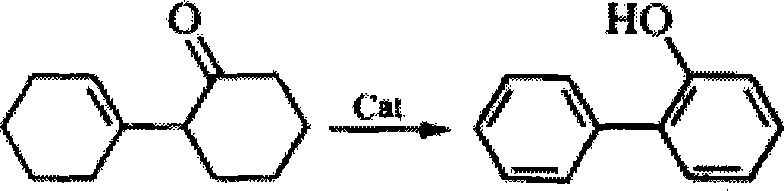

Method for preparing catalyst for use in production of o-phenylphenol

A technology of o-phenylphenol and catalyst, which is applied in the field of catalyst preparation, can solve problems such as unstable performance, rapid decline in catalyst activity, and short catalyst life, and achieve fast drying speed, improved activity and service life, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the specific surface is 180m 2 / g, the pore volume is 0.4cm 3 / g of 100g spherical γ-Al 2 o 3 After calcining in a high-temperature furnace at 500°C for 4 hours, cool to room temperature. Dissolve 2 grams of citric acid and 1.2 grams of chloroplatinic acid in 70 ml of deionized water to prepare an impregnation solution, and pour the solution into spherical γ-Al 2 o 3 In a container, stir evenly, and place in the air for 5 hours. Then the impregnated carrier was placed in a blast oven at a temperature of 120° C., dried for 5 hours and taken out. Put it into the dehydrogenation reaction tube, raise the temperature to 360°C, and the space velocity is 200ml.g -1 .h -1 Roasting under nitrogen flow for 4 hours, then switch to hydrogen, at a space velocity of 30ml.g -1 .h -1 After 5 hours of reduction under a stream of hydrogen, the catalyst was taken out. Configure 5% sodium sulfate solution, add it to the reduced catalyst, stir evenly and then soak fo...

Embodiment 2

[0029] Embodiment 2: the specific surface is 240m 2 / g, the pore volume is 0.38cm 3 / g of 100g strip γ-Al 2 o 3 The carrier was calcined in a high-temperature furnace at 500° C. for 5 hours, and then cooled to room temperature. Take 3 grams of oxalic acid to prepare 65ml of oxalic acid solution, pour the solution into a container containing the carrier, stir evenly, and place it in the air for 2 hours. Then the impregnated carrier was placed in a blast oven at a temperature of 120° C., dried for 5 hours and taken out. Then take by weighing 2 grams of chloroplatinic acid and be mixed with 65ml aqueous solution, this solution is poured into the dry container containing γ-Al 2 o 3 In the container of the carrier, stir evenly, and place it in the air for 6 hours. Then the impregnated carrier was placed in a blast oven at a temperature of 150° C., dried for 3 hours and taken out. Put it into the dehydrogenation reaction tube, raise the temperature to 355°C, and the space vel...

Embodiment 3

[0030] Embodiment 3: the specific surface is 280m 2 / g, the pore volume is 0.4cm 3 / g of 100g spherical γ-Al 2 o 3 The carrier was calcined in a high-temperature furnace at 600° C. for 6 hours, and then cooled to room temperature. Take 3 grams of trichloroacetic acid to prepare 70ml solution, pour the solution into a container containing the carrier, stir evenly, and place it in the air for 8 hours. Then the impregnated carrier was placed in a blast oven at a temperature of 110° C., dried for 5 hours and taken out. Then take by weighing 1.5 grams of chloroplatinic acid and be mixed with 70ml aqueous solution, pour this solution into the dried gamma-Al 2 o 3 In the carrier, stir evenly, place it in the air and soak for 10 hours. Then the impregnated carrier was placed in a blast oven at a temperature of 150° C., dried for 4 hours and taken out. Put it into the dehydrogenation reaction tube, raise the temperature to 390°C, and the space velocity is 100ml.g -1 .h -1 Roas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com