Thermoplastic material solid-sealed polar pole with voltage class of 35kV and above and preparation method thereof

A technology of thermoplastic materials and voltage levels, applied in the direction of circuits, electric switches, electrical components, etc., can solve problems such as shrinkage cavity, inability to be completely wrapped, deformation of vacuum interrupter, etc., to improve electrical safety margin and good electrical insulation characteristics, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

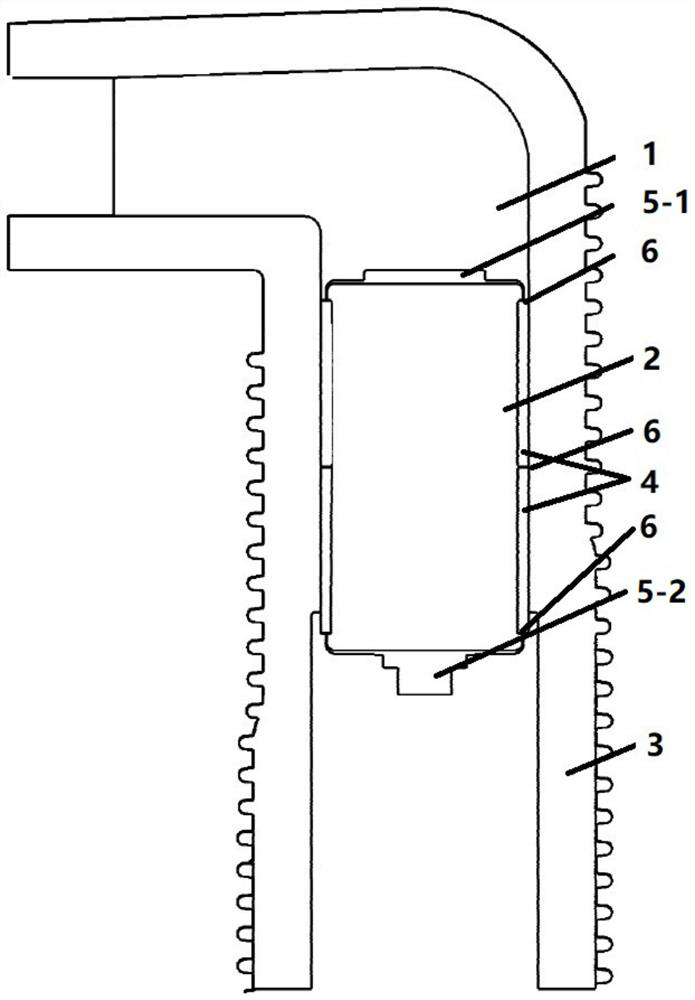

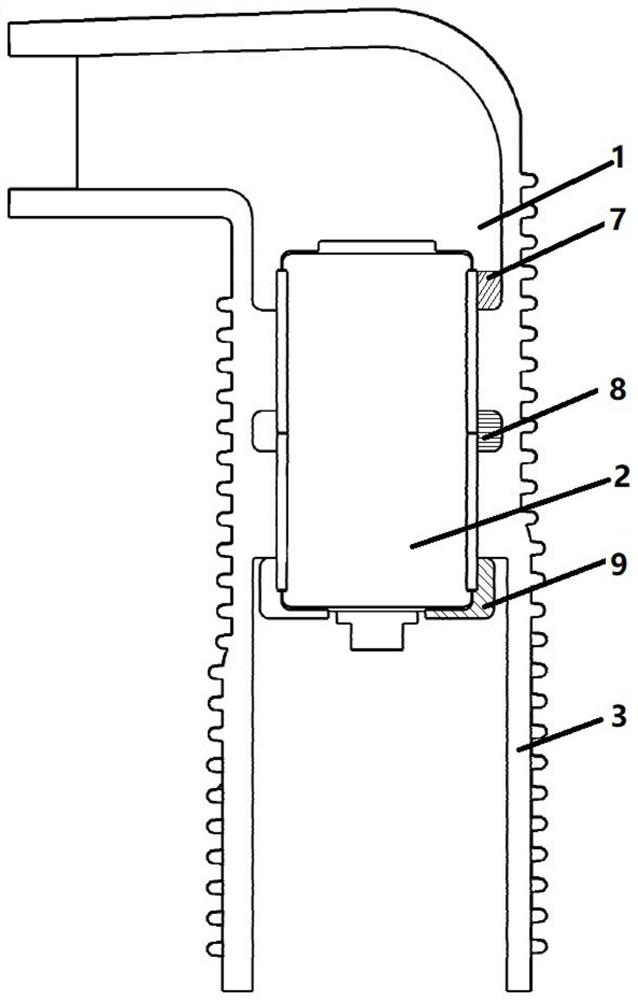

[0026] Such as figure 1 As shown, a thermoplastic material solid-sealed pole for 35 kV and above voltage level includes a vacuum interrupter, the vacuum interrupter includes a ceramic insulator, a stainless steel cover plate 1 is arranged on the upper part of the ceramic insulator, and the ceramic insulator The lower part of the stainless steel cover plate is provided with two stainless steel cover plates, and the upper outlet metal insert is arranged on the upper part of the stainless steel cover plate one, and the outside of the vacuum interrupter is a thermoplastic shell, which is characterized in that: the connection between the stainless steel cover plate one and the ceramic insulator A protective layer 1 is arranged on the outside of the part to isolate the stainless steel cover plate 1 from the thermoplastic shell.

[0027] The protective layer 1 is an outlet metal insert extending downwards along the edge of the stainless steel cover plate 1 to cover the entire outer s...

Embodiment 2

[0035] Such as figure 1As shown, a thermoplastic material solid-sealed pole for 35 kV and above voltage level includes a vacuum interrupter, the vacuum interrupter includes a ceramic insulator, a stainless steel cover plate 1 is arranged on the upper part of the ceramic insulator, and the ceramic insulator The lower part of the stainless steel cover plate is provided with the second stainless steel cover plate, and the upper outlet metal insert is arranged on the upper part of the stainless steel cover plate, and the outside of the vacuum interrupter is a thermoplastic shell, which is characterized in that: at the junction of the stainless steel cover plate one and the ceramic insulator A protective layer 1 is arranged on the outside to isolate the stainless steel cover 1 from the thermoplastic shell.

[0036] The protective layer one is a conductive polymer material one or an insulating material one with good process characteristics arranged outside the junction of the stainl...

Embodiment 3

[0050] Such as figure 1 As shown, a thermoplastic material solid-sealed pole for 35 kV and above voltage level includes a vacuum interrupter, the vacuum interrupter includes a ceramic insulator, a stainless steel cover plate 1 is arranged on the upper part of the ceramic insulator, and the ceramic insulator The lower part of the stainless steel cover plate is provided with two stainless steel cover plates, and the upper outlet metal insert is arranged on the upper part of the stainless steel cover plate one, and the outside of the vacuum interrupter is a thermoplastic shell, which is characterized in that: the connection between the stainless steel cover plate one and the ceramic insulator A protective layer 1 is arranged on the outside of the part to isolate the stainless steel cover plate 1 from the thermoplastic shell.

[0051] The ceramic insulator includes an upper ceramic insulator and a lower ceramic insulator, and a second protective layer is provided outside the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com