Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Excellent electrical insulation properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

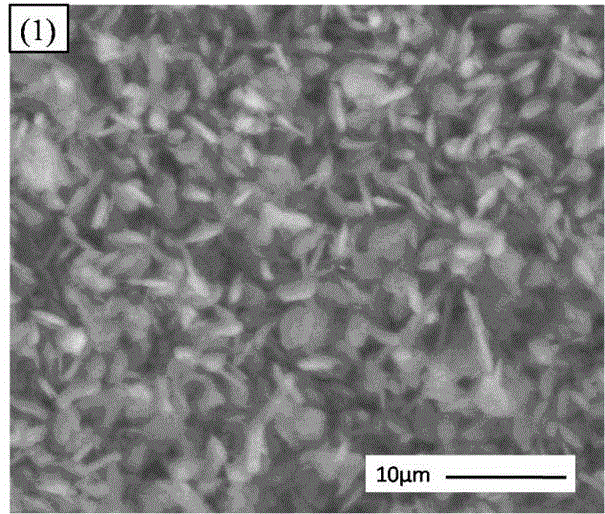

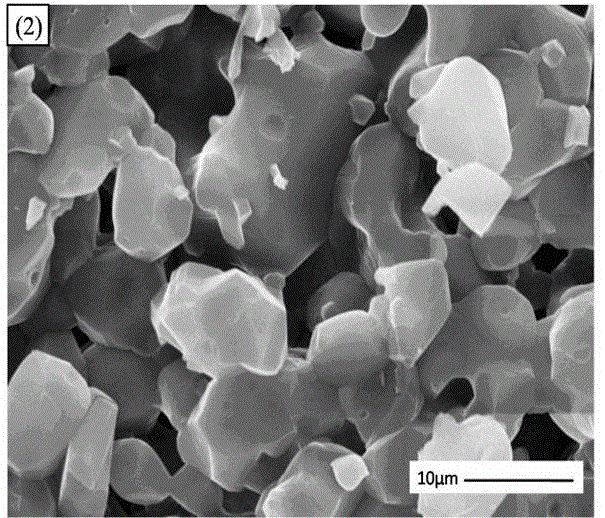

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

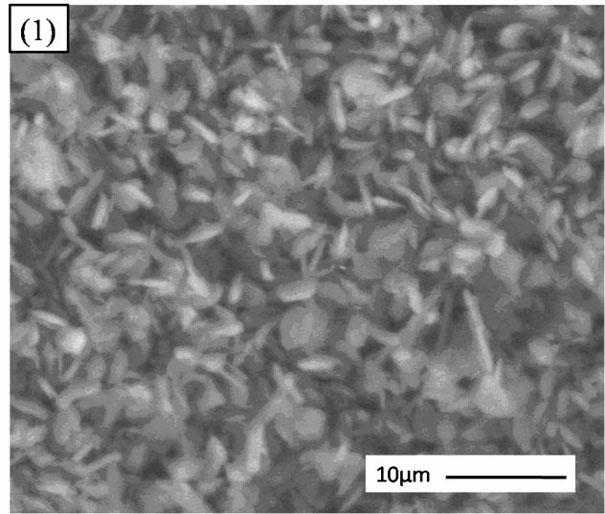

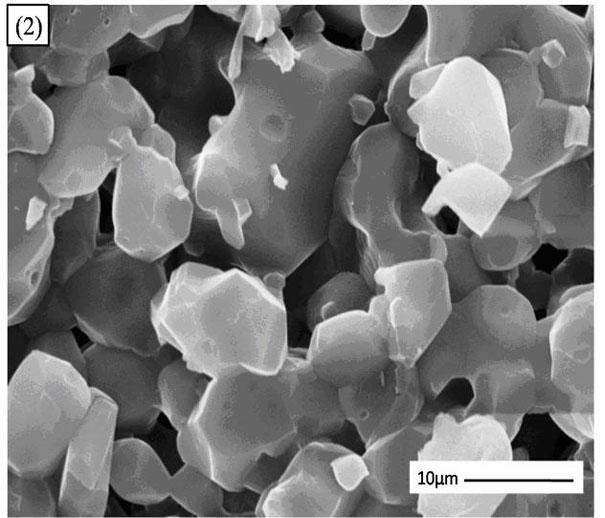

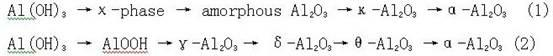

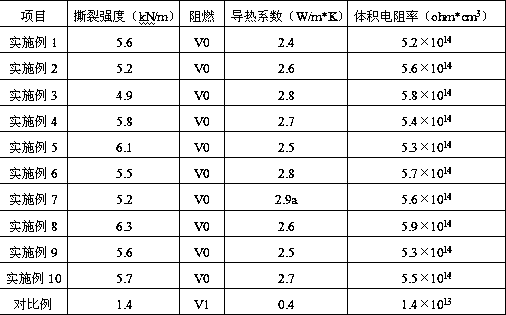

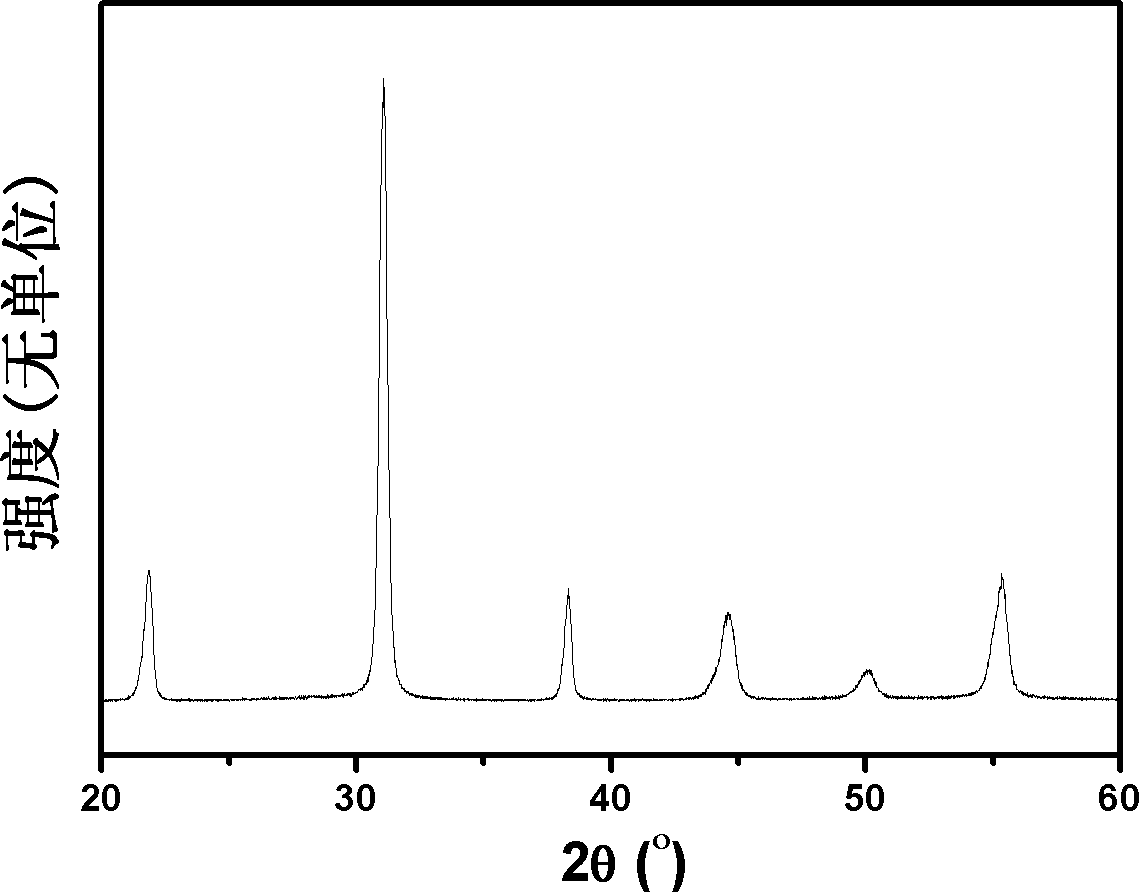

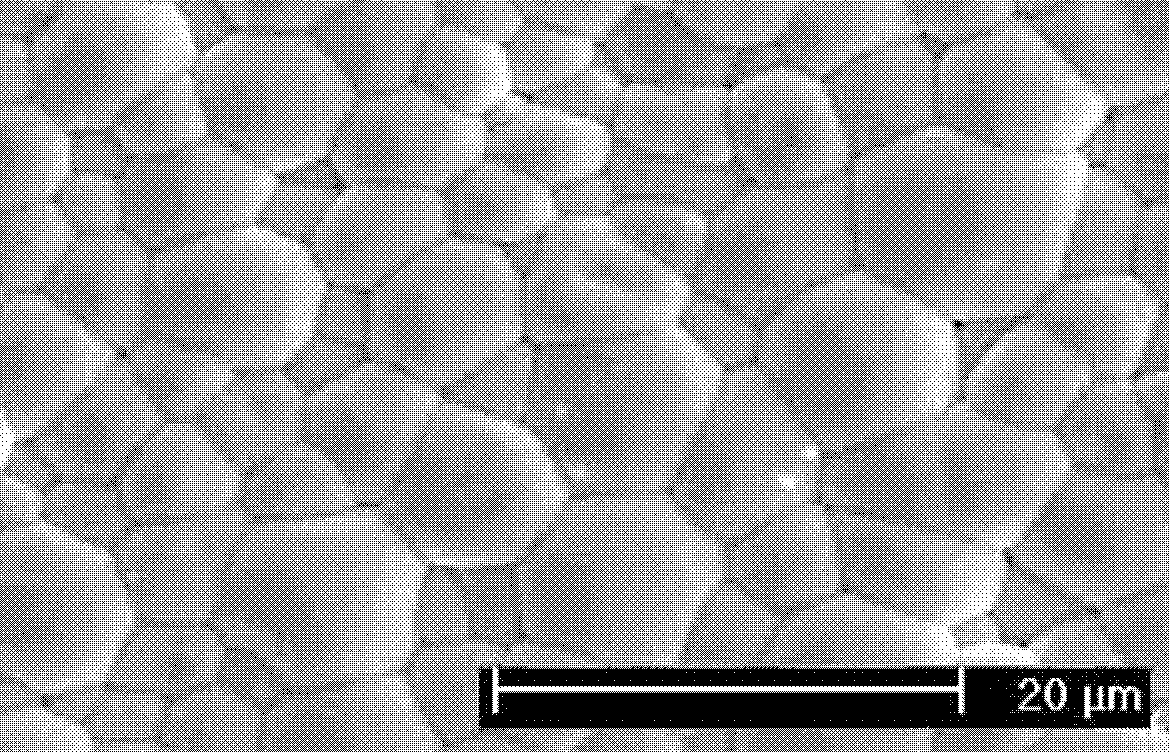

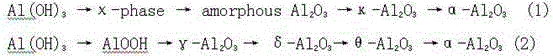

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Insulation silica gel material and silicon fabric used for new-energy vehicle battery heater

InactiveCN108178929AExcellent electrical insulation propertiesImprove flame retardant performanceFiberElectrical battery

The invention relates to an insulation silicon material and a silicon fabric used for a new-energy vehicle battery heater. The insulation silicon material comprises the following raw materials in parts by weight: 90-120 parts of silicone rubber, 15-40 parts of a composite fire retardant, 40-60 parts of a filling material, 2-6 parts of a lubricant, 1-5 parts of a promoter, and 2-12 parts of a vulcanizing agent; the silicon fiber comprises a glass fiber cloth, a sulfurated insulation silicon layer arranged at one surface of the glass fiber cloth, an un-sulfurated insulation silicon layer arranged at the other surface of the glass fiber cloth, and a PE membrane. Compared with the prior art, the silicon material has excellent electrical isolation characteristic, good flame retardation effect,and protruded heat conduction effect, the silicon fabric prepared by the insulation silicon material has good flexibility and compression performance, can tightly attach on the surface of a power battery, has the advantages of good shock resistance, good aging-resistant performance, and convenient installation and dismounting, is repeatedly usable, and has good application prospect.

Owner:无锡市辉英电力电子有限公司

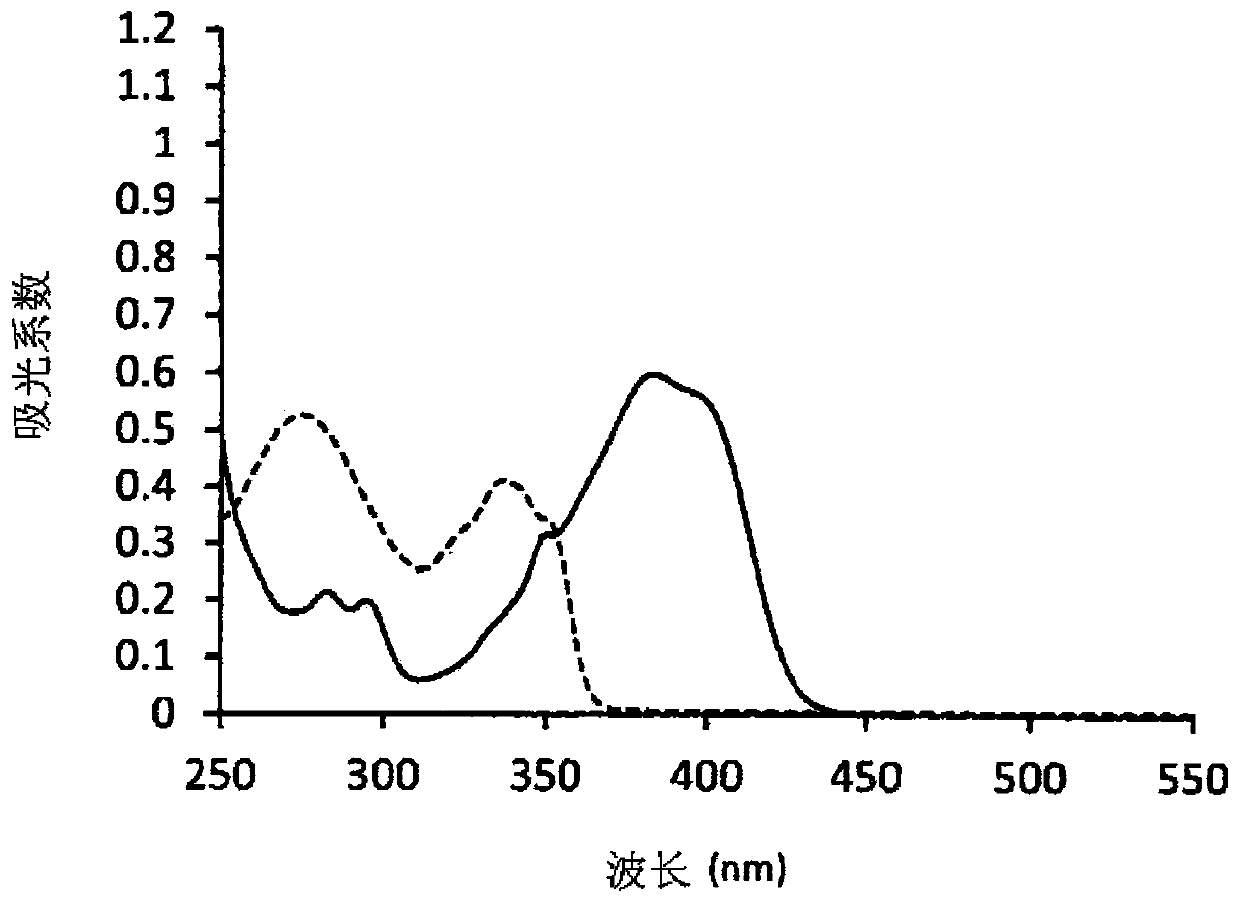

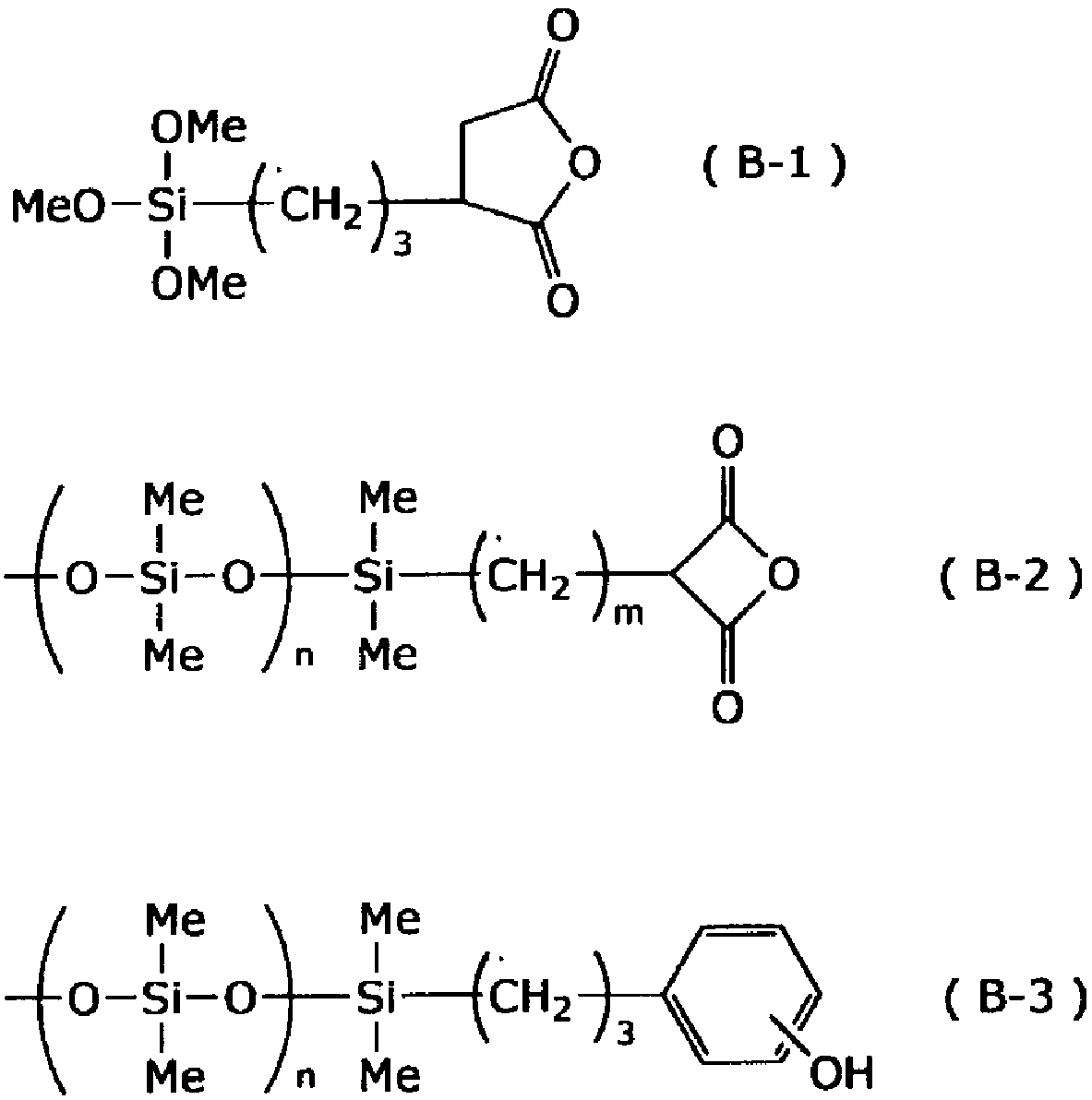

Negative photosensitive composition being capable of low temperature curing

ActiveCN104238271AGood optical clarityHigh environmental tolerancePhotomechanical apparatusLow temperature curingSolvent

The invention provides a negative photosensitive composition being capable of low temperature curing. A cured film with high transparency and high chemical resistance can be obtained. A pattern forming method employing the composition is provided. The negative photosensitive composition is characterized by comprising a polysiloxane, (methyl) acrylic polymers, a compound comprising more than two (methyl) acryloyl groups, a polymerization initiator and a solvent.

