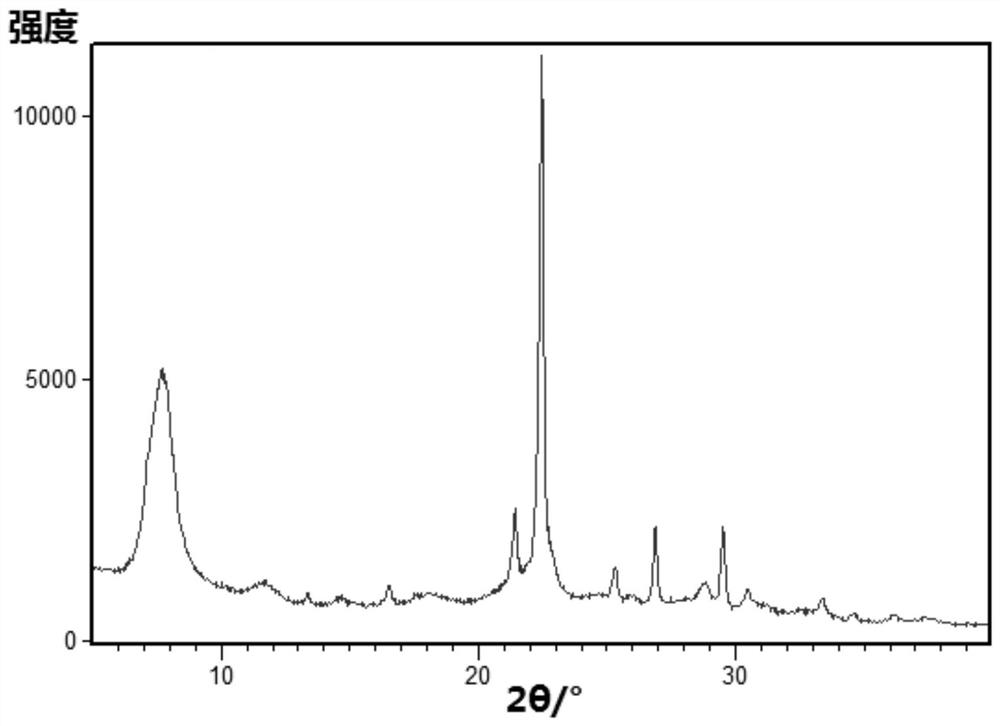

Preparation method of beta molecular sieve

InactiveCN110156037AHigh yieldHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveHeating time

The invention discloses a preparation method of a beta molecular sieve. The preparation method comprises the steps of: 1. synthesis of initial gel: mixing a silicon source, an aluminum source, a template agent, an alkaline metal source, water and a beta molecular sieve seed crystal evenly to synthesize an initial gel, wherein the silicon source is calculated in terms of SiO2, the aluminum source is calculated in terms of Al2O3, the template agent is calculated in terms of TEA<+>, the alkaline metal source is calculated in terms of Na2O, and the raw materials for synthesizing the initial gel are in the following mole ratios that: SiO2 / Al2O3=25-150:1, TEA<+> / SiO2=0.07-0.23:1, Na2O / SiO2=0.03-0.12:1, and H2O / SiO2=3.0-11.5:1, the beta molecular sieve seed crystal has a Si-Al ratio of SiO2 / Al2O3=20-100:1, and in terms of mass, the adding amount is 0%-10% of the mass of SiO2; and 2. microwave heating crystallization reaction: conducting microwave heating treatment on the initial gel preparedby step 1, controlling the heating temperature at 120DEG C-180DEG C and the heating time at 4-25h, thus obtaining a beta molecular sieve product. The method provided by the invention can synthesize the beta molecular sieve with high crystallinity and abundant pore structures by only one step, and compared with the conventional hydrothermal synthesis method, the method provided by the invention cangreatly shorten the synthesis time of the beta molecular sieve, the grain size of the molecular sieve is smaller, and the pore channels are smoother.

