A preparation method of mesoporous alumina binder and its application in heavy oil catalytic cracking catalyst

A cracking catalyst, heavy oil catalysis technology, applied in the direction of catalytic cracking, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of unsatisfactory demand, low specific surface area and pore volume, etc., to achieve excellent heavy oil catalytic cracking performance, large specific gravity Effects of increased surface and pore volume, heavy oil conversion, and light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

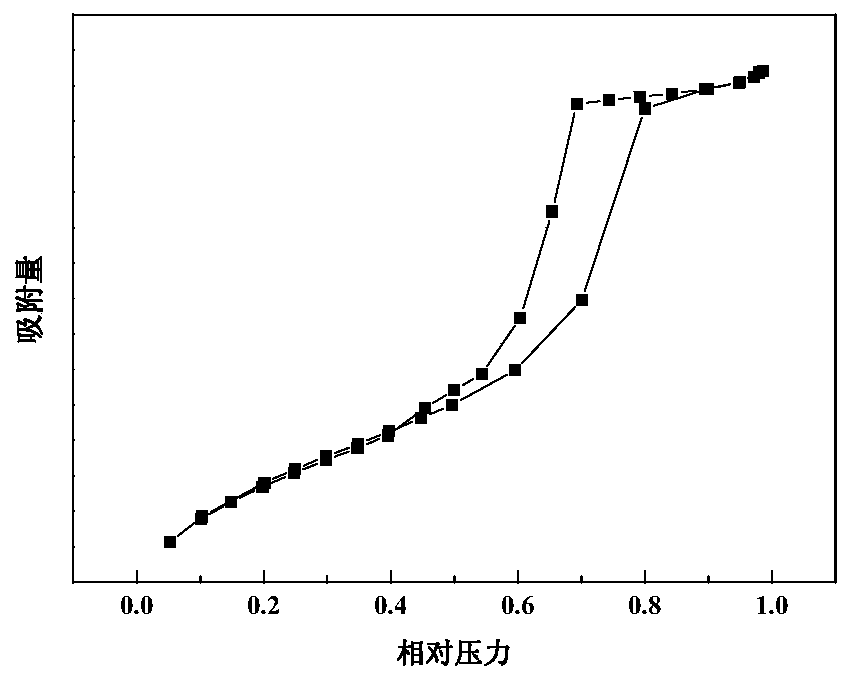

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a mesoporous alumina binder, comprising:

[0031] 1). Preparation of mesoporous alumina molecular sieve:

[0032] Mix 2.0-8.0g tri-block polymer template P123 and 40-200ml ethanol, stir well at room temperature for 1-4 hours, so that P123 is fully dissolved in ethanol; add 2.8-12.8ml concentrated nitric acid and 20-80mmol isopropyl Alcohol aluminum, keep stirring for 2-5 hours; put the obtained solution in an oven at 50-80 ° C for 12-48 hours of aging treatment; after the solvent ethanol evaporates, a bright yellow solid is obtained; the obtained bright yellow solid is placed in a muffle furnace Roast at 400-900°C for 2-6 hours to remove the template agent, and finally obtain a white solid powder mesoporous alumina molecular sieve;

[0033] 2). Acid peptization of mesoporous alumina molecular sieve:

[0034] Mix the mesoporous alumina molecular sieve prepared in step 1) with water at a solid content of 5-30% for beating; s...