Owner:MERCK PATENT GMBH

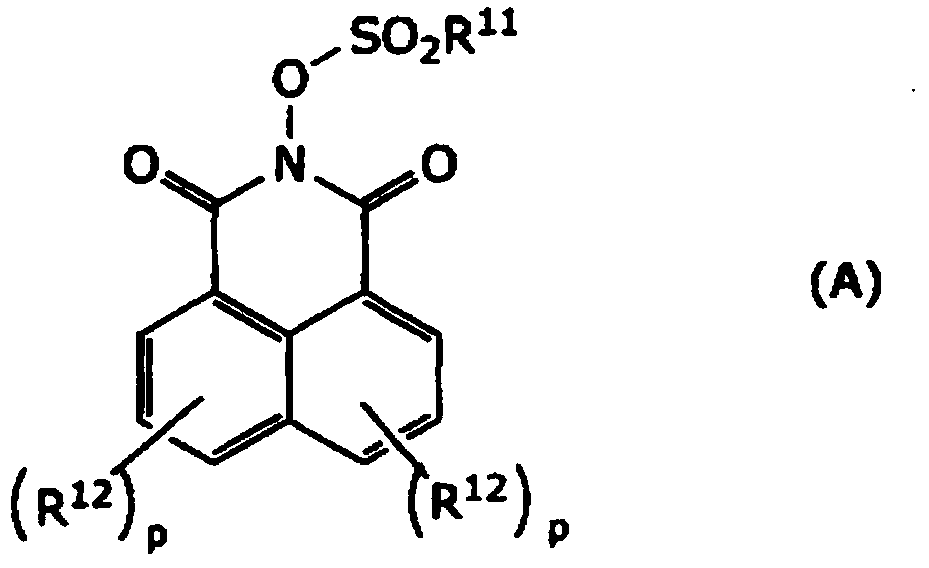

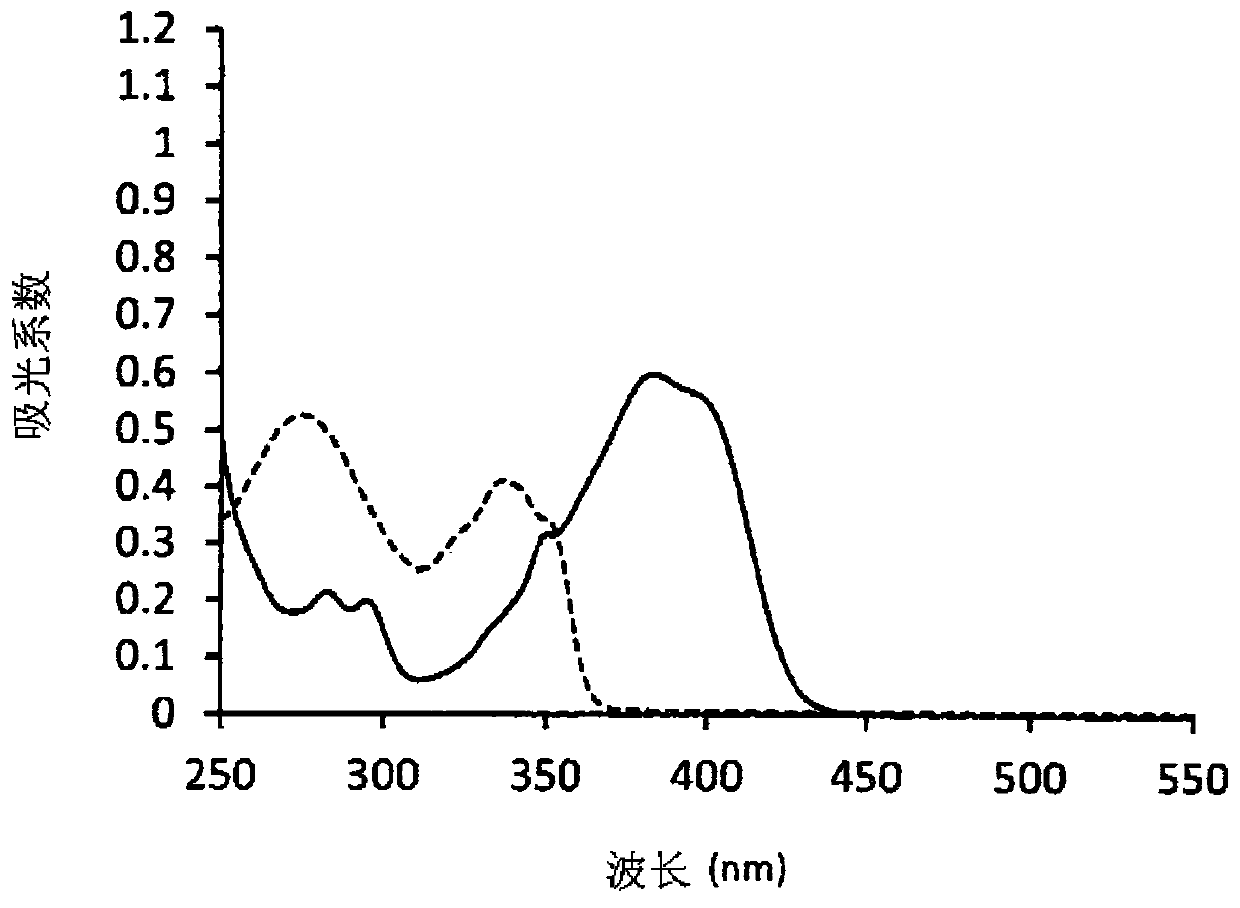

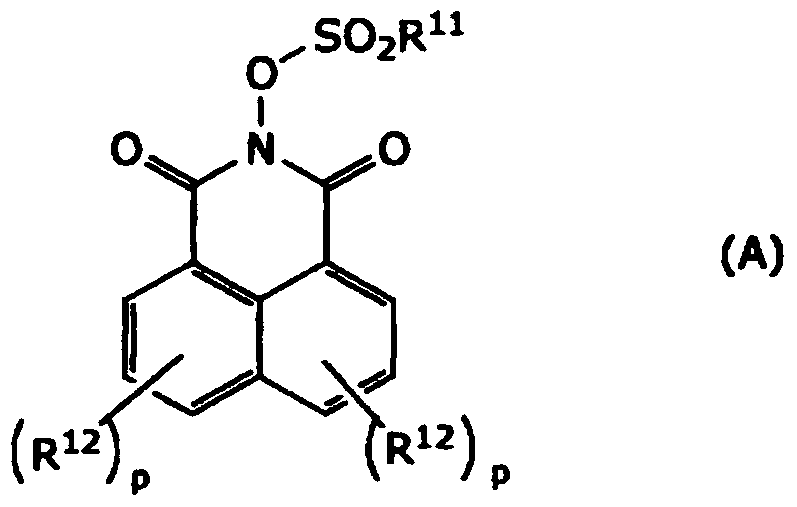

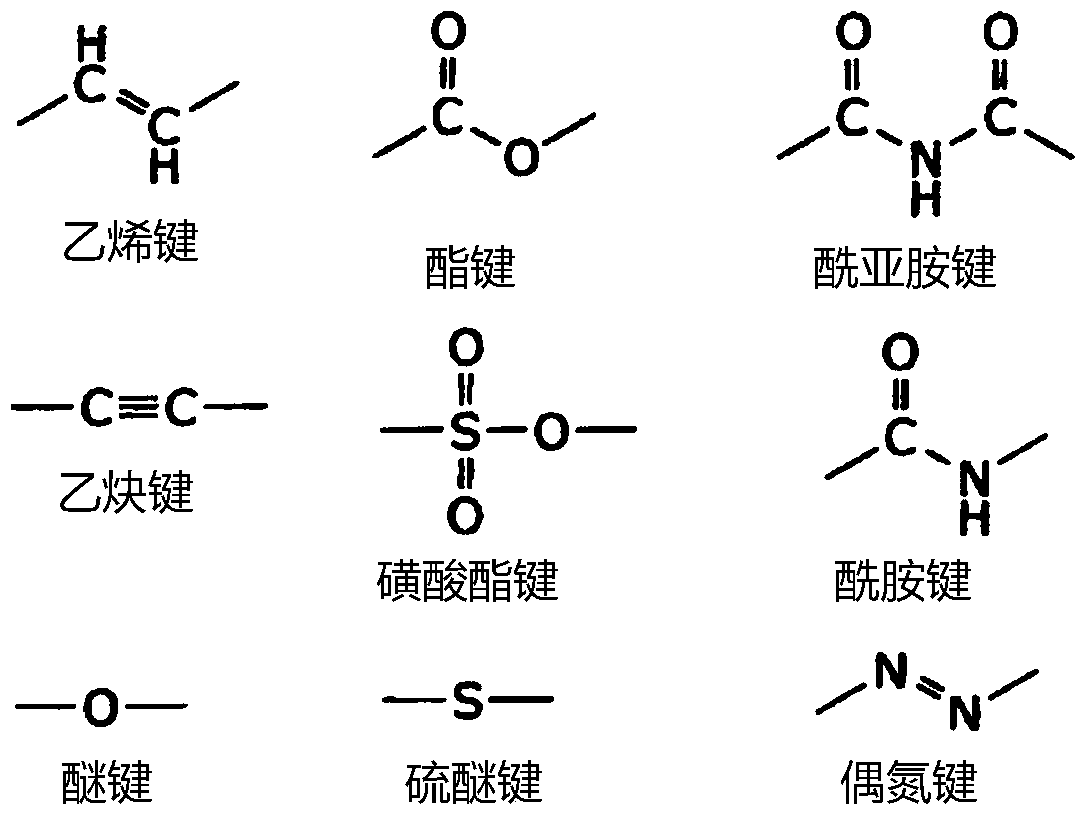

Negative type photosensitive

ActiveCN103995437AHigh sensitivityHigh resolutionPhotosensitive materials for photomechanical apparatusImideNegative type

The invention provides a negative type photosensitive siloxane composition, which is high in resolution, high in temperature resistance, and high in transparency. The negative type photosensitive siloxane composition can inhibit the heat collapse occurring in the heat consolidation without improving the molecular quantity of the high crosslinking agent or the siloxane composition. The negative type photosensitive siloxane composition comprises a (I) polysiloxane, aromatic imide compound released by light radiation and a solvent (III).

Owner:MERCK PATENT GMBH

Semiconductive glaze, its making method and insulator using said glaze

InactiveCN1495806AHigh mechanical strengthLow thermal expansionOxide conductorsInsulatorsThermal expansionUltimate tensile strength

Owner:NGK INSULATORS LTD

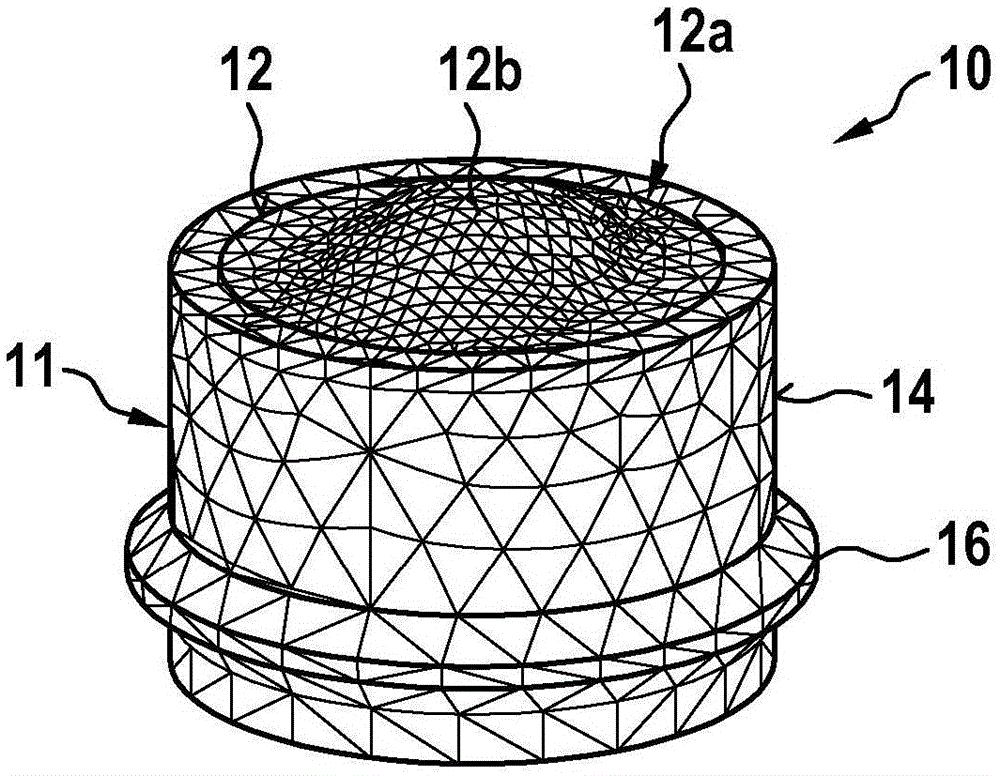

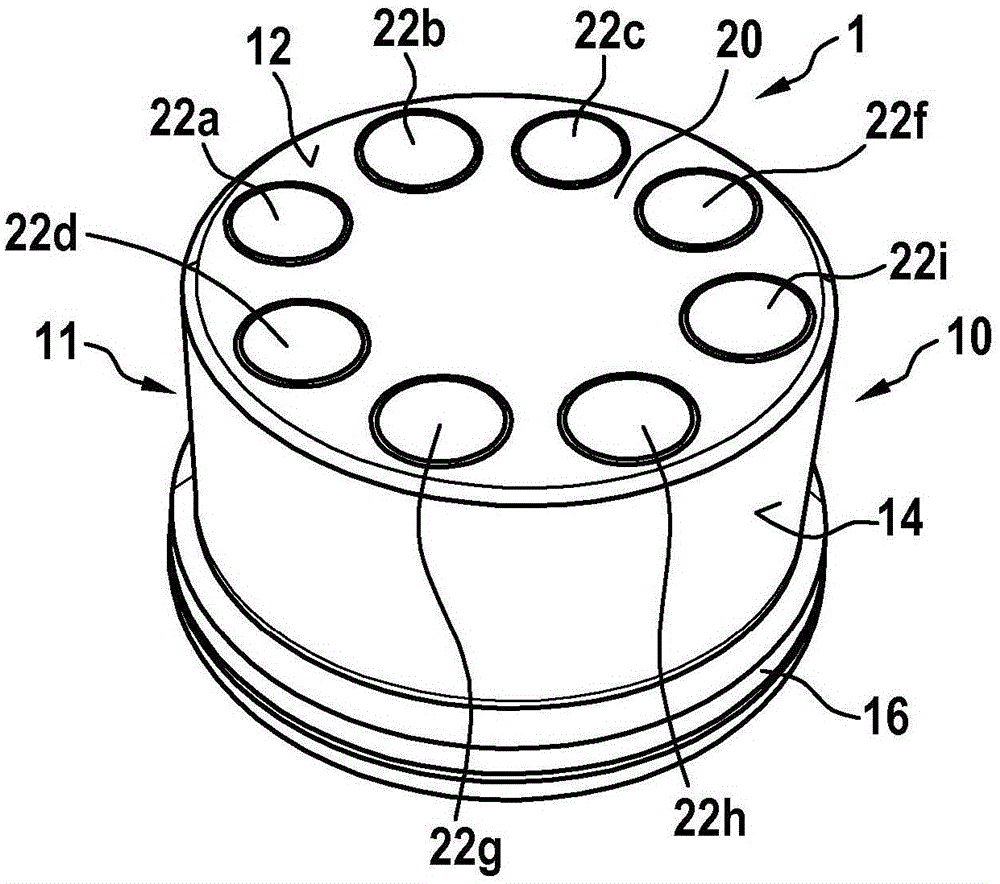

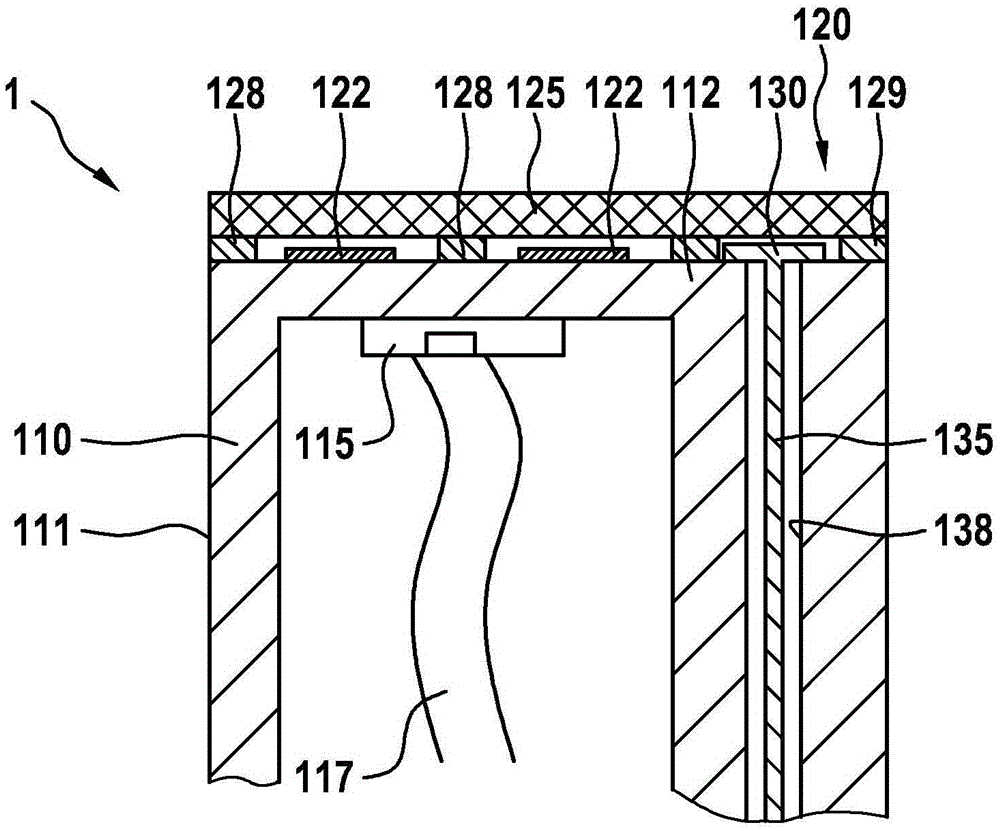

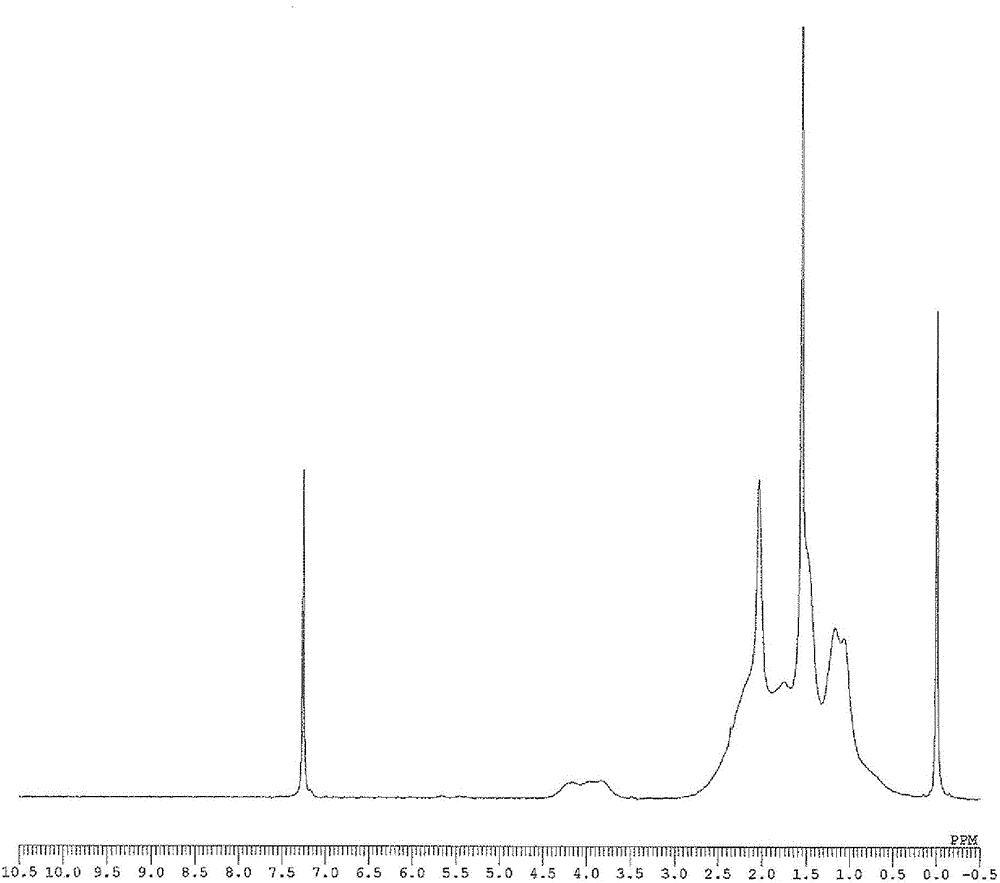

Sensor assembly and method for detecting the surroundings of a vehicle

ActiveCN105073281AEasy to installEasy to manufacturePiezoelectric/electrostrictive device manufacture/assemblyElectrets selectrostatic transducerTransducerAcoustic wave