Owner:PETROCHINA CO LTD

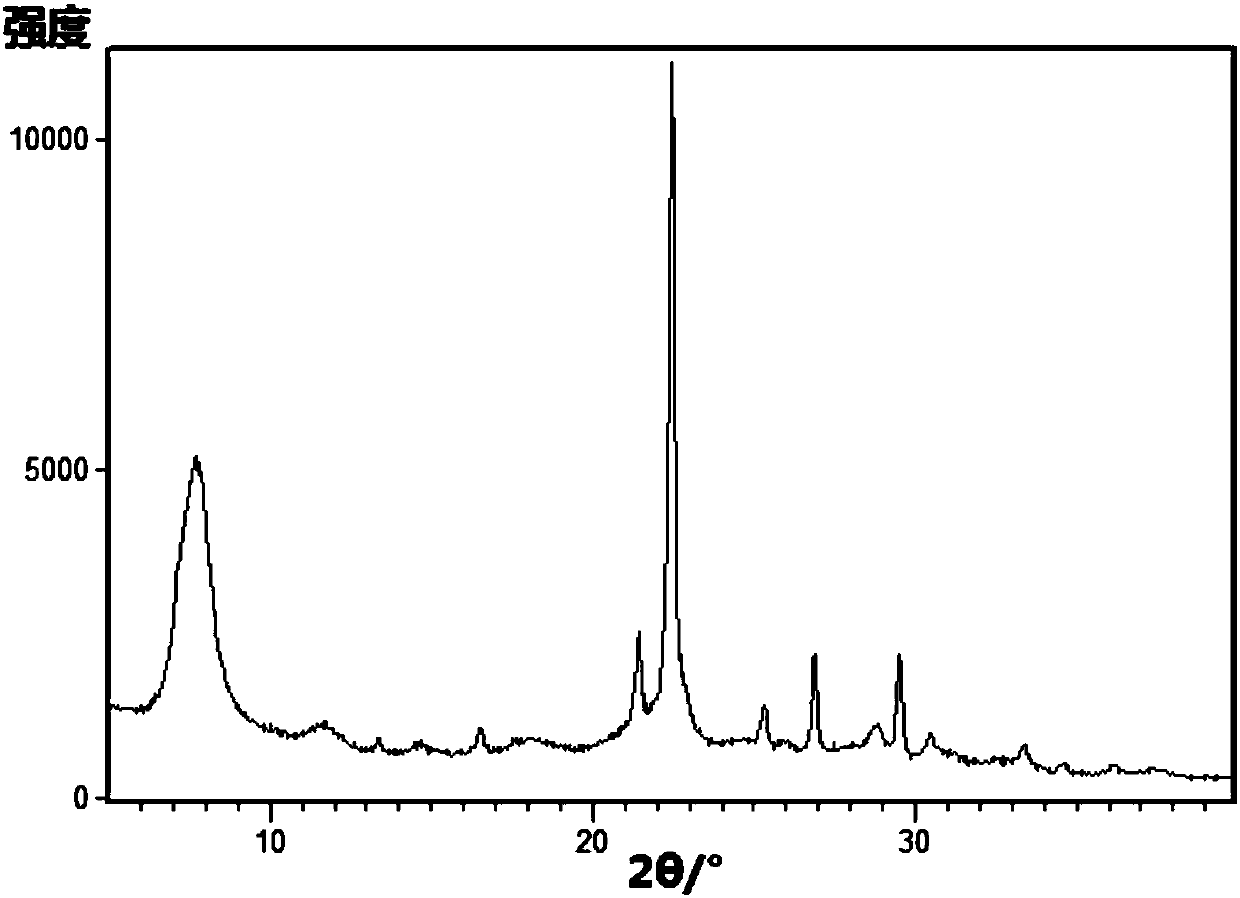

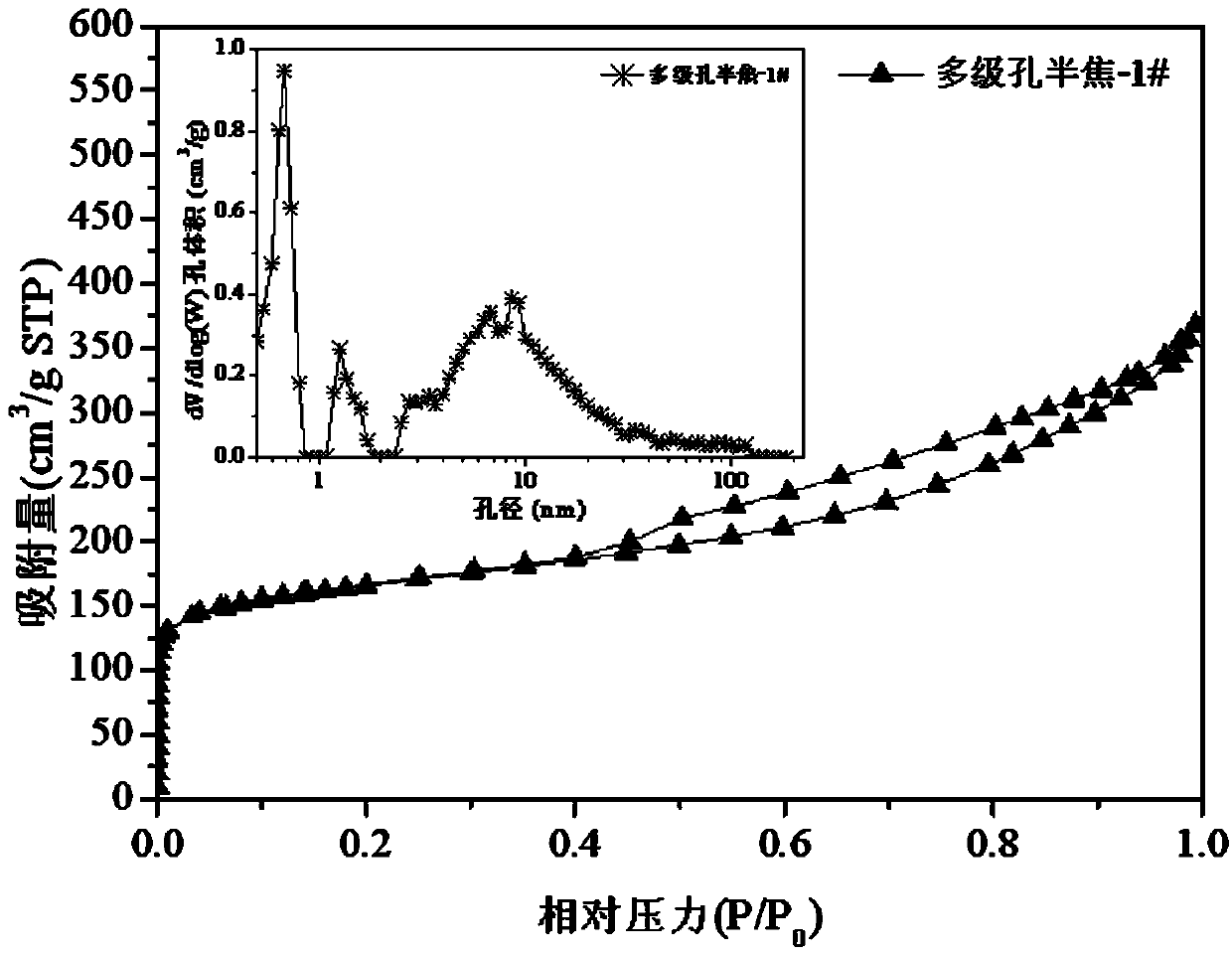

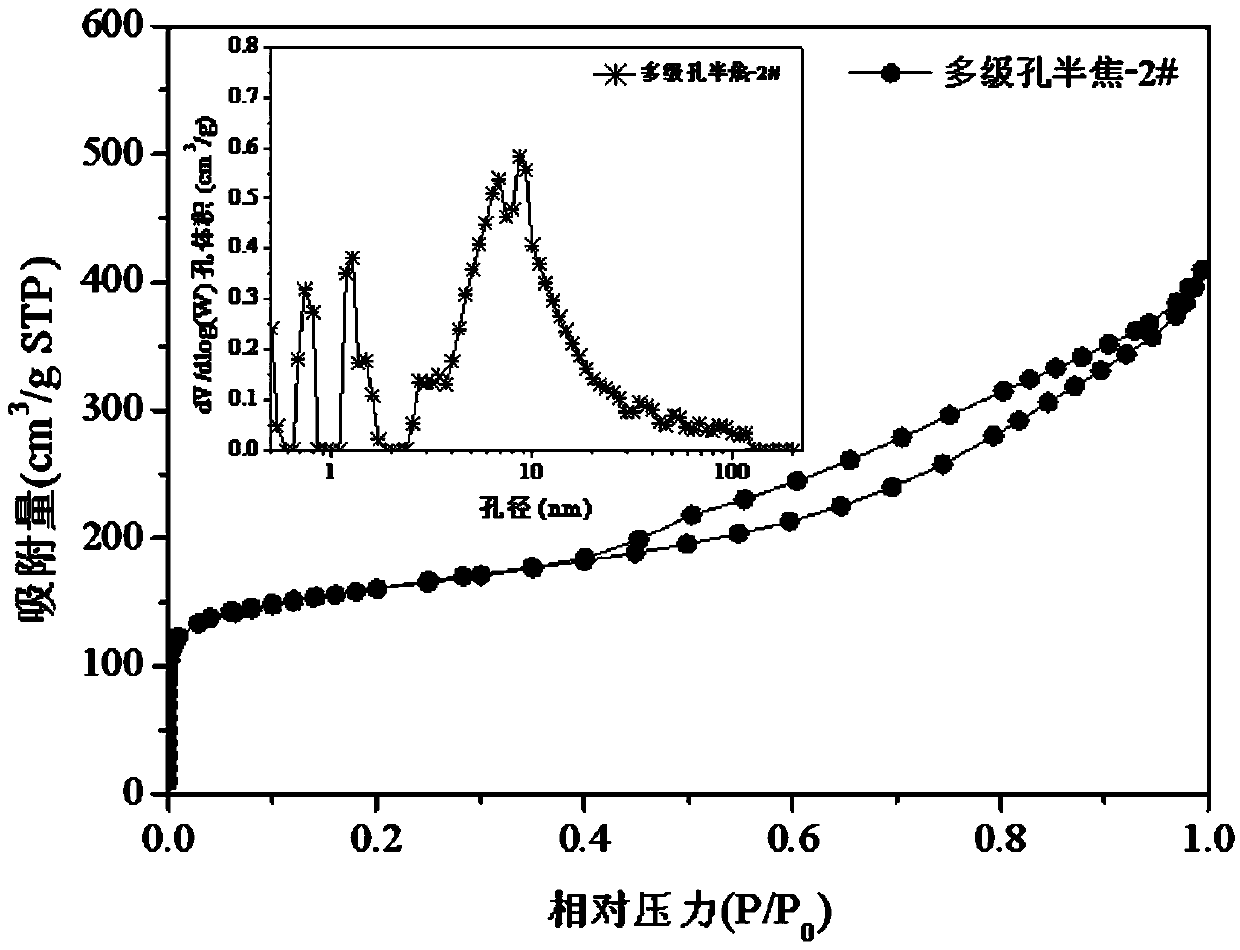

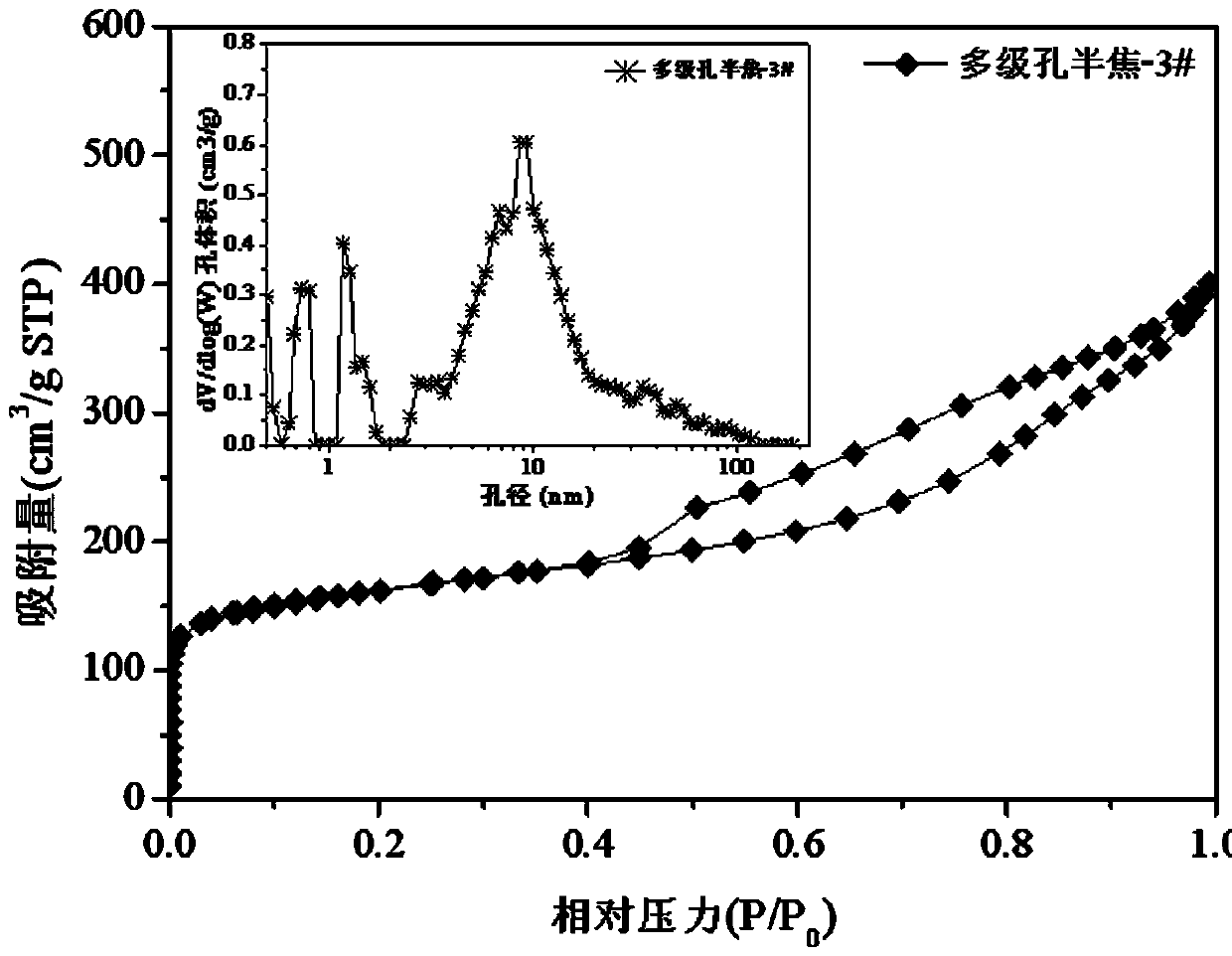

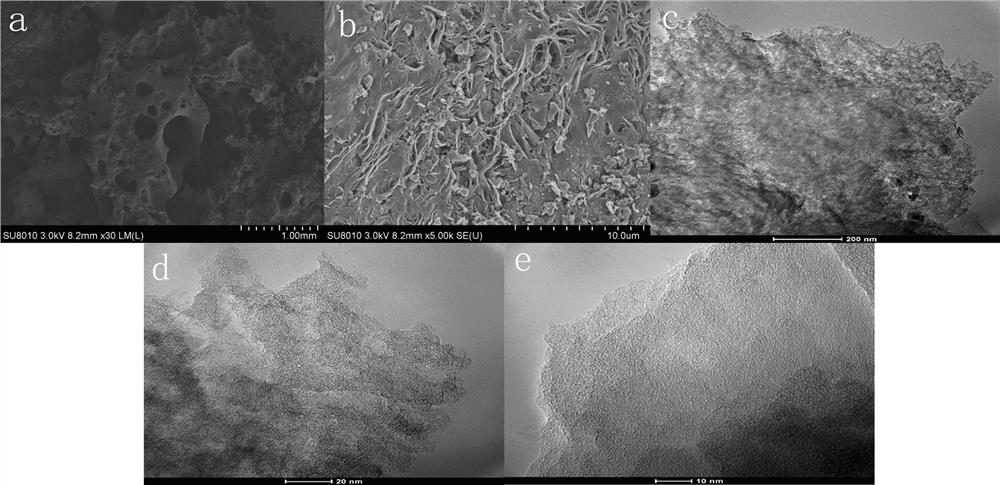

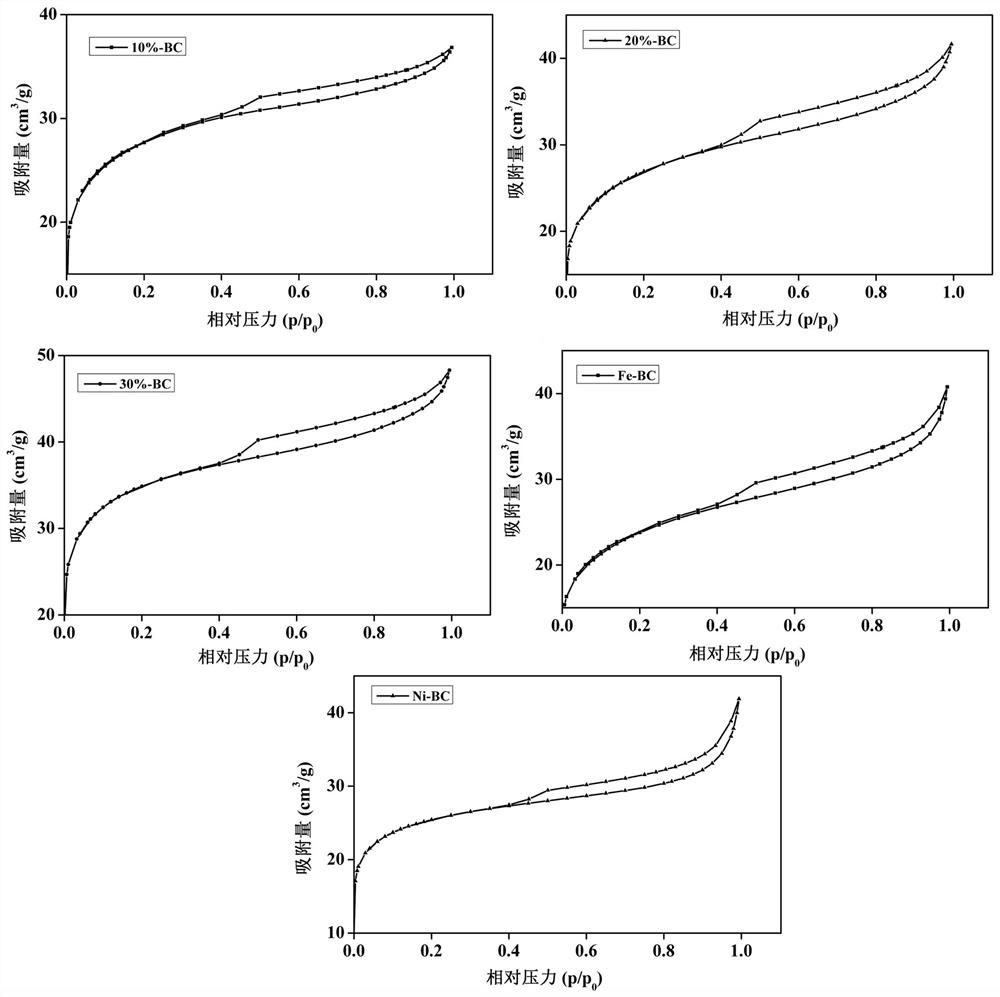

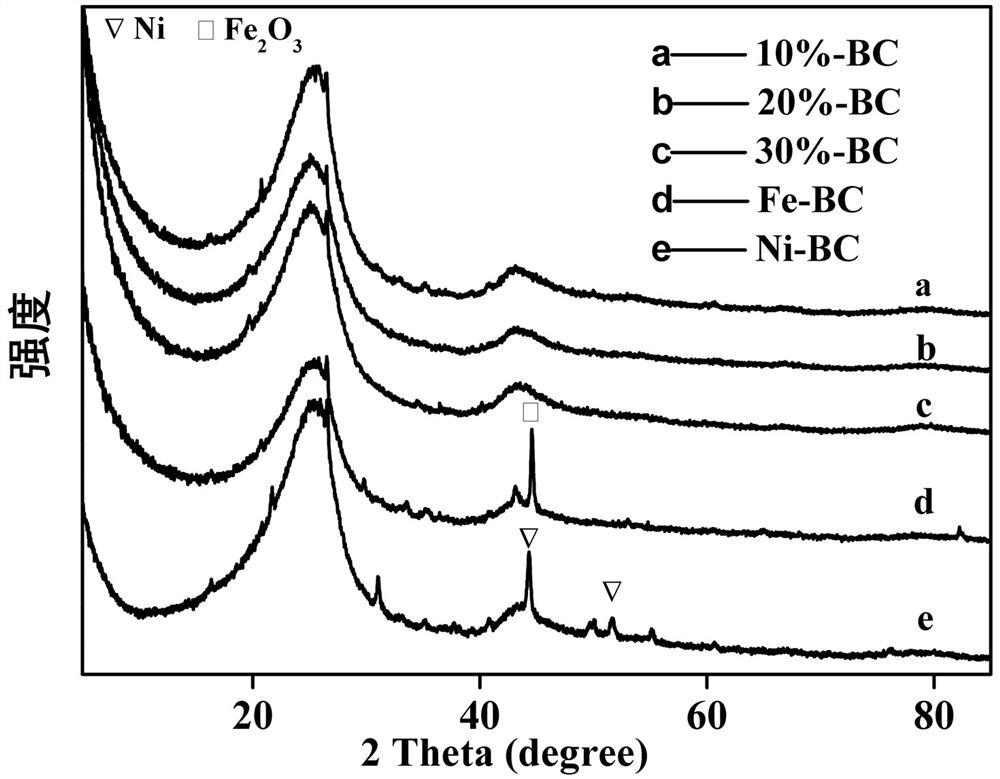

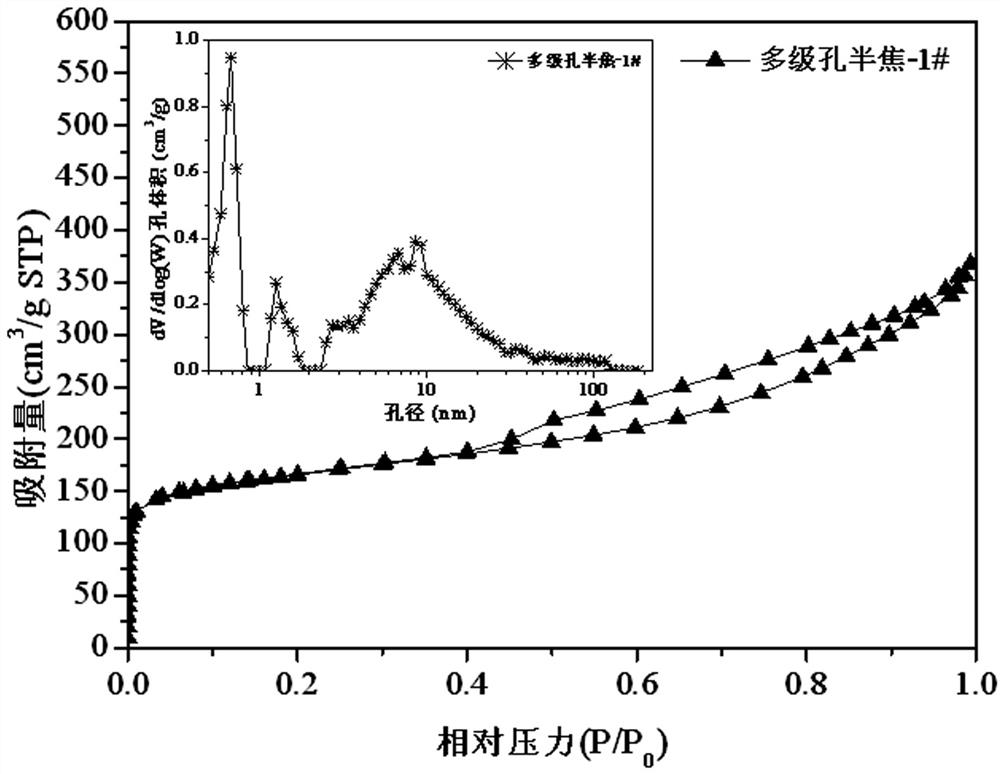

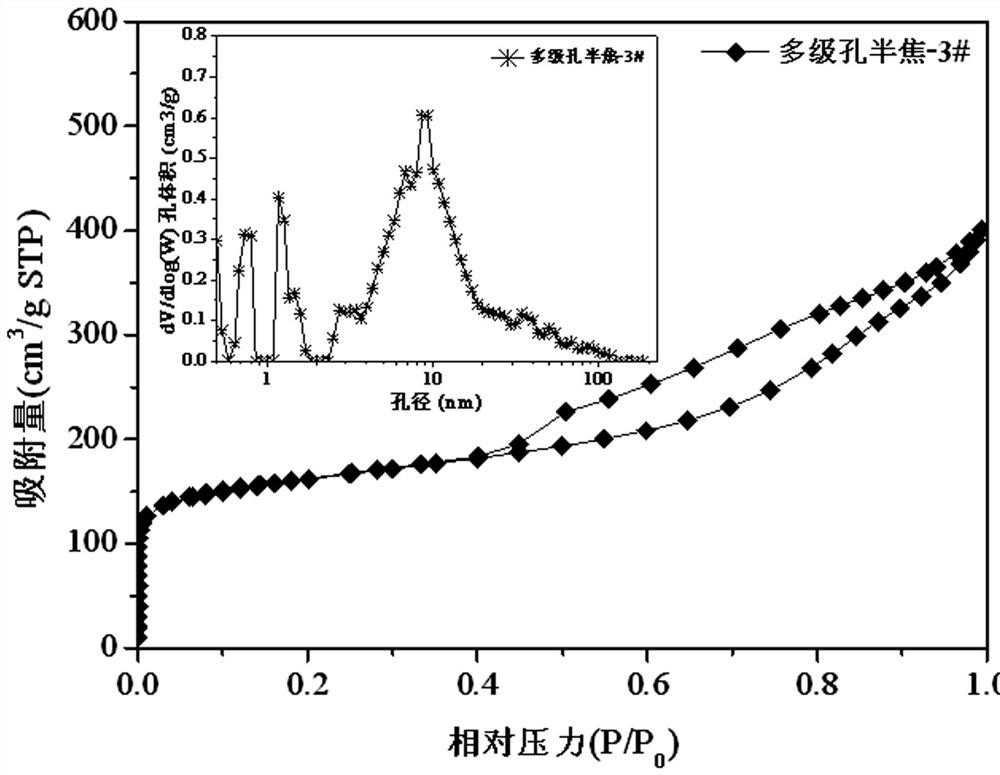

Preparation method of hierarchical pore carbon-based catalyst for catalytic reforming of coal tar

ActiveCN109529853AGood effect of catalytic modification of tarLow costCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsCatalytic reformingDiffusion resistance

A preparation method of a hierarchical pore carbon-based catalyst for catalytic reforming of coal tar belongs to the technical field of preparation of catalysts for catalytic reforming of coal tar, and can solve a problem that the large diffusion resistance of existing microporous carbon-based catalysts having a small pore size is not conducive to the proceeding of a catalytic reaction. The methodcomprises the following steps: carrying out steam activation on low metamorphic coal under the catalysis of a calcium-containing mineral matter to obtain semi-coke with a hierarchical pore structure,and using the semi-coke with the hierarchical pore structure as a carrier to support an active metal in order to prepare the carbon-based catalyst with a hierarchical pore structure. The catalyst hasdeveloped microporous and mesoporous structures, so the diffusion of heavy components in the tar in the pores of the catalyst and the contact of the heavy components with active sites are benefited,and the catalyst has a good catalytic effect in the catalytic reforming of coal tar, and has a broad application prospect.

Owner:TAIYUAN UNIV OF TECH

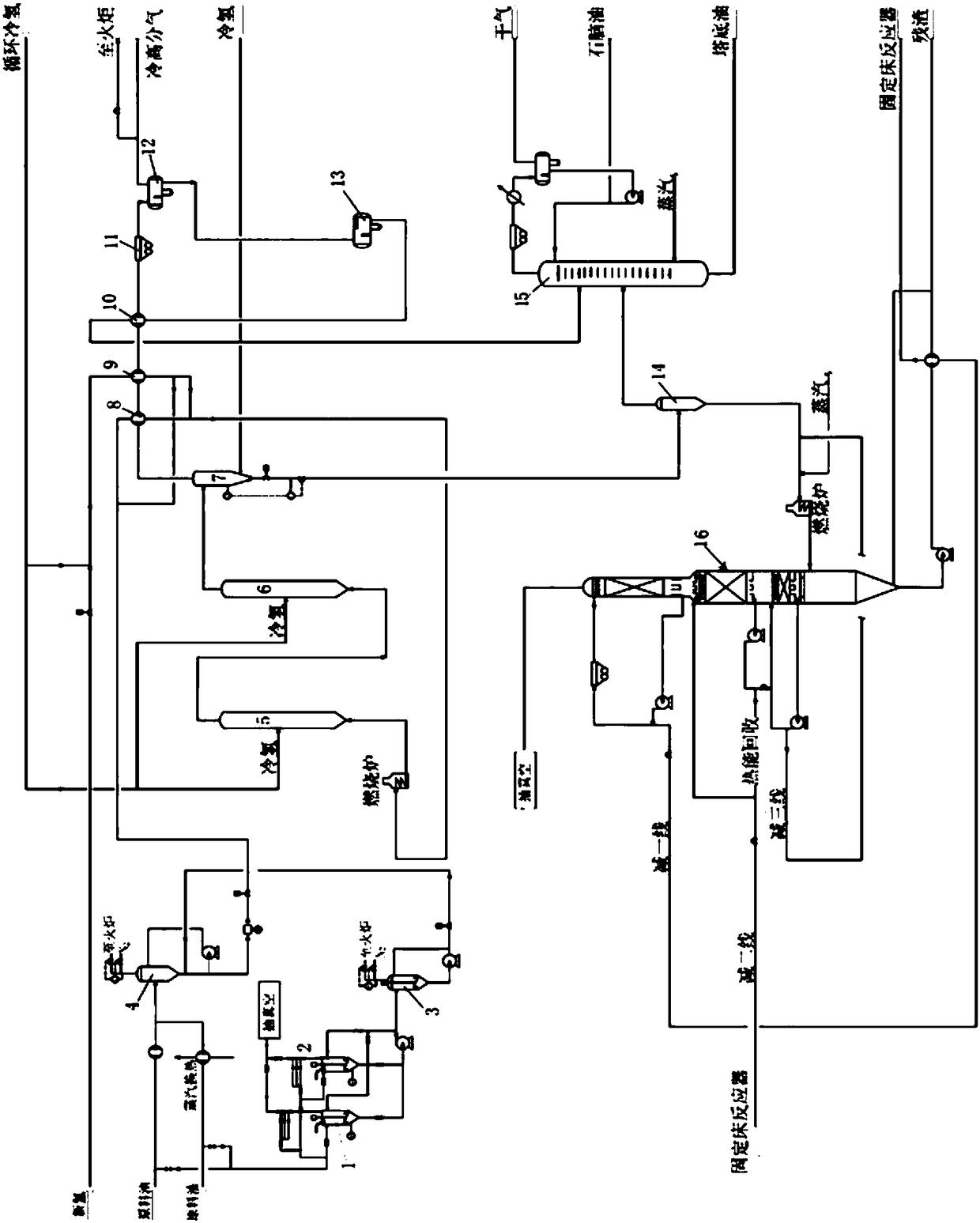

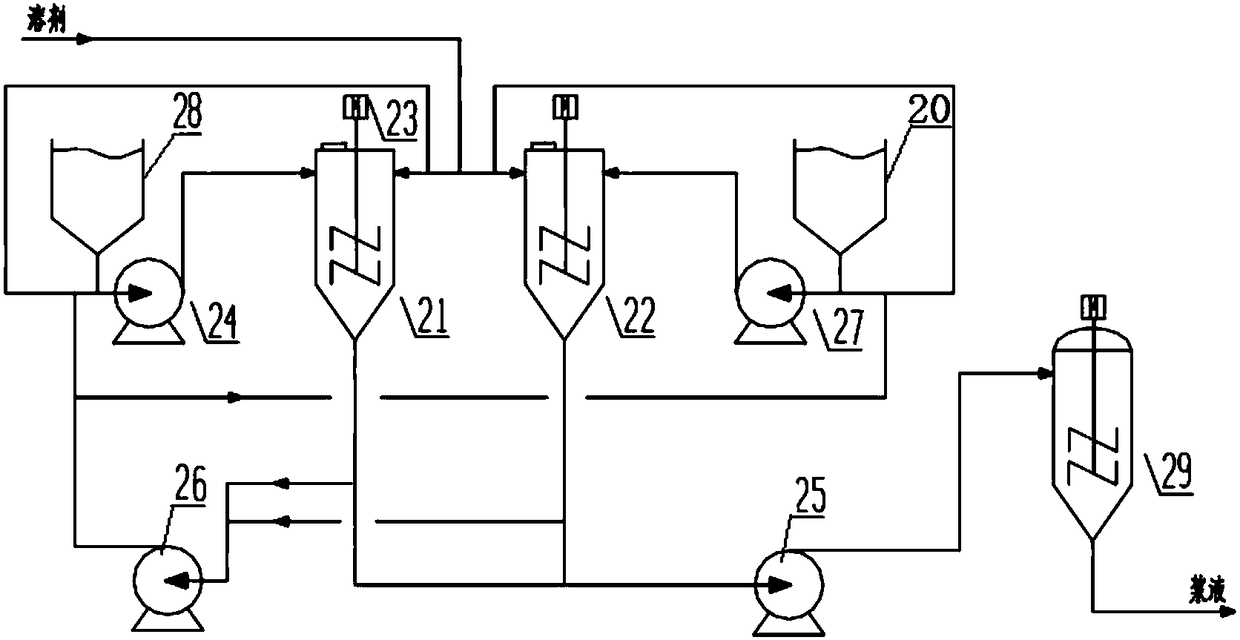

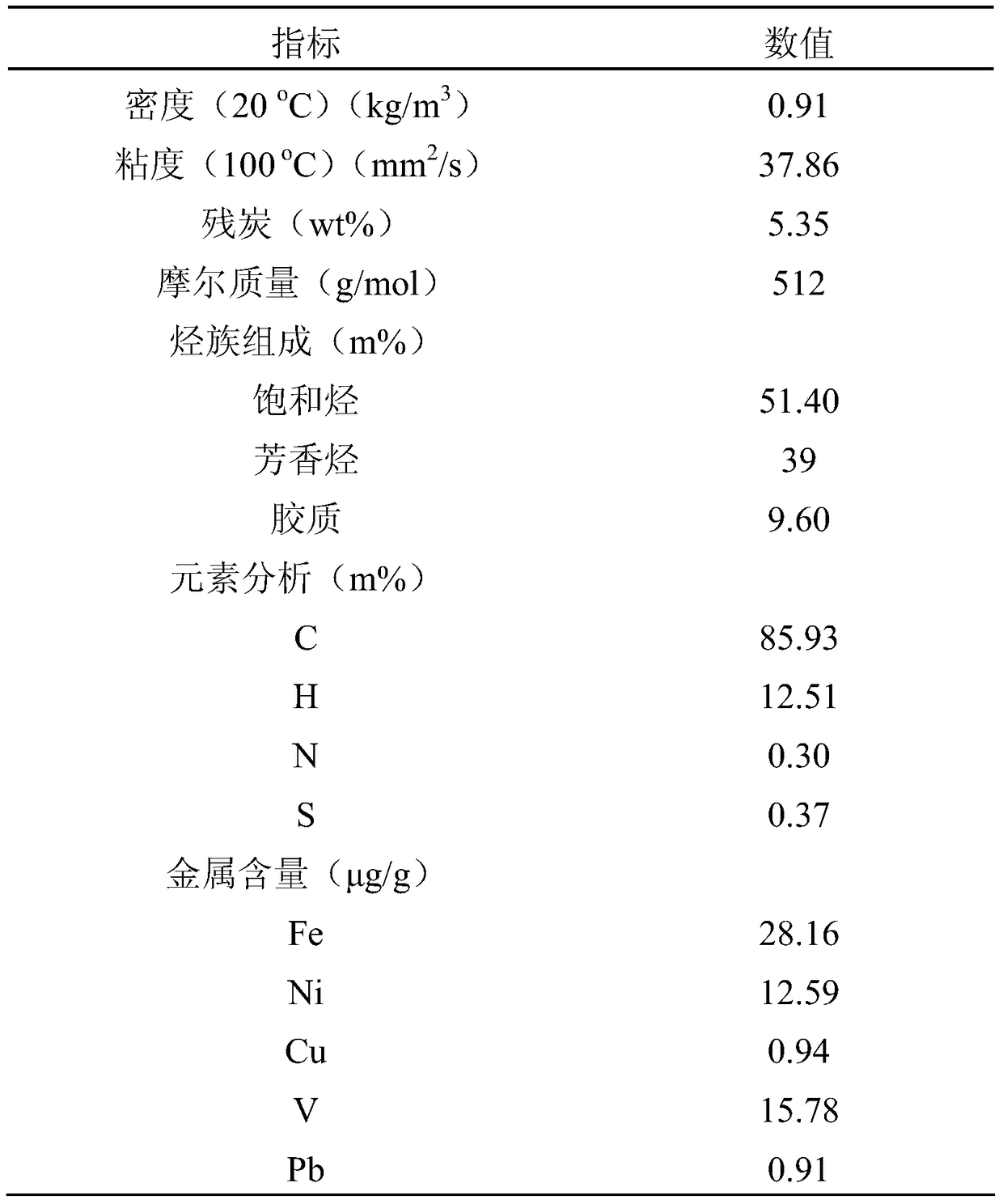

Suspension bed hydrogenation process for processing heavy oil

ActiveCN108264934AImprove conversion rateHigh yieldHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenation reactionHydrogenation process

