A kind of biomass gasification and direct reduction iron co-production method

A biomass and rail co-production technology, applied in the gasification process, fixed bed gasification, bulk chemical production, etc., can solve the problems of biomass energy waste, incomplete cracking of tar, environmental pollution, etc., to promote catalytic cracking , Strengthen the effect of ion offset, reduce the effect of tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

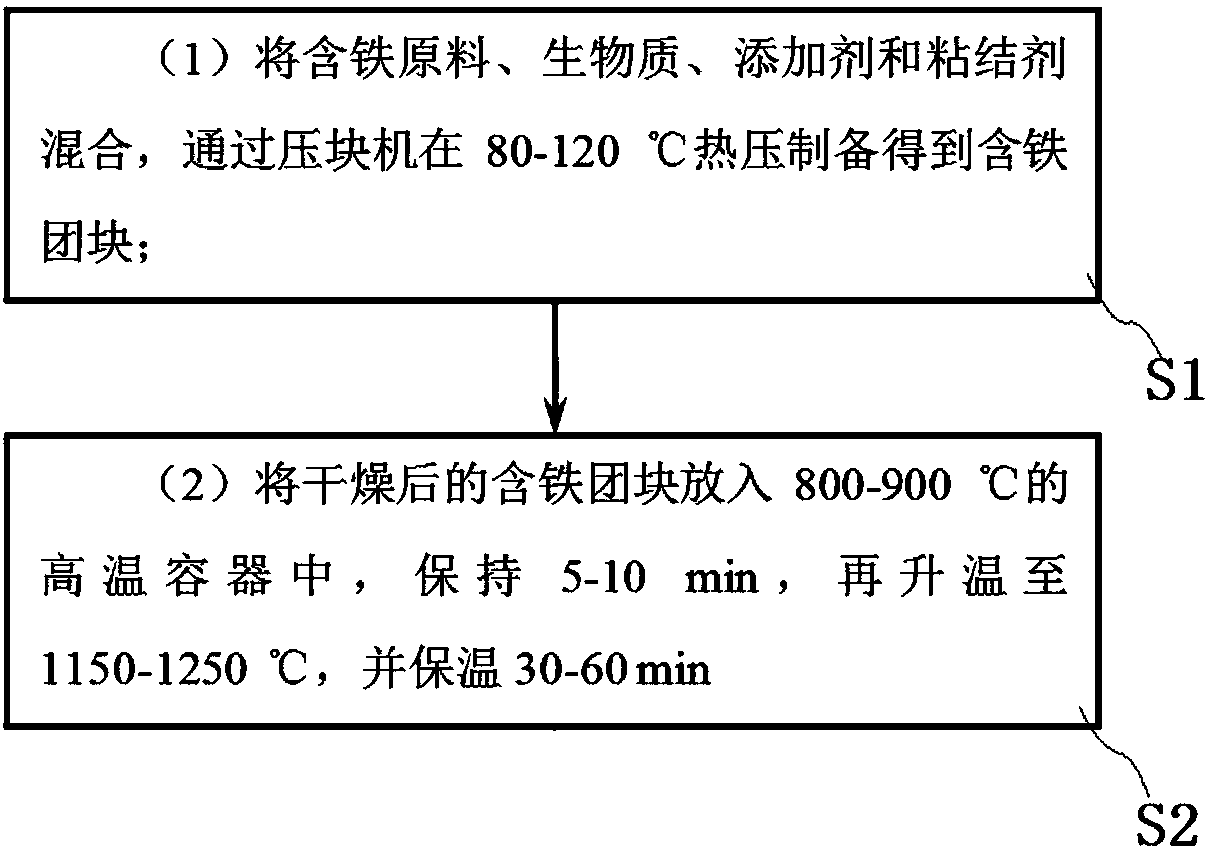

[0031] combine figure 1 , a kind of biomass gasification and direct reduced iron co-production method of the present invention, concrete steps are as follows:

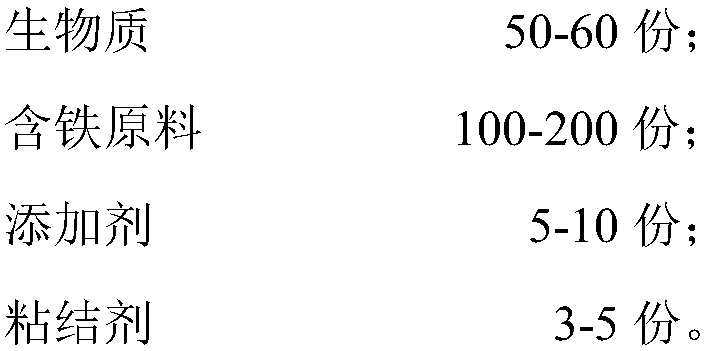

[0032] S1: Step (1) Mix iron-containing raw materials, biomass, additives and binders, and prepare iron-containing agglomerates by hot pressing at 80-120°C through a briquetting machine. The pressure of the iron-containing agglomerates is 20MPa, and then The agglomerate is kept at 105±5°C for 3 hours until it is completely dry; the iron-containing raw materials, biomass, additives and binders are composed of the following parts by mass: 50-60 parts of biomass, preferably 52g; Iron raw material 100-200g, preferably 150g; additive 5-10g, preferably 8g; binder 3-5g, preferably 4g. The iron-containing raw materials mentioned therein include blast furnace ash, sintered ore and iron concentrate, and the mass percentages of each component are: blast furnace ash: 5%, sintered ore: 10%, and iron concentrate: 85%. It is worth ...

Embodiment 2

[0060] The basic content of the present embodiment is the same as that of Example 1, except that the additive is composed of sodium carbonate, laterite nickel ore, dolomite, plant ash and chromium slag; the mass percent of each component is: sodium carbonate: 15%, Laterite nickel ore: 30%, dolomite: 30%, plant ash: 15%, chromium slag: 10%. Described chromium slag chemical composition mass percent is as follows: SiO 2 : 28%, Al 2 o 3 : 8%, CaO: 30%, MgO: 15%, Fe 2 o 3 : 10%, Cr 2 o 6 : 0.8% and Na 2 Cr 2 o 7 : 1%, the rest are impurities. The metallization rate of direct reduced iron, biomass gasification output and tar output were detected after the reaction. The experimental results are recorded in Table 1. On the one hand, the chromium slag can effectively reduce the chromium slag under the high reducing condition of biomass gasification to generate low-priced chromium oxides. The combination of chromium oxides with iron oxides and calcium-magnesium compounds in t...

Embodiment 3

[0062] The iron ore concentrate is composed of Hayangdi, Tubalang powder, Canadian fine powder, Harun powder and Jinbuba powder. The composition of the ore is shown in Table 2. The mass percentage of various mineral powders is: Hayangdi: 10 %, Tubalang powder: 20%, Canadian fine powder: 40%, Harbin powder: 15%, Jinbuba powder: 15%. The metallization rate of direct reduced iron, biomass gasification yield, and tar yield were detected after the reaction. The experimental results are recorded in Table 1.

[0063] Table 2 Mineral powder composition (wt / %)

[0064]

[0065] The metallization rate of direct reduced iron is further improved. Through repeated discussions, the inventor believes that this process may be due to the fact that the crystal water in the iron ore powder is heated and decomposed during the heat preservation process at 900°C, and produces more These gaps increase the catalytic effect of iron oxides and their complex compounds on macromolecular organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com