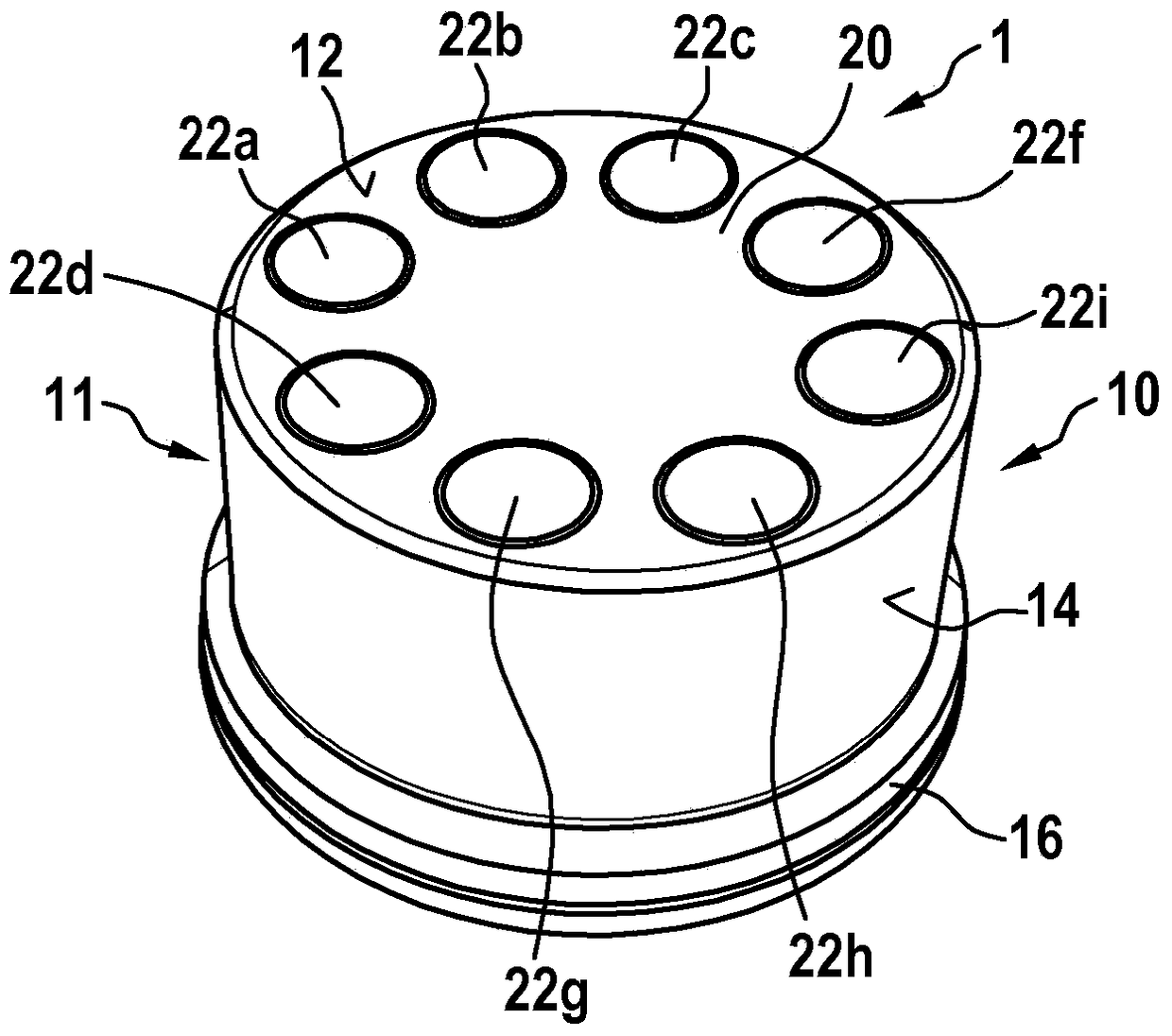

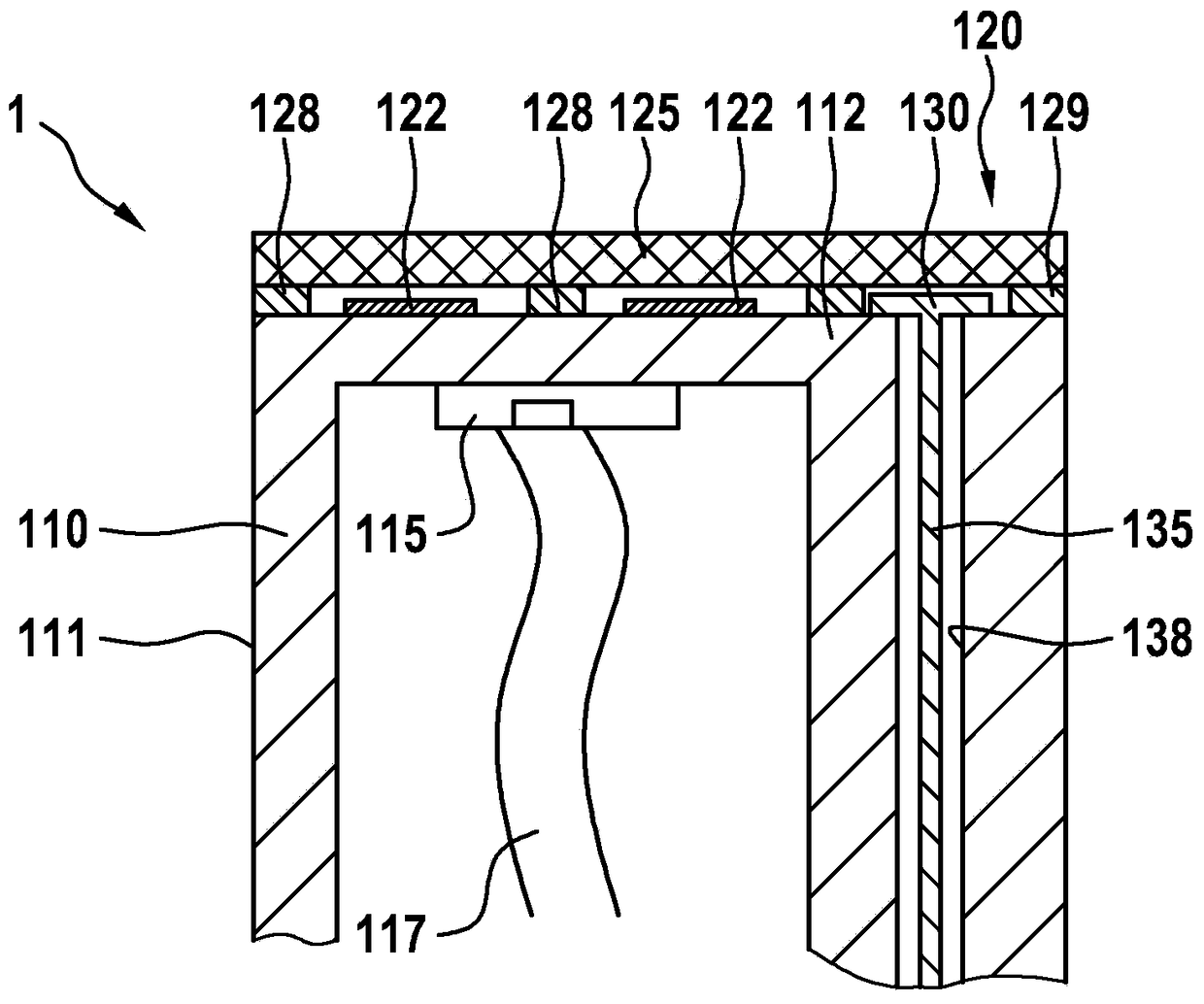

The invention relates to a sensor assembly (1) which comprises a first acoustic transducer assembly (10) having at least one surface formed as a diaphragm (12), the diaphragm (12) being suitable to emit sound waves. An acoustic converter assembly (10) of this type is also designated a flexible resonator and can generate sound waves having a comparatively high acoustic pressure. The sensor assembly (1) according to the invention has a second acoustic transducer assembly (20), comprising a plurality of sensor elements (22a - 22i) which are arranged in an array. Provision is made for the second acoustic transducer assembly (20) to be arranged on a surface of the first acoustic transducer assembly (10) that is formed as a diaphragm (12). According to the invention, the second acoustic transducer assembly (20) comprises sensor elements (22a - 22i) which are formed as electret converter elements. A sensor assembly (1) of this type can be formed in particular as an ultrasound sensor assembly for detecting the surroundings of a vehicle.

Owner:ROBERT BOSCH GMBH

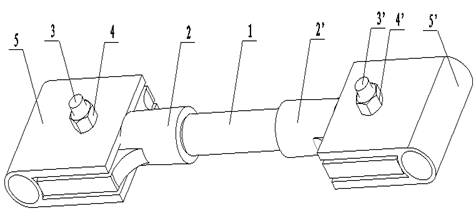

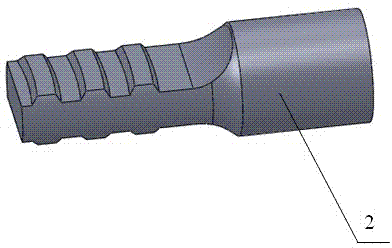

Connection construction member capable of regulating tightness and manufacturing and assembling method thereof

The invention discloses a connection construction member capable of regulating tightness for a transmission tower and a manufacturing and assembling method thereof. The connection construction member is assembled by a connecting rod, two connecting plates and two U-shaped connecting plates, wherein the connecting rod is made of glass fiber reinforced plastic composite material, and two ends of the connecting rod are provided with male threads. The manufacturing and assembling method for the connection construction member capable of regulating the tightness comprises the following steps of: 1) carrying out pultrusion on the connecting rod, and lathing a positive-buckling male thread and a reverse-buckling male thread on two ends of the connecting rod; 2) carrying out pultrusion on a pin, and lathing the male thread on two ends of the pin; 3) carrying out pultrusion on two pairs of nuts; 4) forming the connecting plates and the U-shaped connecting plates in a vacuum flow guide technology; 5) processing pin holes in the center positions where the connecting plates are opposite to the U-shaped connecting plates; and 6) fixedly connecting the connecting rod, the two connecting plates and the two U-shaped connecting plates into a connection construction member by the pin holes, the pin and the nuts. The manufacturing and assembling method is simple and easy to operate, has the characteristics of light weight, corrosion resistance and electric insulation, is adjustable, is safe to assemble, does not need to maintain and repair because the weather resistance lasts for 20 years, and is favorable for popularizing and applying.