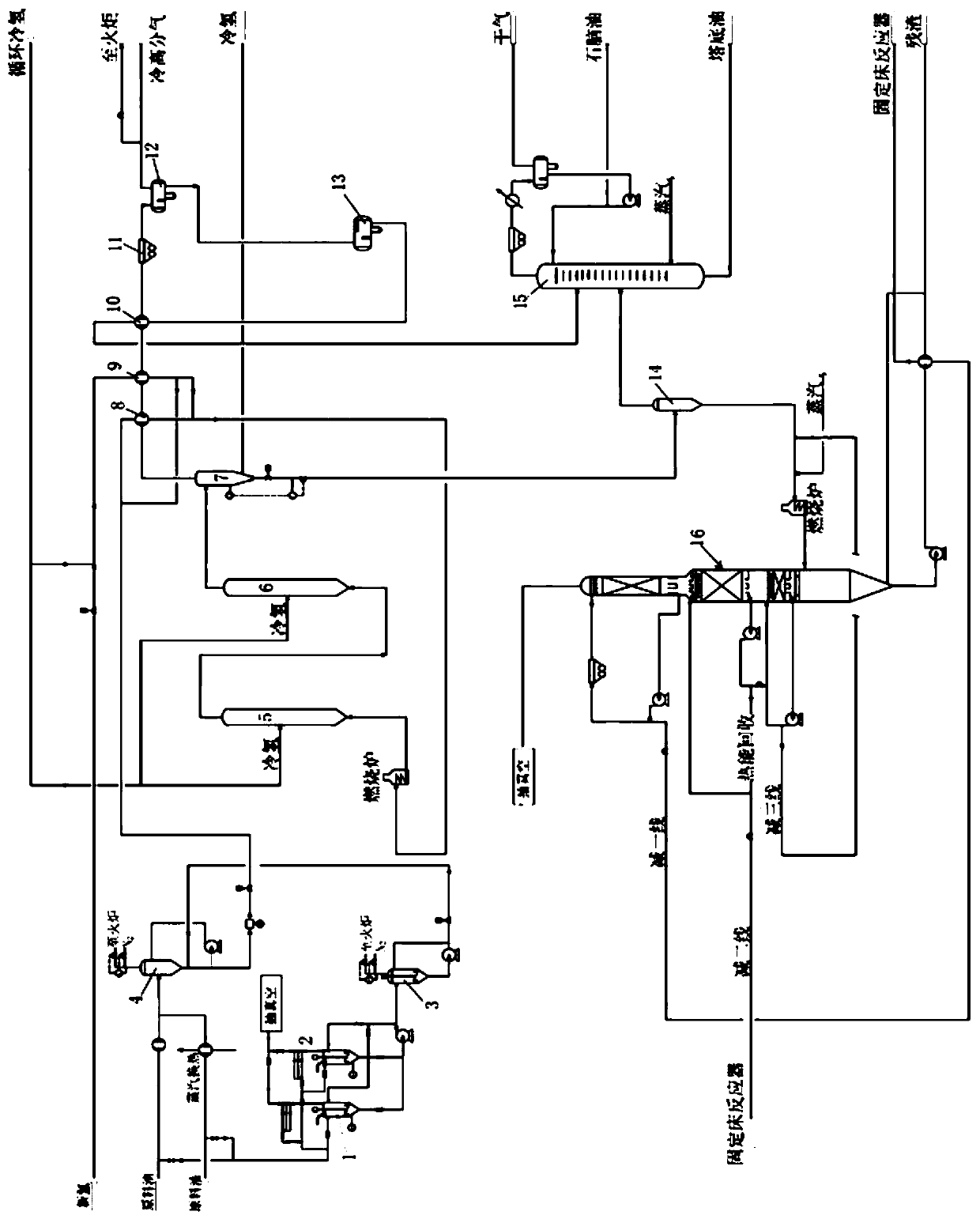

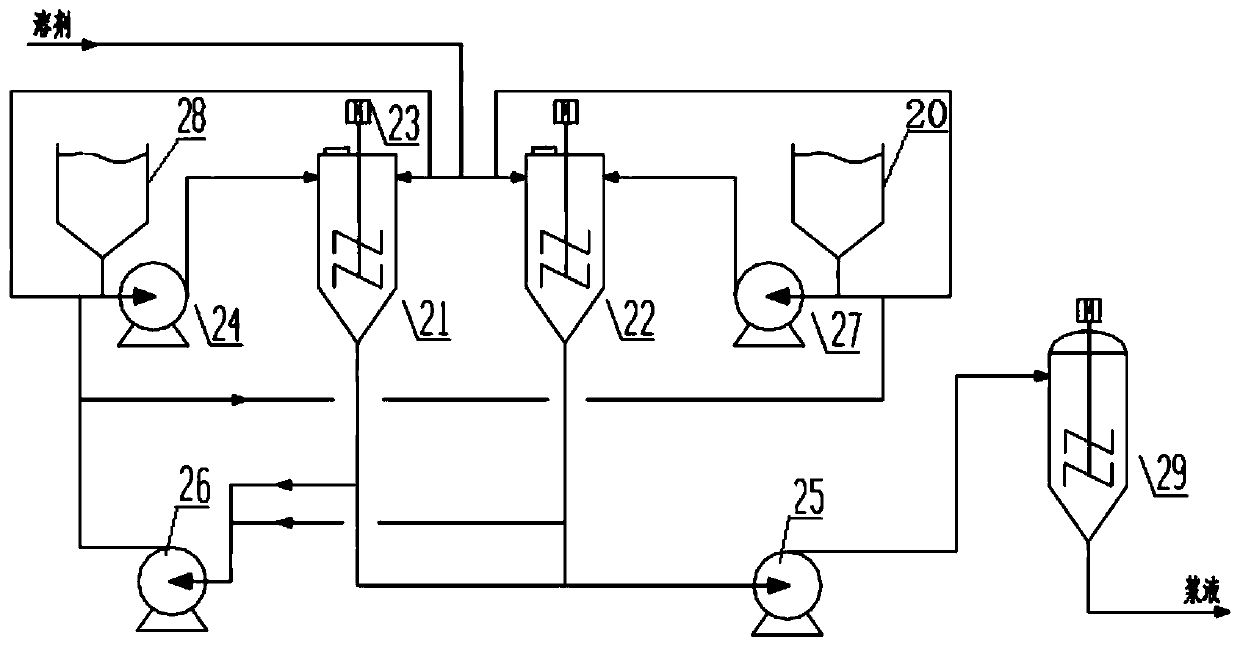

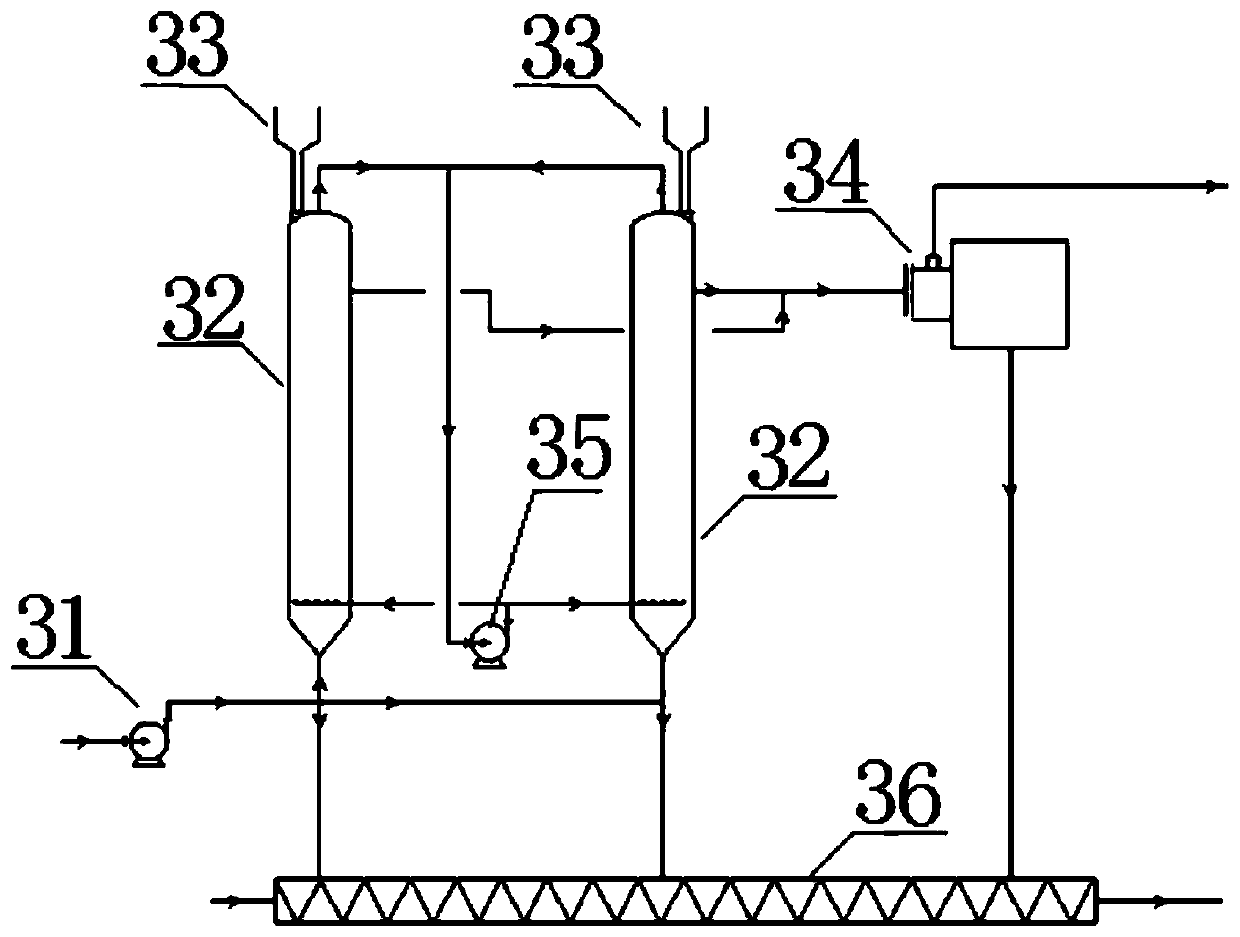

The invention provides a suspension bed hydrogenation process for processing heavy oil. In the process, part of raw oil and a suspension bed hydrocracking catalyst are mixed to form a mixture, the mixture is then subjected to primary shearing and secondary shearing sequentially, and thus high-dispersion mixing of the catalyst and the raw oil can be carried out to obtain catalyst slurry, hydrogenation catalytic activity of the catalyst works well to facilitate increase of raw oil conversion rate and light oil yield; the catalyst slurry, the residual raw oil and hydrogen are mixed and then sentinto a suspension bed hydrogenation reactor, suspension bed hydrogenation products are obtained by controlling suspension bed hydrogenation conditions; a reasonable separating process is utilized according to composition and property of the product, and thus, hydrogenation load of a fixed bed is reduced greatly, yield and quality of light oil are improved to the utmost extent, and above all, service life of the fixed bed catalyst can be prolonged effectively, and energy saving and emission reducing of the whole process are facilitated.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

