Negative Photosensitive Silicone Composition

A technology of photosensitivity and siloxane, which is applied in the direction of optics, optomechanical equipment, and photosensitive materials used in optomechanical equipment, etc. Excellent film ratio and excellent electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

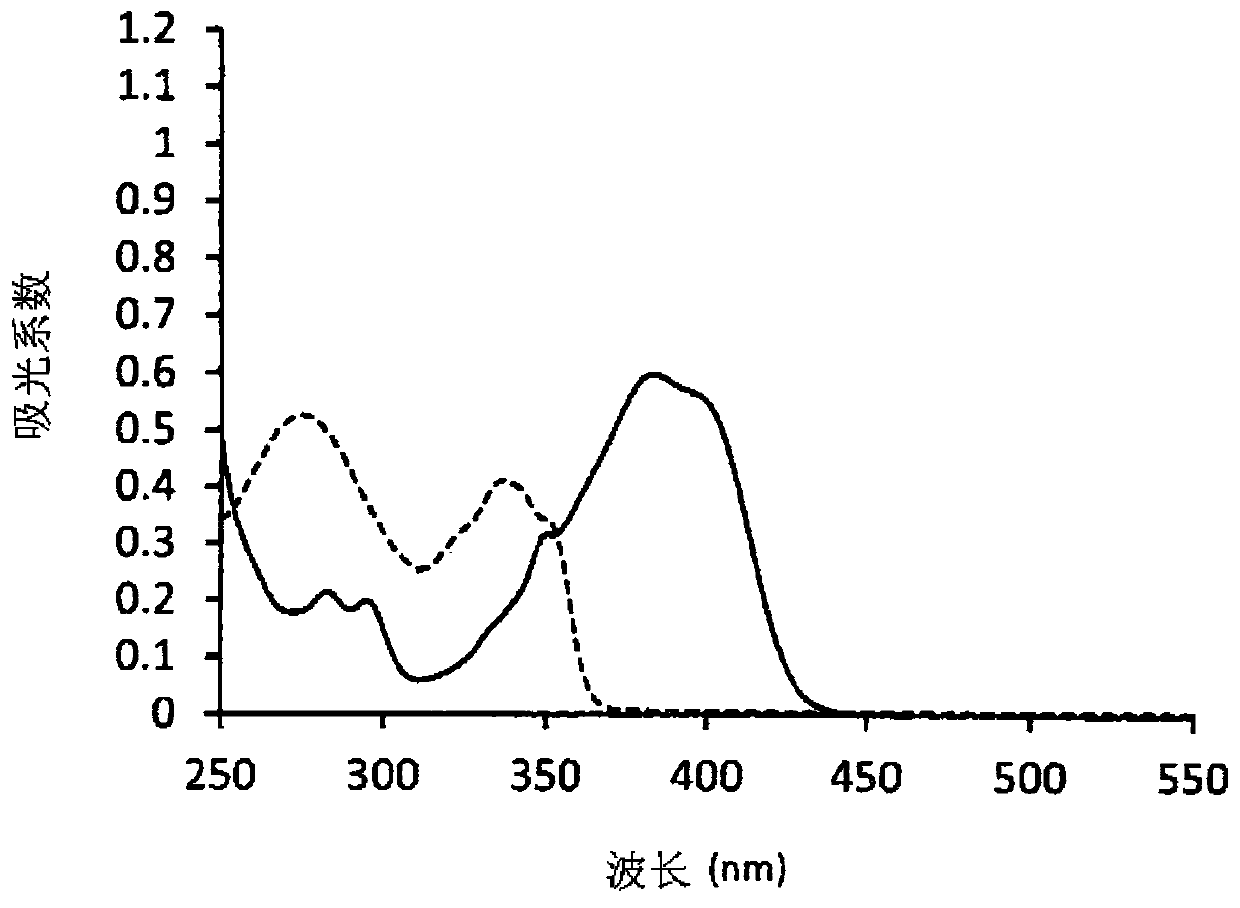

Image

Examples

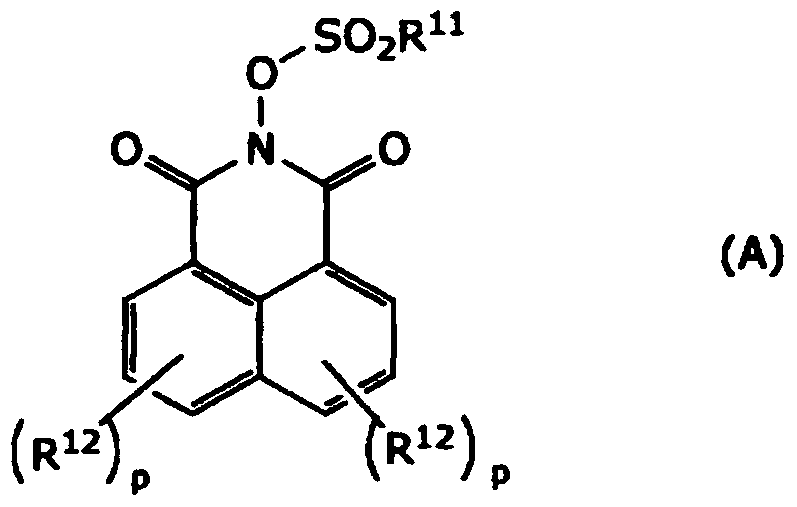

Embodiment 1

[0184] Polysiloxane (Ia-1) and polysiloxane (Ib-1) were mixed at a mixing ratio (30% by weight): (70% by weight). Regarding this polysiloxane mixture, the dissolution rate relative to 2.38% TMAH aqueous solution after prebaking is / second. This polysiloxane mixture was prepared so as to be a 35% PGMEA solution, and 1.0% by weight of the photoacid generator represented by the aforementioned formula (A-1) was added to the polysiloxane. Moreover, 0.3 weight% of KF-53 (trade name, Shin-Etsu Chemical Co., Ltd. make) was added as surfactant with respect to polysiloxane, and the negative photosensitive silicone composition was obtained.

[0185] This photosensitive siloxane composition was applied on a silicon wafer by spin coating, and after application, it was prebaked on a hot plate at 100° C. for 90 seconds, and adjusted so as to have a film thickness of 2 μm. After prebaking, use the g, h line exposure machine of FX-604 type Stepper (trade name, manufactured by Nikon Corporat...

Embodiment 2

[0189] Except that the mixing ratio of polysiloxane (Ia-1) and polysiloxane (Ib-1) was changed to (10% by weight): (90% by weight), it was obtained in the same manner as in Example 1. Negative photosensitive silicone composition. The dissolution rate of the polysiloxane mixture relative to the 2.38% TMAH aqueous solution after pre-baking is / second.

[0190] Instead of using this composition, changing the exposure to 50mJ / cm 2 Other than that, pattern formation and baking hardening were performed similarly to Example 1. Observation of the obtained pattern revealed that the pattern of 5 µm was maintained. However, compared with Example 1, the pattern ridge line portion is rounded at a level that is practically no problem.

Embodiment 3

[0192] Except that the mixing ratio of polysiloxane (Ia-1) and polysiloxane (Ib-1) was changed to (60% by weight): (40% by weight), it was obtained in the same manner as in Example 1. Negative photosensitive silicone composition. The dissolution rate of the polysiloxane mixture relative to the 2.38% TMAH aqueous solution after pre-baking is / second.

[0193] Using this composition, the development time was changed to 150 seconds, and the baking curing was changed to 350°C to obtain a pattern. As a result, a 5 μm pattern without residue was maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com