Owner:北玻电力复合材料有限公司

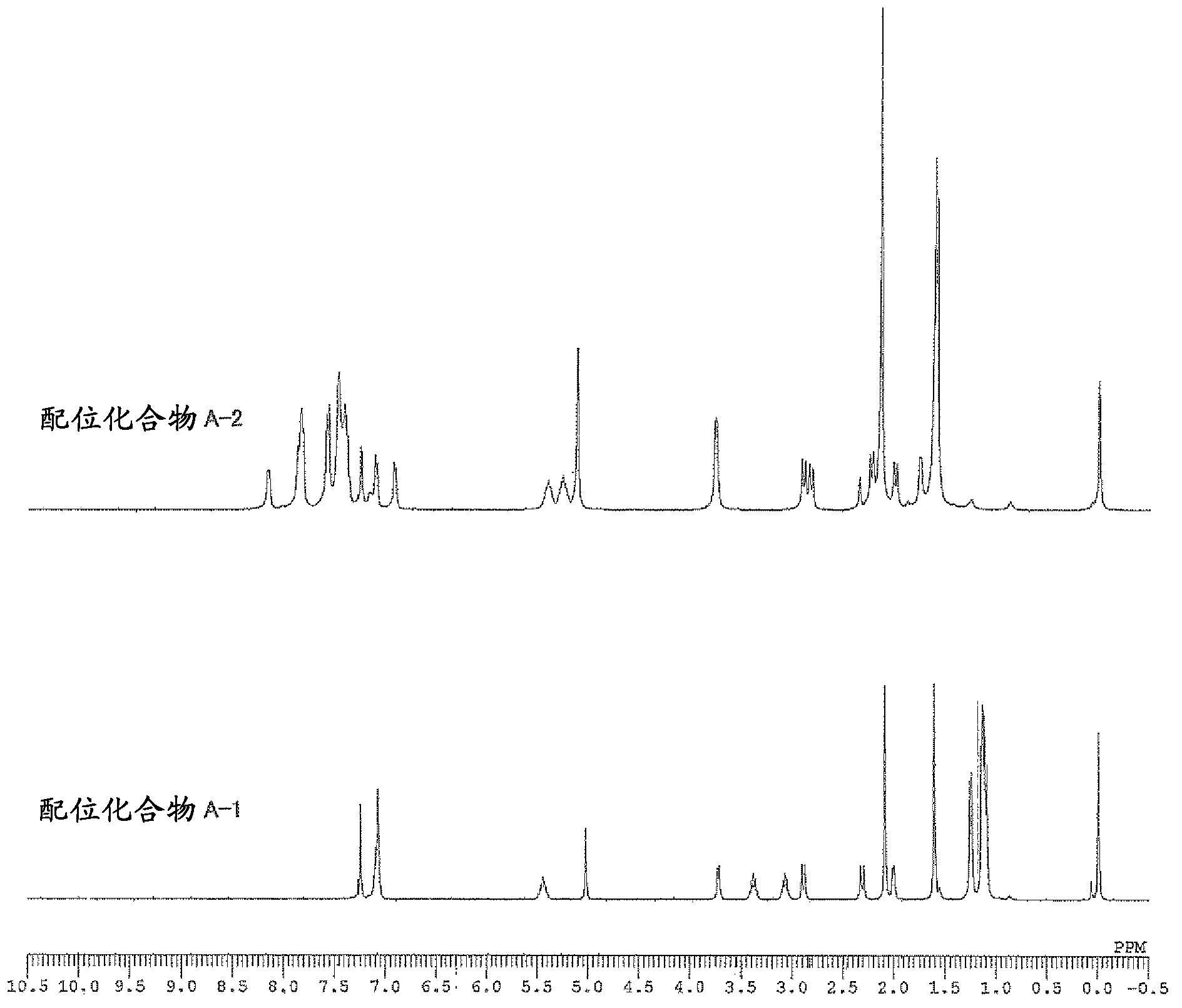

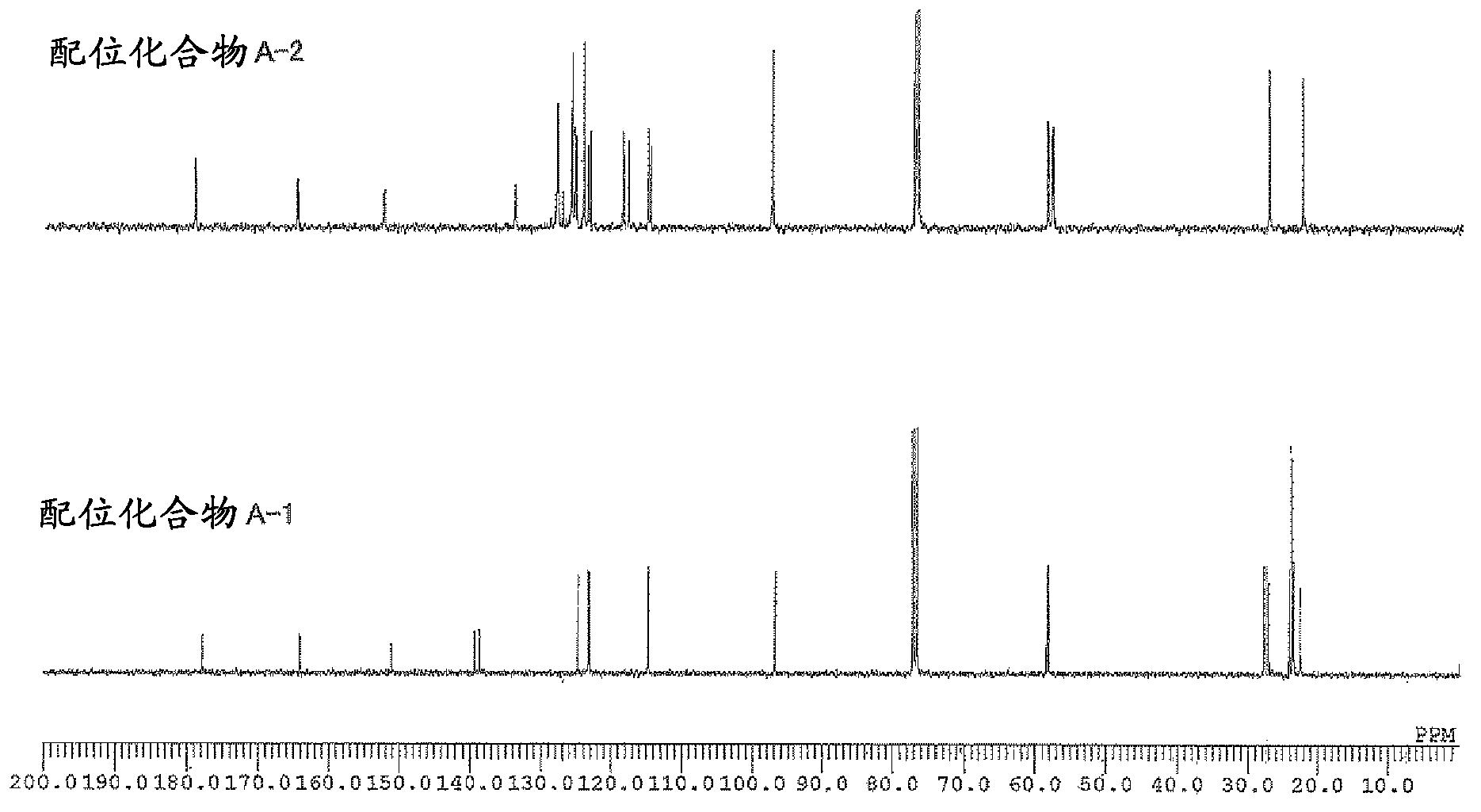

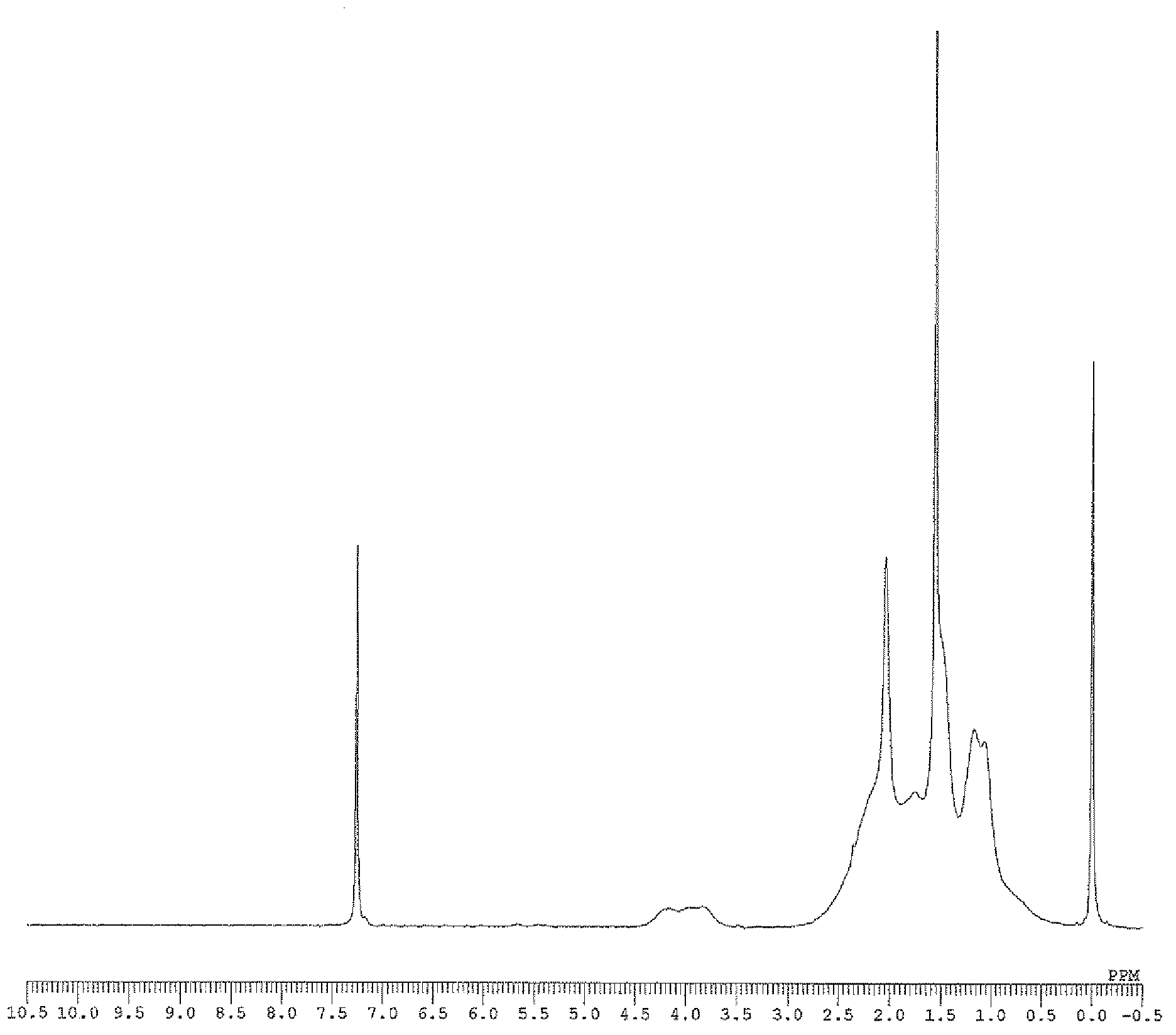

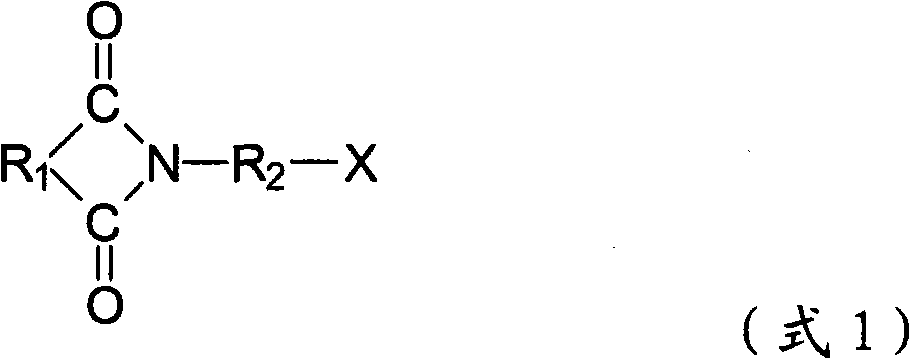

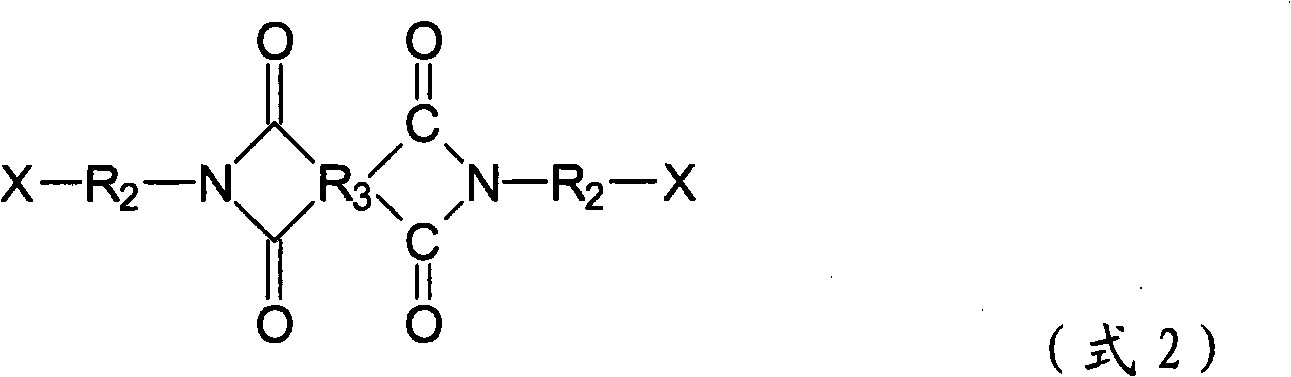

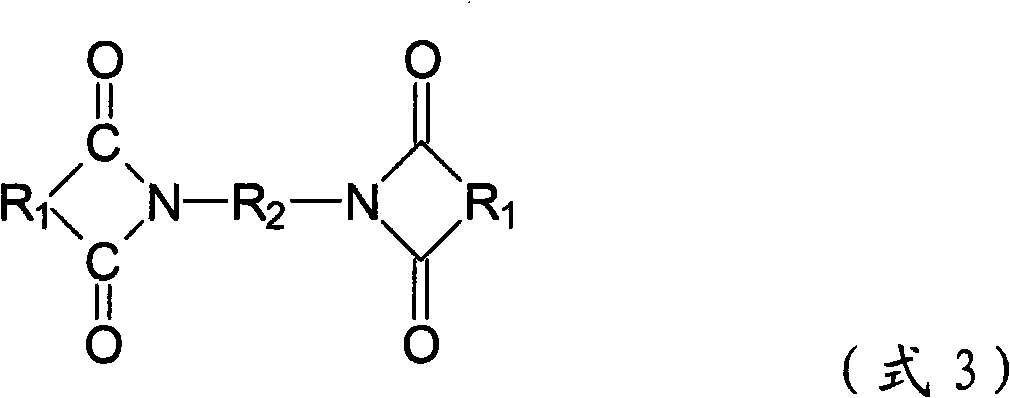

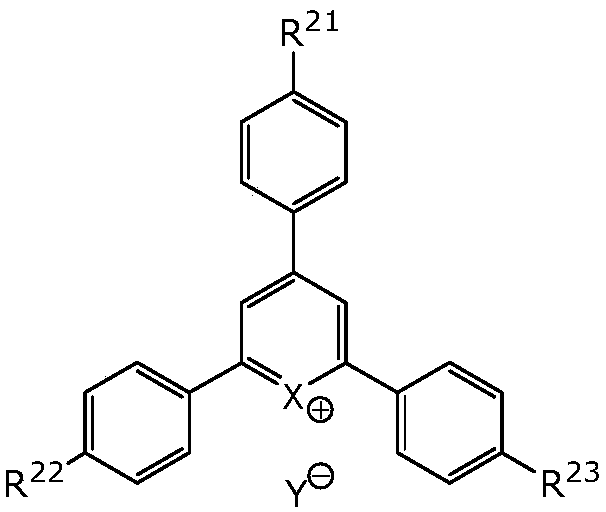

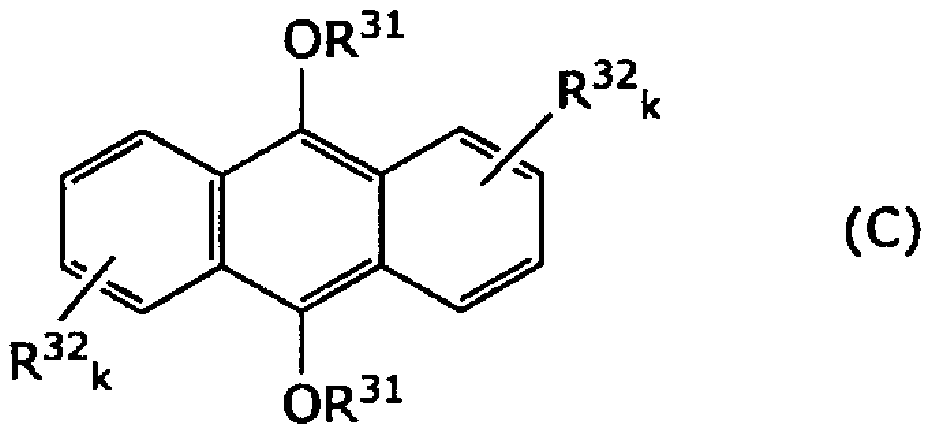

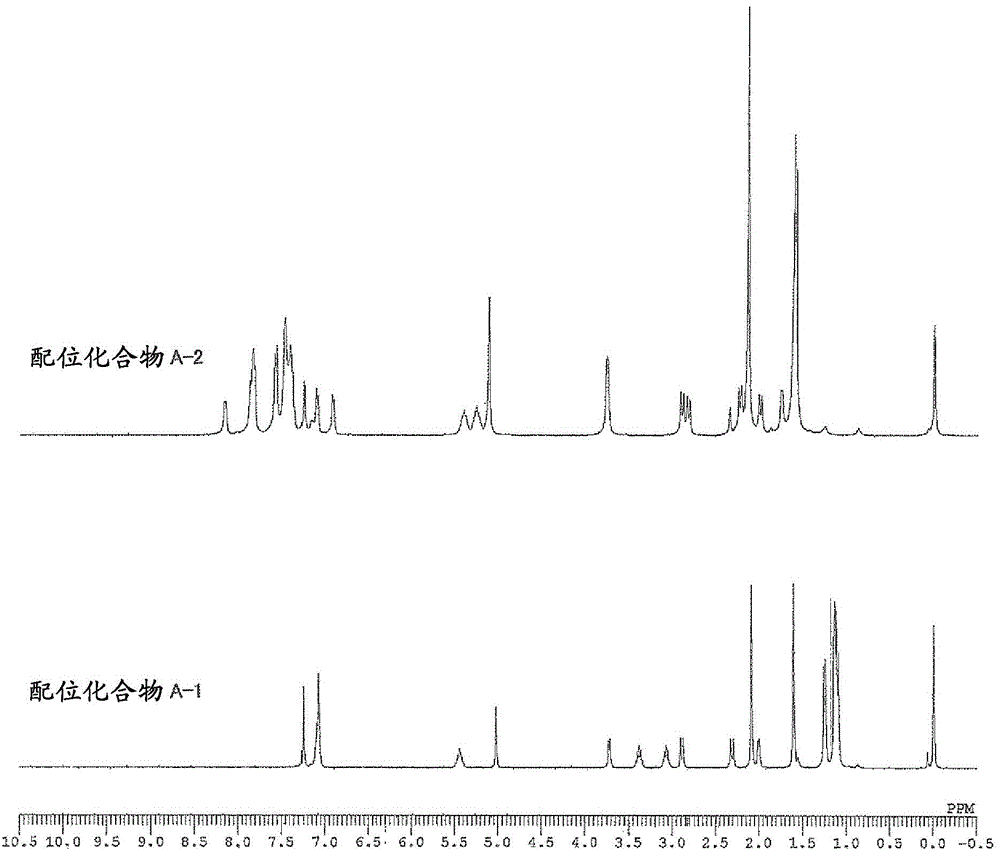

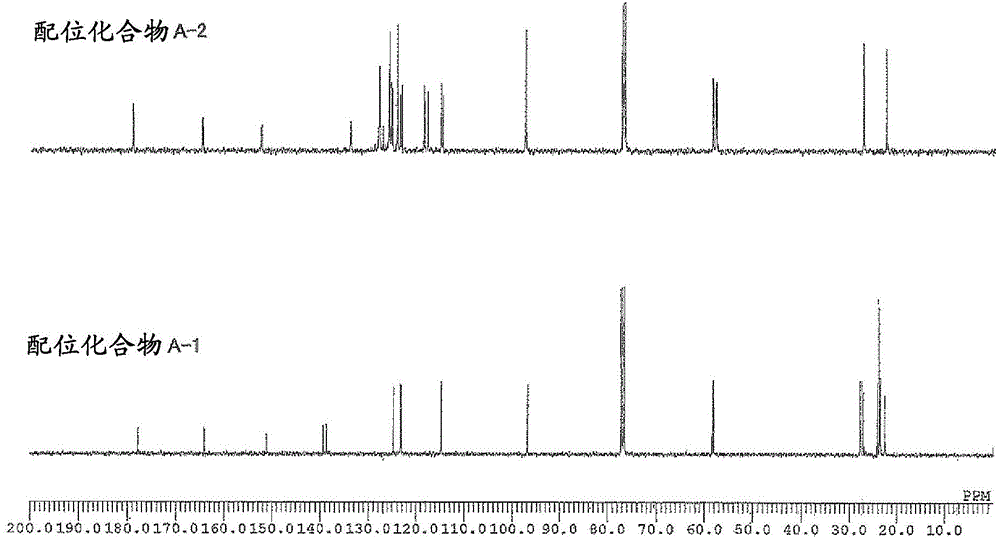

Catalyst for norbornene monomer polymerization and method for producing norbornene polymer

ActiveCN103189397AGood transparencyEfficient preparationPalladium organic compoundsNorbornenePolymerization catalysts

The present invention provides: a catalyst for norbornene polymerization, which contains a transition metal complex (A) that is represented by general formula (1); and a method for producing a norbornene (co)polymer, especially a norbornene copolymer having monomer units that are represented by general formula (2) and general formula (3), wherein a norbornene monomer is homopolymerized or copolymerized in the presence of the polymerization catalyst. Preferable examples of the transition metal complex (A) include (pai-allyl){4-(2,6- diisopropylphenylimino)-2-penten-2-olato-kepa 2N,O}pallarium and (pai-allyl){4-(1-naphthylimino)-2-penten-2-olato- kepa 2N,O}pallarium. (In the formulae, the symbols are defined in the description.) A norbornene (co)polymer which has excellent transparency, excellent heat resistance, excellently low water absorption and excellent electrical insulation characteristics can be efficiently produced by the present invention.

Owner:SHOWA DENKO KK

Composition for fixing wound items

ActiveCN101903454AImprove heat transfer characteristicsExcellent electrical insulation propertiesPlastic/resin/waxes insulatorsImidePolyester

A composition for fixing wound items comprising A) 0 to 90 wt% of at least one alpha, beta-unsaturated polyester and / or polyester imide resin based on at least one unsaturated mono-, di- or tricarboxylic acids and / or mono-, di- or tricarboxylic acid group containing molecules, at least one polyol and / or, in case of an unsaturated polyester imide, at least one imide having 5-membered cyclic imide moieties, B) 0.1 to 80 wt% of at least one inorganic and / or organic-inorganic hybrid component having functionalities to react with component A) and C), C) 2 to 80 wt% of at least one monomeric and / oroligomeric unsaturated component to react with component A) and B), and D) 0 to 15 wt% of customary additives, the wt% being based on the total weight of the composition. The composition provides excellent thermal transfer properties and a high level of electrical insulation properties with excellent adhesion and thermal stability.

Owner:AXALTA COATING SYST GMBH

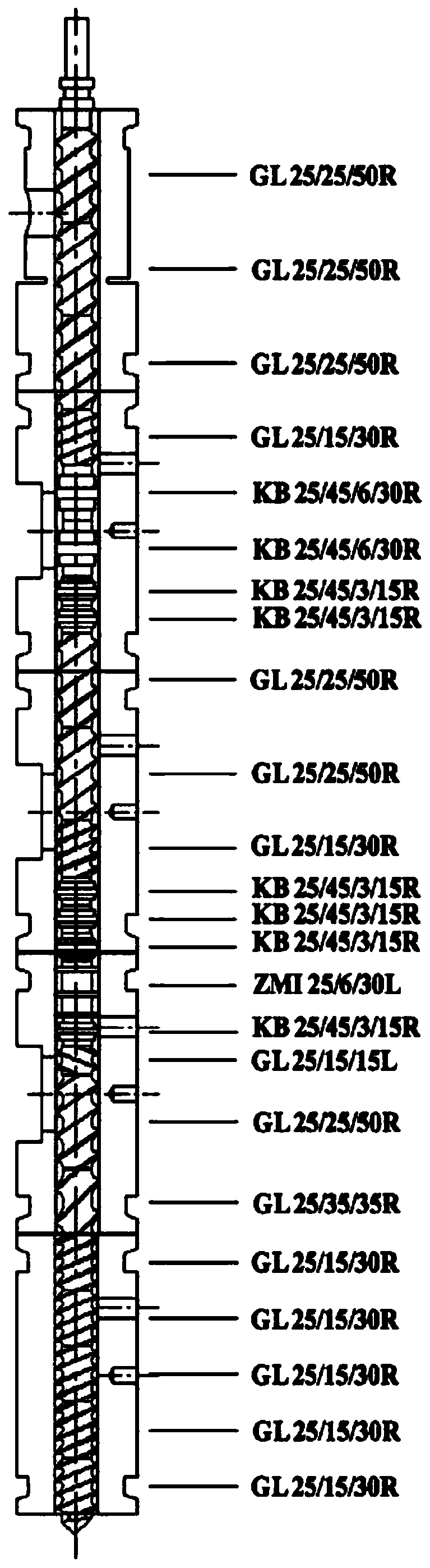

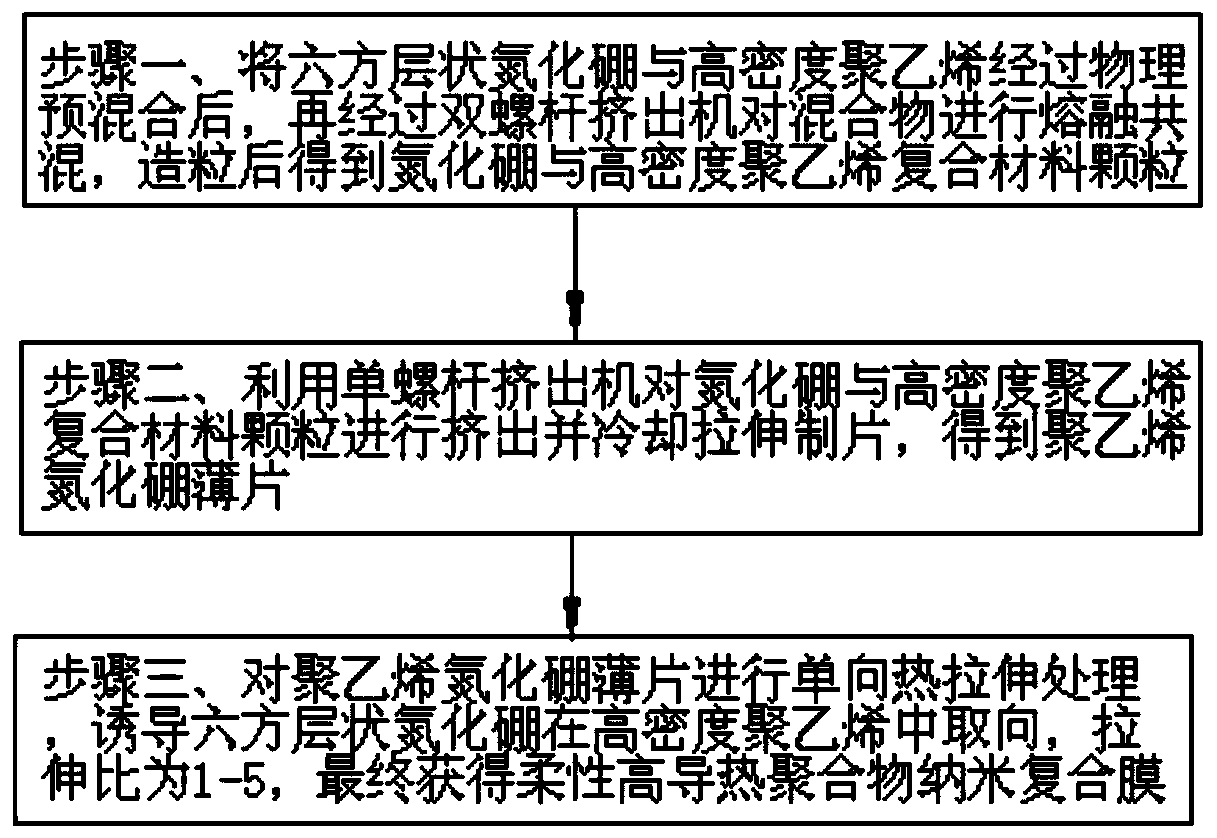

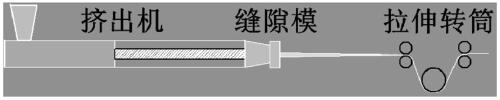

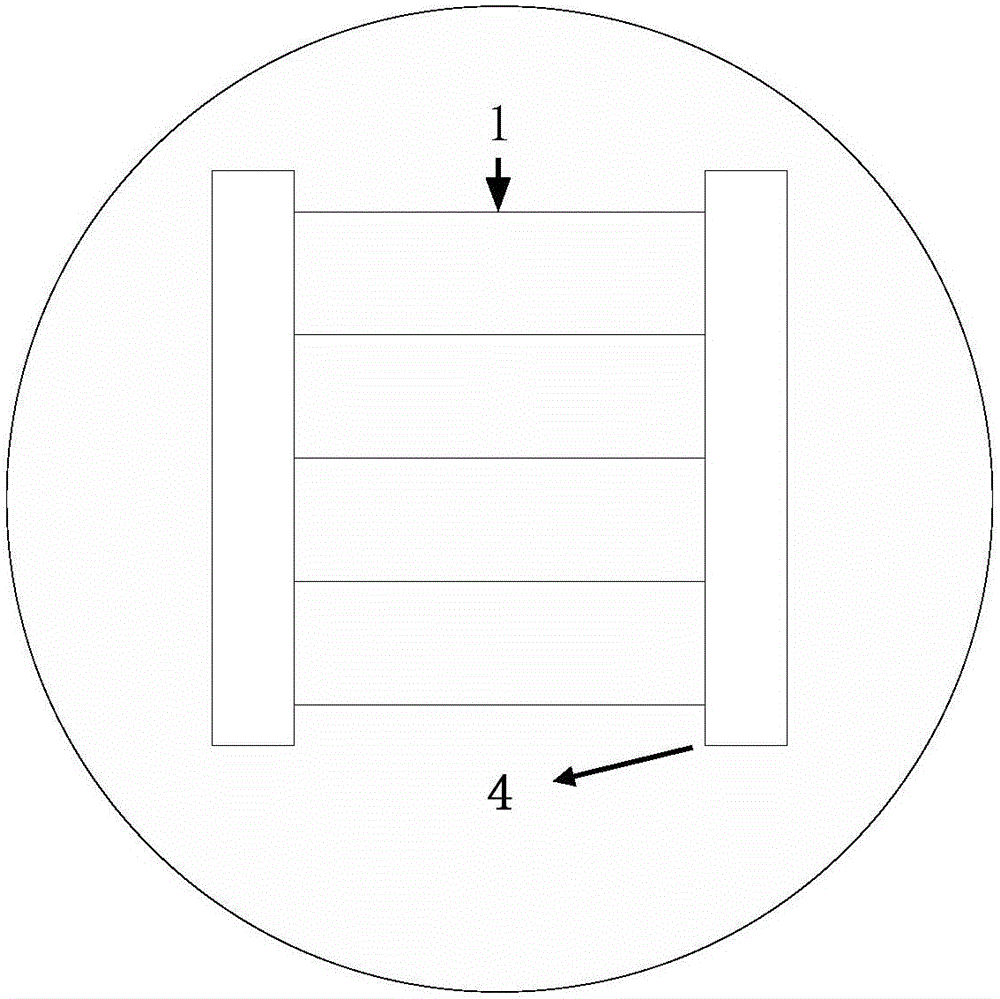

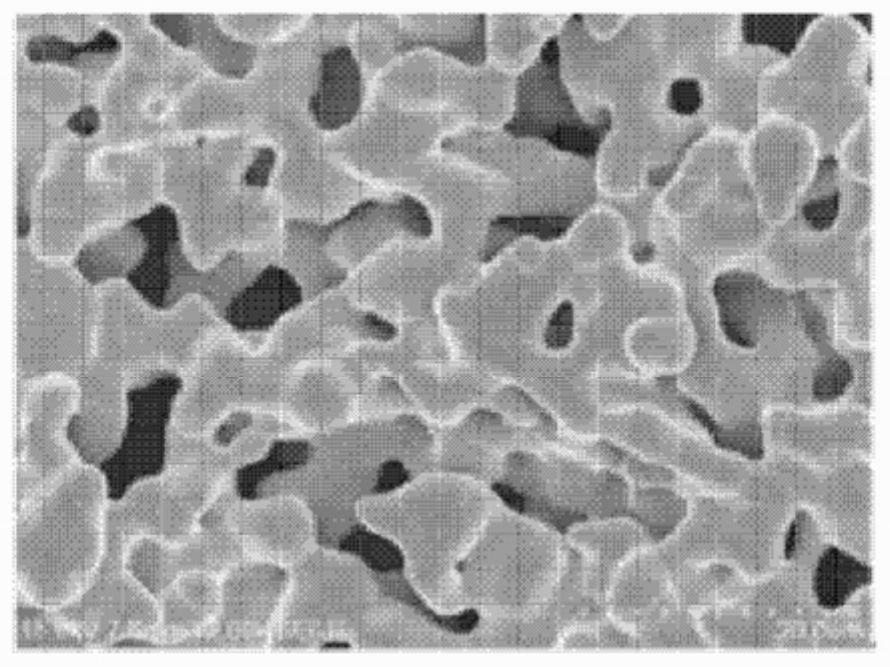

Flexible high-thermal-conductivity polymer nanocomposite film and preparation method thereof