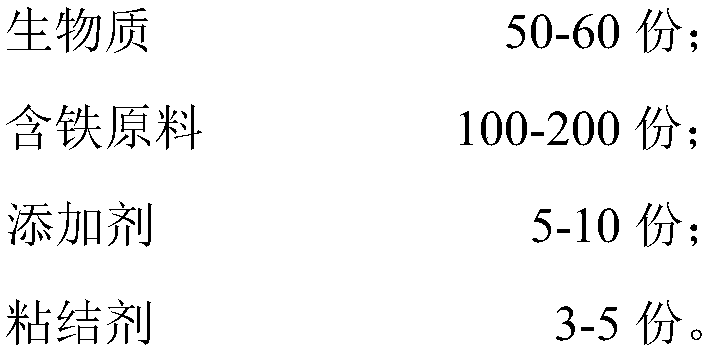

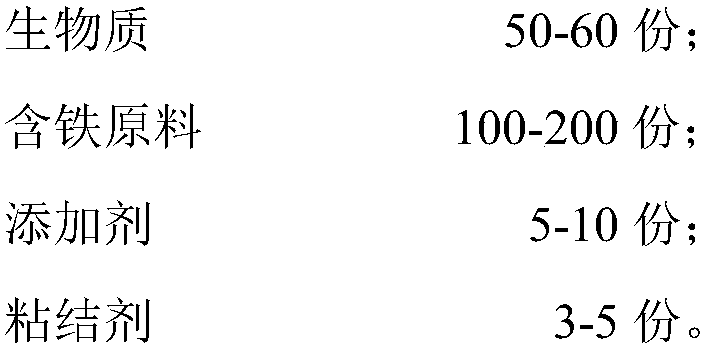

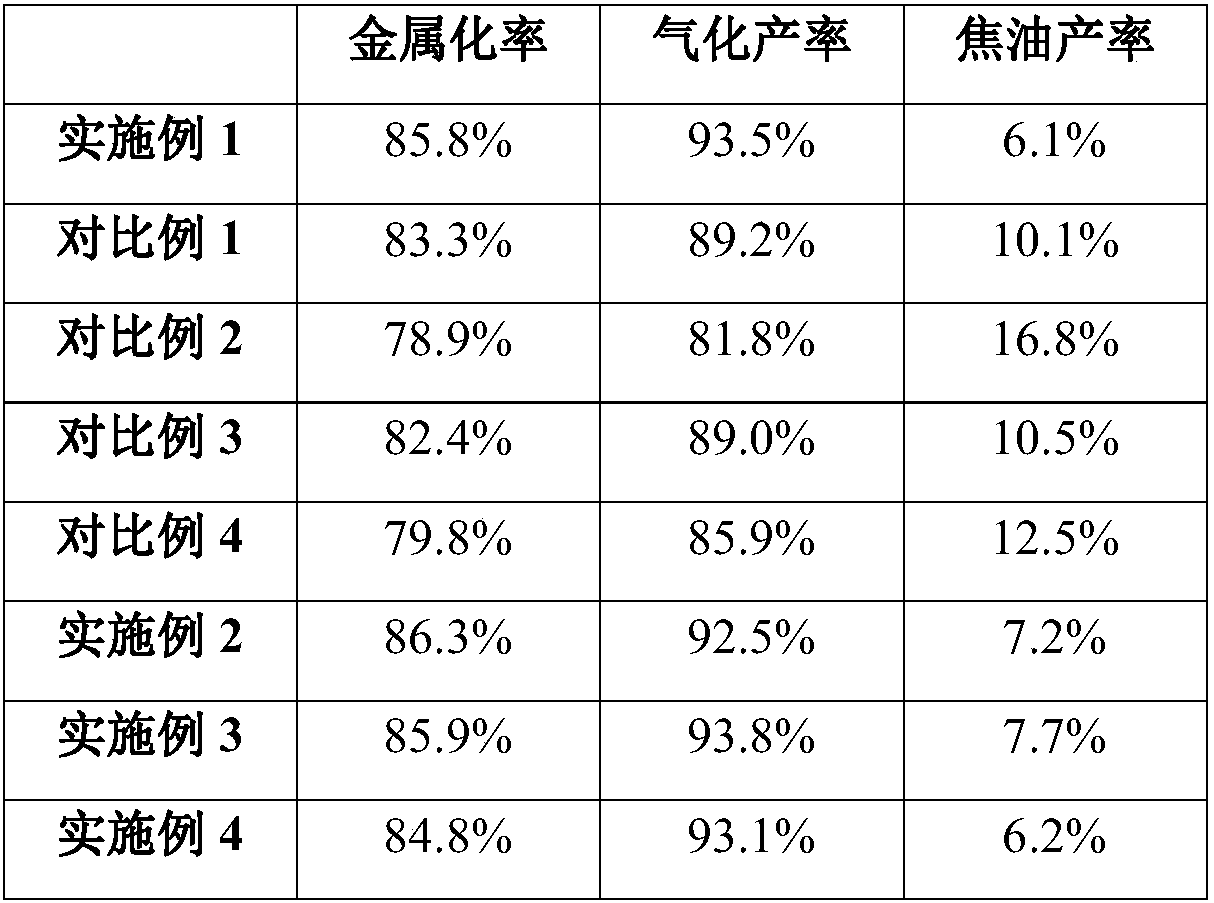

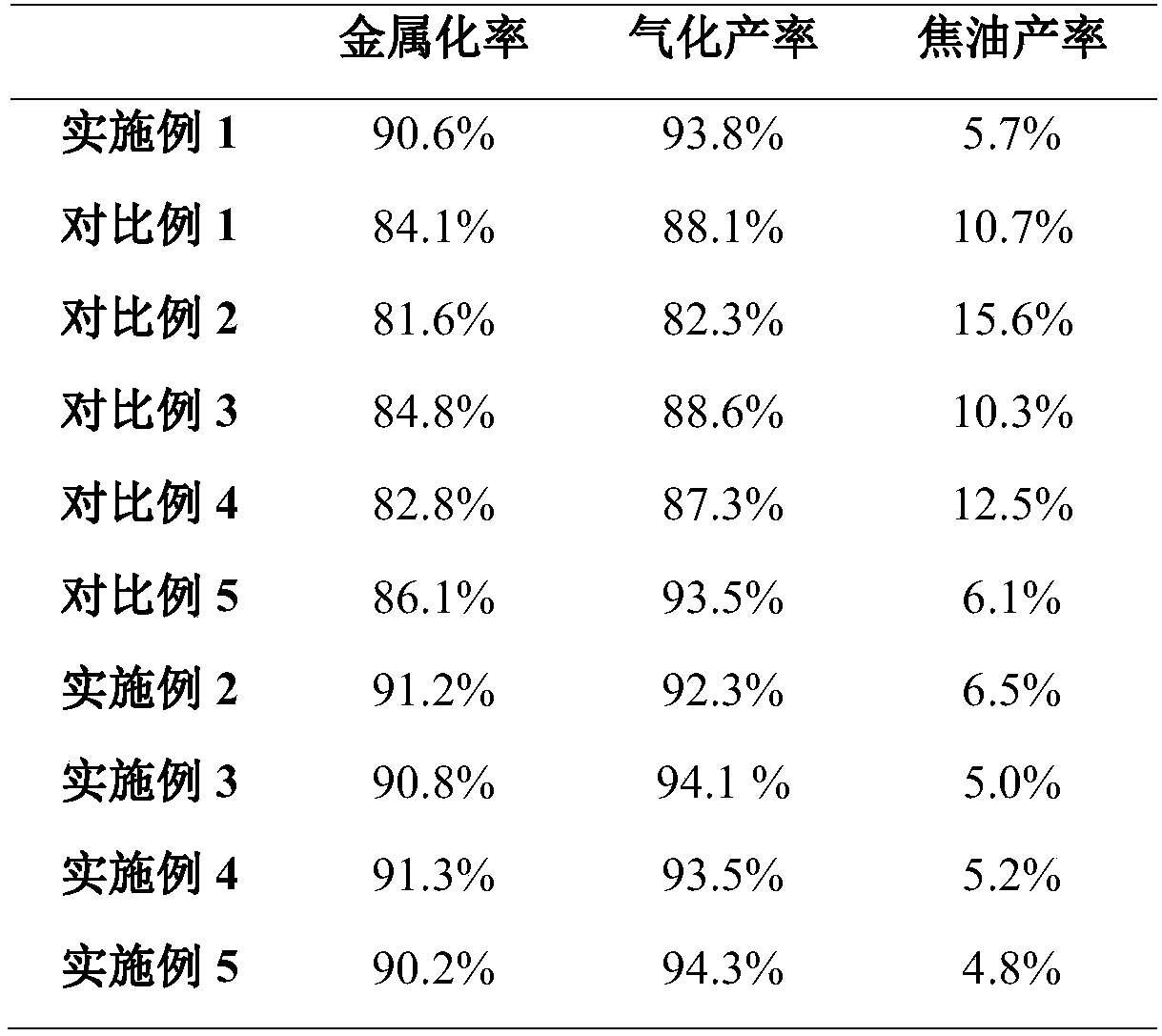

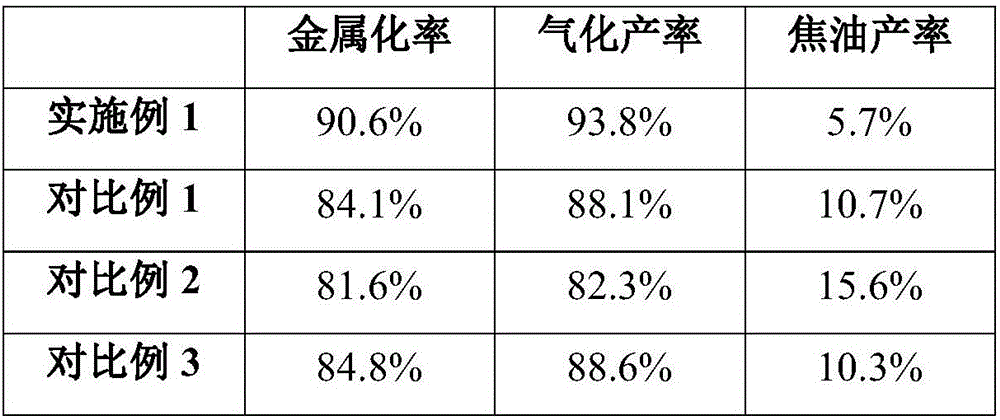

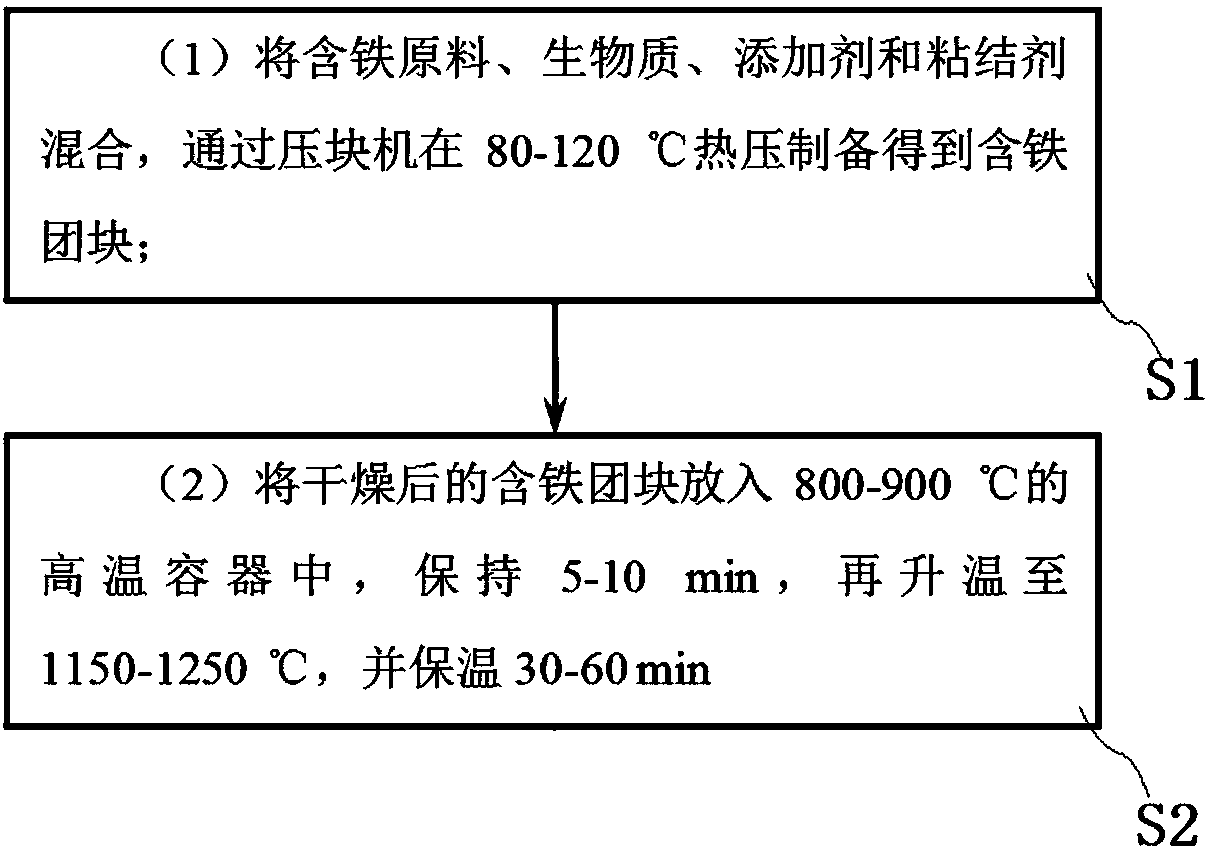

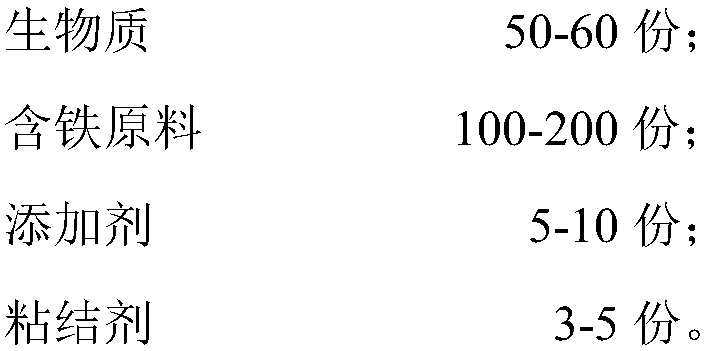

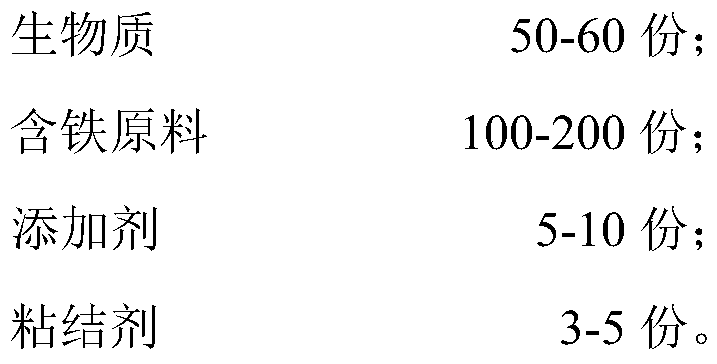

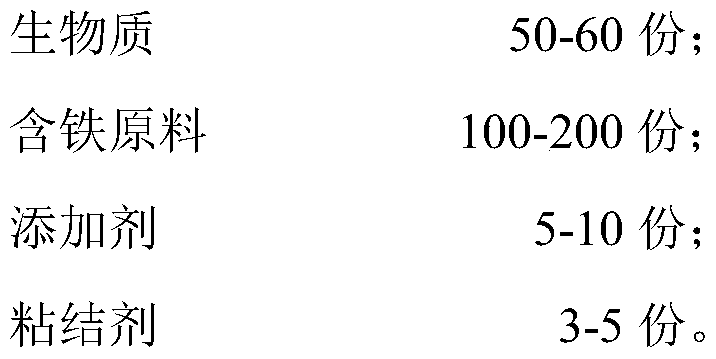

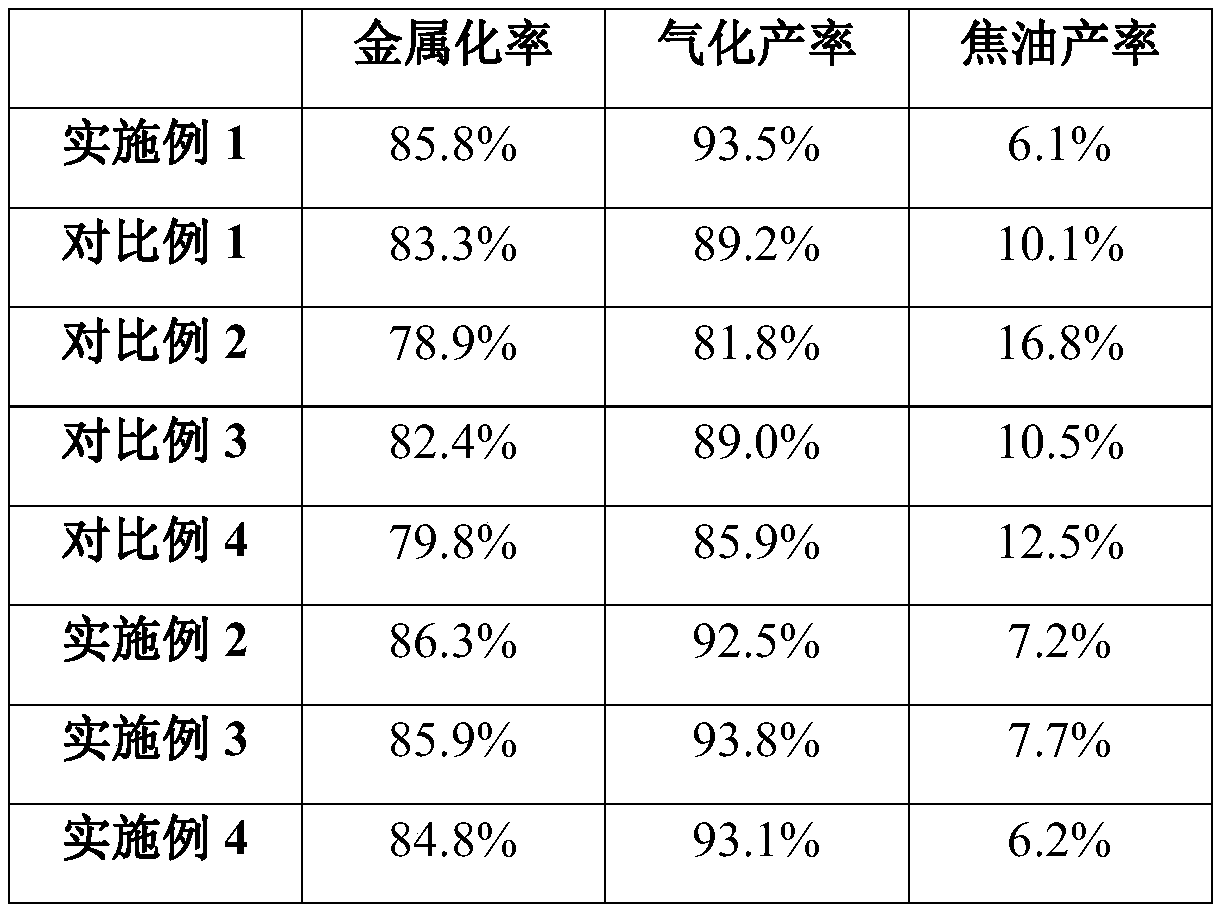

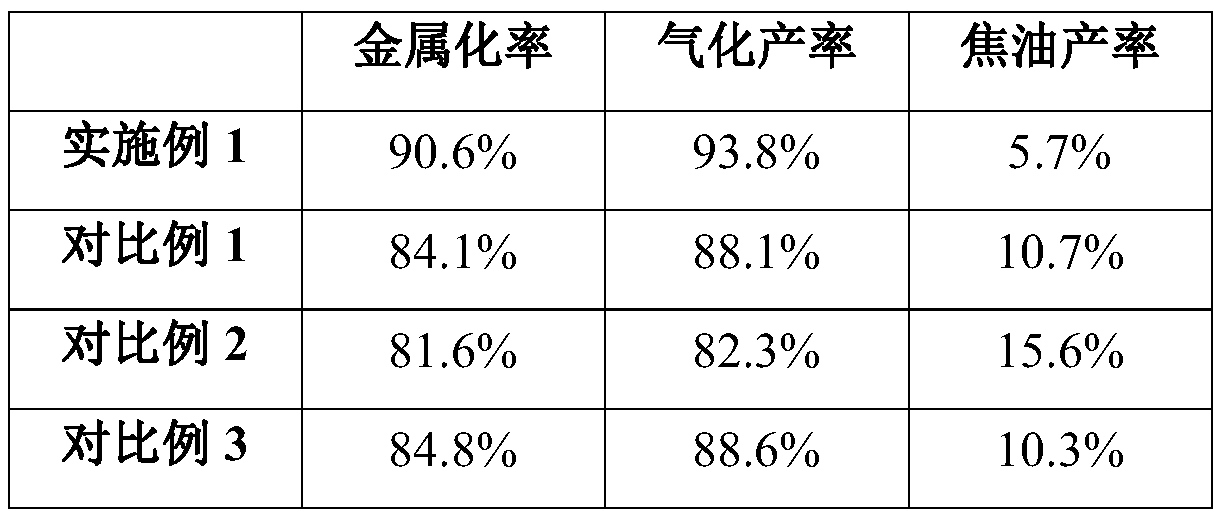

Biomass iron-containing agglomerate for producing combustible gas and DRI and preparation method thereof

ActiveCN108570525AIncrease metallization rateReduce tar contentFluidised-bed furnacesDecompositionOxygen

The invention relates to a biomass iron-containing agglomerate for producing combustible gas and DRI, and a preparation method thereof, belonging to the technical field of iron making. The iron-containing agglomerate of the invention comprises, by mass, 50-60 parts of biomass, 100-200 parts of an iron-containing raw material, 5-10 parts of additives and 3-5 parts of a binder, wherein the additivescomprise sodium carbonate, laterite nickel ore, dolomite and plant ash. The iron-containing agglomerate of the invention reduces the thermal stability of the biomass and its decomposition products; the biomass acts as a reducing agent for iron oxide and a C source and an H source for combustible gas; the iron oxide acts as an iron source for steel preparation and an oxygen source for production of CO through reactions of carbon; so the iron-containing agglomerate promotes the catalytic cracking of tar and the biomass and its decomposition products, improves the gasification yield biomass andincreases the metallization rate of DRI.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