Embodiment 1

[0049] Example 1: Preparation of Mesoporous Alumina Binder Glue

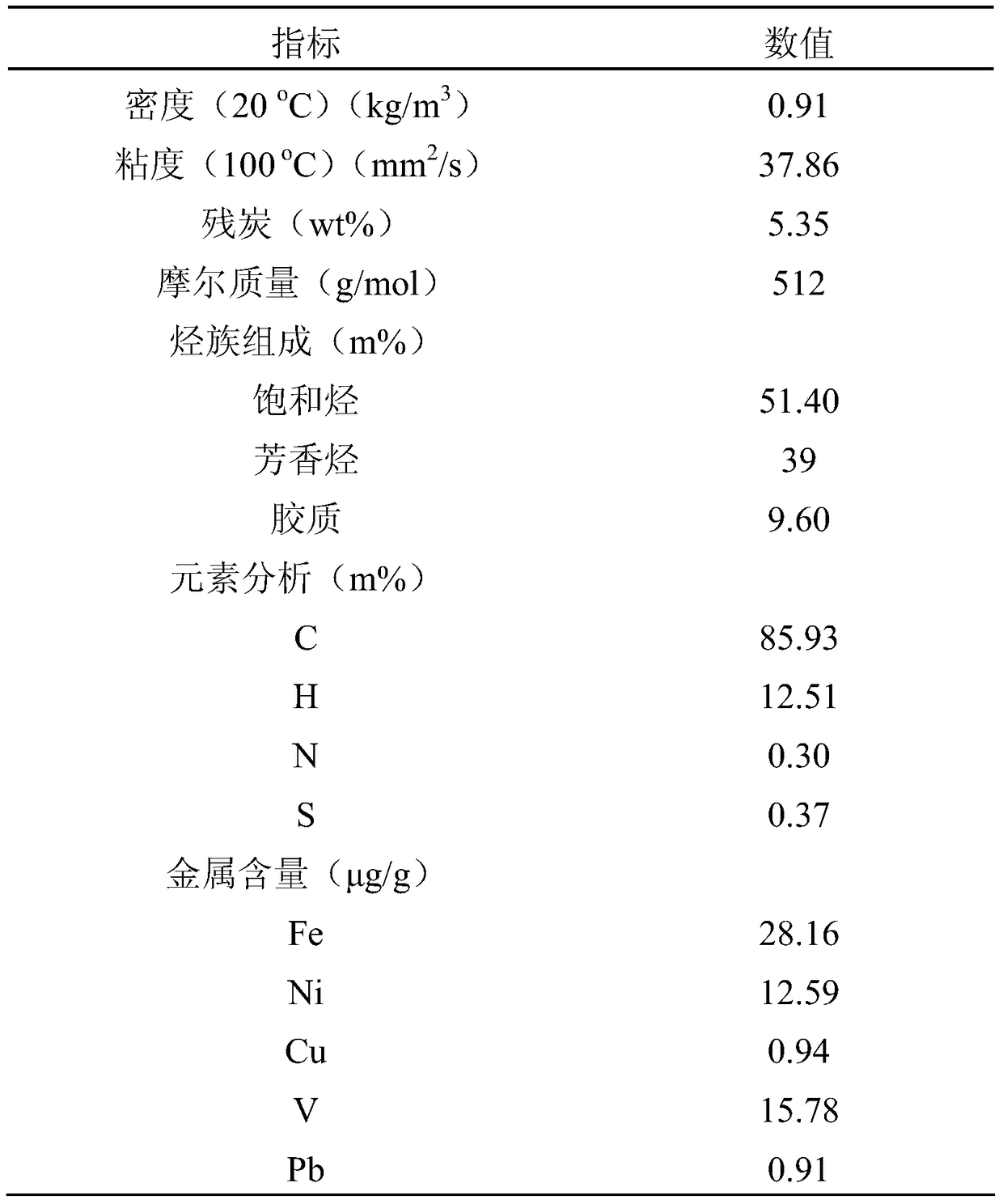

[0050] 1). Preparation of mesoporous alumina molecular sieves (refer to the method in J.Am.Chem.Soc., 2008, 130:3465-3472.): First, dissolve 4.0g of triblock template agent P123 in 80ml of ethanol, room temperature Under continuous stirring for 2h, the P123 was fully dissolved in ethanol. Then, 11.2ml of concentrated nitric acid and 4.08g of aluminum isopropoxide (20mmol) were added, and the reaction was stirred at room temperature for 5h. Then, the obtained solution was aged in an oven at 60° C. for 48 h to obtain a bright yellow solid. The bright yellow solid was calcined in a muffle furnace at 700° C. for 4 hours to remove the template agent and obtain a white solid powder mesoporous alumina molecular sieve.

[0051] 2). Acidification and peptization of mesoporous alumina molecular sieves: Mix the ordered mesoporous alumina molecular sieves prepared in step 1) and an appropriate amount of chemical water for...

Embodiment 2

[0053] Example 2: Preparation of catalytic cracking catalyst containing mesoporous alumina binder

[0054] Fully grind and mix 120g of kaolin and 60g of USY microporous molecular sieve, so that the two are fully mixed, and then add the above mixture to the glue solution of 182g of the mesoporous alumina binder prepared in Example 1 under stirring, and stir for 1h , dried at 120°C for 12h, and the dried sample was roasted in a muffle furnace at 450°C for 1h, and the obtained solid sample was fully ground and sieved to obtain a uniform solid granular heavy oil catalytic cracking catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com