InactiveCN111303521AImprove thermal conductivityImprove insulation performanceHeat-exchange elementsPolymer scienceHigh volume manufacturing

The invention discloses a flexible high-thermal-conductivity polymer nanocomposite film. According to the invention, an h-BN thermal-conductivity filler is adopted and HDPE is used as a matrix. A preparation method for the flexible high-thermal-conductivity polymer nanocomposite film comprises the following steps: physically premixing the h-BN and the HDPE, carrying out melt blending with a twin-screw extruder to increase the dispersibility of the h-BN in the HDPE, extruding a formed h-BN-HDPE composite material through a single-screw extruder, carrying out cooling, stretching and flaking; andfinally, carrying out hot stretching treatment on the composite material to induce the orientation of the layered h-BN in the HDPE, wherein the content of the filler determines the flexibility and the heat-conducting property of the film, and the content of the filler depends on the dispersity of the filler in the polymer matrix. The polymer heat conduction nanocomposite film prepared by the invention has ultrahigh heat conductivity, good heat dissipation capability, good flexibility and excellent comprehensive performance, is applicable to mass production, can be made into various components, and has wide application prospects in the fields of electronic packaging, LED lighting systems, automobiles, aerospace and the like.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

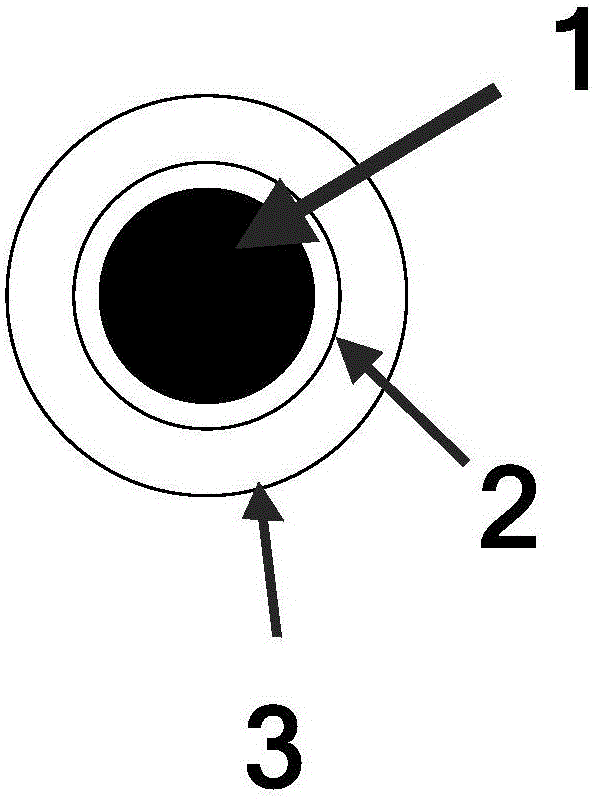

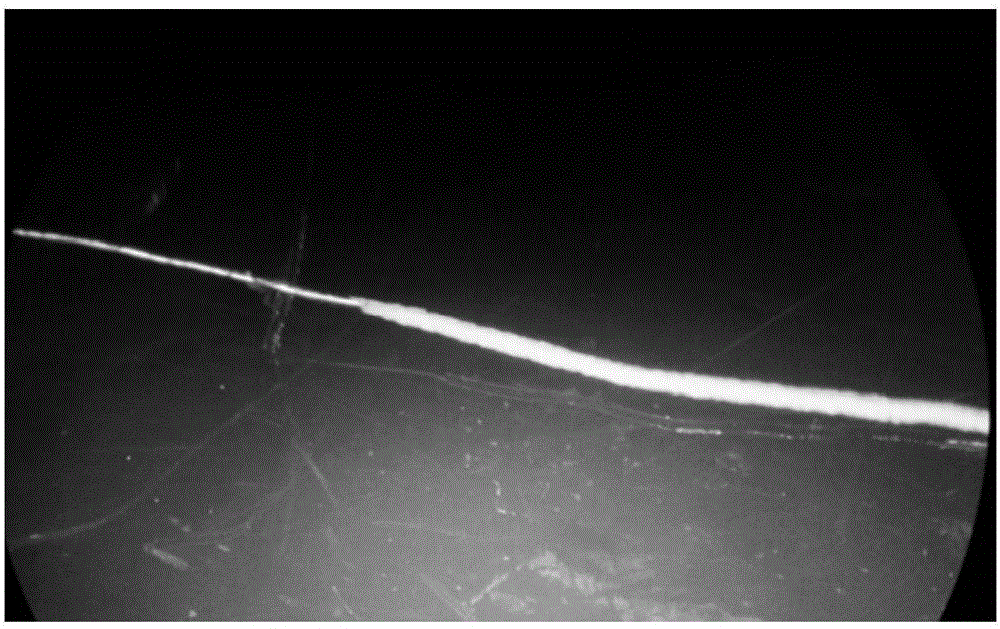

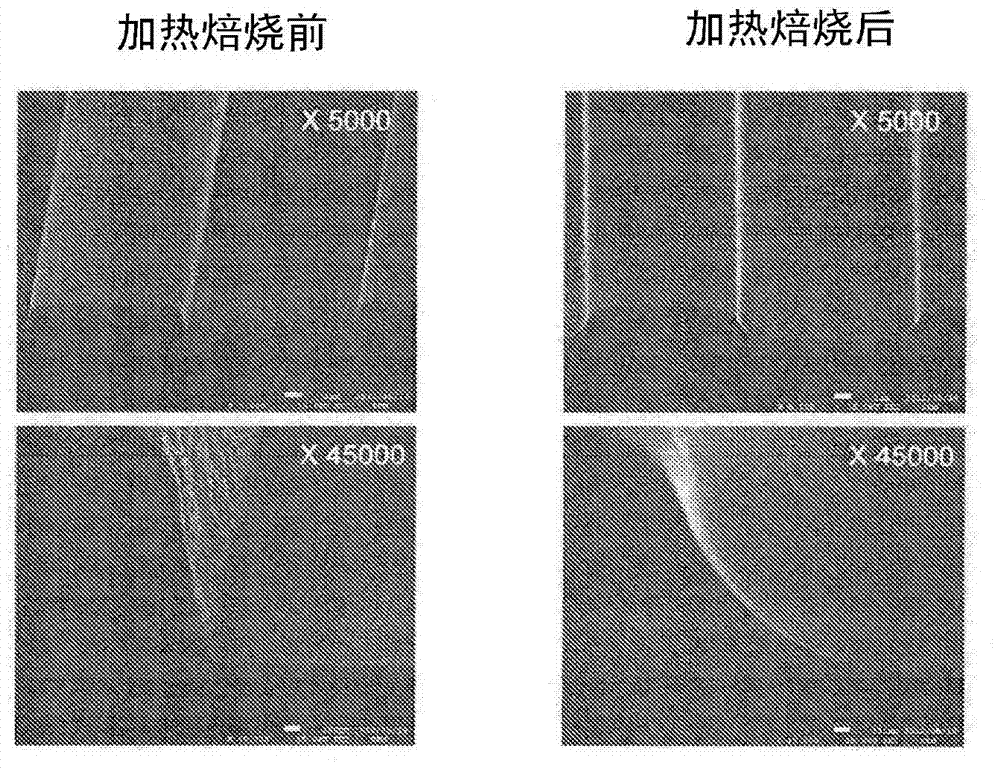

Method for manufacturing high-temperature insulated wire by spraying thermal barrier coating to wrap surface of Pt metal wire

InactiveCN105779924AImprove bindingExcellent electrical insulation propertiesMolten spray coatingEfficient propulsion technologiesElectricityMetallurgy

The invention provides a method for manufacturing a high-temperature insulated wire by spraying a thermal barrier coating to wrap the surface of a Pt metal wire. According to the method, the high-temperature thermal barrier coating material wraps the surface of the Pt metal wire through a spraying method, and therefore the high-temperature insulated wire keeping the insulation characteristic at the highest temperature of 1200 DEG C is formed; the high-temperature thermal barrier coating material is yttria-stabilized zirconia YSZ or aluminum oxide Al2O3; and the high-temperature insulated wire can replace a traditional naked Pt metal wire lead, the high-temperature insulated wire can keep the good electric insulation characteristic under the high-temperature environment with the temperature up to 1200 DEG C, and the insulated wire has the important actual application value and potential in the field of creativeness high-temperature intelligent sensors and can be widely applied to many aviation industry in-situ integration sensors. The technology of the insulated wire can be compatible with the correlation technique of an existing aircraft engine, and can be used for the aviation commercial process in recent years.

Owner:SHANGHAI JIAO TONG UNIV +1

Negative type photosensitive composition curable at low temperature

ActiveCN108700814AGood chemical resistanceImprove environmental resistancePhotomechanical exposure apparatusPhotosensitive material processingPolymer scienceMeth-

Owner:MERCK PATENT GMBH

Zener diode and methods for fabricating and packaging same

InactiveCN1812059AReduce the impedance valueSimple processSolid-state devicesSemiconductor/solid-state device manufacturingEtchingZener diode

A zener diode and methods for fabricating and packaging same are disclosed, whereby contact hole forming process exposing a diffusion layer is removed to enable to simplify the fabricating process, and the diffusion length not contacting the electrode line is determined by the crosswise length toward which the impurity is diffused to enable to reduce the zener impedance value. Furthermore, wet etching is used following the diffusion to remove the diffusion masks such that no damage is given to the diffusion layers to thereby enable to improve the zener diode characteristics.