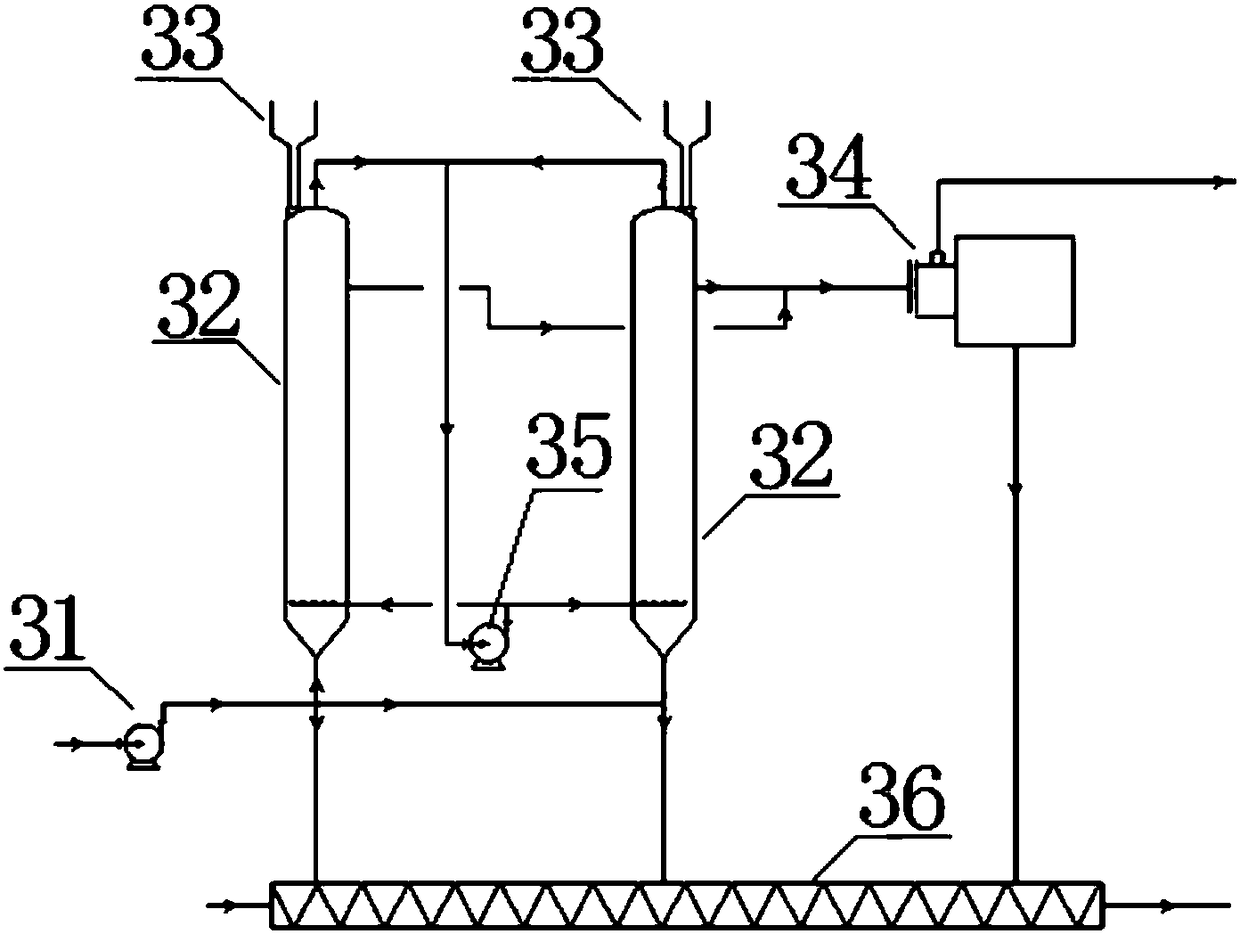

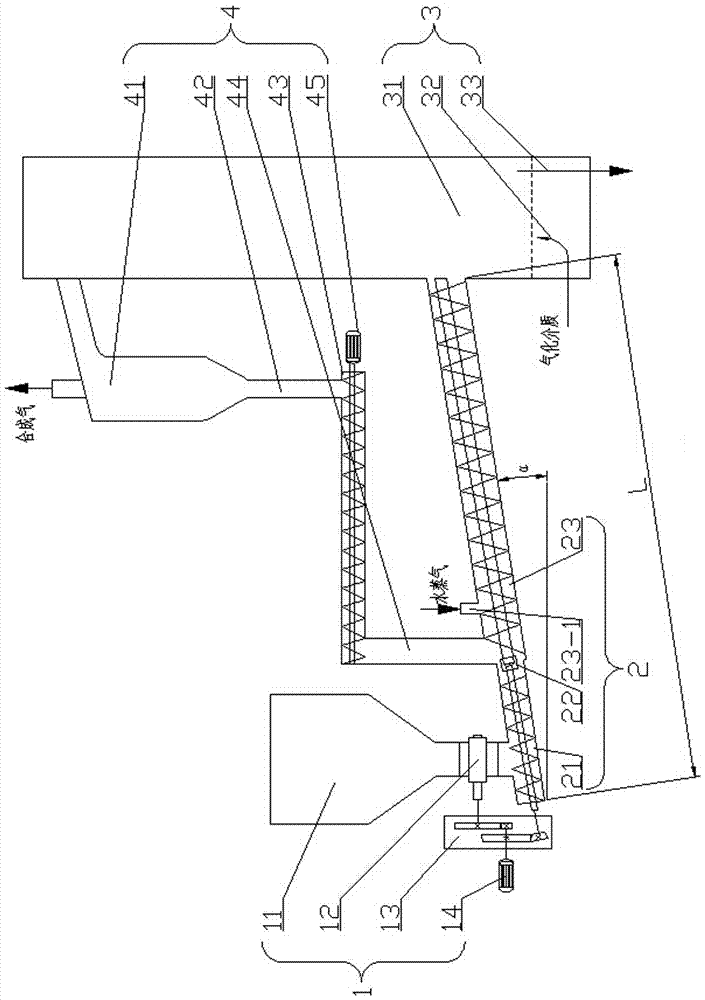

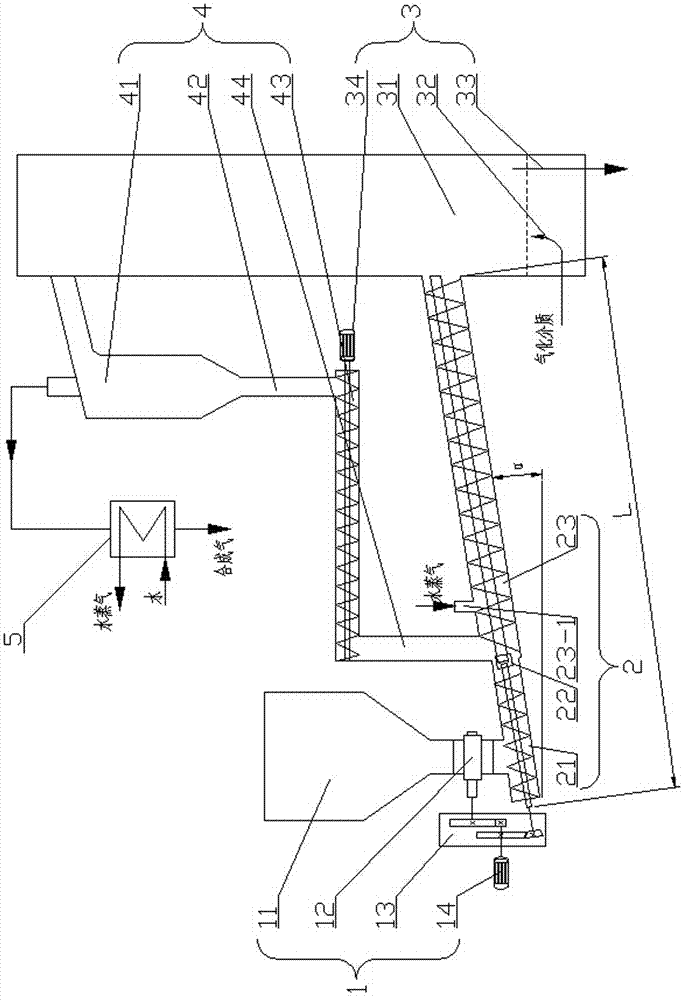

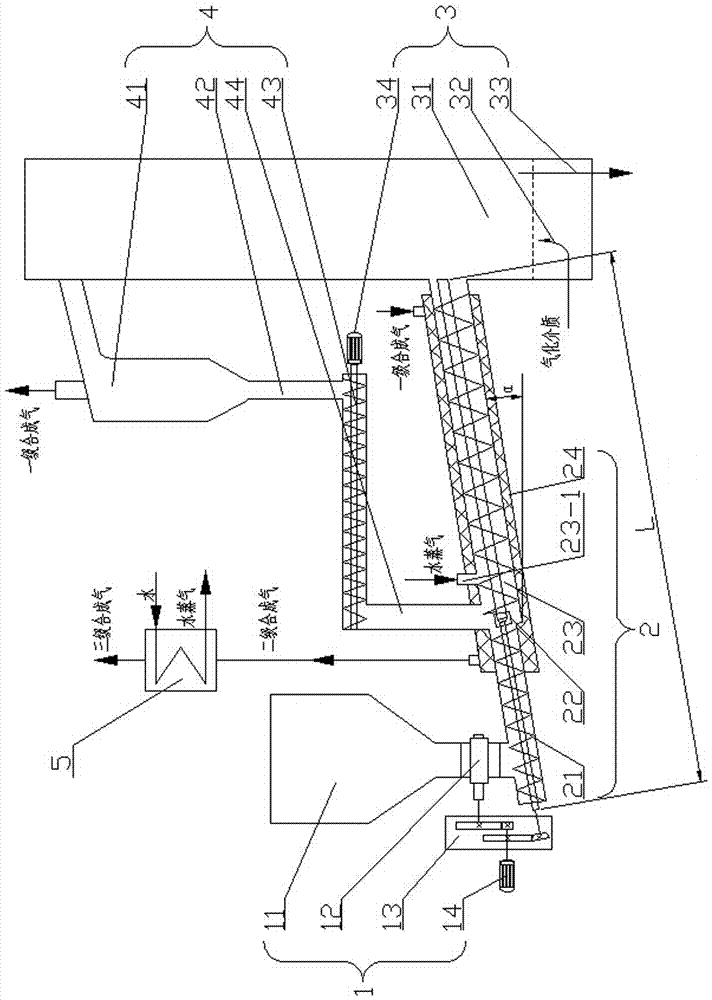

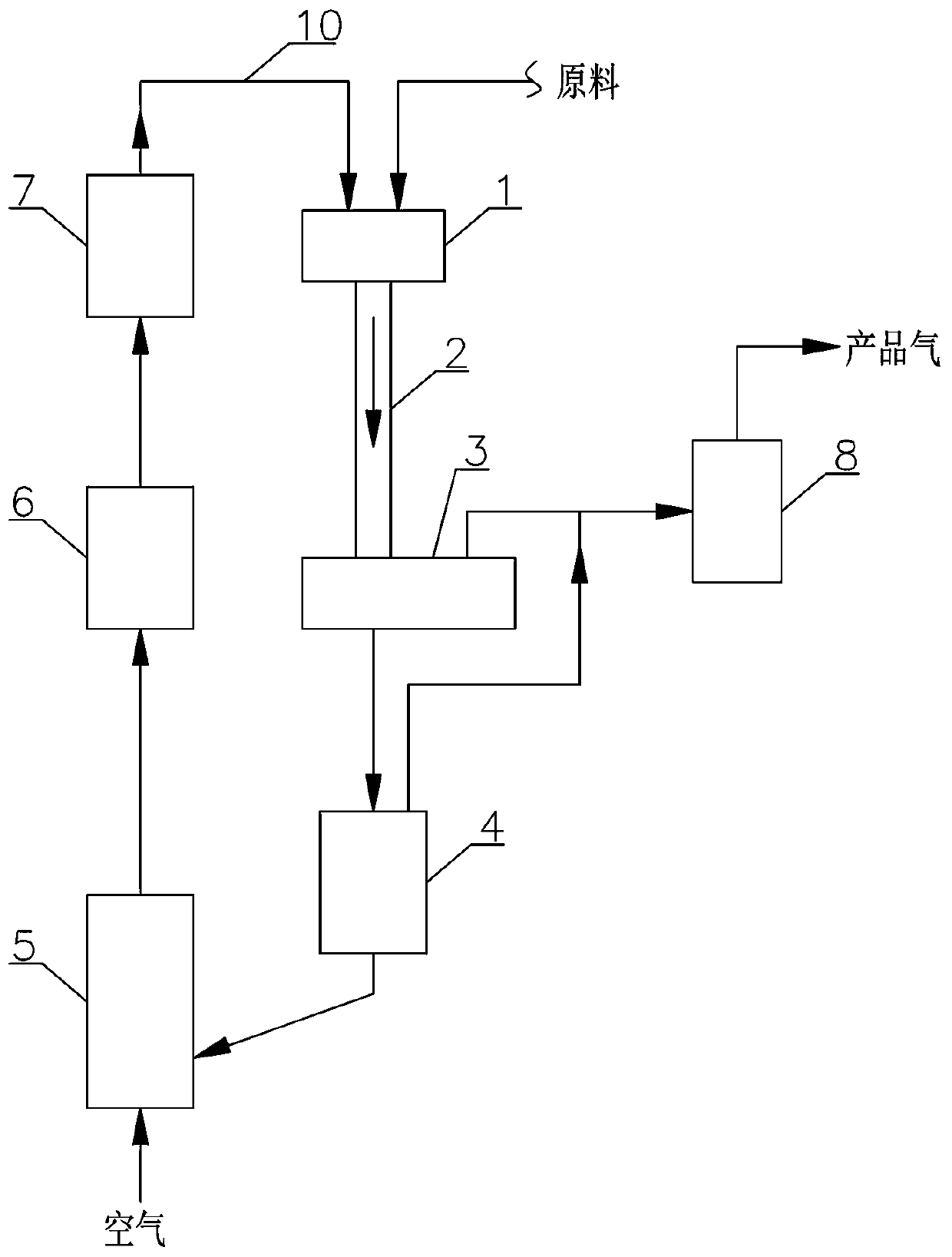

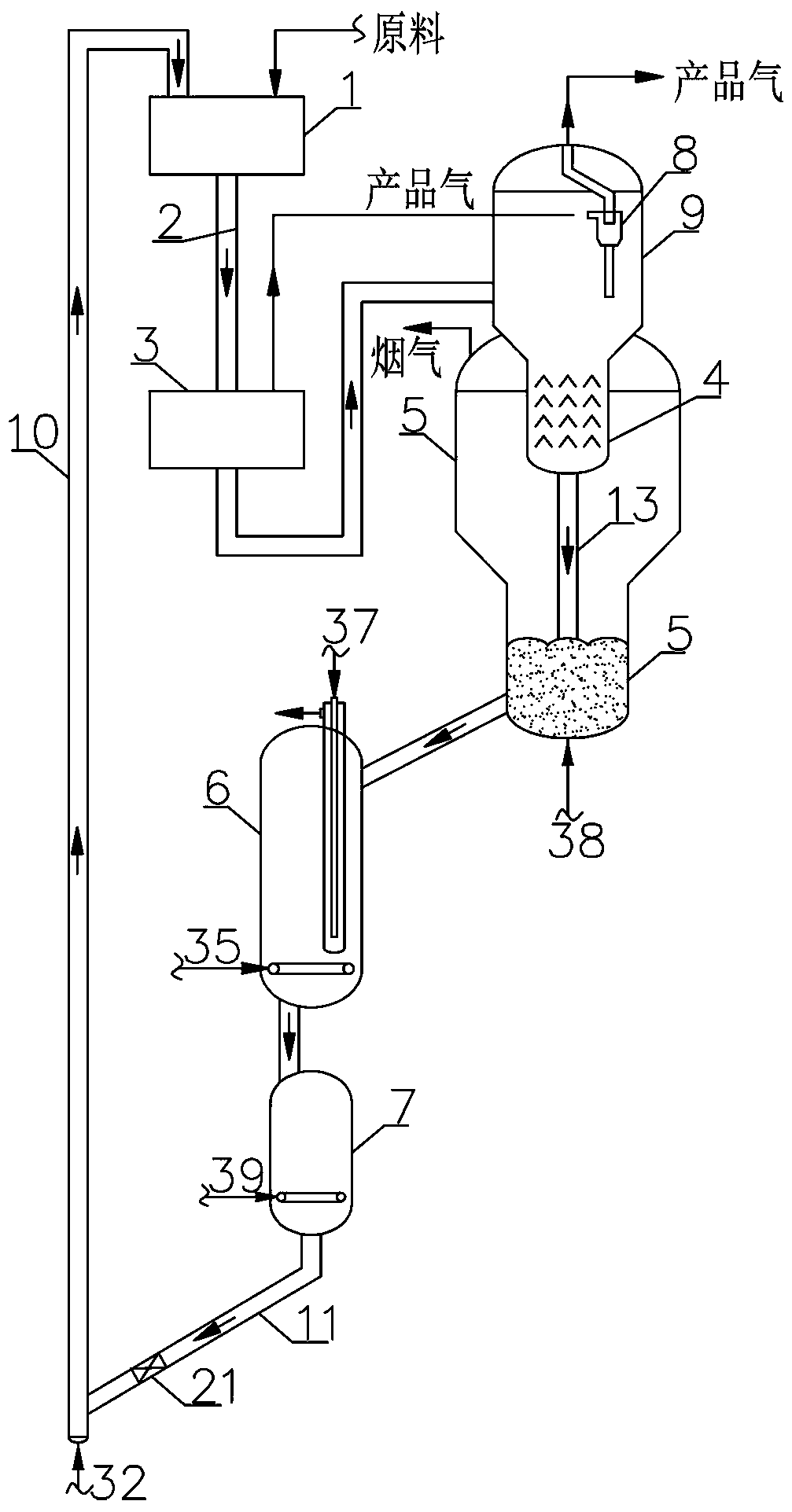

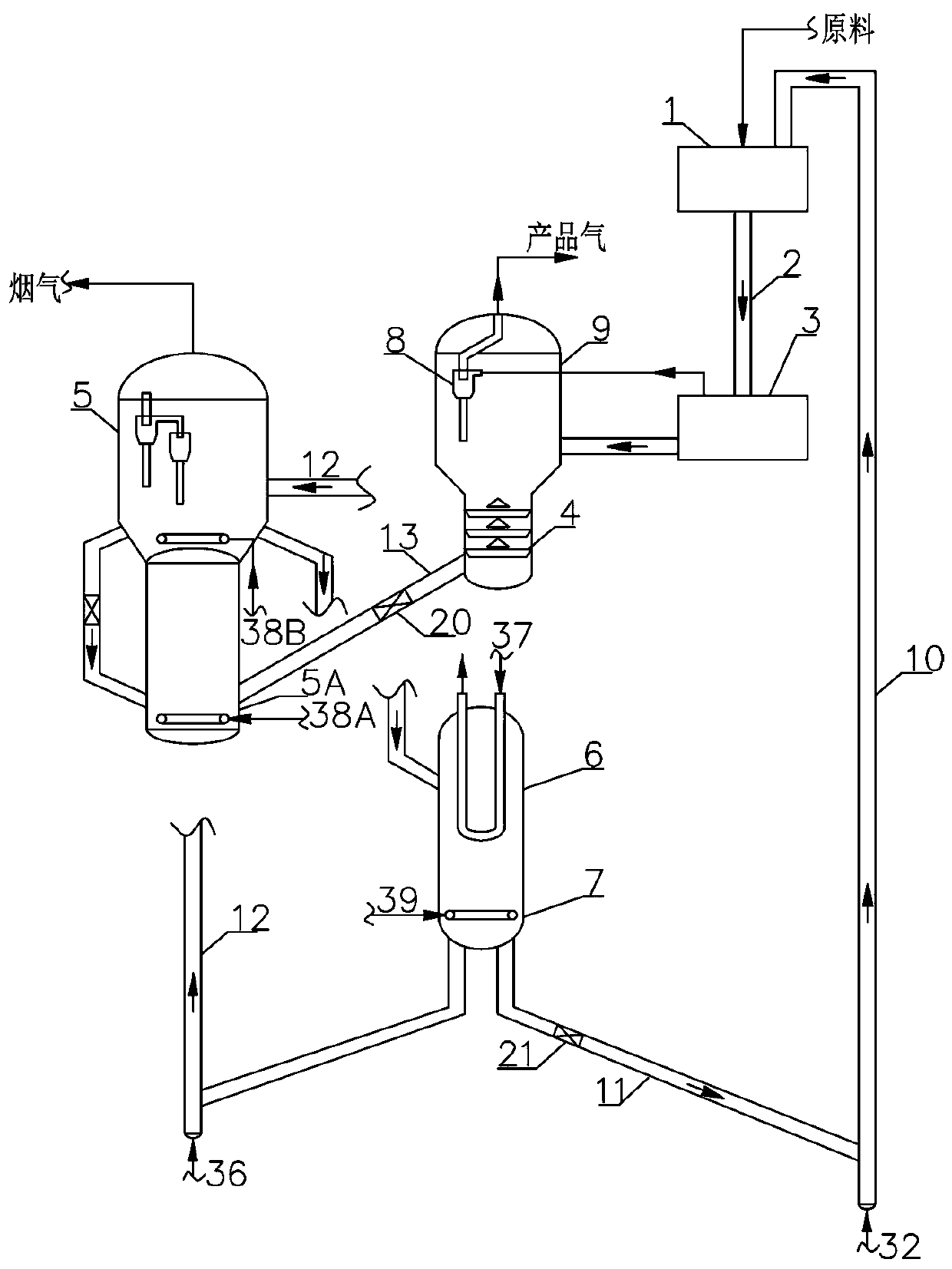

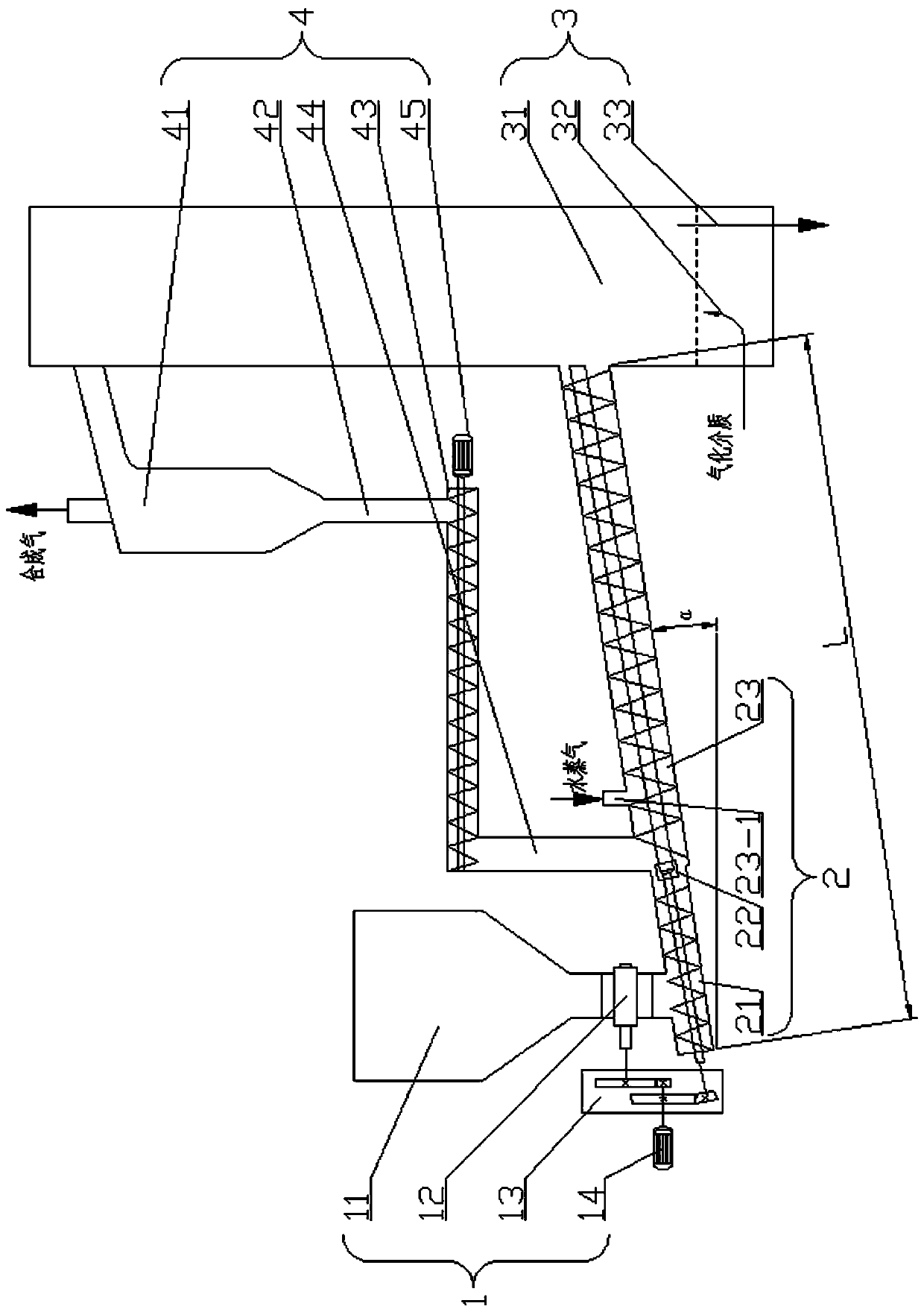

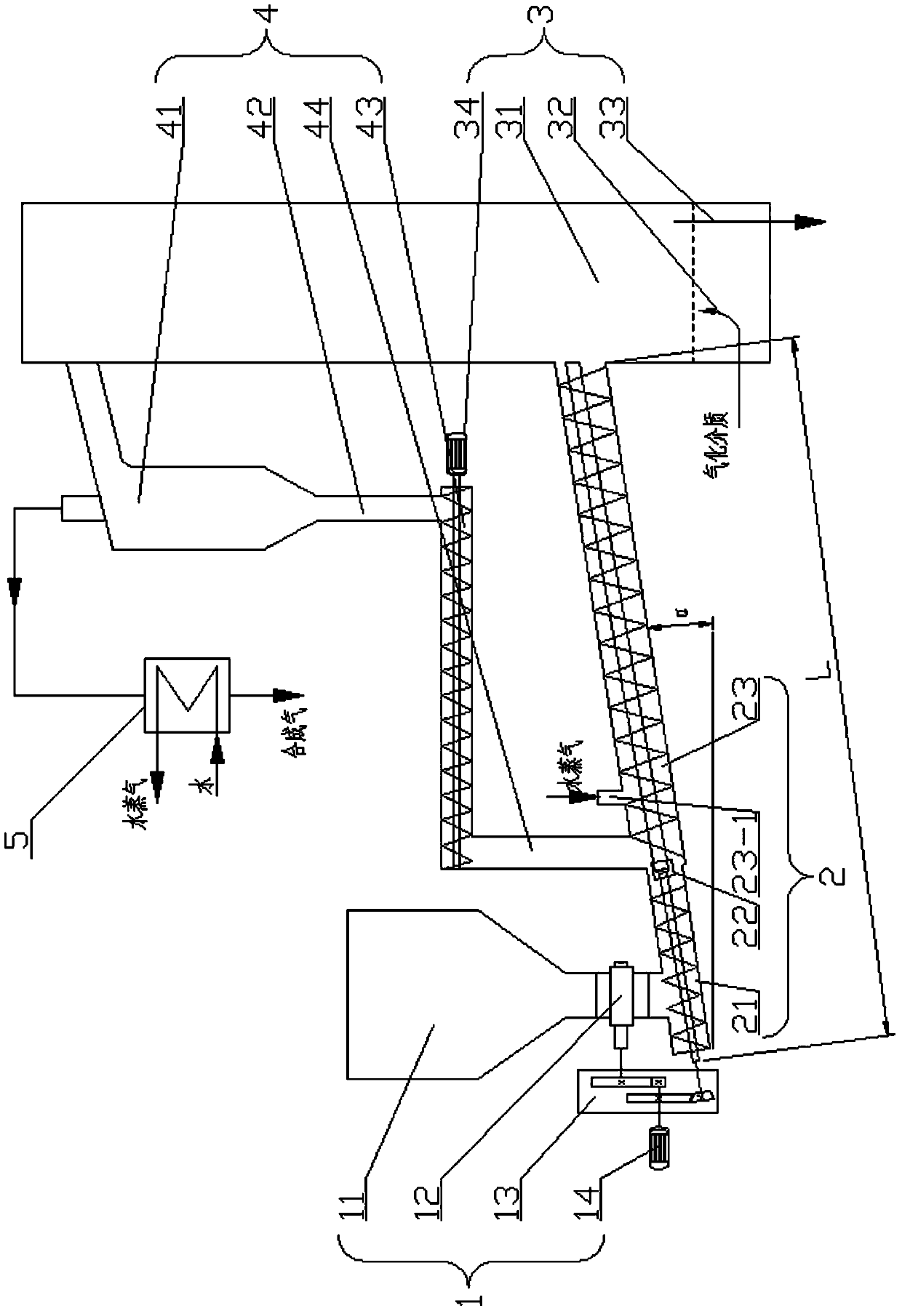

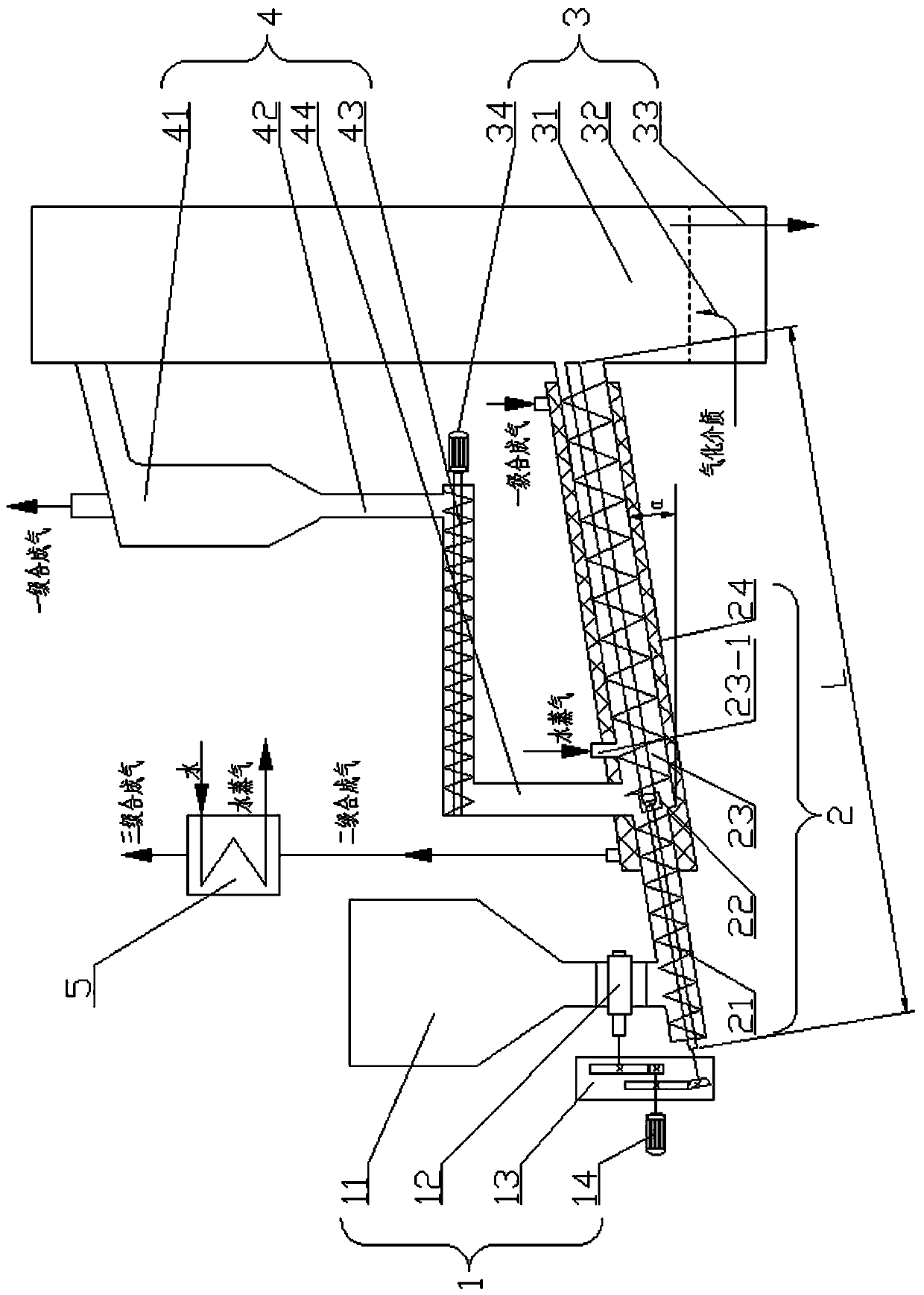

Low-rank fuel low-temperature gasification device based on screw pyrolyzers and fluidized bed gasifier

ActiveCN107400539AReduce contentFacilitated catalytic crackingGasification processes detailsGasification apparatus detailsFluidized bed gasifierWater vapor

A low-rank fuel low-temperature gasification device based on screw pyrolyzers and a fluidized bed gasifier belongs to the field of gasification of low-rank fuels. The power output shaft of a motor 1 is connected with the power input shaft of a transmission gearbox in a transmission mode, a first-order screw pyrolyzer is mutually coupled with a gas lock device through a transmission gearbox, the screw shaft of the first-order screw pyrolyzer is connected with the screw shaft of a second-order screw pyrolyzer through a shaft coupling, and the second-order screw pyrolyzer communicates with the fluidized bed gasifier; the upper part of the second-order screw pyrolyzer is provided with a water vapor inlet; the fluidized bed gasifier communicates with a cyclone separator, the fluidized bed gasifier communicates with a gas inlet system, and a residue discharging tube communicates with the bottom of the fluidized bed gasifier; and the cyclone separator communicates with a first-stage return tube, the first-order return tube communicates with a screw return device, the screw return device communicates with a second-order return tube, and the second-order return tube communicates with the second-order screw pyrolyzer. The in-situ catalytic cracking of parts of tar by pyrolytic coke and the re-adsorbed alkali metal and alkali earth metal catalyzed low-temperature gasification of coal coke are used to realize the high-efficiency low-temperature gasification of the low-rank fuel.

Owner:哈尔滨丰瀛投资有限公司

A preparation method of mesoporous alumina binder and its application in heavy oil catalytic cracking catalyst

ActiveCN105983400BFacilitated catalytic crackingIncrease the areaCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention relates to a preparation method of a mesoporous alumina binder and its application in heavy oil catalytic cracking catalysts. The preparation method of the invention uses the mesoporous alumina molecular sieve as the aluminum source, and adopts the method of acidification and peptization to prepare the mesoporous alumina binder glue. The mesoporous alumina binder prepared by the invention can replace traditional binders and be used in the preparation of heavy oil catalytic cracking catalysts. Moreover, compared with traditional binders, the mesoporous alumina binder prepared by the present invention has a mesoporous channel structure, large specific surface area and large pore volume. Compared with catalysts prepared with traditional binders, catalysts prepared with mesoporous alumina binders have increased conversion of heavy oil and light oil yield, decreased coke yield and heavy oil yield, and have better performance in heavy oil catalytic cracking performance.

Owner:PETROCHINA CO LTD

Preparation method of beta molecular sieve

ActiveCN110143602AHigh yieldHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveIsomerization

The invention discloses a preparation method of a beta molecular sieve. The method comprises the following steps: step 1, synthesizing initial gel: mixing a silicon source, an aluminum source, an alkaline metal source and water, and performing uniform stirring to synthesize the initial gel, wherein based on SiO2 of the silicon source, Al2O3 of the aluminum source, and Na2O of the alkaline metal source, molar ratios of raw materials for synthesizing the initial gel are as follows: SiO2 / Al2O3=(30-150):1, Na2O / SiO2=(0.03-0.35):1, and H2O / SiO2=(3.0-50.0):1; step 2, performing microwave treatment on the initial gel: adding a beta molecular sieve seed crystal into the initial gel prepared in the step 1, wherein a ratio of silicon to aluminum in the seed crystal is as follows: SiO2 / Al2O3=(20-100):1, and the adding amount is 3%-25% by mass of SiO2, performing uniform mixing, and performing microwave heating treatment to obtain crystallized precursor gel; and step 3, performing a crystallization reaction: performing a crystallization reaction on the crystallized precursor gel obtained in the step 2 by microwave heating to obtain the beta molecular sieve product, wherein the reaction temperature is 140-180 DEG C, and the reaction time is 4-20 h. According to the method provided by the invention, the molecular sieve obtained by the method has a smaller particle size, a rich pore structureand a relatively-smooth channel, thereby facilitating promoting catalytic cracking and isomerization.

