Hierarchical pore coke as well as preparation method and application thereof

A multi-stage hole and coke technology, which is applied in the coke field, can solve the problems of heavy components of tar, blockage of pipelines, oil dust blockage, etc., and achieve the effect of improving tar quality, eliminating tar, and increasing contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

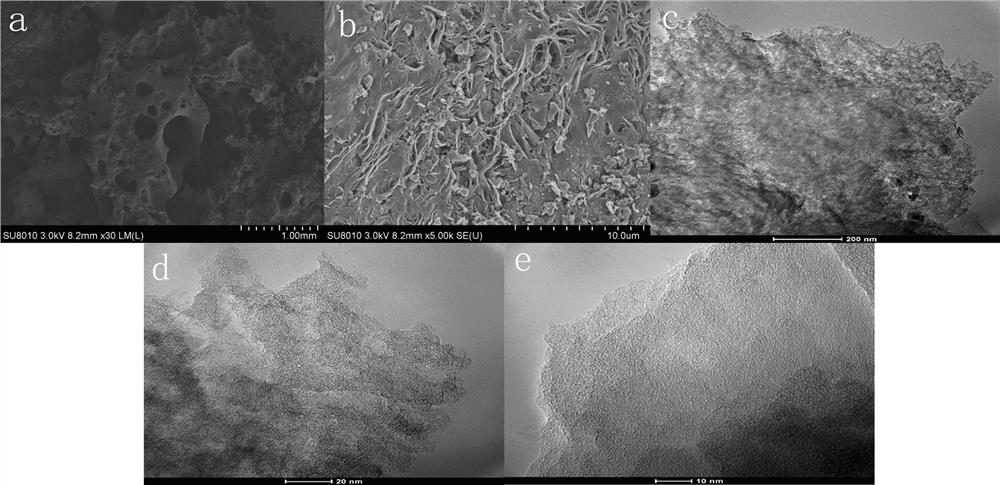

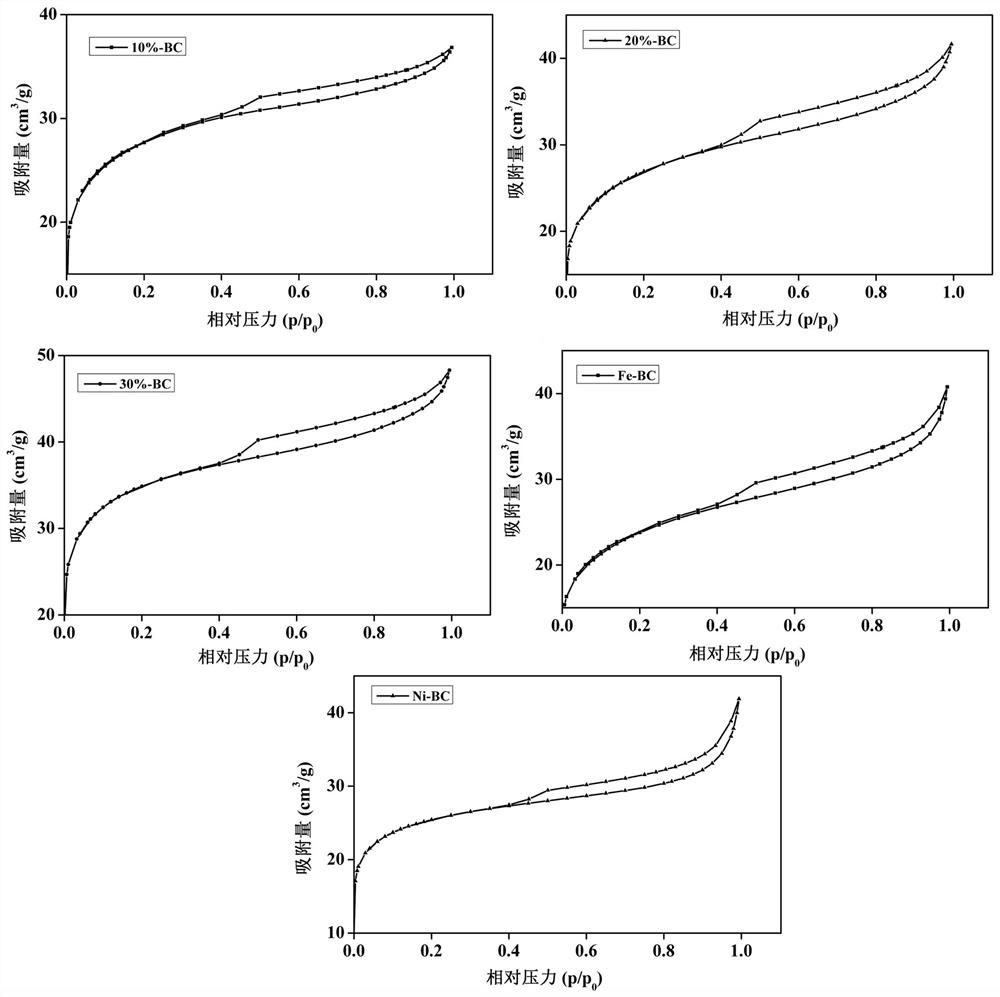

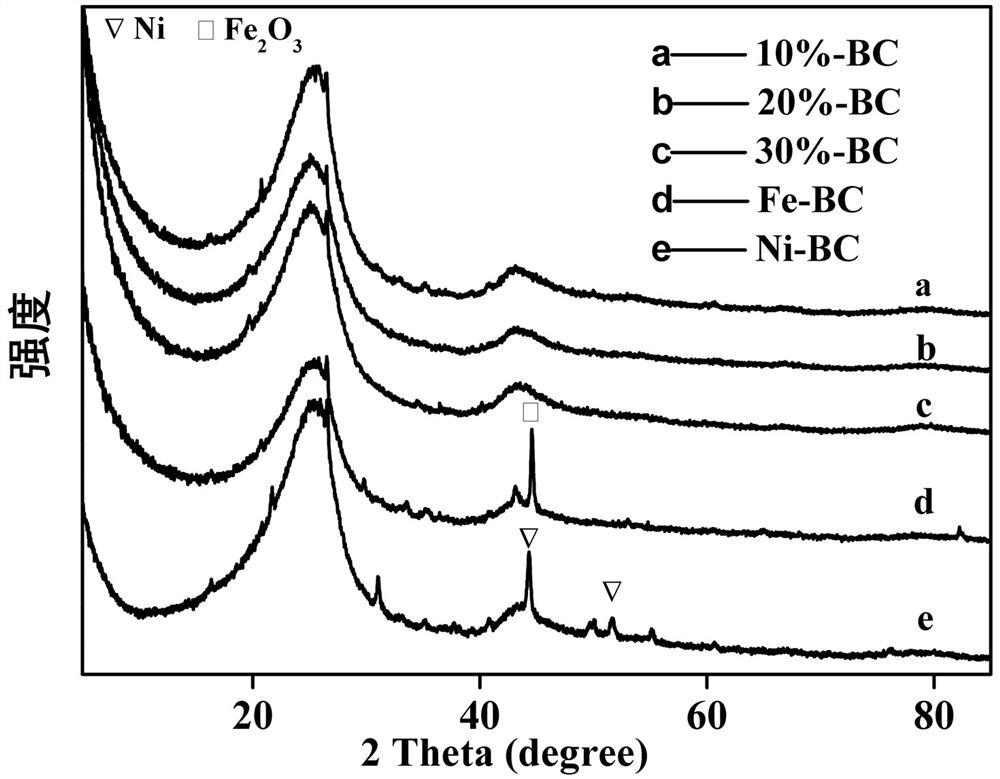

[0051] After crushing the corncob biomass produced in Jining, Shandong Province, under the condition of isolation of air, the heating rate was raised to 650°C at a constant temperature of 1h at a rate of 10°C / min. The product of mm, get corncob semi-coke.

[0052] A kind of fat coal with a caking index of 93 in the Gujiao area of Shanxi was selected. After crushing and screening, coal powder with a particle size of less than 3.00mm was selected as caking coal blending.

[0053] Mix caking coal blending and corn cob semi-coke in a kneader for 30 minutes at a mass ratio of 1:9, and then carbonize at a constant temperature of 950°C at a rate of 3°C / min for 1 hour under the condition of cutting off the air to prepare Hierarchical porous coke, recorded as 10%-BC.

Embodiment 2

[0055] After crushing the corncob biomass produced in Jining, Shandong, under the condition of isolation of air, the heating rate was raised to 600°C at a constant temperature of 1.5h at a rate of 10°C / min. 0.60mm of the product, to obtain corncob semi-coke.

[0056] A kind of fat coal with a caking index of 95 in the Gujiao area of Shanxi was selected. After crushing and screening, coal powder with a particle size of less than 3.00 mm was selected as caking coal blending.

[0057] Mix caking coal blending and corn cob semi-coke in a kneader for 40 minutes at a mass ratio of 2:8, and then carbonize at a constant temperature of 1000°C at a rate of 3°C / min for 1 hour under the condition of cutting off the air to prepare Hierarchical coke, denoted as 20% -BC.

Embodiment 3

[0059] After crushing the corncob biomass produced in Jining, Shandong Province, under the condition of isolation of air, the heating rate was raised to 650°C at a constant temperature of 1h at a rate of 15°C / min. The product of mm, get corncob semi-coke.

[0060] A kind of fat coal with a caking index of 105 in the Gujiao area of Shanxi was selected. After crushing and screening, coal powder with a particle size of less than 3.00mm was selected as caking coal blending.

[0061] Mix caking coal blending and corn cob semi-coke in a kneader for 35 minutes at a mass ratio of 3:7, and then carbonize at a constant temperature of 900°C at a rate of 2.5°C / min for 1.5 hours under the condition of cutting off the air to prepare Get hierarchical porous coke, recorded as 30%-BC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com