Owner:LG ELECTRONICS INC

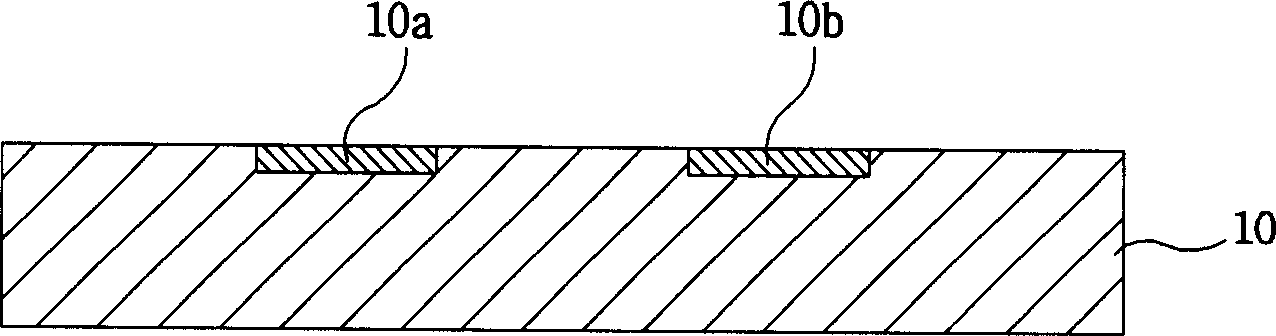

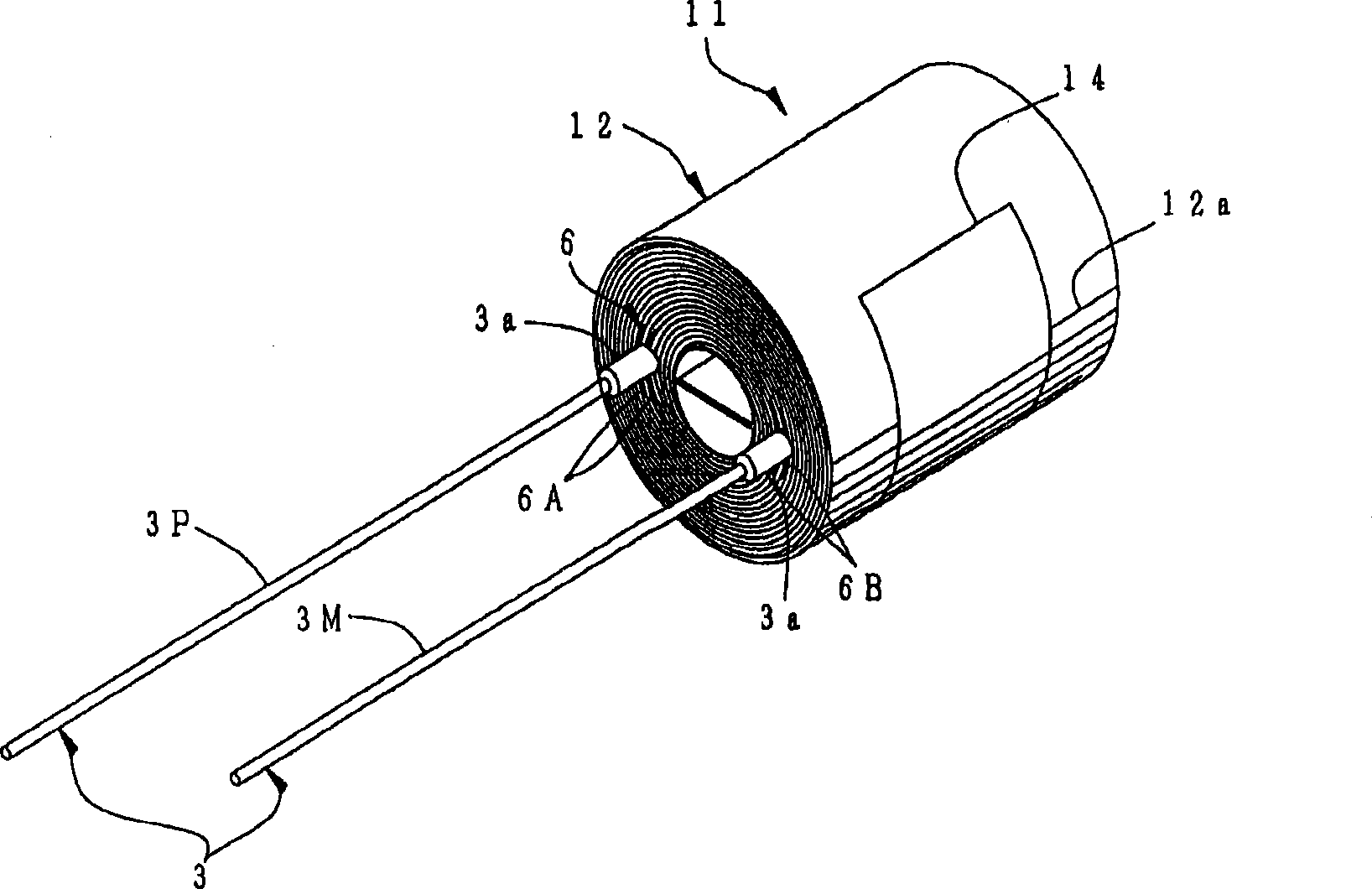

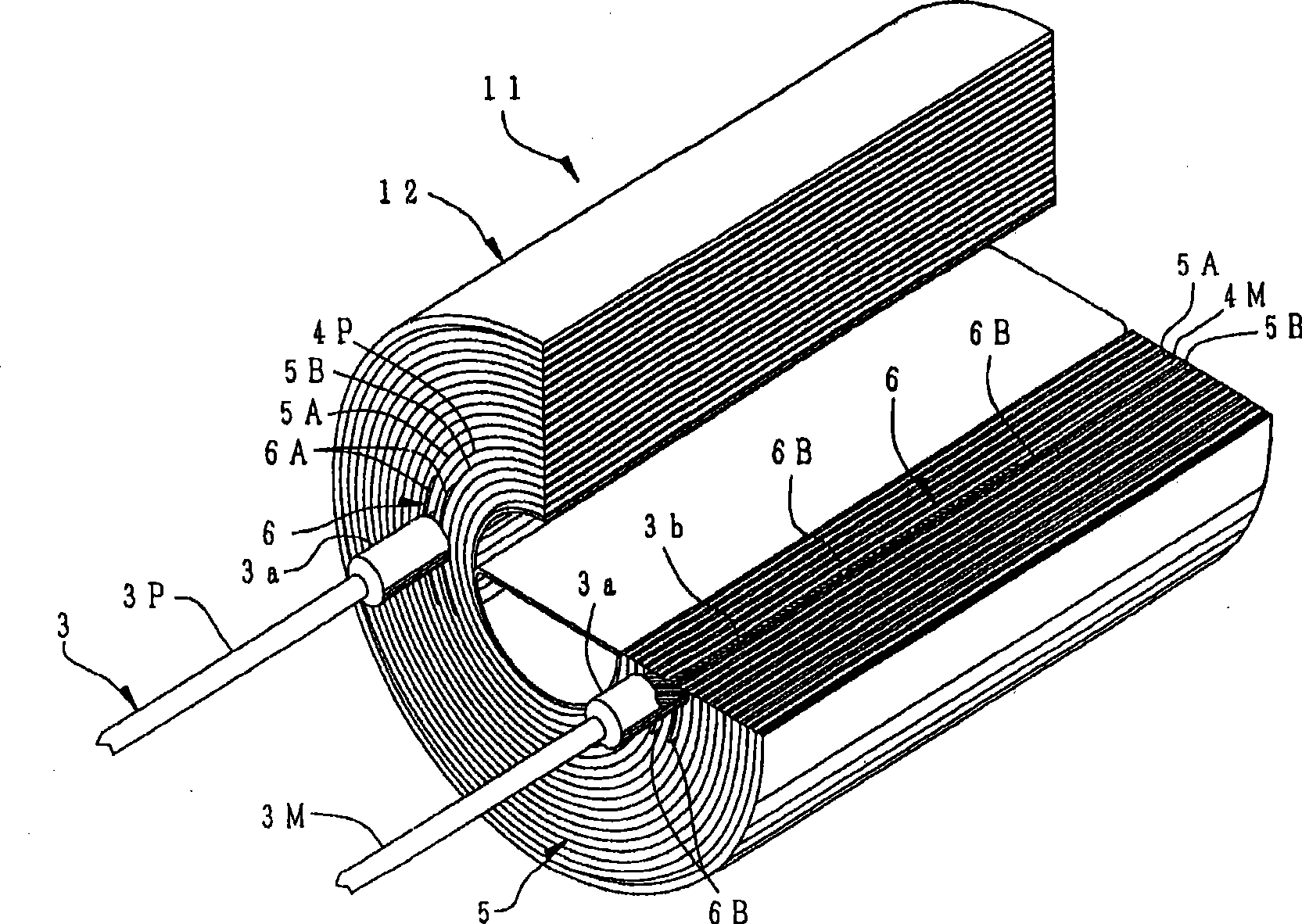

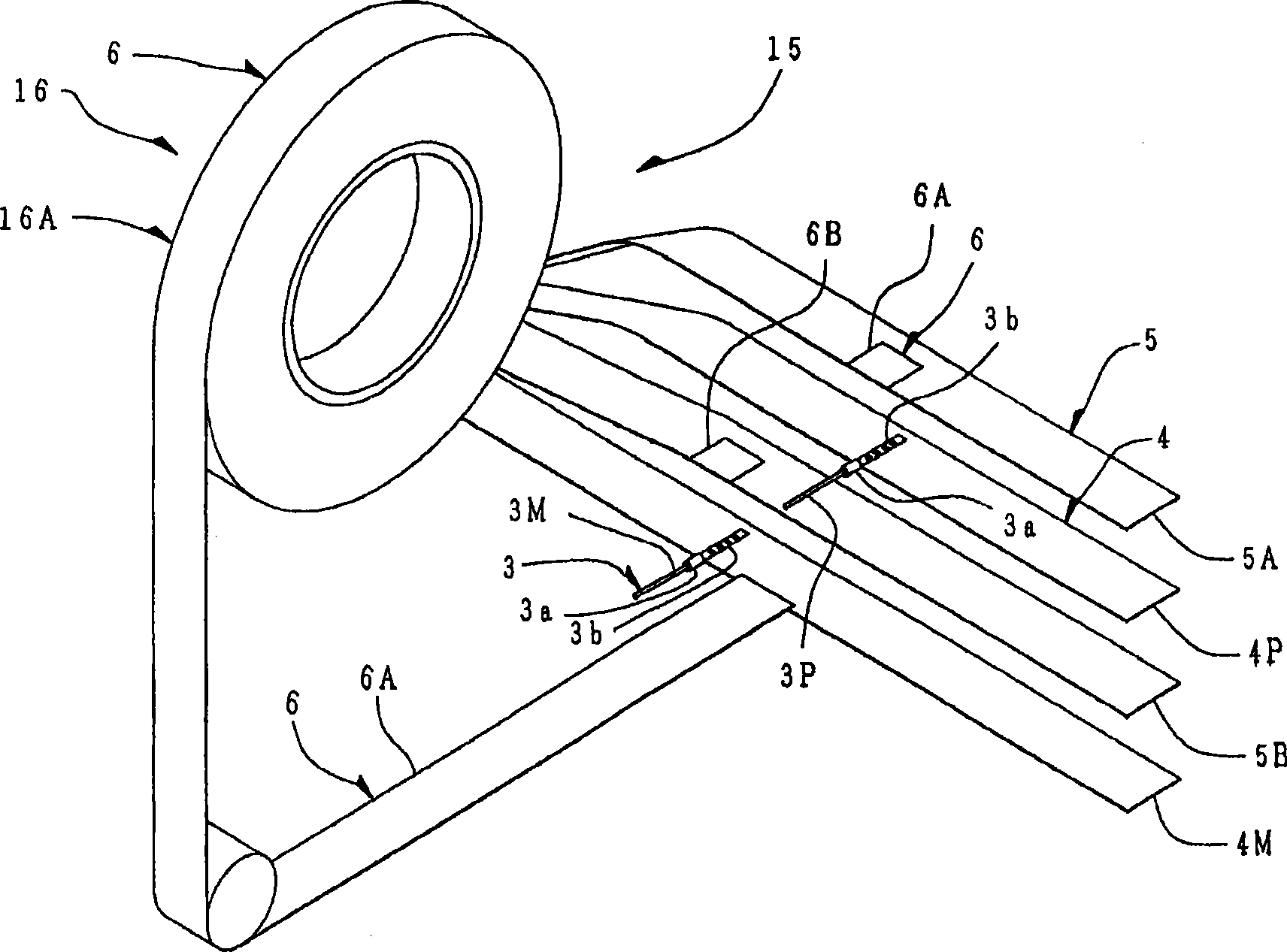

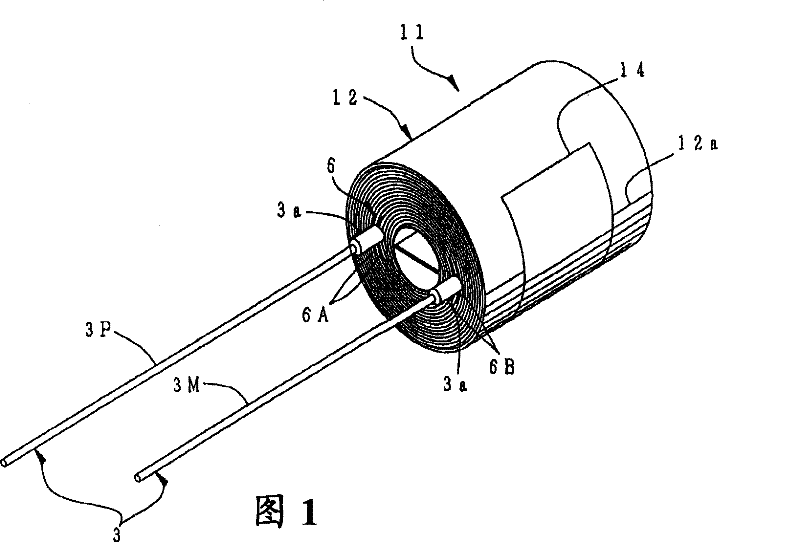

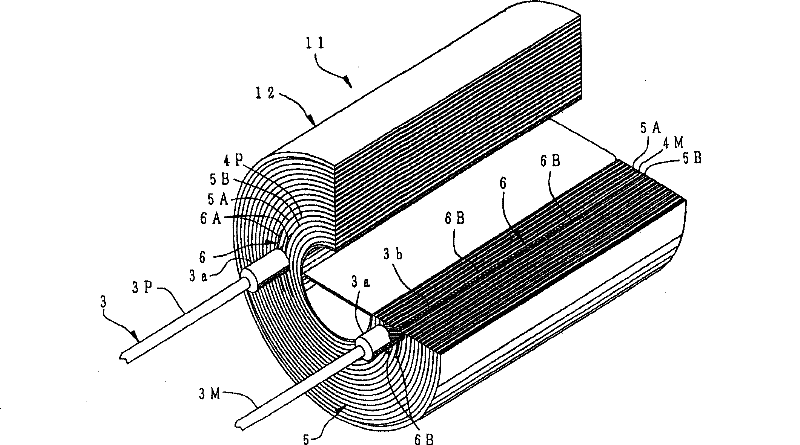

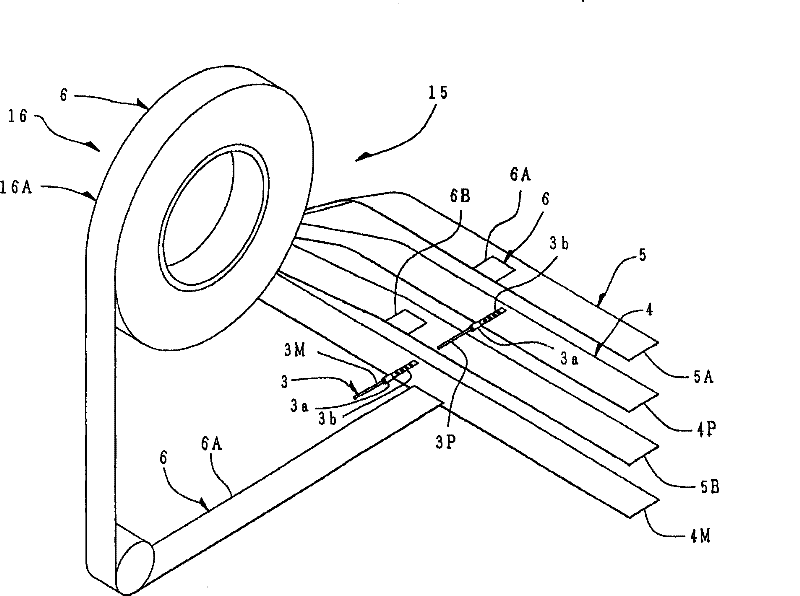

Electronic component and production method thereof

ActiveCN101465209AImprove electrical insulation propertiesReduce weightSolid electrolytic capacitorsCapacitor terminalsPulp and paper industryElectronic component

The invention relates to an electronic part and a production method thereof, more particularly bonds a protective paper on an insulation paper, thus improves an electric insulation characteristic between electric pole foils, and protects two sides of a flat part of the wire. The protective paper has a minimum width, prevents a radial direction substantially thickening, and further prevents an Equivalent Series Resistance (ESR) of the electronic part from increasing. A protective paper (6; 6A, 6B) wider than a wire flat part is bonded on the insulation paper (5; 5A, 5B) for transmitting the protective paper to the insulation paper (5; 5A, 5B) to roll at a basic perpendicular direction to a direction of transmission of the insulation paper (5; 5A, 5B) and an electrode foil (4; 4P, 4M) right before the insulation paper region bonded by the protective papers is rolled.

Owner:JCC ENG

Catalyst for norbornene monomer polymerization and method for producing norbornene polymer

ActiveCN103189397BEfficient preparationHigh transparencyPalladium organic compoundsPolymer scienceHeat resistance

The invention relates to a catalyst for the polymerization of norbornene monomers comprising transition metal complex (A) represented by formula (1); and a method for producing a norbornene (co)polymer, especially a norbornene copolymer containing a monomer unit represented by formulae (2) and (3), wherein a norbornen monomer is homopolyzed or copolymerized in the presence of the polymerization catalyst. Preferable examples of the transition metal complex (A) include (À-allyl){4-(2,6-diisopropylphenylimino)-2-penten-2-olato- º 2 N,O}palladium and (À-allyl){4-(1-naphthylimino)-2-penten-2-olato- º 2 N,O}palladium. In the formulae, the symbols are as defined in the description. A norbornene (co)polymer which has excellent transparency, excellent heat resistance, excellently low water absorption and excellent electrical insulation characteristics can be efficiently produced by the present invention.

Owner:RESONAC CORPORATION

Sensor device and method for detection of the surrounding environment of a vehicle

ActiveCN105073281BEasy to installImprove heat resistancePiezoelectric/electrostrictive device manufacture/assemblyElectrets selectrostatic transducerTransducerAcoustic wave

According to the invention, a sensor device (1) is proposed, which includes a first acoustic transducer device (10) having at least one surface configured as a diaphragm (12), wherein the diaphragm (12) is suitable for Emit ultrasonic waves. Such a sound transducer device (10) is also called a flexural vibration device and can generate sound waves with a relatively high sound pressure. The sensor device (1) according to the invention has a second acoustic transducer device (20) comprising a plurality of sensor elements (22a-22i) arranged in an array. It is proposed that the second sound transducer device (20) is arranged on a surface (12) of the first sound transducer device (10) configured as a diaphragm. According to the invention, the second acoustic transducer device (20) includes a sensor element (22a-22i) configured as an electret transducer element. Such a sensor device (1) may in particular be designed as an ultrasonic sensor device for detecting the surroundings of the vehicle.