Owner:PETROCHINA CO LTD

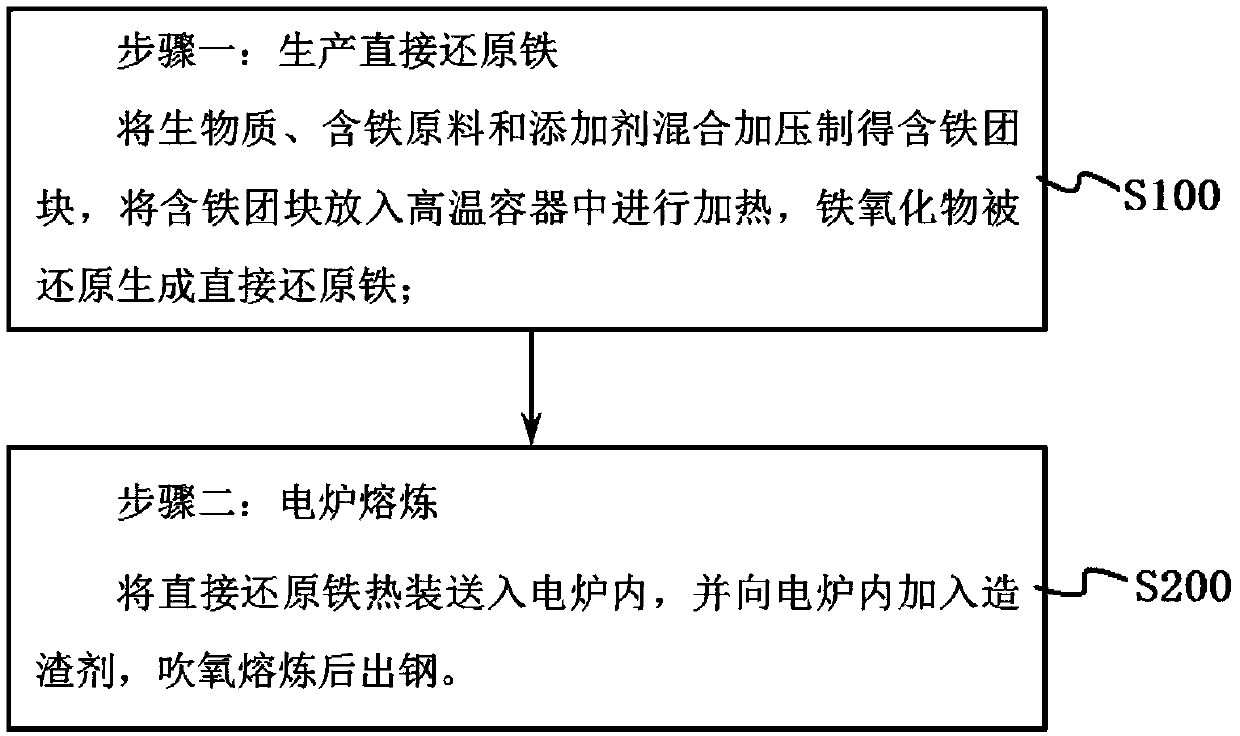

A short-process steelmaking process of biomass iron-containing agglomerates and a method for producing stainless steel

ActiveCN107119166BRealization of short-process steelmakingImprove utilization efficiencyProcess efficiency improvementElectric furnaceSteelmakingOxygen

The invention provides a biomass iron-containing block mass short-course steel-making method and a biomass iron-containing block mass stainless steel production method and belongs to the technical field of ferrous metallurgy. The steel-making method comprises the following steps: step I, producing direct reduction iron: iron-containing block masses are placed in a high-temperature container to be heated, and a ferric oxide is reduced to generate direct reduction iron; and step II, smelting in an electric furnace: direct reduction iron is hot-charged and fed into the electric surface, a slag former is added into the electric furnace, and steel is discharged after oxygen blowing smelting. The biomass iron-containing block mass stainless steel production method is characterized in that molten steel is added into an AOD furnace to be decarbonized and heated, a chromium-containing metal raw material is added into the furnace for alloying, and molten steel is conveyed into a VOD furnace for deep decarbonization to obtain stainless steel. The iron-containing block masses are reduced to generate direct reduction iron, and direct reduction iron is hot-charged and fed into the electric furnace to be smelted to obtain qualified molten steel, so that short-course steel-making of the biomass iron-containing block masses is realized, and the energy utilization efficiency is improved; and stainless steel can be further produced through smelting.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

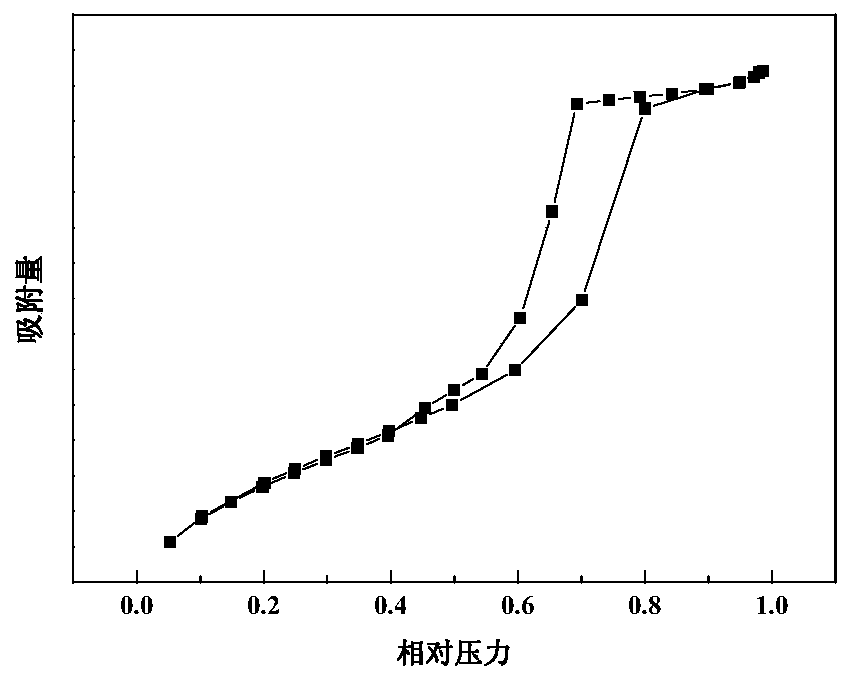

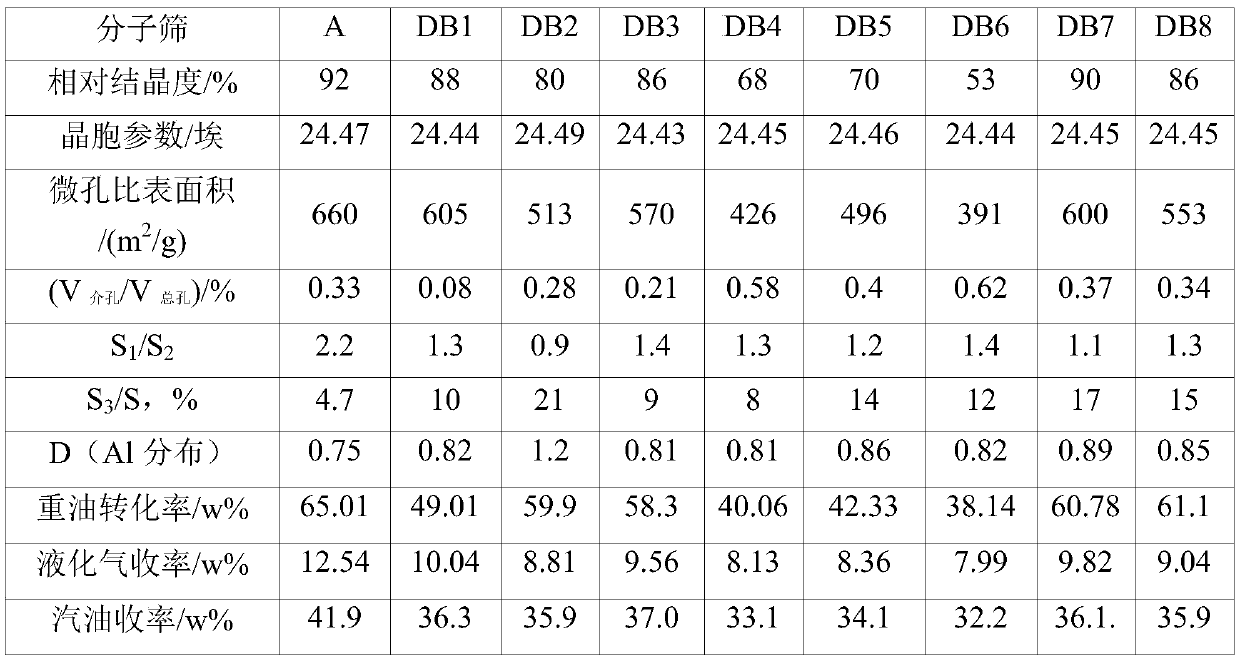

A mesoporous-rich molecular sieve and preparation method thereof

ActiveCN107973313BFacilitated catalytic crackingImprove responseCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

The present disclosure relates to a Y molecular sieve rich in mesopores and a preparation method thereof. The unit cell parameter of the molecular sieve is 24.35-24.55 Angstroms, and the relative crystallinity is ≥90%; the Al distribution parameter D of the molecular sieve satisfies: 0.3≤D ≤0.8; the micropore specific surface area of the molecular sieve is 650-800 meters 2 / g; the mesopore volume of the molecular sieve accounts for 20-65% of the total pore volume; the molecular sieve has a 27 In the Al MAS NMR spectrum, the ratio of the peak area of the resonance signal with a chemical shift of 60ppm±2ppm to the peak area of the resonance signal with a chemical shift of 55ppm±2ppm is (1.5-5):1, and the peak area of the resonance signal with a chemical shift of 0±2ppm The area accounts for no more than 5% of the total peak area. Using the disclosed Y molecular sieve as an active component to prepare a catalyst has excellent heavy oil conversion ability and higher gasoline and liquefied gas yield when used for catalytic cracking of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

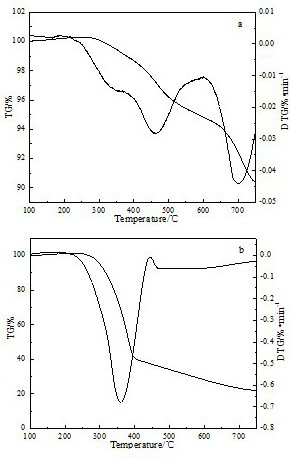

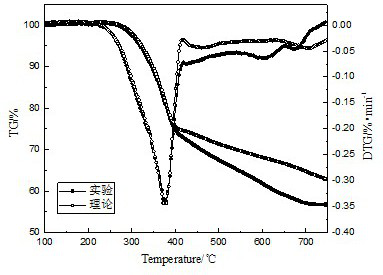

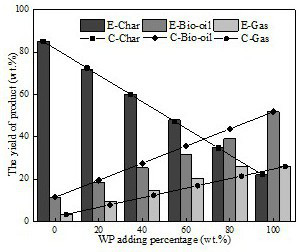

Method for preparing combustible gas through co-pyrolysis of sludge and biomass

PendingCN111995210AIncreased thermal mass loss ratePromote pyrolysisSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEnvironmental geologyManufacturing engineering

The invention relates to a method for preparing combustible gas through co-pyrolysis of sludge and biomass, and belongs to the field of environmental protection and energy. Municipal sludge is dried,and the dried municipal sludge and biomass are respectively crushed; the crushed municipal sludge is mixed with the biomass, wherein the mass ratio of the biomass in the mixture is 20-80%; the mixtureis placed in a reactor to be pyrolyzed at 700-900 DEG C, and generated gas is used as combustible gas. After wood flour is doped into the sludge, catalytic cracking of tar is promoted, the yield of co-pyrolysis product tar is reduced, and the gas yield is increased. Particularly, when the mixing ratio of the wood flour is 20% at 900 DEG C, the volume percentage of the combustible gas is obviouslyincreased and is 20.47% higher than the theoretically calculated value, and the calorific value of the gas is increased by 47.02%.

