Catalytic cracking catalyst and its preparation method and application

A catalytic cracking and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. , improve the conversion rate, improve the yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

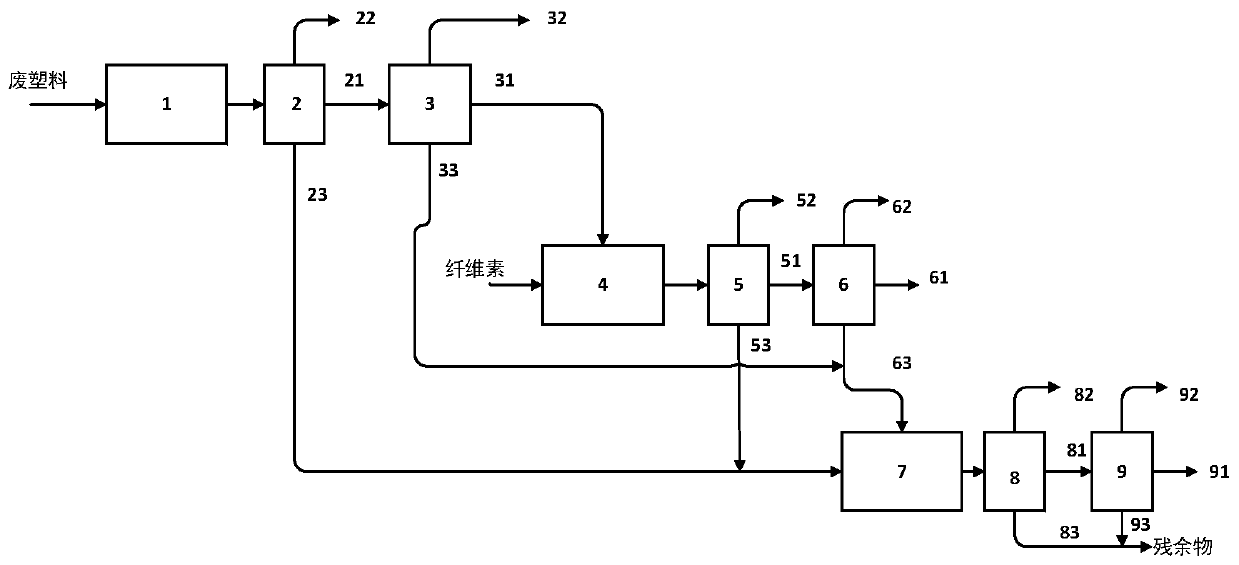

Image

Examples

preparation example Construction

[0053] The preparation method of the catalyst 2-A used in the embodiment of the present invention is as follows: 1) kaolin and montmorillonite raw powder were roasted at 430 ° C for 6 h, and the heating rate to the roasting temperature was 7 ° C / min; 2) step 1 ) the kaolin that is obtained after roasting is added in the reactor, then in the reactor, the impregnating solution of ferric naphthenate and molybdenum naphthenate dilute hydrochloric acid is added to carry out supersaturated impregnation, and the amount of impregnating solution is 1.2 times of the theoretical amount of saturated adsorbed water, The impregnating liquid is ethanol solution, wherein the mass fraction of hydrochloric acid is 12%, and stirring is carried out at a stirring rate of 125r / min for a stirring time of 1.5h; 3) the reacted material in step 2) is dried at 130°C for 4h, and then pressed Tablet molding, sieving, and taking the solid particles with a particle size of 40 mesh to 60 mesh as catalyst 2-...

Embodiment 1

[0059]Select a total of 2g of a mixture of 50wt% HDPE, 30wt% PET, and 20wt% PS as the raw material for the reaction of waste plastics, add it to the slurry bed catalytic cracking reactor A, and carry out the process under the catalytic action of the HY molecular sieve catalyst. Catalytic cracking reaction, the addition amount of HY molecular sieve is 12% of the total mass of waste plastics, the reaction conditions of catalytic cracking reaction are as follows: the reaction temperature is 440 ℃, the reaction time is 60 minutes, the stirring speed is 440 rpm, the reaction needs to Pass into hydrogen in the catalytic reactor A, hydrogen partial pressure is 2.7MPa, the product after reaction is separated, obtains liquid product I, gas I and insoluble matter I; After liquid product I is cooled to room temperature, successively pass into tetrahydrofuran, Hexanaphthene solvent carries out extraction, obtains the tetrahydrofuran solution containing liquid product II, the cyclohexane so...

Embodiment 2

[0062] Just change the reaction conditions of the catalytic cracking reaction carried out in the catalytic cracking reactor A in the slurry bed catalytic cracking reactor A among the embodiment 1: temperature of reaction is 460 ℃, and the reaction times is 120 minutes, and stirring speed is 480 rev / mins, needs in the reaction Pass hydrogen into the slurry bed catalytic cracking reactor A, the hydrogen partial pressure is 3.2MPa, the conditions for the deep catalytic cracking reaction of the slurry bed catalytic cracking reactor C are changed to: the reaction temperature is 590°C, and the reaction time is 80 minutes , the stirring rate is 500 revs / min, and the need in the reaction feeds hydrogen into the slurry bed catalytic cracking reactor C, and the hydrogen partial pressure is 7.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com