Owner:ROBERT BOSCH GMBH

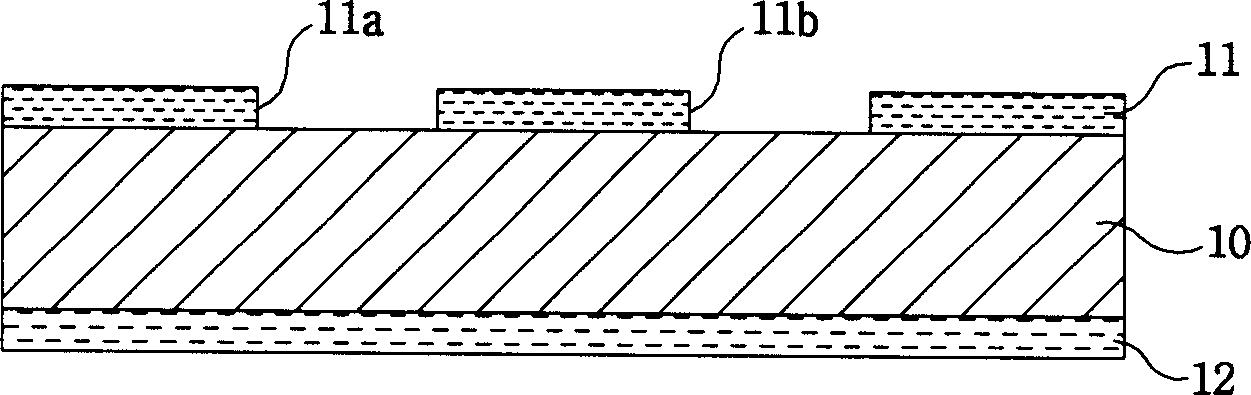

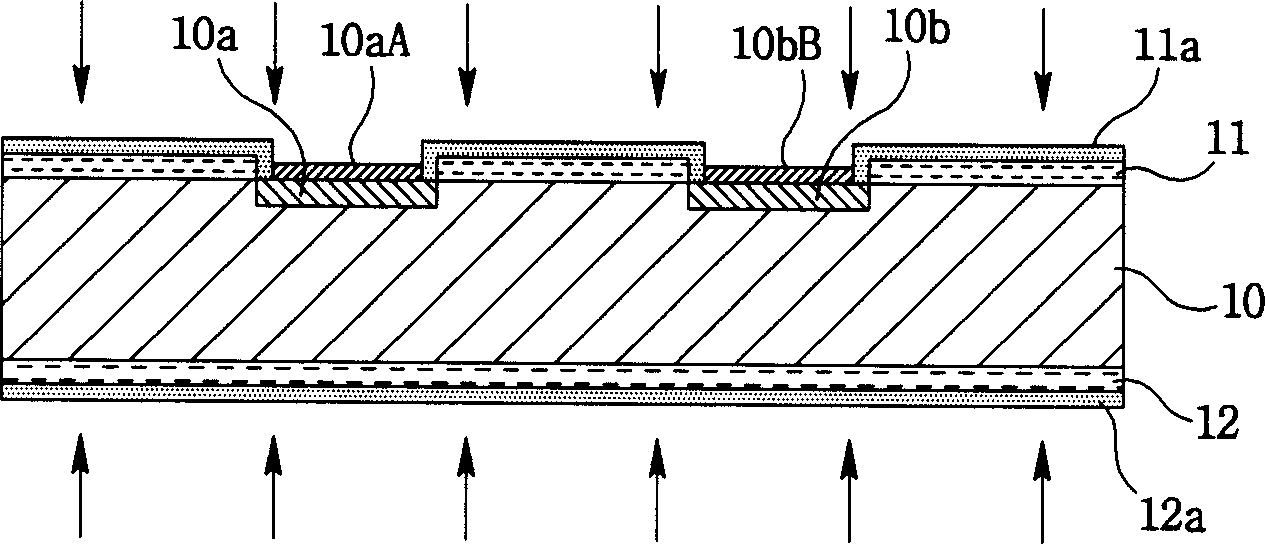

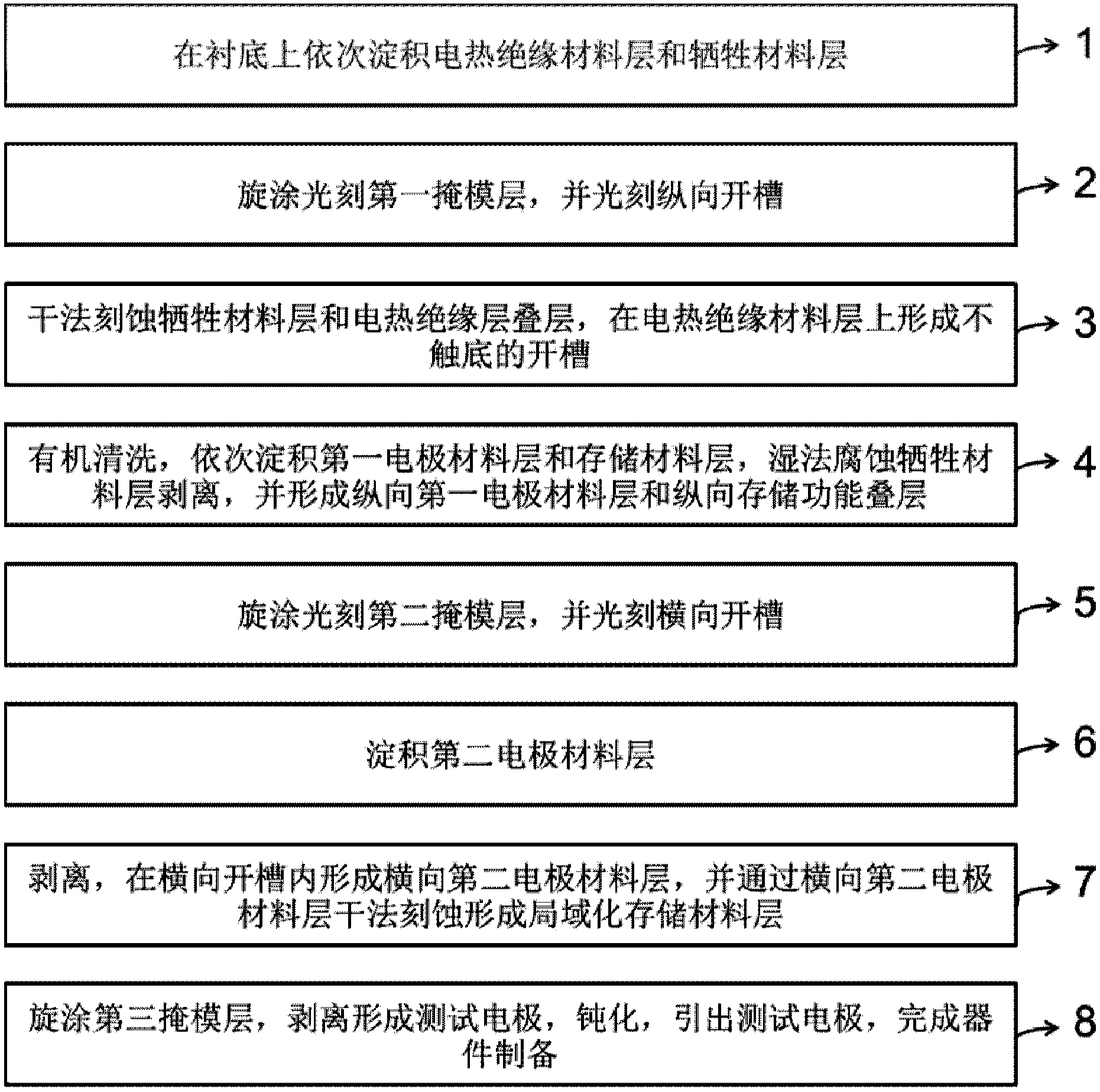

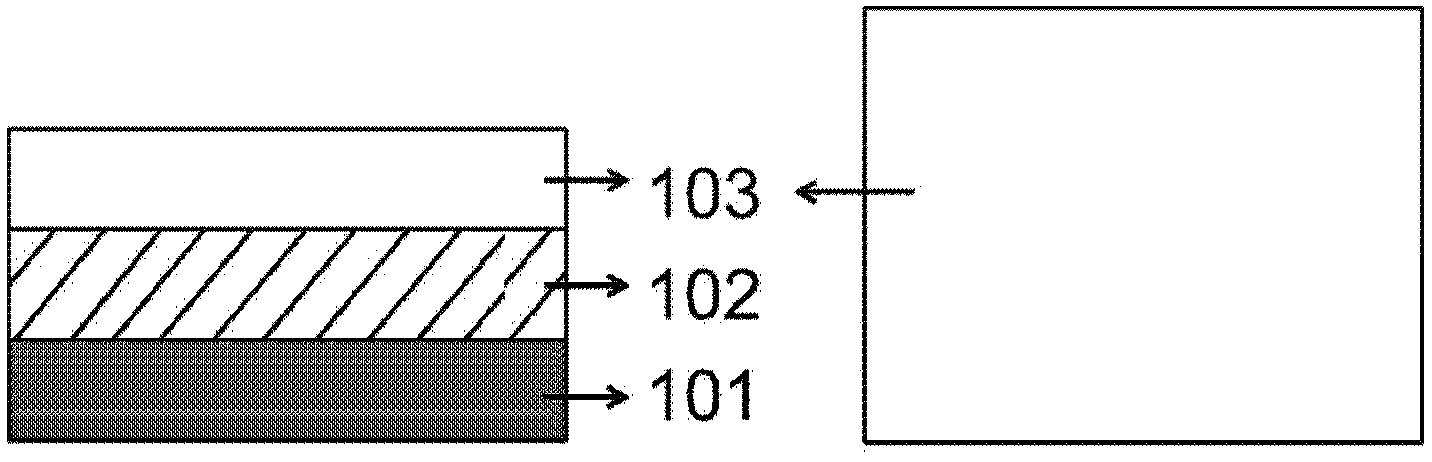

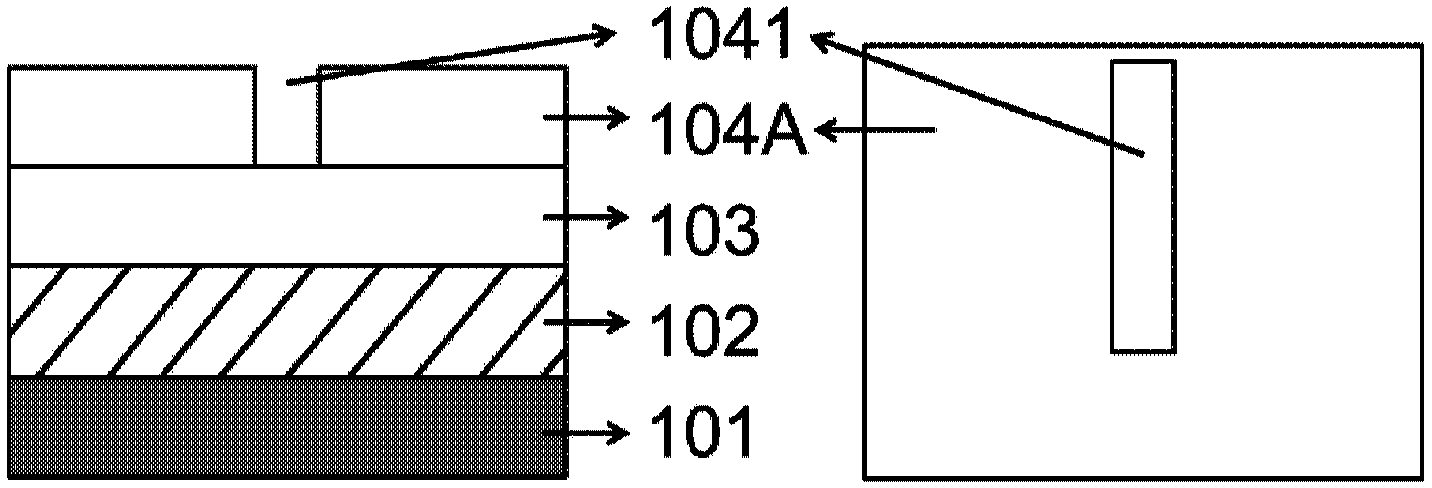

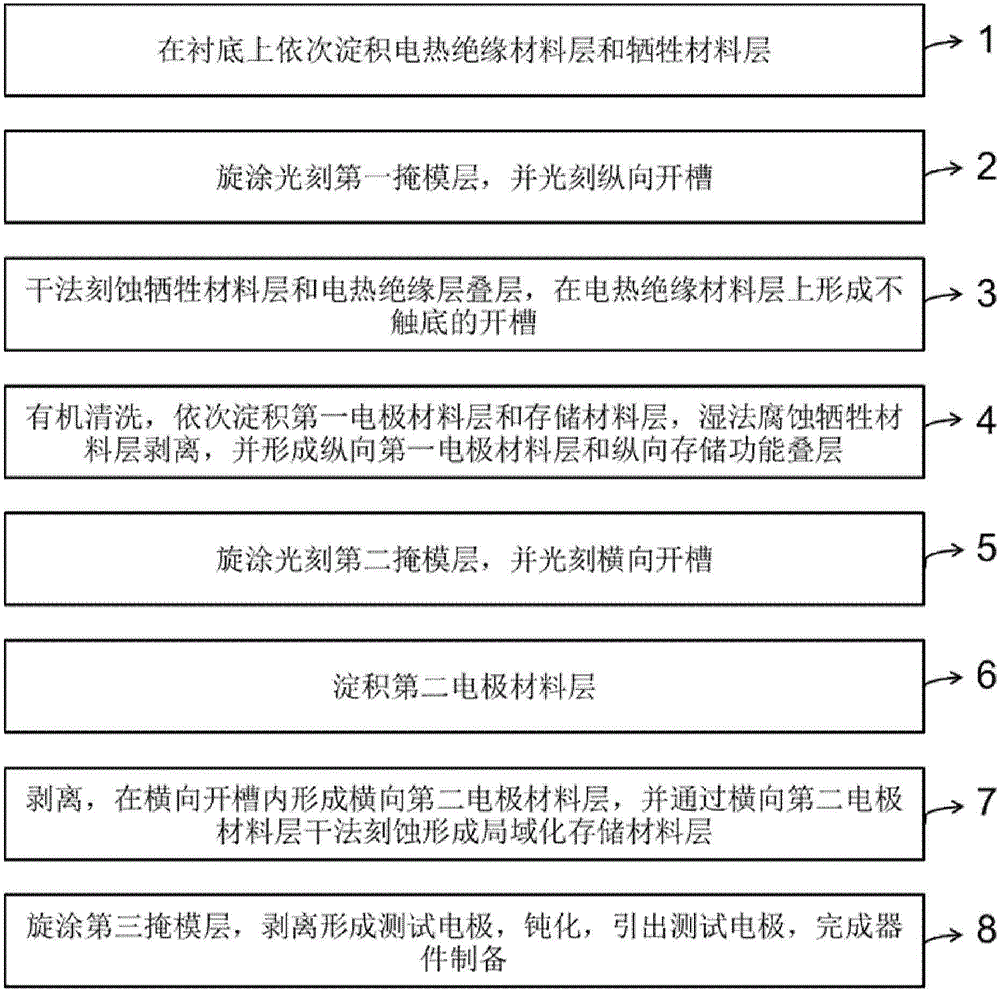

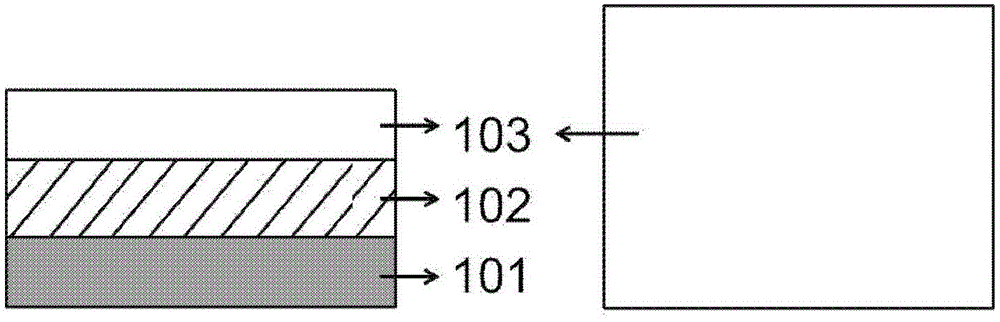

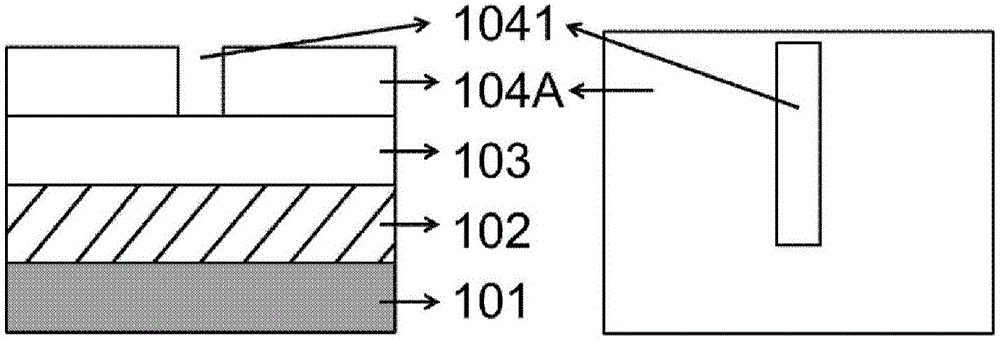

Method for preparing storage of vertical structure on basis of buried layer

InactiveCN103779497AAvoid dependenceExcellent electrical insulation propertiesElectrical apparatusEtchingParticle beam

The invention discloses a method for preparing a storage of a vertical structure on the basis of a buried layer. According to the method, a bottom electrode is buried, a function material layer is stored, and accordingly good electric heating insulation is achieved, and the situation that a CMP is relied on when a component of a vertical structure is prepared in the prior art is eliminated. According to the method, under the assistance of high-precision linear photoetching means such as electron beam lithography and focused particle beam etching and high-precision thin-film deposition and etching processes, the defects that the development cycle is long, development is difficult, cost is high and adaptability is poor due to development bottlenecks of a CMP technique are solved in development of the vertical structure in the prior art, and the method has great advantages in preparation precision, preparation efficiency, economical performance, compatibility with an existing CMOS process and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Negative Photosensitive Silicone Composition

ActiveCN103995437BHigh sensitivityHigh resolutionPhotosensitive materials for photomechanical apparatusImideNegative type

Owner:MERCK PATENT GMBH

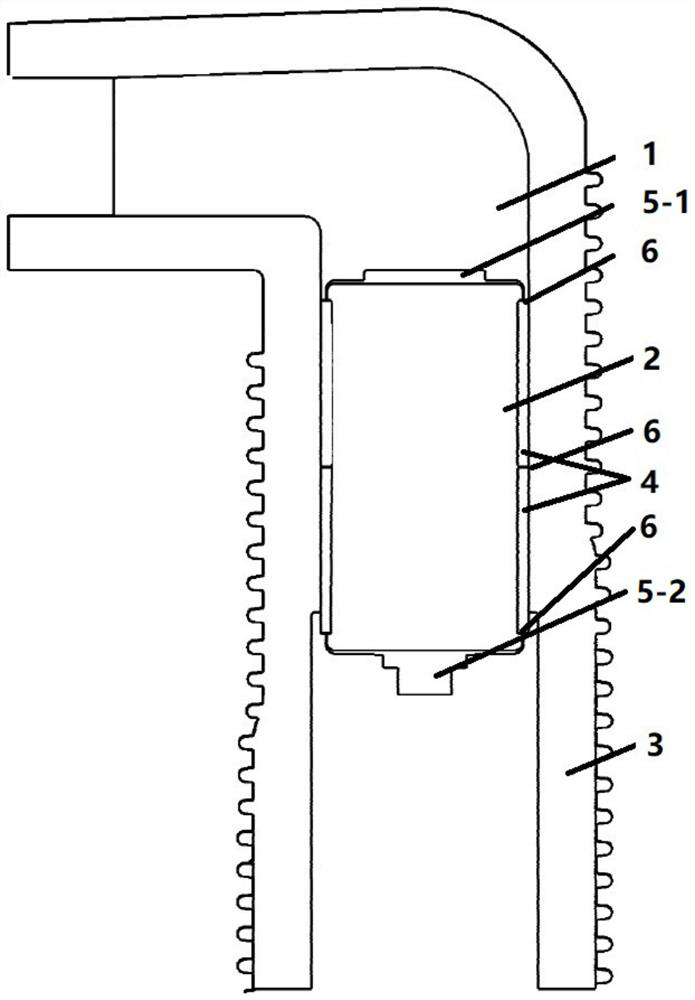

Thermoplastic material solid-sealed polar pole with voltage class of 35kV and above and preparation method thereof

InactiveCN112103124AAdapt to injection molding process requirementsExcellent electrical insulation propertiesHigh-tension/heavy-dress switchesAir-break switchesProtection layerMetal insert

The invention discloses a thermoplastic material solid-sealed polar pole with voltage class of 35kV and above and a manufacturing method thereof. The solid-sealed polar pole comprises a vacuum arc-extinguishing chamber, the vacuum arc-extinguishing chamber comprises a ceramic insulator, the upper part of the ceramic insulator is provided with a stainless steel cover plate 1, and the lower part ofthe ceramic insulator is provided with a stainless steel cover plate 2; an upper outgoing line metal insert is arranged at the upper part of the stainless steel cover plate, a thermoplastic shell is arranged outside the vacuum arc-extinguishing chamber, and the vacuum arc-extinguishing chamber is characterized in that a protective layer 1 is arranged at the outer side of the joint of the stainlesssteel cover plate 1 and the ceramic insulator, so that the stainless steel cover plate 1 is isolated from the thermoplastic shell. The solid-sealed polar pole provided by the invention has a good electrical insulation characteristic, and the electrical safety margin of the whole product is effectively improved.

Owner:STATE GRID ELECTRIC POWER RES INST +4

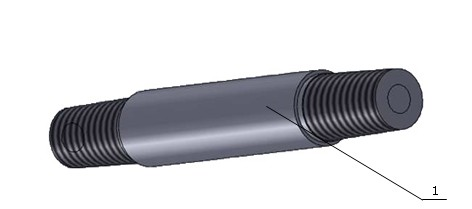

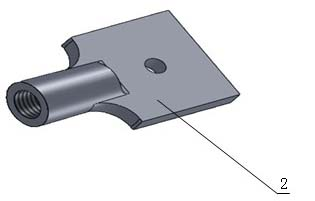

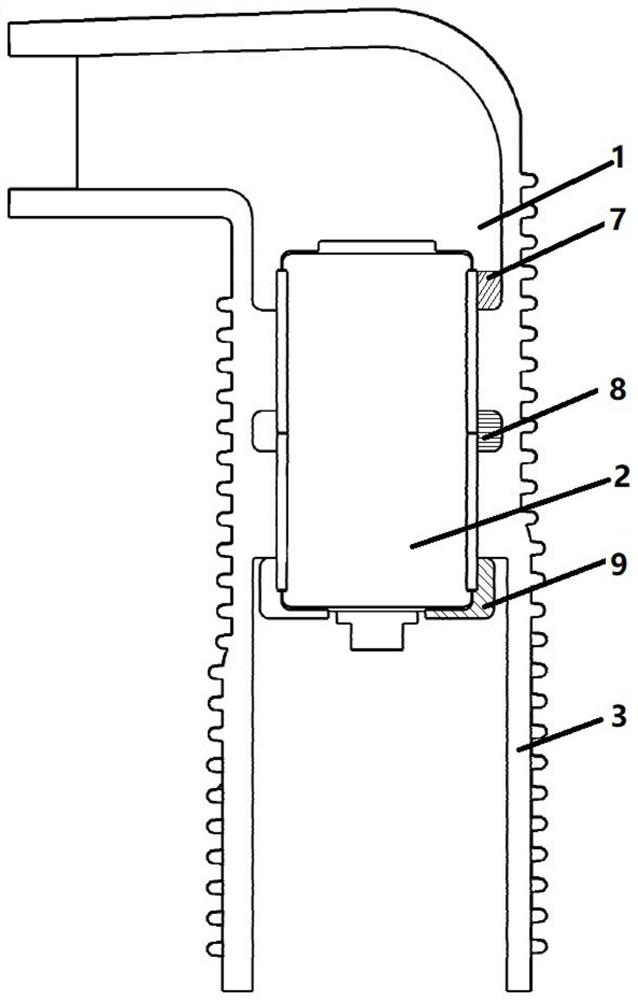

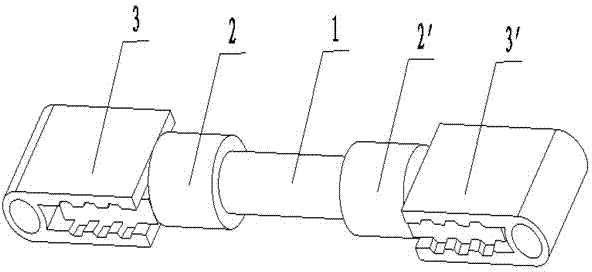

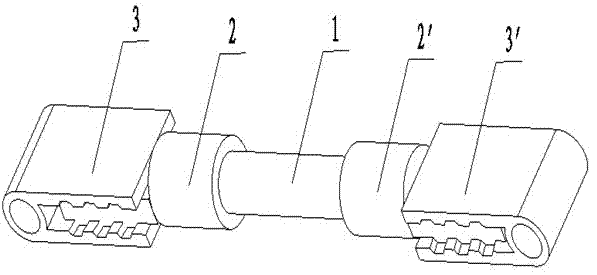

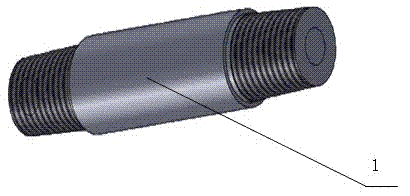

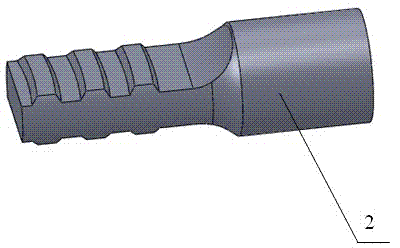

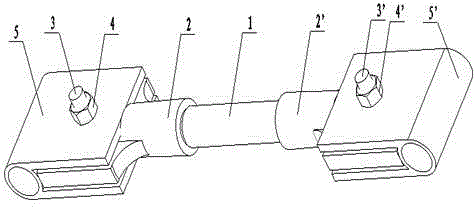

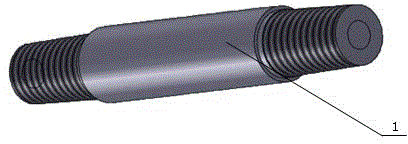

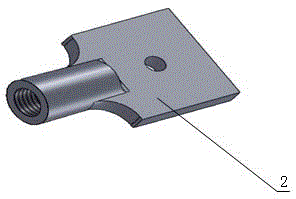

Tightness-adjustable composite material coupling member and fabrication method and assembly of coupling member

The invention relates to a tightness-adjustable composite material coupling member and a fabrication method and an assembly of the coupling member. The coupling member is formed by assembling of a cylindrical connecting bar of which two ends are prefabricated with male threads, two connecting plates and two U-shaped connecting plates. The coupling member is characterized in that the connecting plates consist of cylindrical connecting rods and rectangular plates, and the two cylindrical connecting rods are in threaded connection with two ends of the cylindrical connecting bar; arc-shaped bosses are prefabricated on the upper surfaces and the lower surfaces of the connecting plates, and arc-shaped grooves corresponding to the arc-shaped bosses are prefabricated on the internal opposite surfaces of the U-shaped connecting plates; and the connecting plates are buckled and fixed into the arc-shaped grooves in the internal opposite surfaces of the U-shaped connecting plates in a screw-in manner through the arc-shaped bosses on the connecting plates so as to form the coupling member. The fabrication method of the coupling member comprises the following steps: Forming the male threads at the two ends of the cylindrical connecting bar; forming the connecting plates and the U-shaped connecting plates with the vacuum diversion process; and after the assembly, rotating the cylindrical connecting bar so as to adjust the tightness of the connecting plates at the two ends. The tightness-adjustable composite material coupling member has the characteristics of simple structure, easiness for operation, light weight, corrosion resistance, electric insulation and the like, and can be free of maintenance and conveniently popularized and applied.