Owner:HUAZHONG NORMAL UNIV +1

A kind of preparation method of β molecular sieve

ActiveCN110143602BHigh yieldHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveReaction temperature

The invention discloses a preparation method of beta molecular sieve. Step 1, synthesizing initial gel: mix silicon source, aluminum source, alkaline metal source, water, stir evenly, and synthesize initial gel; silicon source is SiO 2 In terms of aluminum source as Al 2 o 3 In terms of alkaline metal sources as Na 2 In terms of O, the molar ratio of raw materials for synthesizing the initial gel is: SiO 2 / Al 2 o 3 =30~150:1, Na 2 O / SiO 2 =0.03~0.35:1, H 2 O / SiO 2 =3.0~50.0:1; step 2, microwave treatment of the initial gel: add β molecular sieve seed crystals to the initial gel prepared in step 1, the ratio of silicon to aluminum to SiO 2 / Al 2 o 3 =20~100:1, the amount added is calculated as SiO by mass 2 3% to 25% of the mass, mixed evenly and heated with microwaves to obtain a crystallized precursor gel; step 3, crystallization reaction: crystallize the crystallized precursor gel obtained in step 2 with microwave heating Reaction, the reaction temperature is 140°C-180°C, the reaction time is 4-20h, and the β molecular sieve product is obtained. The molecular sieve obtained by the method of the invention has small particle size, rich pore structure, and relatively unobstructed channels, which is beneficial to promoting catalytic cracking and isomerization.

Owner:PETROCHINA CO LTD

A Suspension Bed Hydrogenation Process for Treating Heavy Oil

ActiveCN108264934BImprove conversion rateHigh yieldHydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention provides a suspended bed hydrogenation process for treating heavy oil. The process forms a mixture by mixing part of the feed oil with a suspended bed hydrocracking catalyst, and then sequentially performs primary shearing and secondary shearing on the mixture. This can achieve highly dispersed mixing of the catalyst and the feed oil to obtain a catalyst slurry, ensuring that the catalyst can better exert its hydrogenation catalytic activity, which is beneficial to improving the conversion rate of the feed oil and the yield of light oil; and then the catalyst slurry is It is mixed with the remaining feed oil and hydrogen and sent into the suspended bed hydrogenation reactor. The suspended bed hydrogenation conditions are controlled to obtain the suspended bed hydrogenation product, and a reasonable separation process is adopted according to its composition and properties, which not only greatly reduces the fixed bed The hydrogenation load, more importantly, maximizes the yield and quality of light oil, and can also effectively extend the service life of the fixed bed catalyst, which is beneficial to energy saving and emission reduction of the entire process.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

Synthetic process of ZSM-5 and MAPO-5 two-structure molecular sieve

InactiveCN100390058CImprove distributionImproved acid distributionMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesSynthesis methodsCatalytic decomposition

This invention relates to a method to synthesize ZSM-5 and MAPO-5 binary structure molecular sieves, which mainly adopts M heteroatom source, aluminium source, phosgene source, template reagent, ZSM-5 and deionized water as raw materials, and the mole ratio of MxOy, Al2O3, P2O5, R and H2O is (0.5~1.5) : (5~15) : (4~20) : (4~20) : (100~2000), where x and y represent the number of M and O atoms in the heteroatom source; R represents template reagent; ZSM-5 is original ZSM-5 powder and is taken at any ratio to the mixture. The raw materials are mixed at 10~95 deg. C, stirred to homogeneity and crystallized at 20~200 deg. C for 5~200 hours after aging. The product is recycled, filtered, washed, exchanged, dried and baked to obtain catalyst product. In the molecular sieves synthesized in this invention, MAPO-5 can be more equably distributed on the surface of ZSM-5, and this method has potential value in catalytic cracking, catalytic decomposition and hydrogenation cracking of heavy oil and some other fine chemical fields.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

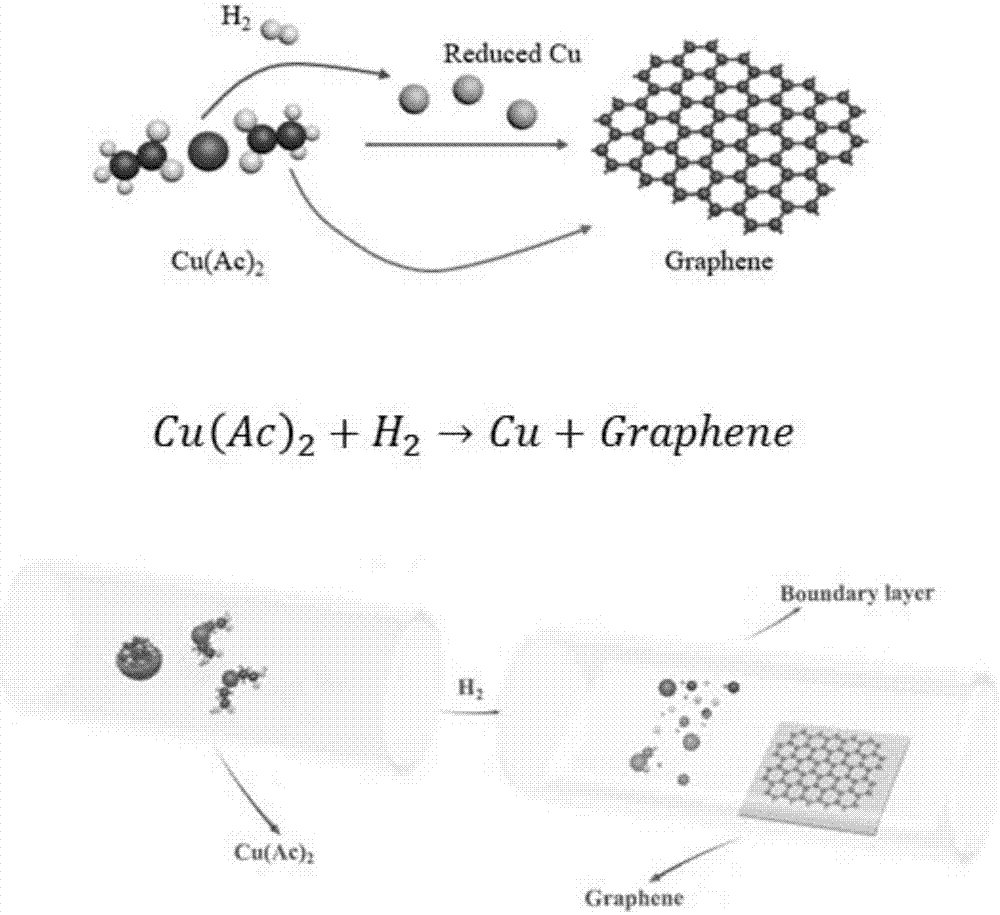

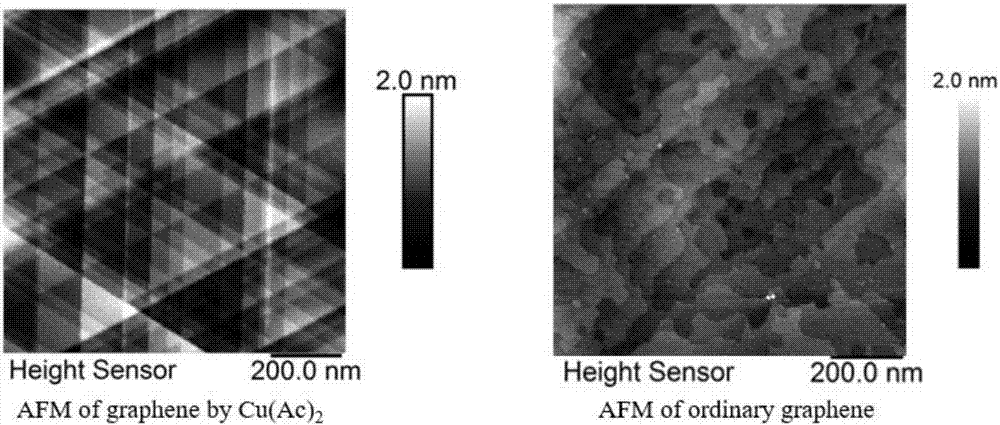

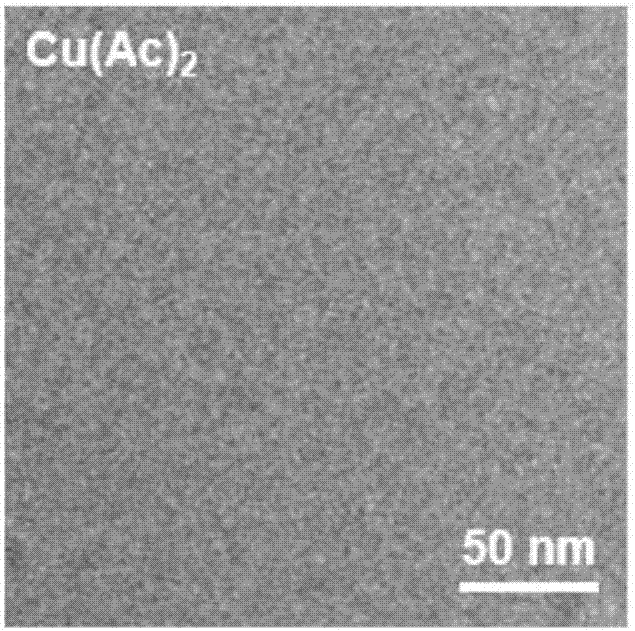

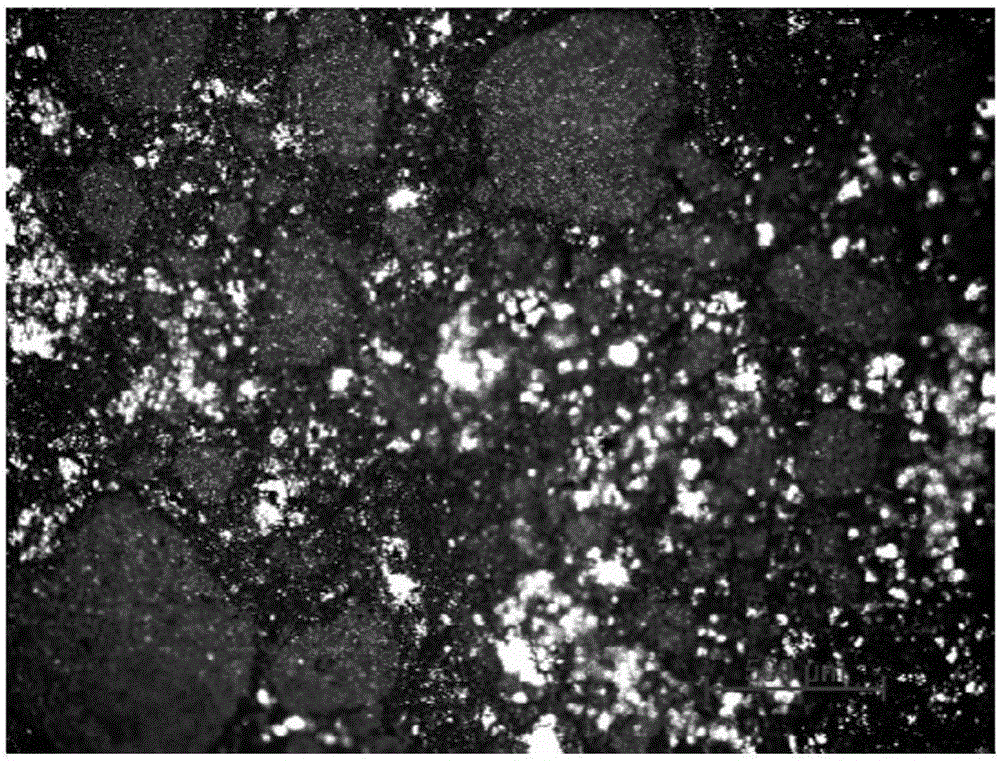

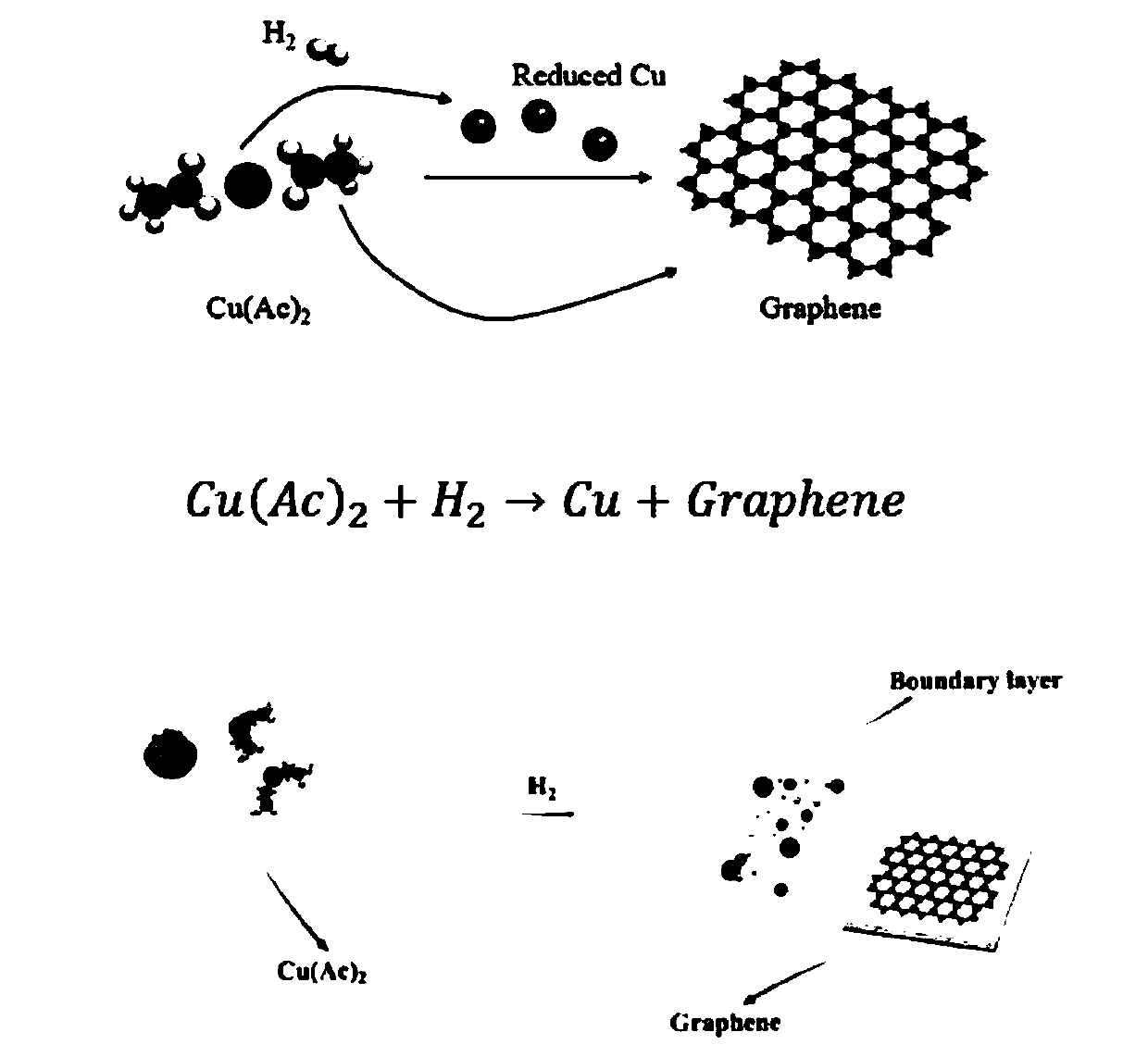

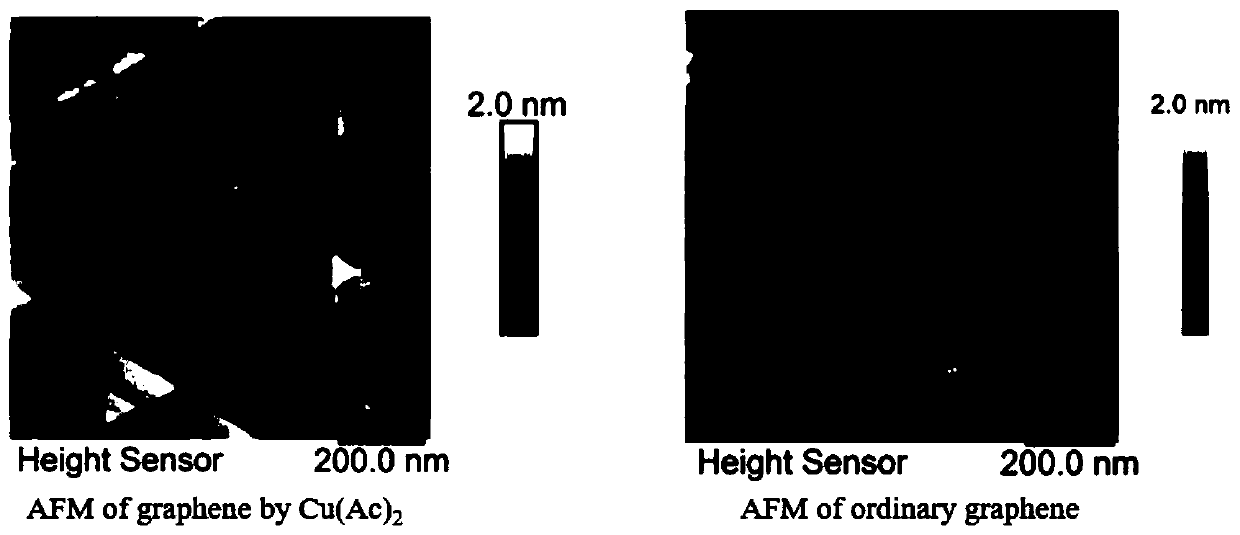

Method for preparing ultra-clean graphene by utilizing copper acetate

The invention discloses a method for preparing ultra-clean graphene by utilizing copper acetate. The method comprises the following steps: sequentially putting the copper acetate and copper substrates at intervals in directions of an air path from upstream to downstream; introducing hydrogen for chemical gas phase deposition; obtaining the ultra-clean graphene after deposition is completed, wherein temperature of a temperature zone in which the copper acetate is located is volatilization temperature of the copper acetate. The preparation method is simple, raw materials are easy to get, the cleanliness of the graphene is superior to a result obtained by growth of methane, so that a single layer of graphene film with ultra-cleanliness and high quality can be obtained; moreover, the graphene film has great application prospects in the fields of optics, electricity and the like.

