A battery module and its gluing equipment and process

A battery module and glue coating technology, which is applied to secondary batteries, coatings, circuits, etc., can solve the problems of certain mechanical strength requirements for modules and liquid-cooled plates, difficulty in discharging air bubbles, difficulty in automation, etc., and achieve good results The effect of electrical insulation properties, low contact thermal resistance, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

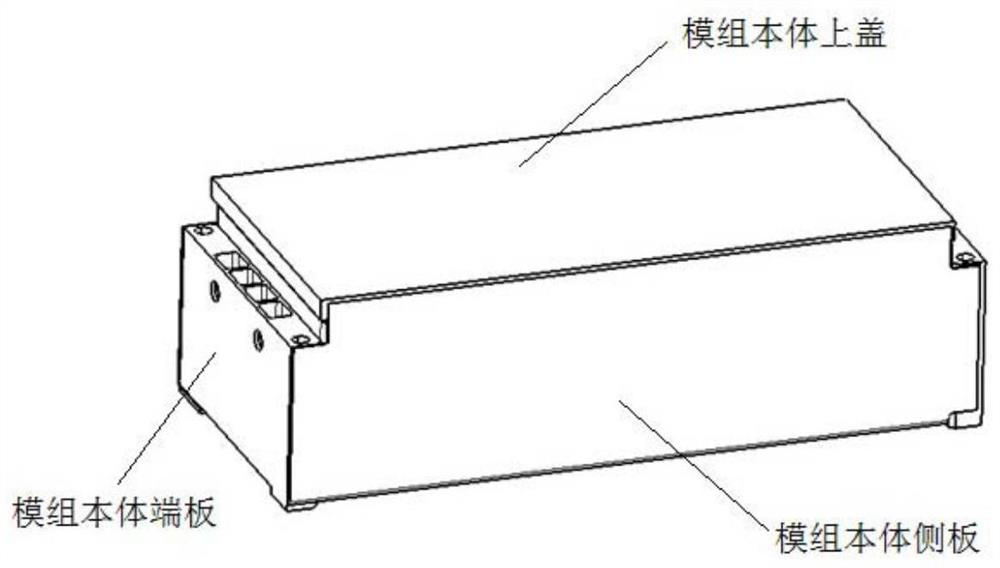

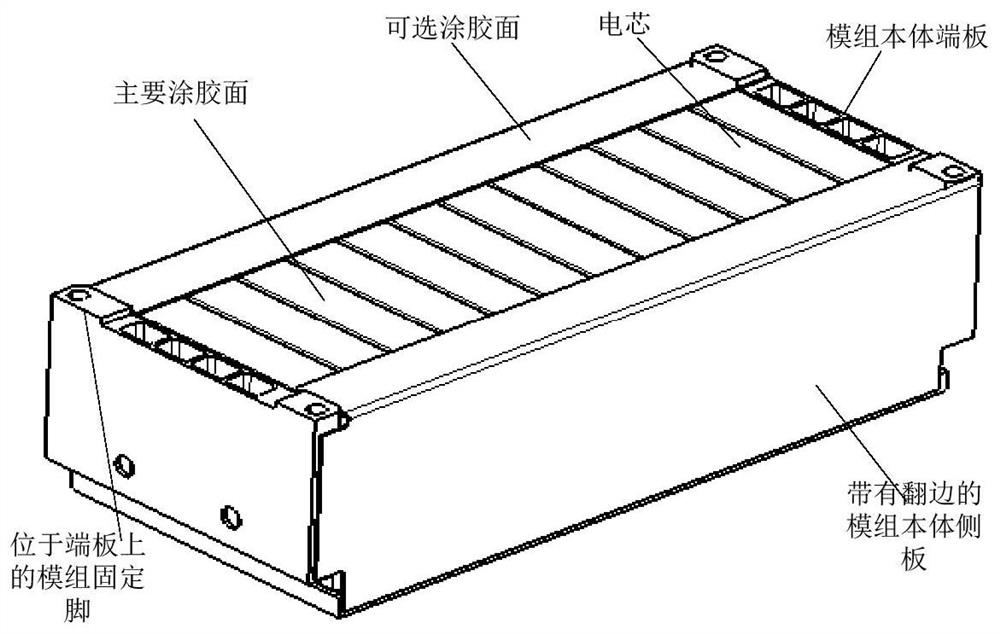

[0056] Such as Figure 1~4 As shown, a battery module includes a module body, and the module body includes a cell arrangement composed of several cells, a module body upper cover, a module body end plate, a module body side plate, and a module signal acquisition The side plate of the module body has a flange facing the battery; optionally, the module body can also include a module bottom plate, and the module bottom plate is located at the bottom of the battery cell arrangement;

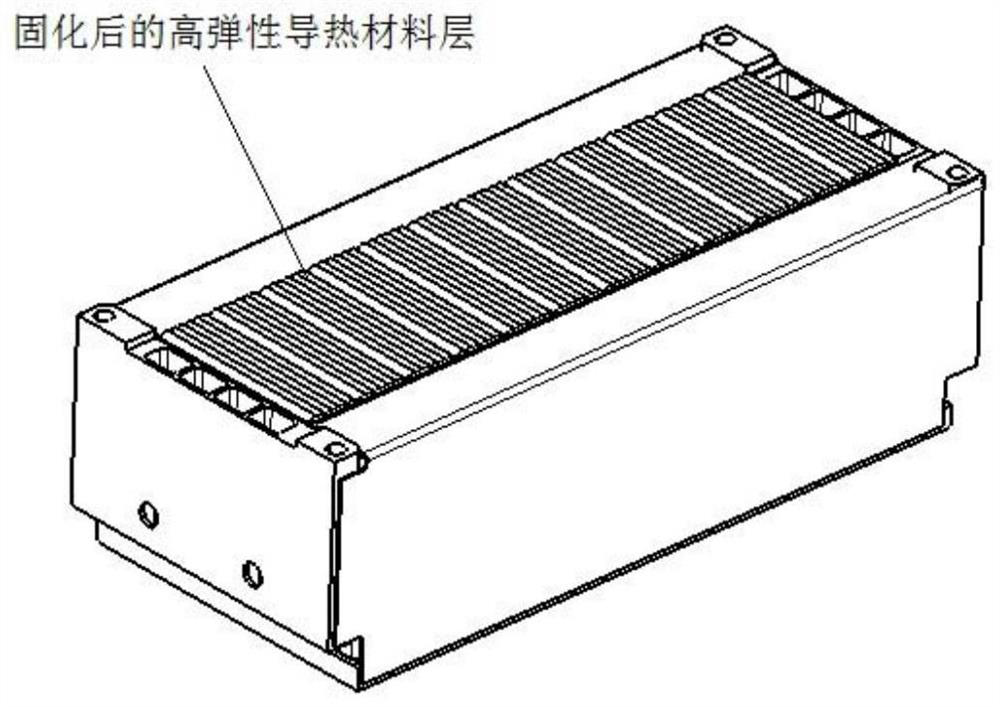

[0057] In this example, the external heat transfer surface of the module body is coated with a layer of highly elastic heat-conducting material; the main external heat transfer surface of the battery module is for the liquid-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com