Owner:北玻电力复合材料有限公司

Fabrication method of vertical structure memory based on buried layer

InactiveCN103779497BAvoid dependenceExcellent electrical insulation propertiesElectrical apparatusEtchingParticle beam

The invention discloses a method for preparing a storage of a vertical structure on the basis of a buried layer. According to the method, a bottom electrode is buried, a function material layer is stored, and accordingly good electric heating insulation is achieved, and the situation that a CMP is relied on when a component of a vertical structure is prepared in the prior art is eliminated. According to the method, under the assistance of high-precision linear photoetching means such as electron beam lithography and focused particle beam etching and high-precision thin-film deposition and etching processes, the defects that the development cycle is long, development is difficult, cost is high and adaptability is poor due to development bottlenecks of a CMP technique are solved in development of the vertical structure in the prior art, and the method has great advantages in preparation precision, preparation efficiency, economical performance, compatibility with an existing CMOS process and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

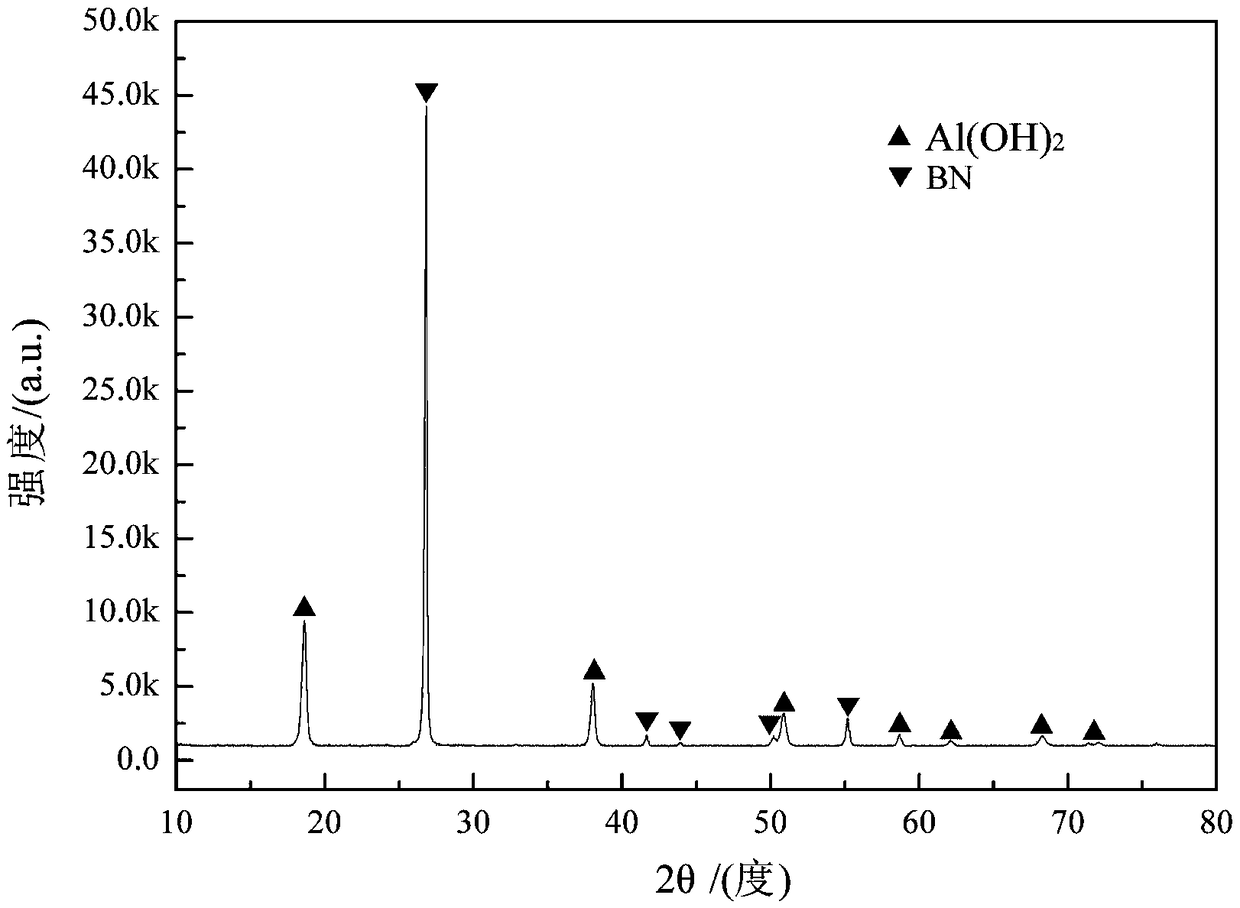

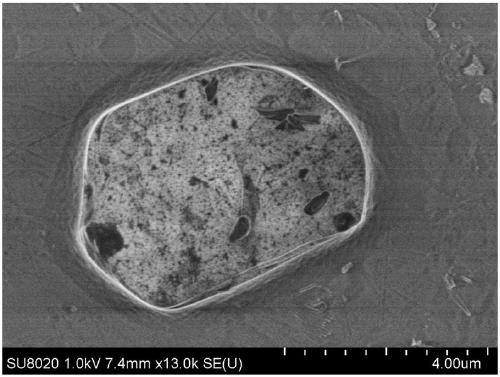

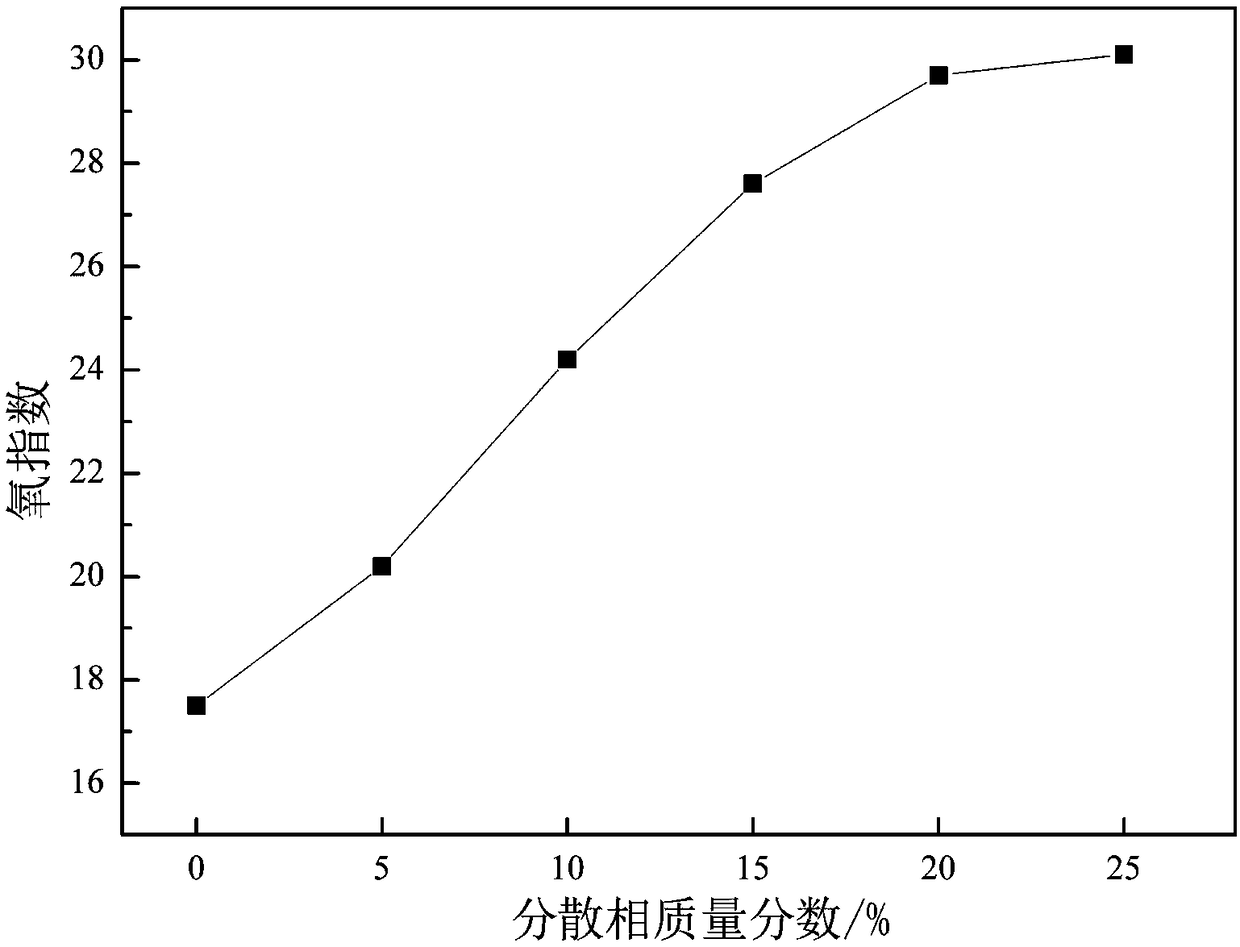

High-heat-conducting and flame-retardant polyethylene-based composite material and preparation method thereof

ActiveCN109337167AImprove flame retardant performanceImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsHexagonal boron nitrideHeat conducting

The invention discloses a high-heat-conducting and flame-retardant polyethylene-based composite material and a preparation method thereof, belongs to the field of flame-retardant cables, and aims to solve the technical problems of poor heat conductivity and flame retardance inside a material during heat accumulation of a polyethylene-based cable. The preparation method comprises the following steps: firstly, mixing aluminum hydroxide particles with hexagonal boron nitride according to a certain ratio, and performing ultrasonic dispersion; then, performing surface modification on composite powder by using silane with an amino functional group; finally, uniformly mixing the composite powder with polyethylene according to a certain ratio by an internal mixer, and performing hot-press moldingby using a flat vulcanizer to obtain the high-heat-conducting and flame-retardant polyethylene-based composite material. A synthesis technology and required equipment are simple, raw materials and intermediates are low in price, the preparation method is environmentally-friendly, pollution-free and easy to implement, and the heat-conducting and flame-retardant performance of the prepared polyethylene-based composite material is significantly improved.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC

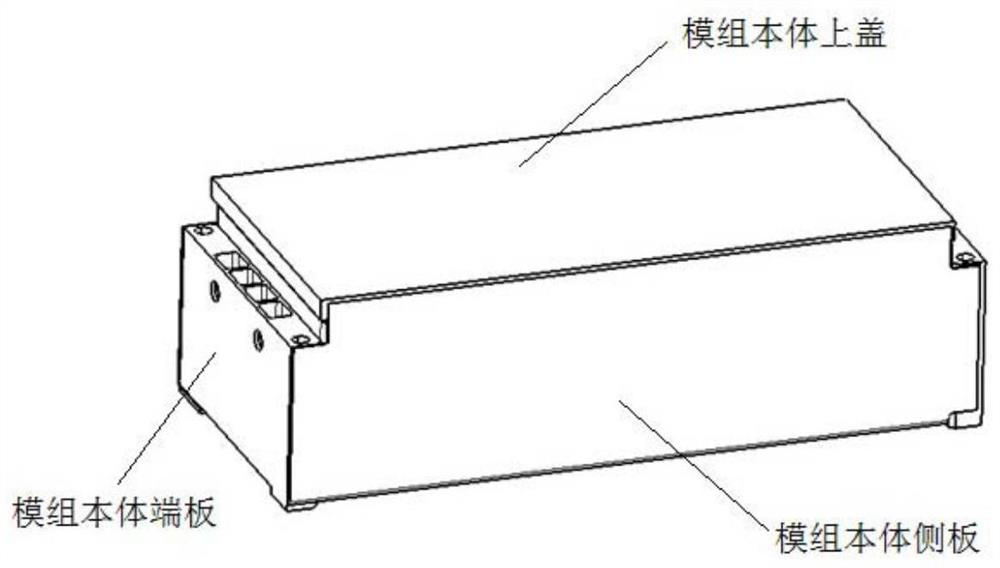

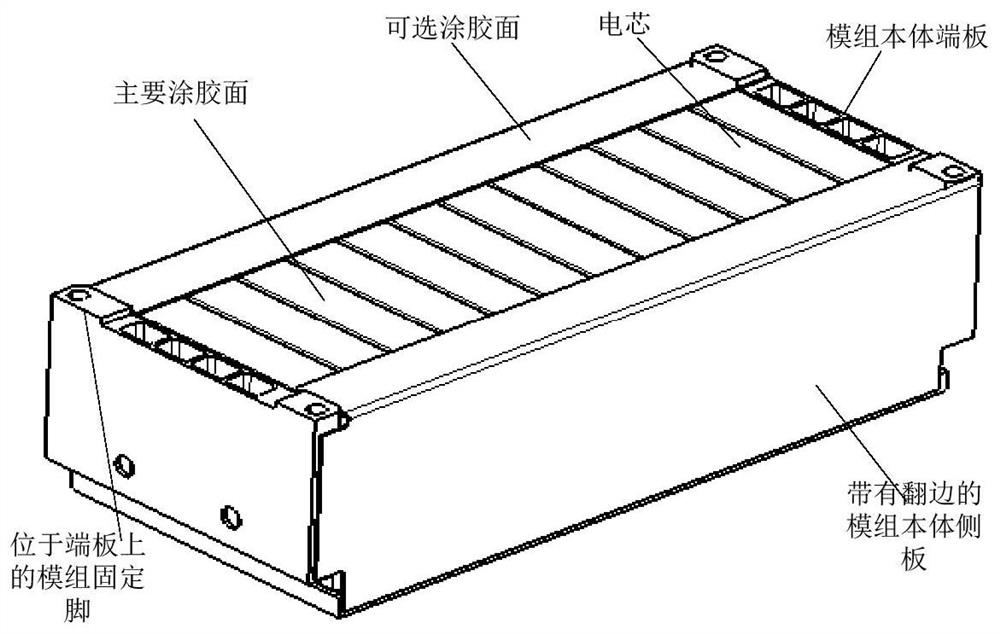

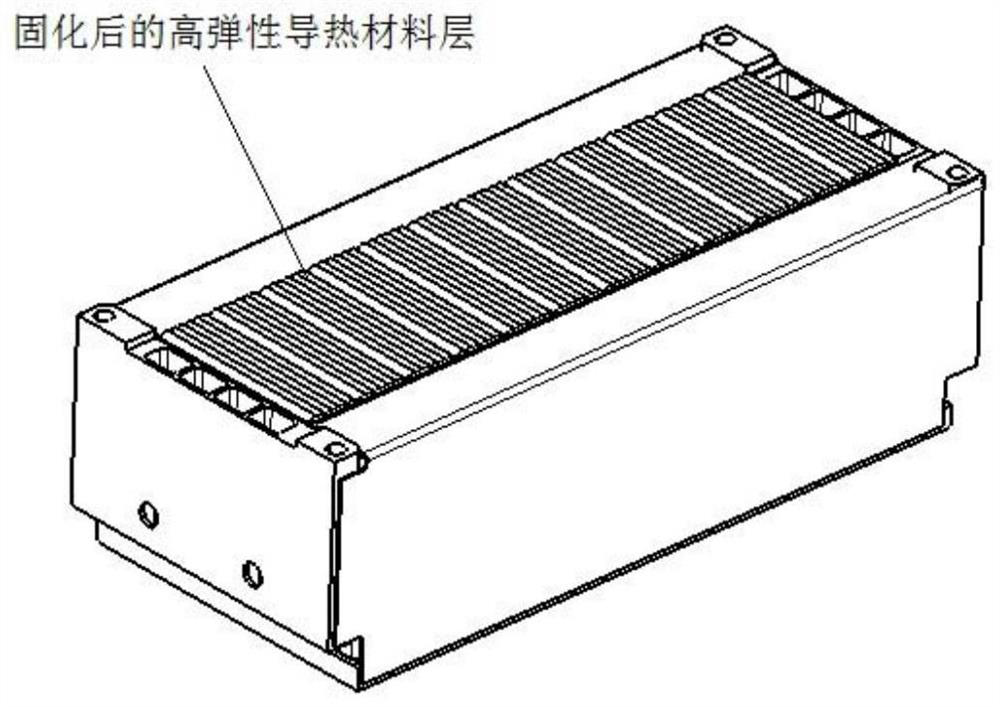

A battery module and its gluing equipment and process

ActiveCN111509329BCompressibleMeet fillPretreated surfacesSecondary cellsSolenoid valveAdhesive glue

A battery module and its gluing equipment and process. The battery module includes a module body, and the external heat transfer surface of the module body is coated with a layer of high-elastic heat-conducting material. The gluing process includes two ways of controlling the solenoid valve and controlling the stepping motor. The way to control the solenoid valve is to control the extrusion speed of the glue by adjusting the opening of the valve; the way to control the stepping motor is to control the moving speed of the glue head. Control the glue extrusion speed; the glue application equipment includes a detection system, a glue system, a constant temperature system and a computer terminal; the glue system includes a glue extrusion device and a movement mechanism that controls the extrusion device; It is used to receive the signal from the computer terminal and adjust the opening of the valve; the movement mechanism is controlled by a stepper motor, and the stepper motor receives the signal from the computer terminal to control the moving speed of the movement mechanism. Achieve higher production efficiency and lower process cost than sticking thermal pads, and prevent air bubbles on the mating surface.

Owner:厦门通测电子有限公司

Electronic component and production method thereof

ActiveCN101465209BImprove electrical insulation propertiesReduce weightSolid electrolytic capacitorsCapacitor terminalsElectrical resistance and conductanceElectricity

The invention relates to an electronic part and a production method thereof, more particularly bonds a protective paper on an insulation paper, thus improves an electric insulation characteristic between electric pole foils, and protects two sides of a flat part of the wire. The protective paper has a minimum width, prevents a radial direction substantially thickening, and further prevents an Equivalent Series Resistance (ESR) of the electronic part from increasing. A protective paper (6; 6A, 6B) wider than a wire flat part is bonded on the insulation paper (5; 5A, 5B) for transmitting the protective paper to the insulation paper (5; 5A, 5B) to roll at a basic perpendicular direction to a direction of transmission of the insulation paper (5; 5A, 5B) and an electrode foil (4; 4P, 4M) rightbefore the insulation paper region bonded by the protective papers is rolled.

Owner:JCC ENG

Tightness-adjustable composite material coupling member and fabrication method and assembly of coupling member

The invention relates to a tightness-adjustable composite material coupling member and a fabrication method and an assembly of the coupling member. The coupling member is formed by assembling of a cylindrical connecting bar of which two ends are prefabricated with male threads, two connecting plates and two U-shaped connecting plates. The coupling member is characterized in that the connecting plates consist of cylindrical connecting rods and rectangular plates, and the two cylindrical connecting rods are in threaded connection with two ends of the cylindrical connecting bar; arc-shaped bosses are prefabricated on the upper surfaces and the lower surfaces of the connecting plates, and arc-shaped grooves corresponding to the arc-shaped bosses are prefabricated on the internal opposite surfaces of the U-shaped connecting plates; and the connecting plates are buckled and fixed into the arc-shaped grooves in the internal opposite surfaces of the U-shaped connecting plates in a screw-in manner through the arc-shaped bosses on the connecting plates so as to form the coupling member. The fabrication method of the coupling member comprises the following steps: Forming the male threads at the two ends of the cylindrical connecting bar; forming the connecting plates and the U-shaped connecting plates with the vacuum diversion process; and after the assembly, rotating the cylindrical connecting bar so as to adjust the tightness of the connecting plates at the two ends. The tightness-adjustable composite material coupling member has the characteristics of simple structure, easiness for operation, light weight, corrosion resistance, electric insulation and the like, and can be free of maintenance and conveniently popularized and applied.

Owner:北玻电力复合材料有限公司

Ternary system high-temperature piezoelectric ceramic of magnesium bismuth titanate, bismuth zinc-based perovskite and lead titanate and preparation method thereof

InactiveCN102336567BExcellent piezoelectric propertiesHigh curie temperaturePiezoelectric/electrostrictive/magnetostrictive devicesCurie temperatureLead titanate

The invention discloses a ternary system high-temperature piezoelectric ceramic of magnesium bismuth titanate, bismuth zinc-based perovskite and lead titanate and a preparation method thereof. The composition of the piezoelectric ceramic is expressed by a general formula (1-n) [uBi(Mg0.5Ti0.5)O3 + vBi(ZnxDy)O3 + (1-u-v) PbTiO3] + nM; and the preparation method comprises the steps of mixing, ball milling, pre-sintering, blank making, sintering, silver coating and polarization. The composition of the piezoelectric ceramic has perovskite structure and has similar phase interface of a rhombic ferroelectric phase and a foursquare ferroelectric phase, so the piezoelectric ceramic has excellent piezoelectric performance and high Curie temperature, is more suitable for high-temperature field, and has low dielectric loss; the electric polarization process is easier and more convenient; and the piezoelectric ceramic can be prepared by adopting a preparation technology of the traditional piezoelectric ceramic, particularly adopting cheap industrial raw materials, and has practicability.

Owner:HEFEI UNIV OF TECH

Negative Photosensitive Silicone Composition

ActiveCN103959168BIncreased sensitivityHigh resolutionPhotomechanical apparatusCross-linkTetramethylammonium hydroxide

[Problem] To provide a photosensitive siloxane composition which has high resolution, high heat resistance and high transparency, does not undergo thermal sagging, which may occur during thermal curing, without the need of increasing the molecular weight of a cross linking agent or a siloxane compound, and has properties including high sensitivity and a high film-remaining rate. [Solution] A negative-type photosensitive polysiloxane composition characterized by comprising: (I) (Ia) a polysiloxane having such a property that a prebaked film thereof is soluble in an aqueous 5-wt% tetramethylammonium hydroxide solution at a dissolution rate of 3,000 Å / sec. or less and (Ib) a polysiloxane mixture containing a polysiloxane and having such a property that the dissolution rate of a prebaked film thereof in an aqueous 2.38-wt% tetramethylammonium hydroxide solution is 150 Å / sec. or more; (II) a curing aid; and (III) a solvent.

Owner:MERCK PATENT GMBH

Electromagnetic wave shielding film

PendingCN112369133AImprove electromagnetic shielding performanceHigh mechanical strengthMagnetic/electric field screeningPretreated surfacesElectromagnetic shieldingCondensed matter physics

The present application relates to an electromagnetic wave shielding film, and can provide an electromagnetic wave shielding film having excellent electromagnetic wave shielding ability and also having excellent mechanical strength, flexibility, electrical insulation, adhesiveness to other elements, stability against oxidation and high temperature, etc.

Owner:LG CHEM LTD

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Connection construction member capable of regulating tightness and manufacturing and assembling method thereof

The invention discloses a connection construction member capable of regulating tightness and a manufacturing and assembling method thereof. The connection construction member is assembled by a connecting rod, two connecting plates and two U-shaped connecting plates, wherein the connecting rod is made of glass fiber reinforced plastic composite material, and two ends of the connecting rod are provided with male threads. The manufacturing and assembling method for the connection construction member capable of regulating the tightness comprises the following steps of: 1) carrying out pultrusion on the connecting rod, and lathing a positive-buckling male thread and a reverse-buckling male thread on two ends of the connecting rod; 2) carrying out pultrusion on a pin, and lathing the male thread on two ends of the pin; 3) carrying out pultrusion on two pairs of nuts; 4) forming the connecting plates and the U-shaped connecting plates in a vacuum flow guide technology; 5) processing pin holes in the center positions where the connecting plates are opposite to the U-shaped connecting plates; and 6) fixedly connecting the connecting rod, the two connecting plates and the two U-shaped connecting plates into a connection construction member by the pin holes, the pin and the nuts. The manufacturing and assembling method is simple and easy to operate, has the characteristics of light weight, corrosion resistance and electric insulation, is adjustable, is safe to assemble, does not need to maintain and repair because the weather resistance lasts for 20 years, and is favorable for popularizing and applying.

Owner:北玻电力复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com