Owner:PEKING UNIV

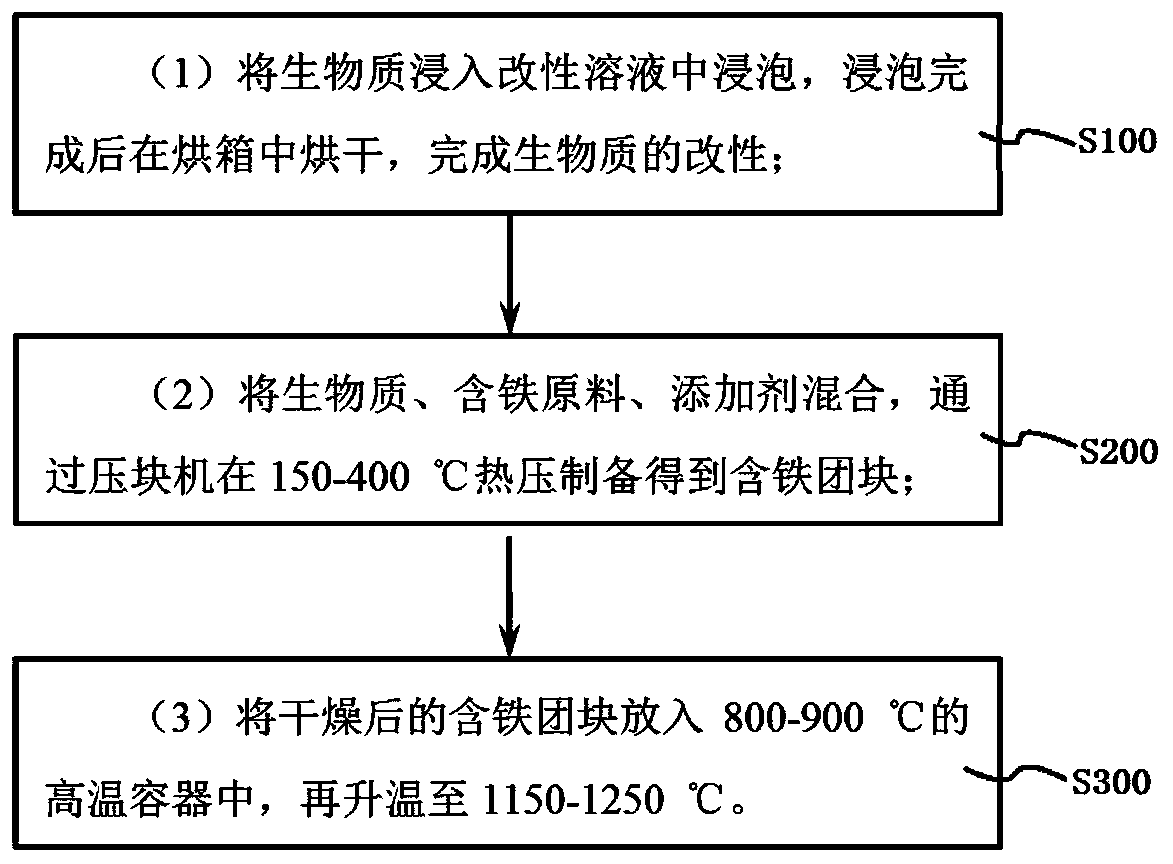

Gas iron co-production method for preparing high-strength iron-contained block mass with biomass as adhesive carrier

The invention discloses a gas iron co-production method for preparing a high-strength iron-contained block mass with biomass as an adhesive carrier, and belongs to the technical field of steel iron smelting. According to the preparing method of the iron-contained block mass, iron-contained raw materials, biomass and an addition agent are mixed, and are subject to hot pressing through a briquetting machine to obtain the iron-contained block mass, and the biomass is subject to modification treatment through a modification solution. According to the specific method, the biomass is immersed into the modified solution to be modified, the modified biomass, the iron-contained raw material and the addition agent are mixed and pressurized, the iron-contained block mass is prepared, the mass is heated in a high-temperature container, the biomass is gasified into combustible gas, and an iron oxide is reduced to generate direct reduction iron. The biomass serves as a reduction agent of the iron oxide and a C source and an H source of combustible gas, the iron oxide serves as an iron source and an oxygen source, a bonding agent does not need to be added, the strength of the iron-contained block mass is improved, the biomass gasifying yield is improved, and meanwhile, the metallization rati of iron direct reduction is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Hierarchical pore coke as well as preparation method and application thereof

ActiveCN113717741AFacilitated catalytic crackingFacilitated DiffusionBiofuelsGas purification by catalytic conversionDust controlProcess engineering

The invention relates to hierarchical pore coke, which is prepared by the following steps: pyrolyzing low-grade substances to prepare low-grade substance semi-coke with part of volatile matters, using the low-grade substance semi-coke loading or not loading metal as a raw material, adding caking coal with high caking index in a coal blending coking mode, and performing carbonizing at high temperature to prepare the hierarchical pore coke. The hierarchical pore coke has a developed pore structure, rich active sites and relatively high abrasive resistance, can be used as a filtering medium to be applied to particle bed filtration and dust removal of high-temperature dust-containing and oil-containing coal pyrolysis raw gas, synchronously catalyzes and pyrolyzes the coal pyrolysis raw gas in the dust removal process, and regulates and controls the distribution of pyrolysis products. The pyrolysis tar is lightened; and the purposes of improving the tar quality and removing dust and purifying the raw gas are achieved, so that the flowability of the raw gas is improved, and the problem of oil dust blockage in a low-order pulverized coal pyrolysis process is solved.

Owner:TAIYUAN UNIV OF TECH +1

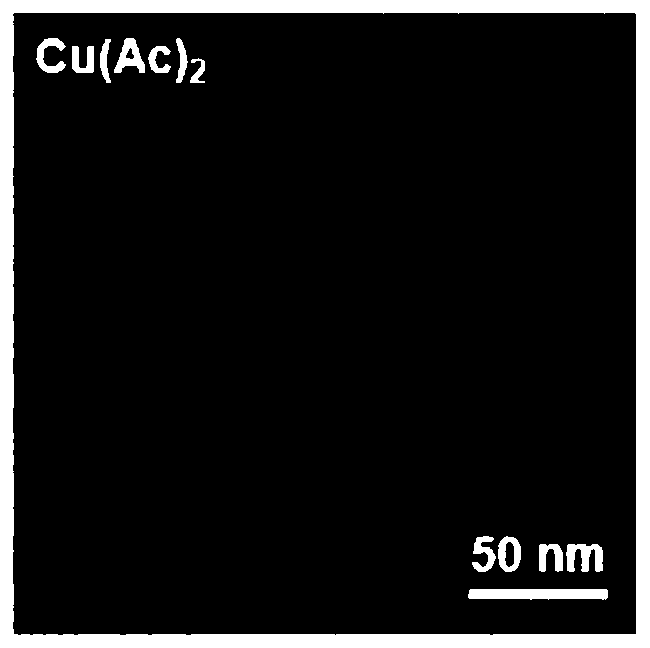

A kind of method utilizing copper acetate to prepare ultra-clean graphene

ActiveCN107500276BFacilitated catalytic crackingReduce contentGrapheneGrapheneChemical vapor deposition

The invention discloses a method for preparing ultra-clean graphene by utilizing copper acetate. The method comprises the following steps: sequentially putting the copper acetate and copper substrates at intervals in directions of an air path from upstream to downstream; introducing hydrogen for chemical gas phase deposition; obtaining the ultra-clean graphene after deposition is completed, wherein temperature of a temperature zone in which the copper acetate is located is volatilization temperature of the copper acetate. The preparation method is simple, raw materials are easy to get, the cleanliness of the graphene is superior to a result obtained by growth of methane, so that a single layer of graphene film with ultra-cleanliness and high quality can be obtained; moreover, the graphene film has great application prospects in the fields of optics, electricity and the like.

Owner:PEKING UNIV

Preparation method and application of coal catalyst

InactiveCN109107592AIncrease dispersionImprove tar yieldPhysical/chemical process catalystsLiquid hydrocarbon mixture productionTarArsenate

The invention discloses a preparation method of a coal catalyst. The method comprises the following steps: mixing aluminum orthoarsenate and an ammonium phosphate solution, and calcining a mixture toobtain phosphorus-modified aluminum arsenate, mixing the phosphorus-modified aluminum orthoarsenate and an erbium acid ammonium solution to obtain a catalyst precursor, and then calcining the catalystprecursor to obtain the catalyst. The invention also discloses a method for catalyzing the hydropyrolysis of low metamorphic coal by using the catalyst, in the present invention, the aluminum orthoarsenate is firstly modified to obtain an acid-enhanced carrier, the active component erbium is then supported on the carrier, and the obtained catalyst can promote a catalytic cracking process of the coal macromolecule, the dispersion of the active component of the catalyst on the carrier is also improved, which promotes the catalytic hydrogenation and pyrolysis process of coal, and improves the tar yield of catalytic hydrogenation pyrolysis of low metamorphic coal.

Owner:镇江瑞德新材料科技研发有限公司

A kind of biomass gasification and direct reduction iron co-production method

ActiveCN106833745BReduce tar contentImprove gasification yieldGasification processes detailsBulk chemical productionCogenerationOxygen

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of biomass iron-containing agglomerate for producing combustible gas and dri and its preparation method

ActiveCN108570525BIncrease metallization rateReduce tar contentFluidised-bed furnacesLateriteDolomite

The invention relates to a biomass iron-containing agglomerate for producing combustible gas and DRI, and a preparation method thereof, belonging to the technical field of iron making. The iron-containing agglomerate of the invention comprises, by mass, 50-60 parts of biomass, 100-200 parts of an iron-containing raw material, 5-10 parts of additives and 3-5 parts of a binder, wherein the additivescomprise sodium carbonate, laterite nickel ore, dolomite and plant ash. The iron-containing agglomerate of the invention reduces the thermal stability of the biomass and its decomposition products; the biomass acts as a reducing agent for iron oxide and a C source and an H source for combustible gas; the iron oxide acts as an iron source for steel preparation and an oxygen source for production of CO through reactions of carbon; so the iron-containing agglomerate promotes the catalytic cracking of tar and the biomass and its decomposition products, improves the gasification yield biomass andincreases the metallization rate of DRI.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

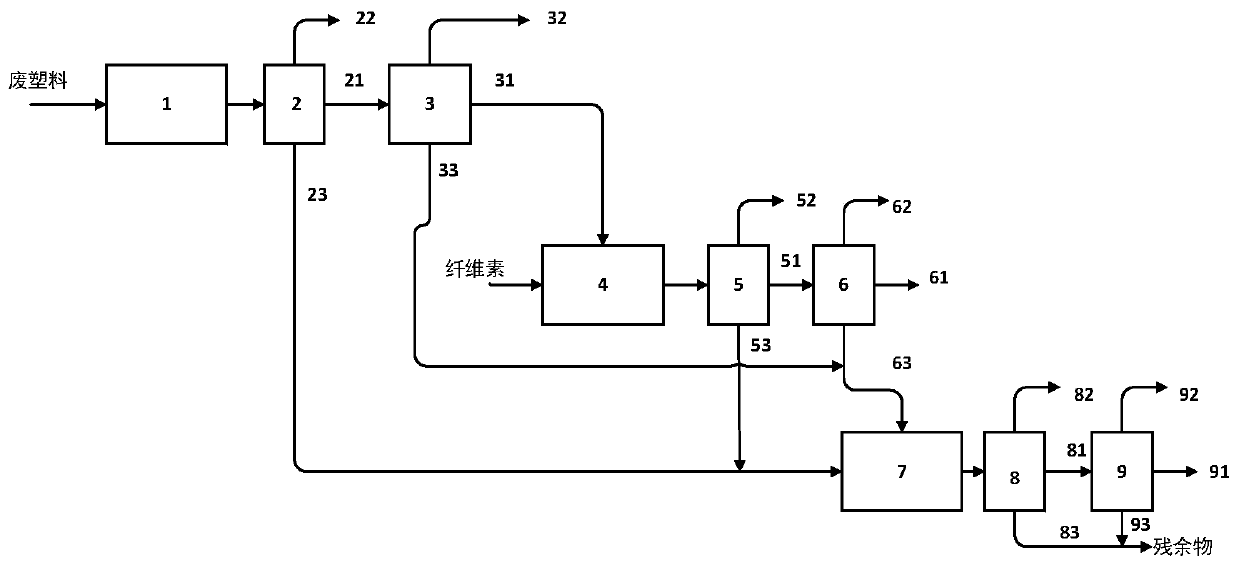

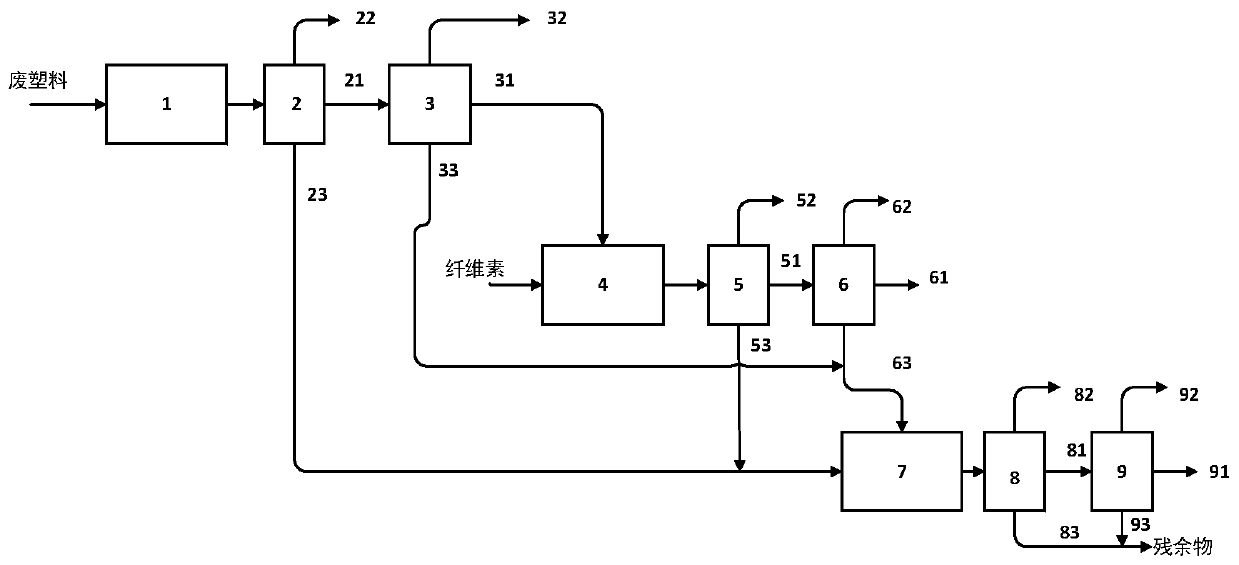

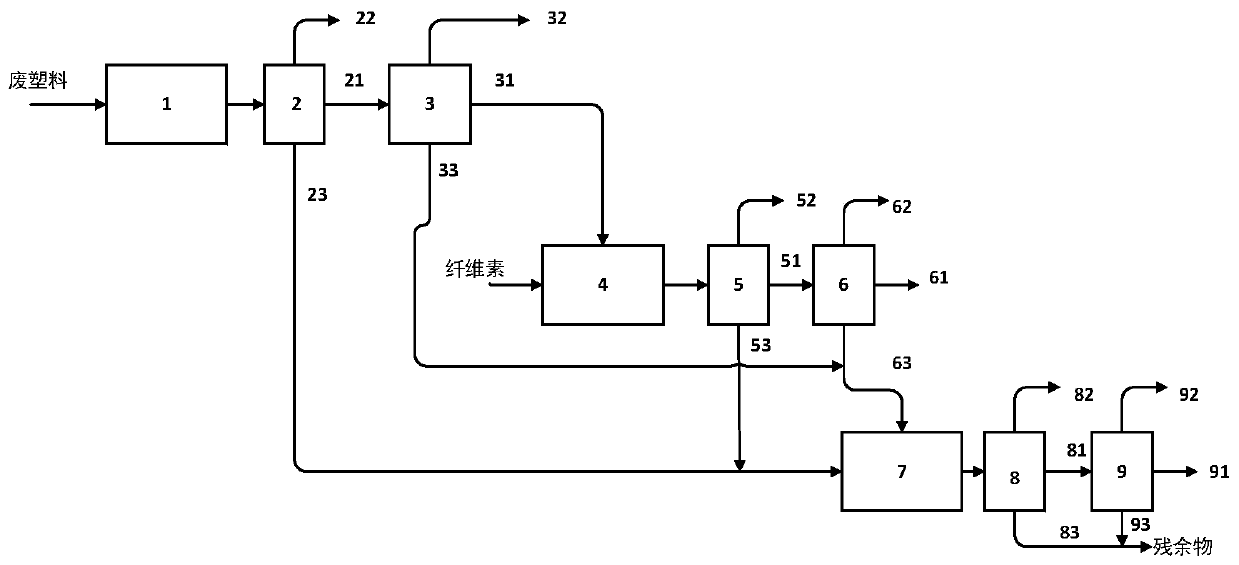

A kind of catalytic cracking catalyst and its preparation method and application

ActiveCN108355711BEasy to separateFacilitated catalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsPlastic recyclingCelluloseActive component

The invention discloses a catalytic cracking catalyst as well as a preparation method and an application thereof. The catalyst takes kaolin or montmorillonoid as a carrier and takes molybdenum naphthenate and / or iron naphthenate as an active component. The preparation method comprises steps as follows: kaolin or montmorillonoid raw powder is added to a reactor after being calcined at the high temperature, a diluted acid impregnation liquid of molybdenum naphthenate and / or iron naphthenate is added for impregnation, a reacted material is dried, and the catalytic cracking catalyst is prepared. The catalytic cracking catalyst can be applied to a process for treating cellulose and waste plastic, the total conversion rate of cellulose and waste plastic is increased, a target reaction is promoted, and the liquid yield is increased.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Downer reactor light hydrocarbon catalytic converting method and device

PendingCN109609175AImprove temperature distributionReduce yieldCatalytic crackingContact timeReaction temperature

The invention provides a downer reactor light hydrocarbon catalytic converting method and device. The method specifically includes the following steps of firstly, making a preheated or non-preheated light hydrocarbon raw material and a low-temperature regenerant from a regenerant cooler enter the inlet end of a downer reactor and flow downwards along the reactor for catalytic cracking and other reactions, and making a mixture of reaction oil gas and a catalyst go downwards to the tail end of the reactor to be rapidly separated so that the catalyst and the oil gas can be rapidly separated, wherein the main operation conditions include the reaction temperature of 520-680 DEG C, the reaction pressure of 0.11-0.4 MPa, the contact time of 0.05-2 seconds and the agent-to-oil ratio of 6-50; secondly, making a separated to-be-generated agent enter a regenerator to be burned and regenerated after the to-be-generated agent is subjected to steam stripping through a to-be-generated agent stripper,wherein the regeneration temperature is controlled to be 630-730 DEG C; thirdly, making a regenerant from the regenerator enter the regenerant cooler to be cooled into 200-720 DEG C, and making the regenerant recycled in the downer reactor.

Owner:李群柱

Low-temperature gasification device for low-order fuel based on spiral pyrolyzer and fluidized bed gasifier

ActiveCN107400539BReduce contentFacilitated catalytic crackingGasification processes detailsGasification apparatus detailsFluidized bed gasifierAlkaline earth metal

Owner:哈尔滨丰瀛投资有限公司

A preparation method of a hierarchical porous carbon-based catalyst for catalytically upgrading coal tar

ActiveCN109529853BRich preparation costSimple production processCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPorous carbon

A method for preparing a hierarchically porous carbon-based catalyst for catalytically upgrading coal tar, belonging to the technical field of preparation of catalytically modifying coal tar catalysts, can solve the problem of existing microporous carbon-based catalysts due to their small pore diameters. The diffusion resistance of the tar reactant is relatively large, which is not conducive to the progress of the catalytic reaction. Firstly, the coal with low metamorphism degree is activated by water vapor under the catalysis of calcium-containing minerals to obtain semi-coke with hierarchical pore structure, and then the hierarchical porous semi-coke is used as the carrier to load active metals to prepare carbon-based carbon with hierarchical pore structure. catalyst. The catalyst has well-developed micropore and mesopore structure, which is conducive to the diffusion of heavy components in the tar in the pores of the catalyst and the contact with the active sites, and shows a good catalytic effect in catalytically modified coal tar. ,with broadly application foreground.

Owner:TAIYUAN UNIV OF TECH

Catalytic cracking catalyst and its preparation method and application

ActiveCN108273558BEasy to separateFacilitated catalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionCelluloseActive component

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

A method of using biomass as a bonding carrier to prepare high-strength iron-containing agglomerates and gas-iron cogeneration

The invention discloses a gas iron co-production method for preparing a high-strength iron-contained block mass with biomass as an adhesive carrier, and belongs to the technical field of steel iron smelting. According to the preparing method of the iron-contained block mass, iron-contained raw materials, biomass and an addition agent are mixed, and are subject to hot pressing through a briquetting machine to obtain the iron-contained block mass, and the biomass is subject to modification treatment through a modification solution. According to the specific method, the biomass is immersed into the modified solution to be modified, the modified biomass, the iron-contained raw material and the addition agent are mixed and pressurized, the iron-contained block mass is prepared, the mass is heated in a high-temperature container, the biomass is gasified into combustible gas, and an iron oxide is reduced to generate direct reduction iron. The biomass serves as a reduction agent of the iron oxide and a C source and an H source of combustible gas, the iron oxide serves as an iron source and an oxygen source, a bonding agent does not need to be added, the strength of the iron-contained block mass is improved, the biomass gasifying yield is improved, and meanwhile, the metallization rati of iron direct reduction is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com